A Strategy to Optimize the Mechanical Properties and Microstructure of Loess by Nano-Modified Soil Stabilizer

Abstract

1. Introduction

2. Materials and Methods

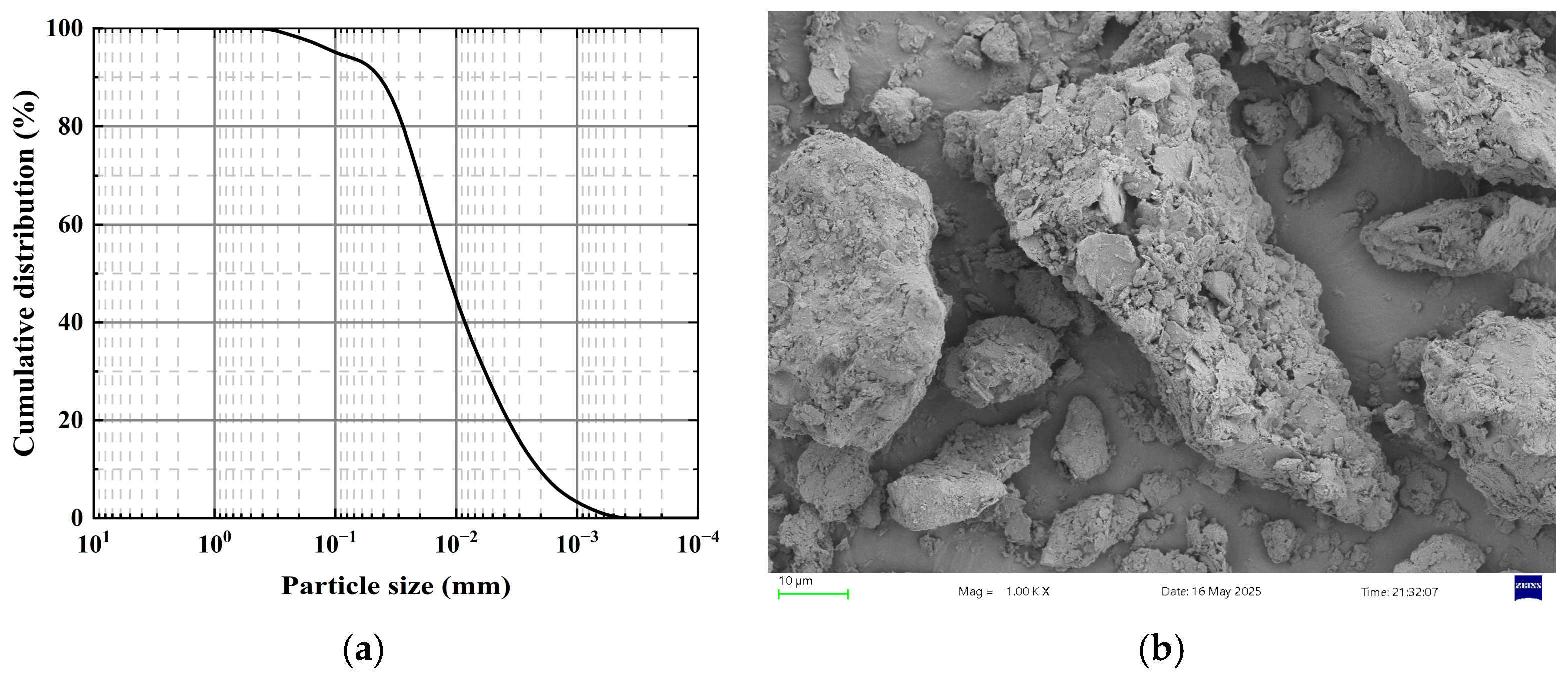

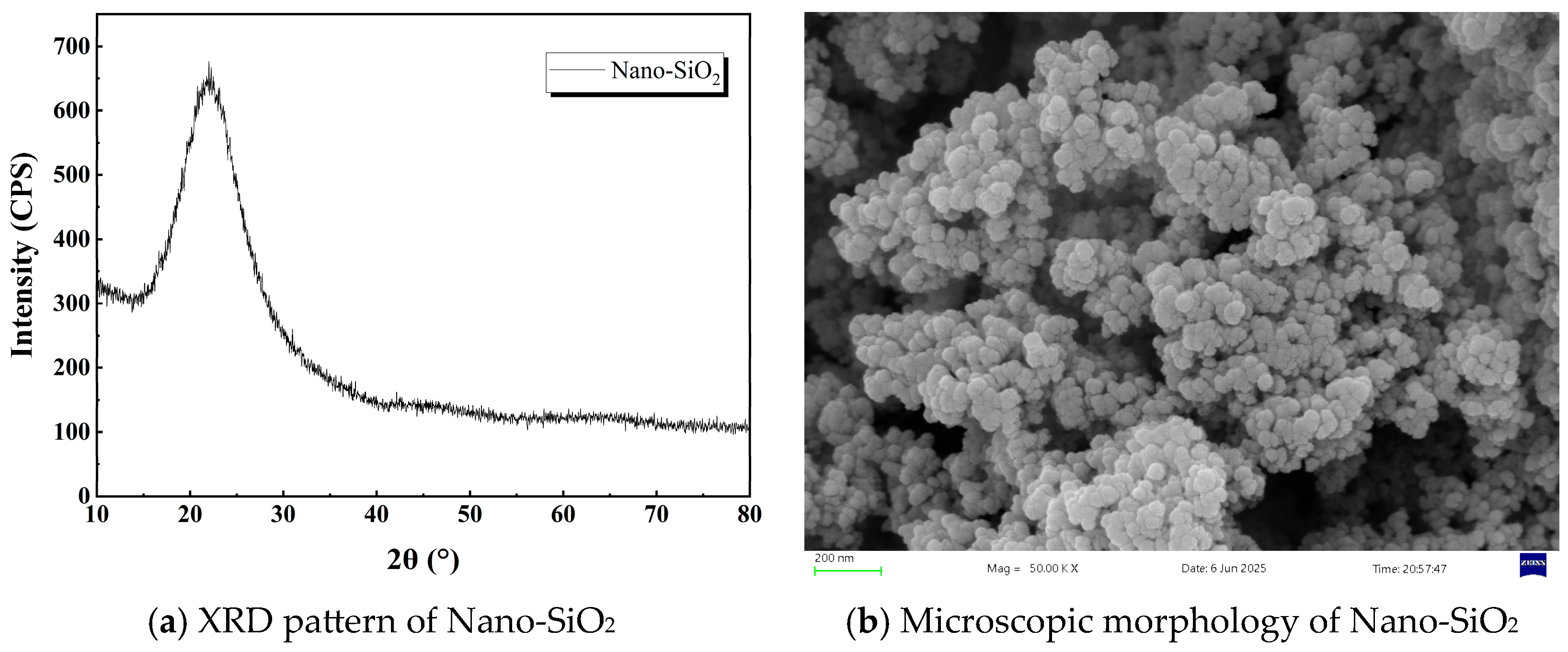

2.1. Materials

2.2. Test Methods

3. Test Results and Analysis

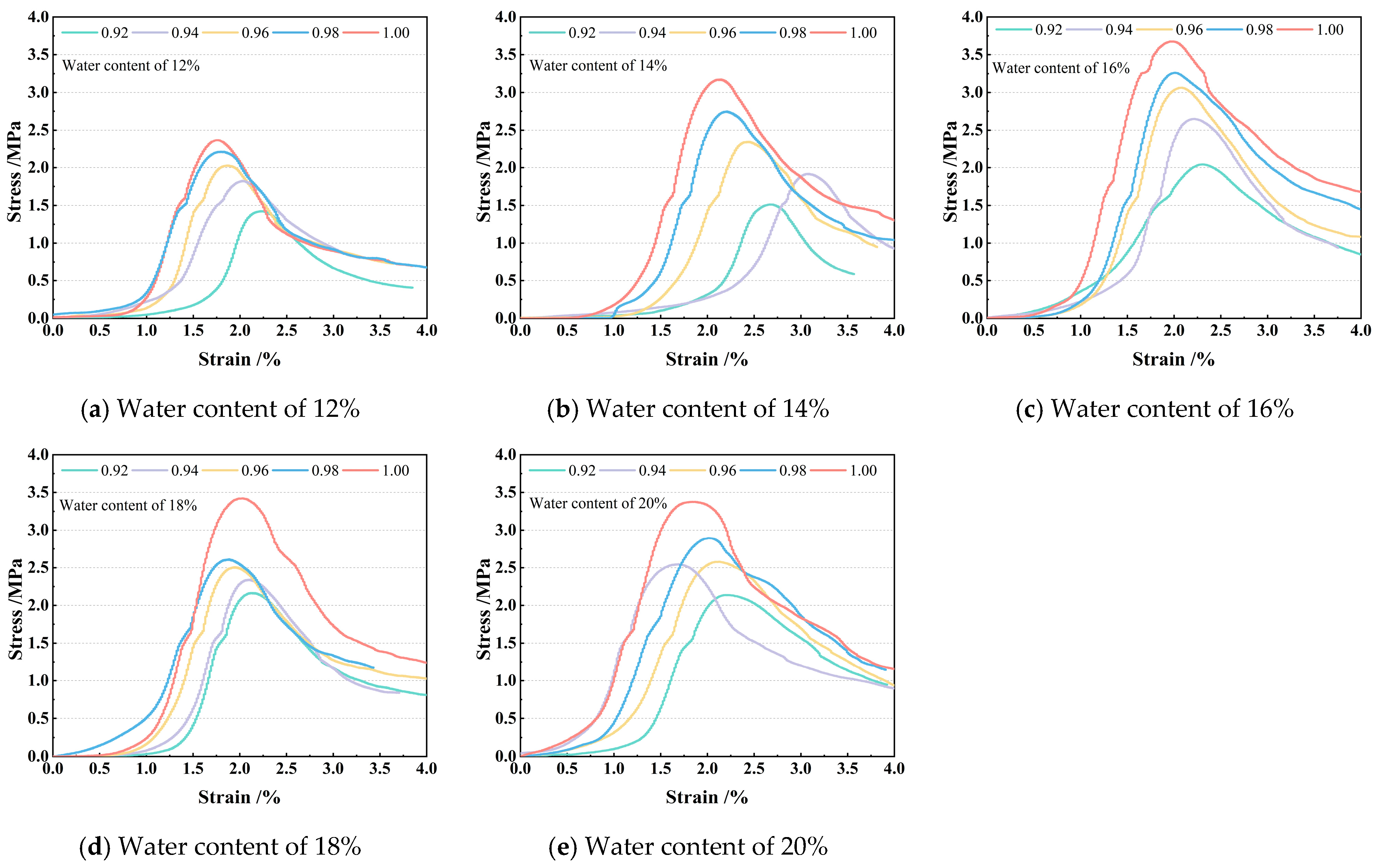

