Free Vibration Analysis of Thin Functionally Graded Plate Bands with Microstructure as a Function of Material Inhomogeneity Distribution and Boundary Conditions

Abstract

1. Introduction

1.1. Subject of Analysis and Aim of the Work

1.2. Literature Review

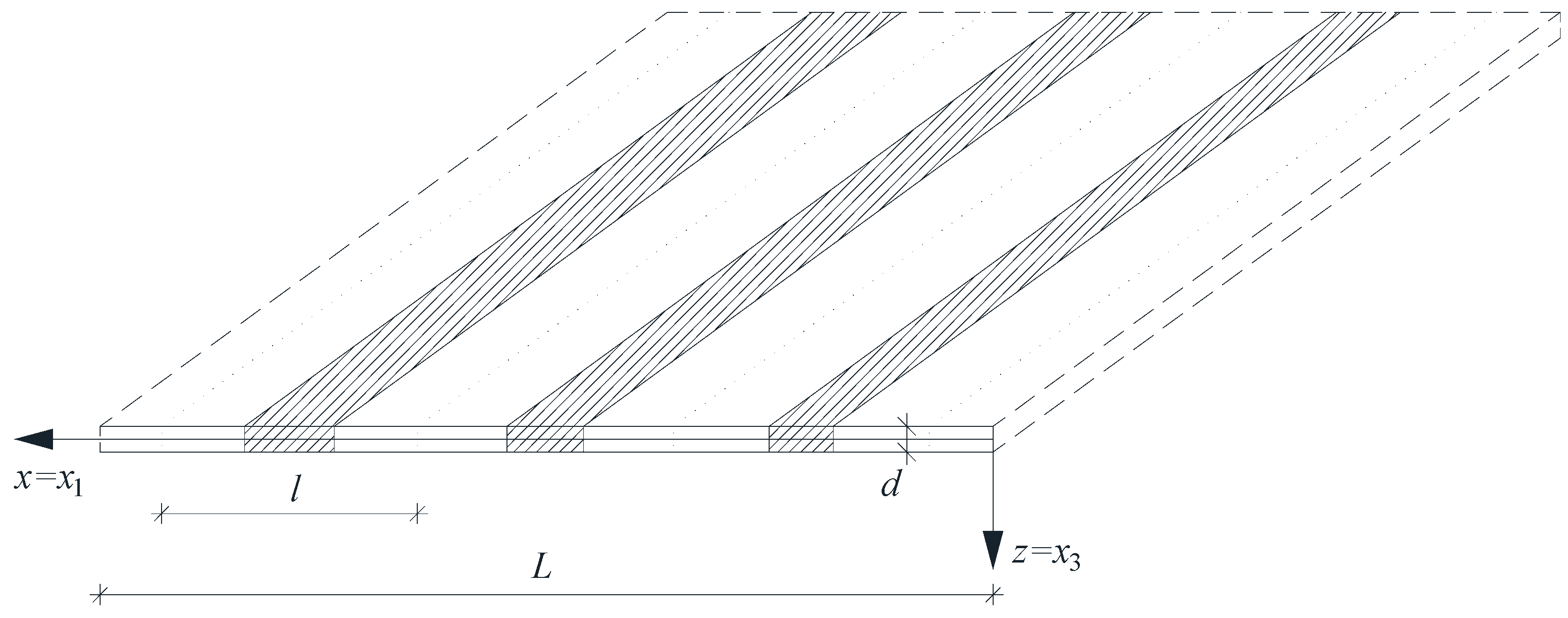

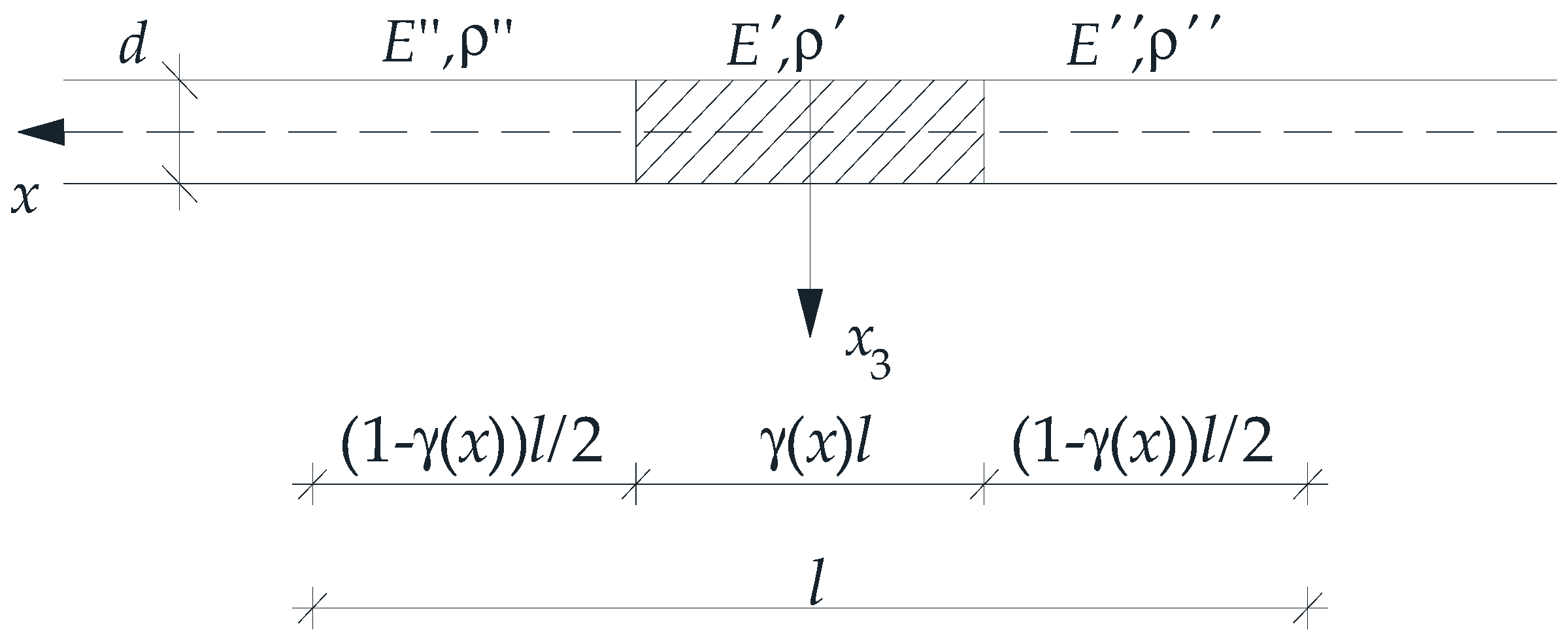

2. Foundations

2.1. Preliminaries

2.2. The Tolerance Modelling

3. Governing Equations of Tolerance-Periodic Plate Bands

3.1. Tolerance Model Equations

3.2. Asymptotic Model Equations

4. Free Vibration Analysis for Tolerance-Periodic Plate Bands with Different Support Conditions

4.1. Introduction

4.2. The Application of the Ritz Method

- The simply supported plate band

- The plate band clamped on both edges

- The clamped–hinged plate band

- The cantilever plate band

- The simply supported plate band

- The plate band clamped on both edges

- The clamped–hinged plate band

- The cantilever plate band

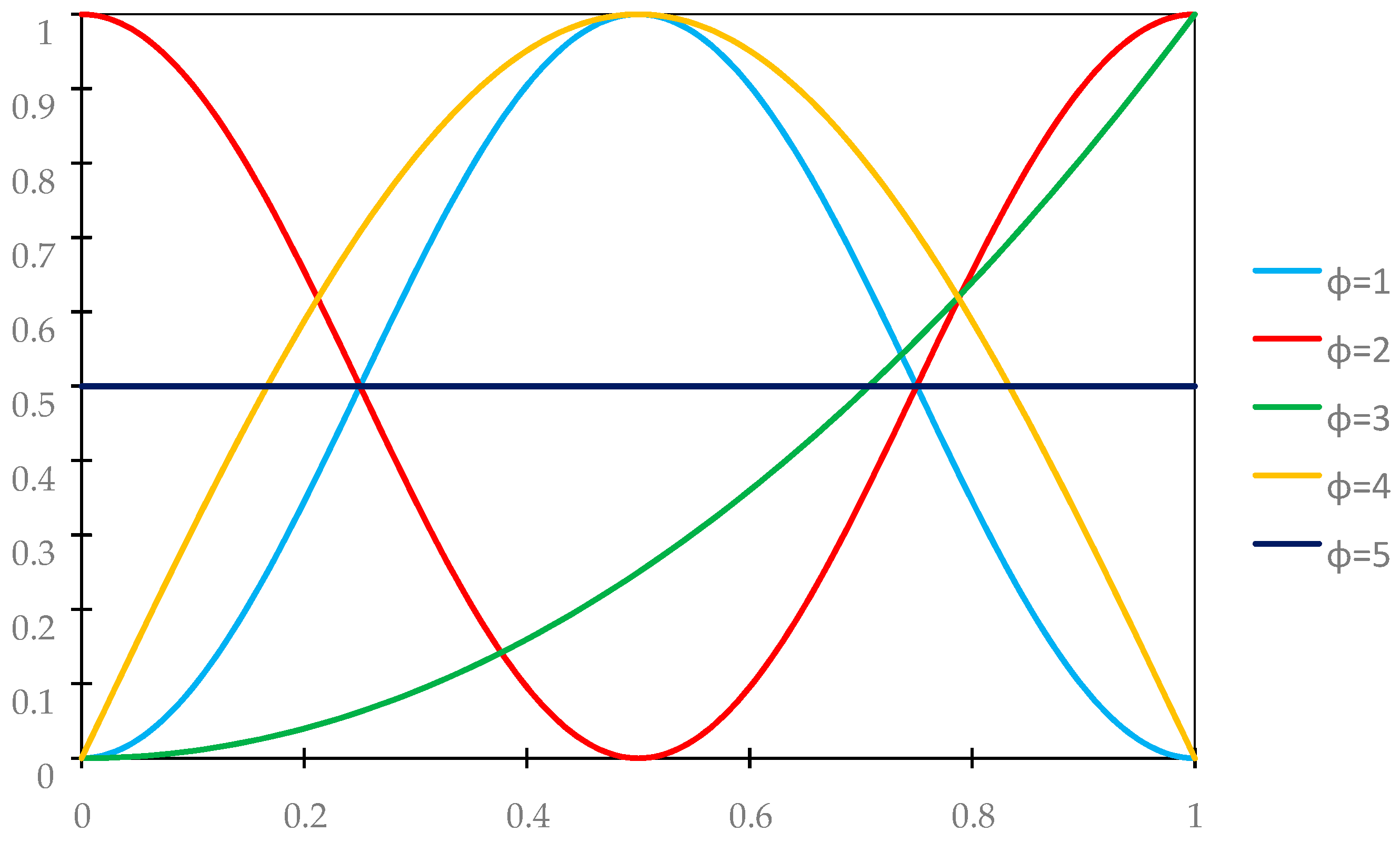

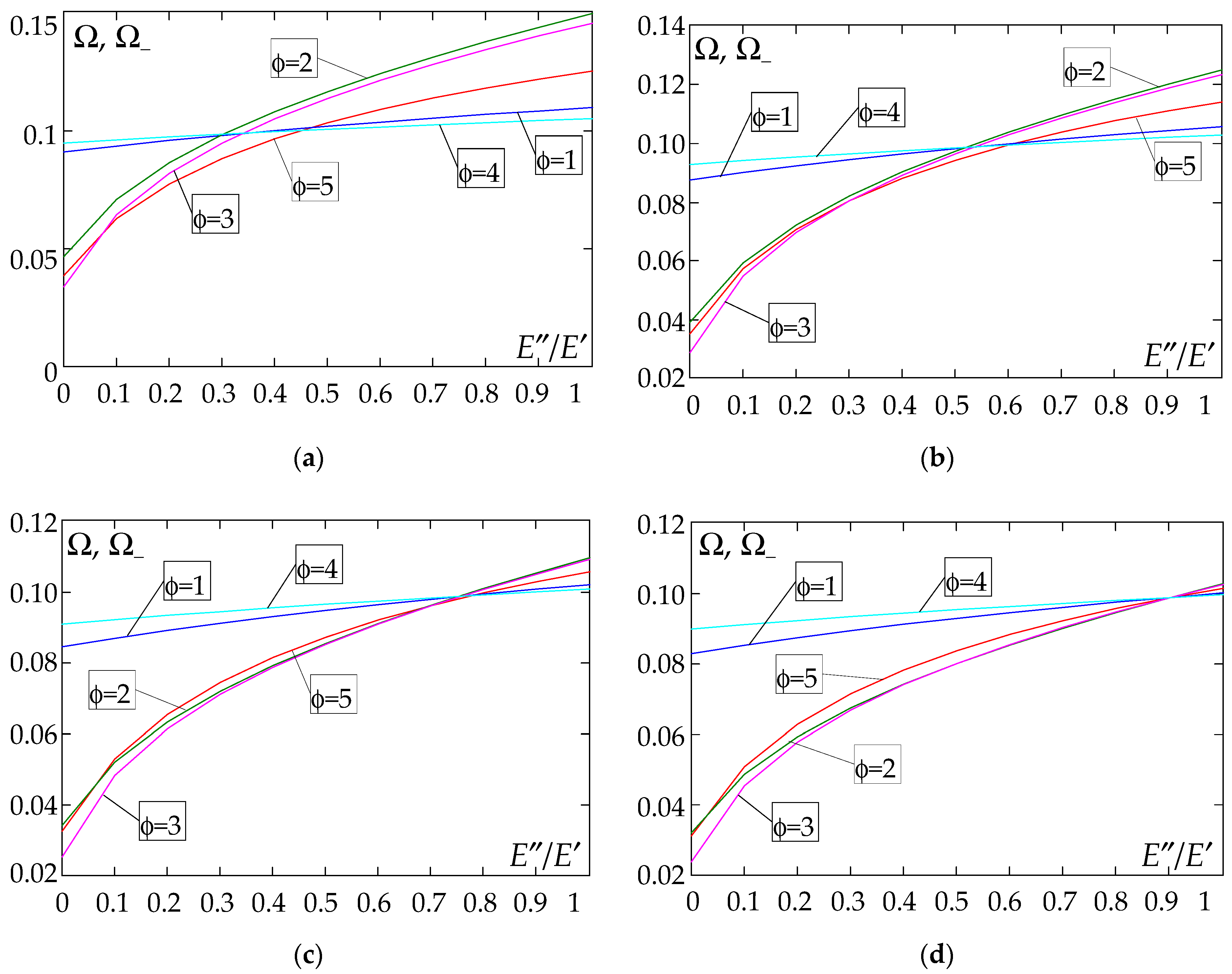

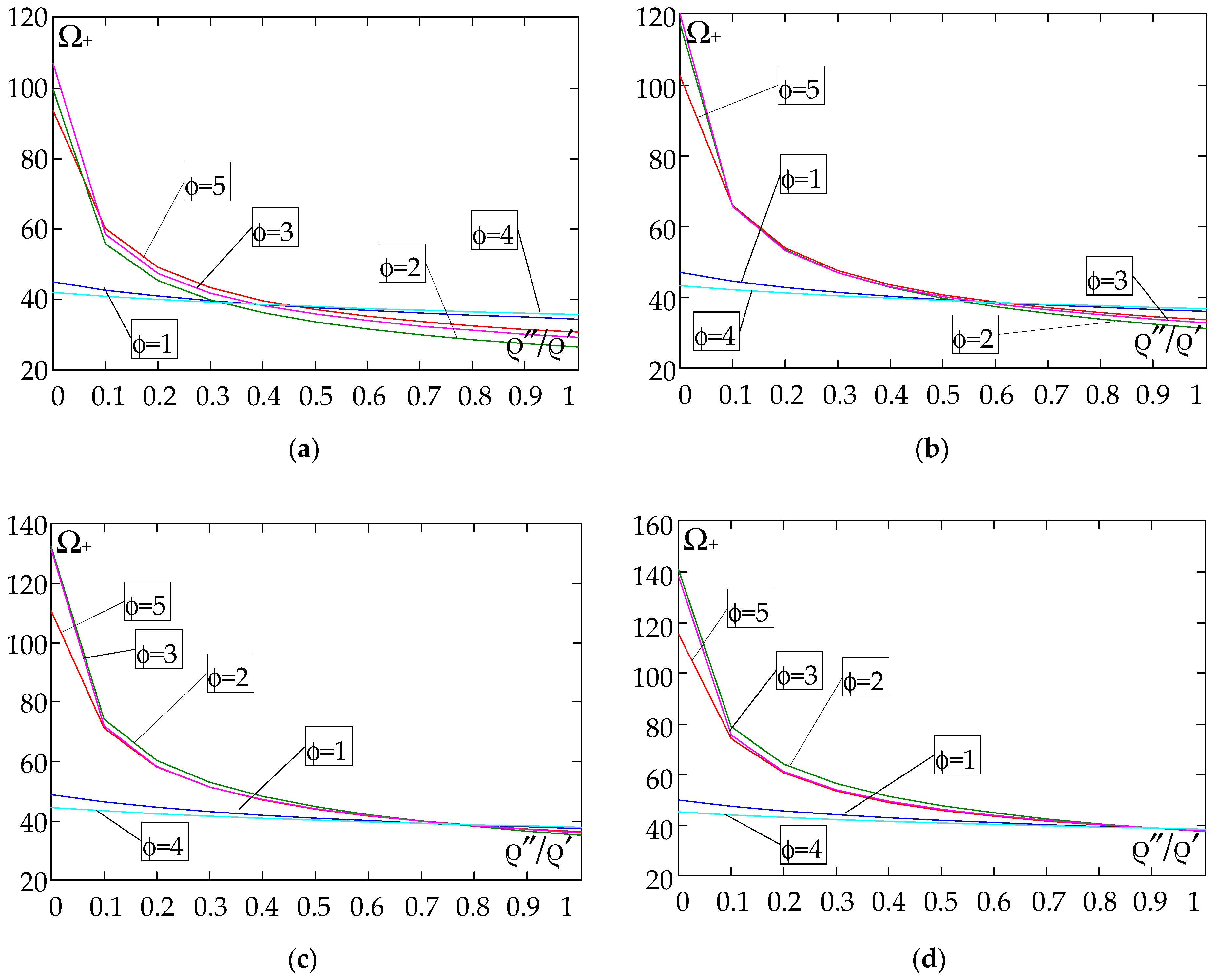

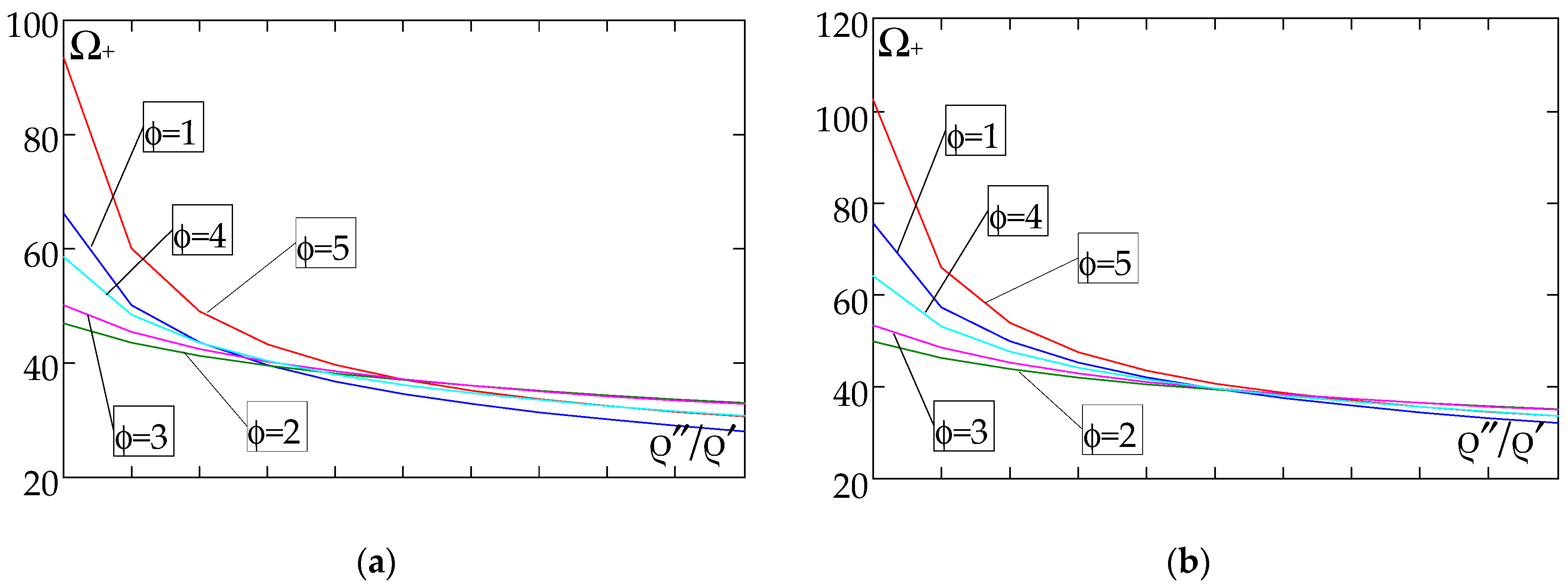

4.3. Calculation of Free Vibration Frequencies

5. Comparison of Fundamental Frequencies Calculated Using the Tolerance Model (TM) and the Finite Element Method (FEM)

6. Some Final Remarks

- For the tolerance model, a system of differential equations is obtained in which some components depend on the microstructure parameter l. This model makes it possible to take into account the effect of the microstructure size on the tolerance-periodic thin plate dynamics problems being solved, such as the “higher order” vibrations, related to the microstructure of the plate.

- The governing equations of the tolerance model make physical sense if their basic unknowns, i.e., the macrodeflection, W, and fluctuation amplitudes, QA, A = 1, …, N, satisfy the a posteriori condition, i.e., they are slowly varying functions.

