The Influence Mechanism of a Scanning Strategy on the Fatigue Life of SLM 316L Stainless Steel Forming Parts

Abstract

1. Introduction

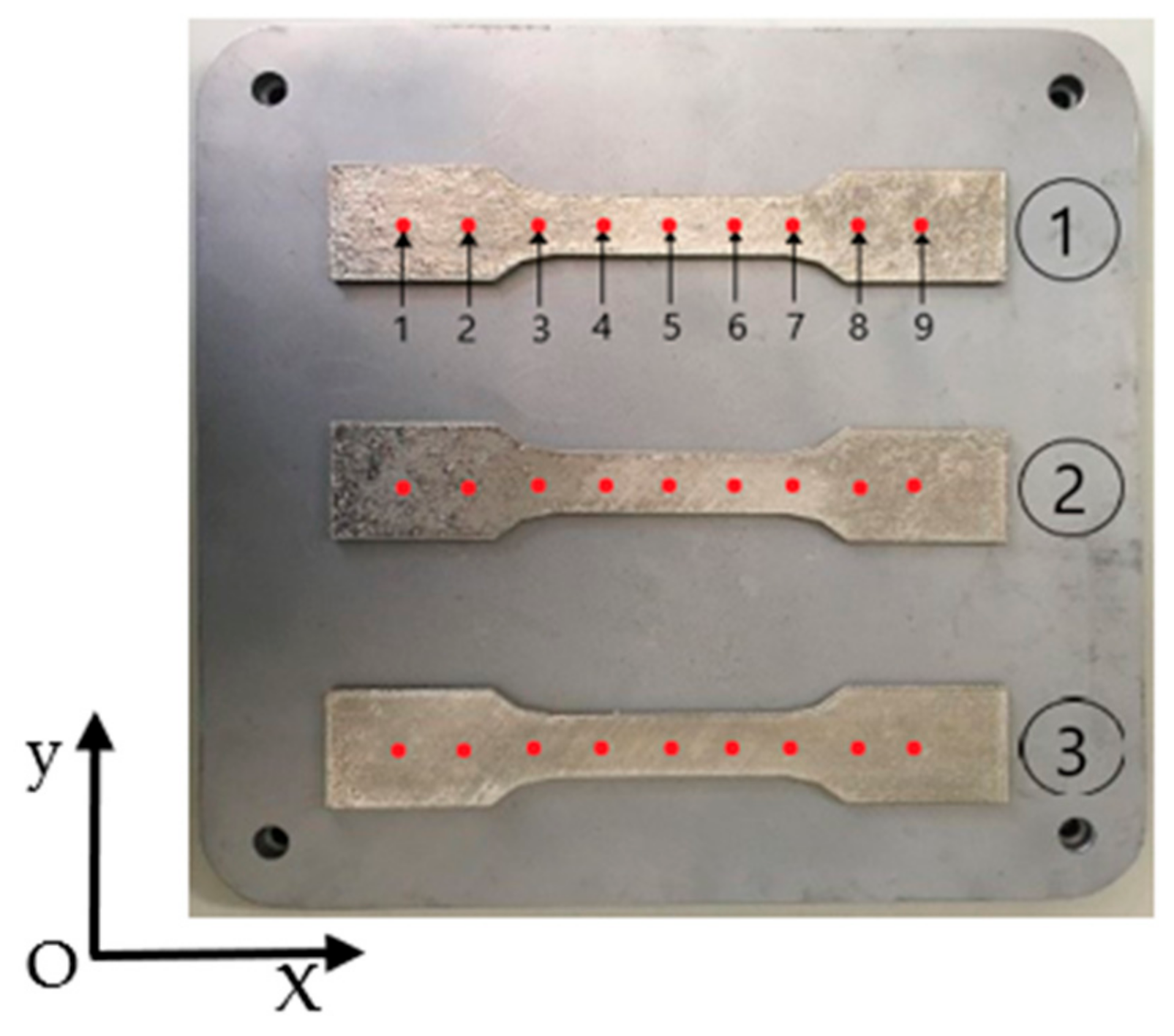

2. Experimental Procedures

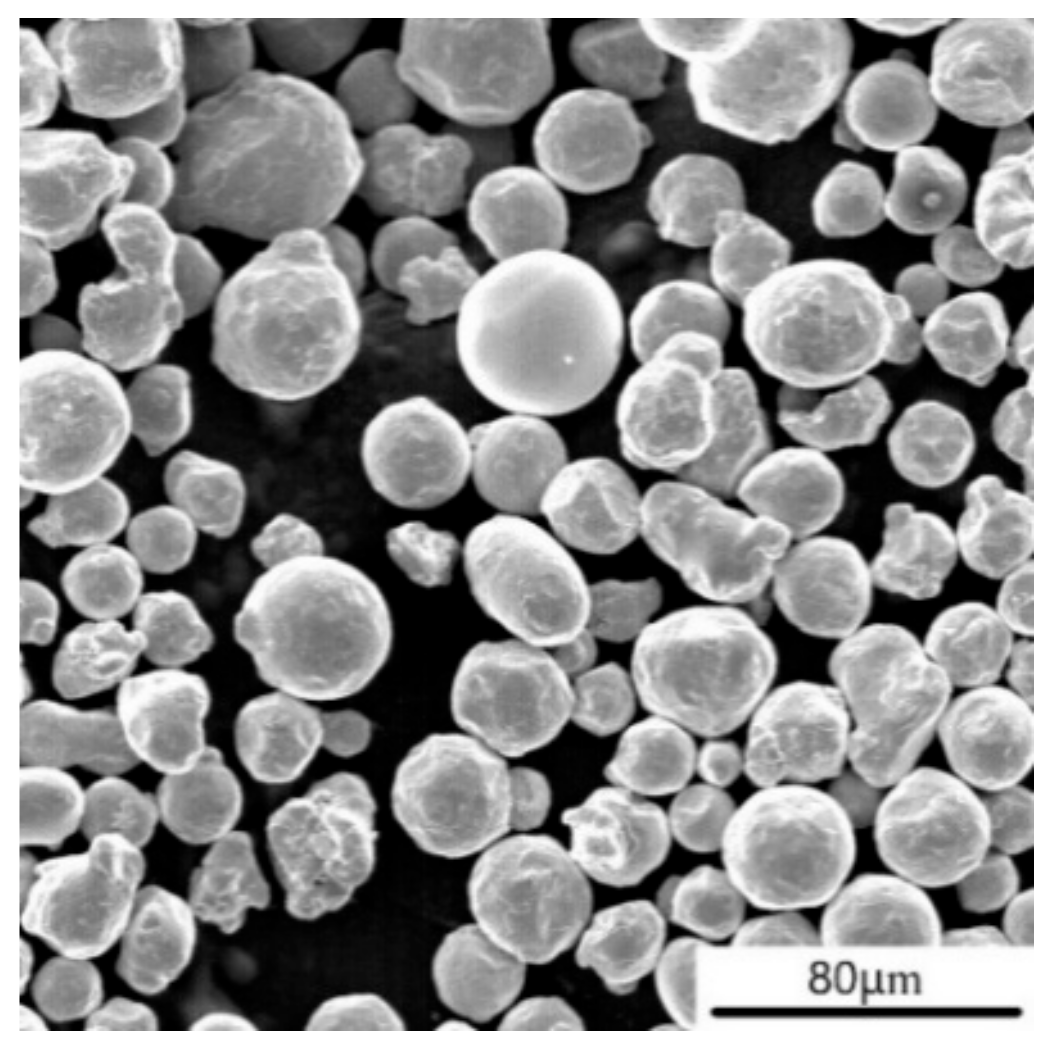

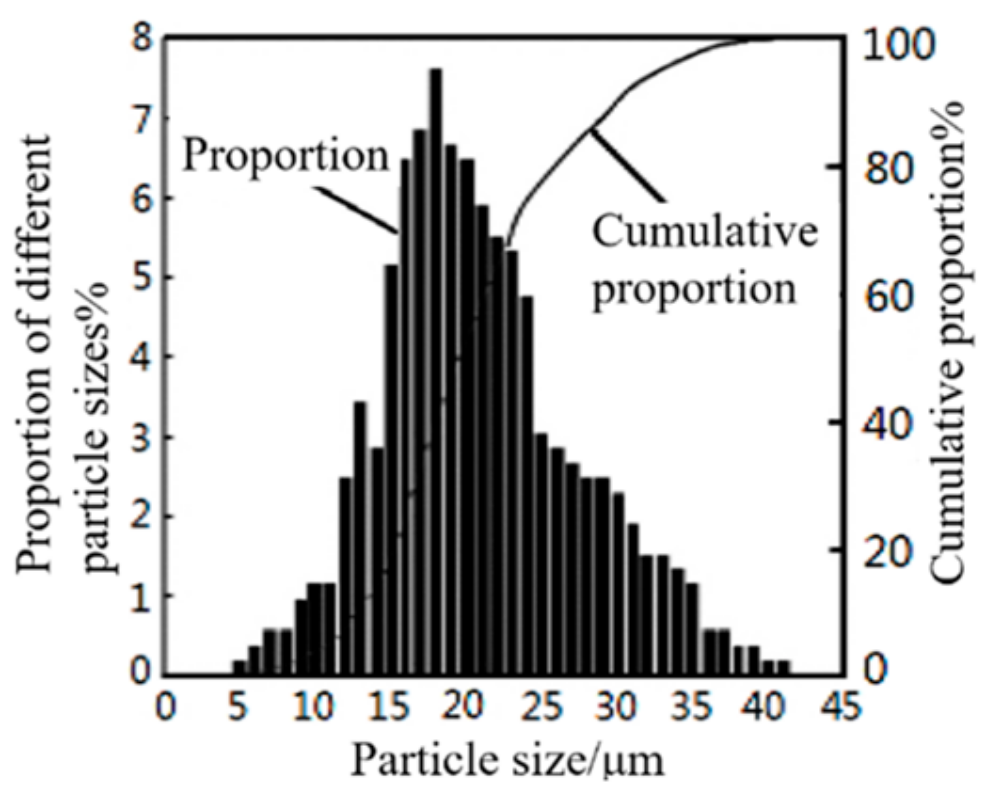

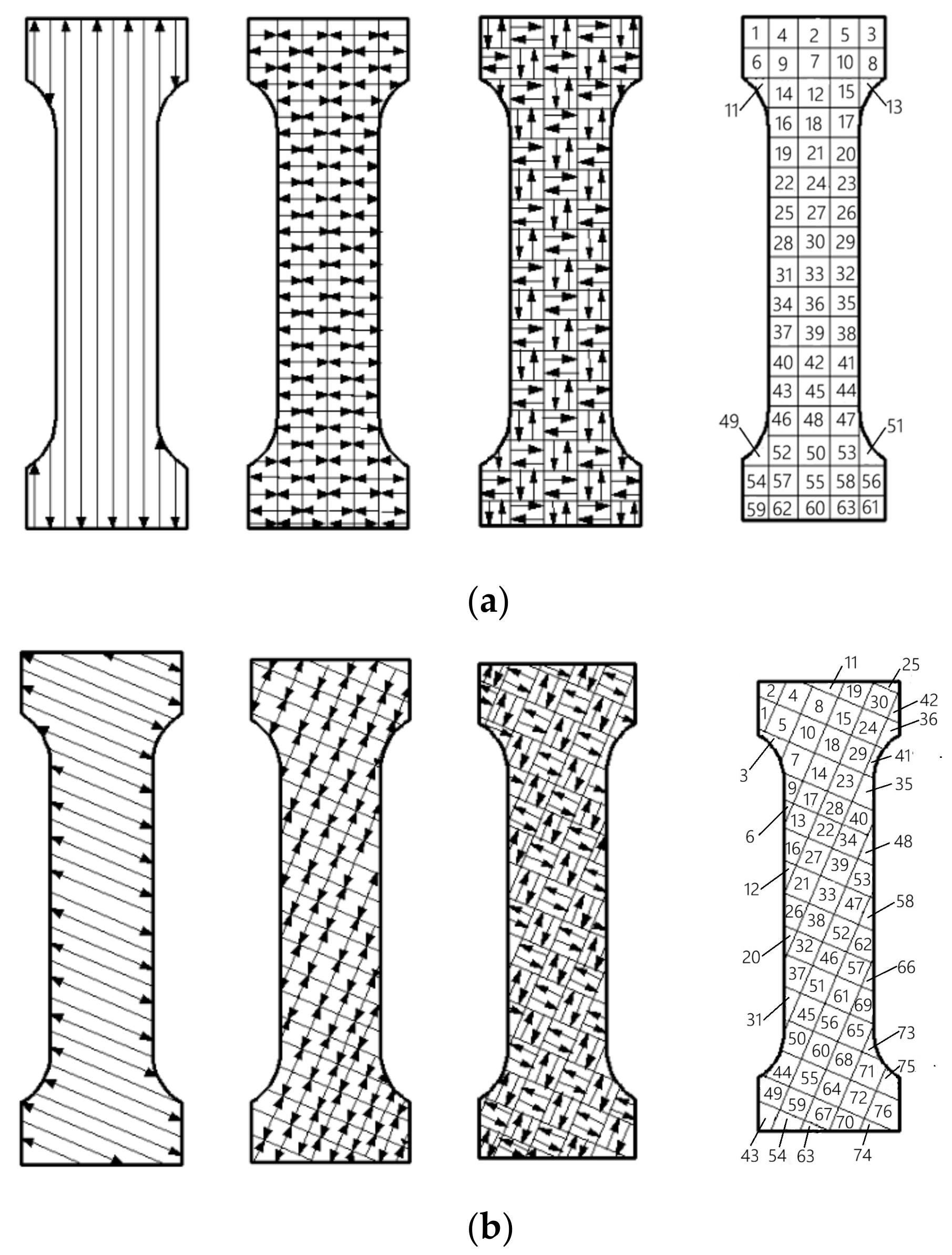

2.1. Material and Specimen Preparation

2.2. Tensile Experiment

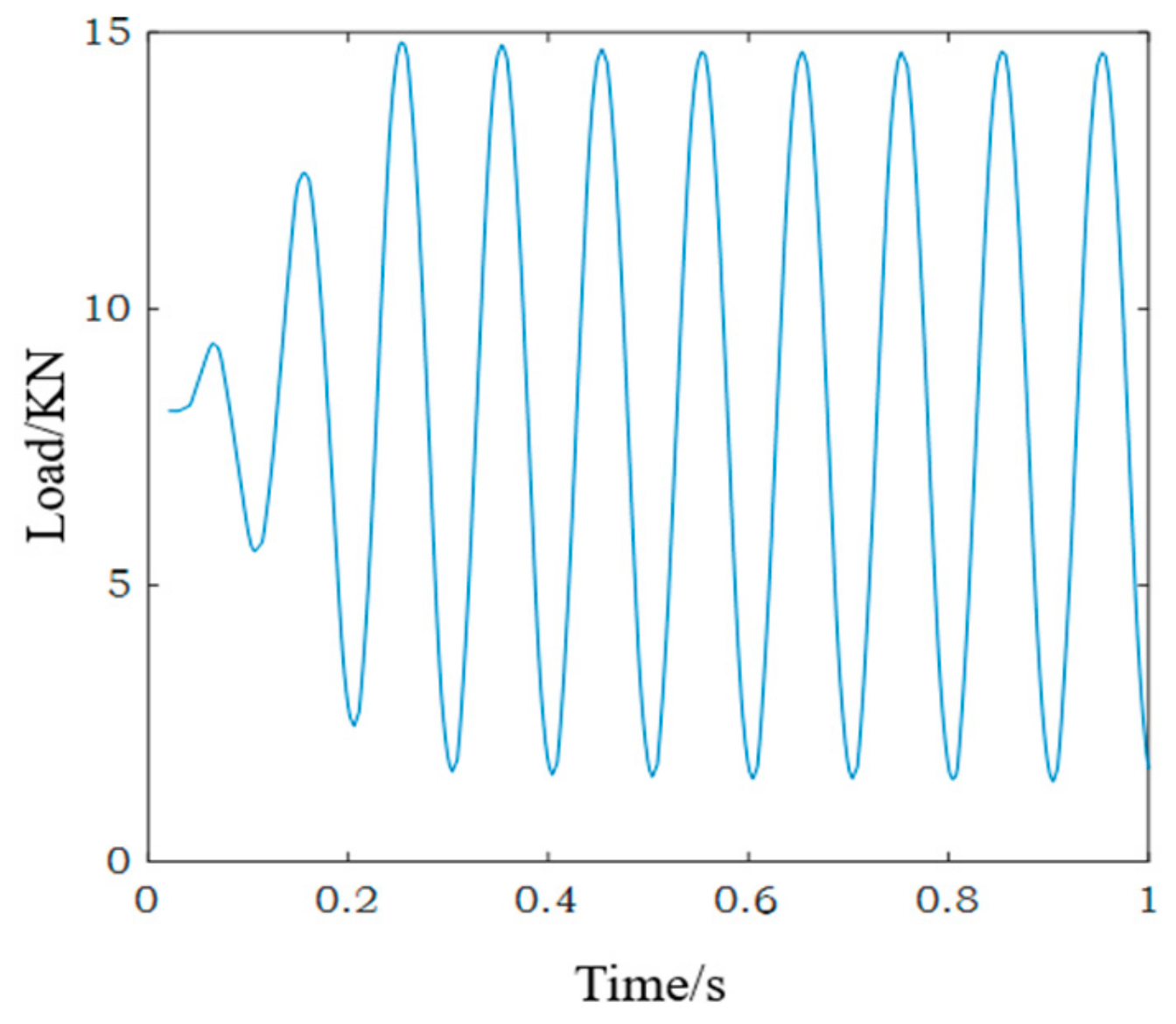

2.3. Fatigue Loading Experiment

3. Experimental Results and Analysis

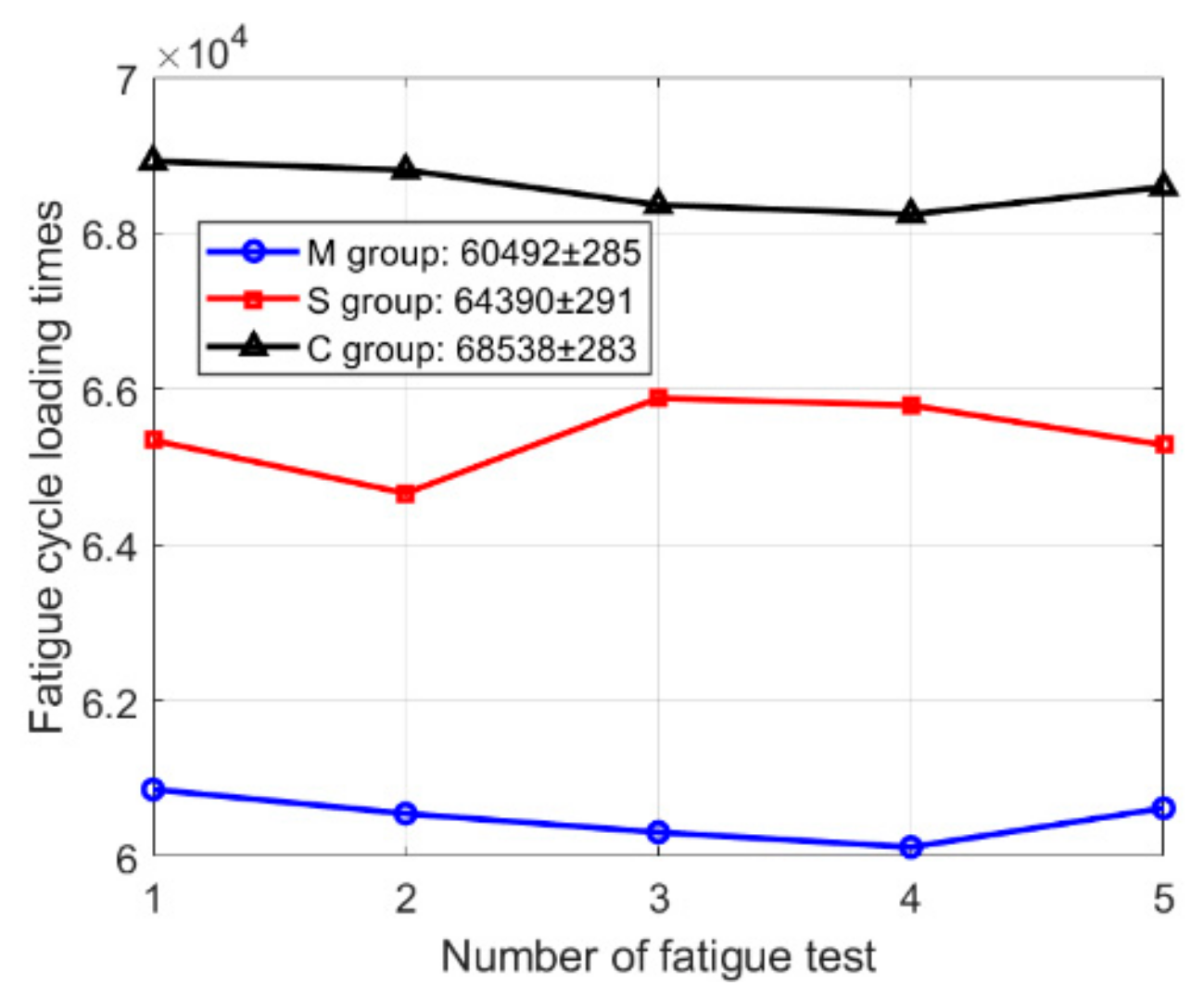

3.1. Experimental Results

3.2. Analysis of Experiment Results Based on Microstructure

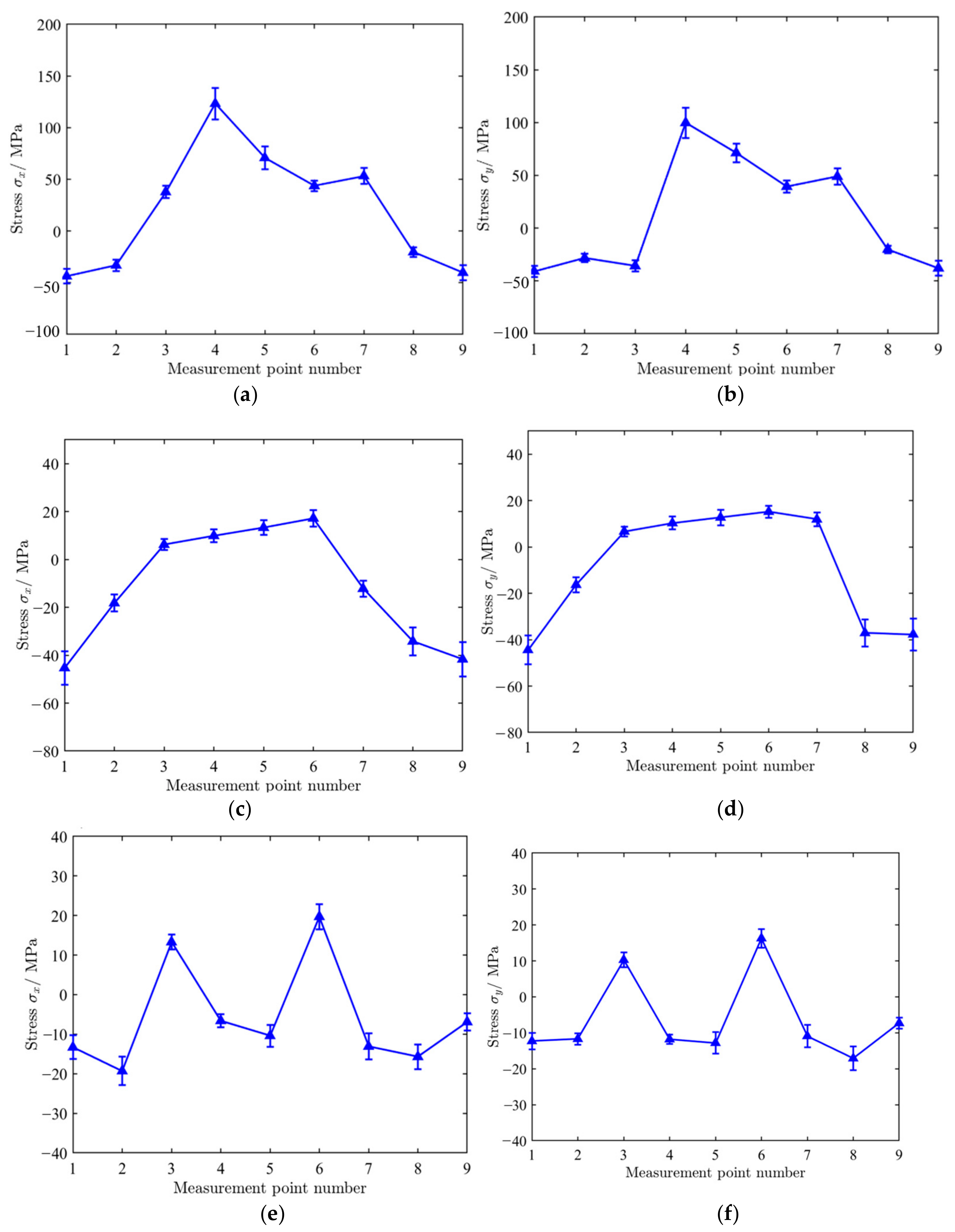

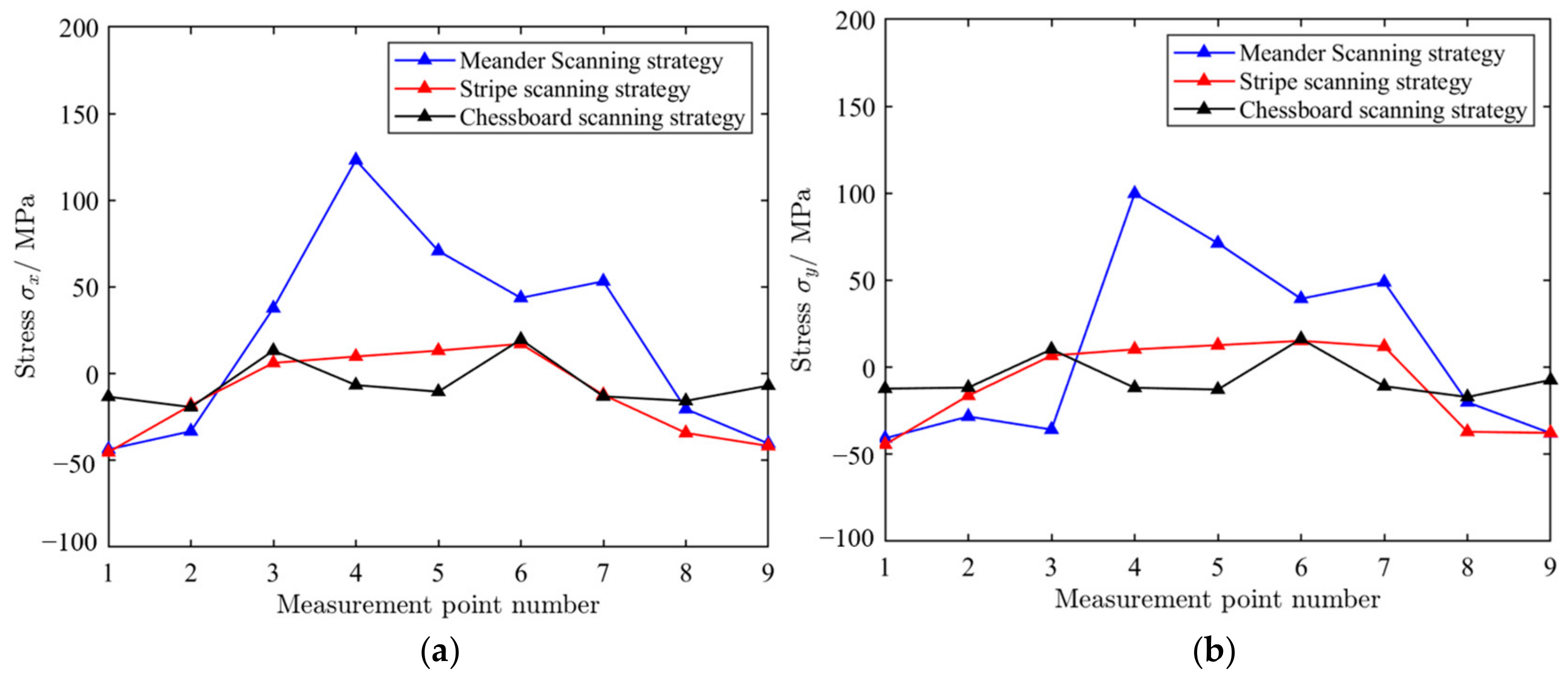

3.3. Analysis of Experiment Results Based on Residual Stress

4. Conclusions

- (1)

