Predictive Correlation Between Hardness and Tensile Properties of Submerged Arc Welded API X70 Steel

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Welding Procedure

2.3. Mechanical Characterization

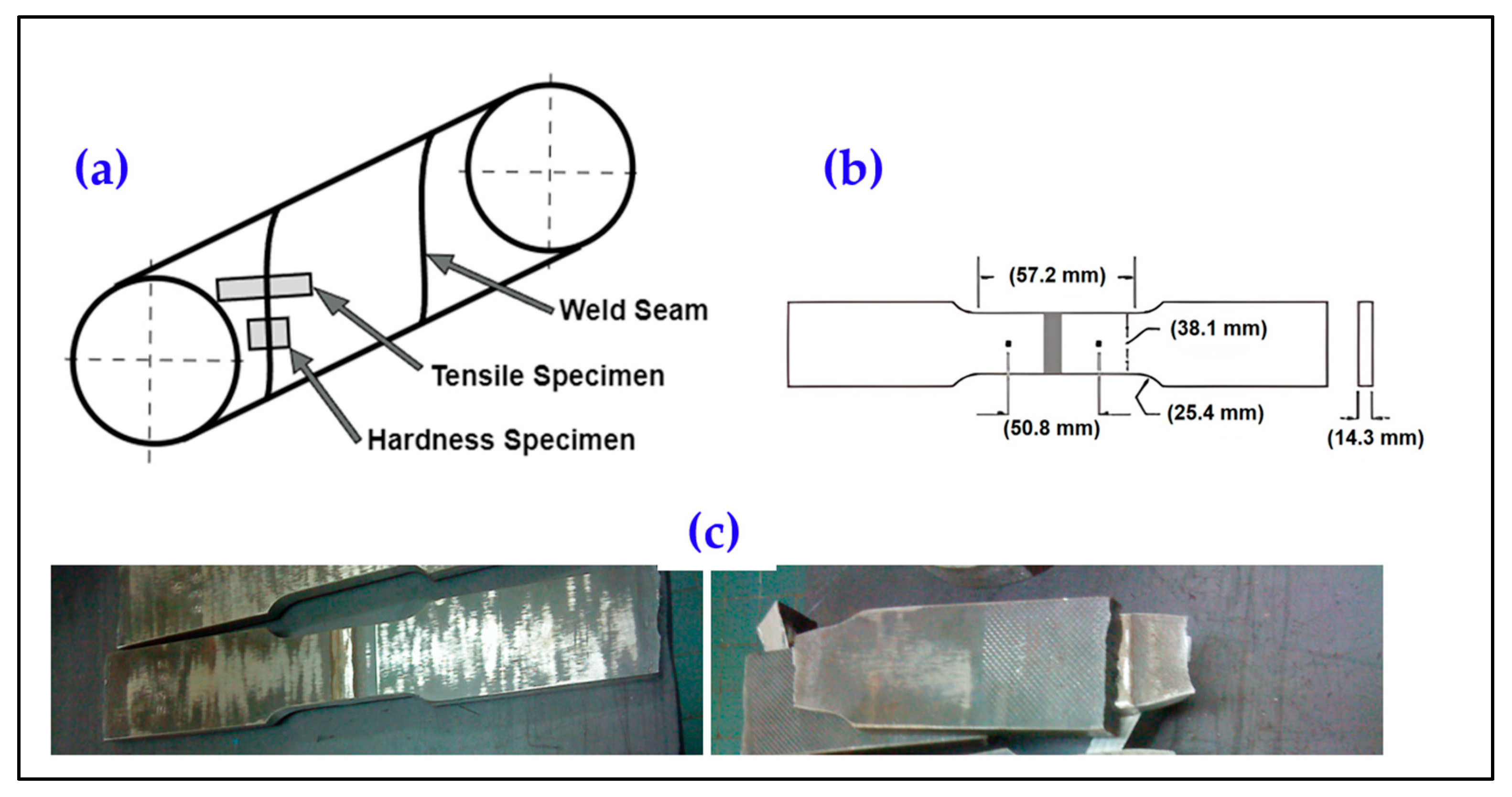

2.3.1. Tensile Tests

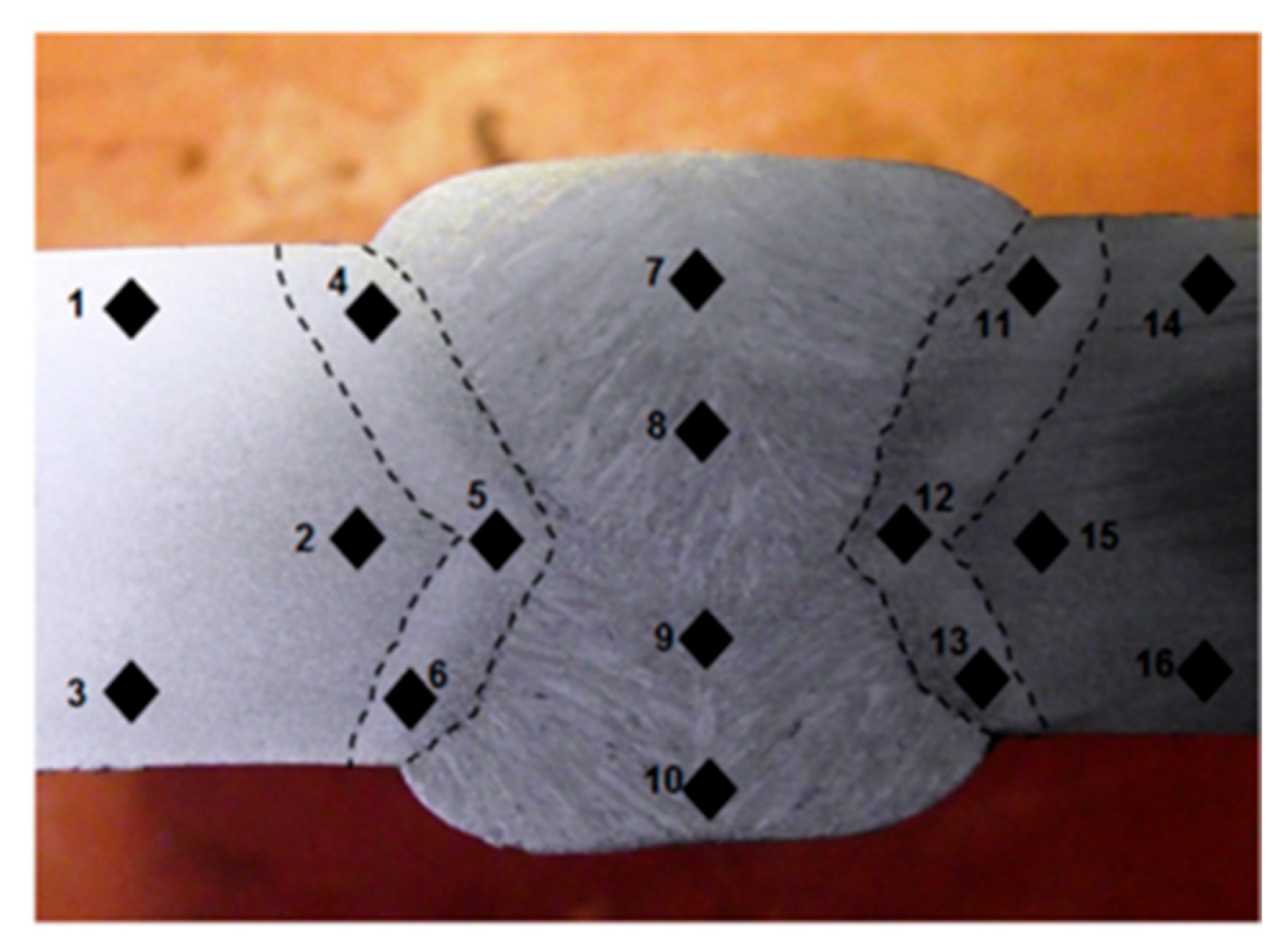

2.3.2. Hardness Experiments