- In the case of the asymptotic model, one differential equation is obtained for the macrodeflection and a system of algebraic equations for the fluctuation amplitudes. These equations do not take into account the effect of microstructure size. Only the basic values of the quantities sought are obtained. It should also be noted that the equations of the asymptotic model can be obtained by applying the appropriate asymptotic modelling procedure, as shown in [3,82] and outlined here in Appendix A, or by omitting components that depend on the microstructure parameter in the equations of the tolerance model.

- Using the asymptotic model, only the lower-order (fundamental) vibrations of the tolerance-periodic plates can be analysed.

- Using the Ritz method of the tolerance model, it is possible to derive formulae for lower-order (fundamental) and higher-order free vibration frequencies for different boundary conditions.

- A number of calculations were carried out for different boundary conditions and different distribution functions of the properties, and the values obtained made it possible to demonstrate the consistency of the results obtained within the tolerance model and the asymptotic model.

- The use of the finite element method made it possible to compare the results obtained by applying the proposed models for the fundamental free vibration frequencies of a thin tolerance-periodic plate band with a functional gradation of properties. It can be seen that the relative error of the values obtained is related to the material proportions assumed for the plate band under consideration. The greater the differences between the Young’s moduli for Material 1 and Material 2 assumed for the calculations, the greater the relative error obtained for the determined frequencies. Significant differences in the stiffness of cell fragments may limit the applicability of the tolerance model.

- Both the models—the tolerance and the asymptotic—allow the consideration of lower free vibration (fundamental) frequencies; but only the tolerance model makes it possible to analyse higher free vibration frequencies, associated with the plate band tolerance-periodic microstructure.

- The values of the lower free frequencies of the tolerance-periodic plate band are dependent on the boundary conditions, as in the case of homogeneous plates.

- The values of the higher free vibration frequencies of the tolerance-periodic plate bands being considered also depend on the support conditions, unlike in the case of periodic plate bands, cf. [4].

