Mechanical Performance and Failure Modes of High-Strength Adhesives in Aluminum Adherend Joints for Aerospace Applications

Abstract

1. Introduction

2. Materials

3. Experimental Methods

3.1. Experiment Design

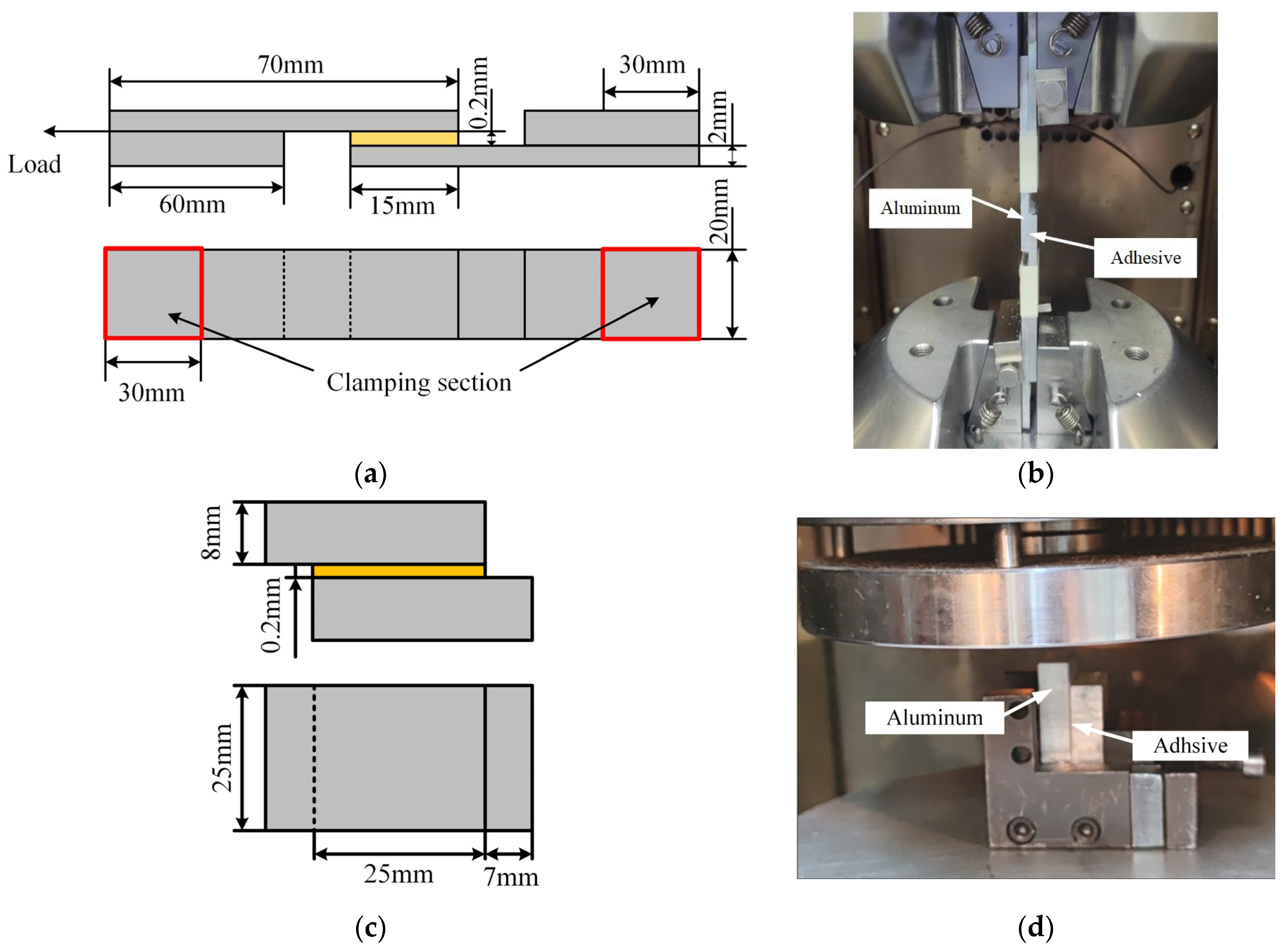

3.2. Specimens and Data Process

4. Results

4.1. Bulk Tensile Test

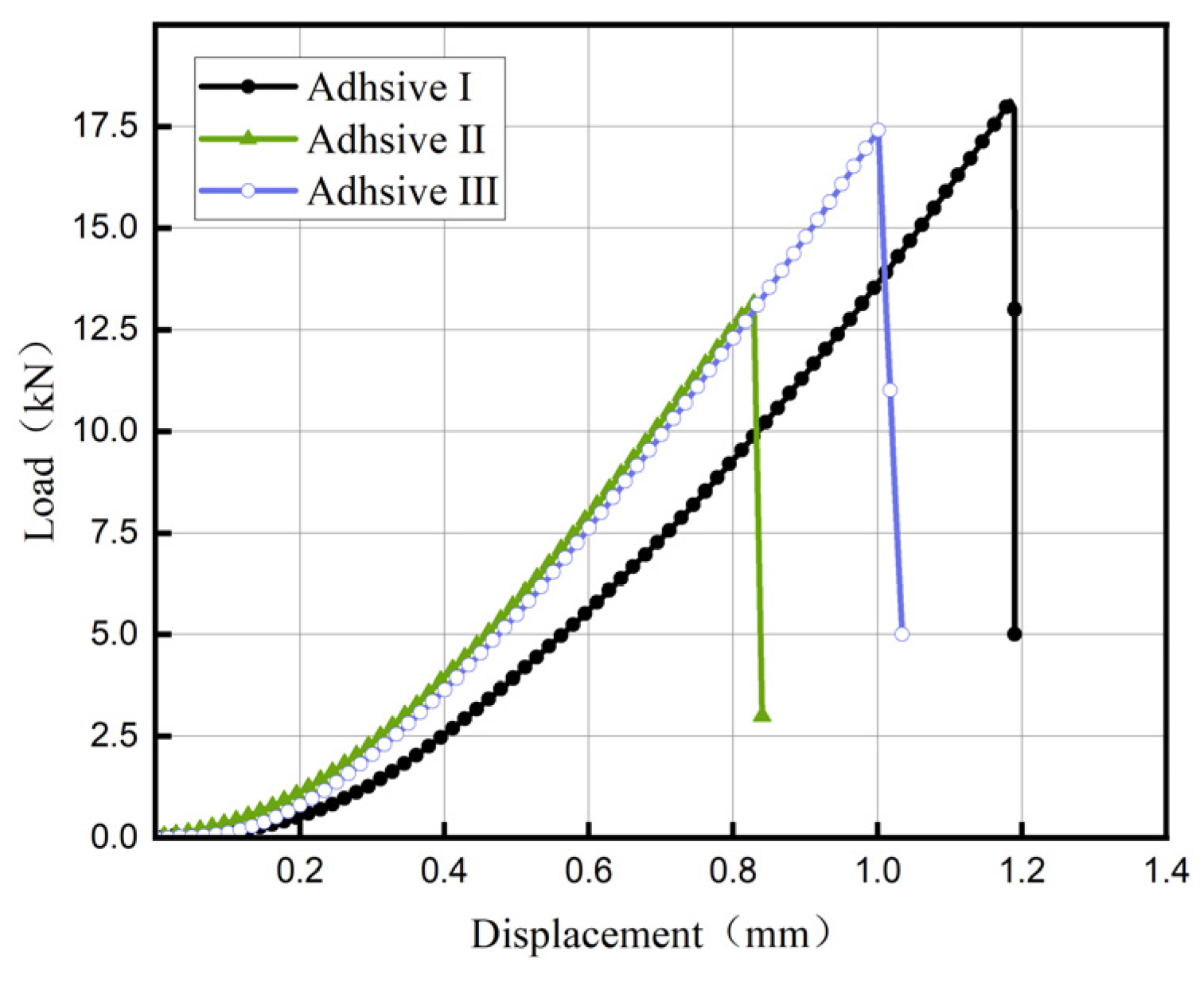

4.2. Butt Joint Tension Test

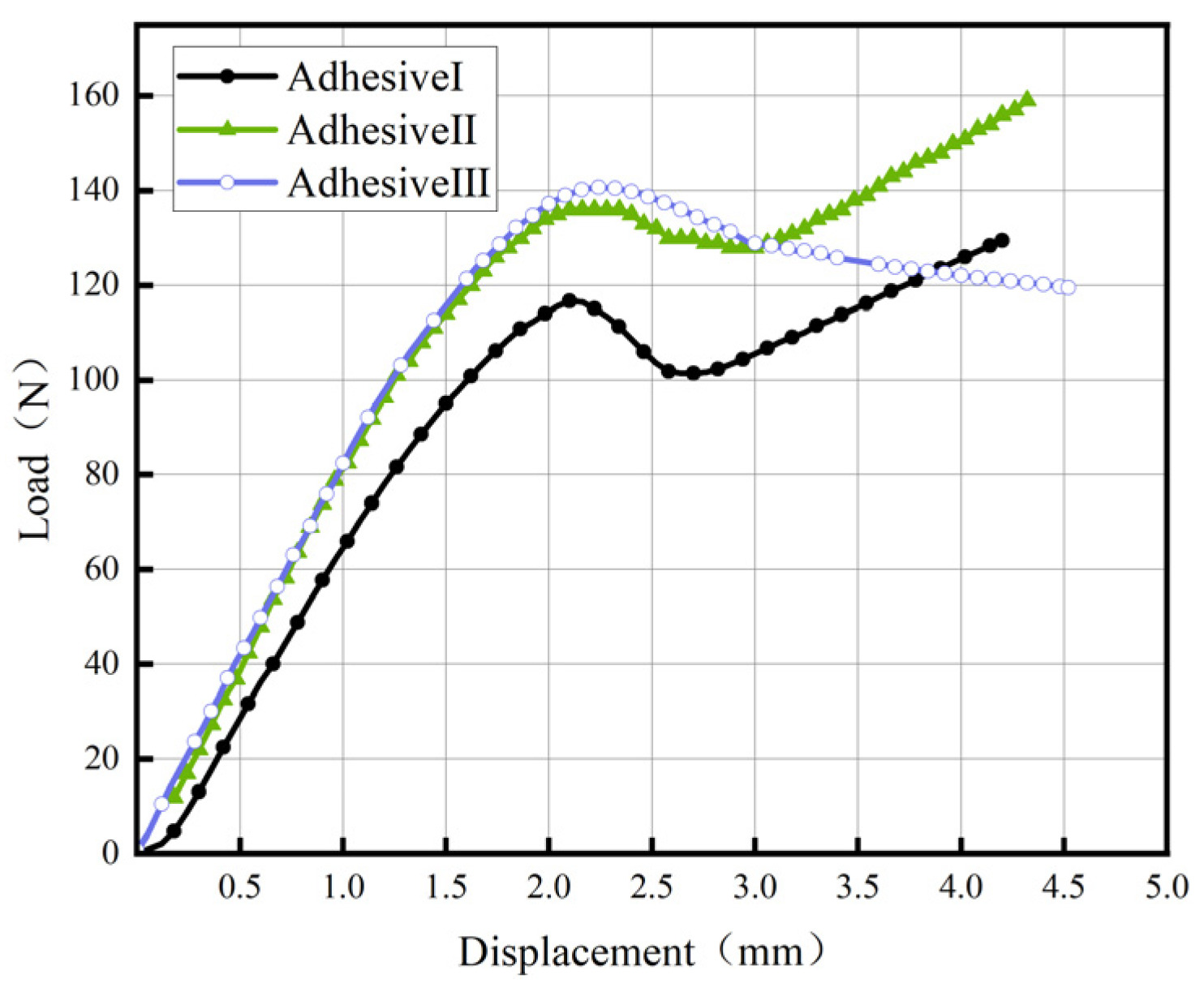

4.3. Shear Test

4.4. Fracture Tests

5. Discussion

6. Conclusions

- The initial null hypothesis H0 (stating no significant differences in elastic modulus, bulk ultimate tensile strength, and mode-I/mode-II fracture toughness between Adhesive III and conventional adhesives) was partially rejected through experimental verification, with the experimental