- The scanning direction determines the growth direction of the grains (epitaxial growth), thereby affecting the anisotropy and performance of SLM 316L stainless steel parts. During the SLM forming process, grains will grow epitaxially from existing crystals along the construction direction. Meander scanning can cause columnar grains to exhibit significant directionality within the scanning plane, leading to anisotropy in mechanical properties (including fatigue resistance). Stripe scanning and chessboard scanning continuously change the direction of heat flow, dispersing the directional growth of columnar crystals and promoting the formation of finer and more uniform equiaxed crystals, thereby improving the uniformity of the structure and overall fatigue performance.

- (2)

- Defects are the ‘origin’ of fatigue cracks, and the vast majority of fatigue cracks originate from surface or near-surface defects of SLM 316L stainless steel parts. Meander scanning is prone to forming continuous defects, while unidirectional long scanning lines can easily connect pores or incomplete fusion zones in the scanning direction, forming defect bands similar to pre-cracks, greatly reducing fatigue life. Partition scanning effectively isolates defects, while chessboard scanning and stripe scanning divide large areas into small units. Even if there are defects within a unit, these defects are confined within the unit, making it difficult to form a long-range continuous defect band, which is equivalent to interrupting the preferred path of fatigue cracks.

- (3)

- The scanning strategy affects the distribution and magnitude of residual stresses by changing the path of heat source movement. The meander scanning strategy can generate directional tensile residual stresses. Under cyclic loading, the superposition of working stress and