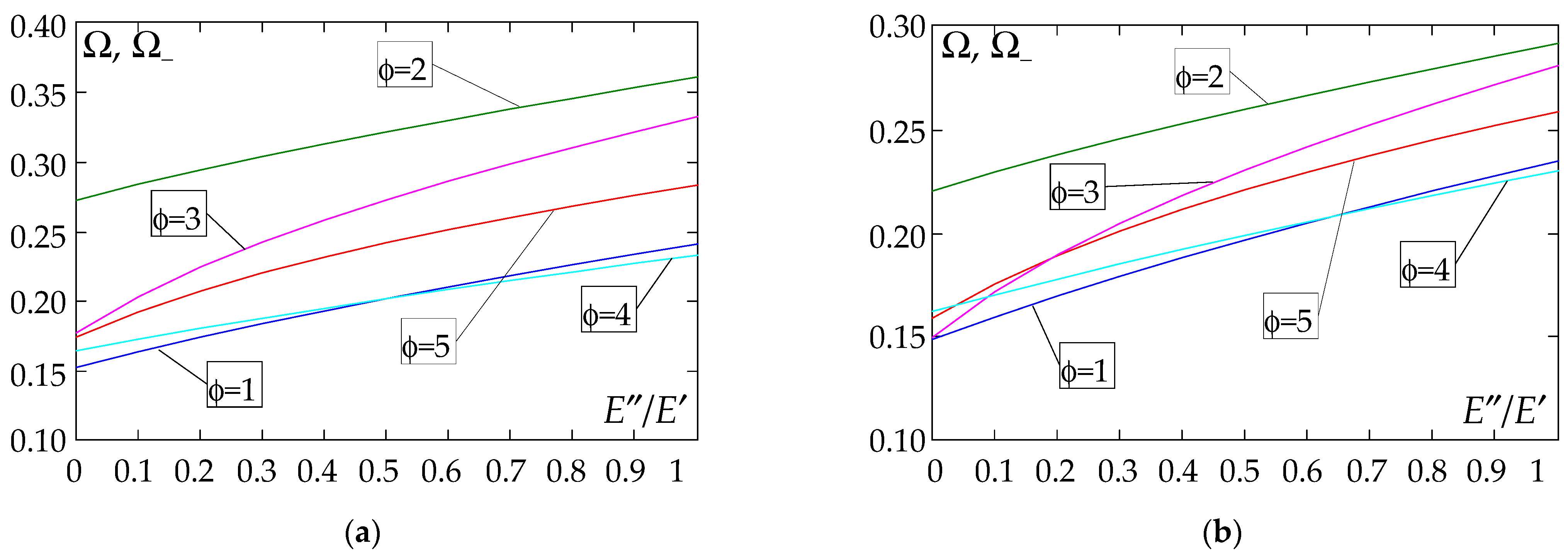

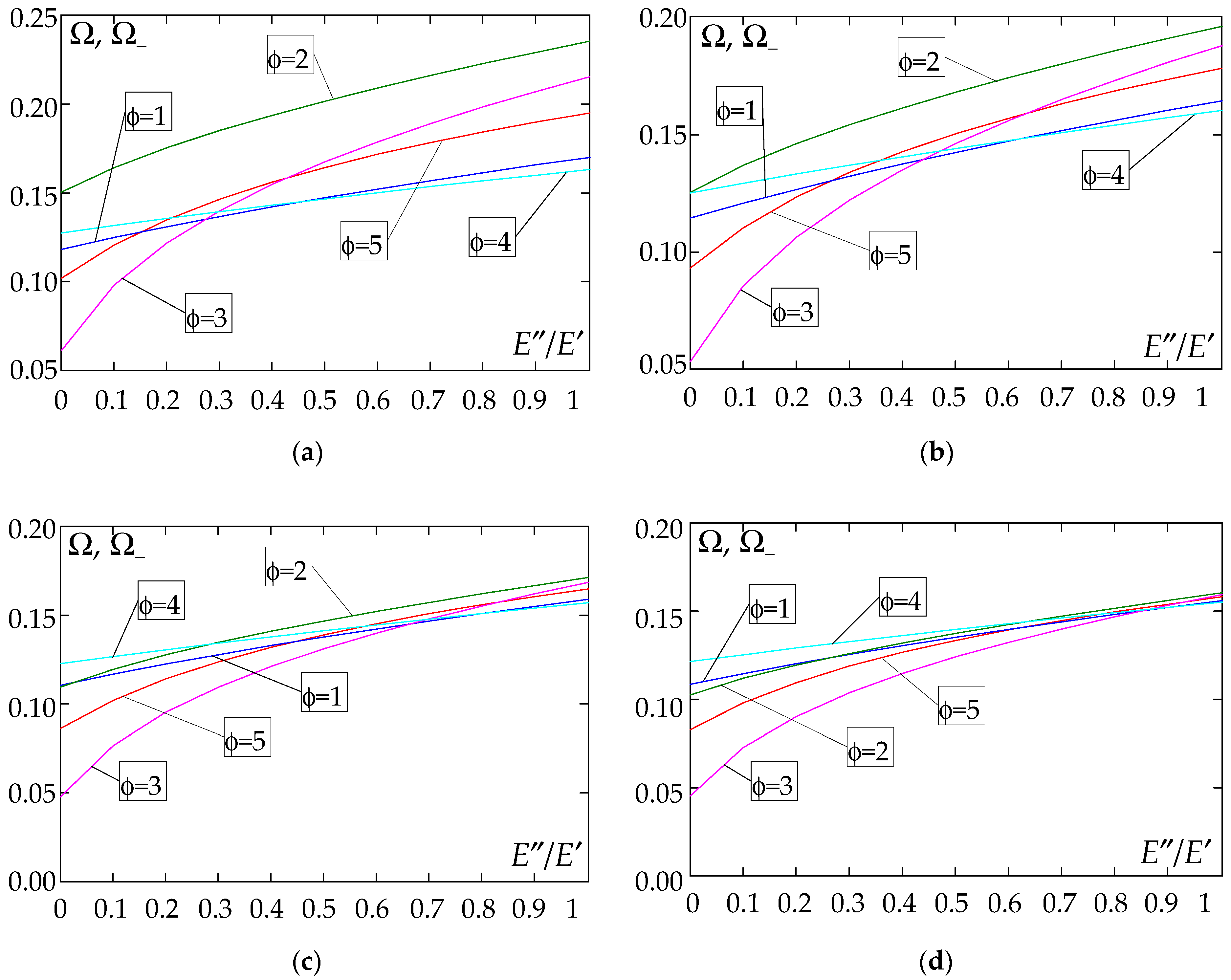

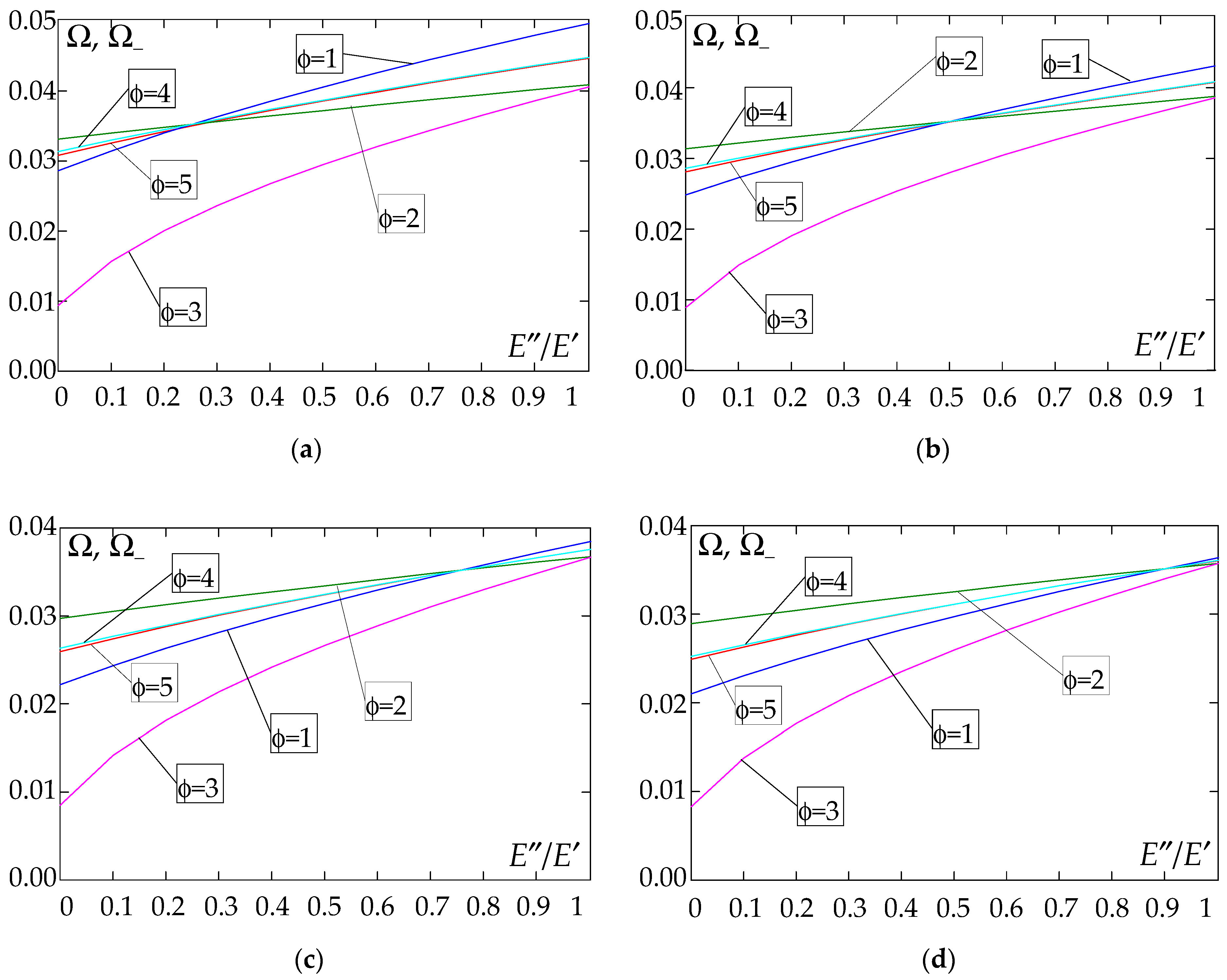

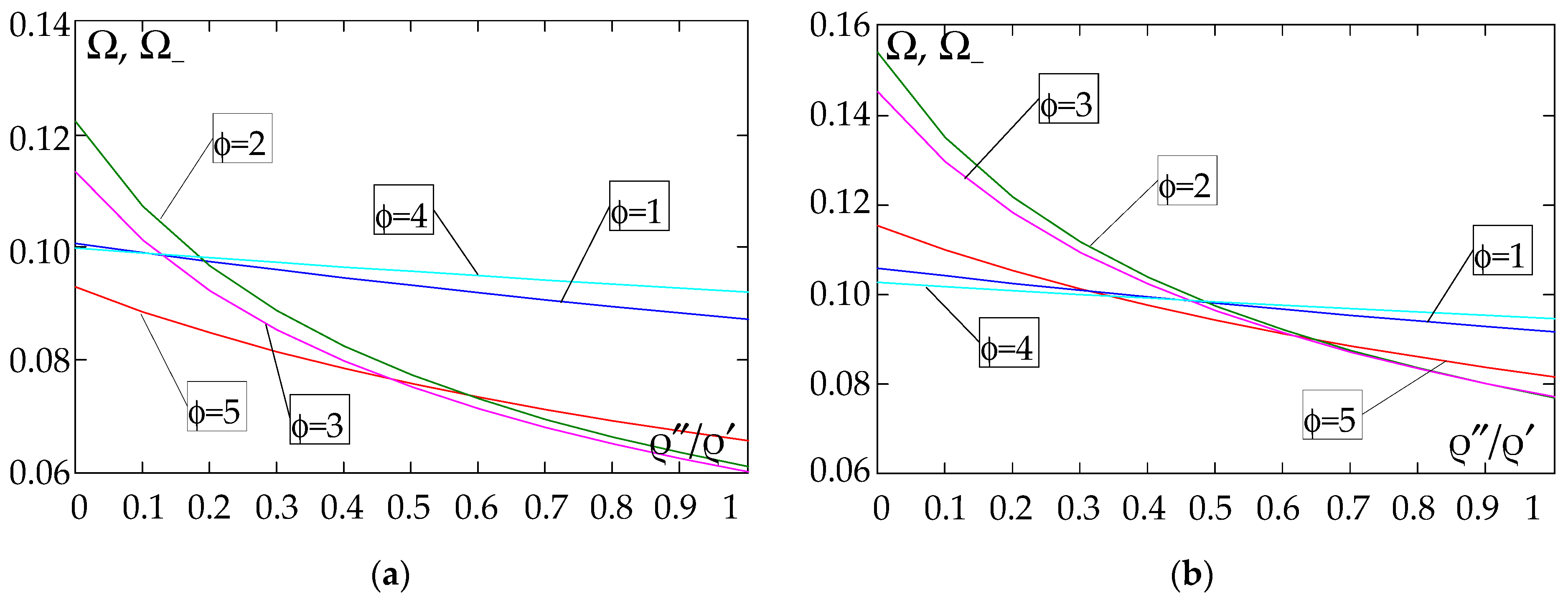

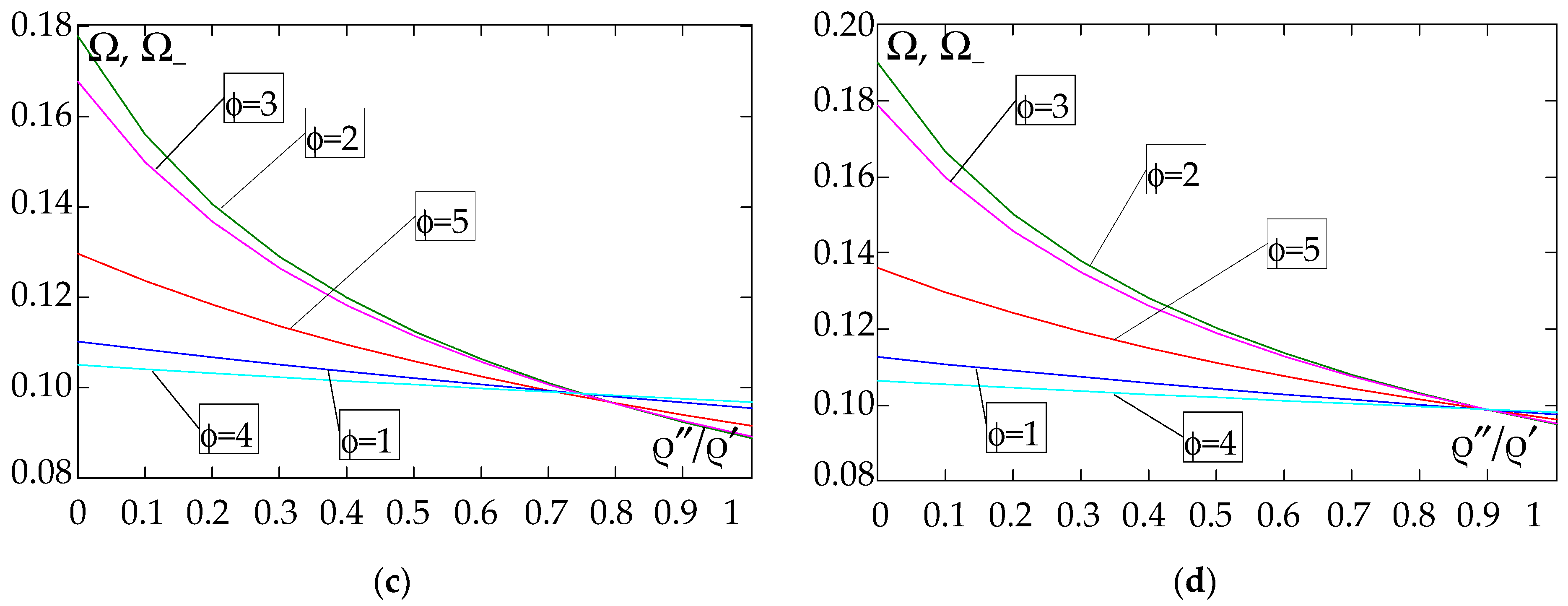

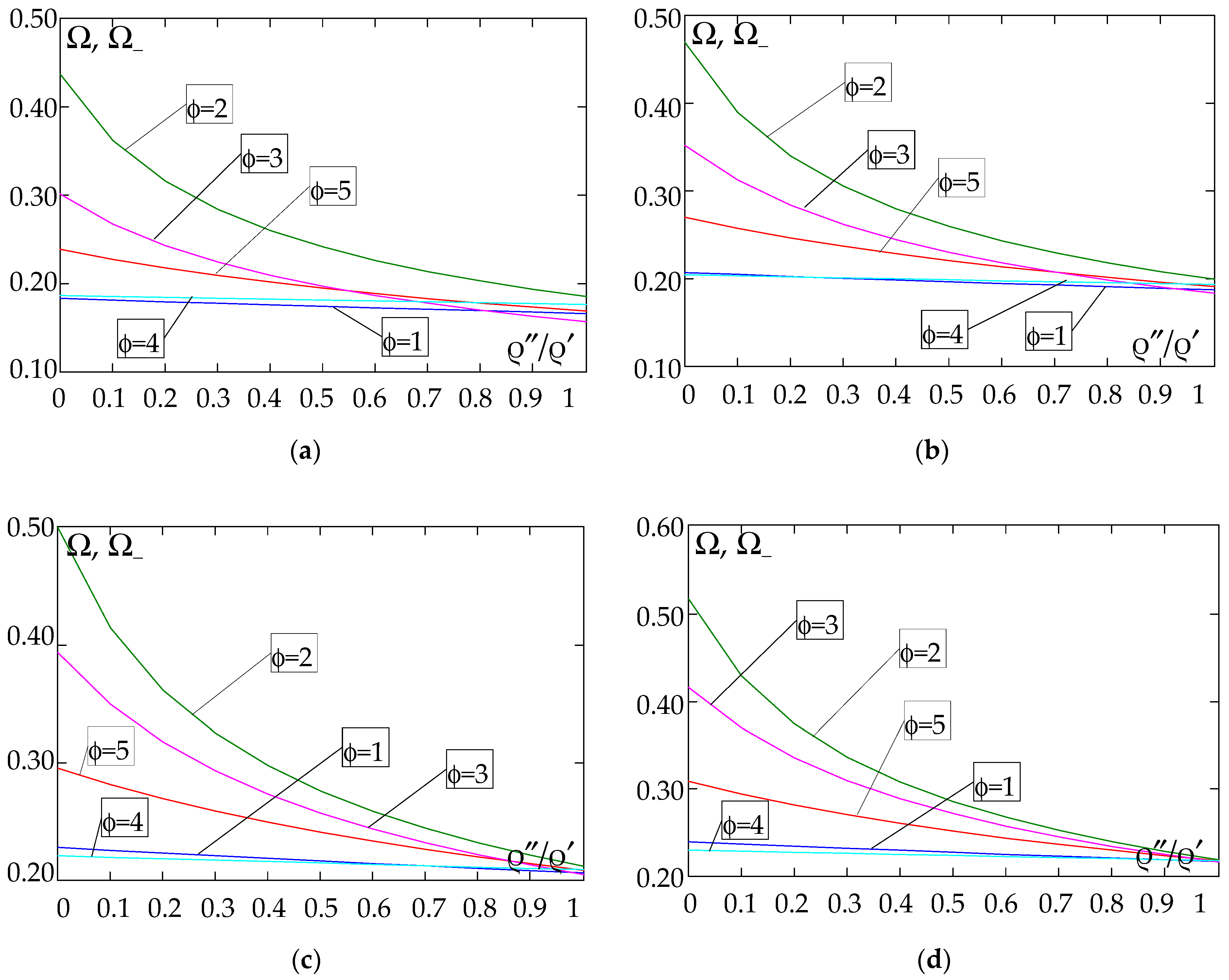

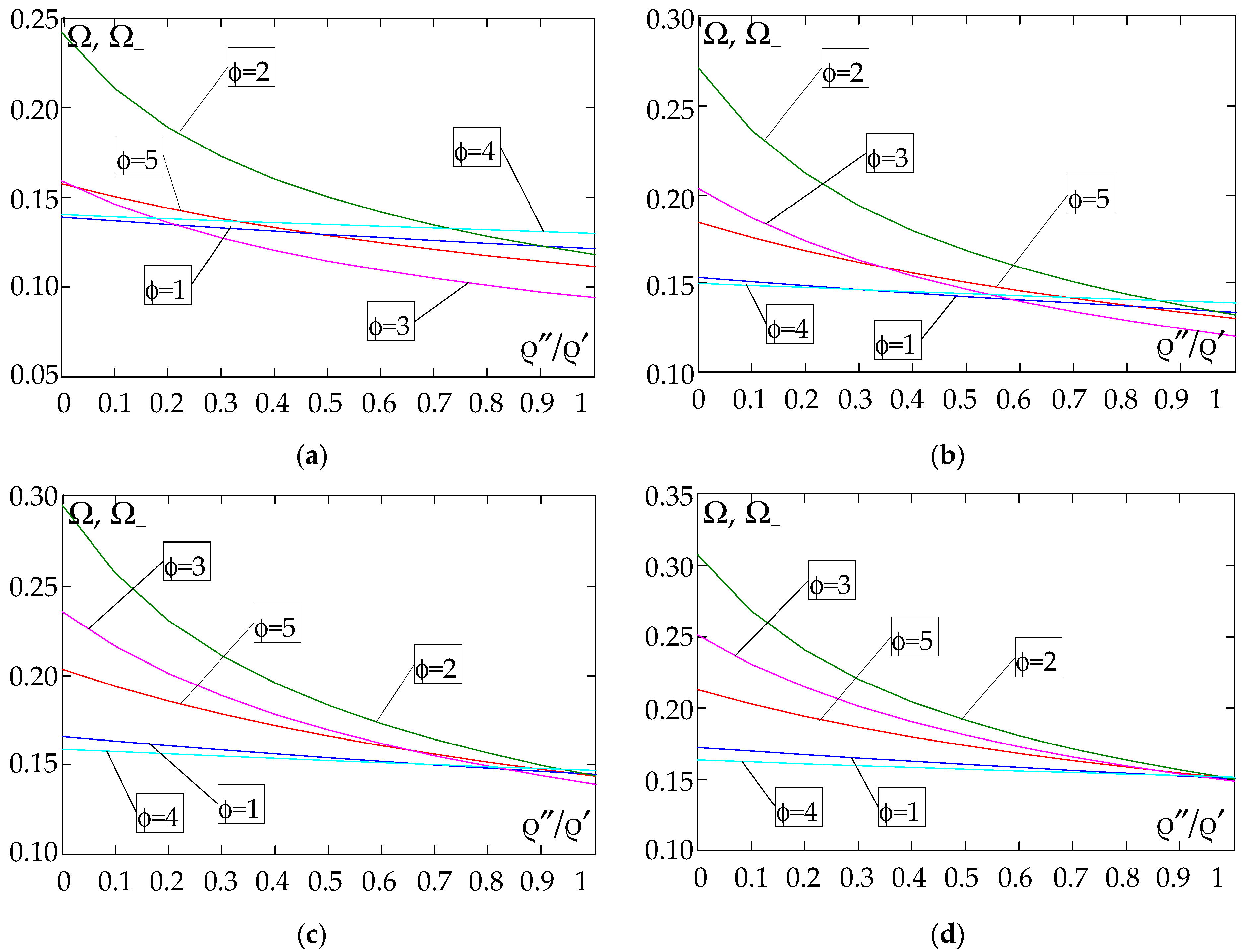

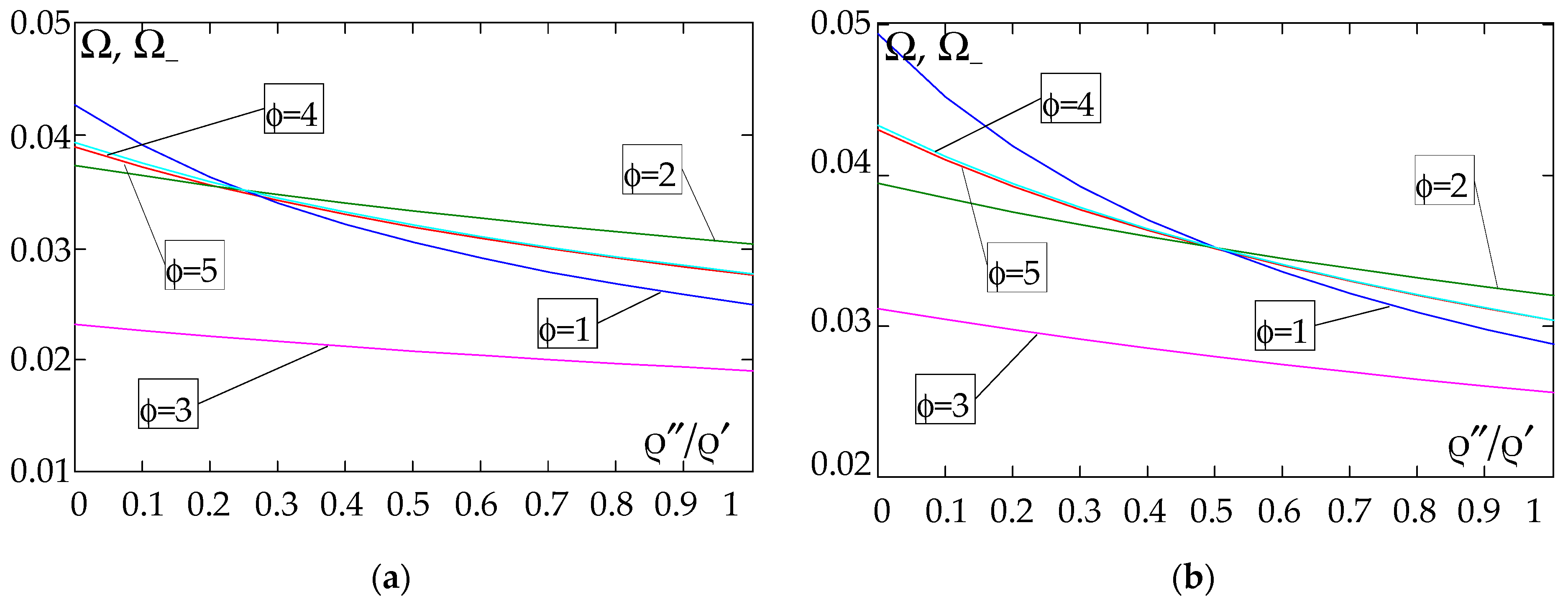

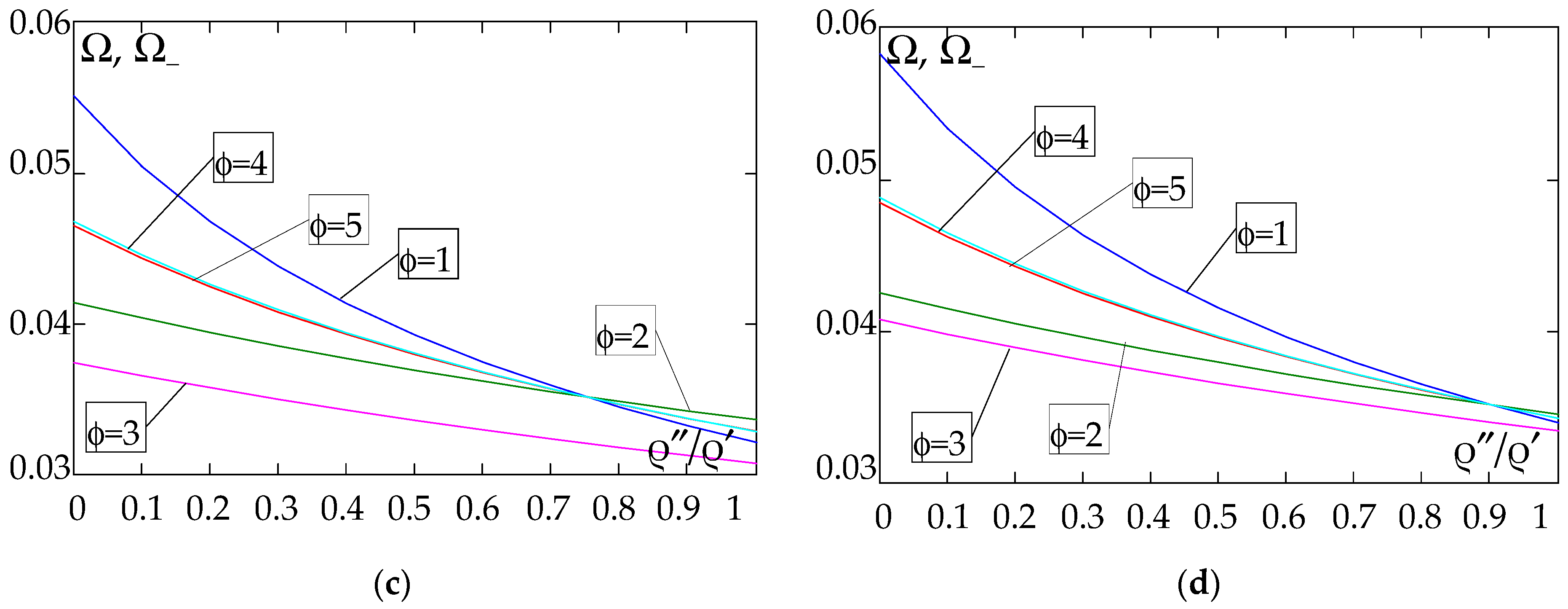

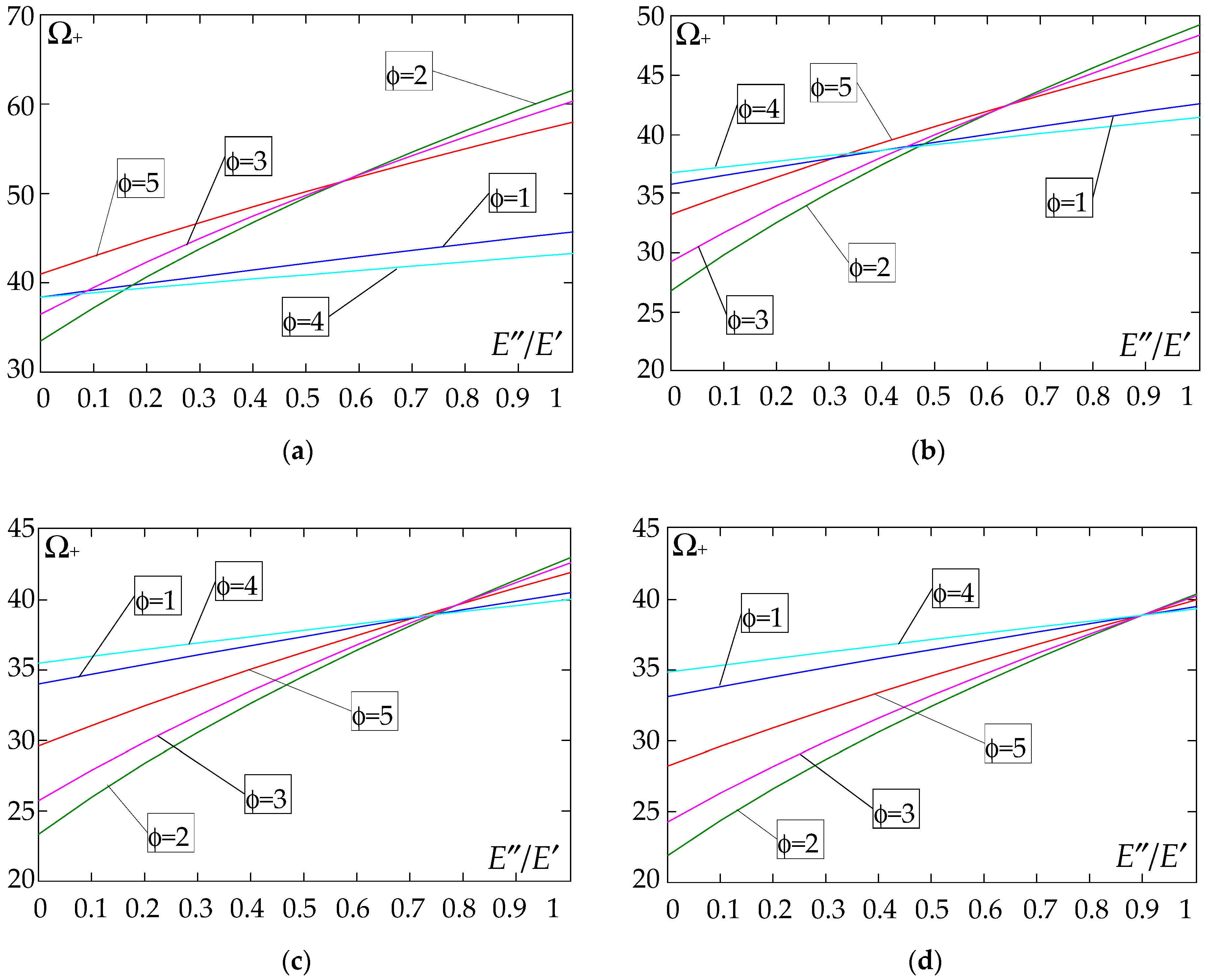

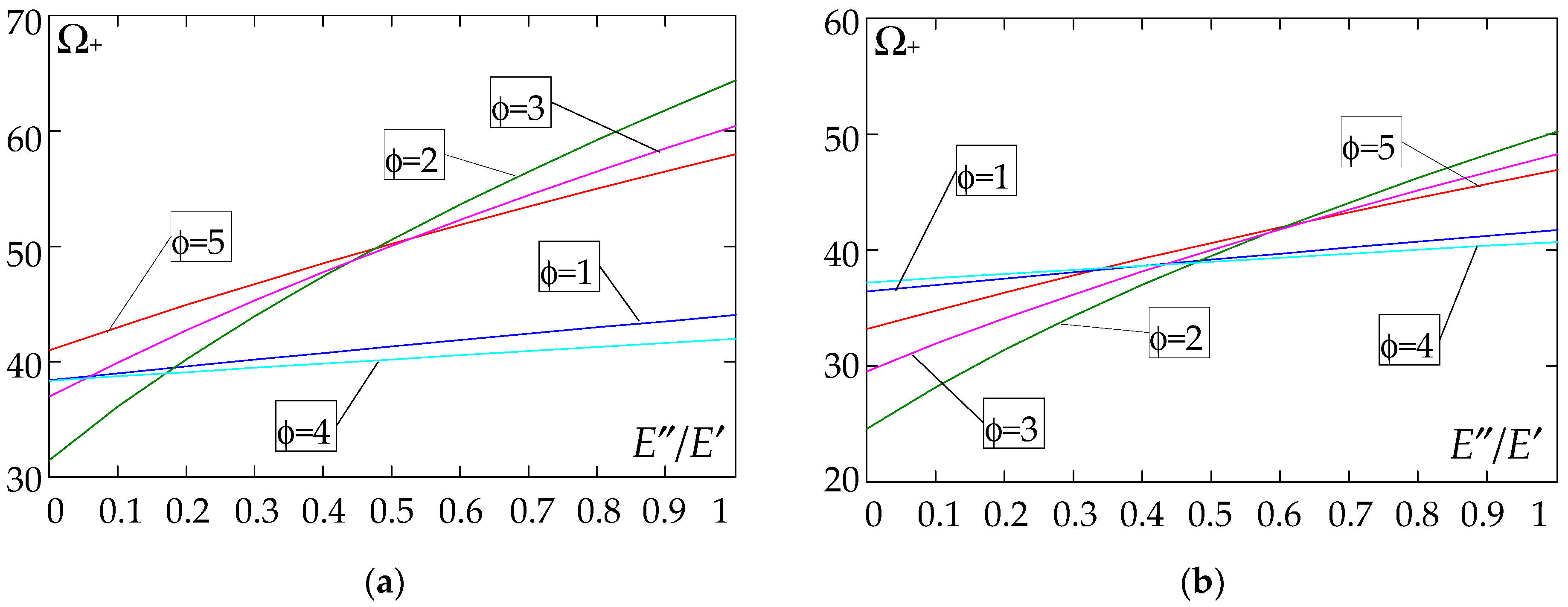

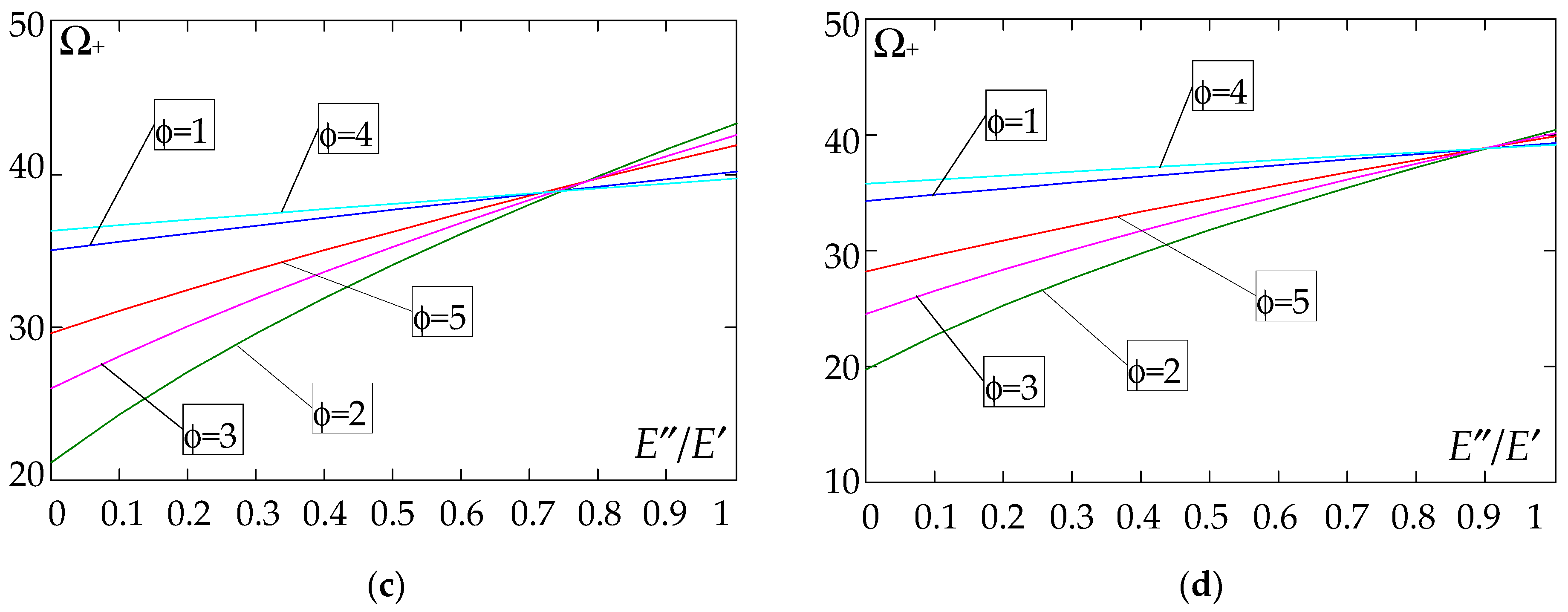

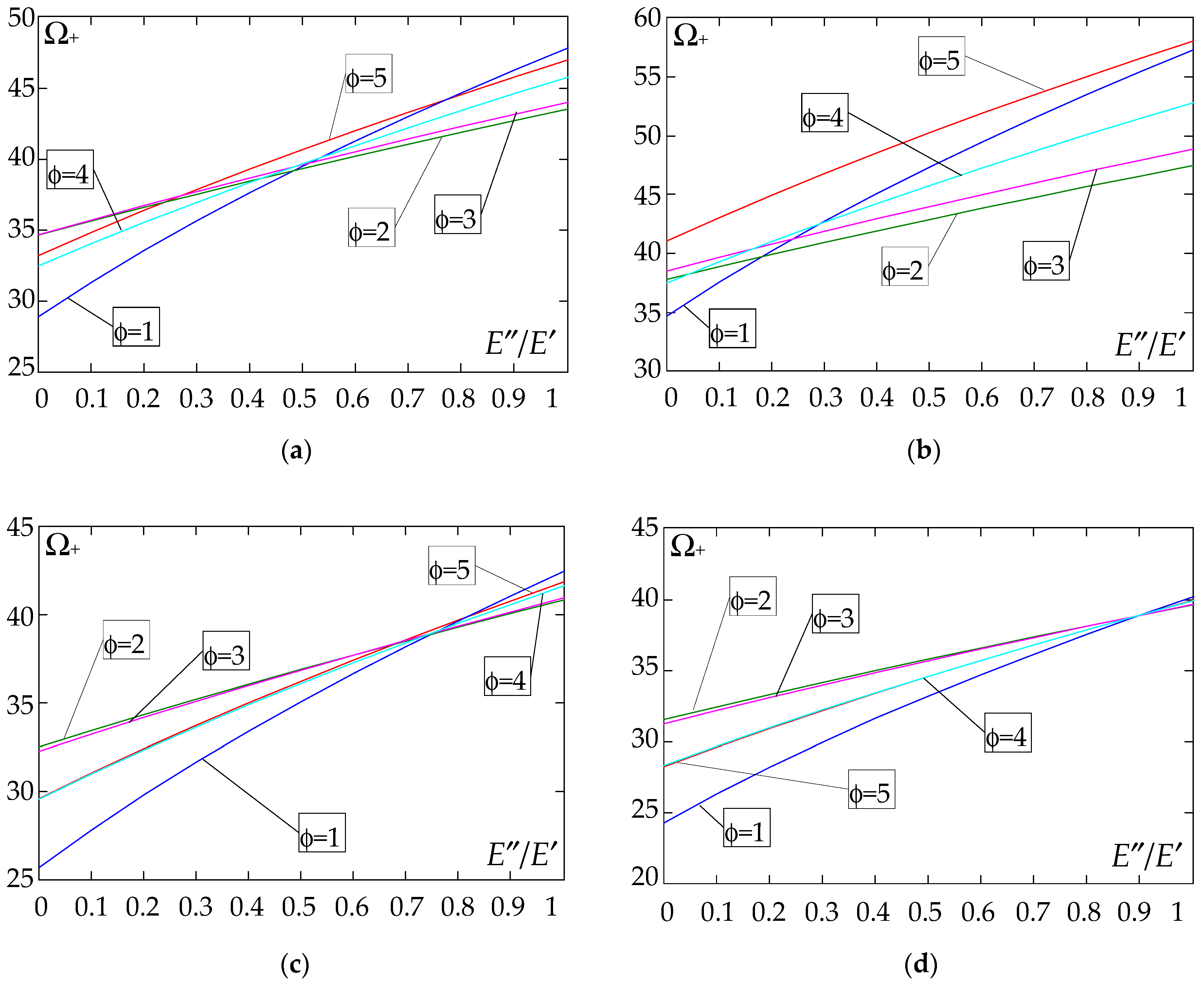

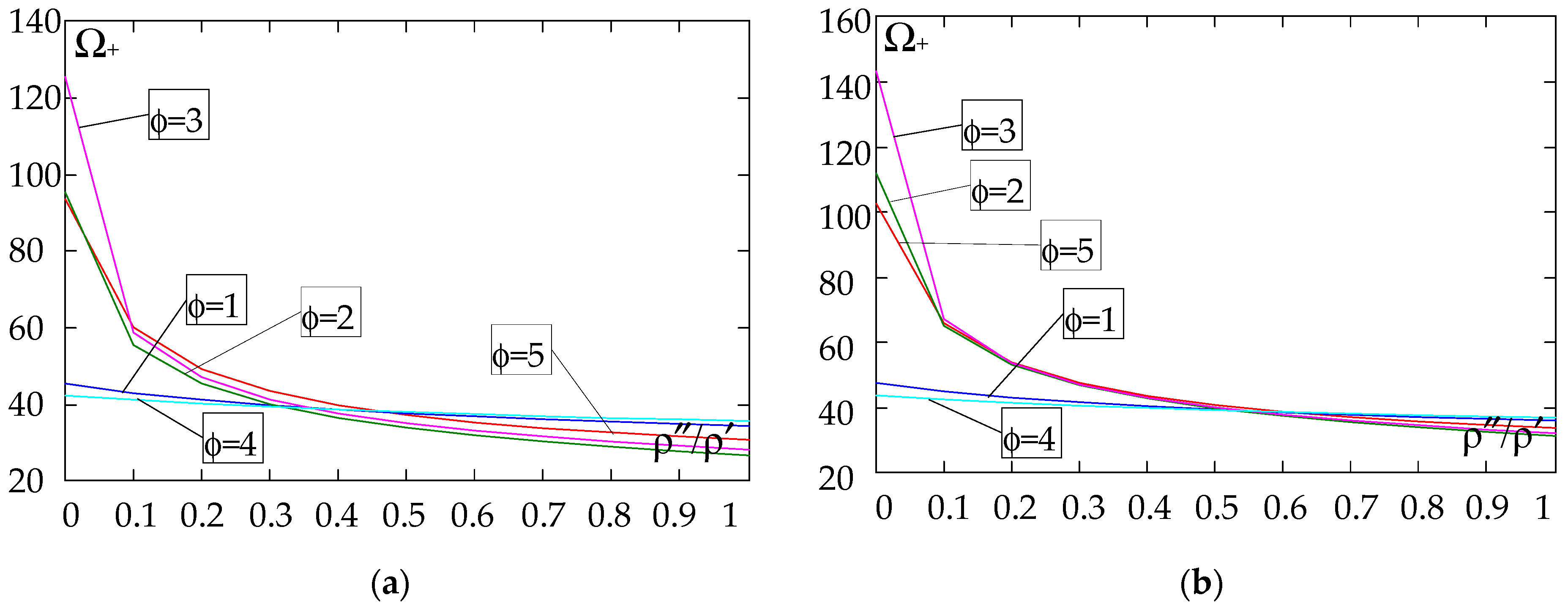

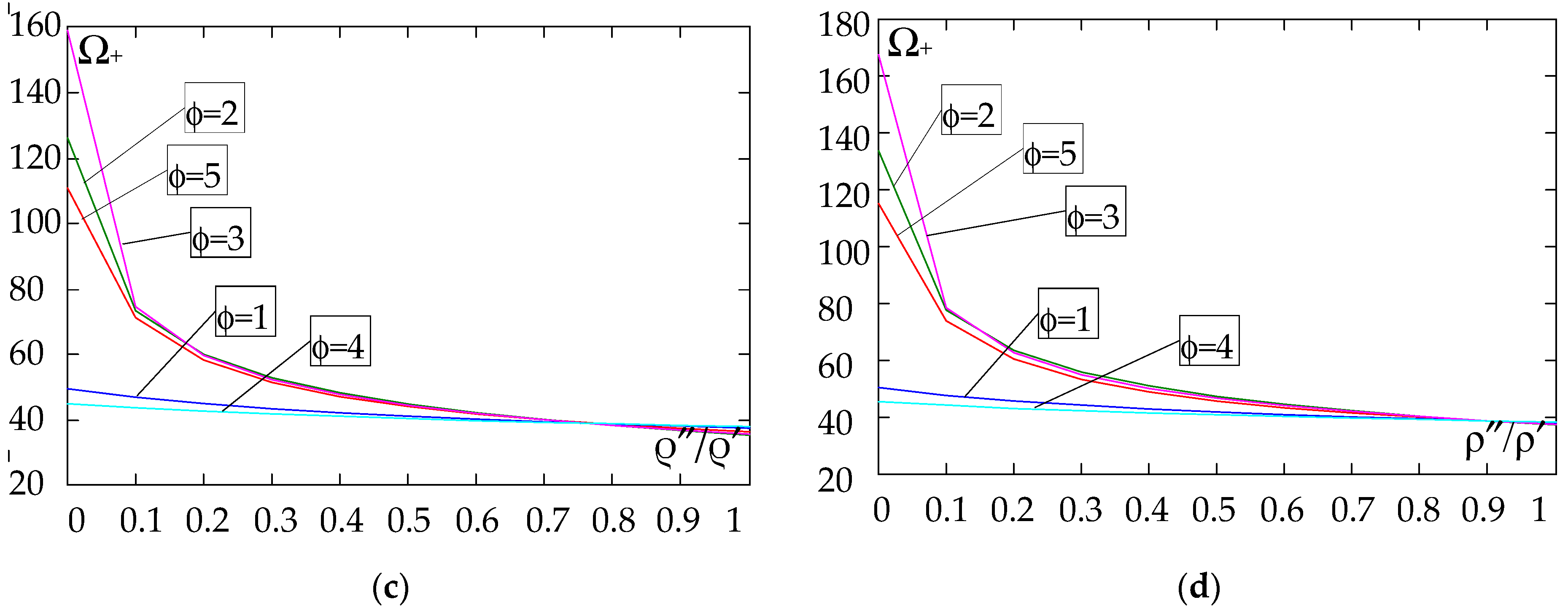

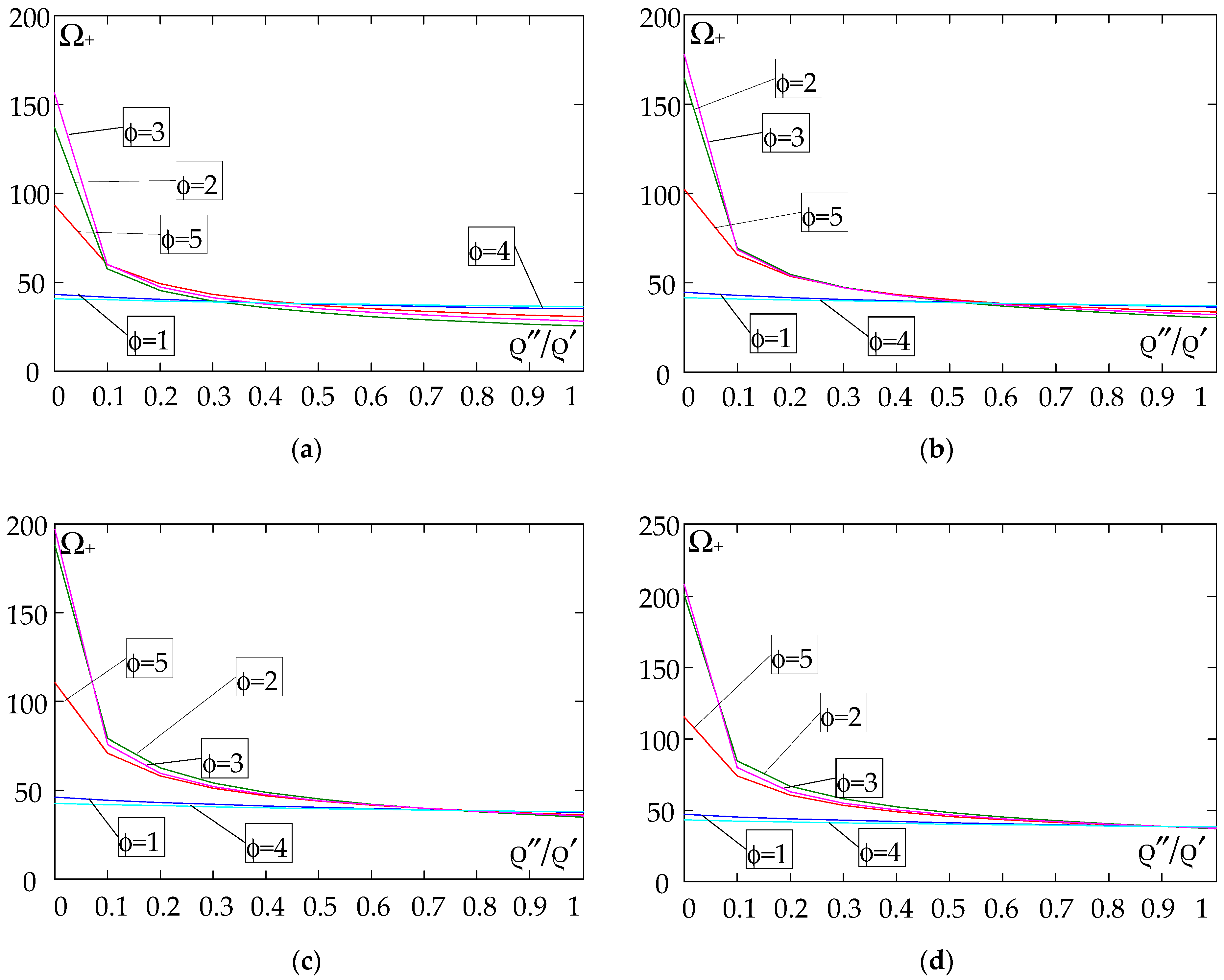

- The influences of differences in material and geometrical parameters such as the ratio of Young’s modulus (E″/E′), the ratio of density (ρ″/ρ′), or thickness-to-plate band span (d/L) on free vibration frequencies are similar in both lower and higher frequency cases.

- The effect of the distribution function material properties γ(x) on the free vibration frequencies, both lower and higher, is quite difficult to describe and different for both types of frequency.

- The influence of the distribution function of material properties γ(x) on the free vibration frequencies, both lower and higher, is also related to material parameters, i.e., Young’s modulus ratio (E″/E′) and mass density ratio (ρ″/ρ′). In addition, the influence also depends on the support conditions of the plate.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A. The Asymptotic Modelling