results showing both consistencies and inconsistencies with expectations. In terms of consistency with expectations, Adhesive III demonstrated significant advantages in stiffness and tensile strength: its elastic modulus reached 4.31 GPa, which was 21.4% and 55.0% higher than that of Adhesive I and Adhesive II, respectively; its bulk ultimate tensile strength was even 126.5% and 242.9% higher than that of the two conventional adhesives. These results fully confirm that Adhesive III possesses excellent deformation resistance and load-bearing potential, aligning with the initial design expectations.

- However, from the perspective of inconsistencies with expectations and performance trade-offs, Adhesive III has obvious shortcomings. On the one hand, its fracture toughness shows an unbalanced performance: the mode-I fracture toughness is only 0.0742 N/mm, significantly lower than that of Adhesive I (0.104 N/mm) and Adhesive II (0.129 N/mm), indicating weak resistance to the initiation of opening-mode cracks; the mode-II fracture toughness (0.149 N/mm) is only superior to that of Adhesive I (0.125 N/mm) and shows no significant difference from Adhesive II (0.146 N/mm). Overall, it exhibits the unanticipated performance characteristic of “high stiffness—low toughness”. On the other hand, Adhesive III has no obvious yield point and exhibits brittle fracture characteristics during fracture, with “river-like” patterns visible on the fracture surface. This further confirms its insufficient toughness and points out the direction for targeted optimization in subsequent work.

