Comparative Study on the Mechanical Behavior of Flax and Glass Fiber Multiaxial Fabric-Reinforced Epoxy Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Textile Reinforcements

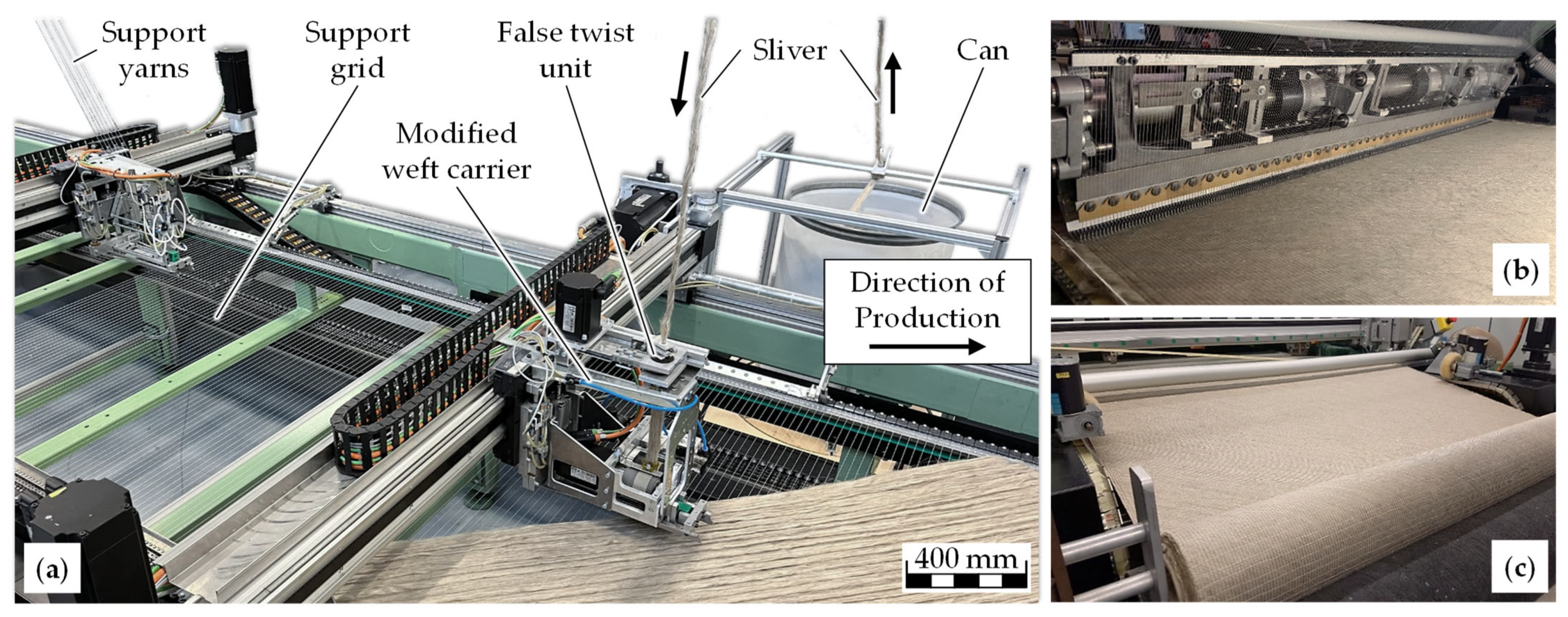

2.2. Production of the Sliver-Based Flax NCF

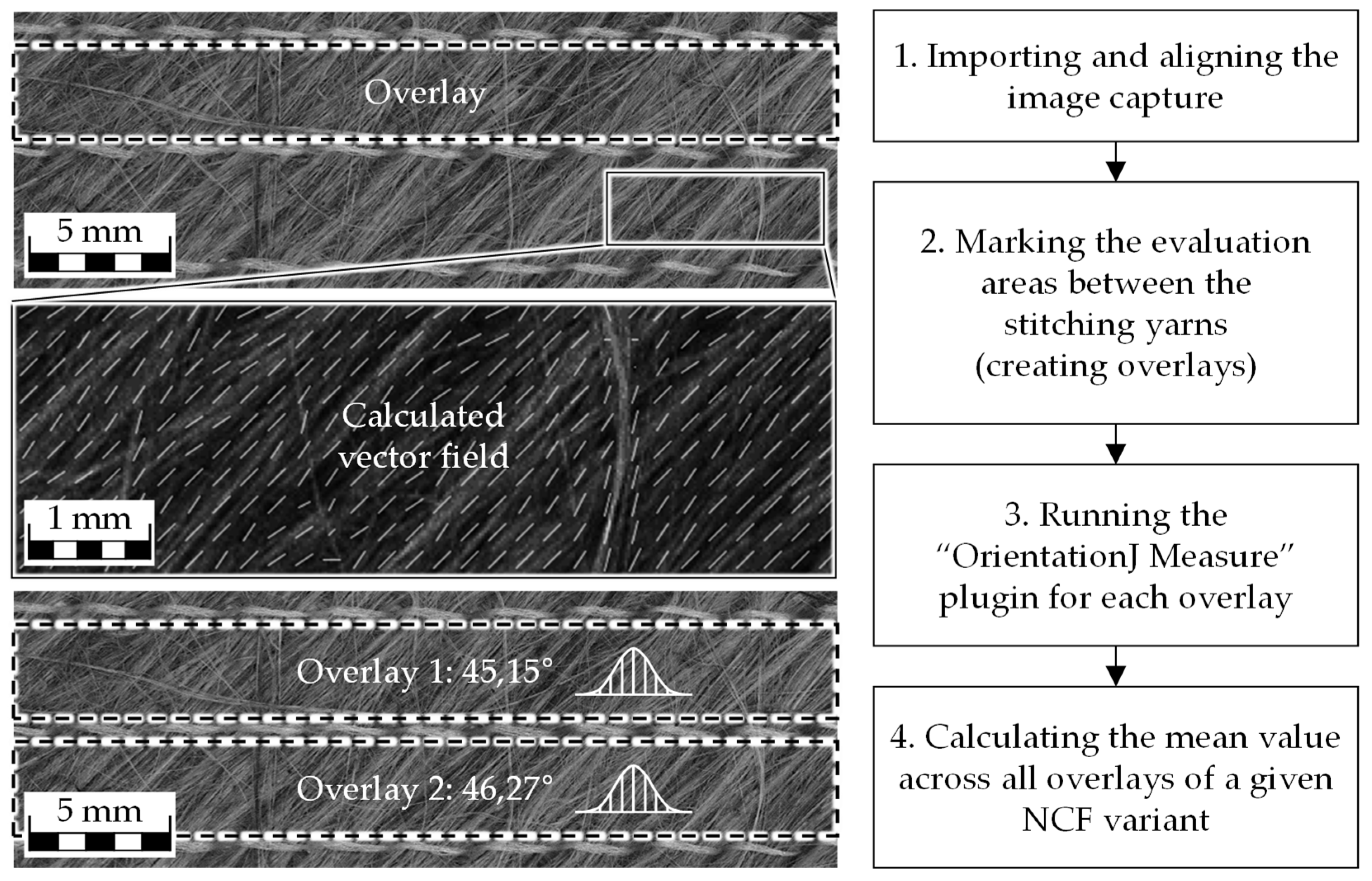

2.3. Fiber Orientation

2.4. Composite Manufacturing

- Lay-up of four NCF plies in a [0/90]4 stacking sequence, aligning the ±45° NCF layers such that their principal fiber orientations corresponded to 0° and 90°;

- Drying in a convection chamber furnace N 60/65SHA (Nabertherm GmbH, Lilienthal, Germany) at 80 °C for 30 min;

- Integration into VARI setup, including peel ply, flow media, and vacuum bagging;

- Resin infusion at ambient temperature under a vacuum of approximately −0.9 bar;

- Bonding of end tabs for tensile and compressive testing;

- Post-curing in a convection chamber furnace N 60/65SHA (Nabertherm GmbH, Lilienthal, Germany) at 80 °C for 10 h;

- Application of strain gauges for compressive testing.

