Study on the Wear Behavior Mechanism of SUS304 Stainless Steel During the Homogenization Process of LFP/NCM Slurry

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Materials

2.2. Experimental Methods

3. Results and Discussion

3.1. LFP/NCM Slurry Analysis

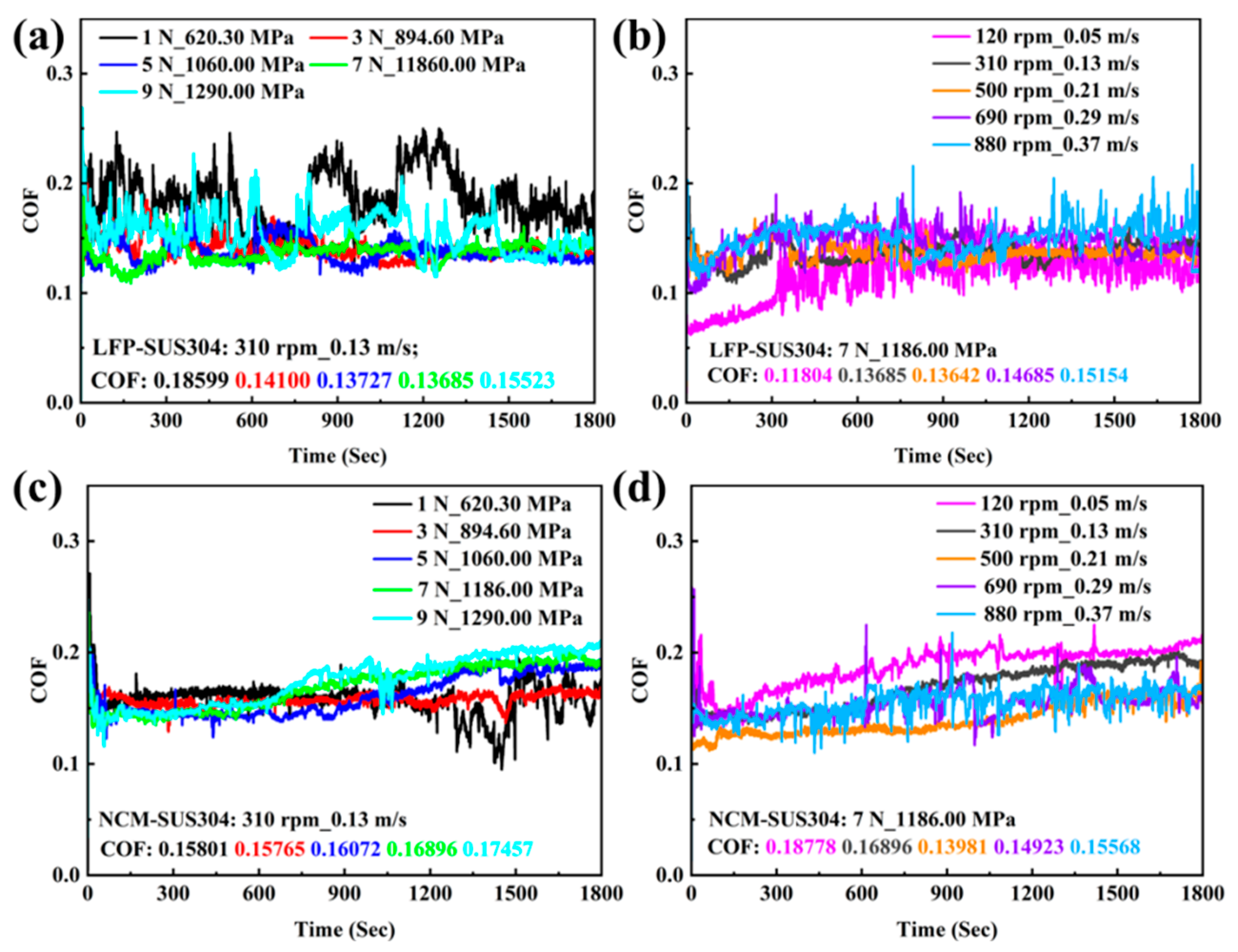

3.2. Tribological Properties of LFP/NCM Slurry Under Different Working Conditions

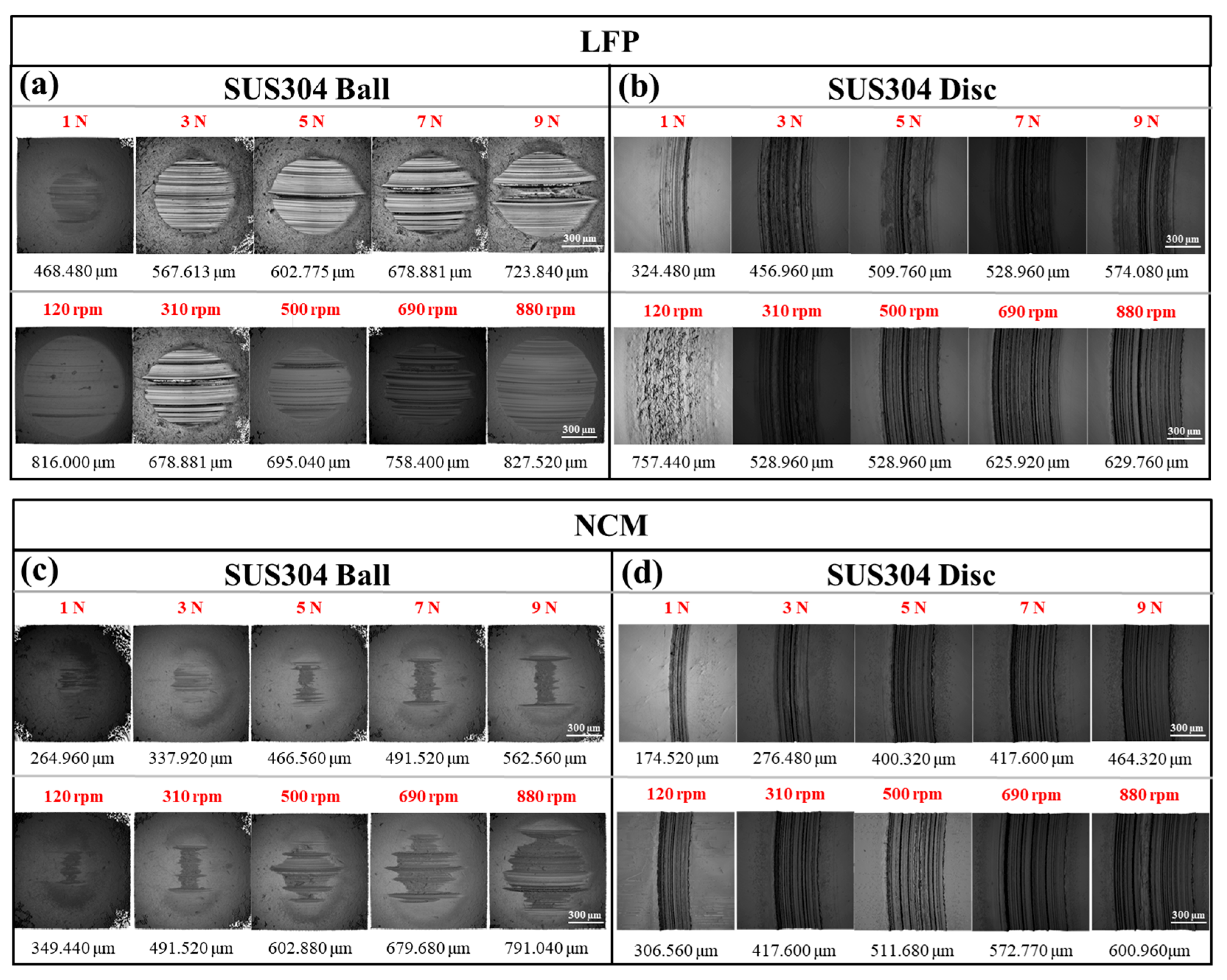

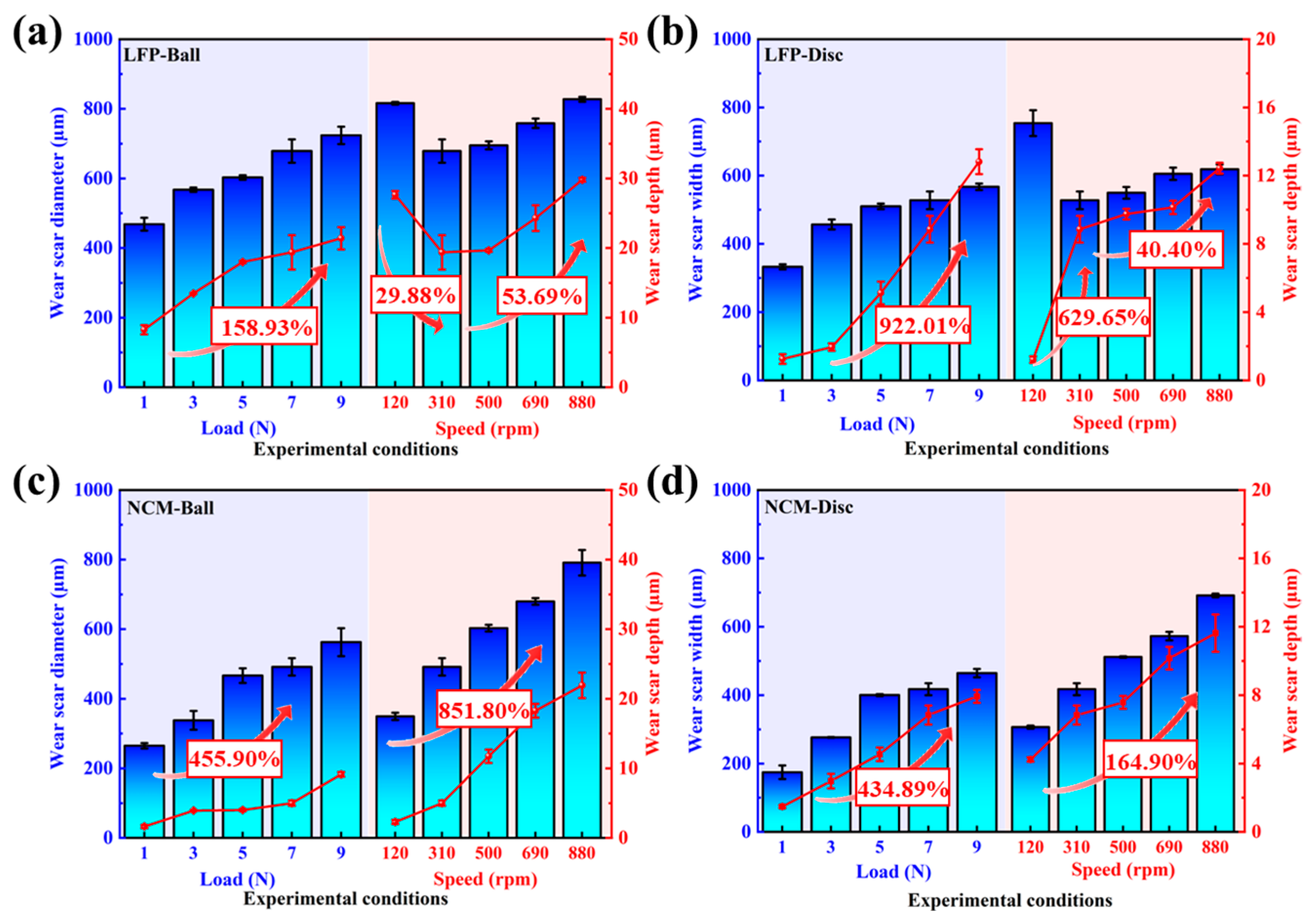

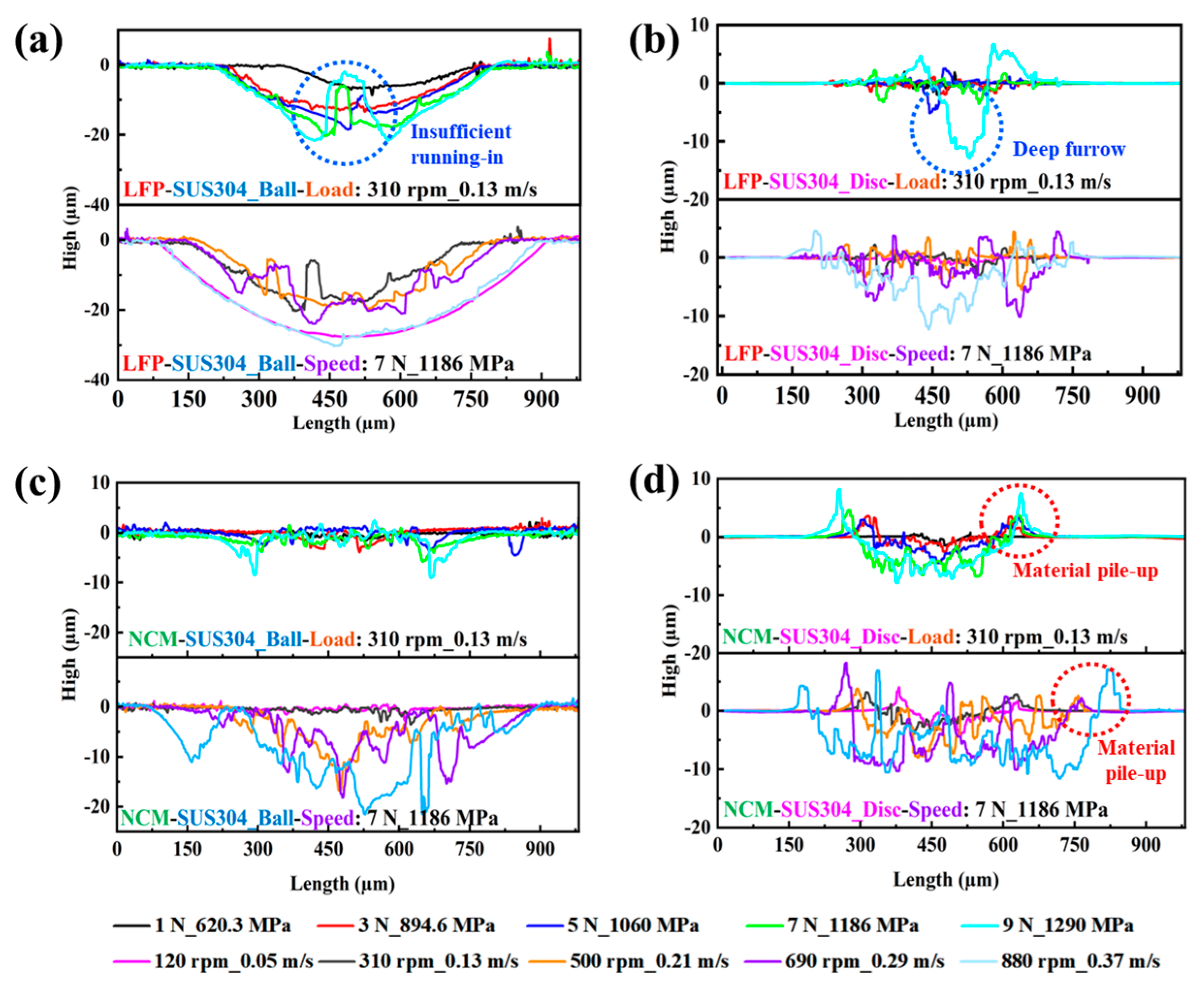