residual tensile stress significantly increases the effective stress amplitude, enabling the SLM 316L stainless steel part to reach the fatigue limit faster and promoting crack initiation and propagation. Compressive stress is a beneficial ‘barrier’, and chessboard scanning can introduce compressive stress, counteract some of the working tensile stress, and even close cracks, thereby delaying the fatigue process and greatly improving the service life. Anisotropy leads to weak directions, while meander scanning results in poorer fatigue performance in SLM 316L stainless steel part parts in the scanning direction compared to other directions. Stripe scanning and chessboard scanning tend to make performance isotropic, without clear weak directions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Boschetto, A.; Bottini, L.; Ghanadi, N. Areal analysis investigation of selective laser melting parts. J. Manuf. Mater. Process. 2022, 6, 83. [Google Scholar] [CrossRef]

- Nandhakumar, R.; Venkatesan, K. A process parameters review on selective laser melting-based additive manufacturing of single and multi-material: Microstructure, physical properties, tribological, and surface roughness. Mater. Today Commun. 2023, 35, 105538. [Google Scholar] [CrossRef]

- Lv, J.L.; Zhou, Z.P.; Wang, Z.Q. Comparing the sensitization behavior and the corrosion resistance of the wrought and selective laser melted 316L stainless steels. Mater. Lett. 2022, 328, 133143. [Google Scholar] [CrossRef]

- Wu, S.L.; Wang, S.J.; Wang, H.T. Research progress in selective laser melting of refractory metals. Rare Met. Mater. Eng. 2024, 53, 1217–1228. [Google Scholar]

- Erutin, D.P.; Popovich, A.A.; Sufiiarov, V.S. Effect of scanning angle on density of 1cp/copper selective laser melted composite. Inorg. Mater. Appl. Res. 2024, 15, 1181–1185. [Google Scholar]

- Wang, Y.F.; Yu, J.; Wang, Z.S. Surface quality improvement at selective laser melting AlSi10Mg by optimizing single point diamond turning parameters. Mater. Test. 2023, 65, 63–76. [Google Scholar] [CrossRef]

- Yan, X.L.; Dong, S.Y.; Xu, B.S.; Cao, Y. Progress and Challenges of Ultrasonic Testing for Stress in Remanufacturing Laser Cladding Coating. Materials 2018, 11, 293. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhang, K.; Liang, Y.R.; Cheng, J.; Dai, Y.L. Selective laser melted magnesium alloys: Fabrication, microstructure and property. Materials 2022, 15, 7049. [Google Scholar] [CrossRef]

- Rusin, N.M.; Skorentsev, A.L.; Akimov, K.O. Al-40Sn alloy produced by selective laser melting of elemental powder mixtures. Phys. Met. Metallogr. 2023, 124, 908–915. [Google Scholar] [CrossRef]