2.5. Mechanical Testing

2.5.1. Tensile Testing

2.5.2. Compressive Testing

2.5.3. Flexural Testing

2.6. Fiber Volume Content and Composite Density

3. Results

3.1. Local Fiber Orientation

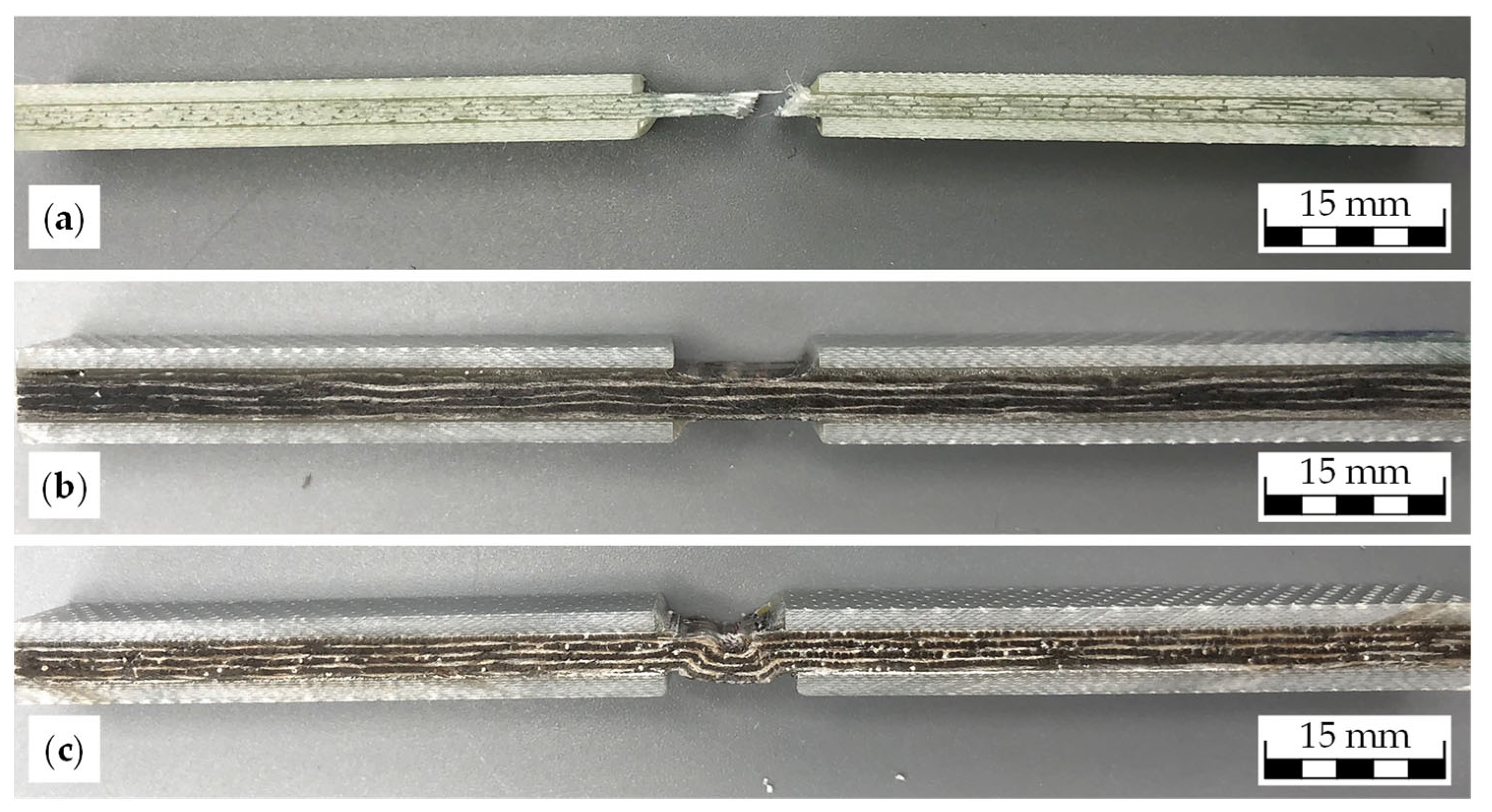

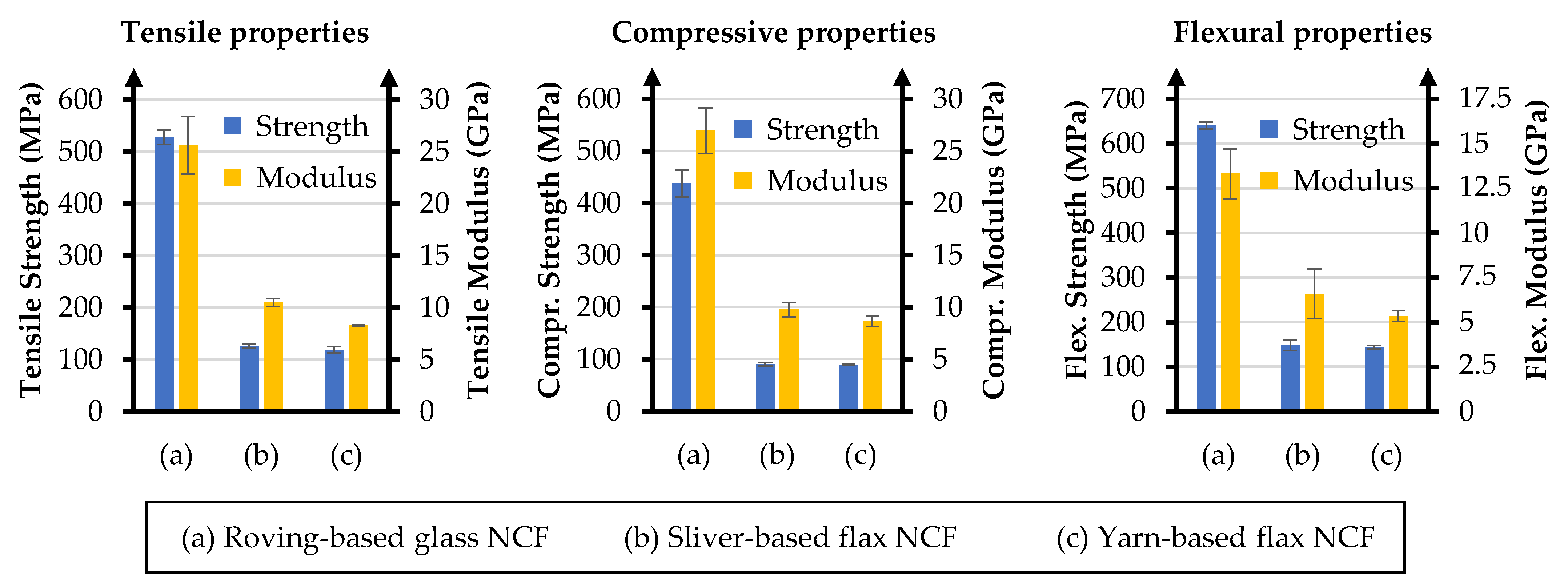

3.2. Tensile Properties

3.3. Compressive Properties

3.4. Flexural Properties

3.5. Specific Mechanical Properties

4. Discussion

4.1. Influence of Fiber Architecture on Stiffness and Strength

4.2. Compressive Behavior and Microbuckling Resistance

4.3. Flexural Response and Combined Loading Effects

4.4. Process-Controlled Comparison and Implications of FVC Differences

4.5. Density-Normalized Performance and Lightweight Potential

4.6. Implications for Design and Industrial Application

4.7. Future Research Directions

- Alternative manufacturing processes—Future work should explore other processing routes, such as Resin Transfer Molding (RTM), which offers the potential to increase fiber volume content by enabling higher compaction pressures and improved resin flow control compared to VARI. Higher fiber volume contents are expected to directly improve stiffness and, in some cases, strength.

- Impregnation quality assessment—Detailed studies on the quality of resin impregnation are required to ensure uniform fiber wet-out, especially in the more complex architecture of sliver-based NCFs. Special attention should be given to quantifying void content through optical microscopy or micro-computed tomography. The measured porosity should be included in the calculation of composite density to provide more accurate density-normalized mechanical property values.