References

- Suresh, S.; Mortensen, A. Fundamentals of Functionally Graded Materials; The University Press: Cambridge, UK, 1998. [Google Scholar]

- Woźniak, C.; Michalak, B.; Jędrysiak, J. (Eds.) Thermomechanics of microheterogeneous solids and structures. In Tolerance Averaging Approach; Publishing House of Łódź University of Technology: Lodz, Poland, 2008. [Google Scholar]

- Kaźmierczak, M.; Jędrysiak, J. Tolerance modelling of vibrations of thin functionally graded plates. Thin Walled Struct. 2011, 49, 1295–1303. [Google Scholar] [CrossRef]

- Jędrysiak, J. The Effect of the Material Periodic Structure on Free Vibrations of Thin Plates with Different Boundary Conditions. Materials 2022, 15, 5623. [Google Scholar] [CrossRef] [PubMed]

- Bensoussan, A.; Lions, J.-L.; Papanicolaou, G. Asymptotic Analysis for Periodic Structures; Elsevier: Amsterdam, The Netherlands, 1978. [Google Scholar]

- Kohn, R.V.; Vogelius, M. A new model of thin plates with rapidly varying thickness. Int. J. Solid Struct. 1984, 20, 333–350. [Google Scholar] [CrossRef]

- Duvaut, G.; Metellus, A.M. Homogéneisation d’une plaque mince en flexion des structure périodique et symmetrique. C. R. Acad. Sci. 1976, 283, 947–950. [Google Scholar]

