3.2. Test Results, Analysis, and Discussion of Porous Asphalt

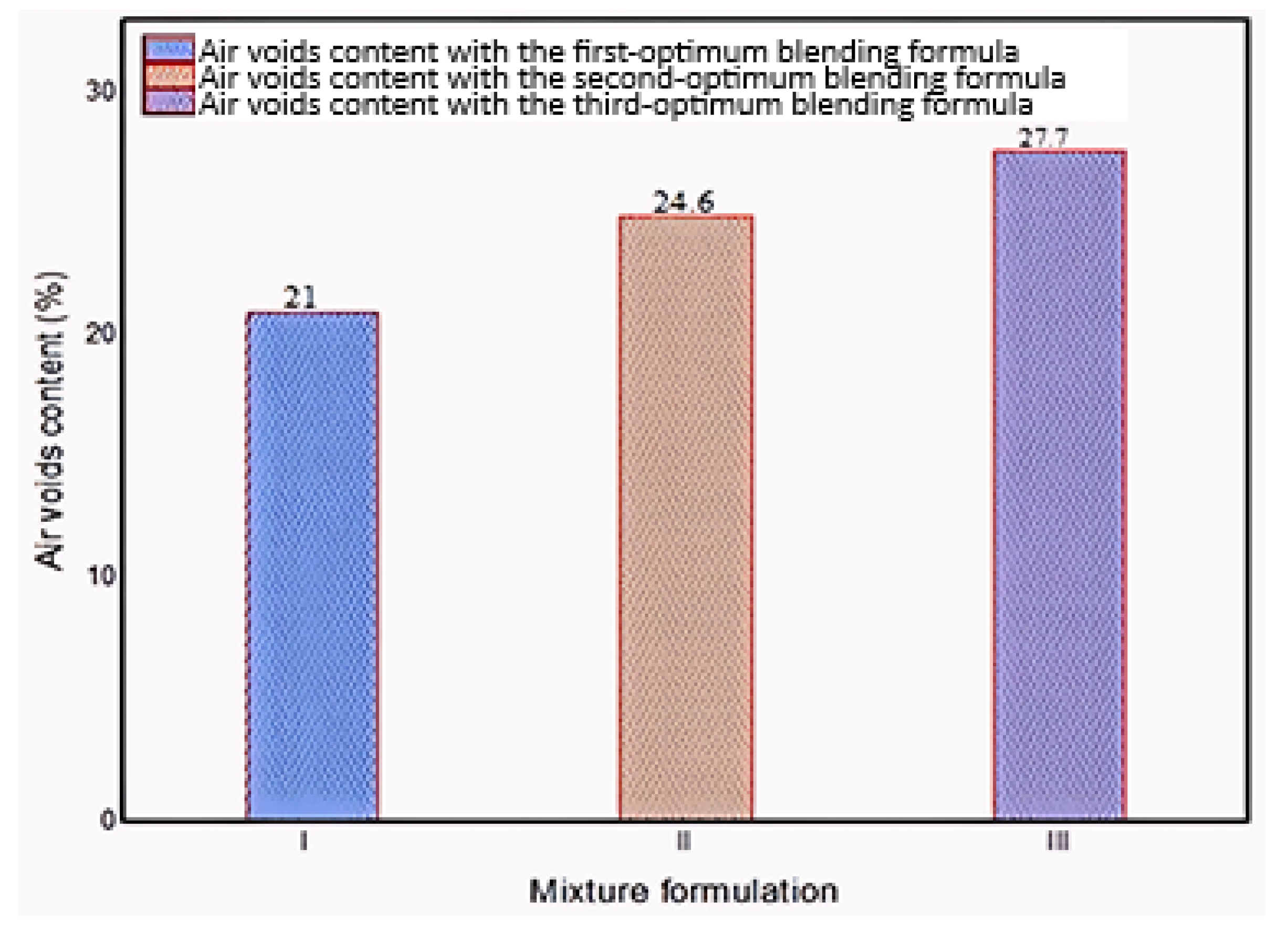

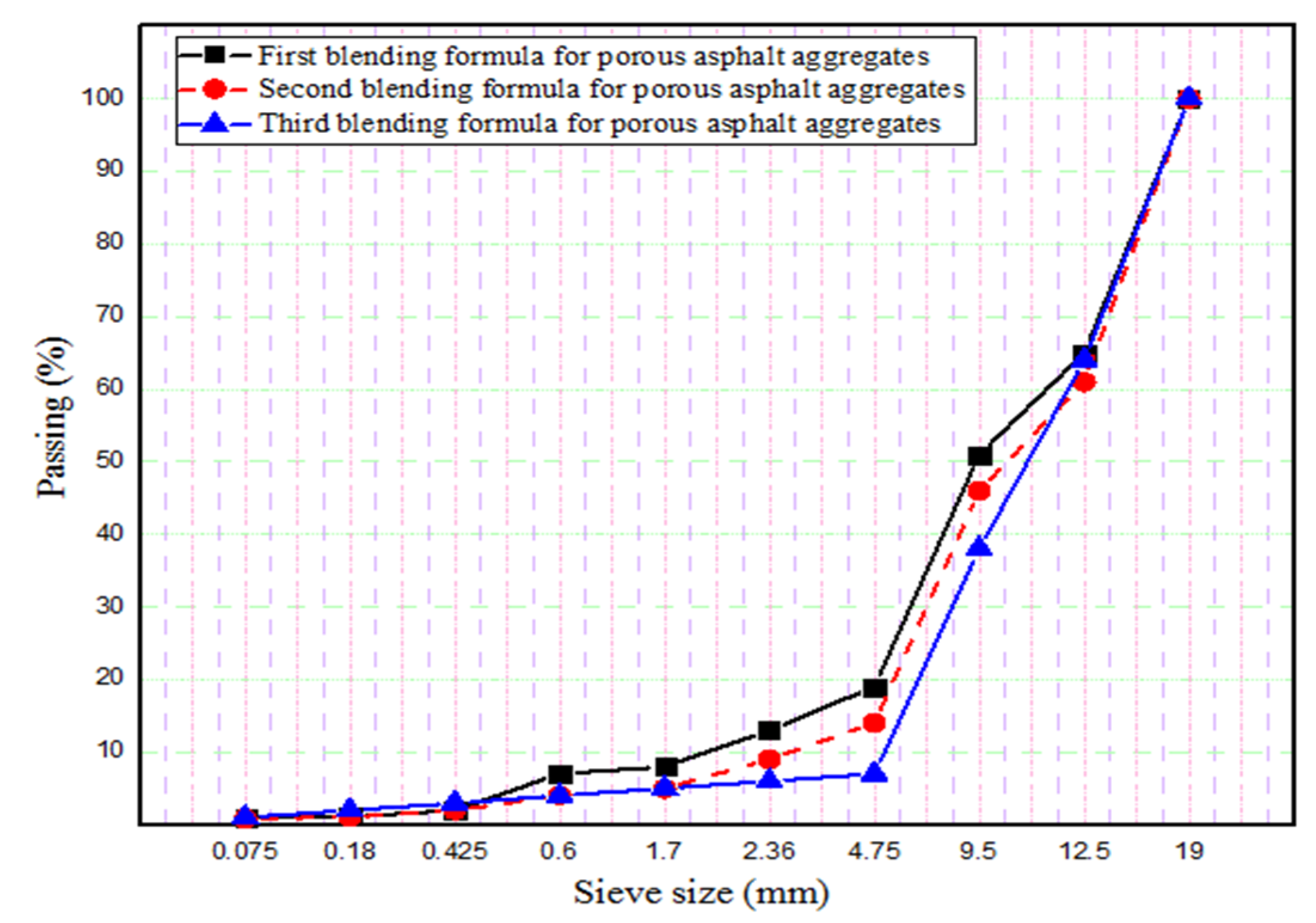

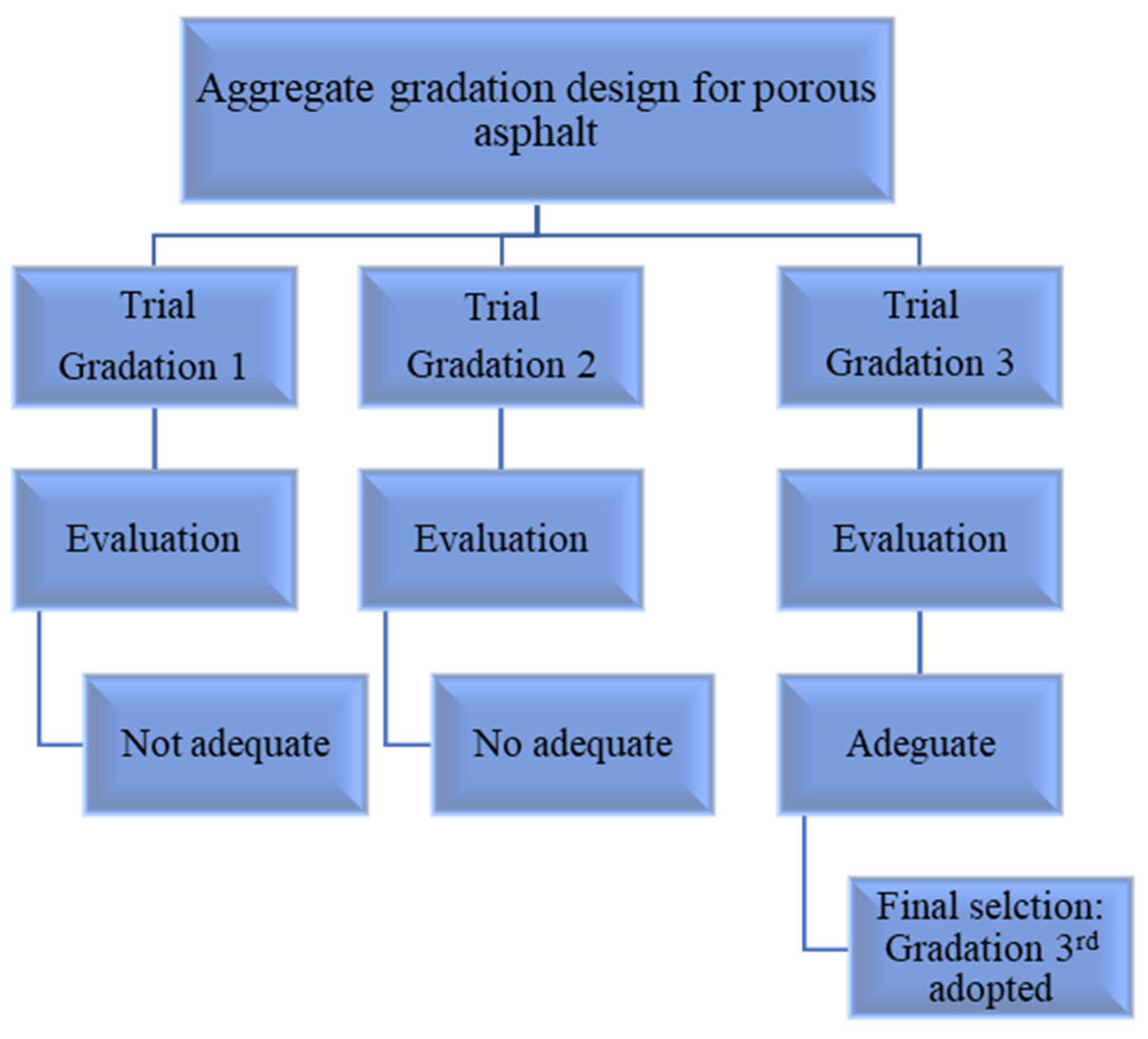

In the first stage of this investigation, a porous asphalt mixture was prepared according to the OBC, and the percentage of each aggregate size was calculated in the first optimum blending formula. As shown in

Figure 11, the Marshall specimens, prepared with the first blending formula do not provide the intended percentage air voids content of porous asphalt (25–35%). Therefore, second and third aggregate gradations were defined in order to obtain more air voids content in the Marshall specimens as shown in

Figure 12. OBC for each blending formula was separately calculated according to the percentage of each aggregate size (3.88%, 3.69%, and 3.65%). The porous asphalt mixture prepared with the third aggregate gradation provided the required air voids content of the asphalt skeleton, which can be used in the SRP. So, the third blending formula for porous asphalt aggregates was chosen as an optimum aggregate gradation after the evaluation of the first and second blending formulas (

Figure 13). As inferred from the OBC values and three different aggregate gradations, OBC decreased in three different asphalt mixtures, respectively, because of the low percentage of fine aggregates. The more specific surface area of fine aggregate may be the main reason for the decreasing values of OBC.

