Comparison of Porosity and Thermal Conductivity of Concrete and Alkali-Activated Hybrid Binders in 3D-Printed Fiber-Reinforced Foamed Composites

Abstract

1. Introduction

2. Materials and Methods

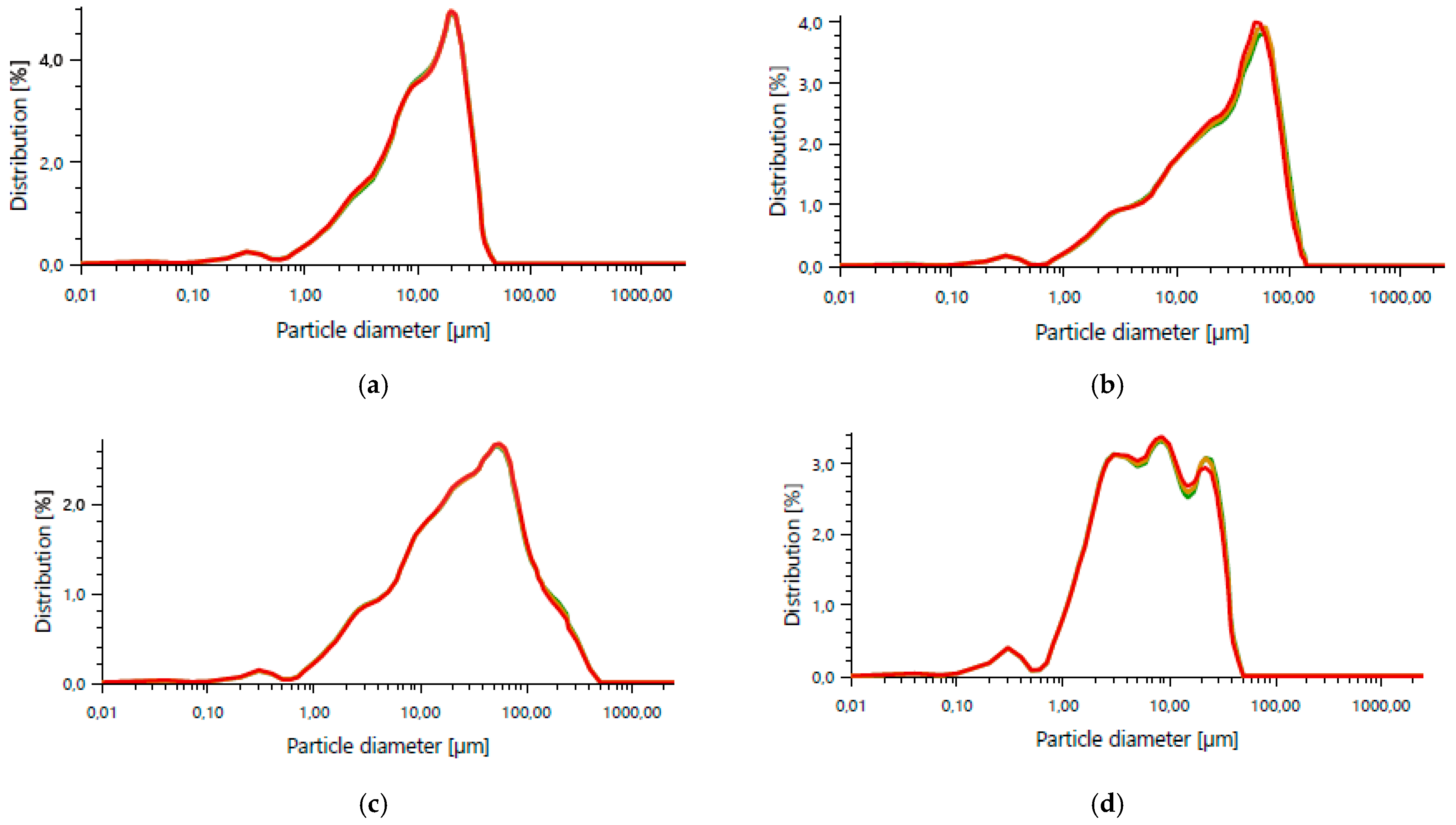

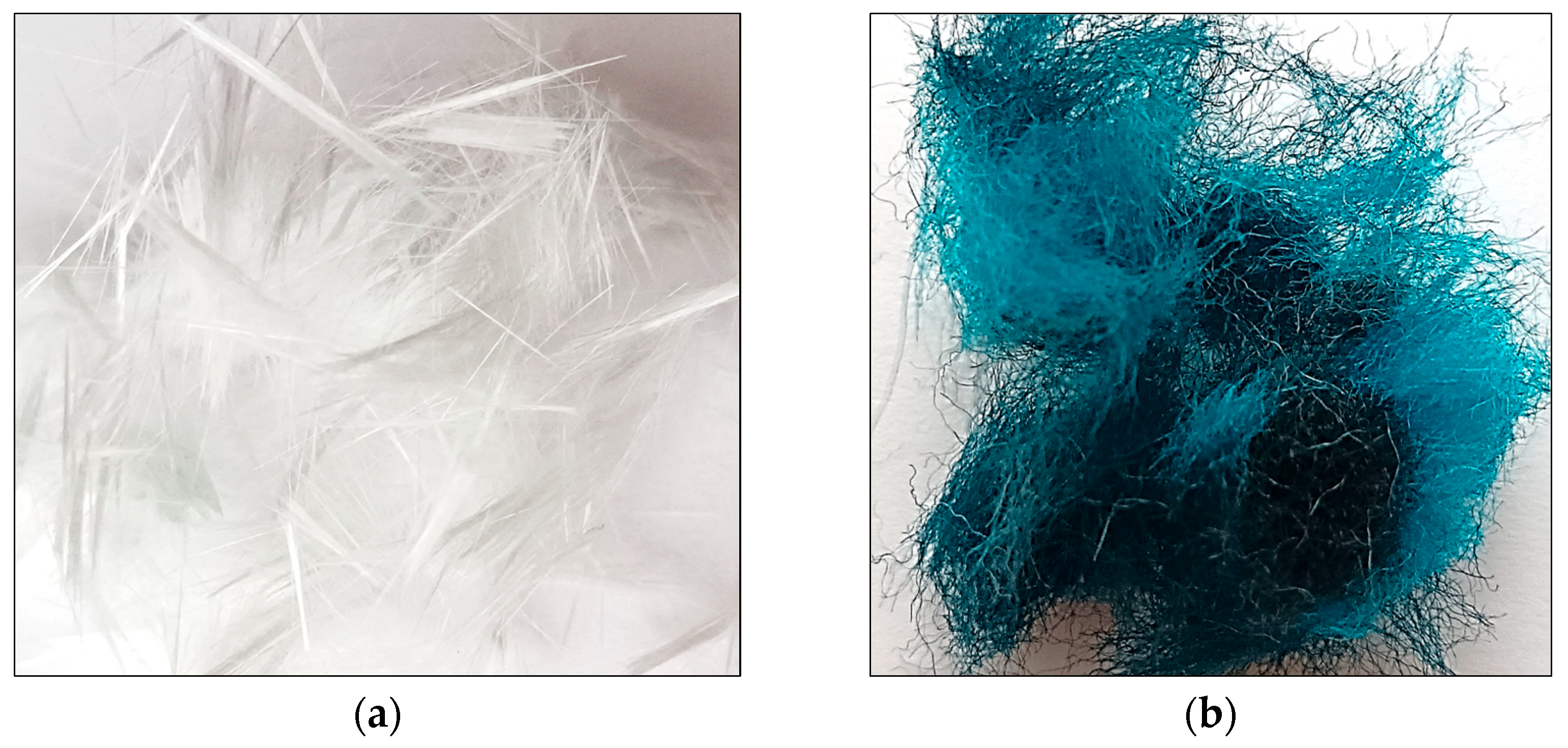

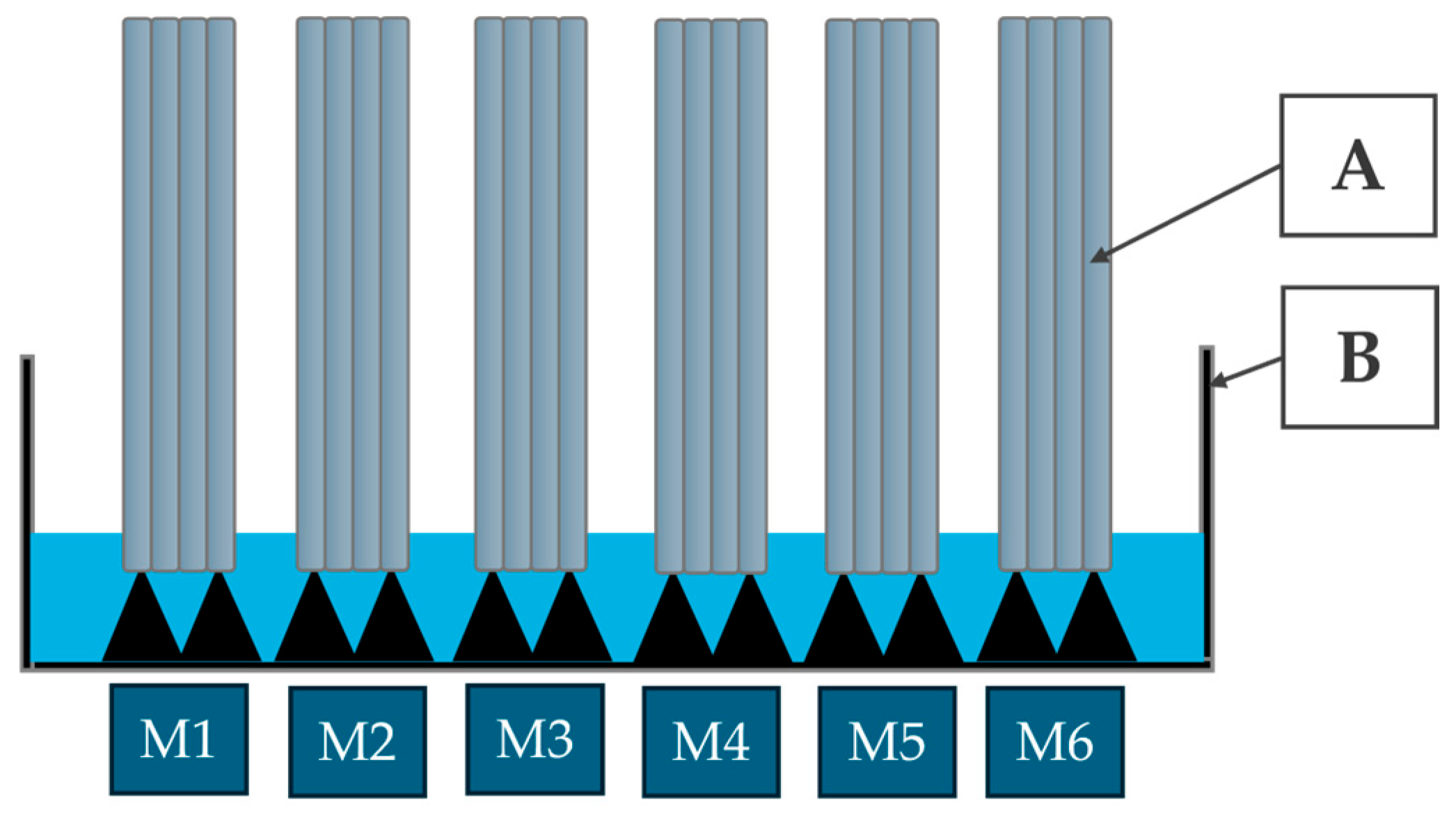

2.1. Materials

2.2. Methods

2.2.1. Shrinkage Test

- εsh—linear shrinkage [%],

- L0—initial length of the specimen (immediately after printing) [mm],

- Lt—length of the specimen after time t = 1, 14, 28 days) [mm].