- Interface optimization—The fiber–matrix interface remains a key factor limiting strength in flax composites. Future research should investigate surface modification methods, such as silane coupling agents, plasma treatment, or enzymatic processing, to improve adhesion and stress transfer between flax fibers and the matrix. Such improvements could help translate the stiffness gains achieved through optimized fiber alignment in sliver-based NCFs into corresponding strength gains.

- Durability and aging studies—Long-term performance under realistic service conditions must be evaluated. This includes testing under cyclic loading, elevated humidity, temperature fluctuations, and UV exposure. These studies will help define suitable application environments and inform protective measures such as coatings or barrier layers.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rajak, D.K.; Pagar, D.D.; Menezes, P.L.; Linul, E. Fiber-Reinforced Polymer Composites: Manufacturing, Properties, and Applications. Polymers 2019, 11, 1667. [Google Scholar] [CrossRef]

- Summerscales, J.; Dissanayake, N.P.J.; Virk, A.S.; Hall, W. A review of bast fibres and their composites. Part 1—Fibres as reinforcements. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1329–1335. [Google Scholar] [CrossRef]

- Pickering, K.L.; Efendy, M.G.A.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef]

- Koronis, G.; Silva, A.; Fontul, M. Green composites: A review of adequate materials for automotive applications. Compos. Part B Eng. 2013, 44, 120–127. [Google Scholar] [CrossRef]

- Dittenber, D.B.; GangaRao, H.V.S. Critical review of recent publications on use of natural composites in infrastructure. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1419–1429. [Google Scholar] [CrossRef]

- Elfaleh, I.; Abbassi, F.; Habibi, M.; Ahmad, F.; Guedri, M.; Nasri, M.; Garner, C. A comprehensive review of natural fibers and their composites: An eco-friendly alternative to conventional materials. Results Eng. 2023, 19, 101271. [Google Scholar] [CrossRef]

- Rayyaan, R.; Kennon, W.R.; Potluri, P.; Akonda, M. Fibre architecture modification to improve the tensile properties of flax-reinforced composites. J. Compos. Mater. 2019, 54, 379–395. [Google Scholar] [CrossRef]

- Goutianos, S.; Peijs, T.; Nystrom, B.; Skrifvars, M. Development of Flax Fibre based Textile Reinforcements for Composite Applications. Appl. Compos. Mater. 2006, 13, 199–215. [Google Scholar] [CrossRef]

- Aisyah, H.A.; Paridah, M.T.; Sapuan, S.M.; Ilyas, R.A.; Khalina, A.; Nurazzi, N.M.; Lee, S.H.; Lee, C.H. A Comprehensive Review on Advanced Sustainable Woven Natural Fibre Polymer Composites. Polymers 2021, 13, 471. [Google Scholar] [CrossRef]