2.3.3. Microstructural Analysis

3. Results

3.1. Tensile Test Results

3.2. Hardness Test Results

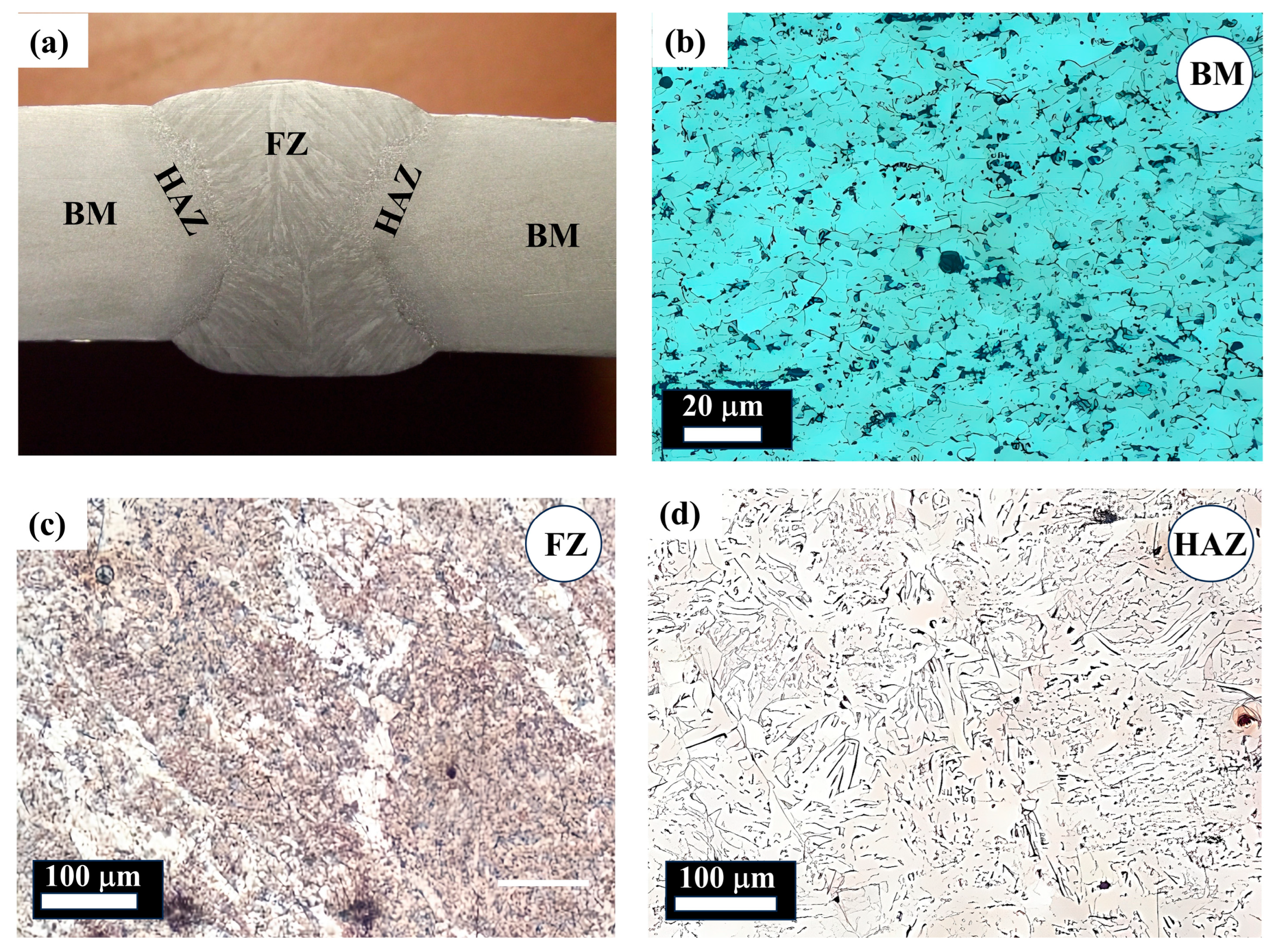

3.2.1. Fusion Zone Hardness and Microstructure

3.2.2. Base Metal and Heat-Affected Zone Characteristics

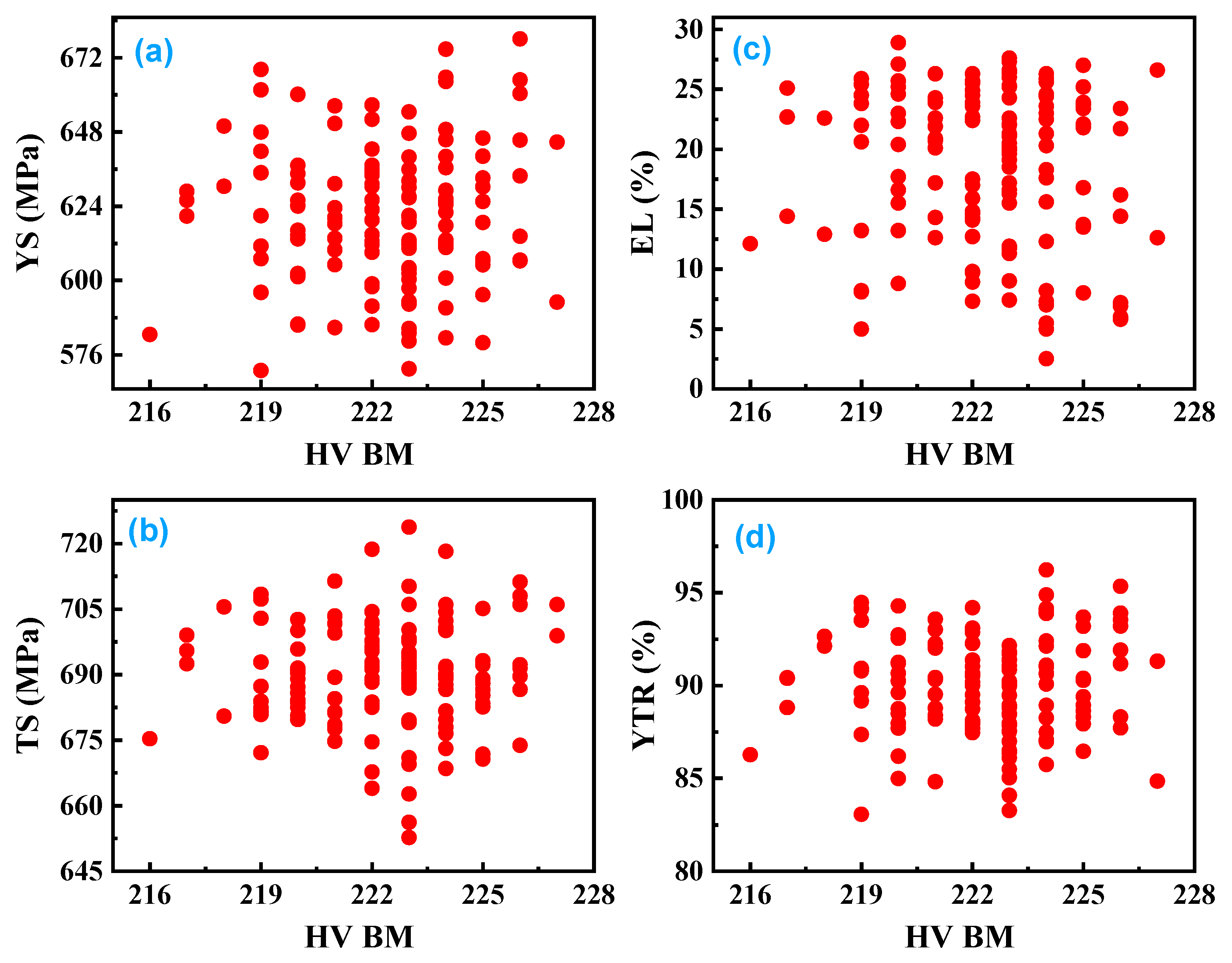

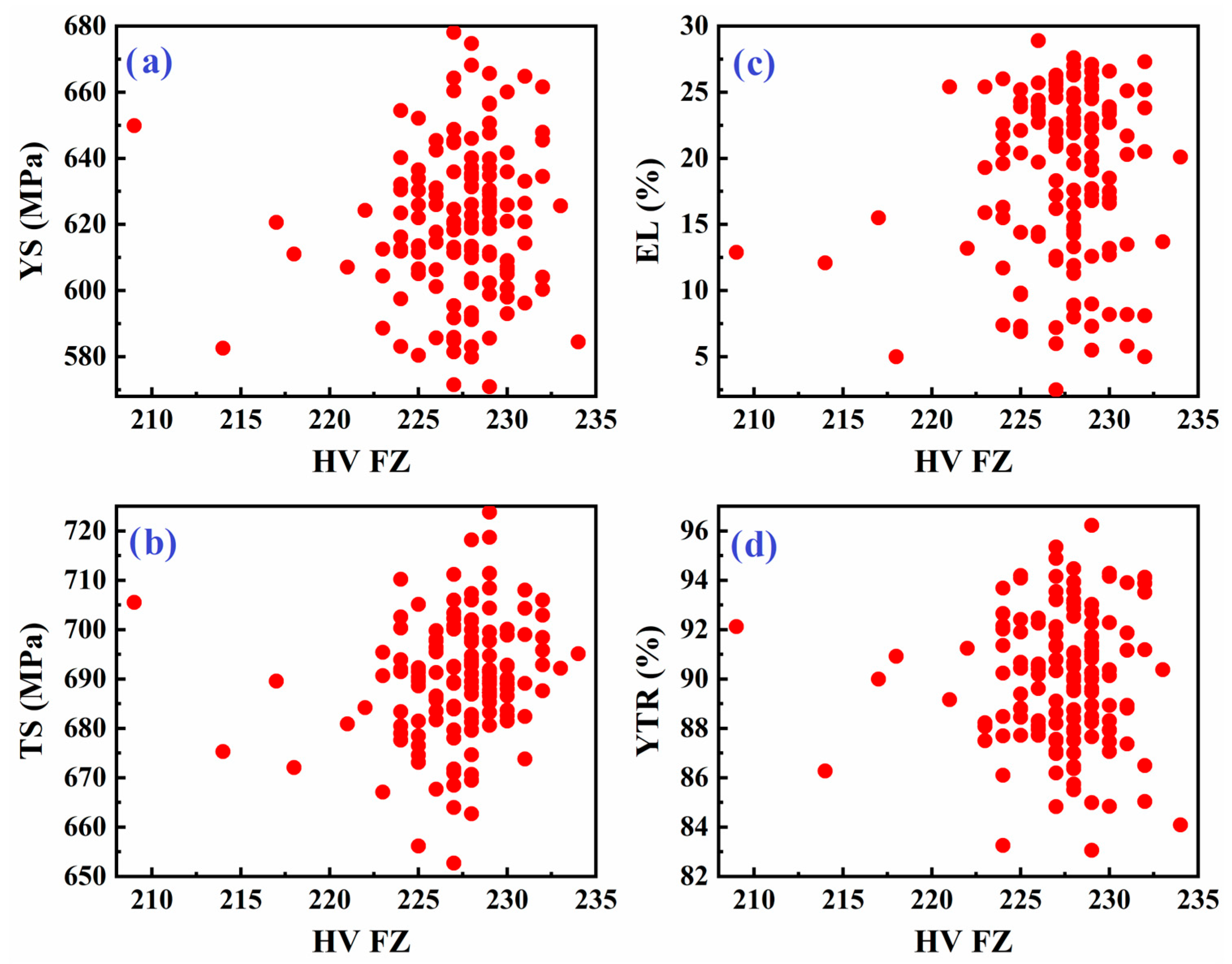

