Optimization of Process Parameters for Laser Cladding of AlCoCrFeNi High-Entropy Alloy Coating Based on the Taguchi-Grey Relational Analysis

Abstract

1. Introduction

2. Materials and Methods

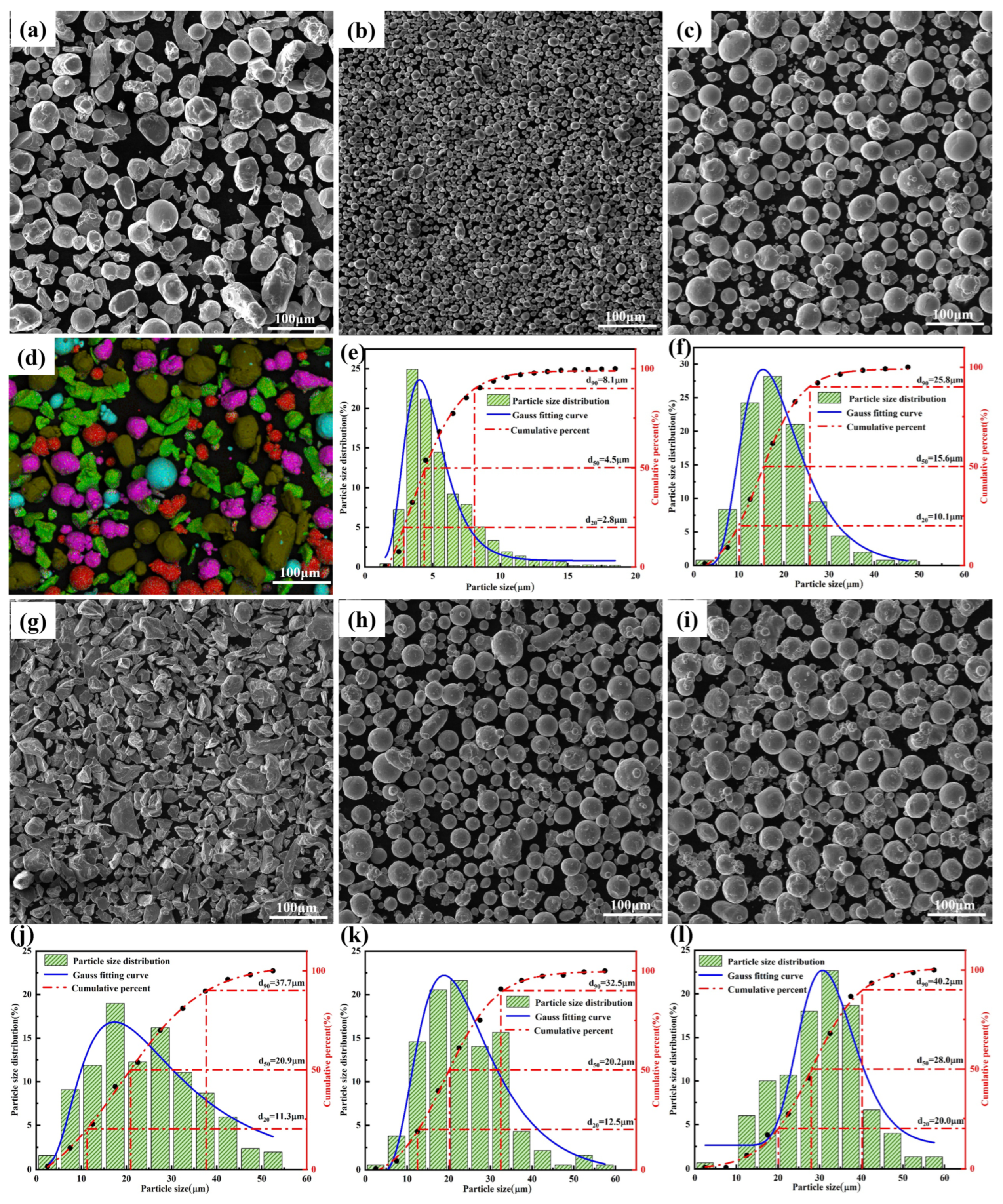

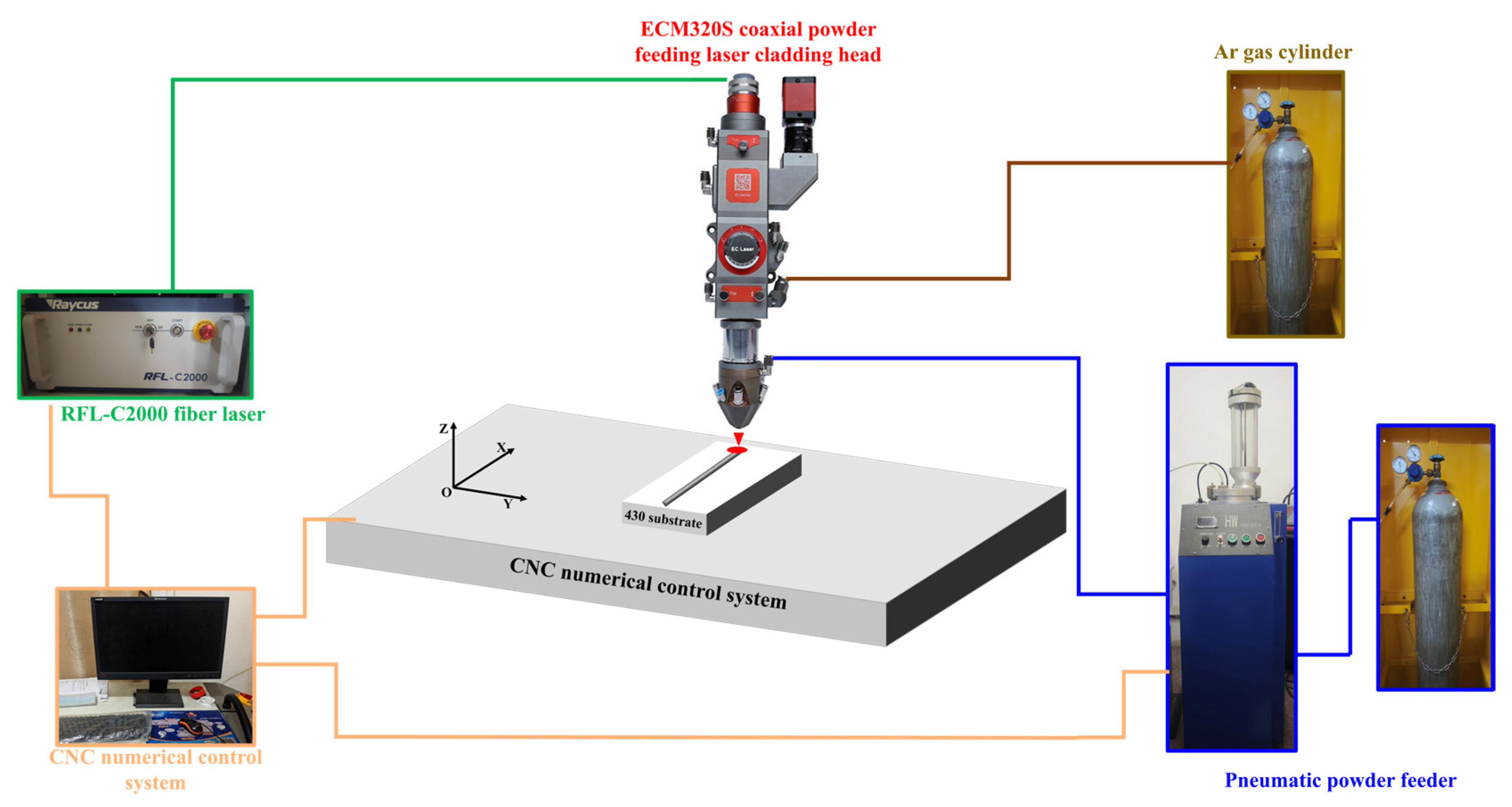

2.1. Experimental Materials and Equipment

2.2. Experimental Design

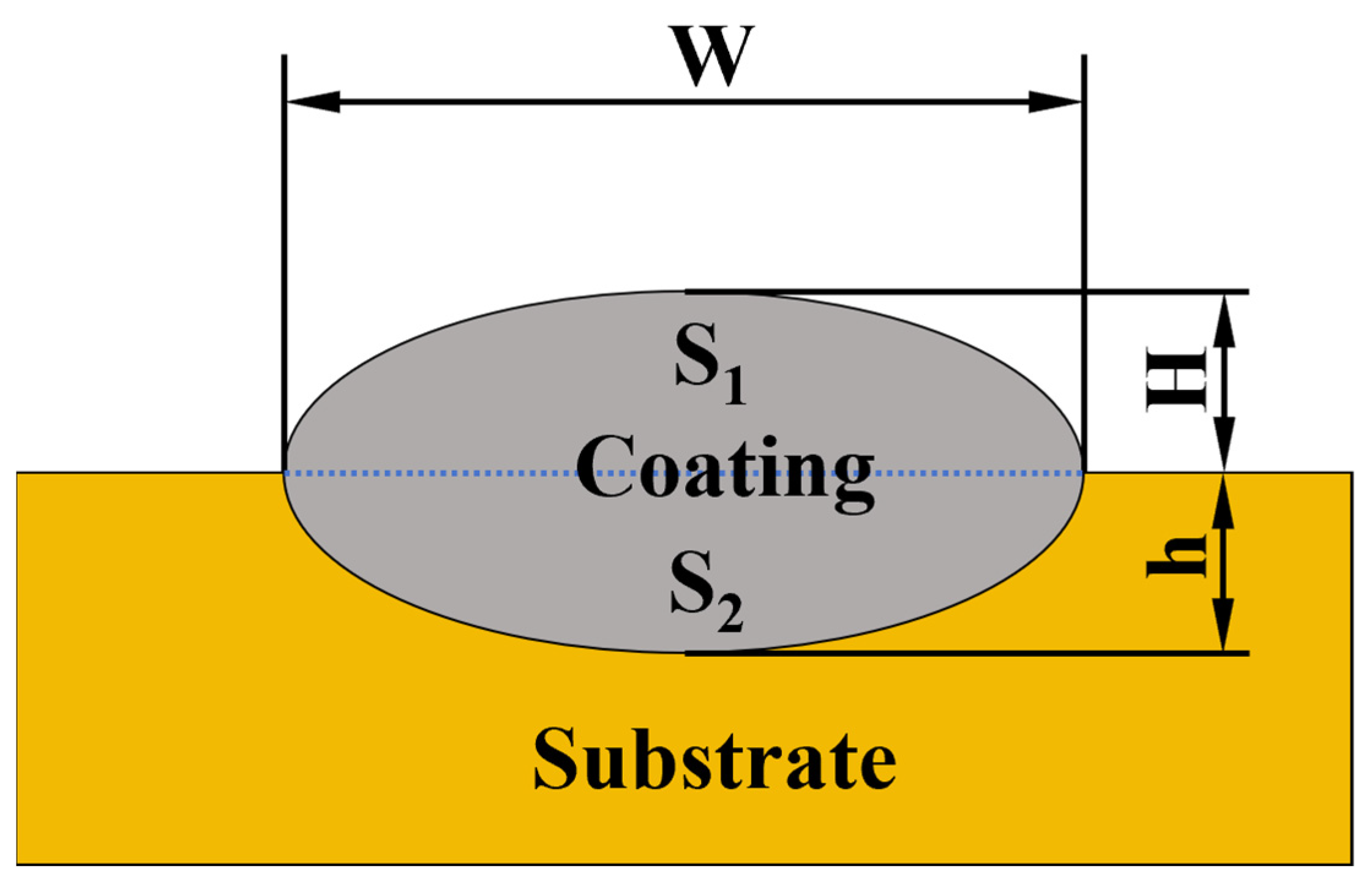

2.3. Sample Characterization and Performance Analysis

3. Results

3.1. Empirical Statistical Models

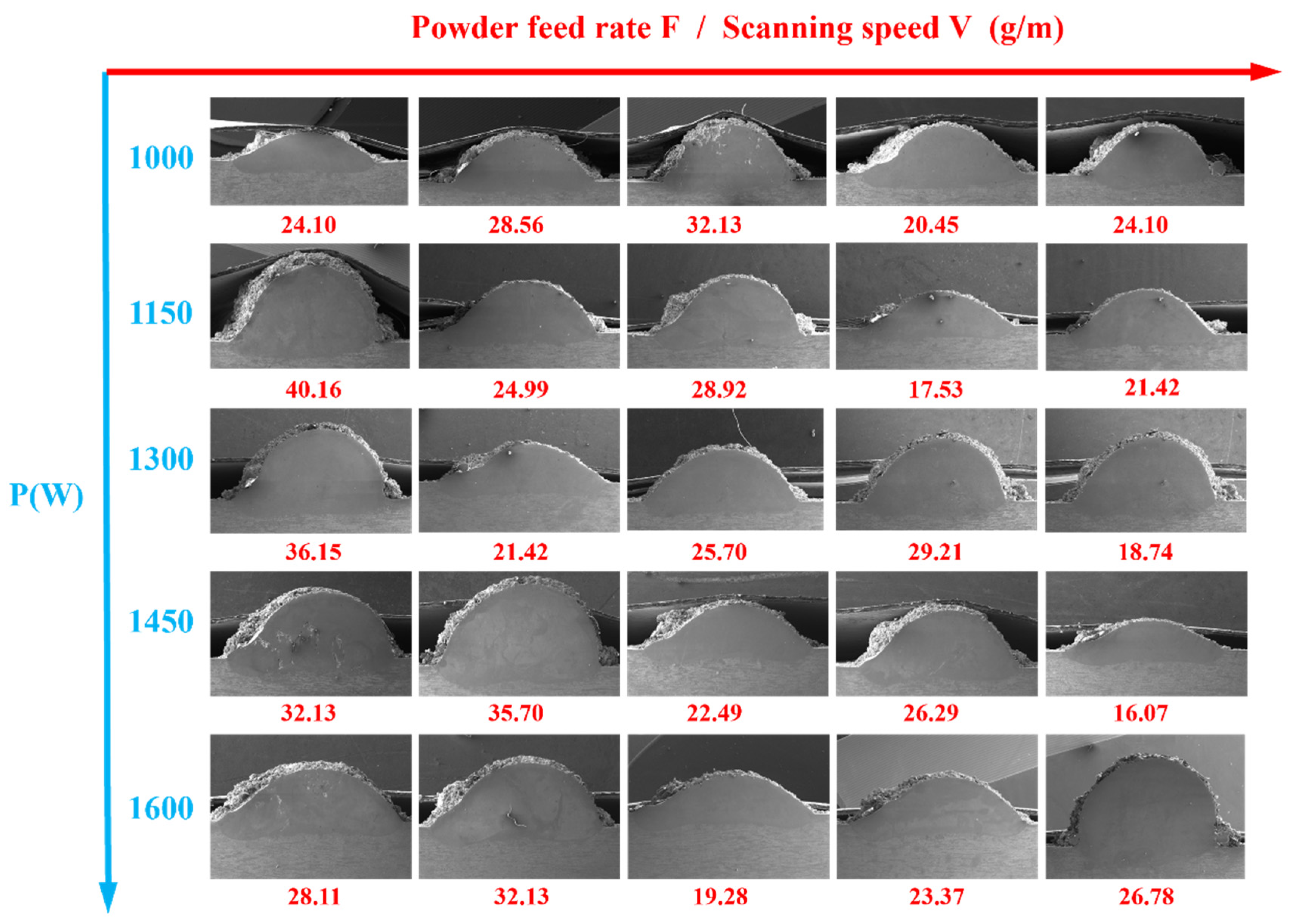