- Shah, D.U. Developing plant fibre composites for structural applications by optimising composite parameters: A critical review. J. Mater. Sci. 2013, 48, 6083–6107. [Google Scholar] [CrossRef]

- Suriani, M.J.; Rapi, H.Z.; Ilyas, R.A.; Petrů, M.; Sapuan, S.M. Delamination and manufacturing defects in natural fiber-reinforced hybrid composite: A review. Polymers 2021, 13, 1323. [Google Scholar] [CrossRef] [PubMed]

- Dalfi, H. Influence of Fibre Architectures on the Mechanical Properties and Damage Failures of Composite Laminates. J. Fail. Anal. Prev. 2024, 24, 1906–1915. [Google Scholar] [CrossRef]

- Blanchard, J.M.F.A.; Sobey, A.J. Comparative design of E-glass and flax structures based on reliability. Compos. Struct. 2019, 225, 111037. [Google Scholar] [CrossRef]

- Uthemann, C. Flax Non-Crimp Fabrics with Improved Fibre Orientation for Sustainable Lightweight Composite Structures. Ph.D. Dissertation, RWTH Aachen University, Aachen, Germany, 2024. [Google Scholar] [CrossRef]

- Fonck, E.; Feigl, G.G.; Fasel, J.; Sage, D.; Unser, M.; Rüfenacht, D.; Stergiopulos, N. Effect of aging on elastin functionality in human cerebral arteries. Stroke 2009, 40, 2552–2556. [Google Scholar] [CrossRef] [PubMed]

- Püspöki, Z.; Storath, M.; Sage, D.; Unser, M. Transforms and Operators for Directional Bioimage Analysis: A Survey; Springer: Cham, Switzerland, 2016; pp. 69–93. [Google Scholar] [CrossRef]

- Schneider, C.; Rasband, W.; Eliceiri, K. NIH Image to ImageJ: 25 years of image analysis. Nat. Methods 2012, 9, 671–675. [Google Scholar] [CrossRef]

- Rezakhaniha, R.; Agianniotis, A.; Schrauwen, J.T.; Griffa, A.; Sage, D.; Bouten, C.V.; van de Vosse, F.N.; Unser, M.; Stergiopulos, N. Experimental investigation of collagen waviness and orientation in the arterial adventitia using confocal laser scanning microscopy. Biomech. Model. Mechanobiol. 2012, 11, 461–473. [Google Scholar] [CrossRef]

- Sunny, T.; Joseph, K.; Joseph, S.; Joseph, K.; Oksman, K. Fibre Orientation Distribution Assessment of Dynamically Sheet Formed Hemp Fibre Mats by Image Analysis. Appl. Mech. Mater. 2018, 884, 23–28. [Google Scholar] [CrossRef]

- Sietins, J.M.; Sun, J.C.; Knorr, D.B. Fiber Orientation Quantification Utilizing X-ray Micro-Computed Tomography. J. Compos. Mater. 2021, 55, 2747–2759. [Google Scholar] [CrossRef]

- Huling, J.; Götz, A.; Grabow, N.; Illner, S. GIFT: An ImageJ macro for automated fiber diameter quantification. PLoS ONE 2022, 17, e0275528. [Google Scholar] [CrossRef]

- Clemons, T.D.; Bradshaw, M.; Toshniwal, P.; Chaudhari, N.; Stevenson, A.W.; Lynch, J.; Fear, M.W.; Wood, F.M.; Iyer, K.S. Coherency Image Analysis to Quantify Collagen Architecture: Implications in Scar Assessment. RSC Adv. 2018, 8, 9661–9669. [Google Scholar] [CrossRef]

- Marcotti, S.; de Freitas, D.B.; Trouphton, L.D.; Kenny, F.N.; Shaw, T.J.; Stramer, B.M.; Oakes, P.W. A Workflow for Rapid Unbiased Quantification of Fibrillar Feature Alignment in Biological Images. Front. Comput. Sci. 2021, 3, e745831. [Google Scholar] [CrossRef] [PubMed]

- DIN EN ISO 527-4; Plastics—Determination of Tensile Properties—Part 4: Test Conditions for Isotropic and Orthotropic Fibre-Reinforced Plastic Composites. Beuth: Berlin, Germany, 1997.