- Caillerie, D. Thin elastic and periodic plates. Math. Methods Appl. Sci. 1984, 6, 159–191. [Google Scholar] [CrossRef]

- Matysiak, S.J.; Nagórko, W. Microlocal parameters in the modelling of microperiodic plates. Ing. Arch. 1989, 59, 434–444. [Google Scholar] [CrossRef]

- Sebestianiuk, P.; Perkowski, D.M.; Kulchytsky-Zhyhailo, R. On stress analysis of load for microperiodic composite half-plane with slant lamination. Meccanica 2019, 54, 573–593. [Google Scholar] [CrossRef]

- Perkowski, D.M.; Kulchytsky-Zhyhailo, R.; Matysiak, S.J.; Tokovyy, Y.V. Thermal surface deflection of a medium with multilayer coatings. Int. J. Mech. Sci. 2025, 287, 109984. [Google Scholar] [CrossRef]

- Batra, R.C.; Qian, L.F.; Chen, L.M. Natural frequencies of thick square plates made of orthotropic, trigonal, monoclinic, hexagonal and triclinic materials. J. Sound Vib. 2004, 270, 1074–1086. [Google Scholar] [CrossRef]

- Królak, M.; Kowal-Michalska, K.; Mania, R.J.; Świniarski, J. Stability and load carrying capacity of multi-cell thin-walled columns of rectangular cross-sections. J. Theor. Appl. Mech. 2009, 47, 435–456. [Google Scholar]

- Pawlus, D. Dynamic behaviour of three-layered annular plates with viscoelastic core under lateral loads. J. Sound Vib. 2015, 53, 775–788. [Google Scholar] [CrossRef][Green Version]