2.2.2. Flexural and Compressive Strength Testing Procedures

2.2.3. Thermal Conductivity Testing Procedures

2.2.4. Thermographic Moisture Assessment of the Material

2.2.5. Layer Adhesion Tests

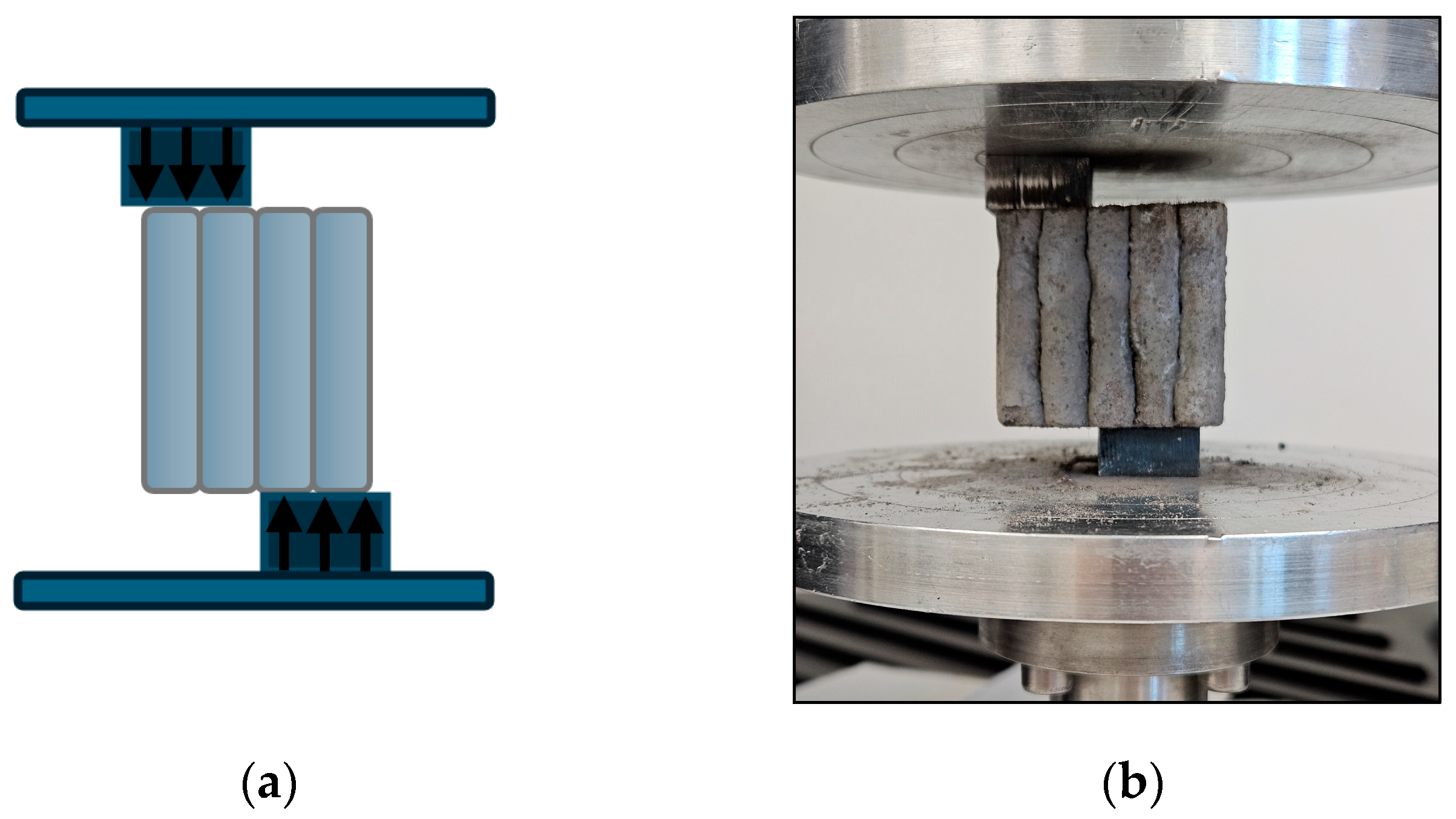

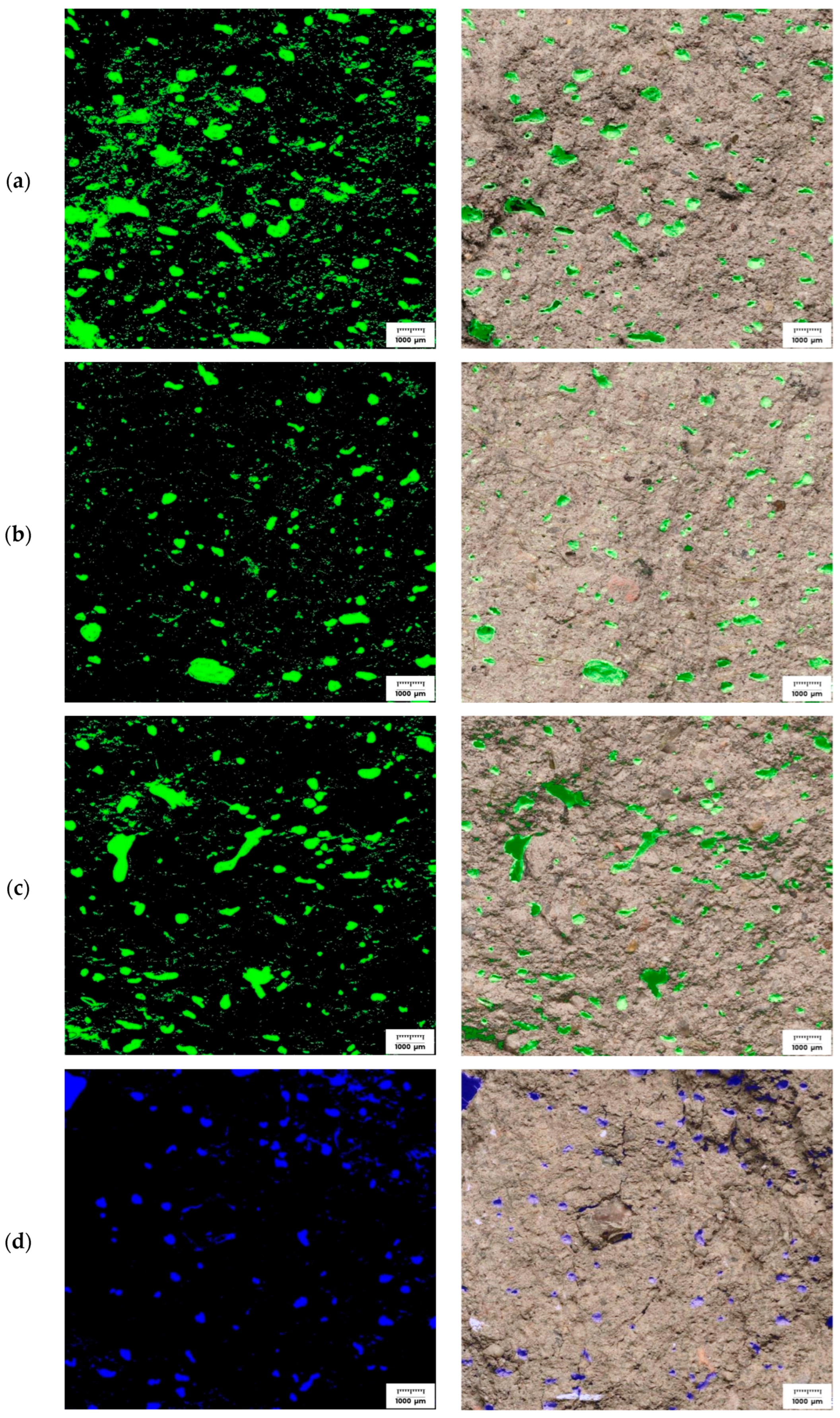

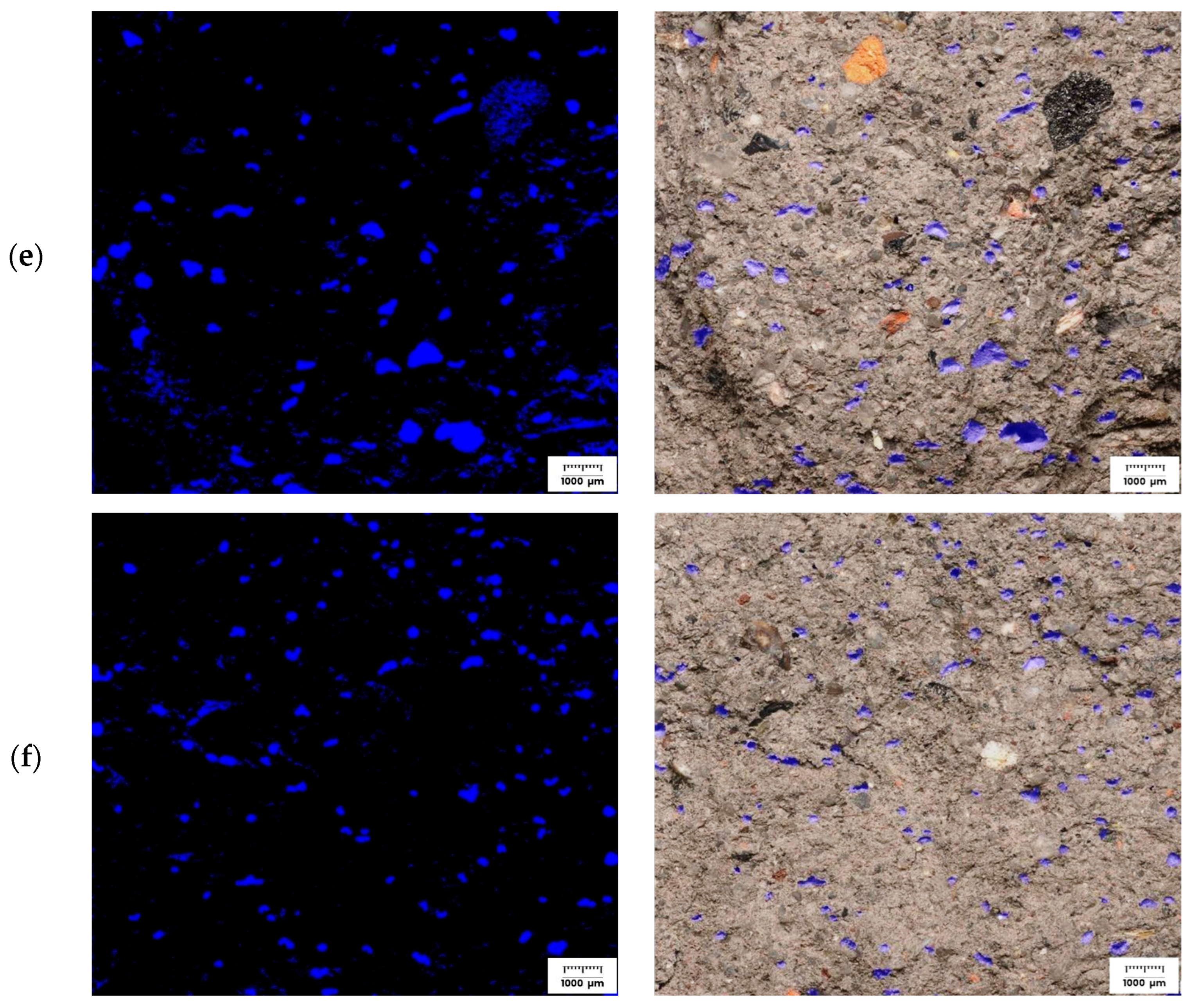