3.1.1. Trajectory Morphology

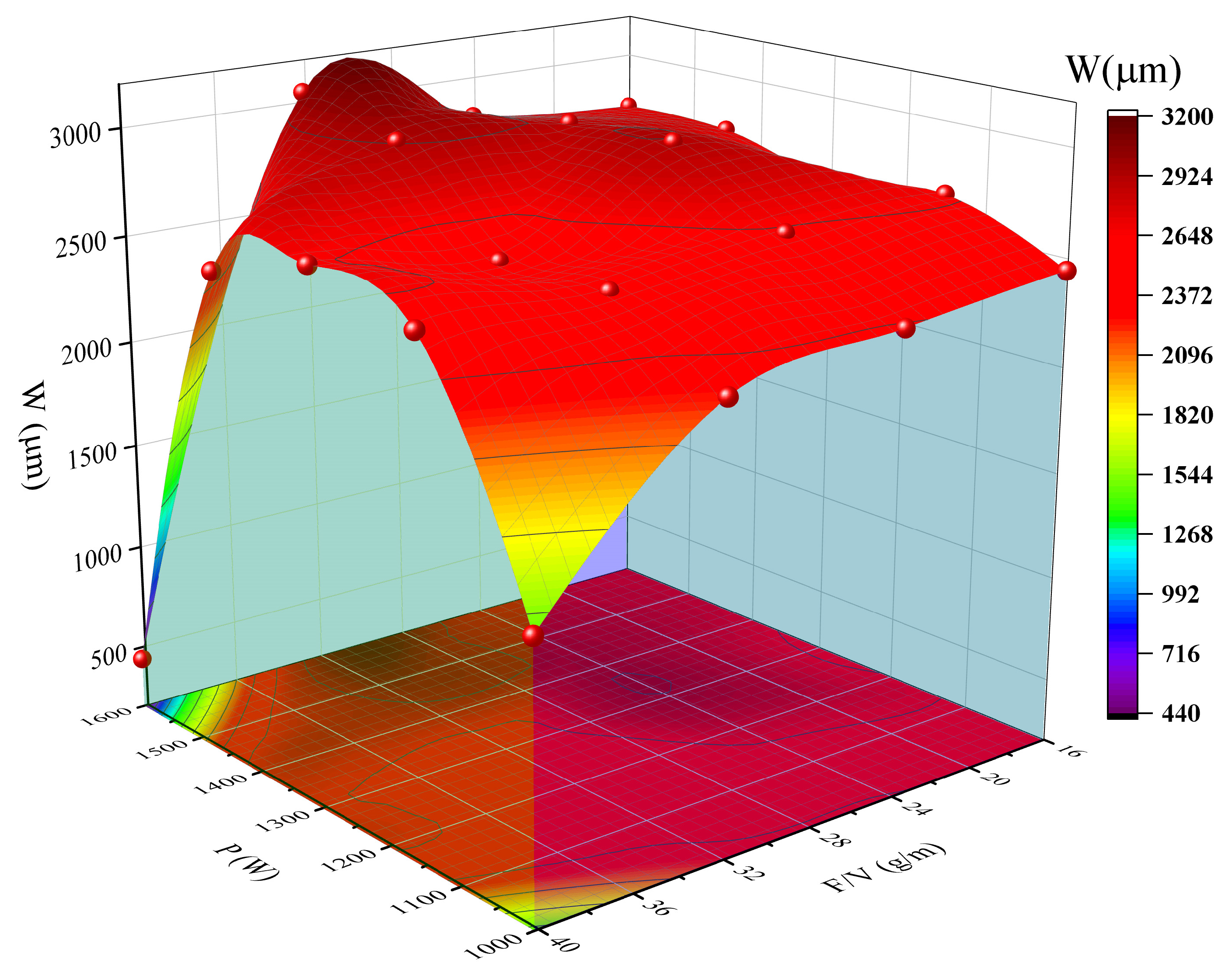

3.1.2. Clad Width

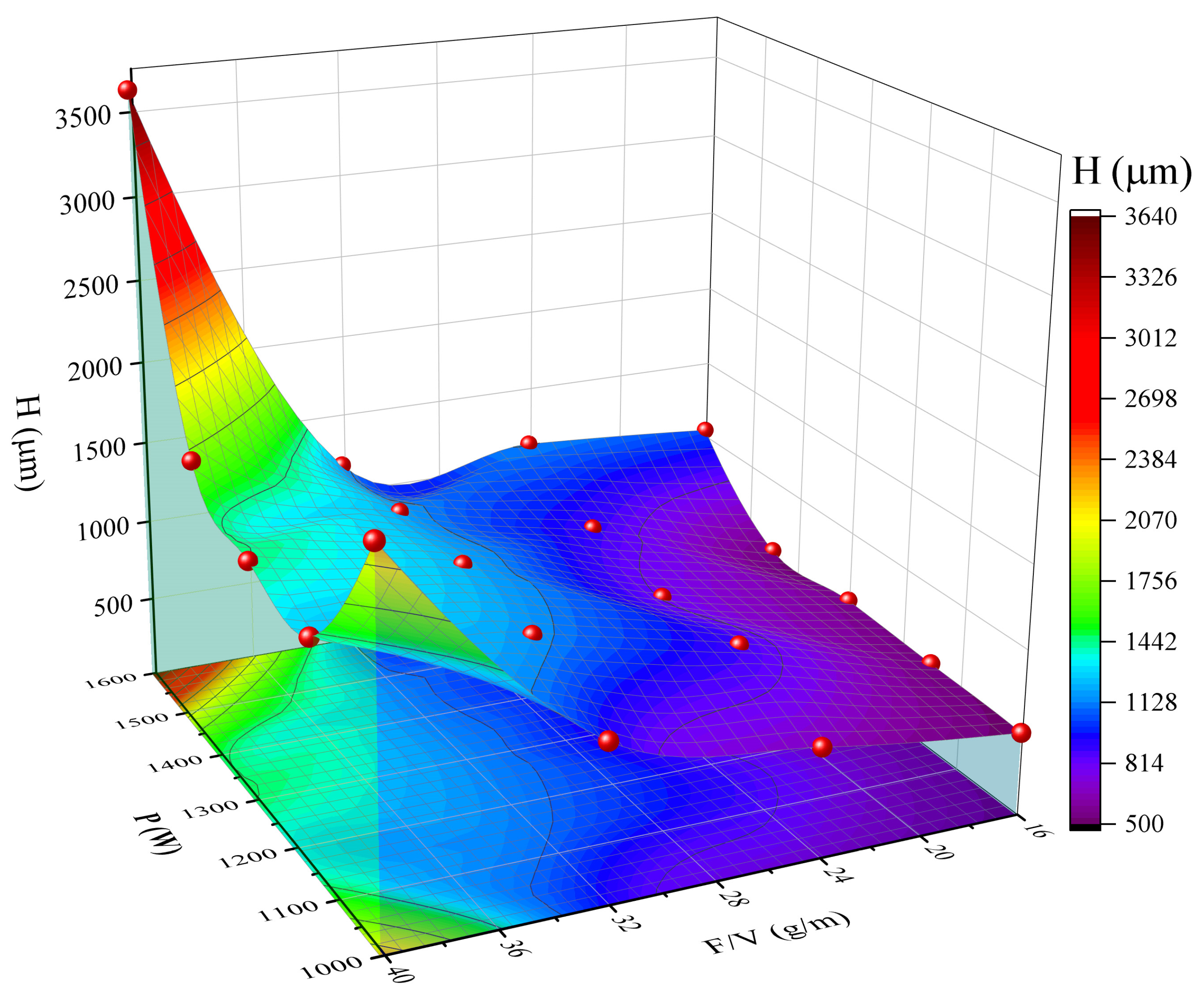

3.1.3. Clad Height

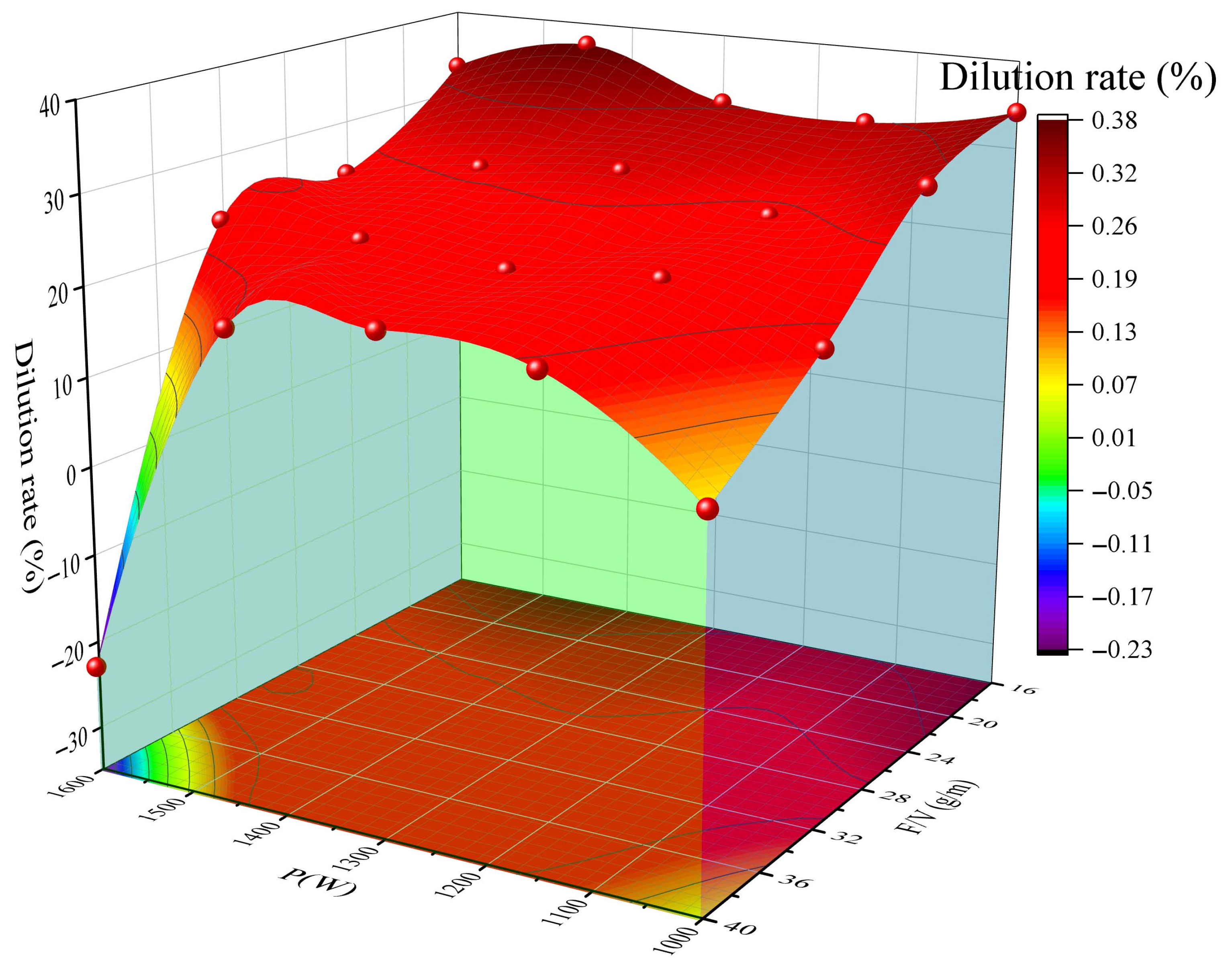

3.1.4. Dilution Rate

3.1.5. Element Deviation

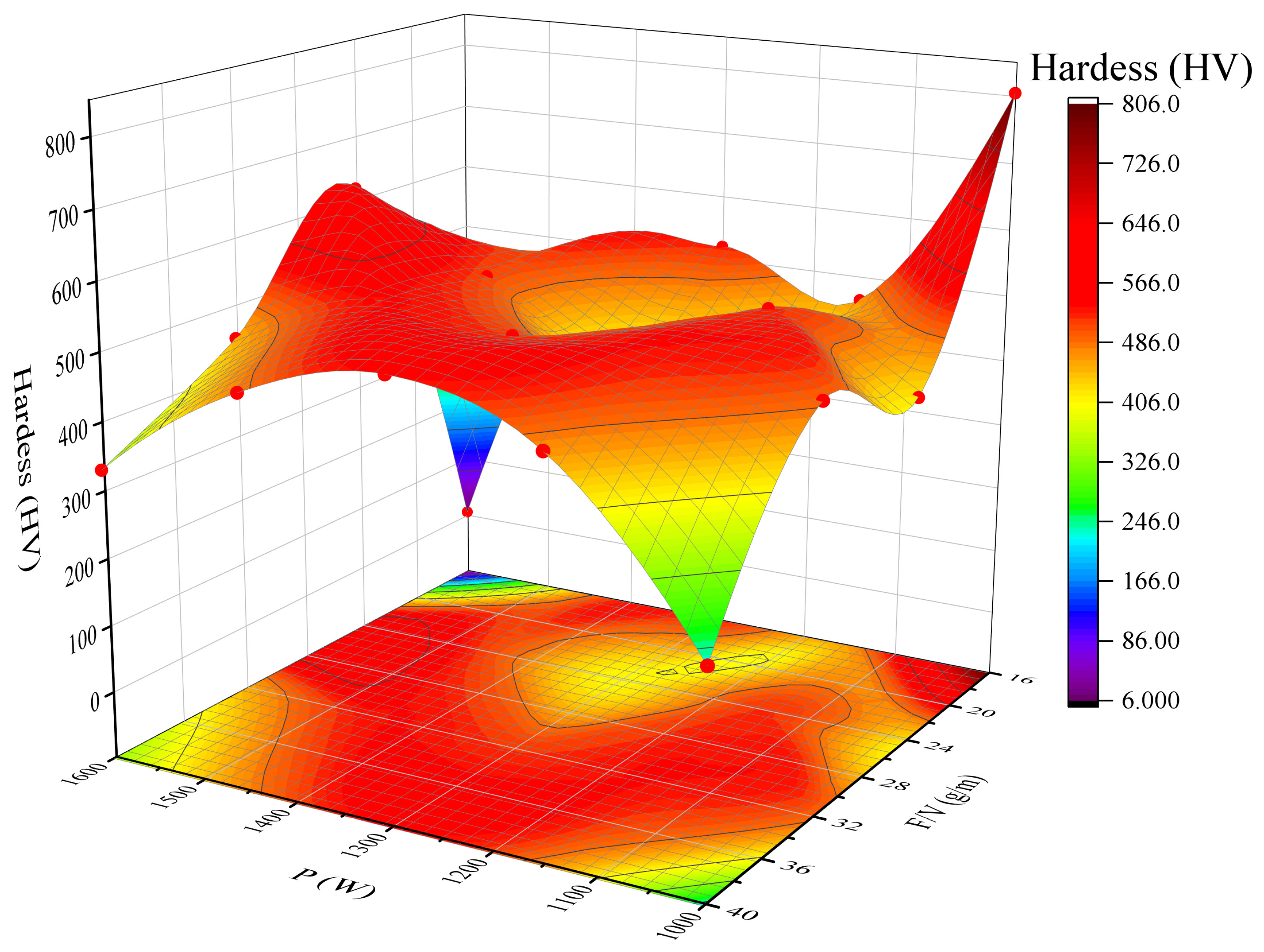

3.1.6. Hardness

3.2. Signal-to-Noise Ratio Analysis and Variance Analysis of Taguchi Method

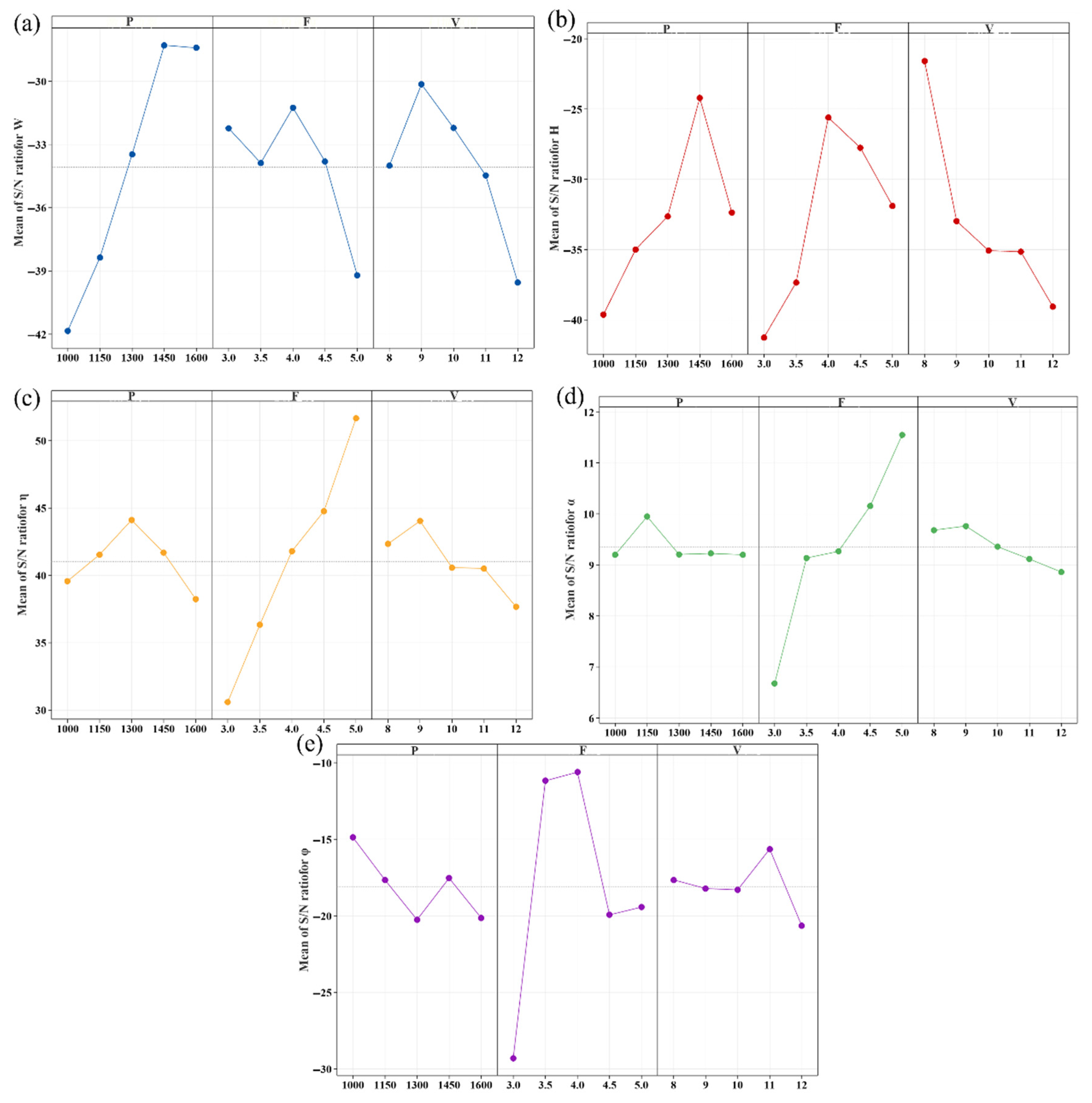

3.2.1. Signal-to-Noise Ratio Analysis

3.2.2. Analysis of Variance

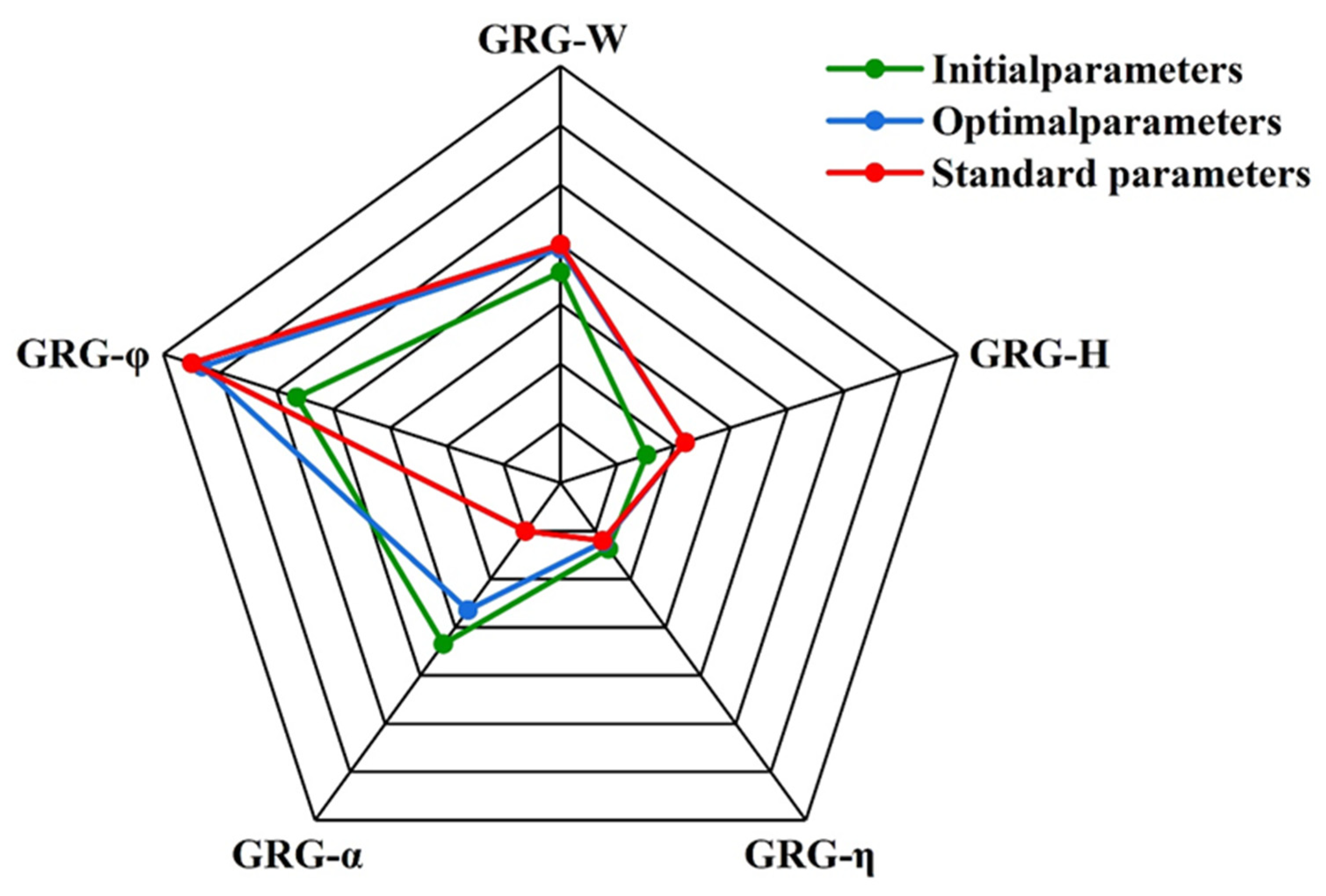

3.3. Multi-Objective Optimization Based on GRA