- DIN EN ISO 14126; Fibre-Reinforced Plastic Composites—Determination of Compressive Properties in the In-Plane Direction. Beuth: Berlin, Germany, 2000.

- DIN EN ISO 14125; Fibre-Reinforced Plastic Composites—Determination of Flexural Properties. Beuth: Berlin, Germany, 1995.

- Ueki, Y.; Lilholt, H.; Madsen, B. Experimental evaluation of stiffness predictions of multiaxial flax fibre composites by classical laminate theory. PLoS ONE 2020, 15, e0234701. [Google Scholar] [CrossRef] [PubMed]

- Yan, L.; Chouw, N.; Jayaraman, K. Flax Fibre and Its Composites—A Review. Compos. Part B Eng. 2014, 56, 296–317. [Google Scholar] [CrossRef]

- Bos, H.L.; van den Oever, M.J.A.; Peters, O.C.J.J. Tensile and compressive properties of flax fibres for natural fibre reinforced composites. J. Mater. Sci. 2002, 37, 1683–1692. [Google Scholar] [CrossRef]

- Zhu, J.; Zhu, H.; Njuguna, J.; Abhyankar, H. Recent Development of Flax Fibres and Their Reinforced Composites Based on Different Polymeric Matrices. Materials 2013, 6, 5171–5198. [Google Scholar] [CrossRef]

| Property | Roving-Based Glass NCF | Yarn-Based Flax NCF | Sliver-Based Flax NCF |

|---|---|---|---|

| Reinforcing Fiber | E-glass, ~2.6 g/cm3 | Flax, ~1.4 g/cm3 | Flax, ~1.4 g/cm3 |

| Fiber form | Roving, 300 tex | Yarn, 105 tex | Sliver, 5,000 tex |

| Stitching yarn | text. PES, 76 dtex | text. PES, 76 dtex | text. PES, 76 dtex |

| Stitching pattern | Fringe | Fringe | Fringe |

| Layer configuration | +45°/−45° | +45°/−45° | +45°/−45° |

| Total areal weight | 606 g/m2 | 350 g/m2 | 395 g/m2 |

| Product name | HP-B600E | ampliTex 5008 | - |

| Producer/ distributor | HP-Textiles GmbH, Schapen, Germany | Bcomp Ltd., Fribourg, Switzerland | ITA of RWTH, Aachen, Germany |

| Module | Function |

|---|---|

| Sliver feeding unit | Continuous, twist-free delivery of flax slivers from a rotating can |

| False-twist unit | Temporary twisting of the slivers for consolidation during feeding |

| Weft carrier | Placement of slivers at ±45° angles onto a supporting polyester grid |

| Stitching unit | Fixation of the layers using polyester stitching yarns |

| Winding unit | Winding of the finished NCF onto rolls |

| Material | Sample Thickness (mm) | Sample Width (mm) | Sample Length (mm) | Support Span (mm) |

|---|---|---|---|---|

| Roving-based glass NCF | 1.85 | 15.00 | 55.50 | 37.00 |

| Yarn-based flax NCF | 2.98 | 15.00 | 89.40 | 59.60 |

| Sliver-based flax NCF | 3.55 | 15.00 | 106.50 | 71.00 |

| Material | Average Local Fiber Orientation (°) | Average Absolute Deviation from 45° (°) |