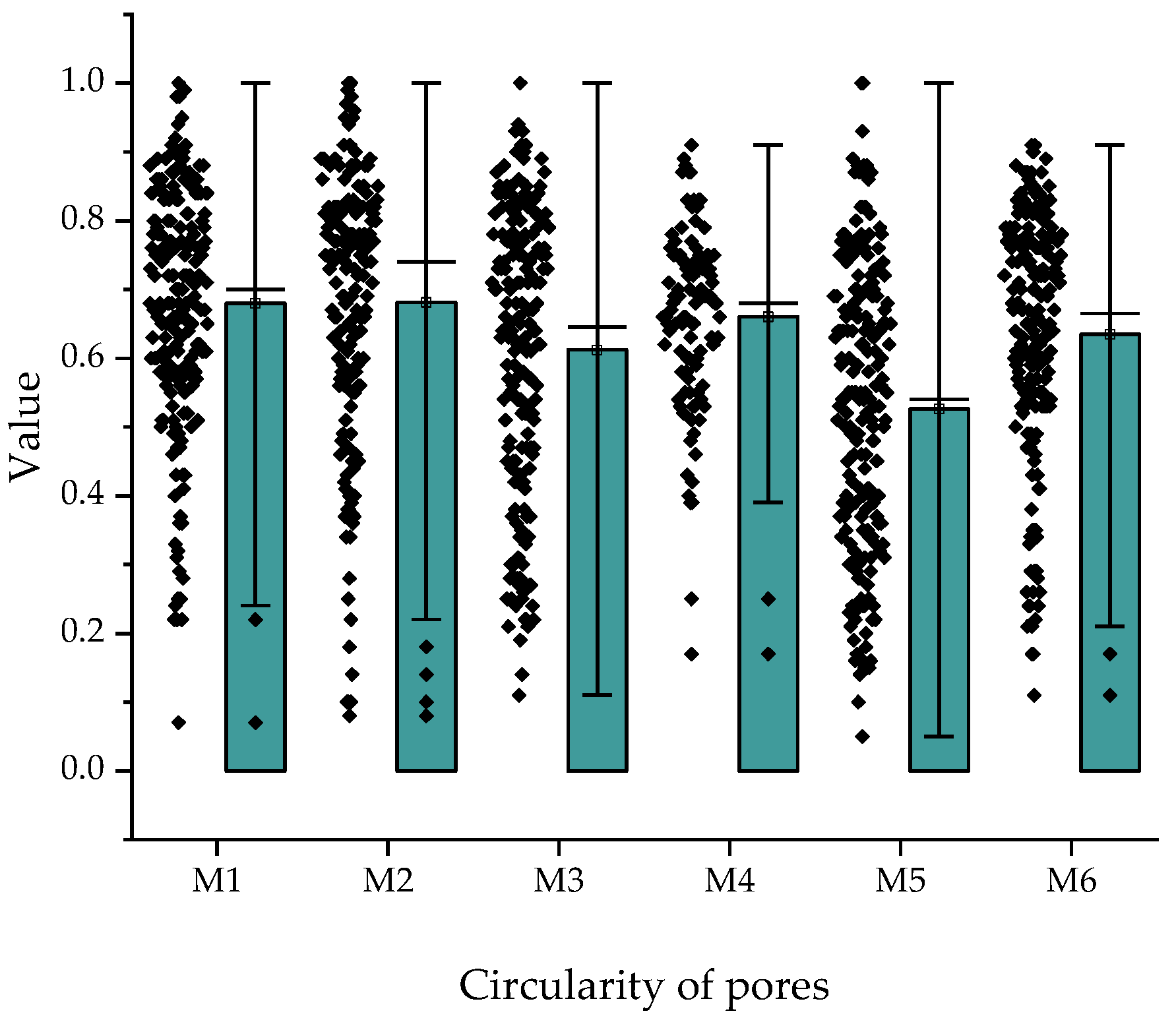

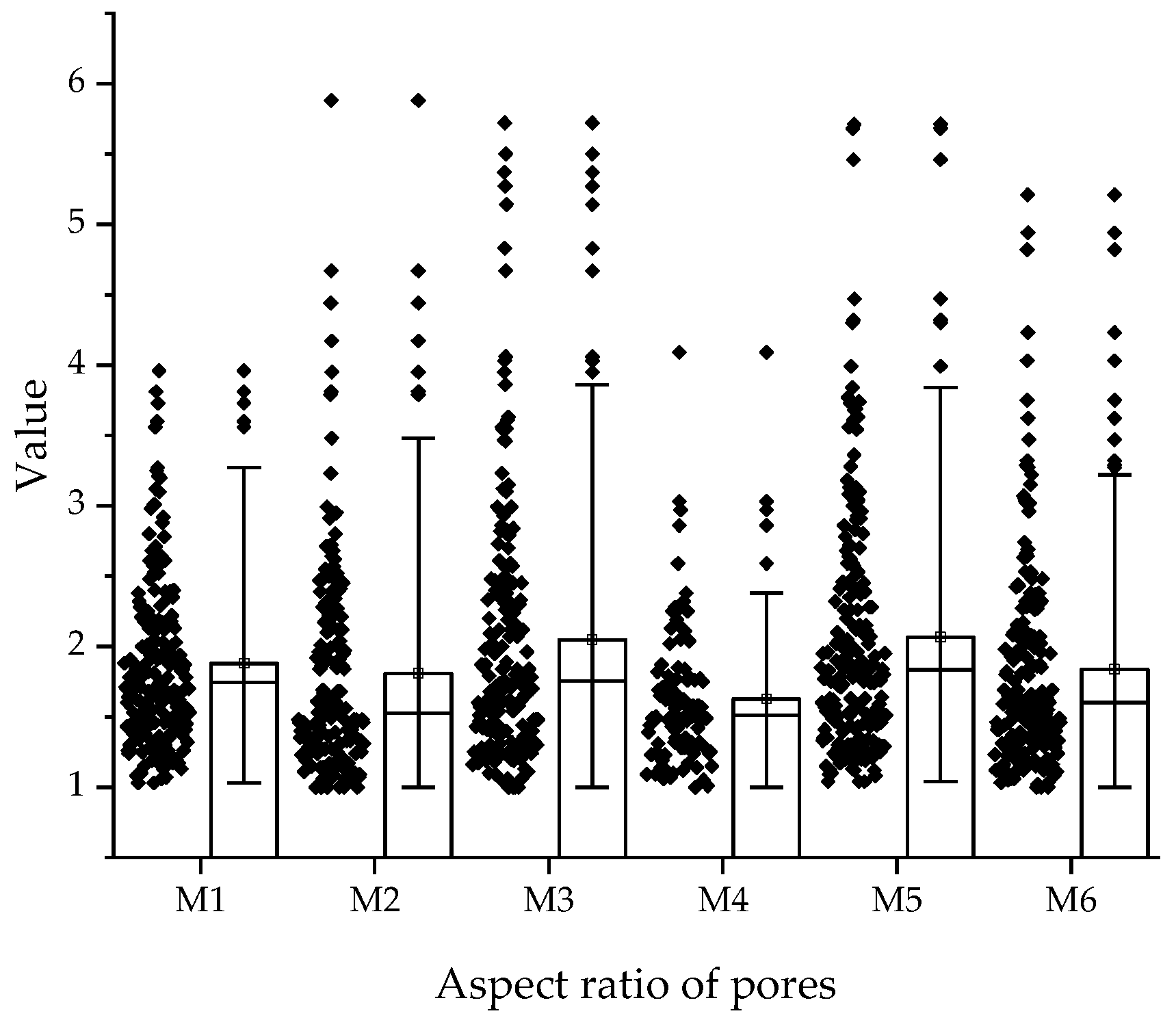

2.2.6. Microscopy Analysis

3. Results

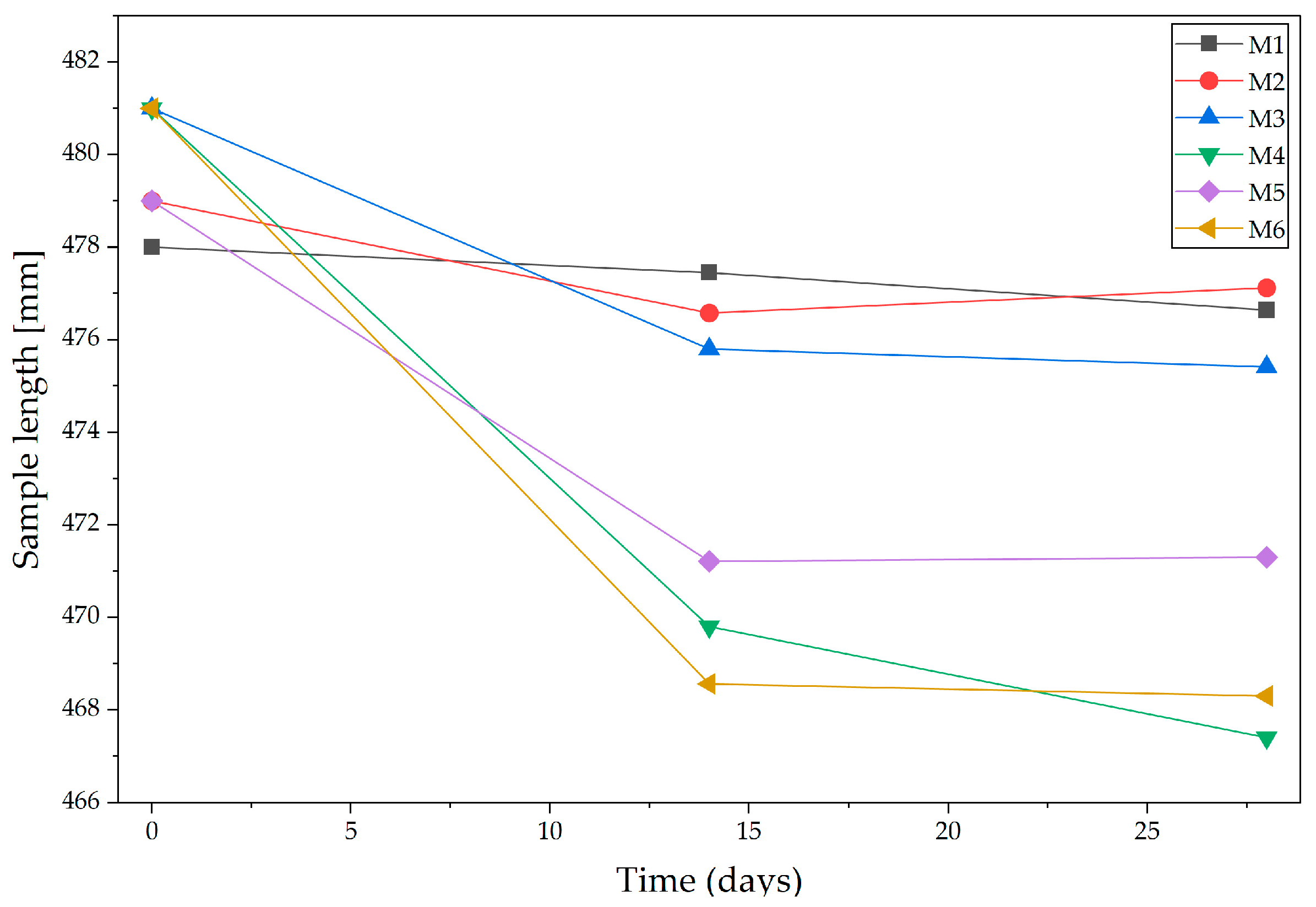

3.1. Shrinkage Test

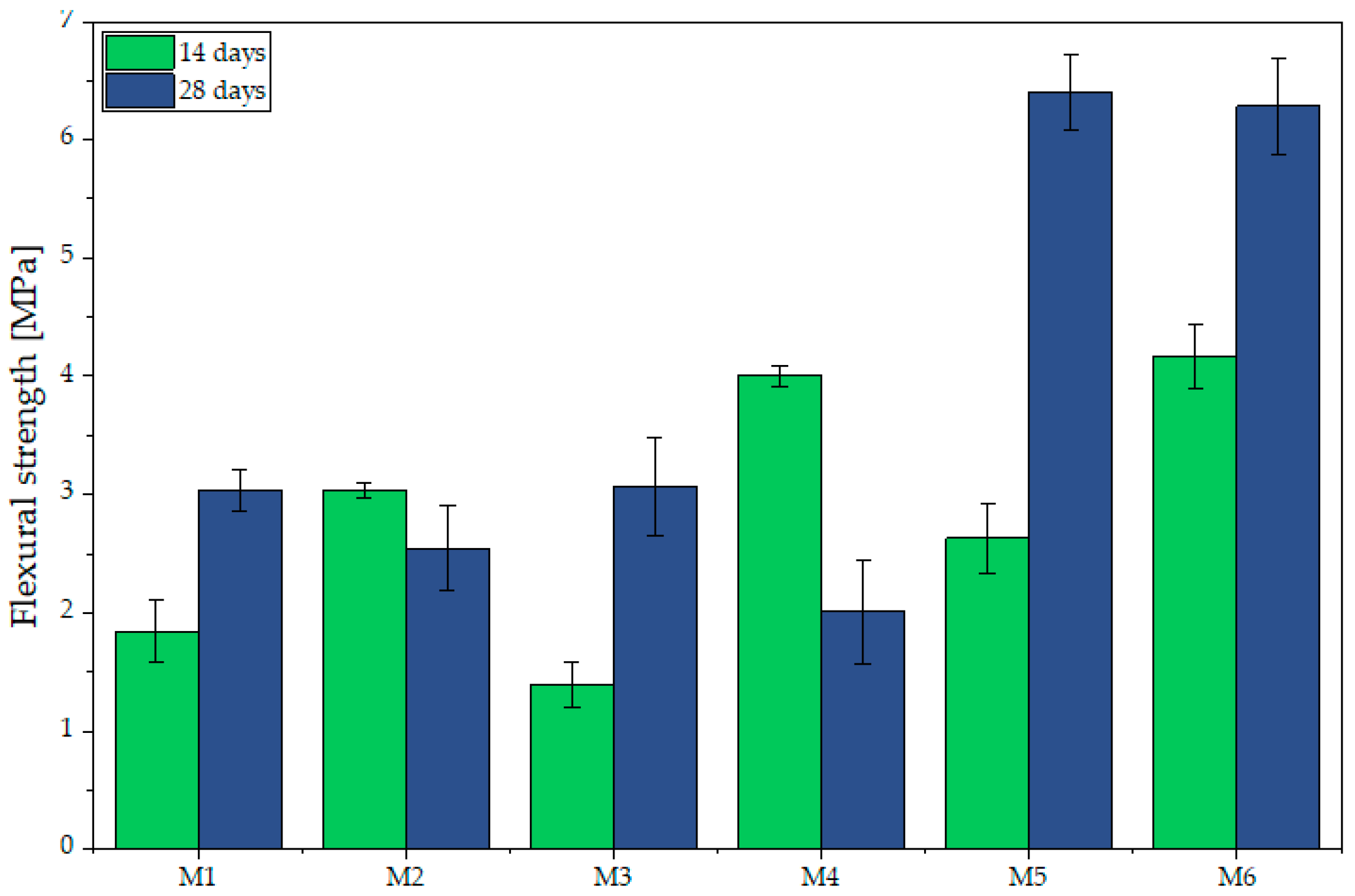

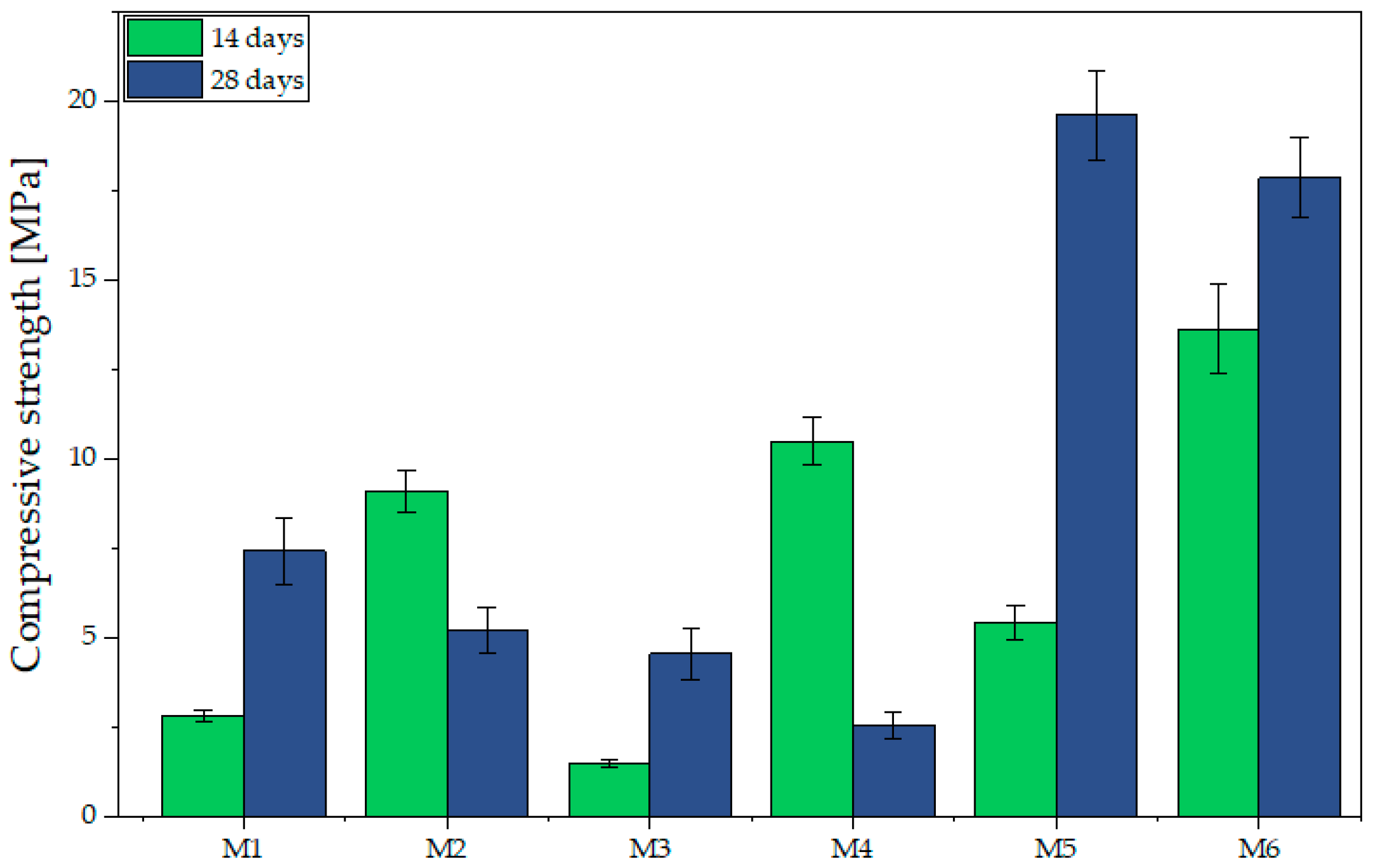