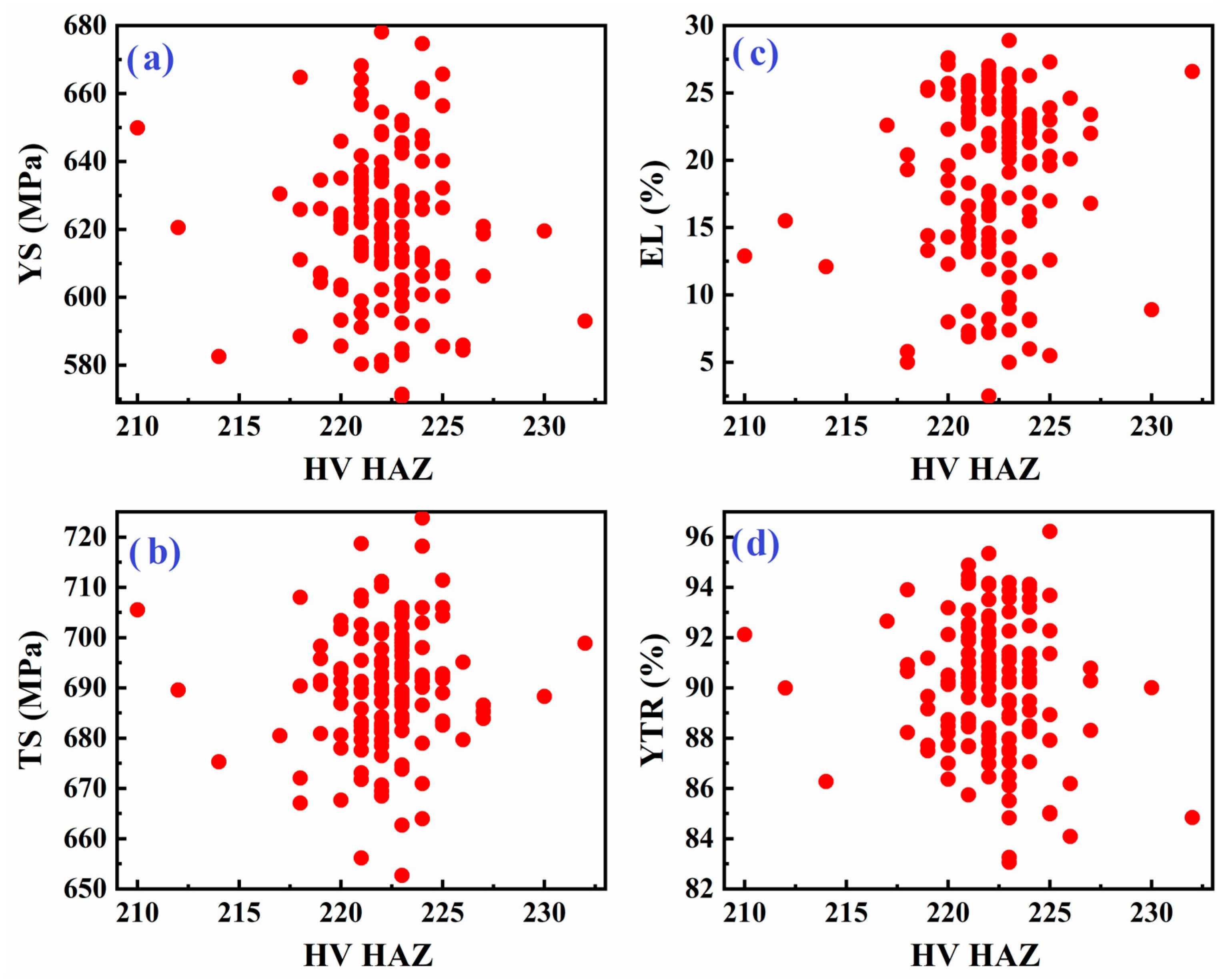

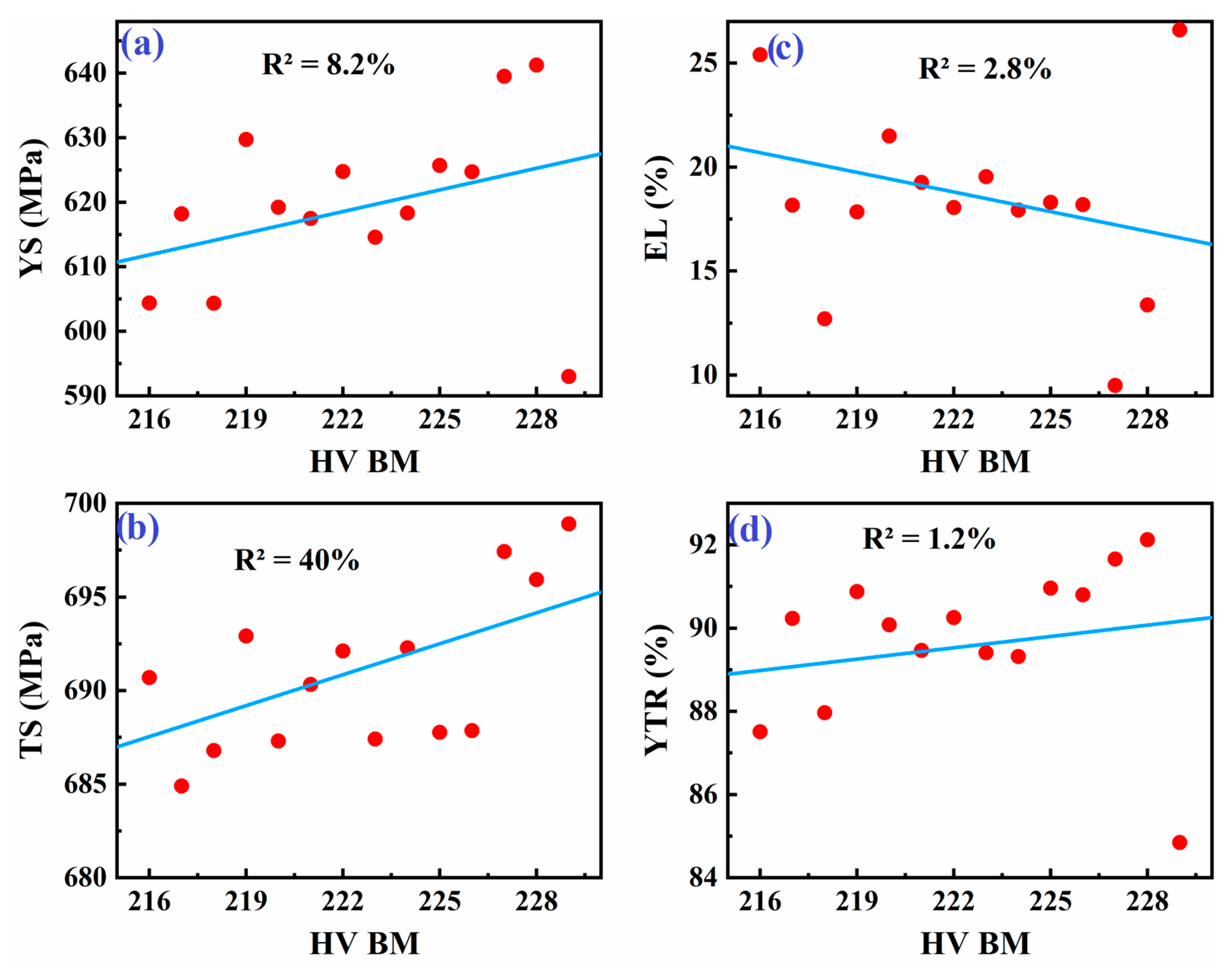

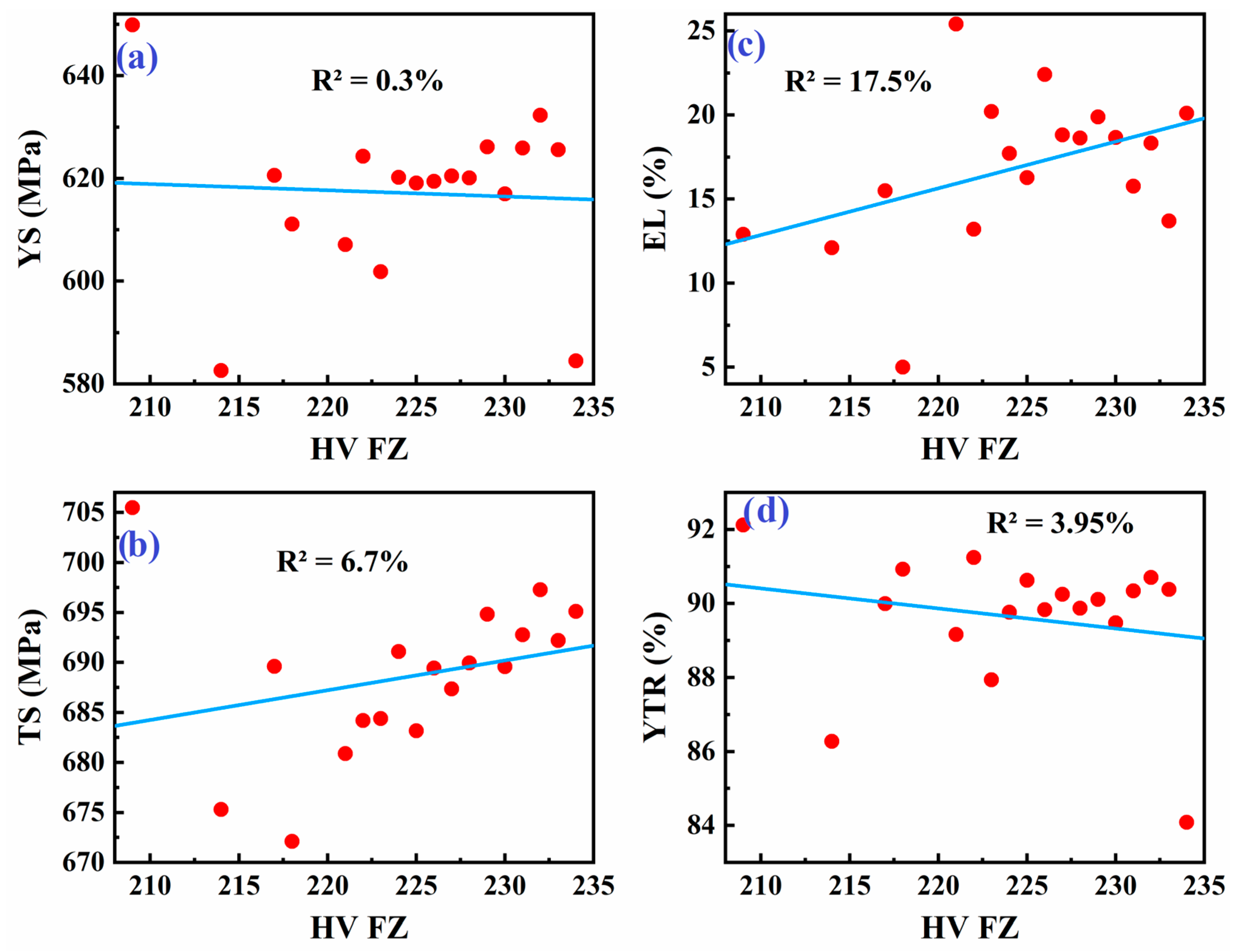

3.3. Relationship Between Tensile and Hardness

- ▪

- Step 1 (Model 1): Initial regression models were constructed using averaged data (e.g., mean values of grouped hardness or tensile properties).

- ▪

- Step 2 (Model 2): Outliers were identified in Model 1 using the standardized residual criterion. If present, these outliers were removed, and the model was rebuilt using the cleaned data.

- ▪

- Step 3 (Model 3): A second round of residual analysis was conducted on Model 2. If additional outliers were detected, they were removed to generate a final cleaned model.