- In addition, results from fracture analysis and joint tests indicate that the failure mode of Adhesive III shows regular characteristics with changes in load type: under normal loading, it exhibits a mixed failure mode of “cohesive failure + interfacial debonding”. Based on scanning electron microscopy (SEM), energy-dispersive spectroscopy (EDS), and image analysis, the proportion of cohesive failure was found to be 69.32%, while that of adhesive failure was 30.68%. Under shear loading, it presents complete cohesive failure. This regularity not only verifies the hypothesis that “the interior of the adhesive layer tends to become a stress weak zone under shear loading” but also provides key experimental basis for the adhesive design of multi-layer structures in aerospace applications. Comprehensively, Adhesive III, with its stable cohesive failure characteristic under shear loading, is suitable for aerospace thermal protection systems dominated by shear loading. However, its relatively low mode-I fracture toughness still requires optimization and improvement in subsequent research.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| TPS | Thermal Protection System |

| TDCB | Tapered Double Cantilever Beam |

| ENF | End-Notched Flexure |

| CV | Coefficient of Variation |

References

- Zhou, Q.C.; Xu, J.S.; Chen, X.; Zhou, C.S. Review of the Adhesively Bonded Interface in a Solid Rocket Motor. J. Adhes. 2015, 92, 402–428. [Google Scholar] [CrossRef]

- Maloney, K.; Fleck, N. Toughening strategies in adhesive joints. Int. J. Solids Struct. 2019, 158, 66–75. [Google Scholar] [CrossRef]

- Feng, C.-W.; Keong, C.-W.; Hsueh, Y.-P.; Wang, Y.-Y.; Sue, H.-J. Modeling of long-term creep behavior of structural epoxy adhesives. Int. J. Adhes. Adhes. 2005, 25, 427–436. [Google Scholar] [CrossRef]

- Alia, C.; Arenas, J.M.; Suárez, J.C.; Pinilla, P. Mechanical behavior of polyurethane adhesive joints used in laminated materials for marine structures. Ocean Eng. 2016, 113, 64–74. [Google Scholar] [CrossRef]

- Banea, M.D.; Rosioara, M.; Carbas, R.J.C.; da Silva, L.F.M. Multi-material adhesive joints for automotive industry. Compos. Part B Eng. 2018, 151, 71–77. [Google Scholar] [CrossRef]

- Szeptyński, P.; Nowak, M. Qualitative analysis of the influence of the non-linear material characteristics of flexible adhesive on the performance of lap joints. Compos. Struct. 2021, 260, 113539. [Google Scholar] [CrossRef]

- Tsai, M.Y.; Oplinger, D.W.; Morton, J. Improved theoretical solutions for adhesive lap joints. Int. J. Solids Struct. 1998, 35, 1163–1185. [Google Scholar] [CrossRef]

- Lane, M.; Duskard, A.; Vainchtein, R.H. Plasticity contributions to interface adhesion in thin-film interconnect structures. J. Mater. Res. 2000, 15, 2758–2769. [Google Scholar] [CrossRef]

- Xu, W.; Wei, Y. Strength and interface failure mechanism of adhesive joints. Int. J. Adhes. Adhes. 2012, 34, 80–92. [Google Scholar] [CrossRef]

- Seong, M.-S.; Kim, T.-H.; Nguyen, K.-H.; Kweon, J.-H.; Choi, J.-H. A parametric study on the failure of bonded single-lap joints of carbon composite and aluminum. Compos. Struct. 2008, 86, 135–145. [Google Scholar] [CrossRef]

- Rudawska, A. Adhesive joint strength of hybrid assemblies: Titanium sheet-composites and aluminium sheet-composites—Experimental and numerical verification. Int. J. Adhes. Adhes. 2010, 30, 574–582. [Google Scholar] [CrossRef]

- Ganesh Gupta, K.B.N.V.S.; Hiremath, M.M.; Fulmali, A.O.; Prusty, R.K.; Ray, B.C. Investigation of adhesively bonded multi-material joints: An assessment on joint efficiency and fracture morphology. Mater. Today Proc. 2020, 27, 1180–1185. [Google Scholar] [CrossRef]

- Golewski, P. Tensile Behaviour of Double- and Triple-Adhesive Single Lap Joints Made with Spot Epoxy and Double-Sided Adhesive Tape. Materials 2022, 15, 7855. [Google Scholar] [CrossRef] [PubMed]

- Morello, D.; Leone, C.; Lamanna, G.; Silvio, G. A two-step full laser surface treatment to improve the adhesive bonding of aluminium-aluminium joints. Int. J. Adhes. Adhes. 2025, 142, 104089. [Google Scholar] [CrossRef]

- ASTM D1002; Standard Test Method for Apparent Shear Strength of Single-Lap-Joint Adhesively Bonded Metal Specimens by Tension Loading (Metal-to-Metal). ASTM: West Conshohocken, PA, USA, 1972.

