Study on the Durability of Graphene Oxide Concrete Composite Under Chloride and Sulfate Environments

Abstract

1. Introduction

2. Experiment

2.1. Materials and Instruments

2.2. Preparation of Graphene Oxide Concrete Composite

- (i)

- (ii)

- Pre-screening: pilot compressive-strength tests (5 d, 7 d, and 28 d) peaked at 0.07 wt% GO, corroborating the 27.7% gain reported in Section 3.1.

- (iii)

- Economic factor: at 0.07 wt% GO, the additional binder cost is <2% of the cement price, an increment considered acceptable for marine-grade concrete; hence 0.09 wt% was adopted as the upper bound in this durability study.

2.3. Experimental Scheme

3. Results and Discussion

3.1. Compressive Strength Analysis

3.2. The Impact on GO-CC’s Compressive Strength

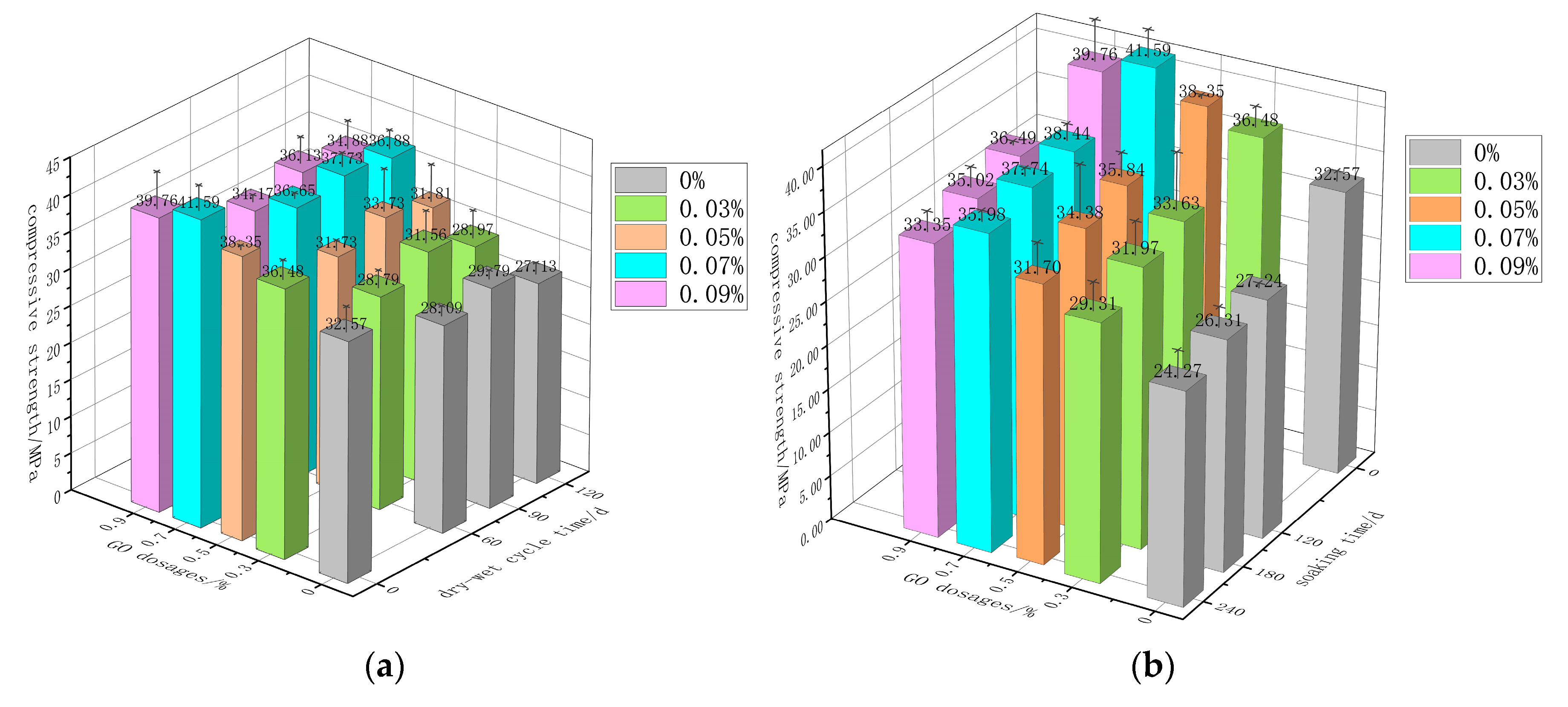

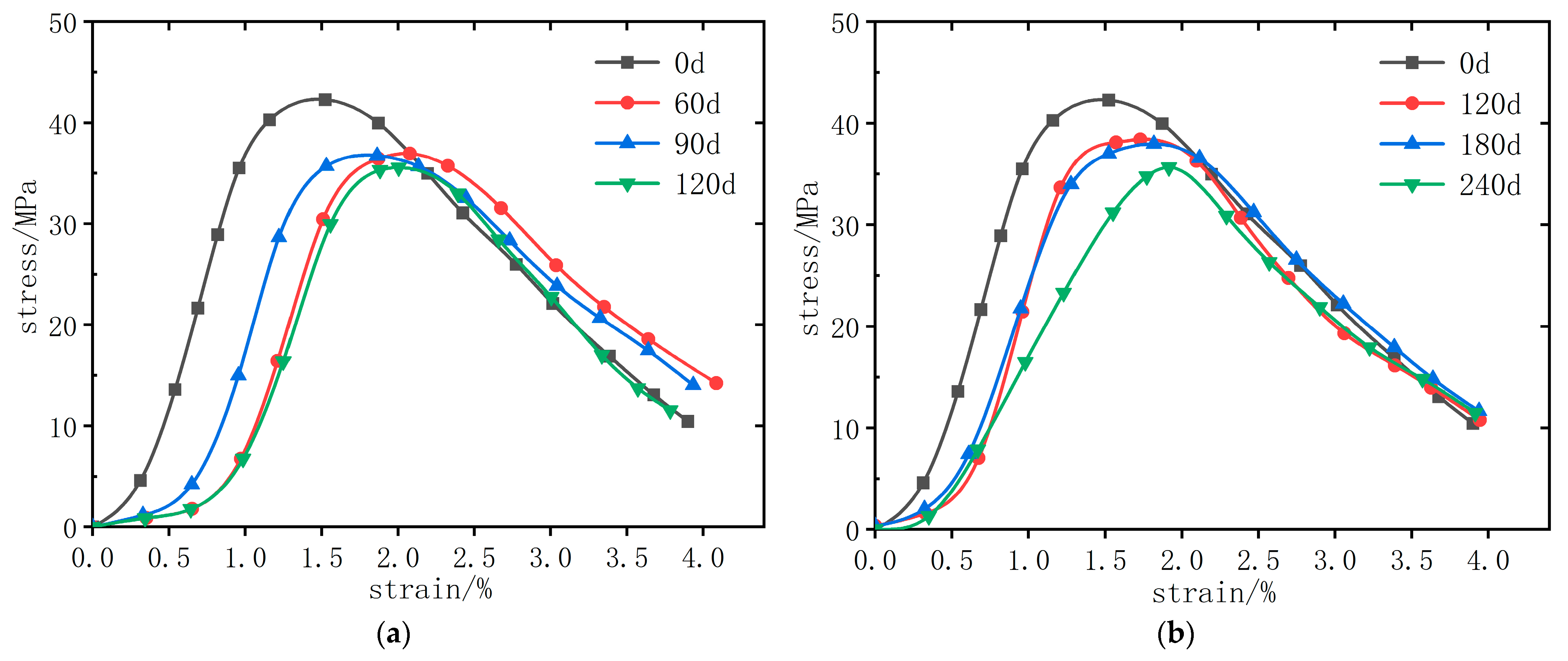

3.2.1. GO-CC Compressive Strength

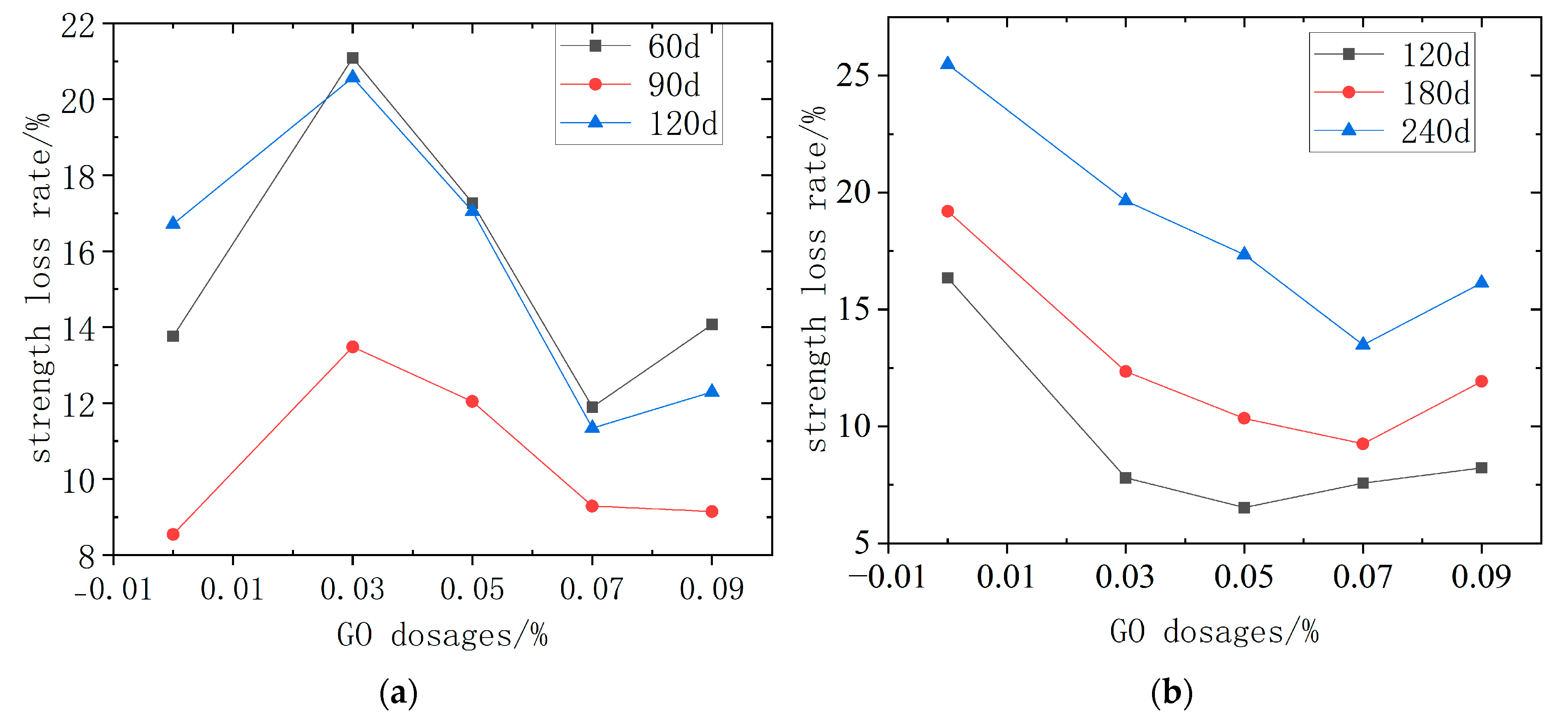

3.2.2. Strength Loss Rate

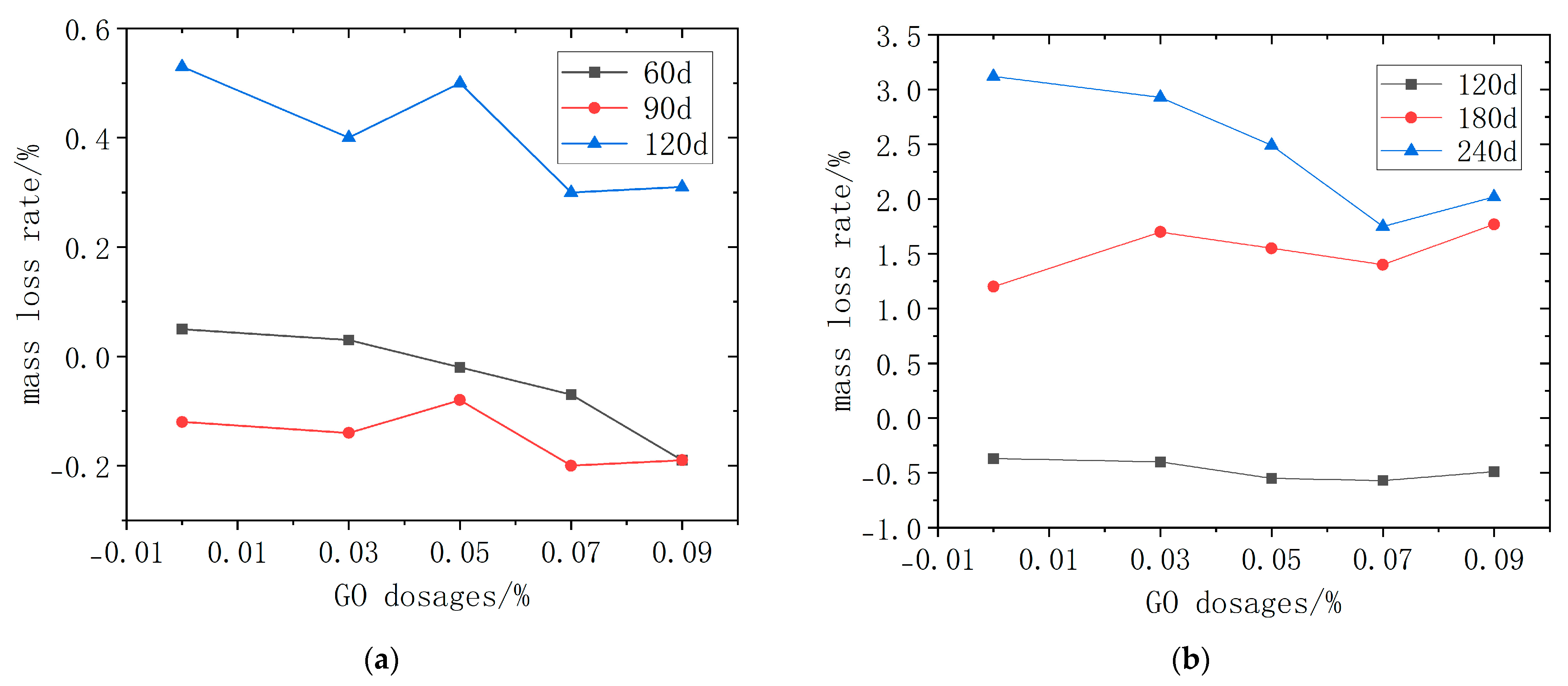

3.3. The Impact on GO Test Blocks’ Mass Loss

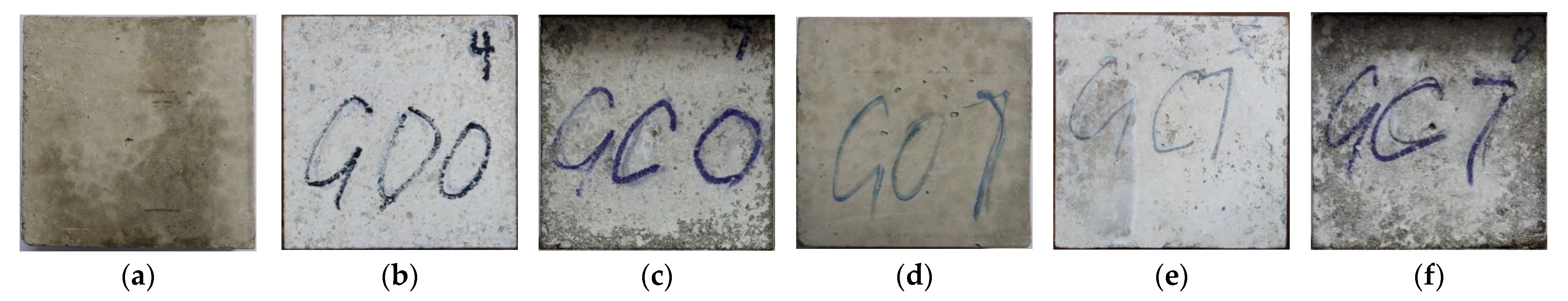

3.3.1. Changes in the Appearance of the Specimen

3.3.2. The Impact of the Quality Loss Rate

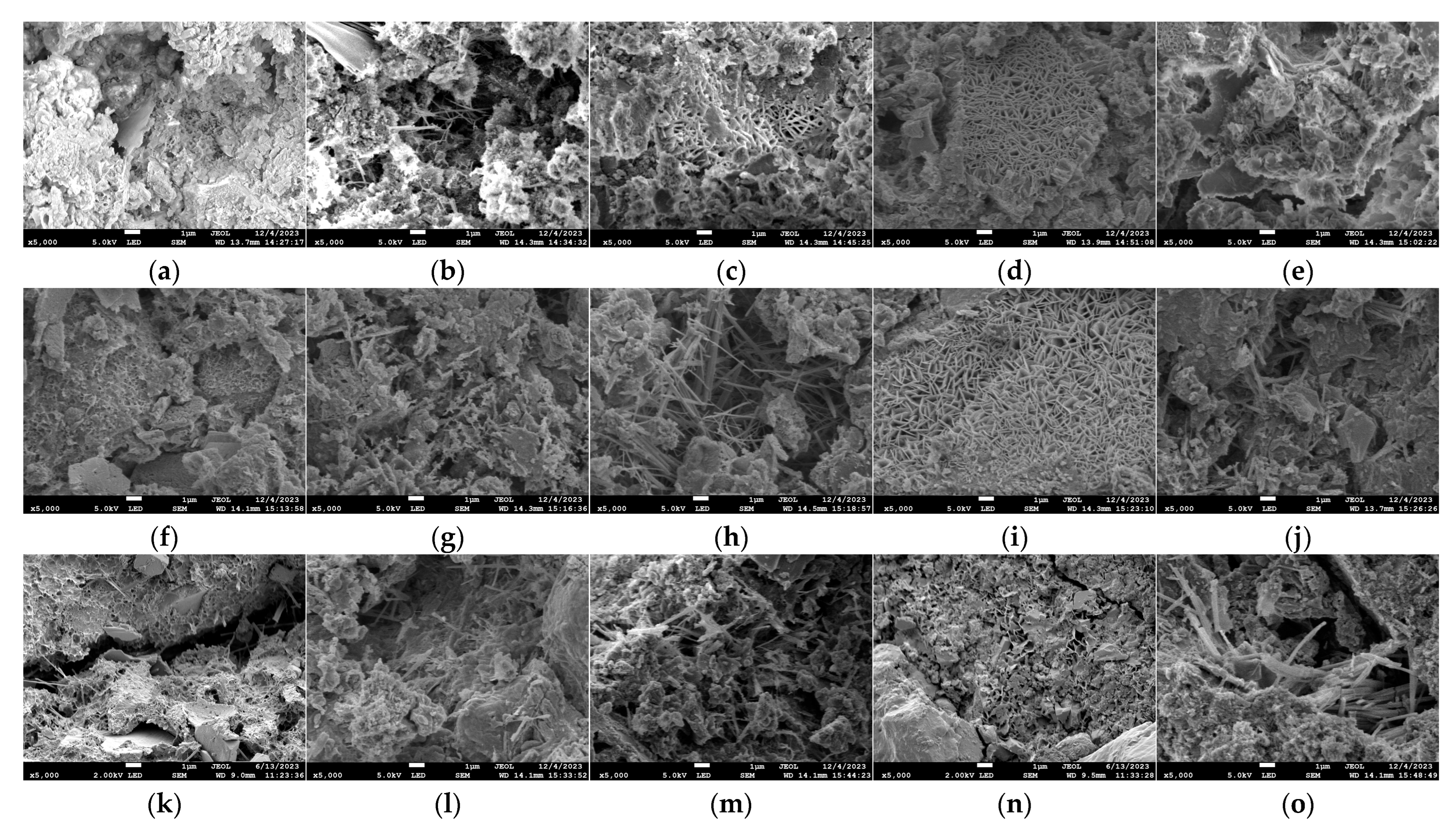

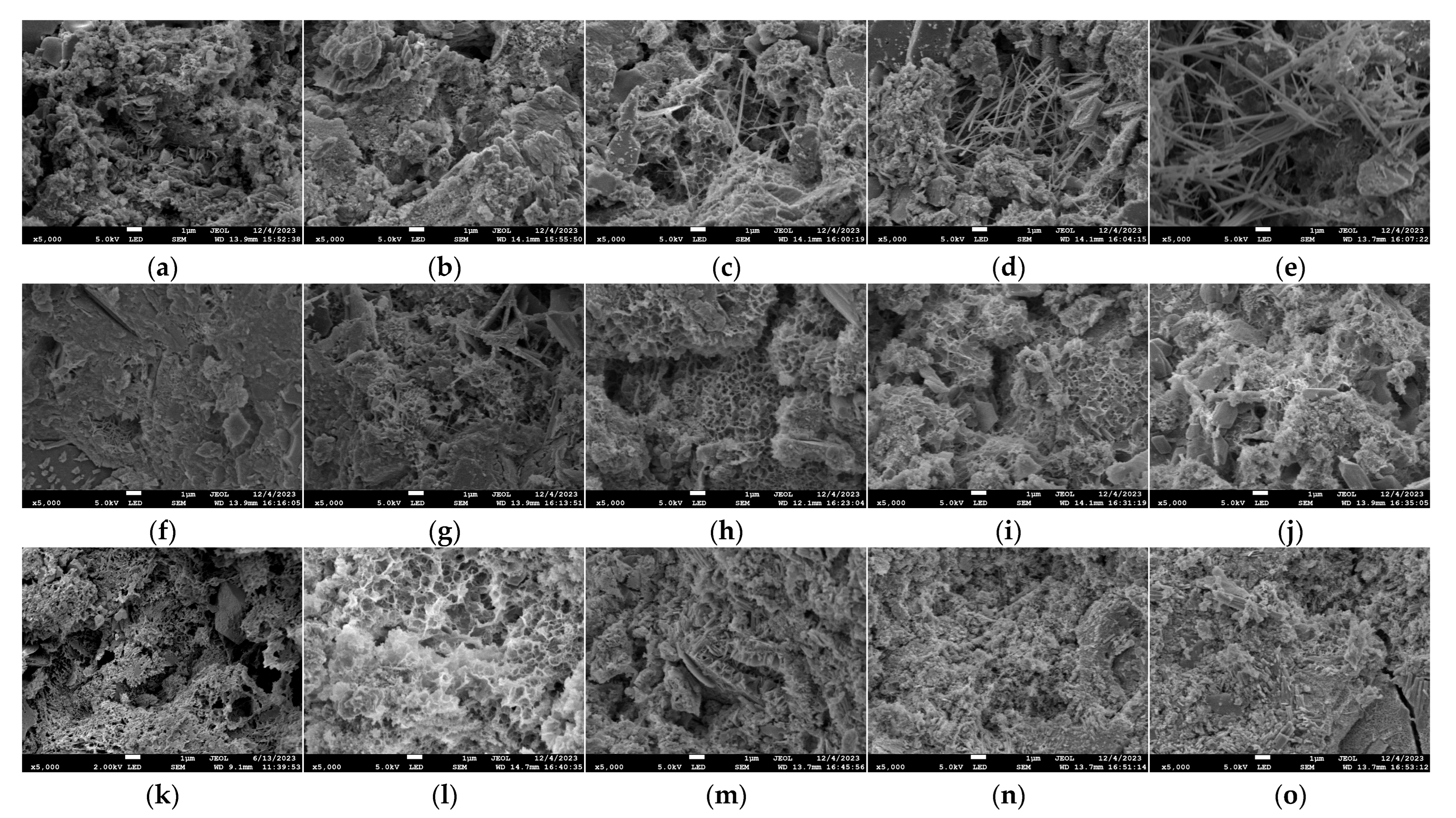

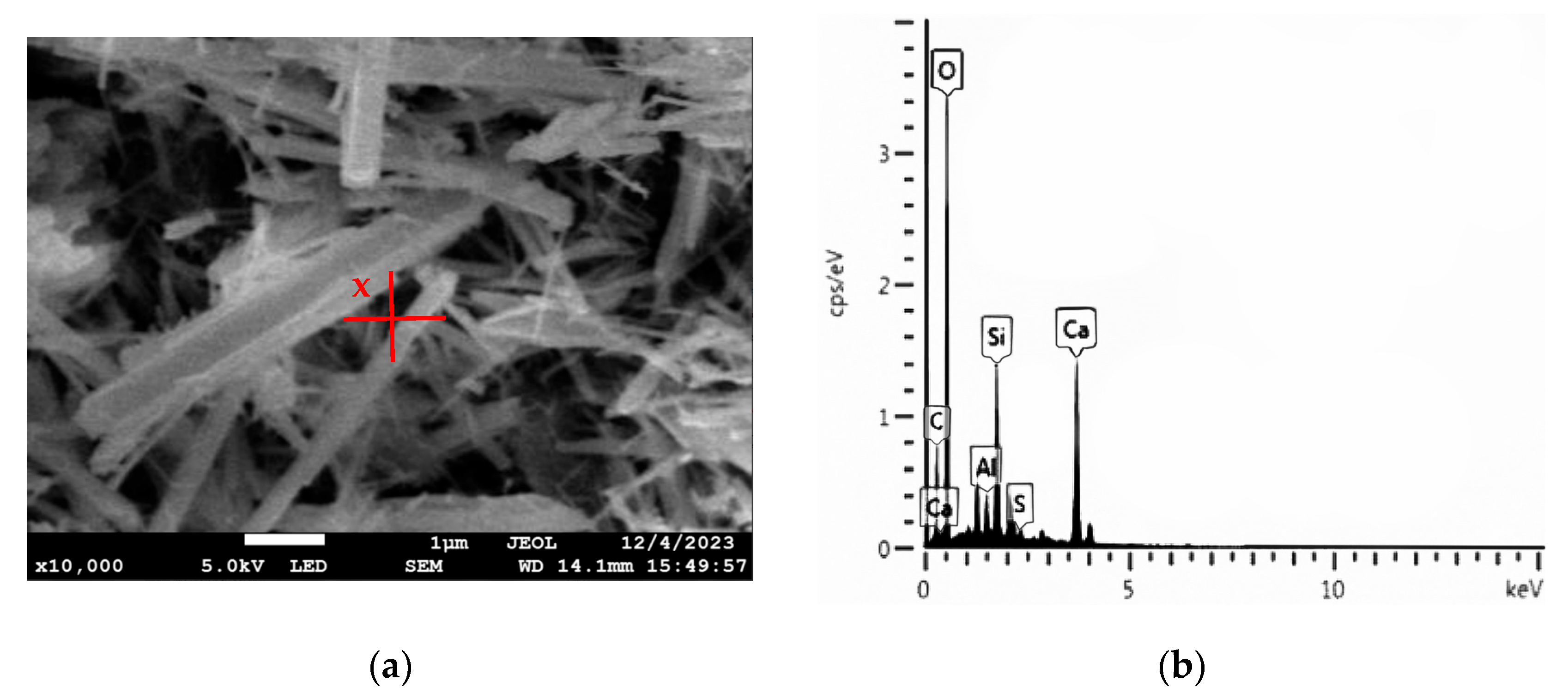