3.2. Flexural and Compressive Strength

3.3. Thermal Conductivity and Density

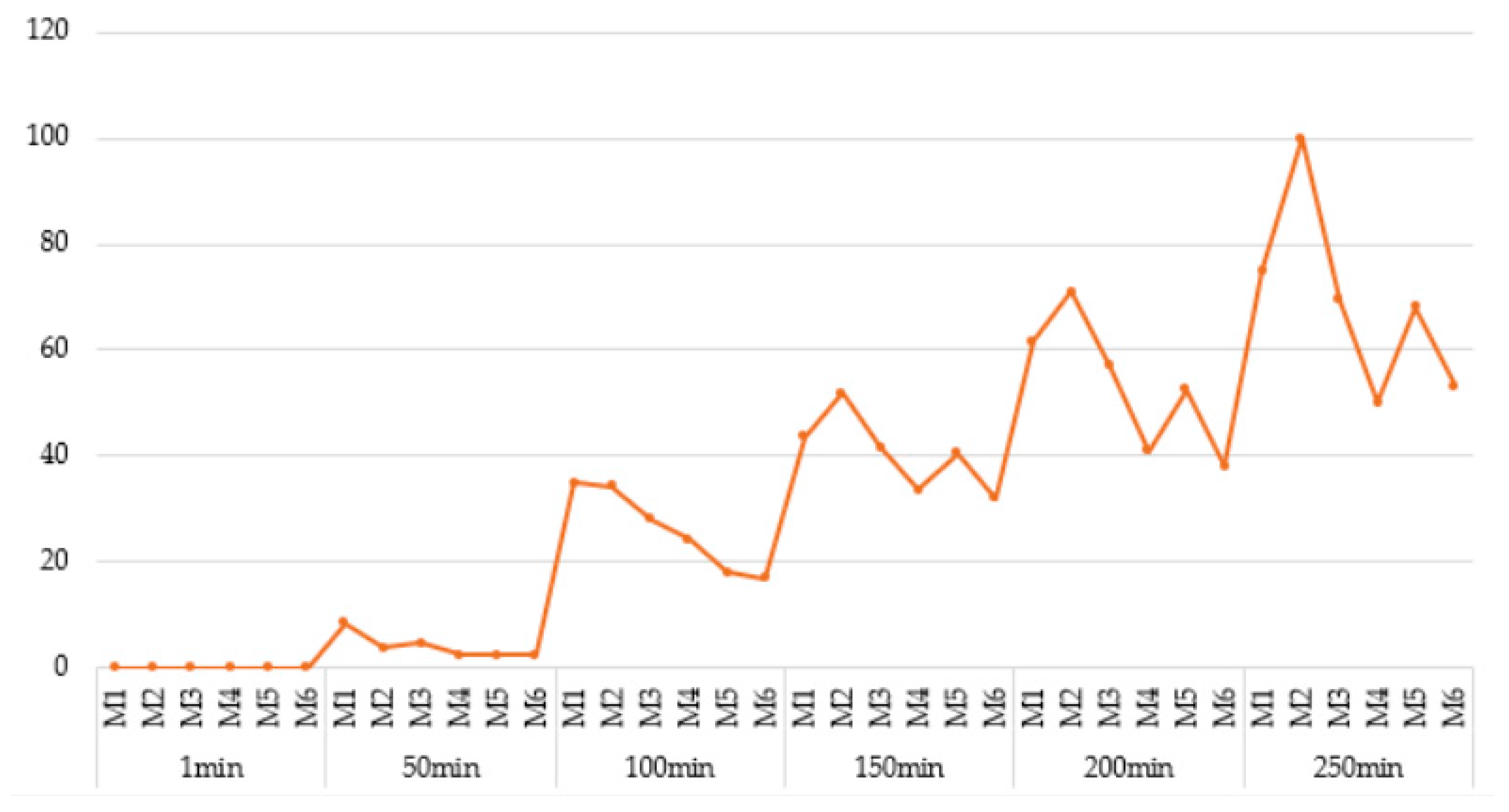

3.4. Water Absorption

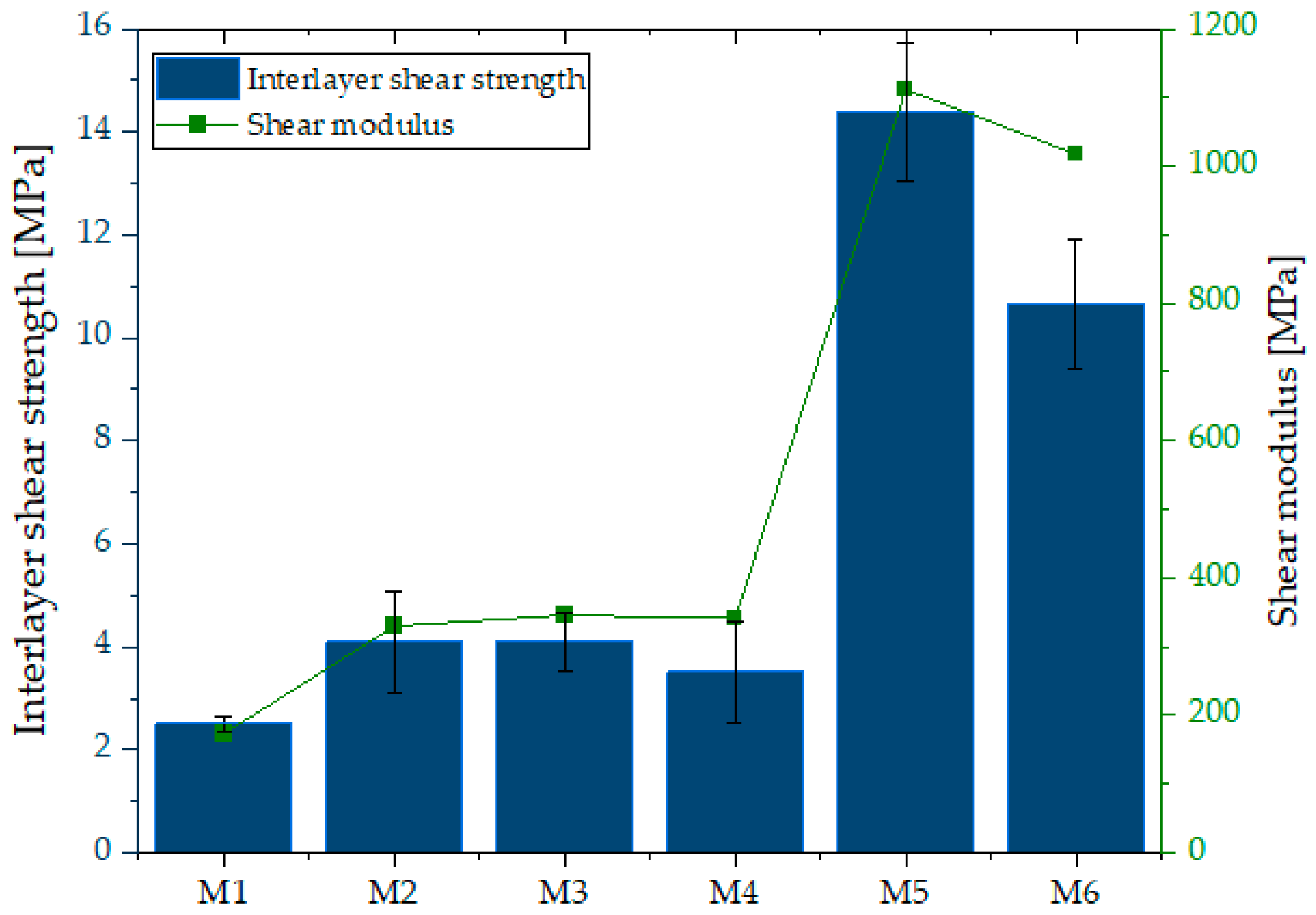

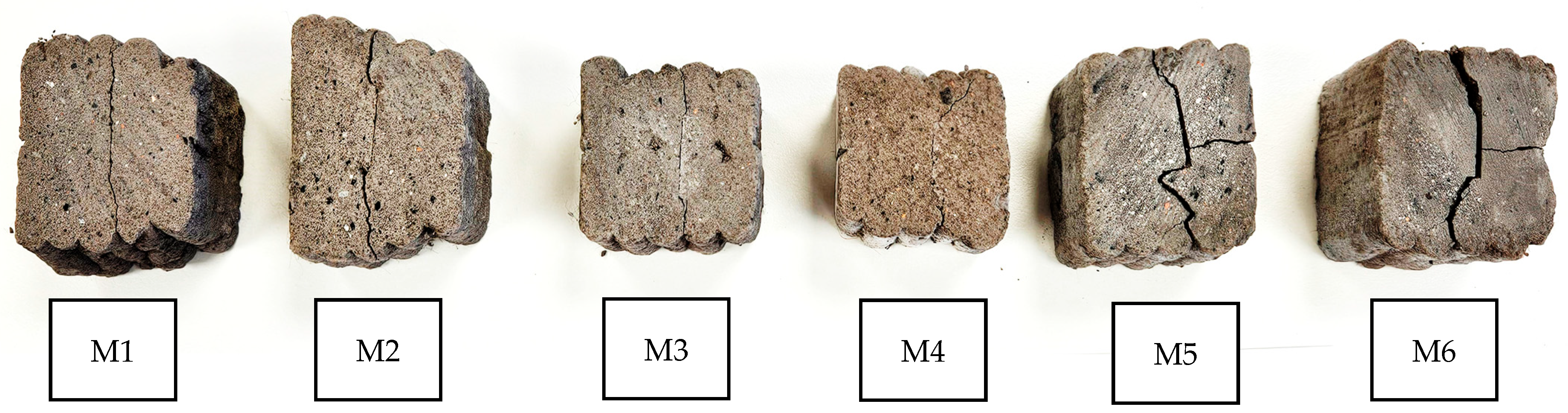

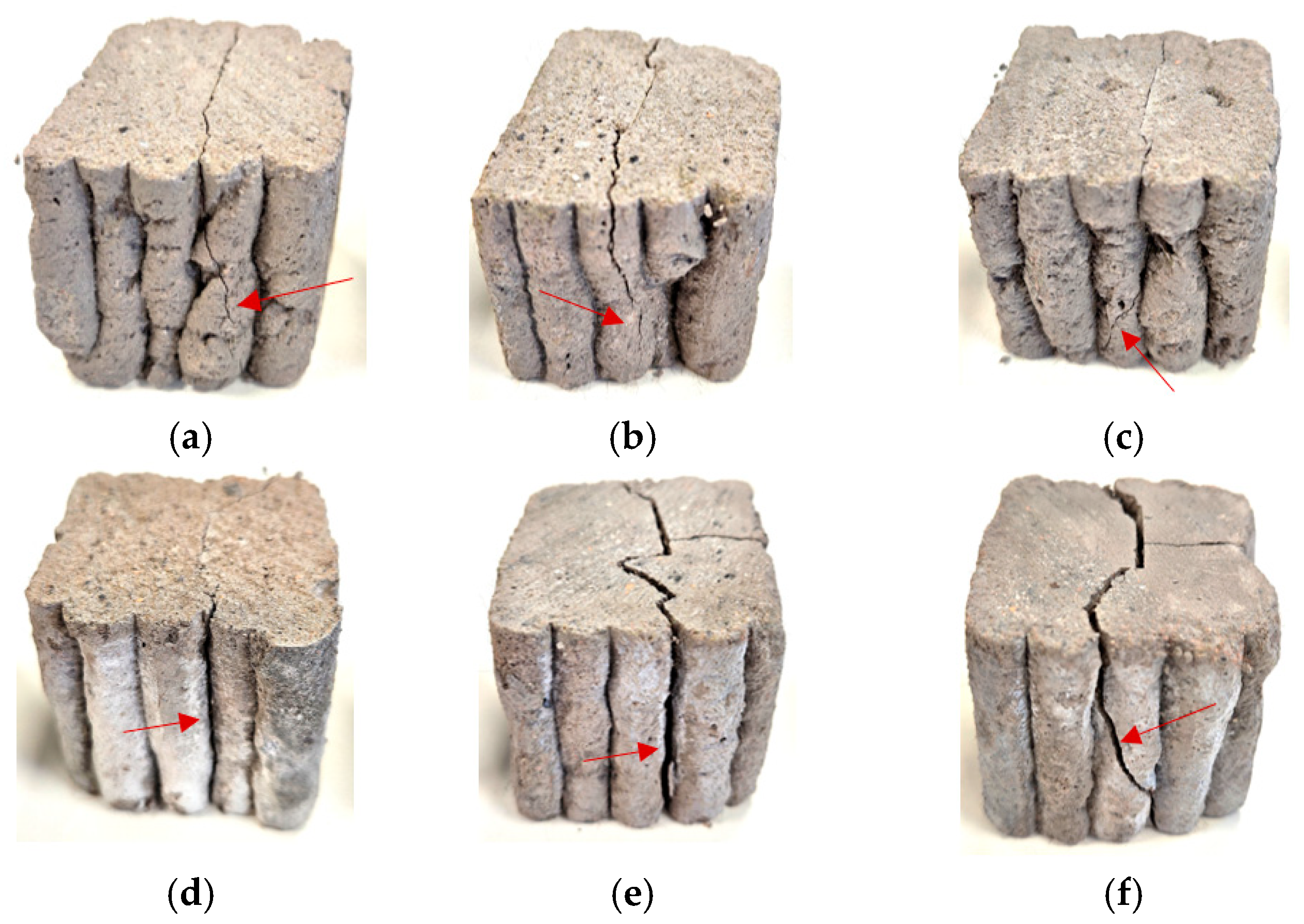

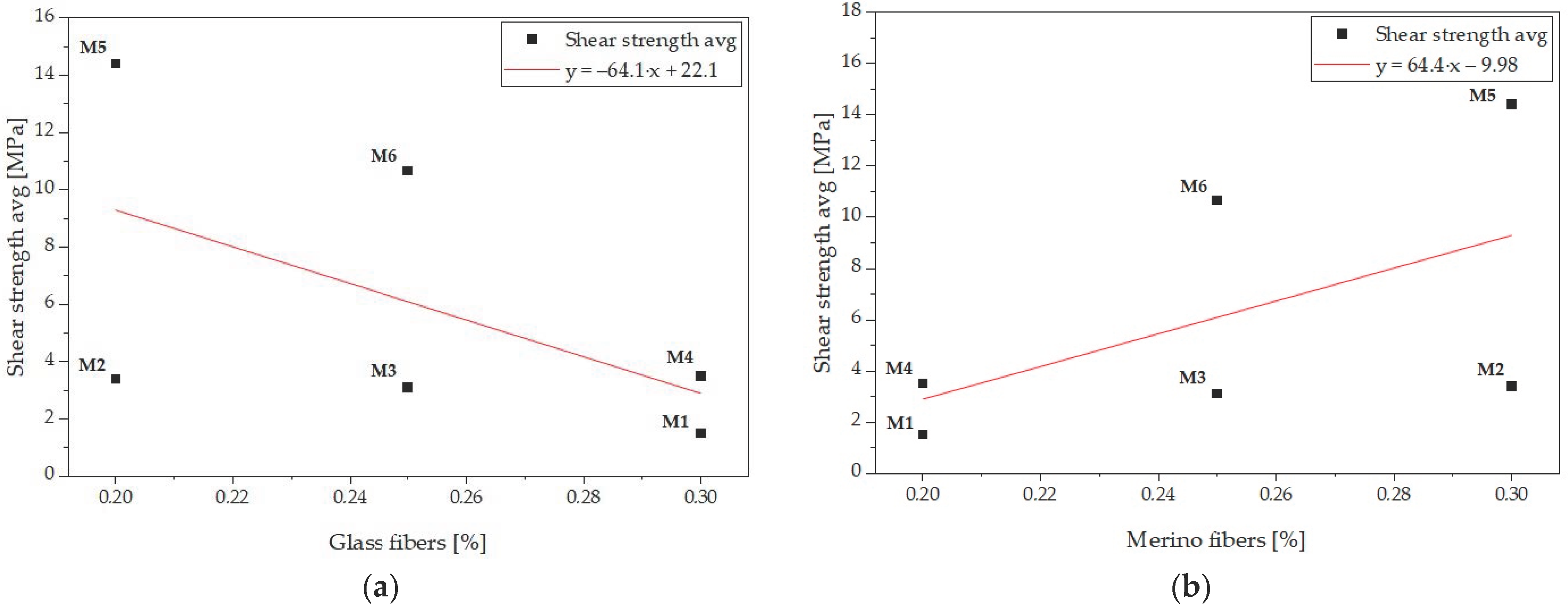

3.5. Layer Adhesion

3.6. Microscopy Observation

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Council of the European Union. European Green Deal. Consilium (Council of the European Union). Available online: https://www.consilium.europa.eu/en/policies/european-green-deal/ (accessed on 18 August 2025).