- ASTM D905; Standard Test Method for Strength Properties of Adhesive Bonds in Shear by Compression Loading. ASTM: West Conshohocken, PA, USA, 2008.

- ASTM D3433; Standard Test Method for Fracture Strength in Cleavage of Adhesives in Bonded Metal Joints. ASTM: West Conshohocken, PA, USA, 1999.

- ASTM D638; Standard Test Method for Tensile Properties of Plastics. ASTM: West Conshohocken, PA, USA, 2022.

- ASTM D897; Standard Test Method for Tensile Properties of Adhesive Bonds. ASTM: West Conshohocken, PA, USA, 1995.

- ASTM D7905; Standard Test Method for Determination of the Mode II Interlaminar Fracture Toughness of Unidirectional Fiber-Reinforced Polymer-Matrix Composites. ASTM: West Conshohocken, PA, USA, 2019.

- Dadian, A.; Rahnama, S.; Zolfaghari, A. Experimental study of the CTBN effect on mechanical properties and mode I and II fracture toughness of a new epoxy resin. J. Adhes. Sci. Technol. 2020, 34, 2389–2404. [Google Scholar] [CrossRef]

- Nunes, F.A.A.; Campilho, R.D.S.G.; Cardoso, M.G.; Silva, F.J.G. Fracture envelope estimation of a structural adhesive by dedicated fracture tests. Procedia Manuf. 2019, 38, 1252–1259. [Google Scholar] [CrossRef]

- ASTM D5573; Standard Practice for Classifying Failure Modes in Fiber-Reinforced-Plastic (FRP) Joints. ASTM: West Conshohocken, PA, USA, 2019.

| Name | Adhesive I | Adhesive II | Adhesive III |

|---|---|---|---|

| Manufacturer | Aerospace Research Institute of Materials & Processing Technology | Aerospace Research Institute of Materials & Processing Technology | Aerospace Research Institute of Materials & Processing Technology |

| Mix Ratio/Components | Component A:Component B = 145:13 | Component A:Component B = 147:8 | Component A:Component B:Component C = 100:29:10 |

| ) | 1.235 | 1.044 | 1.187 |

| ) | 15,868 | 86,382 | 8000–15,000 |

| Color | Translucent white | Pale yellow | Pale yellow |

| Curing Temperature (°C) | 23–25 | 70–75 | 80–110 |

| Curing Time | Not less than 7 days | Not less than 3 h | 23–25 °C for 24 h, followed by stepped curing for not less than 12 h |

| Adhesive I | Adhesive II | Adhesive III | Adhesive Used in Reference [22] | |

|---|---|---|---|---|

| (N/mm) | 0.104 | 0.129 | 0.0742 | 0.410 |

| (%) | 6.9 | 7.8 | 9.1 | 0.422 |

| (N/mm) | 0.125 | 0.146 | 0.149 | 0.079 |

| (%) | 3.1 | 1.6 | 8.3 | 0.002 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hou, B.; Jia, L.; Zhang, L.; Xu, B.; Hou, J. Mechanical Performance and Failure Modes of High-Strength Adhesives in Aluminum Adherend Joints for Aerospace Applications. Materials 2025, 18, 4445. https://doi.org/10.3390/ma18194445

Hou B, Jia L, Zhang L, Xu B, Hou J. Mechanical Performance and Failure Modes of High-Strength Adhesives in Aluminum Adherend Joints for Aerospace Applications. Materials. 2025; 18(19):4445. https://doi.org/10.3390/ma18194445

Chicago/Turabian StyleHou, Baojiang, Lifeng Jia, Lisheng Zhang, Bo Xu, and Jie Hou. 2025. "Mechanical Performance and Failure Modes of High-Strength Adhesives in Aluminum Adherend Joints for Aerospace Applications" Materials 18, no. 19: 4445. https://doi.org/10.3390/ma18194445

APA StyleHou, B., Jia, L., Zhang, L., Xu, B., & Hou, J. (2025). Mechanical Performance and Failure Modes of High-Strength Adhesives in Aluminum Adherend Joints for Aerospace Applications. Materials, 18(19), 4445. https://doi.org/10.3390/ma18194445