4. Conclusions

- (1)

- Based on Taguchi orthogonal design and GRA, this study systematically reveals the influence of laser power, scanning speed, and powder feeding rate on the geometric formation, elemental segregation, and mechanical properties of AlCoCrFeNi HEA coatings. Notably, laser power exerts the most significant effect on the width of the cladding layer, while the powder feeding rate predominantly influences the height, dilution rate, elemental deviation rate, and hardness.

- (2)

- The Taguchi signal-to-noise ratio and variance analysis indicate that the cladding width is predominantly influenced by laser power, which accounts for a contribution rate of up to 67.1%. In contrast, the coating height, dilution rate, element deviation rate, and hardness are primarily influenced by the powder feed rate, with contributions exceeding 70%. These findings underscore the critical regulatory role of the powder deposition process in determining the overall performance of the cladding layer.

- (3)

- Through multi-objective optimization combined with grey relational analysis, the optimal process parameter combination P4F4V1 was identified, consisting of a laser power of 1450 W, a powder feed rate of 4 r/min, and a scanning speed of 480 mm/min. Verification experiments demonstrated that this combination exhibited superior performance in terms of coating build quality, elemental uniformity, and microhardness. Compared to the initial parameters, significant improvements were observed in the dilution rate and elemental segregation issues, resulting in an approximate 15% increase in hardness.