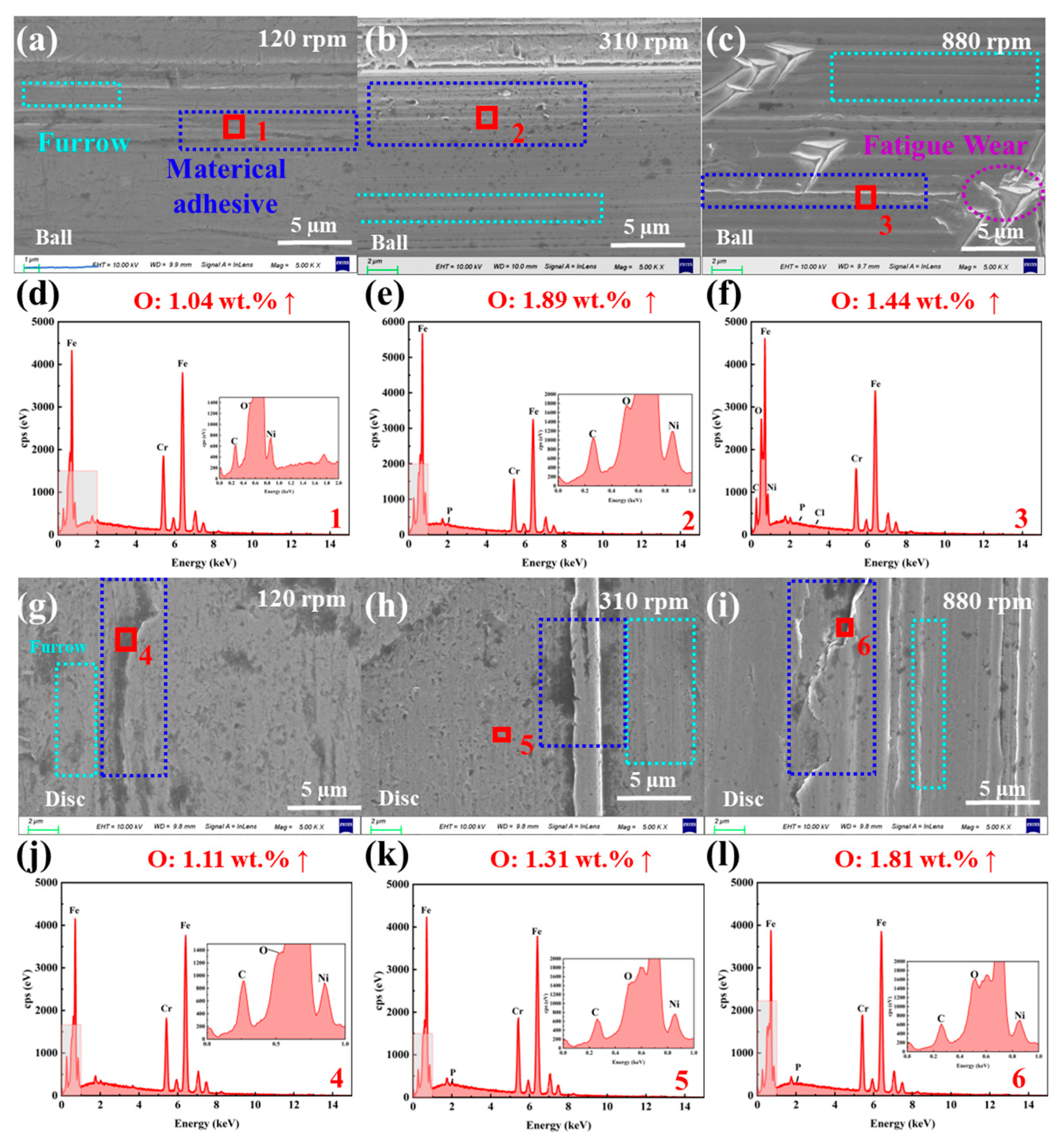

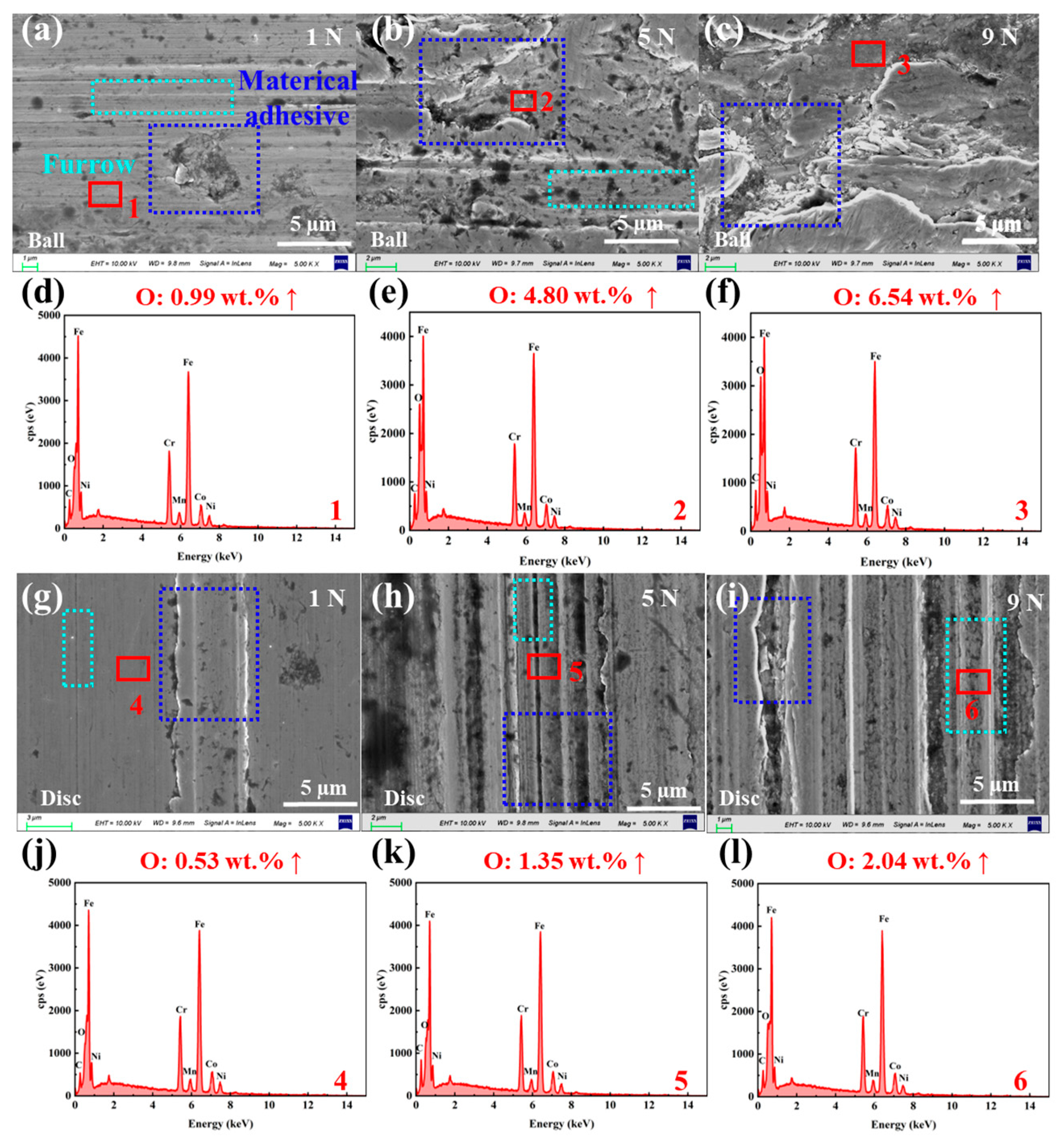

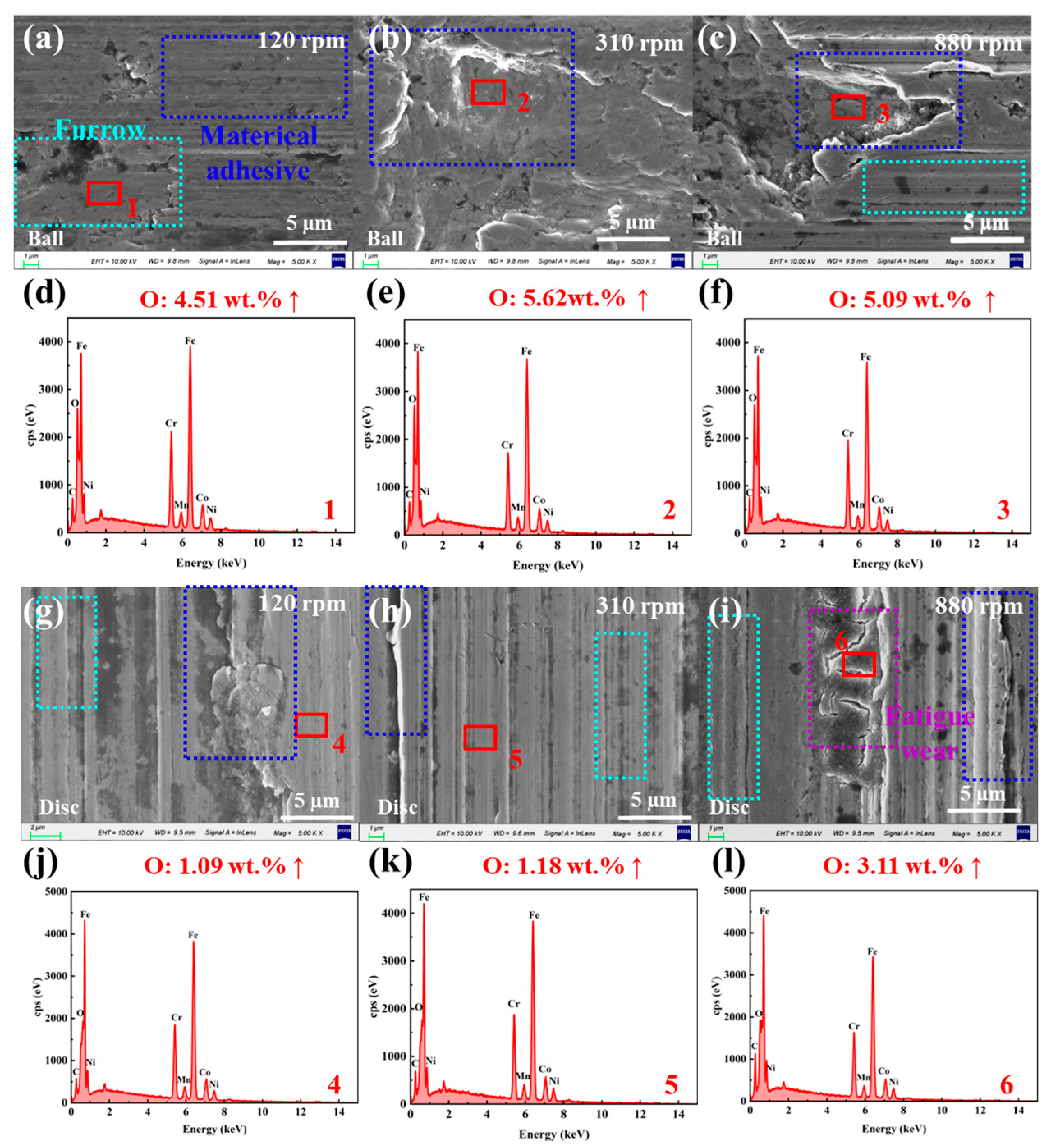

3.3. Micromorphology and Composition Analysis of Wear Area

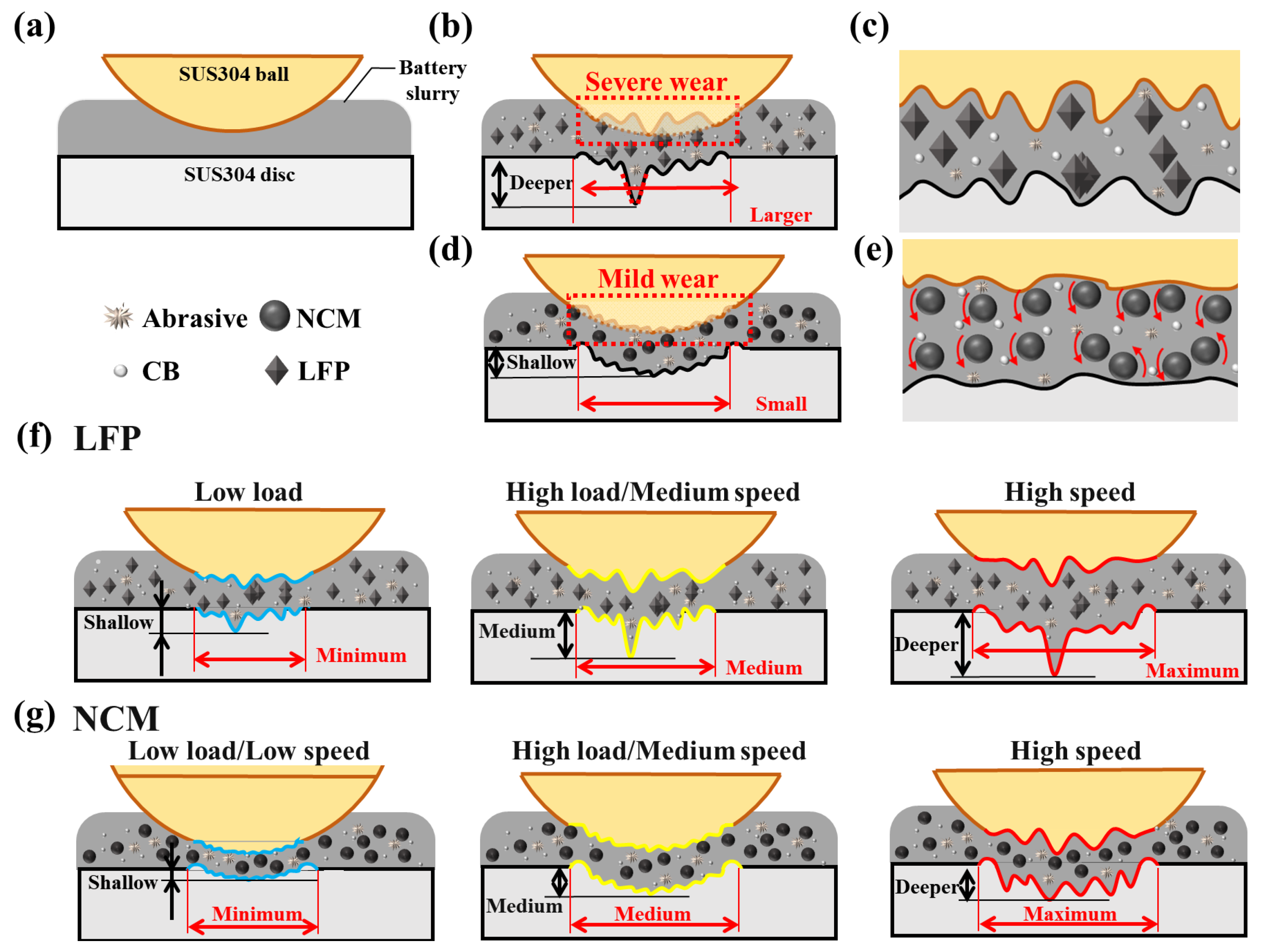

3.4. Analysis of Wear Mechanism

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Manthiram, A. An outlook on lithium ion battery technology. ACS Cent. Sci. 2017, 3, 1063–1069. [Google Scholar] [CrossRef]

- Chang, X.; Zhao, Y.M.; Yuan, B.; Fan, M.; Meng, Q.; Guo, Y.G.; Wan, L.J. Solid-state