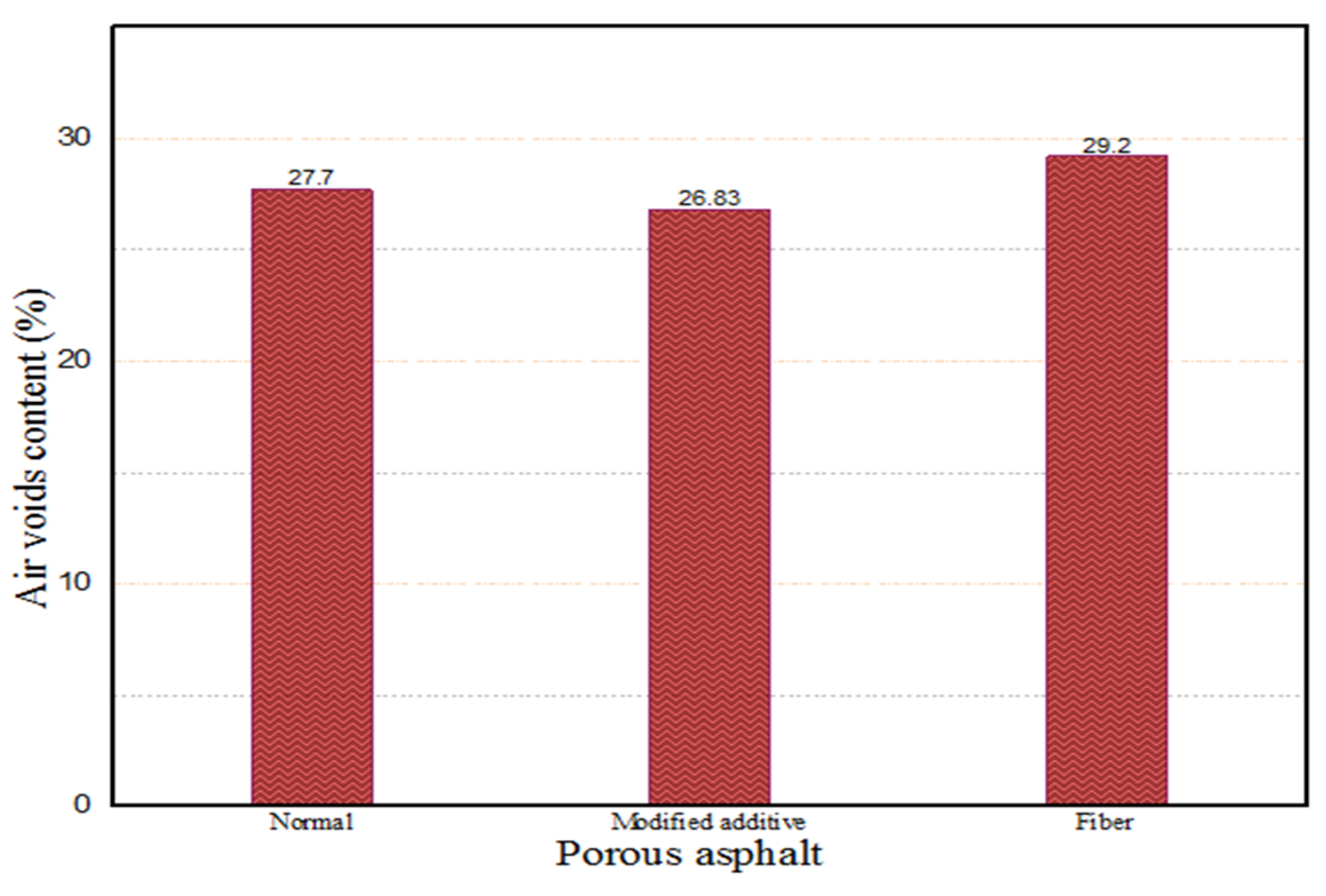

In addition, the air voids content of the porous asphalt mixture was evaluated by the use of two different additives (fiber 0.3% by weight of the mixture and modified additive 3% by weight of bitumen) after the determining of the optimum blending formula. As shown in

Figure 14, Marshall specimens prepared with fiber are more porous than modified additive specimens and specimens without additive. Since the fibers are not uniformly spread and clump together, they hinder proper aggregate packing and compaction, which leads to increased voids in asphalt. On the other hand, the incorporation of cellulose fibers may result in increased air void content within asphalt mixtures. This effect is primarily attributed to the fibers’ absorption of asphalt binder, which reduced the effective binder available for aggregate coating and subsequent compaction. Conversely, modified additives in asphalt mixtures reduce binder stiffness and improve the coating of aggregate particles, thereby enhancing compaction efficiency and leading to a reduction in air void content. This was an expected result because the application of fiber in the mixture increases the air voids content of the asphalt mixture [

37]. At the same time, the existence of fiber in the asphalt mixture increases the mixture permeability coefficient [

38]. Therefore, it may result in more air voids content of the asphalt mixture. On the other hand, the Marshall specimens designed with modified additives provided less air void content due to the reduction in mixture compaction strength. The viscosity of bitumen with modified additive increases at low temperatures (less than 90 °C) and decreases at high temperatures (more than 90 °C) [

39]. Therefore, the low viscosity of bitumen may lead to a decrease in mixture compaction strength. As a result of various experimental tests, the third aggregate gradation, OBC (3.65%), and fiber (0.3% by weight of mixture) were selected as the optimum factors that can provide almost 30% air voids content of porous asphalt.