- (4)

- This study not only validates the effectiveness of the Taguchi-Grey Relational Analysis for optimizing complex multi-index problems but also offers a reliable methodology for the process design of HEA laser cladding coatings. The findings provide technical support for surface strengthening and life extension of critical components, such as aerospace engine turbine discs, under extreme operating conditions. Furthermore, they hold significant implications for the application and promotion of HEA across aerospace and other industries.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Backman, D.G.; Williams, J.C. Advanced Materials for Aircraft Engine Applications. Science 1992, 255, 1082–1087. [Google Scholar] [CrossRef]

- Miller, S. Advanced materials mean advanced engines. Interdiscip. Sci. Rev. 1996, 21, 117–129. [Google Scholar] [CrossRef]

- Jafari, S.; Nikolaidis, T. Thermal Management Systems for Civil Aircraft Engines: Review, Challenges and Exploring the Future. Appl. Sci. 2018, 8, 2044. [Google Scholar] [CrossRef]

- Yan, J.J.; Yan, G.; Chen, H.Y.; Liu, Z.Y.; Yang, L.; Zhou, Y.C. Real-time detection of damage evolution and failure of EB-PVD thermal barrier coatings using an environmental simulator with high-temperature and high-speed rotation. Surf. Coat. Technol. 2022, 439, 128416. [Google Scholar] [CrossRef]

- Everitt, S. Developments in Advanced High Temperature Disc and Blade Materials for Aero-Engine Gas Turbine Applications. Ph.D. Thesis, University of Southampton, Southampton, UK, 2012. [Google Scholar]

- Alnaeli, M.; Alnajideen, M.; Navaratne, R.; Shi, H.; Czyzewski, P.; Wang, P.; Eckart, S.; Alsaegh, A.; Alnasif, A.; Mashruk, S.; et al. High-Temperature Materials for Complex Components in Ammonia/Hydrogen Gas Turbines: A Critical Review. Energies 2023, 16, 6973. [Google Scholar] [CrossRef]

- DeMasi-Marcin, J.T.; Gupta, D.K. Protective coatings in the gas turbine engine. Surf. Coat. Technol. 1994, 68–69, 1–9. [Google Scholar] [CrossRef]

- Peng, Z.; Han, A.; Wang, C.; Jin, H.; Zhang, X. Ultrasonic vibration cutting of advanced aerospace materials: A critical review of in-service functional performance. J. Intell. Manuf. Spec. Equip. 2024, 5, 137–169. [Google Scholar] [CrossRef]

- McLEAN, A.F.; Hartsock, D.L. 2—Design with Structural Ceramics Treatise on Materials Science & Technology Structural Ceramics; Wachtman, J.B., Ed.; Elsevier: Amsterdam, The Netherlands, 1989; Volume 29, pp. 27–97. [Google Scholar]

- Akande, I.G.; Oluwole, O.O.; Fayomi, O.S.I.; Odunlami, O.A. Overview of mechanical, microstructural, oxidation properties and high-temperature applications of superalloys. Mater. Today Proc. 2021, 43, 2222–2231. [Google Scholar] [CrossRef]

- Yuan, W.; Li, R.; Chen, Z.; Gu, J.; Tian, Y. A comparative study on microstructure and properties of traditional laser cladding and high-speed laser cladding of Ni45 alloy coatings. Surf. Coat. Technol. 2021, 405, 126582. [Google Scholar] [CrossRef]

- Wang, K.; Liu, W.; Hong, Y.; Sohan, H.M.S.; Tong, Y.; Hu, Y.; Zhang, M.; Zhang, J.; Xiang, D.; Fu, H.; et al. An Overview of Technological Parameter Optimization in the Case of Laser Cladding. Coatings 2023, 13, 496. [Google Scholar] [CrossRef]

- Prakash, O.; Chandrakar, R.L.M.; Verma, J.; Kumar, A.; Jaiswal, A. Laser cladding technology for high entropy alloys: Effect and applications. Mater. Res. Express 2024, 11, 096510. [Google Scholar] [CrossRef]

- Li, Y.; Zhou, S.; Zhang, Y. Future Research Directions and Applications for High-Entropy Materials. In High-Entropy Materials: Theory, Experiments, and Applications; Brechtl, J., Liaw, P.K., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 721–763. [Google Scholar]

- Wang, X.; Liu, Q.; Wang, X. High-Entropy Materials: From Bulk to Sub-nano. Adv. Funct. Mater. 2025, 35, 2504275. [Google Scholar] [CrossRef]

- Zhang, C.; Zhu, J.; Zheng, H.; Li, H.; Liu, S.; Cheng, G.J. A review on microstructures and properties of high entropy alloys manufactured by selective laser melting. Int. J. Extrem. Manuf. 2020, 2, 032003. [Google Scholar] [CrossRef]

- Brechtl, J.; Chen, S.; Lee, C.; Shi, Y.; Feng, R.; Xie, X.; Hamblin, D.; Coleman, A.M.; Straka, B.; Shortt, H.; et al. A Review of the Serrated-Flow Phenomenon and Its Role in the Deformation Behavior of High-Entropy Alloys. Metals 2020, 10, 1101. [Google Scholar] [CrossRef]

- Lin, C.; Yao, Y. Corrosion-Resistant Coating Based on High-Entropy Alloys. Metals 2023, 13, 205. [Google Scholar] [CrossRef]

- Yu, J.; Mu, R. Research Status of High Entropy Thermal Barrier Coatings: A Review. In Proceedings of the 2021 3rd International Conference on Artificial Intelligence and Advanced Manufacture (AIAM), Manchester, UK, 23–25 October 2021; pp. 47–52. [Google Scholar]

- Li, B.; Sun, J.; Li, X.; Zhao, J. Mechanical behavior of high-entropy intermetallic compounds and high-entropy ceramics. J. Mater. Chem. A 2024, 12, 27855–27891. [Google Scholar] [CrossRef]

- Lu, J.; Chen, Y.; Li, L.; Zhang, H.; Zhang, X.; Zhao, X. An in-situ oxide-dispersion-strengthened AlCoCrFeNiY high-entropy alloy composite coating prepared by AC-HVAF with superior oxidation and spallation resistance. Compos. Part B Eng. 2023, 265, 110933. [Google Scholar] [CrossRef]

- Liu, H.; Liu, J.; Chen, P.; Yang, H. Microstructure and high temperature wear behaviour of in-situ TiC reinforced AlCoCrFeNi-based high-entropy alloy composite coatings fabricated by laser cladding. Opt. Laser Technol. 2019, 118, 140–150. [Google Scholar] [CrossRef]

- Odabas, O.; Karaoglanli, A.C.; Ozgurluk, Y.; Binal, G. Evaluation of high temperature oxidation resistance of AlCoCrFeNiZr high-entropy alloy (HEA) coating system at 1000 °C and 1100 °C. Surf. Coat. Technol. 2025, 512, 132439. [Google Scholar] [CrossRef]

- Joseph, J.; Haghdadi, N.; Shamlaye, K.; Hodgson, P.; Barnett, M.; Fabijanic, D. The sliding wear behaviour of CoCrFeMnNi and AlxCoCrFeNi high entropy alloys at elevated temperatures. Wear 2019, 428, 32–44. [Google Scholar] [CrossRef]

- Zhang, L.; Ye, Q.; Ji, Y.; Wang, Y.; Yang, B. Hot corrosion resistance of AlCoCrFeNi2. 1 coatings at 900 °C. J. Mater. Res. Technol. 2025, 35, 3034–3044. [Google Scholar] [CrossRef]

- Komvopoulos, K.; Nagarathnam, K. Processing and Characterization of Laser-Cladded Coating Materials. J. Eng. Mater. Technol. 1990, 112, 131–143. [Google Scholar] [CrossRef]

- Wang, K.; Zhang, Z.; Xiang, D.; Ju, J. Research and Progress of Laser Cladding: Process, Materials and Applications. Coatings 2022, 12, 1382. [Google Scholar] [CrossRef]

- Xiao, W.; Liu, Y.; Huang, J.; Zou, S.; Ren, Z.; Liu, S.; Wang, Y. Process parameter optimization for laser directed energy deposition B4C/Al neutron absorbing material via Taguchi method. Opt. Laser Technol. 2025, 184, 112507. [Google Scholar] [CrossRef]

- Qasim, A.; Nisar, S.; Shah, A.; Khalid, M.S.; Sheikh, M.A. Optimization of process parameters for machining of AISI-1045 steel using Taguchi design and ANOVA. Simul. Model. Pract. Theory 2015, 59, 36–51. [Google Scholar] [CrossRef]

- Meng, F.; Yang, J. Process capability analysis of Taguchi index Cpm based on generalized p-value. Qual. Reliab. Eng. Int. 2023, 39, 2311–2329. [Google Scholar] [CrossRef]