- United Nations. The 17 Goals; United Nations Sustainable Development Platform (USA, September 2015). Available online: https://sdgs.un.org/goals (accessed on 18 August 2025).

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions: A New Circular Economy Action Plan for a Cleaner and More Competitive Europe, COM/2020/98 Final; European Commission: Brussels, Belgium, 2020; Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=COM:2020:98:FIN (accessed on 18 August 2025).

- Hillsdon, M. Heavy Lift Required to Solve Cement’s Carbon Conundrum. Reuters (Ethical Corporation Magazine), 24 June 2024. Available online: https://www.reuters.com/sustainability/decarbonizing-industries/heavy-lift-required-solve-cements-carbon-conundrum-2024-06-24/ (accessed on 18 August 2025).

- Akindahunsi, A.A.; Avet, F.; Scrivener, K. The Influence of Some Calcined Clays from Nigeria as Clinker Substitute in Cementitious Systems. Case Stud. Constr. Mater. 2020, 13, e00443. [Google Scholar] [CrossRef]

- Berkak, H.; Makhloufi, Z.; Chenafi, H. Impact of Supplementary Cementitious Materials (SCMs) on Physical–Mechanical Properties and Microstructure of Styrene Polyacrylic (SPA) Polymer Modified Mortars. Rev. Constr. 2025, 24, 256–276. [Google Scholar] [CrossRef]

- Ndahirwa, D.; Zmamou, H.; Lenormand, H.; Leblanc, N. The Role of Supplementary Cementitious Materials in Hydration, Durability and Shrinkage of Cement-Based Materials, Their Environmental and Economic Benefits: A Review. Clean. Mater. 2022, 5, 100123. [Google Scholar] [CrossRef]

- Nasir, M.; Mahmood, A.H.; Bahraq, A.A. History, Recent Progress, and Future Challenges of Alkali-Activated Binders—An Overview. Constr. Build. Mater. 2024, 426, 136141. [Google Scholar] [CrossRef]

- Razak, R.; Vizureanu, P.; Abdullah, M.M.A.B.; Mohamed, R.; Chuan Hao, D. Durability Testing Protocols for Concrete Made with Alternative Binders and Recycled Materials. In Mining and Metallurgical Wastes Based Alkali-Activated Materials; Springer: Singapore, 2024. [Google Scholar]

- Xu, M.; Mo, L. Towards Sustainable Artificial Aggregate Production Using Industrial Waste and CO2: A Comprehensive Review. J. Build. Eng. 2024, 97, 110823. [Google Scholar] [CrossRef]

- Demirbaş, A.O.; Tuğluca, M.S.; Şahin, O.; İlcan, H.; Şahmaran, M. A Comprehensive Study on the Valorization of Recycled Concrete Aggregates in 3D-Printable Cementitious Systems. Structures 2025, 77, 109152. [Google Scholar] [CrossRef]

- Ricciotti, L.; Apicella, A.; Perrotta, V.; Aversa, R. Geopolymer Materials for Extrusion-Based 3D-Printing: A Review. Polymers 2023, 15, 4688. [Google Scholar] [CrossRef]

- Kaya, E.; Ciza, B.; Yalçınkaya, Ç.; Felekoğlu, B.; Yazıcı, H.; Çopuroğlu, O. A Comparative Study on the Effectiveness of Fly Ash and Blast Furnace Slag as Partial Cement Substitution in 3D Printable Concrete. J. Build. Eng. 2025, 108, 112841. [Google Scholar] [CrossRef]

- Hoenig, V.; Schall, A.; Sultanov, N.; Papkalla, S.; Ruppert, J. Status and Prospects of Alternative Raw Materials in the European Cement Sector; European Cement Research Academy: Düsseldorf, Germany, 2022; Available online: https://cembureau.eu/media/ez5mwmpq/220502-ecra-alternative-raw-materials-study.pdf (accessed on 31 May 2025).

- Liu, Z.; Takasu, K.; Suyama, H.; Koyamada, H.; Liu, S.; Hao, Q. The Effect of Cementitious Materials on the Engineering Properties and Pore Structure of Concrete with Recycled Fine Aggregate. Materials 2022, 16, 305. [Google Scholar] [CrossRef]

- Suarez-Riera, D.; Restuccia, L.; Falliano, D.; Ferro, G.A.; Tuliani, J.-M.; Pavese, M.; Lavagna, L. An Overview of Methods to Enhance the Environmental Performance of Cement-Based Materials. Infrastructures 2024, 9, 94. [Google Scholar] [CrossRef]

- Althoey, F.; Ansari, W.S.; Sufian, M.; Deifalla, A. Advancements in Low-Carbon Concrete as a Construction Material for the Sustainable Built Environment. Dev. Built Environ. 2023, 16, 100284. [Google Scholar] [CrossRef]

- European Environment Agency. Accelerating the Energy Efficiency Renovation of Residential Buildings—A Behavioural Approach; EEA: Copenhagen, Denmark, 2023; Available online: https://www.eea.europa.eu/publications/accelerating-the-energy-efficiency (accessed on 18 August 2025).

- Cecconi, M.; Cumo, F.; Pennacchia, E.; Romeo, C.; Zylka, C. BEST—Building Energy-Saving Tool for Sustainable Residential Buildings. Appl. Sci. 2025, 15, 6817. [Google Scholar] [CrossRef]

- Igugu, H.O.; Laubscher, J.; Mapossa, A.B.; Popoola, P.A.; Dada, M. Energy Efficiency in Buildings: Performance Gaps and Sustainable Materials. Encyclopedia 2024, 4, 1411–1432. [Google Scholar] [CrossRef]

- Hertwich, E.G.; Ali, S.; Ciacci, L.; Fishman, T.; Heeren, N.; Masanet, E.; Nojavan Asghari, F.; Olivetti, E.; Pauliuk, S.; Tu, Q.; et al. Material Efficiency Strategies to Reducing Greenhouse Gas Emissions Associated with Buildings, Vehicles, and Electronics—A Review. Environ. Res. Lett. 2019, 14, 044004. [Google Scholar] [CrossRef]

- European Environment Agency. Building Renovation: Where Circular Economy and Climate Meet; EEA: Copenhagen, Denmark, 2022; Available online: https://www.eea.europa.eu/publications/building-renovation-where-circular-economy (accessed on 18 August 2025).

- Maaze, M.R.; Shrivastava, S. Selection of Eco-Friendly Alternative Brick for Sustainable Development: A Study on Technical, Economic, Environmental and Social Feasibility. Constr. Build. Mater. 2023, 408, 133808. [Google Scholar] [CrossRef]

- Mostafa, S.A.; Agwa, I.S.; Elboshy, B.; Zeyad, A.M.; Hassan, A.M.S. The Effect of Lightweight Geopolymer Concrete Containing Air Agent on Building Envelope Performance and Internal Thermal Comfort. Case Stud. Constr. Mater. 2024, 20, e03365. [Google Scholar] [CrossRef]

- Nilimaa, J. Smart Materials and Technologies for Sustainable Concrete Construction. Dev. Built Environ. 2023, 15, 100177. [Google Scholar] [CrossRef]

- Fu, H.; Tian, J.; Chin, C.L.; Liu, H.; Yuan, J.-Y.; Tang, S.; Mai, R.; Wu, X. Axial Compression Behavior of GFRP-Steel Composite Tube Confined Seawater Sea-Sand Concrete Intermediate Long Columns. Eng. Struct. 2025, 333, 120157. [Google Scholar] [CrossRef]

- Ibrahim, J.-E.F.M.; Şahin, E.İ.; Kabatas, M.A.B.-M.; Géber, R.; Kocserha, I. Sustainable Fabrication of Lightweight Geopolymer Foams from Silica-Fume and Zeolite Tuffs: Utilizing Al as Foaming Agent for Thermal Insulation. Case Stud. Constr. Mater. 2024, 21, e04024. [Google Scholar] [CrossRef]

- Łach, M. Geopolymer Foams—Will They Ever Become a Viable Alternative to Popular Insulation Materials?—A Critical Opinion. Materials 2021, 14, 3568. [Google Scholar] [CrossRef]

- Ziejewska, C.; Marczyk, J.; Korniejenko, K.; Bednarz, S.; Sroczyk, P.; Łach, M.; Mikuła, J.; Figiela, B.; Szechyńska-Hebda, M.; Hebda, M. 3D Printing of Concrete-Geopolymer Hybrids. Materials 2022, 15, 2819. [Google Scholar] [CrossRef]

- Korniejenko, K.; Pławecka, K.; Kozub, B. An overview for modern energy-efficient solutions for lunar and martian habitats made based on geopolymers composites and 3D printing technology. Energies 2022, 15, 9322. [Google Scholar] [CrossRef]

- Barve, P.; Bahrami, A.; Shah, S. Geopolymer 3D Printing: A Comprehensive Review on Rheological and Structural Performance Assessment, Printing Process Parameters, and Microstructure. Front. Mater. 2023, 10, 1241869. [Google Scholar] [CrossRef]

- Shilar, F.A.; Ganachari, S.V.; Patil, V.B.; Bhojaraja, B.E.; Khan, T.M.Y.; Almakayeel, N. A Review of 3D Printing of Geopolymer Composites for Structural and Functional Applications. Constr. Build. Mater. 2023, 400, 132869. [Google Scholar] [CrossRef]

- Sornlar, W.; Wannagon, A.; Supothina, S. Stabilized Homogeneous Porous Structure and Pore Type Effects on the Properties of Lightweight Kaolinite-Based Geopolymers. J. Build. Eng. 2021, 44, 103273. [Google Scholar] [CrossRef]

- Zhang, X.; Bai, C.; Qiao, Y.; Wang, X.; Jia, D.; Li, H.; Colombo, P. Porous Geopolymer Composites: A Review. Compos. Part A Appl. Sci. Manuf. 2021, 150, 106629. [Google Scholar] [CrossRef]

- Bazan, P.; Figiela, B.; Kozub, B.; Łach, M.; Mróz, K.; Melnychuk, M.; Korniejenko, K. Geopolymer Foam with Low Thermal Conductivity Based on Industrial Waste. Materials 2024, 17, 6143. [Google Scholar] [CrossRef]

- Zhang, Z.; Provis, J.L.; Reid, A.; Wang, H. Mechanical, Thermal Insulation, Thermal Resistance and Acoustic Absorption Properties of Geopolymer Foam Concrete. Cem. Concr. Compos. 2015, 62, 97–105. [Google Scholar] [CrossRef]