lithium-ion batteries for grid energy storage: Opportunities and challenges. Sci. China Chem. 2023, 1–24. [Google Scholar] [CrossRef]

- Chang, Y.H.; Hsieh, Y.C.; Chai, Y.H.; Lin, H.W. Remaining-Useful-Life Prediction for Li-Ion Batteries. Energies 2023, 16, 3096. [Google Scholar] [CrossRef]

- R-Smith, N.A.Z.; Moertelmaier, M.; Gramse, G.; Kasper, M.; Ragulskis, M.; Groebmeyer, A.; Jurjovec, M.; Brorein, E.; Zollo, B.; Kienberger, F. Fast method for calibrated self-discharge measurement of lithium-ion batteries including temperature effects and comparison to modelling. Energy Rep. 2023, 10, 3394–3401. [Google Scholar] [CrossRef]

- Gou, Q.; Li, C.; Zhong, W.; Zhang, X.; Dong, Q.; Lei, C. Hierarchical structured porous N-doped carbon coating MnO microspheres with enhanced electrochemical performances as anode materials for lithium-ion batteries. Electrochim. Acta 2019, 296, 730–737. [Google Scholar] [CrossRef]

- Lu, Y.; Zhao, C.Z.; Yuan, H.; Hu, J.K.; Huang, J.Q.; Zhang, Q. Dry electrode technology, the rising star in solid-state battery industrialization. Matter 2022, 5, 876–898. [Google Scholar] [CrossRef]

- Chen, Y.P.; Chen, X.; Yao, N.; Zheng, Z.; Yu, L.; Gao, Y.C.; Zhu, H.B.; Wang, C.L.; Yao, J.H.; Zhang, Q. A molecular review on weakly solvating electrolytes for lithium batteries. Mater. Today 2025, 85, 304–318. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, J.; Heringa, J.R.; Bai, X.; Wagemaker, M. High-entropy electrolytes for lithium-ion batteries. ACS Energy Lett. 2024, 9, 3796–3806. [Google Scholar] [CrossRef]