- Grygorowicz, M.; Jasion, P.; Magnucki, K. Elastic buckling and post-buckling behaviour of shells of revolution with special meridian. In Insights and Innovations in Structural Engineering, Mechanics and Computation; Zingoni, A., Ed.; CRC Press: Boca Raton, FL, USA, 2016; pp. 789–792. [Google Scholar][Green Version]

- Smyczyński, M.J.; Grygorowicz, M.; Kędzia, P. Buckling of three layer rectangular polyethylene plate with ferrofluid under magnetic field. In Insights and Innovations in Structural Engineering, Mechanics and Computation; Zingoni, A., Ed.; CRC Press: Boca Raton, FL, USA, 2016; pp. 924–928. [Google Scholar][Green Version]

- Stręk, T.; Jopek, H.; Nienartowicz, M. Dynamic response of sandwich panels with auxetic cores. Phys. Status Solidi Basic Res. 2015, 252, 1540–1550. [Google Scholar] [CrossRef]

- Burlaga, B.; Stręk, T. The vibrations induced by fluid flow in plates with different Poisson’s ratios. Vib. Phys. Syst. 2020, 31, 2020301. [Google Scholar]

- Michalski, J.; Stręk, T. Blast resistance of sandwich plate with auxetic anti-tetrachiral core. Vib. Phys. Syst. 2020, 31, 2020316. [Google Scholar]

- Nguyen, N.V.; Nguyen-Xuan, H.; Nguyen, T.N.; Kang, J.; Lee, J. A comprehensive analysis of auxetic honeycomb sandwich plates with graphene nanoplatelets reinforcement. Compos. Struct. 2021, 259, 113213. [Google Scholar] [CrossRef]