- Prałat, K.; Ciemnicka, J.; Koper, A.; Buczkowska, K.E.; Łoś, P. Comparison of the Thermal Properties of Geopolymer and Modified Gypsum. Polymers 2021, 13, 1220. [Google Scholar] [CrossRef]

- Castillo, H.; Collado, H.; Droguett, T.; Sánchez, S.; Vesely, M.; Garrido, P.; Palma, S. Factors Affecting the Compressive Strength of Geopolymers: A Review. Minerals 2021, 11, 1317. [Google Scholar] [CrossRef]

- Liu, Y.-L.; Liu, C.; Qian, L.-P.; Wang, A.-G.; Sun, D.-S.; Guo, D. Foaming Processes and Properties of Geopolymer Foam Concrete: Effect of the Activator. Constr. Build. Mater. 2023, 391, 131830. [Google Scholar] [CrossRef]

- Shen, S.; Tian, J.; Zhu, Y.; Zhang, X.; Hu, P. Synthesis of Industrial Solid Wastes-Based Geopolymer Foams for Building Energy Conservation: Effects of Metallic Aluminium and Reclaimed Materials. Constr. Build. Mater. 2022, 328, 127083. [Google Scholar] [CrossRef]

- Abdellatief, M.; Hassanien, A.E.; Mortagi, M.; Hamouda, H. Geopolymer foam concrete: A review of pore characteristics, compressive strength and artificial intelligence in GFC strength simulations. Discov. Concr. Cem. 2025, 1, 4. [Google Scholar] [CrossRef]

- Siyal, A.A.; Mohamed, R.M.S.R.; Musa, S.; Rassem, H.H.; Khamidun, M.H. A Review of the Performance of Geopolymer Catalysts for Biodiesel Production. Biomass Bioenergy 2024, 190, 107373. [Google Scholar] [CrossRef]

- Siyal, A.A.; Shamsuddin, M.R.; Khan, M.I.; Rabat, N.E.; Zulfiqar, M.; Man, Z.; Siame, J.; Azizli, K.A. A Review on Geopolymers as Emerging Materials for the Adsorption of Heavy Metals and Dyes. J. Environ. Manag. 2018, 224, 327–339. [Google Scholar] [CrossRef]

- Kudłacik-Kramarczyk, S.; Drabczyk, A.; Figiela, B.; Korniejenko, K. Geopolymers: Advanced Materials in Medicine, Energy, Anticorrosion and Environmental Protection. Materials 2023, 16, 7416. [Google Scholar] [CrossRef]

- Al-Ghazali, N.A.; Aziz, F.N.A.A.; Abdan, K.; Nasir, N.A.M.; Huseien, G.F. A State-of-the-Art Review on Fibre-Reinforced Geopolymer Composites. Constr. Build. Mater. 2022, 330, 127187. [Google Scholar] [CrossRef]

- Gaddafi, A.K.F.; Alengaram, U.J.; Bunnori, N.M.; Ibrahim Muhammad, S.I.; Ibrahim, S.; Sumesh, M. Mechanical Properties, Flexural Behaviour, and Ductility Characteristics of Fibre-Reinforced Geopolymer Mortar. Constr. Build. Mater. 2023, 403, 133109. [Google Scholar] [CrossRef]

- Mondragón, S.; Kim, S.; Bertolotti, B.; Nakamatsu, J.; Aguilar, R. Optimization of a Reinforced Geopolymer Composite Using Natural Fibers and Construction Wastes. Constr. Build. Mater. 2020, 258, 119697. [Google Scholar] [CrossRef]

- Walbrück, K.; Drewler, L.; Witzleben, S.; Stephan, D. Factors Influencing Thermal Conductivity and Compressive Strength of Natural Fiber-Reinforced Geopolymer Foams. Open Ceram. 2021, 5, 100065. [Google Scholar] [CrossRef]

- Walbrück, K.; Witzleben, S.; Stephan, D. Design and Characterization of Geopolymer Foams Reinforced with Miscanthus × giganteus Fibres. Heliyon 2024, 10, e35947. [Google Scholar] [CrossRef]

- Agustini, N.K.A.; Triwiyono, A.; Sulistyo, D.; Suyitno, S. Mechanical Properties and Thermal Conductivity of Fly Ash-Based Geopolymer Foams with Polypropylene Fibers. Appl. Sci. 2021, 11, 4886. [Google Scholar] [CrossRef]

- Masi, G.; Rickard, W.D.A.; Bignozzi, M.C.; Van Riessen, A. The Effect of Organic and Inorganic Fibres on the Mechanical and Thermal Properties of Aluminate Activated Geopolymers. Compos. Part B Eng. 2015, 76, 218–228. [Google Scholar] [CrossRef]

- Kozub, B.; Gądek, S.; Tyliszczak, B.; Wojnar, L.; Korniejenko, K. Leveraging 3D Printing Capability for Geopolymer Composites Based on Fly Ash with Cotton Fibers Addition. Int. J. Eng. Technol. Innov. 2024, 14, 231–243. [Google Scholar] [CrossRef]

- Łaźniewska-Piekarczyk, B.; Smyczek, D. The effect of mineral wool fiber additive on several mechanical properties and thermal conductivity in geopolymer binder. Materials 2024, 17, 483. [Google Scholar] [CrossRef]

- Kozub, B.; Bazan, P.; Gailitis, R.; Korniejenko, K.; Mierzwiński, D. Foamed Geopolymer Composites with the Addition of Glass Wool Waste. Materials 2021, 14, 4978. [Google Scholar] [CrossRef] [PubMed]

- Asrani, N.; Murali, G.; Abdelgader, H.; Parthiban, K.; Haridharan, M.K.; Karthikeyan, K. Investigation on Mode I Fracture Behavior of Hybrid Fiber-Reinforced Geopolymer Composites. Arab. J. Sci. Eng. 2019, 44, 8545–8555. [Google Scholar] [CrossRef]

- Yang, L.; Gao, Y.; Chen, H.; Jiao, H.; Dong, M.; Bier, T.A.; Kim, M. Three-Dimensional Concrete Printing Technology from a Rheology Perspective: A Review. Adv. Cem. Res. 2024, 36, 567–586. [Google Scholar] [CrossRef]

- Baziak, A.; Pławecka, K.; Hager, I.; Castel, A.; Korniejenko, K. Development and Characterization of Lightweight Geopolymer Composite Reinforced with Hybrid Carbon and Steel Fibers. Materials 2021, 14, 5741. [Google Scholar] [CrossRef]

- Rudziewicz, M.; Hutyra, A.; Maroszek, M.; Korniejenko, K.; Hebda, M. 3D-Printed Lightweight Foamed Concrete with Dispersed Reinforcement. Appl. Sci. 2025, 15, 4527. [Google Scholar] [CrossRef]

- Rudziewicz, M.; Maroszek, M.; Setlak, K.; Góra, M.; Hebda, M. Optimization of Foams—Polypropylene Fiber-Reinforced ConcreteMixtures Dedicated for 3D Printing. Materials 2024, 17, 4106. [Google Scholar] [CrossRef] [PubMed]

- Garbalińska, H.; Narodowska, K. Wpływ składu mieszanki i wyjściowego zawilgocenia kruszywa lekkiego na sorpcyjność kapilarną betonu keramzytowego. Czas. Inżynierii Lądowej Sr. Archit. 2017, 64, 277–284. [Google Scholar] [CrossRef][Green Version]

- Garbalińska, H.; Walkowiak, M.; Wygocka, A. Ocena Wpływu Rodzaju Cementu na Proces Podciągania Kapilarnego Wody w Zaprawach Modyfikowanych Włóknami Polipropylenowymi. [Assessment of Influence of Cement Type on the Water Capillary Pull-Up Process in Mortars Modified with Polypropylene Fibres]. 2006. Available online: https://www.dnibetonu.com/wp-content/pdfs/2006/garbalinska_walkowiak_wygocka.pdf (accessed on 13 September 2025).[Green Version]

- EN 1015-18:2002; Methods of Test for Mortar for Masonry—Part 18: Determination of Water Absorption Coefficient Due to Capillary Action of Hardened Mortar. European Committee for Standardization: Brussels, Belgium, 2002.[Green Version]

- Hager, I.; Maroszek, M.; Mróz, K.; Kęsek, R.; Hebda, M.; Dvorkin, L.; Marchuk, V. Interlayer Bond Strength Testing in 3D-Printed Mineral Materials for Construction Applications. Materials 2022, 15, 4112. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Liu, E.; Fu, Y. Reduction in Drying Shrinkage and Efflorescence of Recycled Brick and Concrete Fine Powder–Slag-Based Geopolymer. Appl. Sci. 2023, 13, 2997. [Google Scholar] [CrossRef]

- Li, Z.; Chen, Y.; Provis, J.L.; Cizer, Ö.; Ye, G. Autogenous Shrinkage of Alkali-Activated Slag: A Critical Review. Cem. Concr. Res. 2023, 172, 107244. [Google Scholar] [CrossRef]

- Wang, H.; Zheng, Y.; Yu, Z. Influence of Ambient Relative Humidity on the Shrinkage Strain of Engineered Geopolymer Composites Based on Orthogonal Experimental Design. Materials 2024, 17, 4321. [Google Scholar] [CrossRef]

- Beersaerts, G.; Soete, J.; Giels, M.; Eykens, L.; Lucas, S.S.; Pontikes, Y. 3D printing of an iron-rich slag based hybrid mortar: A durable, sustainable and cost-competitive product? Cem. Concr. Compos. 2023, 144, 105304. [Google Scholar] [CrossRef]

- Ma, H.; Zhu, H.; Wu, C.; Fan, J.; Yang, S.; Hang, Z. Effect of Shrinkage Reducing Admixture on Drying Shrinkage and Durability of Alkali-Activated Coal Gangue-Slag Material. Constr. Build. Mater. 2021, 270, 121372. [Google Scholar] [CrossRef]

- Rashad, A.M.; Morsi, W.M.; Khafaga, S.A. Effect of limestone powder on mechanical strength, durability and drying shrinkage of alkali-activated slag pastes. Innov. Infrastruct. Solut. 2021, 6, 127. [Google Scholar] [CrossRef]

- Zhang, B.; Zhu, H.; Cheng, Y.; Huseien, G.F.; Shah, K.W. Shrinkage mechanisms and shrinkage-mitigating strategies of alkali-activated slag composites: A critical review. Constr. Build. Mater. 2022, 318, 125993. [Google Scholar] [CrossRef]

- Nedeljković, M.; Li, Z.; Ye, G. Setting, Strength, and Autogenous Shrinkage of Alkali-Activated Fly Ash and Slag Pastes: Effect of Slag Content. Materials 2018, 11, 2121. [Google Scholar] [CrossRef]

- Wei, Y.; Dou, H.; He, T.; Song, K.; Zhang, Q. Investigation of Shrinkage Mechanism of Alkali-Activated Slag. Case Stud. Constr. Mater. 2024, 21, e03493. [Google Scholar] [CrossRef]

- Alyousef, R.; Alabduljabbar, H.; Mohammadhosseini, H.; Mohamed, A.; Siddika, A.; Alrshoudi, F.; Alaskar, A. Utilization of Sheep Wool as Potential Fibrous Material in the Production of Concrete Composites. J. Build. Eng. 2020, 30, 101216. [Google Scholar] [CrossRef]

- Li, J.; Du, P.; Zhang, T.; Huang, Y.; Zhu, J.; Cheng, X. Strategic Control of Pore Structure in Ultra-High Performance Concrete via Tailored Rheological Property Modulation. Constr. Build. Mater. 2025, 492, 142938. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Y.; Yang, L.; Liu, G.; Chen, Y.; Yu, S.; Du, H. Hardened properties and durability of large-scale 3D printed cement-based materials. Mater. Struct. 2021, 54, 45. [Google Scholar] [CrossRef]