- Konda, K.; Moodakare, S.B.; Kumar, P.L.; Battabyal, M.; Seth, J.R.; Juvekar, V.A.; Gopalan, R. Comprehensive effort on electrode slurry preparation for better electrochemical performance of LiFePO4 battery. J. Power Sources 2020, 480, 228837. [Google Scholar] [CrossRef]

- Pomerantseva, E.; Bonaccorso, F.; Feng, X.; Cui, Y.; Gogotsi, Y. Energy storage: The future enabled by nanomaterials. Science 2019, 366, eaan8285. [Google Scholar] [CrossRef]

- Chen, X.; Tian, Y. Review of graphene in cathode materials for lithium-ion batteries. Energy Fuels 2021, 35, 3572–3580. [Google Scholar] [CrossRef]

- Lara, C.; Maril, M.; Tobosque, P.; Núñez, J.; Pizarro, L.; Carrasco, C. Comprehensive analysis of improved LiFePO4 kinetics: Understanding barriers to fast charging. J. Power Sources 2025, 640, 236747. [Google Scholar] [CrossRef]

- Duan, Y.; Chen, S.P.; Zhang, L.; Guo, L.; Shi, F.N. Review on oxygen release mechanism and modification strategy of nickel-rich NCM cathode materials for lithium-ion batteries: Recent advances and future directions. Energy Fuels 2024, 38, 5607–5631. [Google Scholar] [CrossRef]

- Shen, X.; Zhang, X.Q.; Ding, F.; Huang, J.Q.; Xu, R.; Chen, X.; Yan, C.; Su, F.Y.; Chen, C.M.; Liu, X.; et al. Advanced electrode materials in lithium batteries: Retrospect and prospect. Energy Mater. Adv. 2021, 2021, 1205324. [Google Scholar] [CrossRef]

- Tao, R.; Gu, Y.; Du, Z.; Lyu, X.; Li, J. Advanced electrode processing for lithium-ion battery manufacturing. Nat. Rev. Clean Technol. 2025, 1, 116–131. [Google Scholar] [CrossRef]

- Qu, L.; He, Y.; Fu, Y.; Xie, W.; Ye, C.; Lu, Q.; Li, J.; Li, J.; Pang, Z. Enhancement of leaching of cobalt and lithium from spent lithium-ion batteries by mechanochemical process. Trans. Nonferrous Met. Soc. China 2022, 32, 1325–1335. [Google Scholar] [CrossRef]

- Huber, K.; Adam, A.; Grießl, D.; Kwade, A. Understanding slurry mixing effects on the fast charging capability of lithium-ion battery cells: Methodology and case study. J. Power Sources 2022, 536, 231455. [Google Scholar] [CrossRef]

- Dreger, H.; Bockholt, H.; Haselrieder, W.; Kwade, A. Discontinuous and continuous processing of low-solvent battery slurries for lithium nickel cobalt manganese oxide electrodes. J. Electron. Mater. 2015, 44, 4434–4443. [Google Scholar] [CrossRef]

- Meza Gonzalez, J.F.; Nirschl, H.; Rhein, F. Continuous Anode Slurry Production in Twin-Screw Extruders: Effects of the Process Setup on the Dispersion. Batteries 2024, 10, 145. [Google Scholar] [CrossRef]

- Meng, Z.; Ma, X.; Hou, J.; Zheng, Y.; Wang, Y. Impurity Impacts of Recycling NMC Cathodes. Adv. Energy Mater. 2025, 2405383. [Google Scholar] [CrossRef]

- Gao, K.; Yan, W.; Liu, Z.G.; Zhu, X. Wear characteristics of twin-screw extruder based on discrete element method. China Plast. 2023, 37, 135. [Google Scholar]

- Sun, Y.; Yuan, Y.; Lu, Y.; Pu, W.; Kong, X.; Lu, L.; Wang, H.; Han, X.; Ouyang, M. Life-cycle evolution and failure mechanisms of metal-contaminant defects in lithium-ion batteries. J. Power Sources 2023, 557, 232591. [Google Scholar] [CrossRef]

- Fink, K.E.; Polzin, B.J.; Vaughey, J.T.; Major, J.J.; Dunlop, A.R.; Trask, S.E.; Jeka, G.T.; Spangenberger, J.S.; Keyser, M.A. Influence of metallic contaminants on the electrochemical and thermal behavior of Li-ion electrodes. J. Power Sources 2022, 518, 230760. [Google Scholar] [CrossRef]

- Park, S.; Kim, D.; Ku, H.; Jo, M.; Kim, S.; Song, J.; Yu, J.; Kwon, K. The effect of Fe as an impurity element for sustainable resynthesis of Li[Ni1/3Co1/3Mn1/3]O2 cathode material from spent lithium-ion batteries. Electrochim. Acta 2019, 296, 814–822. [Google Scholar] [CrossRef]

- Zhang, R.; Zheng, Y.; Vanaphuti, P.; Liu, Y.; Fu, J.; Ma, X.; Chen, M.; Yang, Z.; Lin, Y.; Wen, J.; et al. Valence effects of Fe impurity for recovered LiNi0.6Co0.2Mn0.2O2 cathode materials. ACS Appl. Energy Mater. 2021, 4, 10356–10367. [Google Scholar] [CrossRef]

- Wu, F.; Kim, G.T.; Kuenzel, M.; Zhang, H.; Asenbauer, J.; Geiger, D.; Kaiser, U.; Passerini, S. Elucidating the effect of iron doping on the electrochemical performance of cobalt-free lithium-rich layered cathode materials. Adv. Energy Mater. 2019, 9, 1902445. [Google Scholar] [CrossRef]

- Otte, S.; Sufian, N.N.A.M.; Schabel, S.; Fleischer, J. Identification of Relevant Parameters for Traceability in the Continuous Mixing Process in Battery Cell Production. Energy Technol. 2024, 2400493. [Google Scholar] [CrossRef]

- Demirci, A.; Teke, I.; Polychronopoulos, N.D.; Vlachopoulos, J. The role of calender gap in barrel and screw wear in counterrotating twin screw extruders. Polymers 2021, 13, 990. [Google Scholar] [CrossRef]

- Haarmann, M.; Grießl, D.; Kwade, A. Continuous processing of cathode slurry by extrusion for lithium-ion batteries. Energy Technol. 2021, 9, 2100250. [Google Scholar] [CrossRef]

- Zhou, C.; Qiao, M.; Zhang, X.; Zhu, Y.; Zhang, S.; Chen, J. Production of high internal phase emulsion with a miniature twin screw extruder. ACS Omega 2019, 4, 9957–9963. [Google Scholar] [CrossRef]

- Moro, M.K.; Teixeira, R.S.S.; da Silva, A.S.A.; Fujimoto, M.D.; Melo, P.A.; Secchi, A.R.; da Silva Bon, E.P. Continuous pretreatment of sugarcane biomass using a twin-screw extruder. Ind. Crops Prod. 2017, 97, 509–517. [Google Scholar] [CrossRef]