- Michalski, J.; Stręk, T. Numerical analysis of an auxetic anti-tetrachiral sandwich panel subjected to steady-state harmonic base motion. Vib. Phys. Syst. 2022, 33, 2022323. [Google Scholar]

- Pawlus, D. Static stability of composite annular plates with auxetic properties. Materials 2022, 15, 3579. [Google Scholar] [CrossRef]

- Pawlus, D. The dynamic stability problem of composite annular plates with auxetic properties. Eng. Trans. 2023, 71, 329–349. [Google Scholar]

- Firouzi, N.; Lenci, S.; Amabili, M.; Rabczuk, T. Nonlinear free vibrations of Timoshenko–Ehrenfest beams using finite element analysis and direct scheme. Nonlinear Dyn. 2024, 112, 7199–7213. [Google Scholar] [CrossRef]

- Firouzi, N.; Dohnal, F. Dynamic stability of the Mindlin-Reissner plate using a time-modulated axial force. Mech. Based Des. Struct. Mach. 2024, 53, 446–463. [Google Scholar] [CrossRef]

- Aboudi, J.; Pindera, M.-J.; Arnold, S.M. Thermo-inelastic response of functionally graded composites. Int. J. Solid Struct. 1995, 32, 1675–1710. [Google Scholar] [CrossRef]

- Aboudi, J.; Pindera, M.-J.; Arnold, S.M. A coupled higher-order theory for functionally graded composites with partial homogenization. Compos. Eng. 1995, 5, 771–792. [Google Scholar] [CrossRef]

- Pindera, M.-J.; Dunn, P. Evaluation of the higher-order theory for functionally graded materials via the finite-element method. Compos. Part B 1997, 28, 109–119. [Google Scholar] [CrossRef]

- Aboudi, J.; Pindera, M.-J.; Arnold, S.M. Higher-order theory for functionally graded materials. Compos. Part B 1999, 30, 777–832. [Google Scholar] [CrossRef]

- Goldberg, R.K.; Hopkins, D.A. Thermal analysis of a functionally graded material subject to a thermal gradient using the boundary element method. Compos. Eng. 1995, 5, 793–806. [Google Scholar] [CrossRef]

- Martínez-Pañeda, M. On the finite element implementation of functionally graded materials. Materials 2019, 12, 287. [Google Scholar] [CrossRef]

- Sofiyev, A.H.; Schnack, E. The stability of functionally graded cylindrical shells under linearly increasing dynamic torsional loading. Eng. Struct. 2004, 26, 1321–1331. [Google Scholar] [CrossRef]

- Ferreira, A.J.M.; Batra, R.C.; Roque, C.M.C.; Qian, L.F.; Jorge, R.M.N. Natural frequencies of functionally graded plates by a meshless method. Compos. Struct. 2006, 75, 593–600. [Google Scholar] [CrossRef]

- Bui, T.Q.; Khosravifard, A.; Zhang, C.; Hematiyan, M.R.; Golu, M.V. Dynamic analysis of sandwich beams with functionally graded core using a truly meshfree radial point interpolation method. Eng. Struct. 2013, 47, 90–104. [Google Scholar] [CrossRef]

- Roque, C.M.C.; Ferreira, A.J.M.; Jorge, R.M.N. A radial basis function approach for the free vibration analysis of functionally graded plates using a refined theory. J. Sound Vib. 2007, 300, 1048–1070. [Google Scholar] [CrossRef]

- Tornabene, F.; Liverani, A.; Caligiana, G. FGM and laminated doubly curved shells and panels of revolution with a free-form meridian: A 2-D GDQ solution for free vibrations. Int. J. Mech. Sci. 2011, 53, 443–470. [Google Scholar] [CrossRef]

- Akbarzadeha, A.H.; Abbasib, M.; Eslami, M.R. Coupled thermoelasticity of functionally graded plates based on the third-order shear deformation theory. Thin Walled Struct. 2012, 53, 141–155. [Google Scholar] [CrossRef]

- Oktem, A.S.; Mantari, J.L.; Guedes Soares, C. Static response of functionally graded plates and doubly-curved shells based on a higher order shear deformation theory. Eur. J. Mech. A Solids 2012, 36, 163–172. [Google Scholar] [CrossRef]

- Tornabene, F.; Viola, E. Static analysis of functionally graded doubly-curved shells and panels of revolution. Meccanica 2013, 48, 901–930. [Google Scholar] [CrossRef]

- Tornabene, F.; Fantuzzi, N.; Viola, E.; Batra, R.C. Stress and strain recovery for functionally graded free-form and doubly-curved sandwich shells using higher-order equivalent single layer theory. Compos. Struct. 2015, 119, 67–89. [Google Scholar] [CrossRef]

- Tornebene, F.; Fantuzzi, N.; Bacciocchi, M. On the mechanics of laminated doubly-curved shells subjected to point and line loads. Int. J. Eng. Sci. 2016, 109, 115–164. [Google Scholar] [CrossRef]

- Ashoori, A.R.; Sadough Vanini, S.A. Thermal buckling of annular microstructure-dependent functionally graded material plates resting on an elastic medium. Compos. Part B Eng. 2016, 87, 245–255. [Google Scholar] [CrossRef]

- Jha, D.K.; Kant, T.; Singh, R.K. Free vibration response of functionally graded thick plates with shear and normal deformations effects. Compos. Struct. 2013, 96, 799–823. [Google Scholar] [CrossRef]

- Sheikholeslami, S.A.; Saidi, A.R. Vibration analysis of functionally graded rectangular plates resting on elastic foundation using higher-order shear and normal deformable plate theory. Compos. Struct. 2013, 106, 350–361. [Google Scholar] [CrossRef]

- Derras, M.; Kaci, A.; Draiche, K.; Tounsi, A. Non-linear analysis of functionally graded plates in cylindrical bending based on a new refined shear deformation theory. J. Theor. Appl. Mech. 2013, 51, 339–348. [Google Scholar]

- Huangfu, Y.-G.; Chen, F.-Q. Single-pulse chaotic dynamics of functionally graded materials plate. Acta Mech. Sin. 2013, 29, 593–601. [Google Scholar] [CrossRef]

- Fantuzzi, N.; Tornabene, F.; Viola, E.; Ferreira, A.J.M. A strong formulation finite element method (SFEM) based on RBF and GDQ techniques for the static and dynamic analyses of laminated plates of arbitrary shape. Meccanica 2014, 49, 2503–2542. [Google Scholar] [CrossRef]

- Fantuzzi, N.; Tornabene, F. Strong Formulation Isogeometric Analysis (SFIGA) for laminated composite arbitrarily shaped plates. Compos. Part B Eng. 2016, 96, 173–203. [Google Scholar] [CrossRef]

- Liu, B.; Ferreira, A.J.M.; Xing, Y.F.; Neves, A.M.A. Analysis of composite plates using a layerwise theory and a differential quadrature finite element method. Compos. Struct. 2016, 156, 393–398. [Google Scholar] [CrossRef]

- Kugler, S.; Fotiu, P.; Murin, J. The numerical analysis of FGM shells with enhanced finite elements. Eng. Struct. 2013, 49, 920–935. [Google Scholar] [CrossRef]

- Tornabene, F.; Fantuzzi, N.; Bacciocchi, M.; Viola, E.; Reddy, J.N. A numerical investigation on the natural frequencies of FGM sandwich shells with variable thickness by the local generalized differential quadrature method. Appl. Sci. 2017, 7, 131. [Google Scholar] [CrossRef]

- Tornabene, F.; Bacciocchi, M. Dynamic stability of doubly-curved multilayered shells subjected to arbitrarily oriented angular velocities: Numerical evaluation of the critical speed. Compos. Struct. 2018, 201, 1031–1055. [Google Scholar] [CrossRef]

- Arefi, M.; Bidgoli, E.M.R.; Dimitri, R.; Bacciocchi, M.; Tornabene, F. Application of sinusoidal shear deformation theory and physical neutral surface to analysis of functionally graded piezoelectric plate. Compos. Part B Eng. 2018, 151, 35–50. [Google Scholar] [CrossRef]

- Arefi, M.; Bidgoli, E.M.R.; Dimitri, R.; Tornabene, F. Free vibrations of functionally graded polymer composite nanoplates reinforced with graphene nanoplatelets. Aerosp. Sci. Technol. 2018, 81, 108–117. [Google Scholar] [CrossRef]

- Kołakowski, Z.; Mania, R.J. Dynamic response of thin FG plates with a static unsymmetrical stable postbuckling path. ThinWalled Struct. 2015, 86, 10–17. [Google Scholar] [CrossRef]

- Mania, R.J.; Madeo, A.; Zucco, G.; Kubiak, T. Imperfection sensitivity of post-buckling of FML channel section column. Thin-Walled Struct. 2017, 114, 32–38. [Google Scholar] [CrossRef]

- Teter, A.; Mania, R.J.; Kołakowski, Z. Non-linear multi-mode buckling of non-symmetric FML/FGM thin-walled columns with open cross-sections under compression. Compos. Struct. 2017, 167, 38–49. [Google Scholar] [CrossRef]

- Kołakowski, Z.; Mania, R.J. Influence of the coupling matrix B on the interactive buckling of FML-FGM columns with closed cross-sections under axial compression. Compos. Struct. 2017, 173, 70–77. [Google Scholar] [CrossRef]

- Sadowski, T.; Burlayenko, V.N. Three-dimensional free vibration analysis of thermally loaded FGM sandwich plates. Materials 2019, 12, 2377. [Google Scholar] [CrossRef]

- Cao, Z.; Liang, X.; Deng, Y.; Zha, X.; Zhu, R.; Leng, J. Novel semi-analytical solutions for the transient behaviors of functionally graded material plates in the thermal environment. Materials 2019, 12, 4084. [Google Scholar] [CrossRef] [PubMed]

- Jafari, M.; Chaleshtari, M.H.B.; Abdolalian, H.; Craciun, E.-M.; Feo, L. Determination of forces and moments per unit length in symmetric exponential FG plates with a quasi-triangular hole. Symmetry 2020, 12, 834. [Google Scholar] [CrossRef]

- Tati, A. Finite element analysis of thermal and mechanical buckling behavior of functionally graded plates. Arch. Appl. Mech. 2021, 91, 4571–4587. [Google Scholar] [CrossRef]

- Magnucki, K.; Magnucka-Blandzi, E. Generalization of a sandwich structure model: Analytical studies of bending and buckling problems of rectangular plate. Compos. Struct. 2021, 255, 112944. [Google Scholar] [CrossRef]

- Magnucki, K.; Sowinski, K. Bending of a Sandwich Beam with an Individual Functionally Graded Core. J. Theor. Appl. Mech. 2024, 62, 3–17. [Google Scholar] [CrossRef]

- Pawlus, D. Three-Layered Annular Plate Made of Functionally Graded Material Under a Static Temperature Field. Materials 2024, 17, 5484. [Google Scholar] [CrossRef]

- Magnucki, K.; Magnucka-Blandzi, E.; Sowinski, K. Elastic buckling of a rectangular sandwich plate with an individual functionally graded core. J. Theor. Appl. Mech. 2024, 62, 171–185. [Google Scholar] [CrossRef]

- Kumar, V.; Singh, S.J.; Saran, V.H.; Harsha, S.P. Vibration Response Analysis of Tapered Porous FGM Plate Resting on Elastic Foundation. Int. J. Struct. Stab. Dyn. 2022, 23, 2350024. [Google Scholar] [CrossRef]

- Kumar, R.; Jana, P. Free vibration analysis of uniform thickness and stepped P-FGM plates: A FSDT-based dynamic stiffness approach. Mech. Based Des. Struct. Mach. 2022, 52, 447–476. [Google Scholar] [CrossRef]

- Zhao, Y.; Qin, B.; Wang, Q.; Liang, X. A unified Jacobi–Ritz approach for vibration analysis of functionally graded porous rectangular plate with arbitrary boundary conditions based on a higher-order shear deformation theory. Thin Walled Struct. 2022, 173, 108930. [Google Scholar] [CrossRef]

- Wu, C.P.; Hsu, C.D. A Unified Size-Dependent Theory for Analyzing the Free Vibration Behavior of an FG Microplate Under Fully Simply Supported Conditions and Magneto-Electro-Thermo-Mechanical Loads Considering Couple Stress and Thickness Stretching Effects. J. Compos. Sci. 2025, 9, 201. [Google Scholar] [CrossRef]

- Sobhani, E.; Masoodi, A.R. Natural frequency responses of hybrid polymer/carbon fiber/FG-GNP nanocomposites paraboloidal and hyperboloidal shells based on multiscale approaches. Aerosp. Sci. Technol. 2021, 119, 107111. [Google Scholar] [CrossRef]

- Sobhani, E.; Masoodi, A.R. On the circumferential wave responses of connected elliptical-cylindrical shell-like submerged structures strengthened by nano-reinforcer. Ocean Eng. 2022, 247, 110718. [Google Scholar] [CrossRef]

- Sobhani, E.; Moradi-Dastjerdi, R.; Behdinan, K.; Masoodi, A.R.; Ahmadi-Pari, A.R. Multifunctional trace of various reinforcements on vibrations of three-phase nanocomposite combined hemispherical-cylindrical shells. Compos. Struct. 2022, 279, 114798. [Google Scholar] [CrossRef]

- Shi, P.; Xie, J.; Li, X. Multilayer heterostructure inhomogeneous model for pressurized functionally graded annular structures (cylinder/sphere/annulus) with arbitrary elastic property along the radial direction. Compos. Struct. 2023, 322, 117425. [Google Scholar] [CrossRef]