- Wolfs, R.; Bos, F.; Salet, T. Hardened Properties of 3D Printed Concrete: The Influence of Process Parameters on Interlayer Adhesion. Cem. Concr. Res. 2019, 119, 132–140. [Google Scholar] [CrossRef]

- Lee, Y.J.; Lee, S.-H.; Kim, J.H.; Jeong, H.; Han, S.-J.; Kim, K.S. Interlayer Bond Strength of 3D Printed Concrete Members with Ultra High Performance Concrete (UHPC) Mix. Buildings 2024, 14, 2060. [Google Scholar] [CrossRef]

- Gailitis, R.; Korniejenko, K.; Sprince, A.; Pakrastins, L. Comparison of the Long-Term Properties of Foamed Concrete and Geopolymer Concrete in Compression. AIP Conf. Proc. 2020, 2239, 020012. [Google Scholar] [CrossRef]

- Yliniemi, J.; Luukkonen, T.; Kaiser, A.; Illikainen, M. Mineral Wool Waste-Based Geopolymers. IOP Conf. Ser. Earth Environ. Sci. 2019, 297, 012006. [Google Scholar] [CrossRef]

- Daza-Badilla, L.; Gómez, R.; Díaz-Noriega, R.; Avudaiappan, S.; Skrzypkowski, K.; Saavedra-Flores, E.I.; Korzeniowski, W. Thermal Conductivity in Concrete Samples with Natural and Synthetic Fibers. Materials 2024, 17, 817. [Google Scholar] [CrossRef]

- Santos, A.; Andrejkovičová, S.; Perná, I.; Almeida, F.; Rocha, F. Mechanical and thermal properties of geopolymers derived from metakaolin with iron mine waste. Appl. Clay Sci. 2024, 258, 107452. [Google Scholar] [CrossRef]

- Parcesepe, E.; De Masi, R.F.; Lima, C.; Mauro, G.M.; Maddaloni, G.; Pecce, M.R. Experimental Evaluation of the Mechanical Strengths and the Thermal Conductivity of GGBFS and Silica Fume Based Alkali-Activated Concrete. Materials 2021, 14, 7717. [Google Scholar] [CrossRef] [PubMed]

- Przybek, A.; Romańska, P.; Korniejenko, K.; Krajniak, K.; Hebdowska-Krupa, M.; Łach, M. Thermal Properties of Geopolymer Concretes with Lightweight Aggregates. Materials 2025, 18, 3150. [Google Scholar] [CrossRef] [PubMed]

- Vafaei, D.; Hassanli, R.; Ma, X.; Duan, J.; Zhuge, Y. Sorptivity and mechanical properties of fiber-reinforced concrete made with seawater and dredged sea-sand. Constr. Build. Mater. 2020, 270, 121436. [Google Scholar] [CrossRef]

- Rudziewicz, M.; Maroszek, M.; Hutyra, A.; Góra, M.; Rusin-Żurek, K.; Hebda, M. Influence of Foaming Agents and Stabilizers on Porosity in 3D Printed Foamed Concrete. Processes 2025, 13, 403. [Google Scholar] [CrossRef]

- Ahmad Zaidi, F.; Ahmad, R.; Abdullah, M.M.A.B.; Mohd Tahir, M.F.; Yahya, Z.; Ibrahim, W.M.W.; Sauffi, A. Performance of Geopolymer Concrete When Exposed to Marine Environment. IOP Conf. Ser. Mater. Sci. Eng. 2019, 551, 012092. [Google Scholar] [CrossRef]

- Abdullah, M.M.A.B.; Kamarudin, H.; Binhussain, M.; Nizar, K.; Razak, R.; Yahya, Z. Comparison of Geopolymer Fly Ash and Ordinary Portland Cement to the Strength of Concrete. Adv. Sci. Lett. 2013, 19, 3592–3595. [Google Scholar] [CrossRef]

- Růžek, V.; Louda, P.; Buczkowska, K.; Just, P.; Prałat, K.; Ciemnicka, J.; Plaskota, P. Modifying Geopolymer Wettability by Plasma Treatment and High-Carbon Fly Ash. Front. Built Environ. 2022, 8, 991496. [Google Scholar] [CrossRef]

- Udhaya Kumar, T.; Vinod Kumar, M.; Salunkhe, S.; Cep, R. Evaluation of non-destructive testing and long-term durability of geopolymer aggregate concrete. Front. Built Environ. 2024, 10, 1454687. [Google Scholar] [CrossRef]

- Hao, E.; Li, Y.; Zhang, D.; Zhu, W.; Liu, R.; Wang, X.; Cao, Y.; Gu, Y.; Zheng, X. Research on the mechanism of pore structure on water transportation in cement-based materials. PLoS ONE 2025, 20, e0327659. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, Z.; Wang, L. Interlayer Bond Strength of 3D Printing Cement Paste by Cross-Bonded Method. J. Chin. Ceram. Soc. 2019, 47, 648–652. [Google Scholar]

- Babafemi, A.J.; Kolawole, J.T.; Miah, M.J.; Paul, S.C.; Panda, B. A Concise Review on Interlayer Bond Strength in 3D Concrete Printing. Sustainability 2021, 13, 7137. [Google Scholar] [CrossRef]

- Nerella, V.N.; Hempel, S.; Mechtcherine, V. Effects of layer-interface properties on mechanical performance of concrete elements produced by extrusion-based 3D-printing. Constr. Build. Mater. 2019, 205, 586–601. [Google Scholar] [CrossRef]

- Lv, C.; Shen, H.; Liu, J.; Wu, D.; Qu, E.; Liu, S. Properties of 3D Printing Fiber-Reinforced Geopolymers Based on Interlayer Bonding and Anisotropy. Materials 2022, 15, 8032. [Google Scholar] [CrossRef] [PubMed]

- Ding, Y.; Ou, X.; Qi, H.; Xiong, G.; Nishiwaki, T.; Liu, Y.; Liu, J. Interlayer Bonding Performance of 3D Printed Engineered Cementitious Composites (ECC): Rheological Regulation and Fiber Hybridization. Cem. Concr. Compos. 2024, 154, 105805. [Google Scholar] [CrossRef]

- Luo, B.; Su, Y.; Ding, X.; Chen, Y.; Liu, C. Modulation of Initial CaO/Al2O3 and SiO2/Al2O3 Ratios on the Properties of Slag/Fly Ash-Based Geopolymer Stabilized Clay: Synergistic Effects and Stabilization Mechanism. Mater. Today Commun. 2025, 47, 113295. [Google Scholar] [CrossRef]

- Longhi, M.A.; Zhang, Z.; Rodríguez, E.D.; Kirchheim, A.P.; Wang, H. Efflorescence of Alkali-Activated Cements (Geopolymers) and the Impacts on Material Structures: A Critical Analysis. Front. Mater. 2019, 6, 89. [Google Scholar] [CrossRef]

- Srinivasamurthy, L.; Chevali, V.S.; Zhang, Z.; Wang, H. Phase Changes under Efflorescence in Alkali Activated Materials with Mixed Activators. Constr. Build. Mater. 2021, 283, 122678. [Google Scholar] [CrossRef]

- Dhasindrakrishna, D.; Pasupathy, K.; Ramakrishnan, S.; Sanjayan, J. Progress, Current Thinking and Challenges in Geopolymer Foam Concrete Technology. Cem. Concr. Compos. 2021, 116, 103886. [Google Scholar] [CrossRef]

- Cui, Y.; Zhao, J.; Li, D.; Ng, S.; Rui, Y. Effect of Calcium Stearate Based Foam Stabilizer on Pore Characteristics and Thermal Conductivity of Geopolymer Foam Material. J. Build. Eng. 2018, 20, 21–29. [Google Scholar] [CrossRef]

- Walbrück, K.; Maeting, F.; Witzleben, S.; Stephan, D. Natural Fiber-Stabilized Geopolymer Foams-A Review. Materials 2020, 13, 3198. [Google Scholar] [CrossRef]

- Alzeer, M.; MacKenzie, K.J.D. Synthesis and Mechanical Properties of New Fibre-Reinforced Composites of Inorganic Polymers with Natural Wool Fibres. J. Mater. Sci. 2012, 47, 6958–6965. [Google Scholar] [CrossRef]

| Oxide composition (%) | MgO | Al2O3 | SiO2 | SO3 | Cl | K2O |

| 3.32% | 23.64% | 58.03% | 0.22% | 0.10% | 3.95% | |

| CaO | TiO2 | Cr2O3 | MnO | Fe2O3 | ZrO2 | |

| 1.99% | 1.06% | 0.09% | 0.06% | 7.00% | 0.29% |

| Fibers | Diameter [µm] | Length [mm] | Density [g/cm3] |

|---|---|---|---|

| Glass (G) | 20.00 | 6 mm | 2.50 |

| Merino wool (M) | 18.20 | 6 mm | 4.55 |

| No. | Designation of the Mixtures | w/c | Cement [%] | Sand [%] | Fly Ash [%] | Coal Slag [%] | Ground Bricks [%] | Glass Fibers [%] | Merino Fibers [%] |

|---|---|---|---|---|---|---|---|---|---|

| 1 | M1 | 0.34 | 27 | 37 | 5 | 15 | 15 | 0.3 | 0.2 |

| 2 | M2 | 0.34 | 27 | 37 | 5 | 15 | 15 | 0.2 | 0.3 |

| 3 | M3 | 0.34 | 27 | 37 | 5 | 15 | 15 | 0.25 | 0.25 |

| 4 | M4 | 0.34 | 27 | 37 | 5 | 15 | 15 | 0.3 | 0.2 |

| 5 | M5 | 0.34 | 27 | 37 | 5 | 15 | 15 | 0.2 | 0.3 |

| 6 | M6 | 0.34 | 27 | 37 | 5 | 15 | 15 | 0.25 | 0.25 |

| Designation of Sample | Density (kg/m3) | λ (W/m·K) | R (m2·K/W) |

|---|---|---|---|

| M1 | 1351 | 0.65 | 0.074 |

| M2 | 1330 | 0.73 | 0.067 |

| M3 | 1387 | 1.05 | 0.049 |

| M4 | 1431 | 0.71 | 0.069 |

| M5 | 1561 | 1.27 | 0.038 |

| M6 | 1580 | 1.06 | 0.045 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rudziewicz, M.; Maroszek, M.; Hebda, M. Comparison of Porosity and Thermal Conductivity of Concrete and Alkali-Activated Hybrid Binders in 3D-Printed Fiber-Reinforced Foamed Composites. Materials 2025, 18, 4498. https://doi.org/10.3390/ma18194498

Rudziewicz M, Maroszek M, Hebda M. Comparison of Porosity and Thermal Conductivity of Concrete and Alkali-Activated Hybrid Binders in 3D-Printed Fiber-Reinforced Foamed Composites. Materials. 2025; 18(19):4498. https://doi.org/10.3390/ma18194498

Chicago/Turabian StyleRudziewicz, Magdalena, Marcin Maroszek, and Marek Hebda. 2025. "Comparison of Porosity and Thermal Conductivity of Concrete and Alkali-Activated Hybrid Binders in 3D-Printed Fiber-Reinforced Foamed Composites" Materials 18, no. 19: 4498. https://doi.org/10.3390/ma18194498

APA StyleRudziewicz, M., Maroszek, M., & Hebda, M. (2025). Comparison of Porosity and Thermal Conductivity of Concrete and Alkali-Activated Hybrid Binders in 3D-Printed Fiber-Reinforced Foamed Composites. Materials, 18(19), 4498. https://doi.org/10.3390/ma18194498