- Wang, Q.Y.; Gao, M.D.; Li, Q.; Liu, C.H.; Li, L.; Li, X.Y.; Liu, Z.F. A Review on energy consumption and efficiency of selective laser melting considering support: Advances and prospects. Int. J. Precis. Eng. Manuf. Green Technol. 2024, 11, 259–276. [Google Scholar] [CrossRef]

- Walker, K.F.; Liu, Q.; Brandt, M. Evaluation of fatigue crack propagation behavior in Ti-6Al-4V manufactured by selective laser melting. Int. J. Fatigue 2017, 104, 302–308. [Google Scholar] [CrossRef]

- Chen, Y.F.; Wang, X.W.; Shen, J.W.; Peng, Y.W.; Jiang, Y.; Yang, X.Y.; Leen, S.B.; Gong, J.M. Deformation mechanisms of selective laser melted 316L austenitic stainless steel in high temperature low cycle fatigue. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2022, 843, 143123. [Google Scholar] [CrossRef]

- Liang, W.G.; Li, C.; Zhao, L.; Yan, X.J.; Sun, S.Y. Summarization of remaining life prediction methods for special power plants. Appl. Sci. 2023, 13, 9365. [Google Scholar] [CrossRef]

- Qian, G.; Jian, Z.M.; Pan, X.N.; Berto, F. In-situ investigation on fatigue behaviors of Ti-6Al-4V manufactured by selective laser melting. Int. J. Fatigue 2020, 133, 105424. [Google Scholar] [CrossRef]

- Brandl, E.; Heckenberger, U.; Holzinger, V.; Buchbinder, D. Additive manufactured AlSi10Mg samples using Selective Laser Melting (SLM): Microstructure, high cycle fatigue, and fracture behavior. Mater. Des. 2012, 34, 159–169. [Google Scholar] [CrossRef]

- Lin, J.D.; Lin, Z.; Liao, G.B.; Yin, H.P. A novel product remaining useful life prediction approach considering fault effects. IEEE CAA J. Autom. Sin. 2021, 8, 1762–1773. [Google Scholar] [CrossRef]

- Yu, J.; Oh, H. AI-based degradation index from the microstructure image and life prediction models based on bayesian inference. Sustainability 2023, 15, 7298. [Google Scholar] [CrossRef]

- Duan, Y.H.; Liu, Z.; Li, H.H.; Zhang, C.; Zhang, N. A hybrid-driven remaining useful life prediction method combining asymmetric dual-channel autoencoder and nonlinear Wiener process. Appl. Intell. 2023, 53, 25490–25510. [Google Scholar] [CrossRef]

- Sampath, S.; Jang, J.; Sohn, H. Ultrasonic Lamb wave mixing based fatigue crack detection using a deep learning model and higher-order spectral analysis. Intern. J. Fatigue 2022, 163, 107028. [Google Scholar] [CrossRef]

- Lu, Y.J.; Wu, S.Q.; Gan, Y.L.; Huang, T.T.; Yang, C.G.; Lin, J.J.; Lin, J.X. Study on the microstructure, mechanical property and residual stress of SLM Inconel-718 alloy manufactured by differing island scanning strategy. Opt. Laser Technol. 2015, 75, 197–206. [Google Scholar] [CrossRef]

- Vastola, G.; Zhang, G.; Pei, Q.X.; Zhang, Y.W. Modeling the microstructure evolution during additive manufacturing of Ti6Al4V: A comparison between electron beam melting and selective laser melting. Jom 2016, 68, 2296. [Google Scholar] [CrossRef]

- Riemer, A.; Leuders, S.; Thöne, M.; Richard, H.A.; Tröster, T.; Niendorf, T. On the fatigue crack growth behavior in 316L stainless steel manufactured by selective laser melting. Eng. Fract. Mech. 2014, 120, 15–25. [Google Scholar] [CrossRef]

- He, X.; Kong, D.J.; Song, R.G. Microstructures and properties of laser cladding Al-TiC-CeO2 composite coatings. Materials 2018, 11, 198. [Google Scholar] [CrossRef] [PubMed]

- Fang, J.X.; Dong, S.Y.; Wang, Y.J.; Xu, B.S.; Zhang, Z.H.; Xia, D.; He, P. The effects of solid-state phase transformation upon stress evolution in laser metal powder deposition. Mater. Des. 2015, 87, 807–814. [Google Scholar] [CrossRef]

- Jang, J.I. Estimation of residual stress by instrumented indentation: A review. J. Ceram. Process. Res. 2009, 10, 391–400. [Google Scholar]

- Sufiyarov, V.S.; Borisov, E.V. Effect of heat treatment modes on the structure and properties of alloy VT6 after selective laser melting. Met. Sci. Heat Treat. 2019, 60, 745–748. [Google Scholar] [CrossRef]

- Jeyaprakash, N.; Yang, C.H.; Prabu, G.; Radhika, N. Mechanism correlating microstructure and wear behavior of Ti-6Al-4V plate produced using selective laser melting. Metals 2023, 13, 575. [Google Scholar] [CrossRef]

- Qozam, H.; Chaki, S.; Bourse, G.; Robin, C.; Walaszek, H.; Bouteille, P. Microstructure effect on the Lcr elastic wave for welding residual stress measurement. Exp. Mech. 2010, 50, 179–185. [Google Scholar] [CrossRef]

- Zhan, X.L.; Sun, L.M.H. Detection of crack coefficients of aluminum plates based on nonlinear ultrasonic. Laser Optoelectron. Progress. 2021, 58, 1716002. [Google Scholar]

- Yun, H.G.; Rayhana, R.; Pant, S.; Genest, M.; Liu, Z. Nonlinear ultrasonic testing and data analytics for damage characterization: A review. Measurement 2021, 186, 110155. [Google Scholar] [CrossRef]