- Kuo, Y.; Yang, T.; Huang, G.-W. The use of a grey-based Taguchi method for optimizing multi-response simulation problems. Eng. Optim. 2008, 40, 517–528. [Google Scholar]

- Al-Refaie, A. Grey-data envelopment analysis approach for solving the multi-response problem in the Taguchi method. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2010, 224, 147–158. [Google Scholar] [CrossRef]

- Li, N.; Chen, Y.-J.; Kong, D.-D. Multi-response optimization of Ti-6Al-4V turning operations using Taguchi-based grey relational analysis coupled with kernel principal component analysis. Adv. Manuf. 2019, 7, 142–154. [Google Scholar] [CrossRef]

- Lu, H.S.; Chang, C.K.; Hwang, N.C.; Chung, C.T. Grey relational analysis coupled with principal component analysis for optimization design of the cutting parameters in high-speed end milling. J. Mater. Process. Technol. 2009, 209, 3808–3817. [Google Scholar] [CrossRef]

| S. No. | Element | Make | Purity | Particle Size |

|---|---|---|---|---|

| 1 | Al | Changsha Tianjiu Metal Materials Co., Changsha, China | 99.9% | 45–106 μm |

| 2 | Co | Changsha Tianjiu Metal Materials Co., Changsha, China | 99.9% | 45–106 μm |

| 3 | Cr | Changsha Tianjiu Metal Materials Co., Changsha, China | 99.9% | 15–53 μm |

| 4 | Fe | Changsha Tianjiu Metal Materials Co., Changsha, China | 99.9% | 45–106 μm |

| 5 | Ni | Changsha Tianjiu Metal Materials Co., Changsha, China | 99.9% | 15–53 μm |

| C | Si | Mn | Ni | Cr | Fe |

|---|---|---|---|---|---|

| ≤0.12 | ≤0.75 | ≤1 | ≤0.6 | 16~18 | Bal. |

| Level | 1 | 2 | 3 | 4 | 5 |

| P/W | 1000 | 1150 | 1300 | 1450 | 1600 |

| V/mm·min−1 | 480 | 540 | 600 | 660 | 720 |

| F/r·min−1 | 3 | 3.5 | 4 | 4.5 | 5 |

| NO. | P (W) | V (mm/min) | F (r/min) | NO. | P (W) | V (mm/min) | F (r/min) |

|---|---|---|---|---|---|---|---|

| 1 | 1000 | 480 | 3 | 14 | 1300 | 660 | 5 |

| 2 | 1000 | 540 | 4 | 15 | 1300 | 720 | 3.5 |

| 3 | 1000 | 600 | 5 | 16 | 1450 | 480 | 4 |

| 4 | 1000 | 660 | 3.5 | 17 | 1450 | 540 | 5 |

| 5 | 1000 | 720 | 4.5 | 18 | 1450 | 600 | 3.5 |

| 6 | 1150 | 480 | 5 | 19 | 1450 | 660 | 4.5 |

| 7 | 1150 | 540 | 3.5 | 20 | 1450 | 720 | 3 |

| 8 | 1150 | 600 | 4.5 | 21 | 1600 | 480 | 3.5 |

| 9 | 1150 | 660 | 3 | 22 | 1600 | 540 | 4.5 |

| 10 | 1150 | 720 | 4 | 23 | 1600 | 600 | 3 |

| 11 | 1300 | 480 | 4.5 | 24 | 1600 | 660 | 4 |

| 12 | 1300 | 540 | 3 | 25 | 1600 | 720 | 5 |

| 13 | 1300 | 600 | 4 |

| No. | W (μm) | H (μm) | η (%) | α (%) | φ (HV) |

|---|---|---|---|---|---|

| 1 | 2539.11 | 518.05 | 36.96% | 234% | 365 |

| 2 | 2498.21 | 514.56 | 22.64% | 155% | 553 |

| 3 | 2246.01 | 947.48 | 17.69% | 142% | 492 |

| 4 | 2368.70 | 637.33 | 32.43% | 170% | 556 |

| 5 | 2177.84 | 817.97 | 23.11% | 179% | 475 |

| 6 | 2539.11 | 1370.10 | 18.77% | 118% | 469 |

| 7 | 2661.81 | 903.17 | 23.84% | 163% | 519 |

| 8 | 2597.05 | 1049.73 | 23.11% | 143% | 535 |

| 9 | 2600.46 | 616.88 | 30.71% | 214% | 483 |

| 10 | 2515.25 | 800.93 | 28.21% | 173% | 519 |

| 11 | 2702.71 | 1288.30 | 21.97% | 153% | 602 |

| 12 | 2941.28 | 681.64 | 34.84% | 222% | 254 |

| 13 | 2787.91 | 923.62 | 22.41% | 167% | 534 |

| 14 | 2532.29 | 1121.30 | 20.52% | 144% | 524 |

| 15 | 2580.01 | 746.40 | 27.99% | 192% | 495 |

| 16 | 2931.05 | 1199.69 | 22.55% | 164% | 532 |

| 17 | 2770.87 | 1414.40 | 20.77% | 135% | 514 |

| 18 | 2954.91 | 835.01 | 28.69% | 179% | 517 |

| 19 | 2808.36 | 978.15 | 23.99% | 153% | 499 |

| 20 | 2729.97 | 548.72 | 37.47% | 256% | 479 |

| 21 | 3227.57 | 954.30 | 27.79% | 171% | 544 |

| 22 | 3046.93 | 1175.83 | 22.65% | 151% | 451 |

| 23 | 3121.91 | 719.13 | 34.85% | 235% | 296 |

| 24 | 3057.16 | 865.68 | 28.39% | 206% | 597 |

| 25 | 2467.54 | 1605.26 | 16.65% | 125% | 600 |

| Cladding width (W) | Level | P | V | F |

| 1 | −41.85 | −34.00 | −32.23 | |

| 2 | −38.36 | −30.14 | −33.88 | |

| 3 | −33.47 | −32.22 | −31.25 | |

| 4 | −28.29 | −34.47 | −33.81 | |

| 5 | −28.41 | −39.55 | −39.21 | |

| Delta | 13.56 | 9.41 | 7.96 | |

| Sorting | 1 | 2 | 3 | |

| Cladding height (H) | Level | P | V | F |

| 1 | −39.64 | −21.59 | −41.26 | |

| 2 | −35.01 | −32.97 | −37.35 | |

| 3 | −32.64 | −35.08 | −25.60 | |

| 4 | −24.20 | −35.15 | −27.76 | |

| 5 | −32.37 | −39.07 | −31.89 | |

| Delta | 15.44 | 17.48 | 15.66 | |

| Sorting | 3 | 2 | 1 | |

| Dilution rate (η) | Level | P | V | F |

| 1 | 39.57 | 42.34 | 30.60 | |

| 2 | 41.54 | 44.04 | 36.33 | |

| 3 | 44.11 | 40.58 | 41.79 | |

| 4 | 41.69 | 40.52 | 44.77 | |

| 5 | 38.24 | 37.67 | 51.66 | |

| Delta | 5.87 | 6.37 | 21.06 | |

| Sorting | 3 | 2 | 1 | |

| Element Deviation (α) | Level | P | V | F |

| 1 | 9.19 | 9.68 | 6.67 | |

| 2 | 9.94 | 9.76 | 9.13 | |

| 3 | 9.20 | 9.35 | 9.26 | |

| 4 | 9.22 | 9.11 | 10.15 | |

| 5 | 9.20 | 8.86 | 11.54 | |

| Delta | 0.74 | 0.90 | 4.87 | |

| Sorting | 3 | 2 | 1 | |

| Hardness (φ) | Level | P | V | F |

| 1 | −14.88 | −17.65 | −29.30 | |

| 2 | −17.65 | −18.22 | −11.18 | |

| 3 | −20.25 | −18.30 | −10.62 | |

| 4 | −17.54 | −15.64 | −19.93 | |

| 5 | −20.14 | −20.65 | −19.43 | |

| Delta | 5.38 | 5.01 | 18.68 | |

| Sorting | 2 | 3 | 1 |

| Response Target | Level | Laser Power (A) | Scan Speed (B) | Powder Feed Rate (C) | Deviation | Total |