- Meza Gonzalez, J.F.; Nirschl, H. Numerical Investigation of the Local Shear Rate in a Twin-Screw Extruder for the Continuous Processing of Li-Ion Battery Electrode Slurries. Energy Technol. 2023, 11, 2201517. [Google Scholar] [CrossRef]

- Platen, K.; Langer, F.; Schwenzel, J. Influence of Screw Design and Process Parameters on the Product Quality of PEO: LiTFSI Solid Electrolytes Using Solvent-Free Melt Extrusion. Batteries 2024, 10, 183. [Google Scholar] [CrossRef]

- Lee, B.M.; Gao, X.; Kim, H.S.; Hwang, W.R. Flow modeling for conveying sections in a co-rotating twin-screw extruder based on energy dissipation rate for continuous mixing of lithium-ion battery slurries. Chem. Eng. Sci. 2023, 281, 119113. [Google Scholar]

- Matsushita, M.; Ohsaki, S.; Nara, S.; Nakamura, H.; Watano, S. Effect of fill level in continuous twin-screw granulator: A combined experimental and simulation study. Adv. Powder Technol. 2022, 33, 103822. [Google Scholar] [CrossRef]

- Wen, X.; Bai, P.; Li, Y.; Cao, H.; Li, S.; Wang, B.; Fang, J.; Meng, Y.; Ma, L.; Tian, Y. Effects of abrasive particles on liquid superlubricity and mechanisms for their removal. Langmuir 2021, 37, 3628–3636. [Google Scholar] [CrossRef]

- Li, L.; Bai, P.; Wen, X.; Zhou, X.; Ma, K.; Meng, Y.; Ding, J.; Tian, Y. Wear mechanism and evolution of tribofilm of ceramic on steel pairs under ester oil lubrication in wide temperature range. J. Mater. Res. Technol. 2023, 27, 6984–6996. [Google Scholar] [CrossRef]

- Reynolds, C.D.; Hare, S.D.; Slater, P.R.; Simmons, M.H.; Kendrick, E. Rheology and structure of lithium-ion battery electrode slurries. Energy Technol. 2022, 10, 2200545. [Google Scholar] [CrossRef]

- Kraytsberg, A.; Ein-Eli, Y. Conveying advanced Li-ion battery materials into practice the impact of electrode slurry preparation skills. Adv. Energy Mater. 2016, 6, 1600655. [Google Scholar] [CrossRef]

- Peng, G.; Huang, X.; Zhou, L.; Zhou, G.; Zhou, H. Solid-liquid two-phase flow and wear analysis in a large-scale centrifugal slurry pump. Eng. Fail. Anal. 2020, 114, 104602. [Google Scholar] [CrossRef]

- Zhang, A.; Wang, Z.; Gao, Q.; Fan, Y.; Wang, H. Calibration and validation of flow parameters of irregular gravel particles based on the multi-response concept. Processes 2023, 11, 268. [Google Scholar] [CrossRef]

- Ma, F.; Fu, Y.; Battaglia, V.; Prasher, R. Microrheological modeling of lithium ion battery anode slurry. J. Power Sources 2019, 438, 226994. [Google Scholar] [CrossRef]

- Cho, K.Y.; Kwon, Y.I.; Youn, J.R.; Song, Y.S. Evaluation of slurry characteristics for rechargeable lithium-ion batteries. Mater. Res. Bull. 2013, 48, 2922–2926. [Google Scholar] [CrossRef]

- Shim, T.Y.; Yoo, Y.W.; Lee, J.K.; Kim, Y.J.; Yoon, J.R.; Kim, K.N.; Lee, S.W. Enhanced C-rate capability and long-term cycling behavior of LiFePO4/C-BaTiO3 composite cathode. J. Energy Storage 2024, 90, 111915. [Google Scholar] [CrossRef]

- Lee, G.W.; Ryu, J.H.; Han, W.; Ahn, K.H.; Oh, S.M. Effect of slurry preparation process on electrochemical performances of LiCoO2 composite electrode. J. Power Sources 2010, 195, 6049–6054. [Google Scholar] [CrossRef]

- Chen, Q.; Zhou, H.; Wang, Y.; Wang, D.; Zhang, Q.; Liu, Y. Erosion wear at the bend of pipe during tailings slurry transportation: Numerical study considering inlet velocity, particle size and bend angle. Int. J. Miner. Metall. Mater. 2023, 30, 1608–1620. [Google Scholar] [CrossRef]

- Qiu, J.; Tian, M.; Zhu, D.; Xiao, C.; Wen, B.; Bin, F.; Chen, H.; Wang, D. Numerical Study of Resistance Loss and Erosive Wear during Pipe Transport of Paste Slurry. Sustainability 2023, 15, 11890. [Google Scholar] [CrossRef]

- Reynolds, C.D.; Walker, H.; Mahgoub, A.; Adebayo, E.; Kendrick, E. Battery electrode slurry rheology and its impact on manufacturing. Energy Adv. 2025, 4, 84–93. [Google Scholar] [CrossRef]

- Chen, J.; Liu, J.; Qi, Y.; Sun, T.; Li, X. Unveiling the roles of binder in the mechanical integrity of electrodes for lithium-ion batteries. J. Electrochem. Soc. 2013, 160, A1502. [Google Scholar] [CrossRef]

- Du, F.; Li, D.; Sa, X.; Li, C.; YU, Y.; Li, C.; Wang, J.; Wang, W. Overview of friction and wear performance of sliding bearings. Coatings 2022, 12, 1303. [Google Scholar] [CrossRef]

- Xu, J.; Kato, K. Formation of tribochemical layer of ceramics sliding in water and its role for low friction. Wear 2000, 245, 61–75. [Google Scholar] [CrossRef]

- Alipovna, M.A.; Karaulovich, K.A.; Vladimirovich, P.A.; Zhanuzakovich, A.Z.; Bolatovna, K.B. Wieleba, W.; Leśniewski, T.; Bakhytuly, N. The study of the tribological properties under high contact pressure conditions of TiN, TiC and TiCN coatings deposited by the magnetron sputtering method on the AISI 304 stainless steel substrate. Mater. Sci. Pol. 2023, 41, 1–14. [Google Scholar] [CrossRef]

- Fabbro, S.; Araujo, L.M.; Engel, J.; Kondratiuk, J.; Kuffa, M.; Wegener, K. Abrasive and adhesive wear behaviour of metallic bonds in a synthetic slurry test for wear prediction in reinforced concrete. Wear 2021, 476, 203690. [Google Scholar] [CrossRef]

- Li, Y.; Schreiber, P.; Schneider, J.; Greiner, C. Tribological mechanisms of slurry abrasive wear. Friction 2023, 11, 1079–1093. [Google Scholar] [CrossRef]