- Liu, B.; Zhao, Z.Y.; Bai, P.K.; Liang, M.J.; Guan, R.G. The compressive behavior of a porous 316L stainless steel prepared by selective laser melting. Lasers Eng. 2019, 42, 381–390. [Google Scholar]

- Qiao, R.; Yan, X.L. The characterization of fatigue damage of 316L stainless steel parts formed by selective laser melting with harmonic generation technique. Materials 2022, 15, 718. [Google Scholar] [CrossRef]

- Kim, Y.; Wang, W.; Carbonetto, P.; Stephens, M. A flexible empirical bayes approach to multiple linear regression, and connections with penalized regression. J. Mach. Learn. Res. 2024, 25, 185. [Google Scholar]

| Element | C | Cr | Ni | Mo | Si | Mn | O | p | Fe |

|---|---|---|---|---|---|---|---|---|---|

| Content | 0.03 | 17.6 | 12.06 | 2.26 | 0.86 | 2 | <0.1 | 0.04 | Bal. |

| Laser Power (W) | Scanning Speed (mm/s) | Layer Thickness (μm) | Scanning Interval (μm) | Spot Diameter (μm) | Volume Fraction of Oxygen (%) |

|---|---|---|---|---|---|

| 300 | 750 | 30 | 60 | 70 | ≤0.03 |

| Specimen Number | Tensile Strength (MPa) | Yield Strength (MPa) | Elastic Modulus (N/mm2) | The Maximum Strain (%) |

|---|---|---|---|---|

| M-1 | 527 | 461 | 114,012 | 17.4 |

| M-2 | 529 | 471 | 115,096 | 17.2 |

| M-3 | 531 | 450 | 116,493 | 17.9 |

| M-4 | 518 | 454 | 114,078 | 18.3 |

| M-5 | 516 | 470 | 114,165 | 17.7 |

| Mean | 524.20 | 461.20 | 114,770 | 17.7 |

| Standard deviation | 6.76 | 9.36 | 1060.00 | 0.43 |

| S-1 | 596.3 | 501 | 151,063 | 27.5 |

| S-2 | 591.8 | 497 | 151,798 | 26.5 |

| S-3 | 596.4 | 509 | 154,273 | 29.3 |

| S-4 | 584.2 | 507 | 154,765 | 27.4 |

| S-5 | 604 | 503 | 151,371 | 28.8 |

| Mean | 594.50 | 503.40 | 152,654 | 27.90 |

| Standard deviation | 7.25 | 4.77 | 1731.20 | 1.13 |

| C-1 | 627 | 543 | 177,904 | 33.8 |

| C-2 | 634.2 | 557 | 177,689 | 34.9 |

| C-3 | 643.7 | 542 | 176,973 | 34.6 |

| C-4 | 624.5 | 547 | 177,521 | 35.0 |

| C-5 | 641.9 | 561 | 176,343 | 36.1 |

| Mean | 634.30 | 550.00 | 177,286 | 34.80 |

| Standard deviation | 8.59 | 8.54 | 629.84 | 0.82 |

| Group Comparison | Difference | 95% Confidence Interval | p-Value | Significance |

|---|---|---|---|---|

| M group vs. S group | −5.0 | [−11.75, 1.75] | 0.21 | |

| M group vs. C group | −10.0 | [−16.75, −3.24] | 0.001 | Highly significant |

| S group vs. C group | −5.0 | [−11.75, 1.74] | 0.21 |

| Measurement Point | σx/MPa | σy/MPa | ||||

|---|---|---|---|---|---|---|

| Meander Scanning | Stripe Scanning | Chessboard Scanning | Meander Scanning | Stripe Scanning | Chessboard Scanning | |

| 1 | −43.7 | −45.3 | −13.3 | −40.8 | −44.4 | −12.3 |

| 2 | −33.2 | −18.2 | −19.3 | −28.3 | −16.3 | −11.7 |

| 3 | 37.8 | 6.2 | 13.3 | −35.8 | 6.7 | 10.3 |

| 4 | 123.2 | 9.9 | −6.6 | 99.8 | 10.3 | −11.8 |

| 5 | 70.8 | 13.3 | −10.4 | 71.3 | 12.7 | −12.8 |

| 6 | 43.7 | 17.18 | 19.7 | 39.4 | 15.2 | 16.3 |

| 7 | 53.3 | −12.2 | −13.1 | 48.9 | 11.9 | −10.9 |

| 8 | −20.4 | −34.2 | −15.7 | −20.1 | −37.1 | −17.1 |

| 9 | −40.3 | −41.7 | −6.9 | −37.9 | −37.7 | −7.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, H.; Yan, X.; Fu, H. The Influence Mechanism of a Scanning Strategy on the Fatigue Life of SLM 316L Stainless Steel Forming Parts. Materials 2025, 18, 4571. https://doi.org/10.3390/ma18194571

Ma H, Yan X, Fu H. The Influence Mechanism of a Scanning Strategy on the Fatigue Life of SLM 316L Stainless Steel Forming Parts. Materials. 2025; 18(19):4571. https://doi.org/10.3390/ma18194571

Chicago/Turabian StyleMa, Huijun, Xiaoling Yan, and Huiwen Fu. 2025. "The Influence Mechanism of a Scanning Strategy on the Fatigue Life of SLM 316L Stainless Steel Forming Parts" Materials 18, no. 19: 4571. https://doi.org/10.3390/ma18194571

APA StyleMa, H., Yan, X., & Fu, H. (2025). The Influence Mechanism of a Scanning Strategy on the Fatigue Life of SLM 316L Stainless Steel Forming Parts. Materials, 18(19), 4571. https://doi.org/10.3390/ma18194571