|---|---|---|---|---|---|---|

| Cladding width (W) | Degrees of freedom | 4 | 4 | 4 | 12 | 24 |

| Adj SS | 1,127,204 | 297,505 | 254,904 | 59,926 | 1,739,539 | |

| Adj MS | 281,801 | 74,376 | 63,726 | 4994 | ||

| F-number | 56.43 | 14.89 | 12.76 | |||

| p-value | 0.000 | 0.000 | 0.000 | |||

| Contribution rate (%) | 67.1 | 17.7 | 15.2 | |||

| Cladding height (H) | Degrees of freedom | 4 | 4 | 4 | 12 | 24 |

| Adj SS | 410,255 | 139,541 | 1,321,199 | 183,347 | 2,054,342 | |

| Adj MS | 102,564 | 34,885 | 330,300 | 15,279 | ||

| F-number | 6.71 | 2.28 | 21.62 | |||

| p-value | 0.004 | 0.120 | 0.000 | |||

| Contribution rate (%) | 21.9 | 7.5 | 70.6 | |||

| Dilution rate (η) | Degrees of freedom | 4 | 4 | 4 | 12 | 24 |

| Adj SS | 0.001071 | 0.001805 | 0.073138 | 0.009176 | 0.085190 | |

| Adj MS | 0.000268 | 0.000451 | 0.018285 | 0.000765 | ||

| F-number | 0.35 | 0.59 | 23.91 | |||

| p-value | 0.839 | 0.676 | 0.000 | |||

| Contribution rate (%) | 1.4 | 2.4 | 96.2 | |||

| Element deviation rate (α) | Degrees of freedom | 4 | 4 | 4 | 12 | 24 |

| Adj SS | 0.08527 | 0.12483 | 2.72517 | 0.21841 | 3.15368 | |

| Adj MS | 0.02132 | 0.03121 | 0.68129 | 0.01820 | ||

| F-number | 1.17 | 1.71 | 37.43 | |||

| p-value | 0.372 | 0.211 | 0.000 | |||

| Contribution rate (%) | 2.9 | 4.3 | 92.8 | |||

| Hardness (φ) | Degrees of freedom | 4 | 4 | 4 | 12 | 24 |

| Adj SS | 2501 | 17,447 | 94,238 | 53,182 | 167,367 | |

| Adj MS | 625.3 | 4361.6 | 23,559.5 | 4431.8 | ||

| F-number | 0.14 | 0.98 | 5.32 | |||

| p-value | 0.964 | 0.452 | 0.011 | |||

| Contribution rate (%) | 2.2 | 15.3 | 82.5 |

| Serial Number | Grey Relational Coefficient | Grey Relational Degree | |||||

|---|---|---|---|---|---|---|---|

| W | H | η | α | φ | Digital | Sorting | |

| 1 | 0.199871 | 0.166759 | 0.167866 | 0.184298 | 0.182566 | 0.180271888 | 25 |

| 2 | 0.194188 | 0.166667 | 0.302078 | 0.365285 | 1 | 0.405643592 | 5 |

| 3 | 0.170913 | 0.186857 | 0.320448 | 0.456337 | 0.2388862 | 0.274688269 | 16 |

| 4 | 0.18034 | 0.170304 | 0.18132 | 0.297478 | 0.6099888 | 0.287886168 | 13 |

| 5 | 0.166667 | 0.177921 | 0.282405 | 0.271582 | 0.2235406 | 0.224423068 | 20 |

| 6 | 0.199871 | 0.196265 | 0.450788 | 1 | 0.219368 | 0.413258282 | 4 |

| 7 | 0.223707 | 0.183263 | 0.260181 | 0.326363 | 0.2863394 | 0.25597062 | 18 |

| 8 | 0.209562 | 0.199414 | 0.282106 | 0.442867 | 0.3725587 | 0.301301646 | 11 |

| 9 | 0.210206 | 0.169634 | 0.188547 | 0.207304 | 0.2299539 | 0.201129065 | 23 |

| 10 | 0.196457 | 0.177029 | 0.20303 | 0.288141 | 0.2874218 | 0.230415781 | 19 |

| 11 | 0.235397 | 0.214156 | 0.345705 | 0.3767 | 0.2464071 | 0.283673074 | 14 |

| 12 | 0.687349 | 0.171862 | 0.173399 | 0.196966 | 0.1666667 | 0.279248601 | 15 |

| 13 | 0.272735 | 0.184833 | 0.314634 | 0.308534 | 0.3641535 | 0.288977808 | 12 |

| 14 | 0.198865 | 0.217639 | 1 | 0.441112 | 0.3029431 | 0.432111891 | 2 |

| 15 | 0.206475 | 0.17446 | 0.204647 | 0.242015 | 0.2420661 | 0.213932776 | 22 |

| 16 | 0.57755 | 1 | 0.306987 | 0.320678 | 0.3488185 | 0.510806663 | 1 |

| 17 | 0.263182 | 0.190642 | 0.644903 | 0.541307 | 0.2737748 | 0.382761688 | 7 |

| 18 | 1 | 0.178864 | 0.199809 | 0.27245 | 0.2829375 | 0.386812055 | 6 |

| 19 | 0.286374 | 0.189839 | 0.256581 | 0.374614 | 0.2478661 | 0.271054908 | 17 |

| 20 | 0.244948 | 0.167594 | 0.166667 | 0.166667 | 0.2273288 | 0.194640689 | 24 |

| 21 | 0.264 | 0.18748 | 0.206177 | 0.293766 | 0.6244996 | 0.315184516 | 9 |

| 22 | 0.199871 | 0.166759 | 0.167866 | 0.184298 | 0.182566 | 0.180271888 | 25 |

| 23 | 0.194188 | 0.166667 | 0.302078 | 0.365285 | 1 | 0.405643592 | 5 |

| 24 | 0.170913 | 0.186857 | 0.320448 | 0.456337 | 0.2388862 | 0.274688269 | 16 |

| 25 | 0.18034 | 0.170304 | 0.18132 | 0.297478 | 0.6099888 | 0.287886168 | 13 |

| Level | P | V | F |

|---|---|---|---|

| 1 | 0.2746 | 0.3406 | 0.2139 |

| 2 | 0.2804 | 0.3485 | 0.2920 |

| 3 | 0.2996 | 0.2932 | 0.3497 |

| 4 | 0.3492 | 0.3010 | 0.2999 |

| 5 | 0.3171 | 0.2375 | 0.3654 |

| Delta | 0.0746 | 0.1110 | 0.1515 |

| Sorting | 3 | 2 | 1 |

| Compare Projects | Initial Parameters | Optimal Parameters | Target |

|---|---|---|---|

| Parameter combination | P1F1V1 | P4F4V1 | |

| W (mm) | 2.539 | 2.931 | Looking |

| H (mm) | 0.518 | 1.200 | Looking |

| η (%) | 36.96% | 22.55 | Looking |

| α (%) | 234% | 164% | Hope |

| φ (HV) | 365 | 532 | Looking |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, A.; Liu, Y.; Liu, J.; Yang, S.; Huang, J. Optimization of Process Parameters for Laser Cladding of AlCoCrFeNi High-Entropy Alloy Coating Based on the Taguchi-Grey Relational Analysis. Materials 2025, 18, 4463. https://doi.org/10.3390/ma18194463

Huang A, Liu Y, Liu J, Yang S, Huang J. Optimization of Process Parameters for Laser Cladding of AlCoCrFeNi High-Entropy Alloy Coating Based on the Taguchi-Grey Relational Analysis. Materials. 2025; 18(19):4463. https://doi.org/10.3390/ma18194463

Chicago/Turabian StyleHuang, Andi, Yilong Liu, Jingang Liu, Shiping Yang, and Jinghao Huang. 2025. "Optimization of Process Parameters for Laser Cladding of AlCoCrFeNi High-Entropy Alloy Coating Based on the Taguchi-Grey Relational Analysis" Materials 18, no. 19: 4463. https://doi.org/10.3390/ma18194463

APA StyleHuang, A., Liu, Y., Liu, J., Yang, S., & Huang, J. (2025). Optimization of Process Parameters for Laser Cladding of AlCoCrFeNi High-Entropy Alloy Coating Based on the Taguchi-Grey Relational Analysis. Materials, 18(19), 4463. https://doi.org/10.3390/ma18194463