3.4. Impact on GO-CC’s Microstructure

4. Conclusions

- Under dry–wet cycling, the compressive strength of GO concrete at every dosage rose to a maximum at 90 d and then declined; under long-term natural immersion, it decreased monotonically. In both regimes, progressive ionic ingress damages the bulk matrix and interfacial zones, leading to systematic strength loss.

- Under dry–wet cycling, GO confers no measurable reduction in strength loss; by contrast, during long-term natural immersion, it markedly mitigates such loss, with optimum performance at 0.07 wt%. Consequently, GO incorporation is recommended for concrete exposed to long-term chloride-sulfate environments.

- Regardless of dry–wet cycling or long-term immersion corrosion regime, the mass of GO modified concrete first increases and then decreases with time. GO addition retards acidic-ion ingress; the optimum resistance to long-term attack is achieved at 0.07 wt%, imparting enhanced durability in the latter stages of corrosion.

- A GO dosage of 0.07 wt% simultaneously maximizes compressive-strength gain and chloride-sulfate durability; this dosage is therefore recommended for concrete enhancement.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Feng, H.; Yuan, C.F. Durability of Concrete Structures; China Architecture & Building Press: Beijing, China, 2024. [Google Scholar]

- Qin, S.S. Study on Deterioration Model of Concrete Under Sulfate Attack and Durability Failure; Harbin Institute of Technology: Harbin, China, 2020. [Google Scholar] [CrossRef]

- Xiao, S.; Su, G.; Tang, M.; Chu, X.; Zhou, J.; Hu, H.; Zhu, W.; Zhang, S. Review on durability of concrete in chloride and sulfate environments. Concrete 2022, 1, 41–45. [Google Scholar] [CrossRef]

- Zeng, J.J.; Gao, Z.Y.; Ruan, D. Effect of graphene oxide on microstructure and mechanical properties of concrete. J. Funct. Mater. 2021, 52, 12123–12128. [Google Scholar]