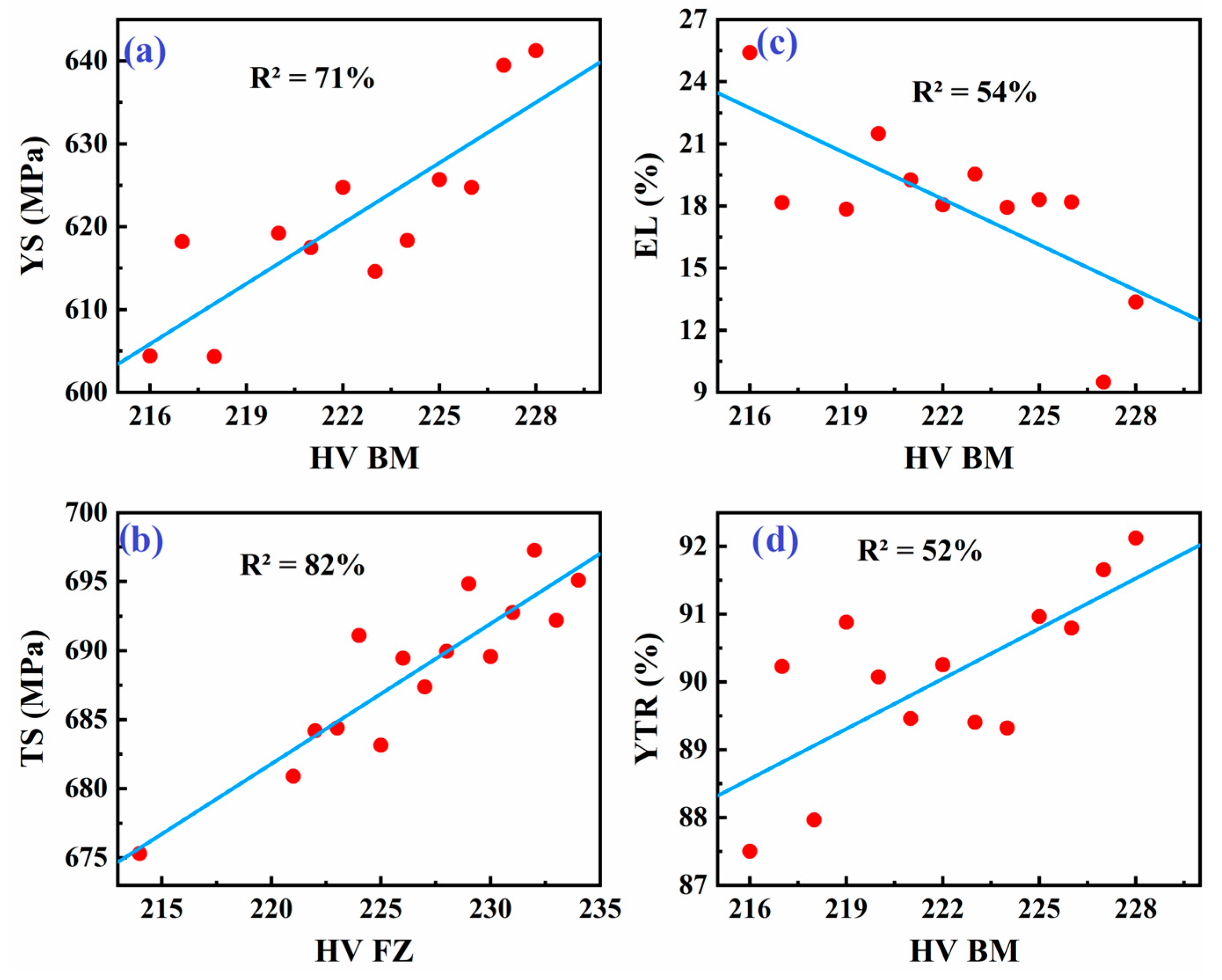

3.3.1. Hardness Correlation with YS and TS

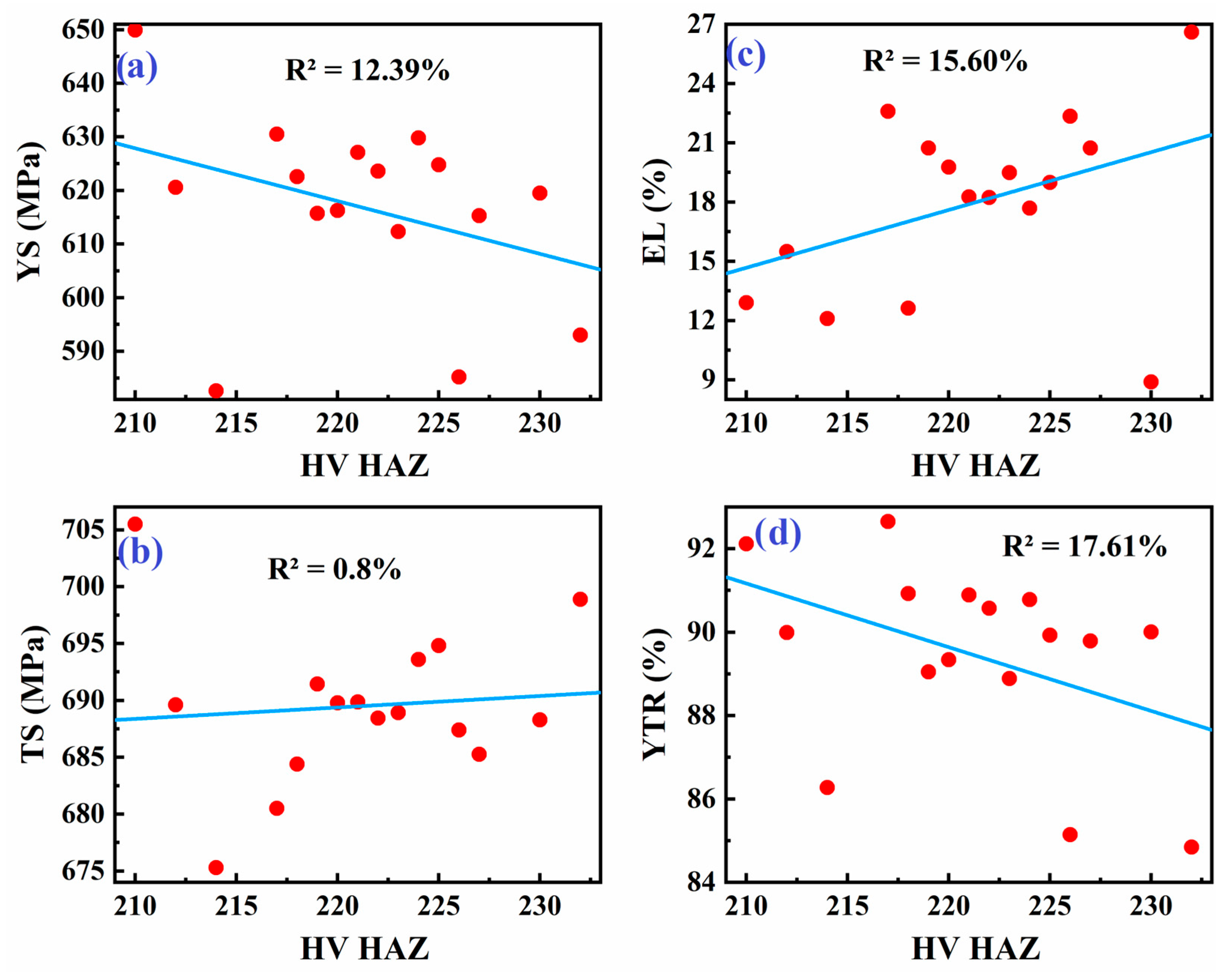

3.3.2. Hardness Correlation with Elongation and Yield-to-Tensile Ratio

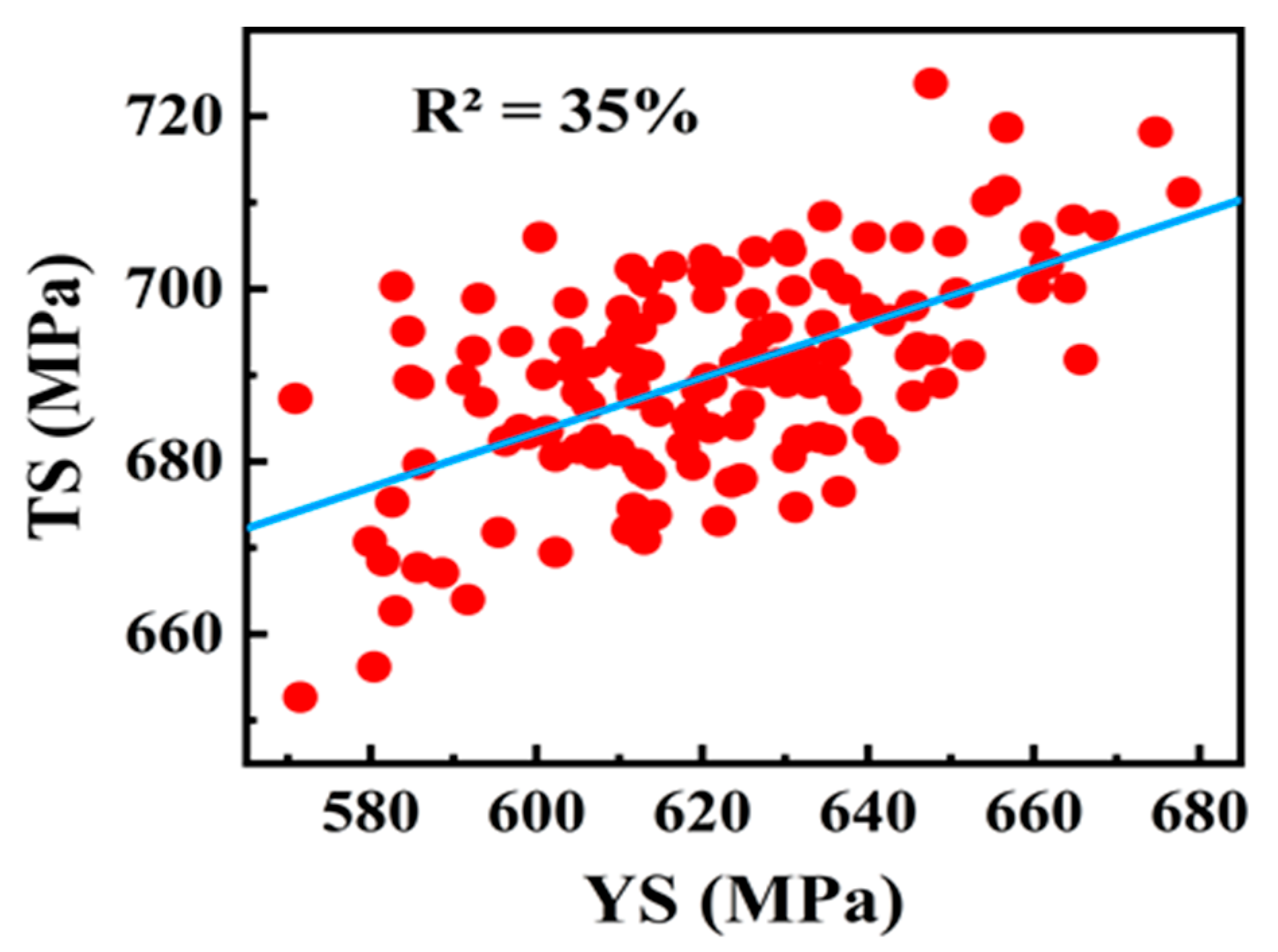

3.4. Relationship Between Yield and Tensile Strength of Welded Joints

4. Discussion

5. Conclusions

- The mean yield strength (620 MPa) and tensile strength (690 MPa) of API X70 weld joints demonstrate compliance with industry standards, while elongation shows significant variability (mean: 18.57%; range: 2.5–28.9%).