|---|---|---|

| Roving-based glass NCF | 44.27 ± 2.06 | 1.43 ± 1.64 |

| Sliver-based flax NCF | 43.29 ± 2.36 | 2.05 ± 2.05 |

| Yarn-based flax NCF | 46.45 ± 0.86 | 1.45 ± 0.86 |

| Material | Tensile Strength (MPa) | Tensile Modulus (GPa) |

|---|---|---|

| Roving-based glass NCF | 527.38 ± 13.59 | 25.61 ± 2.77 |

| Sliver-based flax NCF | 126.47 ± 3.61 | 10.46 ± 0.37 |

| Yarn-based flax NCF | 118.87 ± 6.30 | 8.26 ± 0.05 |

| Material | Compr. Strength (MPa) | Compr. Modulus (GPa) |

|---|---|---|

| Roving-based glass NCF | 437.62 ± 26.31 | 26.98 ± 2.21 |

| Sliver-based flax NCF | 89.64 ± 3.27 | 9.76 ± 0.68 |

| Yarn-based flax NCF | 89.24 ± 1.87 | 8.62 ± 0.51 |

| Material | Flexural Strength (MPa) | Flexural Modulus (GPa) |

|---|---|---|

| Roving-based glass NCF | 640.30 ± 7.19 | 13.31 ± 1.40 |

| Sliver-based flax NCF | 148.59 ± 12.01 | 6.58 ± 1.38 |

| Yarn-based flax NCF | 144.19 ± 3.46 | 5.35 ± 0.30 |

| Property | Roving-Based Glass NCF | Yarn-Based Flax NCF | Sliver-Based Flax NCF |

|---|---|---|---|

| FVC (Vol.-%) | 50.03 | 31.33 | 31.20 |

| Fiber density (g/cm3) | ~2.60 | ~1.40 | ~1.40 |

| Matrix density (g/cm3) | ~1.15 | ~1.15 | ~1.15 |

| Composite density (g/cm3) | 1.88 | 1.23 | 1.23 |

| Material | Spec. Tensile Strength (MPa·cm3/g) | Spec. Tensile Modulus (GPa·cm3/g) | Spec. Compr. Strength (MPa·cm3/g) | Spec. Compr. Modulus (GPa·cm3/g) | Spec. Flexural Strength (MPa·cm3/g) | Spec. Flexural Modulus (GPa·cm3/g) |

|---|---|---|---|---|---|---|

| Roving-based glass NCF | 281.20 ± 7.25 | 13.66 ± 0.32 | 233.34 ± 14.03 | 14.39 ± 1.18 | 341.41 ± 3.83 | 7.10 ± 0.75 |

| Sliver-based flax NCF | 102.99 ± 2.94 | 8.52 ± 0.30 | 73.00 ± 2.66 | 7.95 ± 0.55 | 121.00 ± 9.78 | 5.36 ± 1.12 |

| Yarn-based flax NCF | 96.77 ± 5.13 | 6.73 ± 0.04 | 72.65 ± 1.52 | 7.02 ± 0.42 | 117.38 ± 2.82 | 4.36 ± 0.24 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Uthemann, C.; Gries, T. Comparative Study on the Mechanical Behavior of Flax and Glass Fiber Multiaxial Fabric-Reinforced Epoxy Composites. Materials 2025, 18, 4469. https://doi.org/10.3390/ma18194469

Uthemann C, Gries T. Comparative Study on the Mechanical Behavior of Flax and Glass Fiber Multiaxial Fabric-Reinforced Epoxy Composites. Materials. 2025; 18(19):4469. https://doi.org/10.3390/ma18194469

Chicago/Turabian StyleUthemann, Carsten, and Thomas Gries. 2025. "Comparative Study on the Mechanical Behavior of Flax and Glass Fiber Multiaxial Fabric-Reinforced Epoxy Composites" Materials 18, no. 19: 4469. https://doi.org/10.3390/ma18194469

APA StyleUthemann, C., & Gries, T. (2025). Comparative Study on the Mechanical Behavior of Flax and Glass Fiber Multiaxial Fabric-Reinforced Epoxy Composites. Materials, 18(19), 4469. https://doi.org/10.3390/ma18194469