3.3. Performance of the Semi-Rigid Pavement

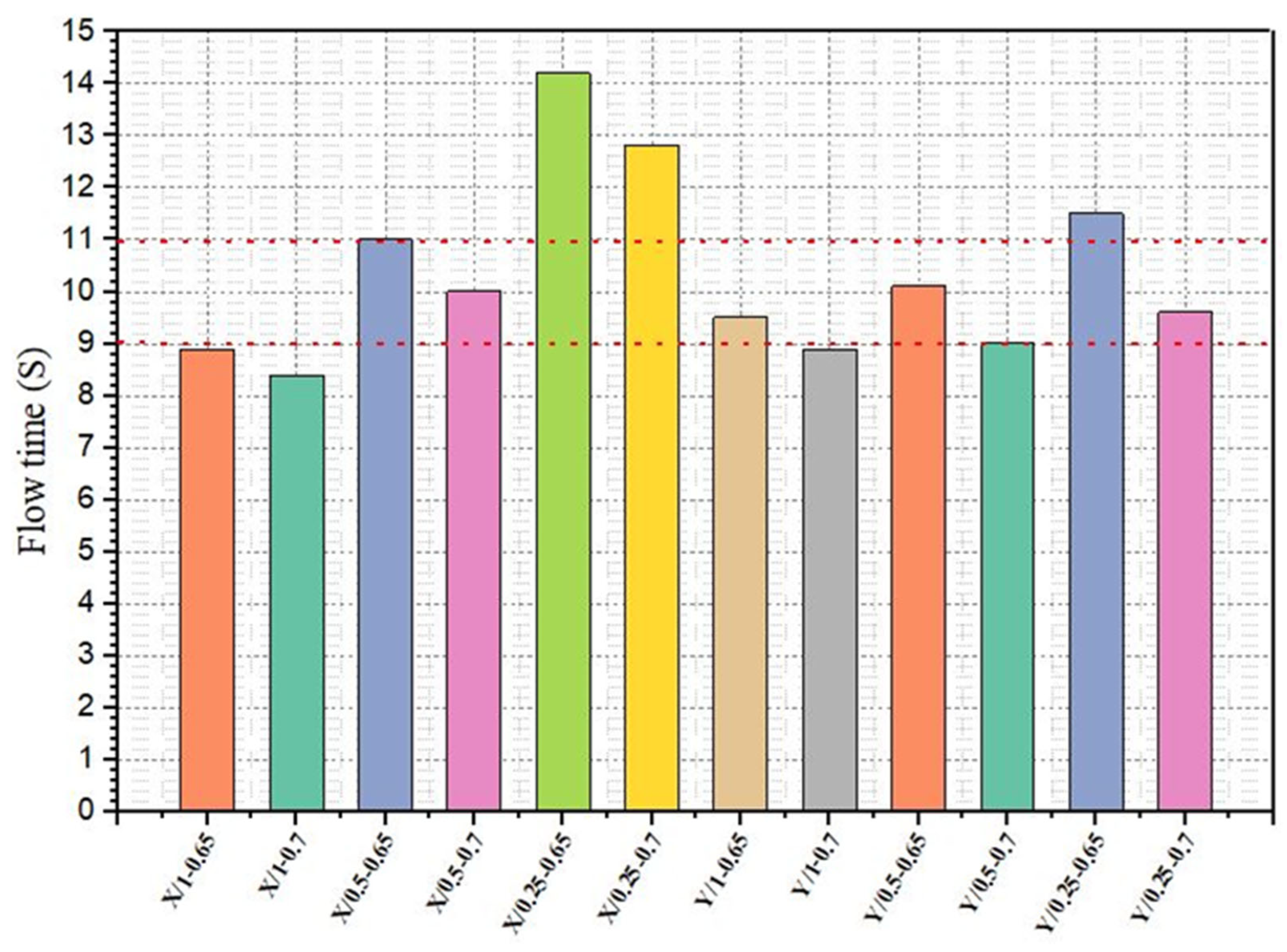

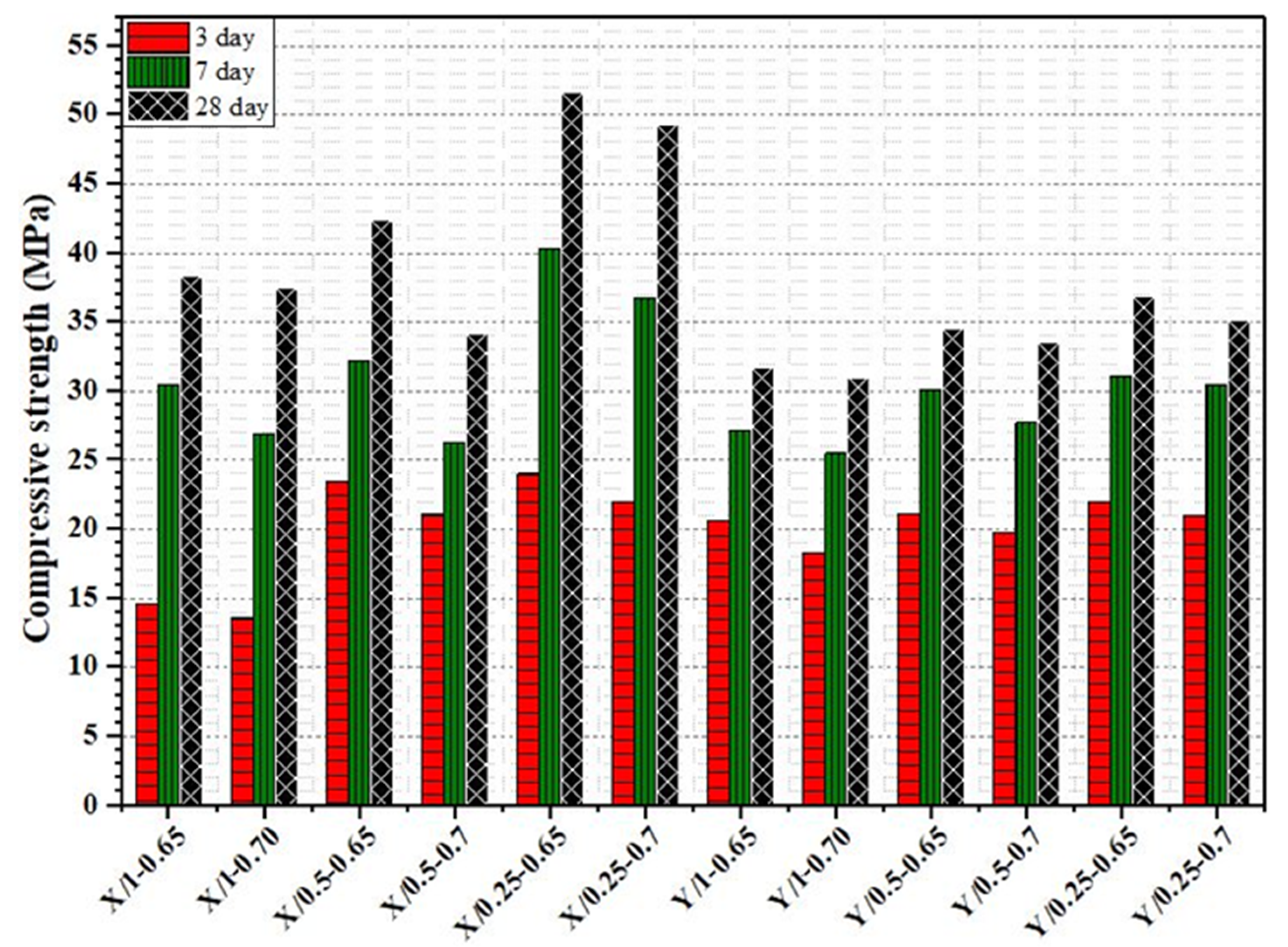

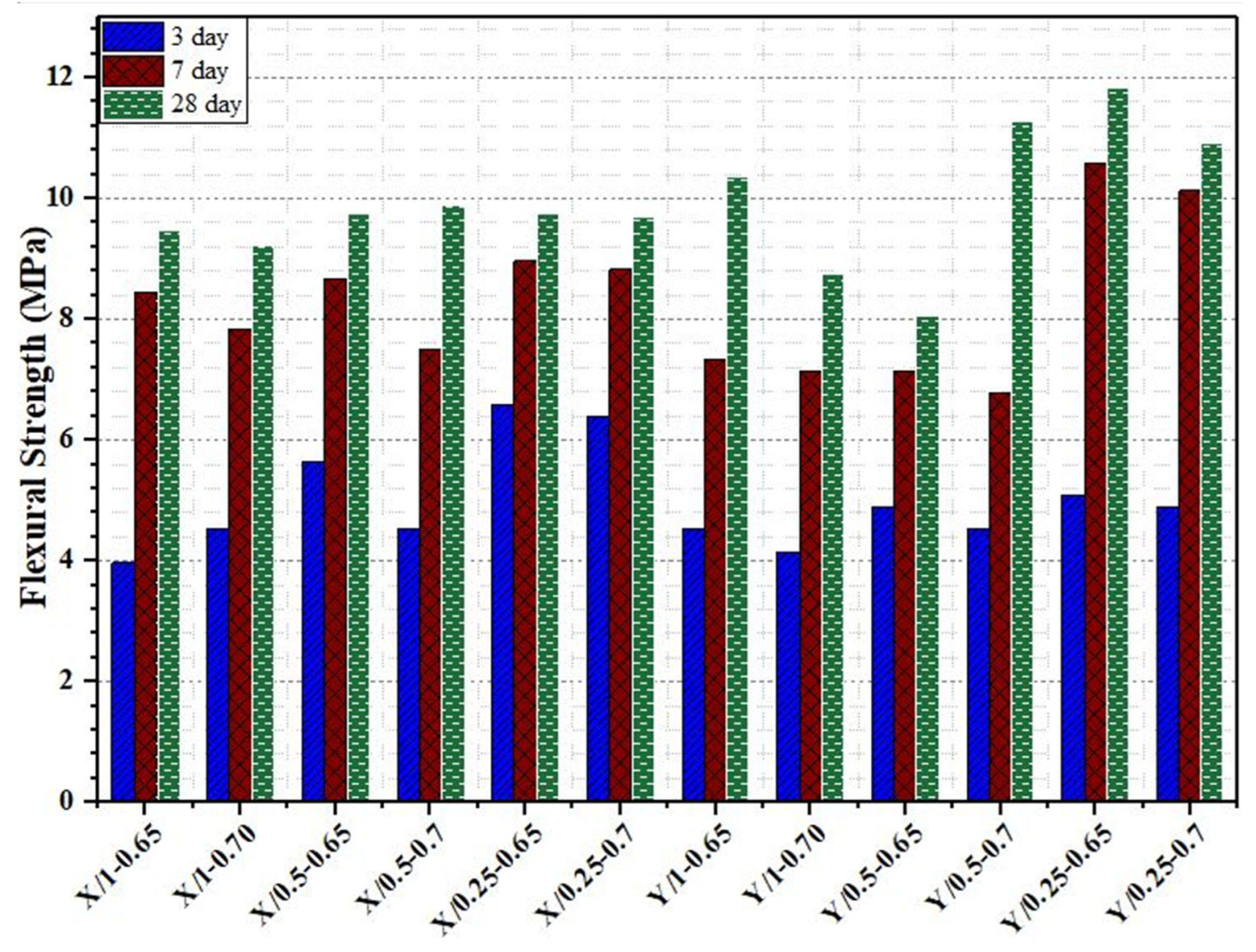

The selection of an appropriate cementitious grout for semi-rigid pavement (SRP) requires balancing three key properties: fluidity, volume stability, and strength. According to the literature, the fluidity of cementitious grout and the air content of porous asphalt play the most critical role in SRP design, as the grout must penetrate the air voids of the porous asphalt under gravitational force and fill at least 95% of the voids [

2,

40]. In this study, the initial grout mixture X/0.25-0.7, with a flow time of 12.8 s, failed to penetrate the porous asphalt (

Figure 15a), while the Y/0.5-0.7 mixture successfully filled the voids completely (

Figure 15b), confirming its superior workability. Y/0.5-0.7 also achieved a flow time within the recommended 9–12 s range (

Figure 7), ensuring full infiltration without the segregation observed in highly fluid mixes like X/1-0.7. Furthermore, it showed much lower drying shrinkage (≈0.085%) than comparable X-based mixtures (≈0.17%) (

Figure 10), providing better dimensional stability and reducing the risk of cracking or debonding. While Y-based mixtures generally had slightly lower 28-day compressive strength (35–49 MPa) than X-based ones, Y/0.5-0.7 still offers sufficient strength (

Figure 8) along with acceptable flexural performance (

Figure 9) to contribute to the load-bearing capacity of SRP. Overall, Y/0.5-0.7 provides the best balance among fluidity, stability, and strength and is therefore selected as the optimum grout mixture for SRP ap-plications.