- Among the weld subzones, the fusion zone exhibited the highest average hardness (227 HV), followed by the base metal (222 HV), and the heat-affected zone (222 HV). All values remained below the API 5L limit of 250 HV.

- A strong positive correlation exists between BM hardness and YS (R2 = 71%).

- FZ hardness strongly correlates with TS (R2 = 82%).

- Moderate correlations were observed for elongation (R2 = 54%) and yield-to-tensile ratio (R2 = 52%) with BM hardness.

- Regression models suggest that Vickers hardness can reliably predict tensile properties after data cleaning, offering a nondestructive alternative to traditional tensile testing.

- These findings support using hardness tests for efficient quality control in pipeline steel applications, emphasizing the importance of controlling welding parameters to achieve desired mechanical properties.

- Future research should investigate advanced machine learning methods to improve predictive accuracy further and address localized variations in weld properties.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Biju, A.T.; Immnuel, P.; Sarran, V.; Venkateshwaran, S.; Sundhar Eashwar, S.K.; Bindu, M.B.; Amrutha, R. Tensile and Hardness Tests on Steel Specimen. Int. J. Innov. Technol. Explor. Eng. 2020, 9, 1607–1610. [Google Scholar] [CrossRef]

- Park, M.; Lee, G.H.; Jang, G.; Kim, H.C.; Kim, B.; Kim, B.J. The Effects of Post Weld Heat Treatment on Microstructure and Mechanical Properties of API X70 Linepipe using Submerged Arc Welding. Arch. Metall. Mater. 2024, 69, 99–102. [Google Scholar] [CrossRef]

- Talarico, P.; Kwon, Y. Hardness and tensile properties of metals subjected to aging conditions. Multiscale Multidiscip. Model. Exp. Des. 2020, 3, 187–200. [Google Scholar] [CrossRef]

- Zhang, P.; Li, S.; Zhang, Z. General relationship between strength and hardness. Mater. Sci. Eng. A 2011, 529, 62–73. [Google Scholar] [CrossRef]

- Zubko, P.; Pešek, L. Prediction of tensile properties based on hardness measurement. Key Eng. Mater. 2014, 606, 35–38. [Google Scholar] [CrossRef]

- Lobanov, M.L.; Khotinov, V.A.; Urtsev, V.N.; Danilov, S.V.; Urtsev, N.V.; Platov, S.I.; Stepanov, S.I. Tensile deformation and fracture behavior of API-5L X70 line pipe steel. Materials 2022, 15, 501. [Google Scholar] [CrossRef] [PubMed]

- Murugan, S.S. Mechanical properties of materials: Definition, testing and application. Int. J. Mod. Stud. Mech. Eng. 2020, 6, 28–38. [Google Scholar] [CrossRef]

- Lee, S.-I.; Hwang, B. Correlation of microstructure with tensile behavior and properties of API X70 pipeline steels subjected to strain aging. J. Iron Steel Res. Int. 2020, 27, 319–324. [Google Scholar] [CrossRef]

- Mohammadijoo, M.; Kenny, S.; Collins, L.; Henein, H.; Ivey, D.G. Characterization of HAZ of API X70 microalloyed steel welded by cold-wire tandem submerged arc welding. Metall. Mater. Trans. A 2017, 48, 2247–2259. [Google Scholar] [CrossRef]

- Gaško, M.; Rosenberg, G. Correlation between hardness and tensile properties in ultra-high strength dual phase steels–short communication. Mater. Eng 2011, 18, 155–159. [Google Scholar]

- Costa, M.; Rodrigues, D.; Leitão, C. Analysis of AA 6082-T6 welds strength mismatch: Stress versus hardness relationships. Int. J. Adv. Manuf. Technol. 2015, 79, 719–727. [Google Scholar] [CrossRef]

- Li, M.; Li, X.; Li, H.; Niu, L. A study of correlation between tensile strength and hardness of aluminum alloy 2219 and its welded joints. Met. Sci. Heat Treat. 2020, 62, 199–204. [Google Scholar] [CrossRef]

- Rajakumar, S.; Balasubramanian, V. Correlation between weld nugget grain size, weld nugget hardness and tensile strength of friction stir welded commercial grade Aluminiumalloy joints. Mater. Des. 2012, 34, 242–251. [Google Scholar] [CrossRef]

- Čapek, J.; Trojan, K.; Kec, J.; Černý, I.; Ganev, N.; Němeček, S. On the Weldability of thick P355NL1 pressure vessel steel plates using laser welding. Materials 2020, 14, 131. [Google Scholar] [CrossRef]

- Tiryakioğlu, M.; Robinson, J.S.; Salazar-Guapuriche, M.A.; Zhao, Y.Y.; Eason, P.D. Hardness–strength relationships in the aluminum alloy 7010. Mater. Sci. Eng. A 2015, 631, 196–200. [Google Scholar] [CrossRef]

- Lu, W.; Shi, Y.; Li, X.; Lei, Y. Correlation between tensile strength and hardness of electron beam welded TC4-DT joints. J. Mater. Eng. Perform. 2013, 22, 1694–1700. [Google Scholar] [CrossRef]

- Borisenko, V.; Krashchenko, V.P.; Lastovets, Y.P.; Oksametnaya, O.B.; Rudnitskii, N.P. Correlations between characteristics of strength and hardness of niobium alloys at different temperatures. Strength Mater. 1991, 23, 1085–1090. [Google Scholar] [CrossRef]

- Keist, J.S.; Palmer, T.A. Development of strength-hardness relationships in additively manufactured titanium alloys. Mater. Sci. Eng. A 2017, 693, 214–224. [Google Scholar] [CrossRef]

- Krishna, S.C.; Gangwar, N.K.; Jha, A.K.; Pant, B. On the prediction of strength from hardness for copper alloys. J. Mater. 2013, 2013, 352578. [Google Scholar] [CrossRef]

- Hashemi, S. Strength–hardness statistical correlation in API X65 steel. Mater. Sci. Eng. A 2011, 528, 1648–1655. [Google Scholar] [CrossRef]

- Hamada, S.; Nakanishi, M.; Moriyama, T.; Noguchi, H. Re-Examination of correlation between hardness and tensile properties by numerical analysis. Exp. Mech. 2017, 57, 773–781. [Google Scholar] [CrossRef]

- Pamnani, R.; Karthik, V.; Jayakumar, T.; Vasudevan, M.; Sakthivel, T. Evaluation of mechanical properties across micro alloyed HSLA steel weld joints using Automated Ball Indentation. Mater. Sci. Eng. A 2016, 651, 214–223. [Google Scholar] [CrossRef]

- Alipooramirabad, H.; Paradowska, A.; Nafisi, S.; Reid, M.; Ghomashchi, R. Post-weld heat treatment of API 5L X70 high strength low alloy steel welds. Materials 2020, 13, 5801. [Google Scholar] [CrossRef]

- Oyyaravelu, R.; Kuppan, P.; Arivazhagan, N. Metallurgical and mechanical properties of laser welded high strength low alloy steel. J. Adv. Res. 2016, 7, 463–472. [Google Scholar] [CrossRef]

- Castelluccio, G.M.; Yawny, A.A.; Perez Ipiña, J.E.; Ernst, H.A. In Situ Evaluation of Tensile Properties of Heat-Affected Zones from Welded Steel Pipes. Strain 2012, 48, 68–74. [Google Scholar] [CrossRef]

- Midawi, A.; Simha, C.; Gerlich, A. Assessment of yield strength mismatch in X80 pipeline steel welds using instrumented indentation. Int. J. Press. Vessel. Pip. 2018, 168, 258–268. [Google Scholar] [CrossRef]

- Sun, W.-J.; Kothari, S.; Sun, C.C. The relationship among tensile strength, Young’s modulus, and indentation hardness of pharmaceutical compacts. Powder Technol. 2018, 331, 1–6. [Google Scholar] [CrossRef]

- Peng, Y.; Wu, C.; Gan, J.; Dong, J. Characterization of heterogeneous constitutive relationship of the welded joint based on the stress-hardness relationship using micro-hardness tests. Constr. Build. Mater. 2019, 202, 37–45. [Google Scholar] [CrossRef]

- Zhang, Z.; Ma, Y.; Liu, S.; Su, L.; Fletcher, L.; Li, H.; Wang, B.; Zhu, H. Inhomogeneous Strain Behaviors of the High Strength Pipeline Girth Weld under Longitudinal Loading. Materials 2024, 17, 2855. [Google Scholar] [CrossRef]