- Liang, Q.; Gao, Z.Y.; Ruan, D.; Zhang, Y.; Liu, H. Effect of graphene oxide and specimen shape on mechanical properties of cement-based composites. Concrete 2022, 11, 77–81+86. [Google Scholar]

- Ioni, Y.V.; Ivannikova, A.S.; Shapovalov, S.S.; Gubin, S.P. Study of the interaction of graphene oxide with chlorine. Russ. Chem. Bull. 2022, 71, 675–679. [Google Scholar] [CrossRef]

- Ioni, Y.; Ibragimova, V. Study of sorption activity of carbon nanomaterials for capture of chlorine-containing gases. Clean Technol. 2025, 7, 39. [Google Scholar] [CrossRef]

- Zhang, R.J.; Chen, G.L.; Song, C.C.; Zhu, Y.F. Effect of graphene oxide on mechanical properties and chloride ion permeability of UHPC with recycled sand. Inorg. Salt Ind. 2024, 56, 54–59. [Google Scholar] [CrossRef]

- Yang, Y.L.; Yuan, X.Y.; Shen, X.; Yin, L. Study on corrosion resistance of cement mortar modified by graphene oxide. J. Funct. Mater. 2017, 48, 5144–5148. [Google Scholar]

- Li, X.G.; Ren, Z.F.; Xu, P.H.; Liu, Z.L.; Jiang, W.G. Study on mechanical properties and durability of graphene oxide composite PVA fiber reinforced cement-based materials. Bull. Chin. Ceram. Soc. 2018, 37, 245–250. [Google Scholar] [CrossRef]

- Li, J.X. Study on the effect of graphene oxide on the properties of cement-based composites. People’s Yellow River 2020, 42, 54–57+62. [Google Scholar]