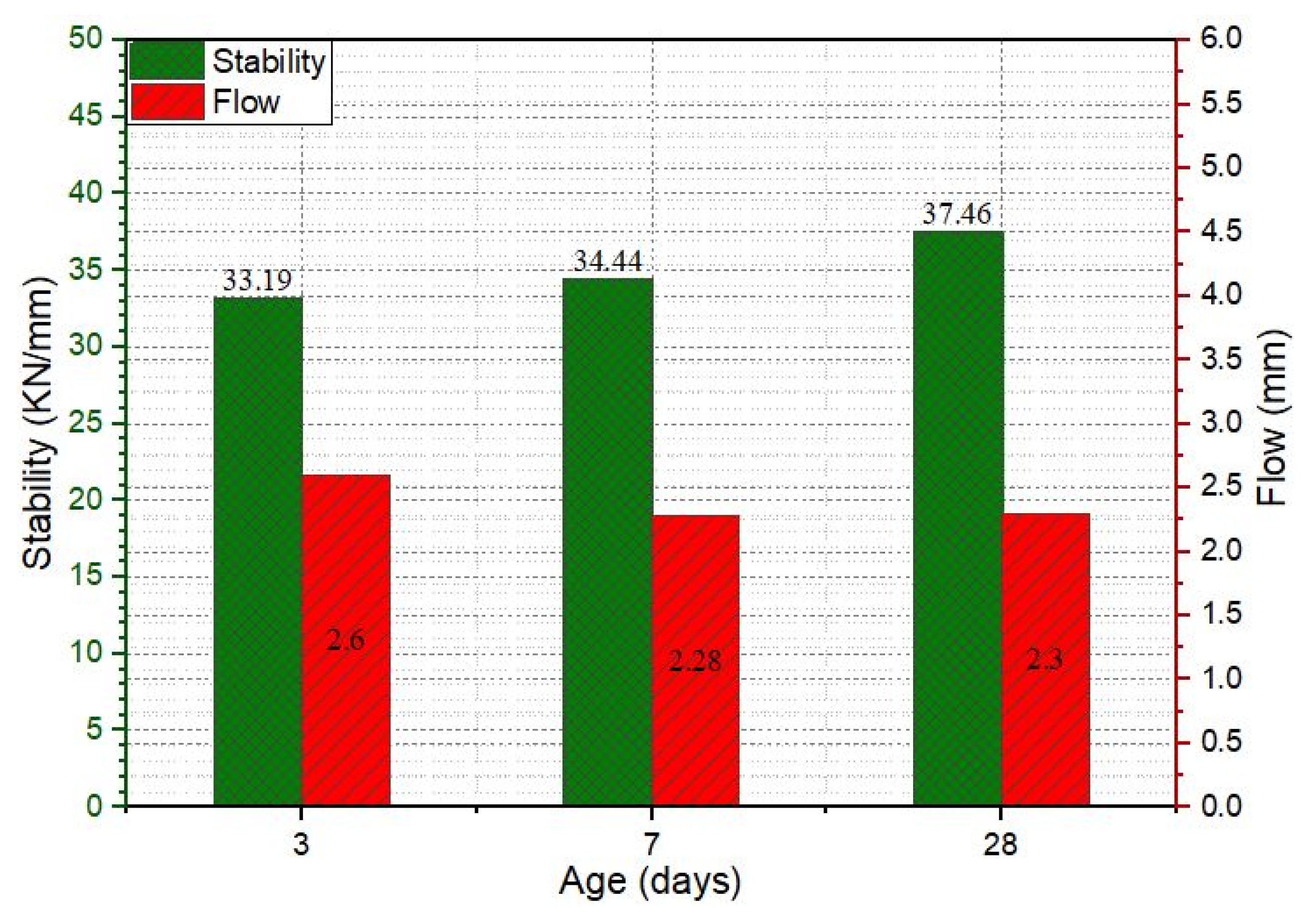

Stability value refers to the structural strength of the pavement. Prepared SRP specimens were subjected to the Marshall stability test after 3, 7, and 28-day air curing, and the results are shown in

Figure 16. As indicated in

Figure 16, the stability value of specimens increased by increasing curing time and reached 37.46 kN until 28 days. The integration of cementitious grout within the porous asphalt results in a composite structure that effectively brings together the mechanical advantages of both cementitious grout and porous asphalt. Cementitious grout, with its high compressive strength, enables the composite to withstand heavy traffic-induced stresses. At the same time, the asphalt skeleton contributes flexibility and promotes strong bonding with the aggregate particles, thereby minimizing friability and enhancing the overall durability of the SRP composite. According to Turkish Highway Construction Specification 2013 (THCS), an adequate Marshall stability value for the wearing course of flexible pavement is 900 kg (8.89 kN). The Asphalt Institute [

41] proposes a minimum stability value of 8 kN; similarly, ERA [

42] indicates a minimum stability value of 9 kN for a very heavy traffic class pavement. Deshmukh obtained the maximum stability value of SRP as 22.7 kN [

43]. By comparing the Marshall stability of SRP results of the current study with the literature review, it can be concluded that the mechanical properties of cementitious grout improved the performance of the SRP mixture. Flow value is an indication of the plasticization of the deformation of pavement under traffic load. According to THCS, the flow value for wearing courses is between 2 and 4 mm. As shown in

Figure 15, the flow value is inside the limits of THCS.