- Ege, N.; Erbaş, B.; Kaplunov, J.; Noori, N. Low-frequency vibrations of a thin-walled functionally graded cylinder (plane strain problem). Mech. Adv. Mater. Struct. 2023, 30, 1172–1180. [Google Scholar] [CrossRef]

- Brillouin, L. Wave Propagation in Periodic Structures; Dover Pub. Inc.: Dover, UK, 1953. [Google Scholar]

- Wu, Z.-J.; Li, F.-M.; Wang, Y.-Z. Vibration band gap properties of periodic Mindlin plate structure using the spectral element method. Meccanica 2014, 49, 725–737. [Google Scholar] [CrossRef]

- Zhou, X.Q.; Yu, D.Y.; Shao, X.; Wang, S.; Tian, Y.H. Band gap characteristics of periodically stiffened-thin-plate based on center-finite-difference-method. Thin Walled Struct. 2014, 82, 115–123. [Google Scholar] [CrossRef]

- Zhou, X.Q.; Yu, D.Y.; Shao, X.; Wang, S.; Zhang, S.Q. Simplified-super-element-method for analyzing free flexural vibration characteristics of periodically stiffened-thin-plate filled with viscoelastic damping material. Thin Walled Struct. 2015, 94, 234–252. [Google Scholar] [CrossRef]

- Cheng, Z.B.; Xu, Y.G.; Zhang, L.L. Analysis of flexural wave bandgaps in periodic plate structures using differential quadrature element method. Int. J. Mech. Sci. 2015, 100, 112–125. [Google Scholar] [CrossRef]

- Woźniak, C.; Wierzbicki, E. Averaging techniques in thermomechanics of composite solids. In Tolerance Averaging Versus Homogenization; Pubishing House of Częstochowa University of Technology: Częstochowa, Poland, 2000. [Google Scholar]

- Woźniak, C. (Ed.) Mathematical Modelling and Analysis in Continuum Mechanics of Microstructured Media; Publishing House of Silesian University of Techn.: Gliwice, Poland, 2010. [Google Scholar]

- Dell’Isola, F.; Rosa, L.; Woźniak, C. A micro-structural continuum modelling compacting fluid-saturated grounds. Acta Mech. 1998, 127, 165–182. [Google Scholar] [CrossRef]

- Wierzbicki, E.; Woźniak, C. On the dynamics of combined plane periodic structures. Arch. Appl. Mech. 2000, 70, 387–398. [Google Scholar] [CrossRef]

- Baron, E.; Woźniak, C. On the micro-dynamics of composite plates. Arch. Appl. Mech. 1995, 66, 126–133. [Google Scholar] [CrossRef]

- Jędrysiak, J. Dynamics of thin periodic plates resting on a periodically inhomogeneous Winkler foundation. Arch. Appl. Mech. 1999, 69, 345–356. [Google Scholar] [CrossRef]

- Michalak, B. The meso-shape functions for the meso-structural models of wavy-plates. ZAMM 2001, 81, 639–641. [Google Scholar] [CrossRef]

- Nagórko, W.; Woźniak, C. Nonasymptotic modelling of thin plates reinforced by a system of stiffeners. Electr. J. Pol. Agric. Univ. Civ. Eng. 2002, 5, 8. [Google Scholar]

- Mazur-Śniady, K.; Woźniak, C.; Wierzbicki, E. On the modelling of dynamic problems for plates with a periodic structure. Arch. Appl. Mech. 2004, 74, 179–190. [Google Scholar] [CrossRef]

- Tomczyk, B. Dynamic stability of micro-periodic cylindrical shells. Mech. Mech. Eng. 2010, 14, 137–150. [Google Scholar]

- Tomczyk, B.; Gołąbczak, M.; Litawska, A.; Gołąbczak, A. Extended tolerance modelling of dynamic problems for thin uniperiodic cylindrical shells. Contin. Mech. Thermodyn. 2023, 35, 183–210. [Google Scholar] [CrossRef]

- Tomczyk, B.; Bagdasaryan, V.; Gołąbczak, M.; Litawska, A. A new combined asymptotic-tolerance model of thermoelasticity problems for thin biperiodic cylindrical shells. Compos. Struct. 2023, 309, 116708. [Google Scholar] [CrossRef]

- Domagalski, Ł.; Jędrysiak, J. On the tolerance modelling of geometrically nonlinear thin periodic plates. Thin Walled Struct. 2015, 87, 183–190. [Google Scholar] [CrossRef]

- Domagalski, Ł.; Świątek, M.; Jędrysiak, J. An analytical-numerical approach to vibration analysis of periodic Timoshenko beams. Compos. Struct. 2019, 211, 490–501. [Google Scholar] [CrossRef]

- Marczak, J.; Jędrysiak, J. Some remarks on modelling of vibrations of periodic sandwich structures with inert core. Compos. Struct. 2018, 202, 752–758. [Google Scholar] [CrossRef]

- Marczak, J. A comparison of dynamic models of microheterogeneous asymmetric sandwich plates. Compos. Struct. 2021, 256, 113054. [Google Scholar] [CrossRef]

- Ostrowski, P.; Jędrysiak, J. Heat conduction in periodic laminates with probabilistic distribution of material properties. Heat Mass Transf. 2017, 53, 1425–1437. [Google Scholar] [CrossRef]

- Kubacka, E.; Ostrowski, P. Heat conduction issue in biperiodic composite using Finite Difference Method. Compos. Struct. 2021, 261, 113310. [Google Scholar] [CrossRef]

- Kubacka, E.; Ostrowski, P. Influence of Composite Structure on Temperature Distribution-An Analysis Using the Finite Difference Method. Materials 2023, 16, 5193. [Google Scholar] [CrossRef]

- Jędrysiak, J. Non-asymptotic modelling of dynamics and stability for visco-elastic periodic beams on a periodic damping foundation. Compos. Struct. 2021, 259, 113442. [Google Scholar] [CrossRef]

- Marczak, J.; Michalak, B.; Wirowski, A. A multi-scale analysis of stress distribution in thin composite plates with dense system of ribs in two directions. Adv. Eng. Softw. 2021, 153, 102960. [Google Scholar] [CrossRef]

- Jędrysiak, J. On the tolerance modeling of thermoelasticity problems for transversally graded laminates. Arch. Civ. Mech. Eng. 2011, 11, 61–74. [Google Scholar] [CrossRef]

- Michalak, B.; Wirowski, A. Dynamic modelling of thin plate made of certain functionally graded materials. Meccanica 2012, 47, 1487–1498. [Google Scholar] [CrossRef][Green Version]

- Wirowski, A.; Michalak, B.; Gajdzicki, M. Dynamic modelling of annular plates of functionally graded structure resting on elastic heterogeneous foundation with two modules. J. Mech. 2015, 31, 493–504. [Google Scholar] [CrossRef]

- Perliński, W.; Gajdzicki, M.; Michalak, B. Modelling of annular plates stability with functionally graded structure interacting with elastic heterogeneous subsoil. J. Theor. Appl. Mech. 2014, 52, 485–498. [Google Scholar]

- Michalak, B. 2D tolerance and asymptotic models in elastodynamics of a thin-walled structure with dense system of ribs. Arch. Civ. Mech. Eng. 2015, 15, 449–455. [Google Scholar] [CrossRef]

- Rabenda, M.; Michalak, B. Natural vibrations of prestressed thin functionally graded plates with dense system of ribs in two directions. Compos. Struct. 2015, 133, 1016–1023. [Google Scholar] [CrossRef]

- Ostrowski, P.; Michalak, B. The combined asymptotic-tolerance model of heat conduction in a skeletal micro-heterogeneous hollow cylinder. Compos. Struct. 2015, 134, 343–352. [Google Scholar] [CrossRef]

- Ostrowski, P.; Michalak, B. A contribution to the modelling of heat conduction for cylindrical composite conductors with non-uniform distribution of constituents. Int. J. Heat Mass Transf. 2016, 92, 435–448. [Google Scholar] [CrossRef]

- Pazera, E.; Ostrowski, P. Heat transfer in functionally graded laminate—Third type boundary conditions. AIP Conf. Proc. 2020, 2239, 020040. [Google Scholar]

- Szlachetka, O.; Giorgio, I. Heat conduction in multi-component step-wise FGMs. Contin. Mech. Thermodyn. 2024, 36, 1393–1411. [Google Scholar] [CrossRef]

- Jędrysiak, J. Tolerance modelling of free vibration frequencies of thin functionally graded plates with one-directional microstructure. Compos. Struct. 2017, 161, 453–468. [Google Scholar] [CrossRef]

- Jędrysiak, J. Tolerance modelling of free vibrations of medium thickness functionally graded plates. Compos. Struct. 2018, 202, 1253–1262. [Google Scholar] [CrossRef]

- Tomczyk, B.; Szczerba, P. Tolerance and asymptotic modelling of dynamic problems for thin microstructured transversally graded shells. Compos. Struct. 2017, 162, 365–373. [Google Scholar] [CrossRef]

- Tomczyk, B.; Szczerba, P. Combined asymptotic-tolerance modelling of dynamic problems for functionally graded shells. Compos. Struct. 2018, 183, 176–184. [Google Scholar] [CrossRef]

- Tomczyk, B.; Gołąbczak, M.; Bagdasaryan, V. Tolerance modelling of vibrations of thin functionally graded cylindrical shells. Compos. Struct. 2025, 356, 118890. [Google Scholar] [CrossRef]

- Tomczyk, B.; Gołąbczak, M.; Kubacka, E.; Bagdasaryan, V. Mathematical modelling of stability problems for thin transversally graded cylindrical shells. Contin. Mech. Thermodyn. 2024, 36, 1661–1684. [Google Scholar] [CrossRef]

| ϕ | E″/E′ = 1.00 | E″/E′ = 0.75 | E″/E′ = 0.50 | E″/E′ = 0.30 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ρ″/ρ′ | Ω− | Ω0 | ε [%] | Ω− | Ω0 | ε [%] | Ω− | Ω0 | ε [%] | Ω− | Ω0 | ε [%] | |

| 1 | 0.3 | 0.0329 | 0.0327 | 0.61 | 0.0318 | 0.0315 | 0.94 | 0.0305 | 0.0293 | 3.93 | 0.0294 | 0.0261 | 11.22 |

| 0.5 | 0.0319 | 0.0318 | 0.31 | 0.0309 | 0.0305 | 1.29 | 0.0296 | 0.0284 | 4.05 | 0.0285 | 0.0253 | 11.23 | |

| 0.7 | 0.0311 | 0.0309 | 0.64 | 0.0300 | 0.0297 | 1.00 | 0.0288 | 0.0276 | 4.17 | 0.0277 | 0.0245 | 11.55 | |

| 1.0 | 0.0299 | 0.0297 | 0.67 | 0.0289 | 0.0285 | 1.38 | 0.0277 | 0.0265 | 4.33 | 0.0267 | 0.0235 | 11.99 | |

| 2 | 0.3 | 0.0433 | 0.0429 | 0.92 | 0.0390 | 0.0385 | 1.28 | 0.0338 | 0.0327 | 3.25 | 0.0285 | 0.0262 | 8.07 |

| 0.5 | 0.0378 | 0.0375 | 0.79 | 0.0340 | 0.0336 | 1.18 | 0.0294 | 0.0285 | 3.06 | 0.0248 | 0.0228 | 8.06 | |

| 0.7 | 0.0339 | 0.0337 | 0.59 | 0.0305 | 0.0302 | 1.00 | 0.0264 | 0.0256 | 3.03 | 0.0223 | 0.0204 | 8.52 | |

| 1.0 | 0.0299 | 0.0297 | 0.67 | 0.0269 | 0.0266 | 1.12 | 0.0233 | 0.0225 | 3.43 | 0.0196 | 0.0180 | 8.16 | |

| 5 | 0.3 | 0.0370 | 0.0368 | 0.54 | 0.0344 | 0.0341 | 0.87 | 0.0306 | 0.0301 | 1.63 | 0.0261 | 0.0251 | 3.83 |

| 0.5 | 0.0345 | 0.0343 | 0.58 | 0.0320 | 0.0317 | 0.94 | 0.0285 | 0.0280 | 1.75 | 0.0243 | 0.0233 | 4.12 | |

| 0.7 | 0.0324 | 0.0322 | 0.62 | 0.0301 | 0.0298 | 1.00 | 0.0268 | 0.0263 | 1.87 | 0.0228 | 0.0219 | 3.95 | |

| 1.0 | 0.0299 | 0.0297 | 0.67 | 0.0277 | 0.0275 | 0.72 | 0.0247 | 0.0243 | 1.62 | 0.0211 | 0.0202 | 4.27 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jędrysiak, J.; Kaźmierczak-Sobińska, M. Free Vibration Analysis of Thin Functionally Graded Plate Bands with Microstructure as a Function of Material Inhomogeneity Distribution and Boundary Conditions. Materials 2025, 18, 4629. https://doi.org/10.3390/ma18194629

Jędrysiak J, Kaźmierczak-Sobińska M. Free Vibration Analysis of Thin Functionally Graded Plate Bands with Microstructure as a Function of Material Inhomogeneity Distribution and Boundary Conditions. Materials. 2025; 18(19):4629. https://doi.org/10.3390/ma18194629

Chicago/Turabian StyleJędrysiak, Jarosław, and Magda Kaźmierczak-Sobińska. 2025. "Free Vibration Analysis of Thin Functionally Graded Plate Bands with Microstructure as a Function of Material Inhomogeneity Distribution and Boundary Conditions" Materials 18, no. 19: 4629. https://doi.org/10.3390/ma18194629

APA StyleJędrysiak, J., & Kaźmierczak-Sobińska, M. (2025). Free Vibration Analysis of Thin Functionally Graded Plate Bands with Microstructure as a Function of Material Inhomogeneity Distribution and Boundary Conditions. Materials, 18(19), 4629. https://doi.org/10.3390/ma18194629