- Guo, K.; Tong, Z.; Zhang, S.F.; Pan, W.H.; Liu, L. Durability of GO-RAC under coupled action of freeze-thaw and chloride attack. J. Build. Mater. 2023, 26, 1183–1191. [Google Scholar]

- Liu, X.Y.; Liu, H.; Wang, X.J.; Zhu, P.H.; Chen, C.H.; Zhou, X.L. Study on anti-sulfate erosion performance of graphene oxide modified recycled aggregate concrete. Mater. Rev. 2023, 37, 148–153. [Google Scholar]

- Muthu, M.; Yang, E.H.; Unluer, C. Resistance of graphene oxide-modified cement pastes to hydrochloric acid attack. Constr. Build. Mater. 2021, 273, 121990. [Google Scholar] [CrossRef]

- Zhou, F. Investigation on Properties of Cementitious Materials Reinforced by Grapheme. Master’s Thesis, University of Pittsburgh, Pittsburgh, PA, USA, 2014. [Google Scholar]

- Devi, S.C.; Khan, R.A. Effect of sulfate attack and carbonation in graphene oxide–reinforced concrete containing recycled concrete aggregate. J. Mater. Civ. Eng. 2020, 32, 04020339. [Google Scholar] [CrossRef]

- Hussain, Z.; Ansari, W.S.; Akbar, M.; Azam, A.; Lin, Z.; Yosri, A.M.; Shaaban, W.M. Microstructural and mechanical assessment of sulfate-resisting cement concrete over portland cement incorporating sea water and sea sand. Case Stud. Constr. Mater. 2024, 21, e03689. [Google Scholar] [CrossRef]

- Yang, F.; Zhao, Z.; Liu, Y.; Li, M.; Song, J.; Hu, D.; Zhou, H. Effect of flow rate on spatio-temporal deterioration of concrete under flowing sulfate attack. Cem. Concr. Res. 2025, 118, 107734. [Google Scholar] [CrossRef]

- Peng, H.; Ge, Y.P.; Yang, Z.T.; Liu, Y.; Lv, Y.G. Mechanical properties and microstructure of graphene oxide reinforced cement-based composites. Acta Mater. Compos. Sin. 2018, 35, 2132–2139. [Google Scholar] [CrossRef]

- Xu, Y.H.; Fan, Y.F. Effect of graphene oxide dispersion on salt-freeze resistance of concrete. Concrete 2022, 2, 1–5. [Google Scholar]

- Zhao, H.F.; Lu, S.H.; Deng, L.J. Structure and properties of graphene oxide toughened cement-based composites. J. Shaanxi Univ. Sci. Technol. Nat. Sci. Ed. 2016, 34, 60–64+81. [Google Scholar]

| Parameter | Number of Layers | Lateral Flake Size & Average Thickness/nm | Purity/% | Moisture/% | Oxygen Content/at.% | Form |

|---|---|---|---|---|---|---|

| Specification | 1–3 | <5 | 99 | 1 | 45–48 | Dry powder |

| Cement | Fine Aggregate | Coarse Aggregate | Water | Water–Cement Ratio |

|---|---|---|---|---|

| 300 | 672 | 1248 | 180 | 0.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, Z.; Shi, Q.; Cui, J.; Lin, J.; Mao, W.; Kosior-Kazberuk, M.; Krassowska, J. Study on the Durability of Graphene Oxide Concrete Composite Under Chloride and Sulfate Environments. Materials 2025, 18, 4522. https://doi.org/10.3390/ma18194522

Gao Z, Shi Q, Cui J, Lin J, Mao W, Kosior-Kazberuk M, Krassowska J. Study on the Durability of Graphene Oxide Concrete Composite Under Chloride and Sulfate Environments. Materials. 2025; 18(19):4522. https://doi.org/10.3390/ma18194522

Chicago/Turabian StyleGao, Zhanyuan, Qifeng Shi, Jintao Cui, Jianfeng Lin, Weiting Mao, Marta Kosior-Kazberuk, and Julita Krassowska. 2025. "Study on the Durability of Graphene Oxide Concrete Composite Under Chloride and Sulfate Environments" Materials 18, no. 19: 4522. https://doi.org/10.3390/ma18194522

APA StyleGao, Z., Shi, Q., Cui, J., Lin, J., Mao, W., Kosior-Kazberuk, M., & Krassowska, J. (2025). Study on the Durability of Graphene Oxide Concrete Composite Under Chloride and Sulfate Environments. Materials, 18(19), 4522. https://doi.org/10.3390/ma18194522