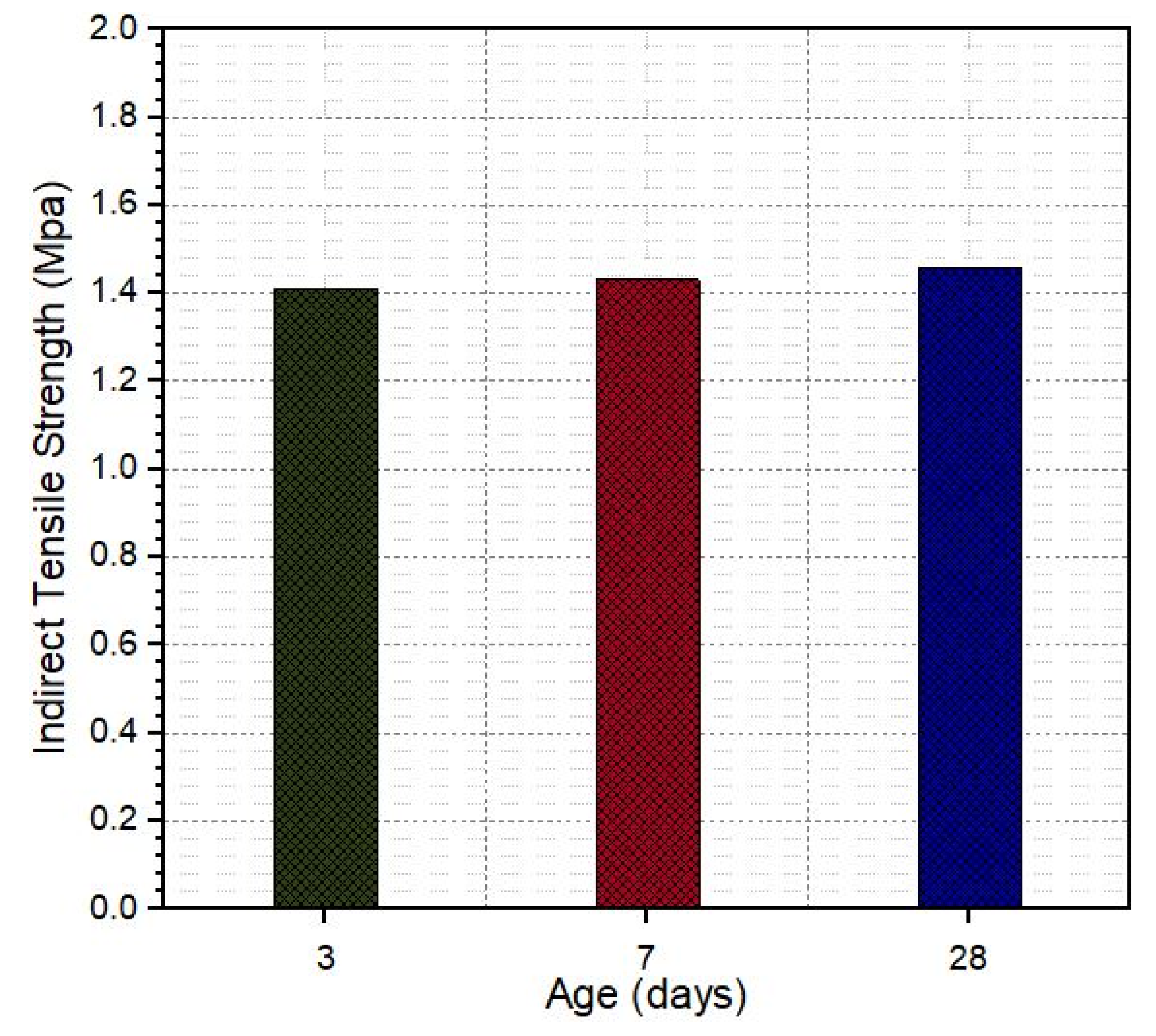

The indirect tensile strength test was performed to determine the fracture strength and stiffness of the pavement mixtures. The test results of SRP specimens at different curing times are shown in

Figure 16. As indicated in

Figure 17, curing time has no significant effect on the tensile strength; the maximum strength obtained at 28 days is 1.46 MPa. Hulala determined the tensile strength of porous asphalt with a % of air content as 0.18 MPa [

44]. The cementitious grout used in the design of SRP specimens in the current study had 10.92 MPa flexural strength at 28 days of curing, so we can conclude the flexural strength of grout increased the indirect tensile strength of SRP (

Figure 17).

The compressive strength of SRP was calculated by dividing the maximum load obtained by the cross-sectional area of the specimen, and the result is shown in

Figure 18. According to the literature review, Densiphalt

® [

45] and DuraTough

® [

46], which are commercial products, declared in their user manuals that the maximum compressive strength is 7 MPa and 5 MPa after 28 days of curing for SRP. As seen in

Figure 18, the compressive strength of the current study is 5.55 MPa at 28 days of curing. Obtained results fall within this range. Therefore, by comparing with the literature review it can be said that the obtained compressive strength is adequate for SRP.