- Xu, R.; Deng, Y.; Jiang, X.; Liu, Y. Superlubrication and wear behavior of SiC/Si3N4 induced by nanoparticles in water-glycol. Wear 2025, 572, 206007. [Google Scholar] [CrossRef]

| Project | Parameters | |

|---|---|---|

| LFP | NCM | |

| Particle size (µm) | 12.46 | 11.21 |

| Tapped density (g/cm3) | 1.64 | 2.32 |

| pH | 9.33 | 11.58 |

| Specific surface area (m2/g) | 7.54 | 0.28 |

| Components (wt.%) | Materialized | Parameters | |

|---|---|---|---|

| Fe | 67–71.5 | σb (MPa) | ≥515–1035 |

| Cr | 17.5–19.5 | σ0.2 (MPa) | ≥205 |

| Ni | 8–10.5 | HV | 201 |

| C | ≤0.07 | ρ (20 °C, g/cm3) | 7.93 |

| Mo | ---- | Melting point (℃) | 1398~1454 |

| Ti | ---- | ν | 0.3 |

| Others | ≤2.29 | Modulus of elasticity (20 °C, KN/mm2) | 193 |

| Project | Parameters | |

|---|---|---|

| Slurry | LFP/NCM | |

| Constant parameter | 310 rpm (0.13 m/s) | 7 N (1186 MPa) |

| Control parameter | 1 N (620.3 MPa), 3 N (894.6 MPa), 5 N (1160 MPa), 7 N (1186 MPa), 9 N (1290 MPa) | 120 rpm (0.05 m/s), 310 rpm (0.13 m/s), 500 rpm (0.21 m/s), 690 rpm (0.29 m/s), 880 rpm (0.37 m/s) |

| Temperature | 25 °C | |

| Humidity | 20% RH | |

| Rotating radius | 4 mm | |

| Sample addition volume | 200 μL | |

| Friction pair | SUS304 ball–disc point contact | |

| Slurry | Working Conditions | SUS304 Ball | SUS304 Disc | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| WSD (µm) | Sa (µm) | Depth (µm) | V (µm3) | WSW (µm) | Sa (µm) | Depth (µm) | V (µm3) | ||||

| LFP | Load | 310 rpm | 1 N | 468.480 | 1.781 | 8.267 | 2.027 × 105 | 324.480 | 0.1790 | 1.254 | 1.290 × 104 |

| 3 N | 567.613 | 3.246 | 13.473 | 4.562 × 105 | 456.960 | 0.3560 | 1.950 | 3.919 × 104 | |||

| 5 N | 602.775 | 3.899 | 17.995 | 7.464 × 105 | 509.760 | 0.7124 | 5.122 | 9.077 × 104 | |||

| 7 N | 678.881 | 4.683 | 19.390 | 1.271 × 106 | 528.960 | 1.0926 | 8.858 | 1.342 × 105 | |||

| 9 N | 723.840 | 5.397 | 21.405 | 1.768 × 106 | 574.080 | 3.4209 | 12.816 | 3.284 × 105 | |||

| Speed | 7 N | 120 rpm | 816.000 | 6.747 | 27.653 | 6.582 × 106 | 757.440 | 0.2270 | 1.214 | 1.671 × 105 | |

| 310 rpm | 678.881 | 4.683 | 19.390 | 1.271 × 106 | 528.960 | 1.0926 | 8.858 | 1.342 × 105 | |||

| 500 rpm | 695.040 | 5.256 | 19.660 | 1.991 × 106 | 558.720 | 2.7162 | 9.745 | 6.588 × 105 | |||

| 690 rpm | 758.400 | 5.571 | 24.299 | 3.076 × 106 | 625.920 | 2.3644 | 10.140 | 9.228 × 105 | |||

| 880 rpm | 827.520 | 7.031 | 29.801 | 5.803 × 106 | 629.760 | 2.9017 | 12.437 | 1.675 × 106 | |||

| NCM | Load | 310 rpm | 1 N | 264.960 | 0.273 | 1.644 | 9.259 × 103 | 192.000 | 0.353 | 1.482 | 2.118 × 104 |

| 3 N | 337.920 | 0.784 | 3.847 | 3.167 × 104 | 276.480 | 0.987 | 2.978 | 1.037 × 105 | |||

| 5 N | 466.560 | 0.721 | 3.990 | 5.208 × 104 | 397.440 | 1.650 | 4.542 | 3.516 × 105 | |||

| 7 N | 491.520 | 0.729 | 5.002 | 7.951 × 104 | 426.240 | 2.483 | 6.838 | 6.812 × 105 | |||

| 9 N | 562.560 | 1.138 | 9.139 | 1.079 × 105 | 472.320 | 2.888 | 7.927 | 1.136 × 106 | |||

| Speed | 7 N | 120 rpm | 349.440 | 0.342 | 2.303 | 1.165 × 104 | 301.440 | 1.119 | 4.390 | 1.623 × 105 | |

| 310 rpm | 491.520 | 0.729 | 5.002 | 6.051 × 104 | 426.240 | 2.483 | 6.838 | 6.812 × 105 | |||

| 500 rpm | 602.880 | 2.405 | 11.742 | 4.630 × 105 | 509.760 | 2.171 | 7.579 | 1.150 × 106 | |||

| 690 rpm | 679.680 | 3.110 | 18.278 | 9.708 × 105 | 569.200 | 3.444 | 10.160 | 2.162 × 106 | |||

| 880 rpm | 791.040 | 4.781 | 21.920 | 1.985 × 106 | 600.960 | 3.456 | 11.629 | 3.416 × 106 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wen, X.; Bi, M.; Li, L.; Ding, J. Study on the Wear Behavior Mechanism of SUS304 Stainless Steel During the Homogenization Process of LFP/NCM Slurry. Materials 2025, 18, 4457. https://doi.org/10.3390/ma18194457

Wen X, Bi M, Li L, Ding J. Study on the Wear Behavior Mechanism of SUS304 Stainless Steel During the Homogenization Process of LFP/NCM Slurry. Materials. 2025; 18(19):4457. https://doi.org/10.3390/ma18194457

Chicago/Turabian StyleWen, Xiangli, Mingkun Bi, Lvzhou Li, and Jianning Ding. 2025. "Study on the Wear Behavior Mechanism of SUS304 Stainless Steel During the Homogenization Process of LFP/NCM Slurry" Materials 18, no. 19: 4457. https://doi.org/10.3390/ma18194457

APA StyleWen, X., Bi, M., Li, L., & Ding, J. (2025). Study on the Wear Behavior Mechanism of SUS304 Stainless Steel During the Homogenization Process of LFP/NCM Slurry. Materials, 18(19), 4457. https://doi.org/10.3390/ma18194457