- Nasrin, T.; Pourali, M.; Pourkamali-Anaraki, F.; Peterson, A.M. Active learning for prediction of tensile properties for material extrusion additive manufacturing. Sci. Rep. 2023, 13, 11460. [Google Scholar] [CrossRef]

- Oyinbade, A.A.; Imoukhuede, K.A.; Akadiri, A.O. A Fuzzy Logic Approach to Predict Tensile Strength in TIG Mild Steel Welds. World J. Eng. Technol. 2023, 11, 199–207. [Google Scholar] [CrossRef]

- Payares-Asprino, C. Prediction of mechanical properties as a function of welding variables in robotic gas metal arc welding of duplex stainless steels SAF 2205 welds through artificial neural networks. Adv. Mater. Sci. 2021, 21, 75–90. [Google Scholar] [CrossRef]

- Saoudi, A.; Fellah, M.; Hezil, N.; Lerari, D.; Khamouli, F.; Atoui, L.H.; Bachari, K.; Morozova, J.; Obrosov, A.; Samad, M.A. Prediction of mechanical properties of welded steel X70 pipeline using neural network modelling. Int. J. Press. Vessel. Pip. 2020, 186, 104153. [Google Scholar] [CrossRef]

- Saoudi, A.; Lerari, D.; Khamouli, F.; Atoui, L.H.; Bachari, K. Prediction of the ultimate tensile strength in API x70 line pipe steel using an artificial neural network model. Solid State Phenom. 2019, 297, 71–81. [Google Scholar] [CrossRef]

- Zhao, T.; Sato, Y.S.; Kokawa, H.; Ito, K. Predicting tensile properties of friction-stir-welded 6063 aluminum with experimentally measured welding heat input. Acta Metall. Sin. (Engl. Lett.) 2020, 33, 1235–1242. [Google Scholar] [CrossRef]

- Zhou, C.; Zhang, Y.; Stasic, J.; Liang, Y.; Chen, X.; Trtica, M. Hardness Predicting of Additively Manufactured High-Entropy Alloys Based on Fabrication Parameter-Dependent Machine Learning. Adv. Eng. Mater. 2023, 25, 2201369. [Google Scholar] [CrossRef]

- Saoudi, A.; Fellah, M.; Sedik, A.; Lerari, D.; Khamouli, F.; Atoui, L.H.; Bachari, K. Assessment and statistical correlation of mechanical properties of double sided single pass submerged arc welded line pipe steel. Eng. Sci. Technol. Int. J. 2020, 23, 452–461. [Google Scholar] [CrossRef]

- De Filippis, L.A.C.; Serio, L.M.; Facchini, F.; Mummolo, G.; Ludovico, A.D. Prediction of the vickers microhardness and ultimate tensile strength of AA5754 H111 friction stir welding butt joints using artificial neural network. Materials 2016, 9, 915. [Google Scholar] [CrossRef] [PubMed]

- Dong, Y.; Liu, D.; Hong, L.; Liu, J.; Zuo, X. Correlation between microstructure and mechanical properties of welded joint of X70 submarine pipeline steel with heavy wall thickness. Metals 2022, 12, 716. [Google Scholar] [CrossRef]

- Siahpour, P.; Miresmaeili, R.; Sabour Rouhaghdam, A. Temperature effect of hot rolling process on microstructure, strength and fracture toughness of X65 pipeline steel. Trans. Indian Inst. Met. 2018, 71, 1531–1541. [Google Scholar] [CrossRef]

- API 5L; Specification for Line Pipe, 44th ed. American Petroleum Institute: Washington, DC, USA, 2007.

- EN 10002-1:2001; Metallic Materials—Tensile Testing—Part 1: Method of Test at Ambient Temperature. European Committee for Standardization (CEN): Brussels, Belgium, 2001.

- Budynas, R.G.; Nisbett, J.K. Shigley’s Mechanical Engineering Design, 10th ed.; McGraw-Hill: New York, NY, USA, 2015. [Google Scholar]

- Tas, Z. Examination of mechanical properties and weld zone of X70 pipe steel after welding. Int. J. Sci. Technol. Res. 2017, 6, 148–152. [Google Scholar]

- Qazi, H.A.A. Study of verification and validation of standard welding procedure specifications guidelines for API 5L X-70 grade line pipe welding. J. Eng. Sci. 2017, 4, B11–B14. [Google Scholar] [CrossRef]

- Sumardiyanto, D.; Susilowati, S.E. Effect of welding parameters on mechanical properties of low carbon steel API 5L shielded metal arc welds. Am. J. Mater. Sci. 2019, 9, 15–21. [Google Scholar] [CrossRef]

- Haissam, A.; Benarrache, S.; Rahmani, R.K.; Mansouri, T.; Benhorma, M.E. Effect of Heat Treatments on the Mechanical and Microstructure Properties of Welded API X70 Steel. In Annales de Chimie. Science des Materiaux; International Information and Engineering Technology Association (IIETA): Edmonton, AB, Canada, 2024. [Google Scholar]

- Abderrahmani, S.; Chérifi, N.; Ghanem, K. Study of the effect of SMAW welding speed on the microstructure and crystal stability of X70 steel using X-ray diffraction. Stud. Eng. Exact Sci. 2024, 5, e9691. [Google Scholar] [CrossRef]

- Sharma, S.K.; Maheshwari, S. A review on welding of high strength oil and gas pipeline steels. J. Nat. Gas Sci. Eng. 2017, 38, 203–217. [Google Scholar] [CrossRef]

- Boumerzoug, Z.; Beziou, O.; Hamdi, I.; Brisset, F.; Baudin, T. Effect of Metal Filler on the Welded Joint of X70 Steel Joined to Duplex Stainless Steel by Gas Arc Welding. Malays. J. Compos. Sci. Manuf. 2025, 16, 19–34. [Google Scholar] [CrossRef]

- Kahraman, S.; Fener, M.; Kozman, E. Predicting the compressive and tensile strength of rocks from indentation hardness index. J. South. Afr. Inst. Min. Metall. 2012, 112, 331–339. [Google Scholar]

- Kavousi Sisi, A.; Mirsalehi, S. Prediction of microstructure and mechanical properties of line pipe welded joints based on hardness map. Sci. Technol. Weld. Join. 2016, 21, 43–52. [Google Scholar] [CrossRef]

- Saoudi, A.; Khamouli, F.; Atoui, L.H.; Zidani, M.; Farh, H. Statistical distribution analysis of mechanical properties of a welded pipeline steel API X70 and correlation between hardness and other mechanical characteristics. Int. J. Eng. Res. Afr. 2017, 30, 49–64. [Google Scholar] [CrossRef]

- Neter, J.; Kutner, M.H.; Nachtsheim, C.J.; Wasserman, W. Applied Linear Statistical Models; WCB McGraw-Hill: New York, NY, USA, 1996. [Google Scholar]

- Wisnowski, J.W.; Montgomery, D.C.; Simpson, J.R. A comparative analysis of multiple outlier detection procedures in the linear regression model. Comput. Stat. Data Anal. 2001, 36, 351–382. [Google Scholar] [CrossRef]

- Hamdollahzadeh, A.; Omidvar, H.; Amirnasiri, A. Microstructure and mechanical characterization of X70 steel welded joints through hardness mapping and tensile strength testing. Arch. Metall. Mater. 2017, 62, 2021–2027. [Google Scholar] [CrossRef]

- Magudeeswaran, G.; Balasubramanian, V.; Reddy, G.M.; Balasubramanian, T.S. Effect of welding processes and consumables on tensile and impact properties of high strength quenched and tempered steel joints. J. Iron Steel Res. Int. 2008, 15, 87–94. [Google Scholar] [CrossRef]

- Harati, E.; Harati, E.; Onochie, U. Effect of post-weld heat treatment on mechanical and microstructural properties of high strength steel weld metal. Weld. Int. 2024, 38, 422–429. [Google Scholar] [CrossRef]