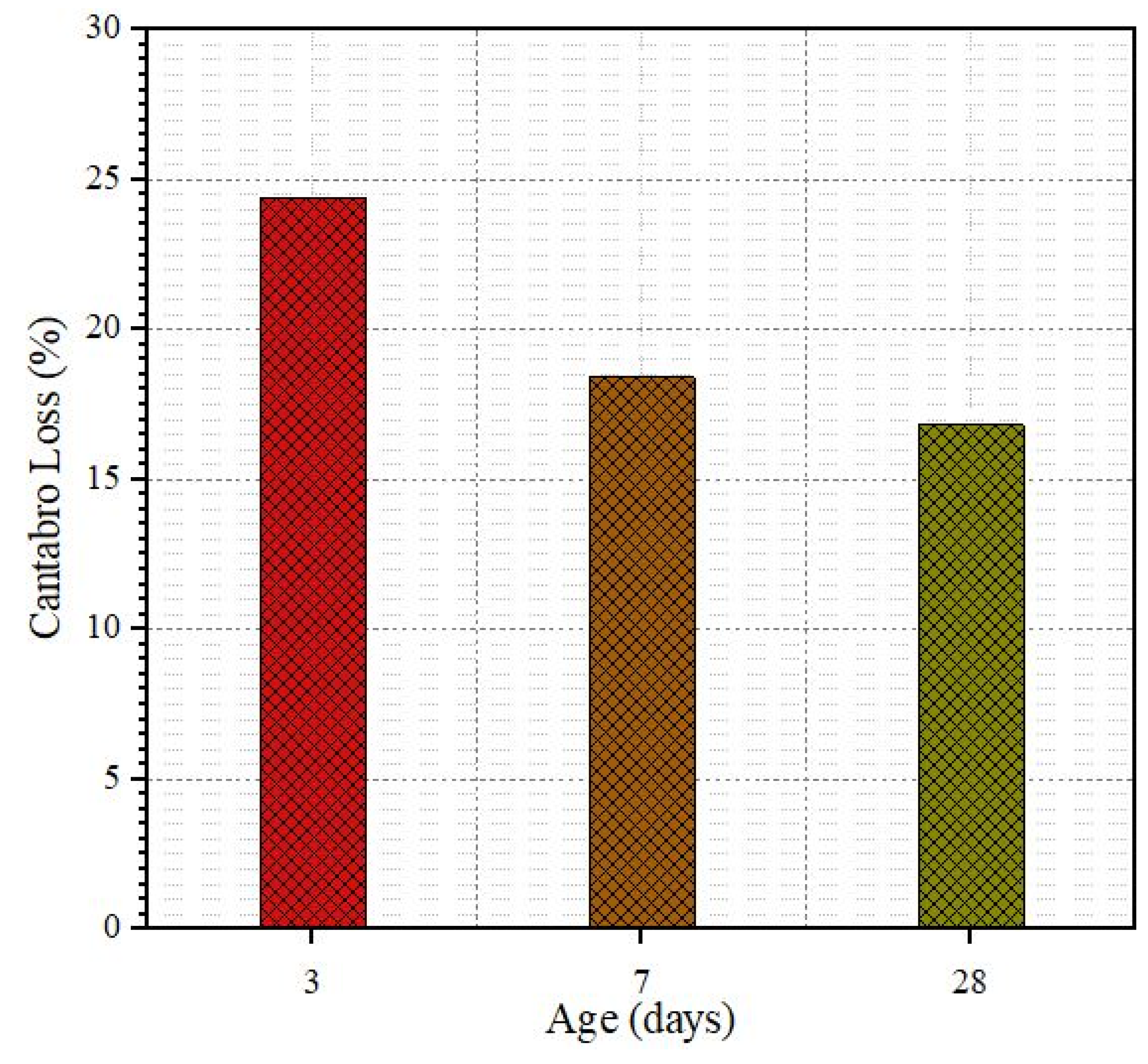

The abrasion resistance or Cantabro test was conducted to estimate the mass loss of SRP specimens at three different air-curing times.

Figure 19 shows the Cantabro test results for 3, 7, and 28 days. As indicated in the figure, the mass loss of SRP specimens decreased over time due to the grout hardening over this time. As the resistance of grout material increases over time, it may lead to better bonding between grout material and porous asphalt mixture.

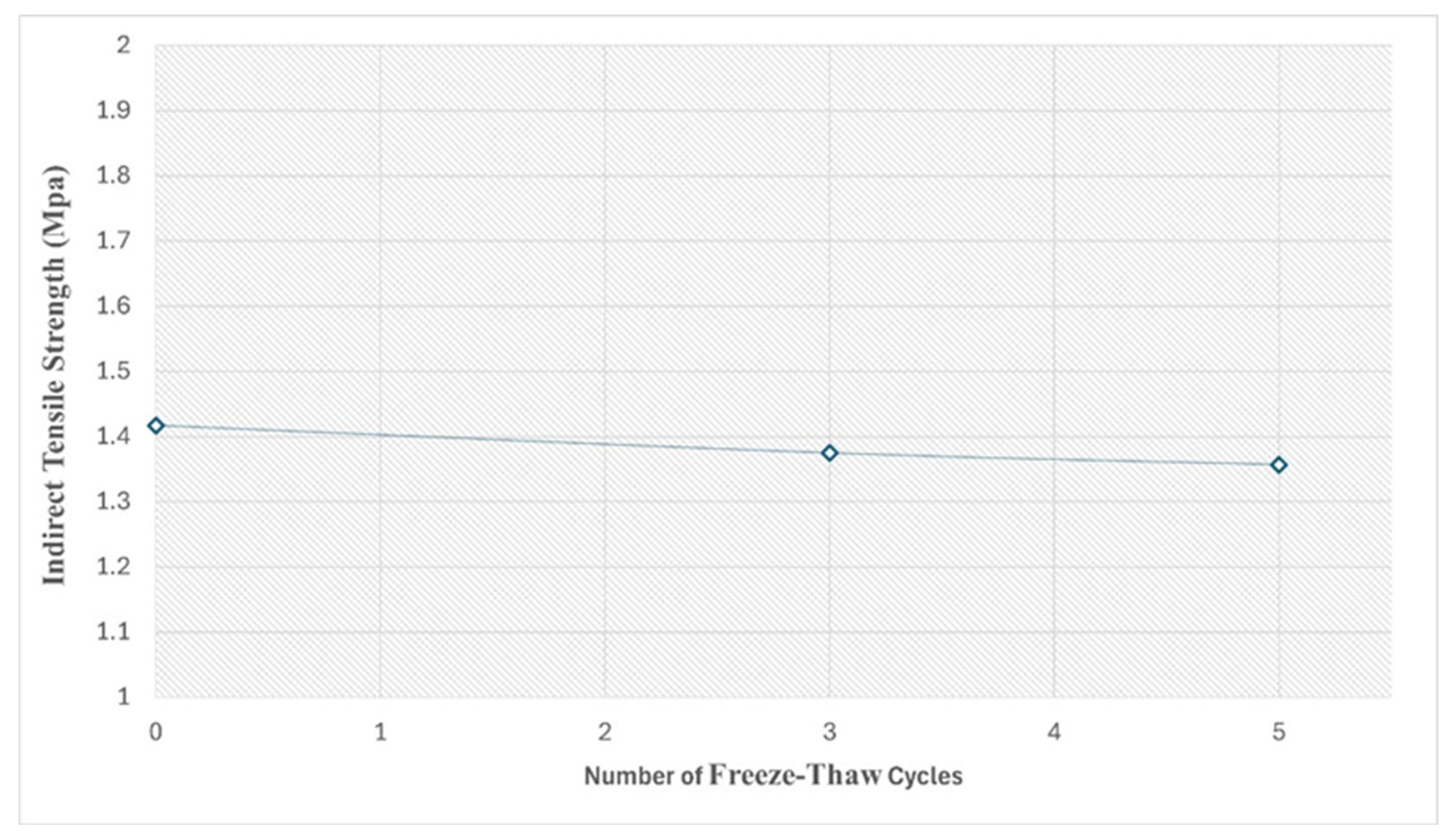

One of the major problems for pavements is the cold climate, which causes early deterioration of the pavement layer. The freeze–thaw test was conducted to evaluate the moisture damage resistance of SRP. Specimens were subjected to indirect tensile strength after 3 and 5 cycles of freeze–thawing, and the results are shown in

Figure 20. Based on the test results, it is seen that the strength losses after 3 and 5 freezing and thawing cycles are 2.1% and 3.2%, respectively. The incorporation of cementitious grout within the porous asphalt enhances the material’s resistance to freeze–thaw cycles by minimizing moisture-induced damage. The grout infiltrates and fills the interconnected voids of the asphalt skeleton, thereby reducing permeability and restricting water infiltration, which is the principal factor contributing to frost damage. Furthermore, the high stiffness and compressive strength of the cementitious grout provide structural reinforcement for the SRP composite and withstand the internal stresses provided by the volumetric expansion of freezing water. This means that SRP can be applied in cold climatic regions in terms of Life Cycle Assessment (LCA) [

47].