- Sarkar, A. Influence of welding heat input and post-weld heat treatment on mechanical and microstructural properties of modified 9Cr-1Mo (P91) steel in submerged arc welding. Weld. Int. 2025, 39, 309–321. [Google Scholar] [CrossRef]

| C | Si | Mn | P | S | Cr | Ni | Mo | Al |

|---|---|---|---|---|---|---|---|---|

| 0.061 | 0.275 | 1.731 | 0.011 | 0 | 0.035 | 0.024 | 0.012 | 0.031 |

| Co | Cu | Nb | Ti | V | Nb+Ti+V | CE | ||

| 0.004 | 0.019 | 0.062 | 0.011 | 0.001 | 0.074 | 0.175 | ||

| Pipe Size (mm) | Bevel Configuration | Weld Seam | Wire | Flux | |

|---|---|---|---|---|---|

| ∅ 711 × 14.3 | Angle 12° V-shape | Internal | S2Mo | BFB | |

| External | S2Mo | BFB | |||

| Polarity | Amp. (A) | Volt. (V) | Travel speed (mm/min) | ||

| DC (+) | 750–800 | 31–34 | 720 | ||

| DC (+) | 750–800 | 31–34 | 720 | ||

| Variable | N | Mean | SD | Minimum | Maximum | API 5L |

|---|---|---|---|---|---|---|

| YS (MPa) | 138 | 620.768 | 22.7224 | 570.9 | 678.1 | NA |

| TS (MPa) | 138 | 689.954 | 12.1865 | 652.7 | 723.8 | 570–760 |

| EL (%) | 138 | 18.5688 | 6.48637 | 2.5 | 28.9 | NA |

| YTR (%) | 138 | 89.9661 | 2.67070 | 83.0642 | 96.2272 | NA |

| Variable | N * | Mean | SD ** | Minimum | Maximum | API 5L |

|---|---|---|---|---|---|---|

| HV BM (HV10) | 138 | 222.452 | 2.40 | 216 | 228.5 | 250 max |

| HV FZ (HV10) | 138 | 227.159 | 3.27 | 209.25 | 234 | 250 max |

| HV HAZ (HV10) | 138 | 222.057 | 2.58 | 210 | 231.667 | 250 max |

| Pair | DATA | Variable | N | Mean | SD | Min | Max | R2 |

|---|---|---|---|---|---|---|---|---|

| HV BM vs. YS | Average | HV BM | 14 | 222.5 | 4.18 | 216 | 229 | 8.23 |

| YS | 14 | 619.66 | 13.19 | 593 | 641.27 | |||

| First Clean. | HV BM_1 | 13 | 222 | 3.89 | 216 | 228 | 56.53 | |

| YS_1 | 13 | 621.71 | 11.16 | 604.35 | 641.27 | |||

| Second Clean. | HV BM_2 | 12 | 222.25 | 3.95 | 216 | 228 | 71.24 | |

| YS_2 | 12 | 621.04 | 11.39 | 604.35 | 641.27 | |||

| HV BM vs. TS | Average | HV BM | 14 | 222.5 | 4.18 | 216 | 229 | 39.54 |

| TS | 14 | 690.9 | 4.26 | 684.9 | 698.9 | |||

| HV BM vs. EL | Average | HV BM | 14 | 222.5 | 4.18 | 216 | 229 | 2.79 |

| EL | 14 | 18.31 | 4.52 | 9.5 | 26.6 | |||

| First Clean. | HV BM_1 | 13 | 222 | 3.89 | 216 | 228 | 28.18 | |

| EL_1 | 13 | 17.67 | 4 | 9.5 | 25.4 | |||

| Second Clean. | HV BM_2 | 12 | 222.33 | 3.87 | 216 | 228 | 53.66 | |

| EL_2 | 12 | 18.09 | 3.87 | 9.5 | 25.4 | |||

| HV BM vs. YTR | Average | HV BM | 14 | 222.5 | 4.18 | 216 | 229 | 1.16 |

| YTR | 14 | 89.68 | 1.89 | 84.85 | 92.13 | |||

| First Clean. | HV BM_1 | 13 | 222 | 3.89 | 216 | 228 | 52.29 | |

| YTR_1 | 13 | 90.05 | 1.33 | 87.51 | 92.13 | |||

| HV FZ vs. YS | Average | HV FZ | 18 | 224.61 | 6.87 | 209 | 234 | 0.28 |

| YS | 18 | 617.13 | 15.84 | 582.6 | 649.9 | |||

| Second Clean. | HV FZ_1 | 15 | 225.73 | 4.92 | 217 | 233 | 34.35 | |

| YS_1 | 15 | 619.43 | 7.82 | 601.83 | 632.33 | |||

| Second Clean. | HV FZ_2 | 14 | 225.93 | 5.05 | 217 | 233 | 40.2 | |

| YS_2 | 14 | 620.68 | 6.35 | 607.1 | 632.33 | |||

| HV FZ vs. TS | Average | HV FZ | 18 | 224.61 | 6.87 | 209 | 234 | 6.7 |

| TS | 18 | 688.6 | 7.89 | 672.1 | 705.5 | |||

| First Clean. | HV FZ_1 | 17 | 225.53 | 5.83 | 214 | 234 | 65.1 | |

| TS_1 | 17 | 687.6 | 6.88 | 672.1 | 697.27 | |||

| Second Clean. | HV FZ_2 | 15 | 226.6 | 5.33 | 214 | 234 | 81.9 | |

| TS_2 | 15 | 688.51 | 5.98 | 675.3 | 697.27 | |||

| HV FZ vs. EL | Average | HV FZ | 18 | 224.61 | 6.87 | 209 | 234 | 17.51 |

| EL | 18 | 16.92 | 4.56 | 5 | 25.4 | |||

| First Clean. | HV FZ_1 | 15 | 226.33 | 5.72 | 214 | 234 | 17.93 | |

| EL_1 | 15 | 17.42 | 2.92 | 12.1 | 22.41 | |||

| Second Clean. | HV FZ_2 | 14 | 225.86 | 5.61 | 214 | 234 | 36.75 | |

| EL_2 | 14 | 17.68 | 2.84 | 12.1 | 22.41 | |||

| HV FZ vs. YTR | Average | HV FZ | 18 | 224.61 | 6.87 | 209 | 234 | 3.95 |

| YTR | 18 | 89.62 | 1.87 | 84.09 | 92.12 | |||

| HV HAZ vs. YS | Average | HV HAZ | 16 | 221.25 | 6.18 | 210 | 232 | 12.39 |

| YS | 16 | 616.8 | 17.29 | 582.6 | 649.9 | |||

| First Clean. | HV HAZ1 | 15 | 221.73 | 6.08 | 210 | 232 | 41.07 | |

| YS_1 | 15 | 619.08 | 15.2 | 585.2 | 649.9 | |||

| Second Clean. | HV HAZ2 | 14 | 221.43 | 6.19 | 210 | 232 | 45.53 | |

| YS_2 | 14 | 621.5 | 12.42 | 593 | 649.9 | |||

| HV HAZ vs. TS | Average | HV HAZ | 16 | 221.25 | 6.18 | 210 | 232 | 0.8 |

| TS | 16 | 689.5 | 6.96 | 675.3 | 705.5 | |||

| First Clean. | HV HAZ1 | 14 | 222.57 | 5.33 | 212 | 232 | 18.86 | |

| TS_1 | 14 | 689.38 | 4.55 | 680.5 | 698.9 | |||

| HV HAZ vs. EL | Average | HV HAZ | 16 | 221.25 | 6.18 | 210 | 232 | 15.6 |

| EL | 16 | 17.97 | 4.58 | 8.9 | 26.6 | |||

| HV HAZ vs. YTR | Average | HV HAZ | 16 | 221.25 | 6.18 | 210 | 232 | 17.61 |

| YTR | 16 | 89.45 | 2.25 | 84.85 | 92.65 | |||

| First Clean. | HV HAZ1 | 15 | 221.73 | 6.08 | 210 | 232 | 37.31 | |

| YTR_1 | 15 | 89.66 | 2.16 | 84.85 | 92.65 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lahouel, A.; Athmani, S.; Sedik, A.; Saoudi, A.; Barille, R.; Khezami, L.; Guesmi, A.; Fellah, M. Predictive Correlation Between Hardness and Tensile Properties of Submerged Arc Welded API X70 Steel. Materials 2025, 18, 4482. https://doi.org/10.3390/ma18194482

Lahouel A, Athmani S, Sedik A, Saoudi A, Barille R, Khezami L, Guesmi A, Fellah M. Predictive Correlation Between Hardness and Tensile Properties of Submerged Arc Welded API X70 Steel. Materials. 2025; 18(19):4482. https://doi.org/10.3390/ma18194482

Chicago/Turabian StyleLahouel, Ali, Sameh Athmani, Amel Sedik, Adel Saoudi, Regis Barille, Lotfi Khezami, Ahlem Guesmi, and Mamoun Fellah. 2025. "Predictive Correlation Between Hardness and Tensile Properties of Submerged Arc Welded API X70 Steel" Materials 18, no. 19: 4482. https://doi.org/10.3390/ma18194482

APA StyleLahouel, A., Athmani, S., Sedik, A., Saoudi, A., Barille, R., Khezami, L., Guesmi, A., & Fellah, M. (2025). Predictive Correlation Between Hardness and Tensile Properties of Submerged Arc Welded API X70 Steel. Materials, 18(19), 4482. https://doi.org/10.3390/ma18194482