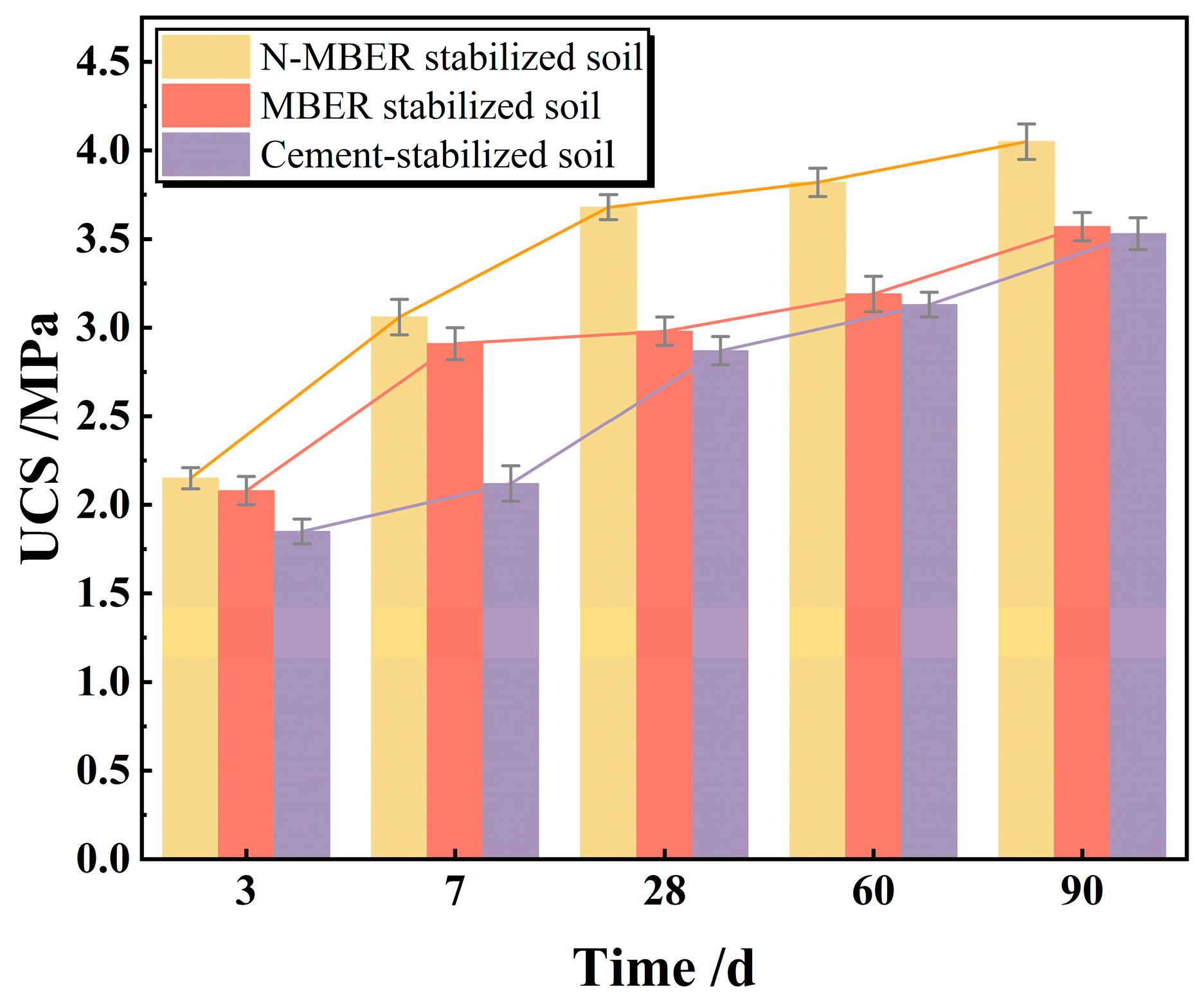

3.1. Unconfined Compressive Strength Test Results

3.2. Softening Coefficient Test Results and Analysis

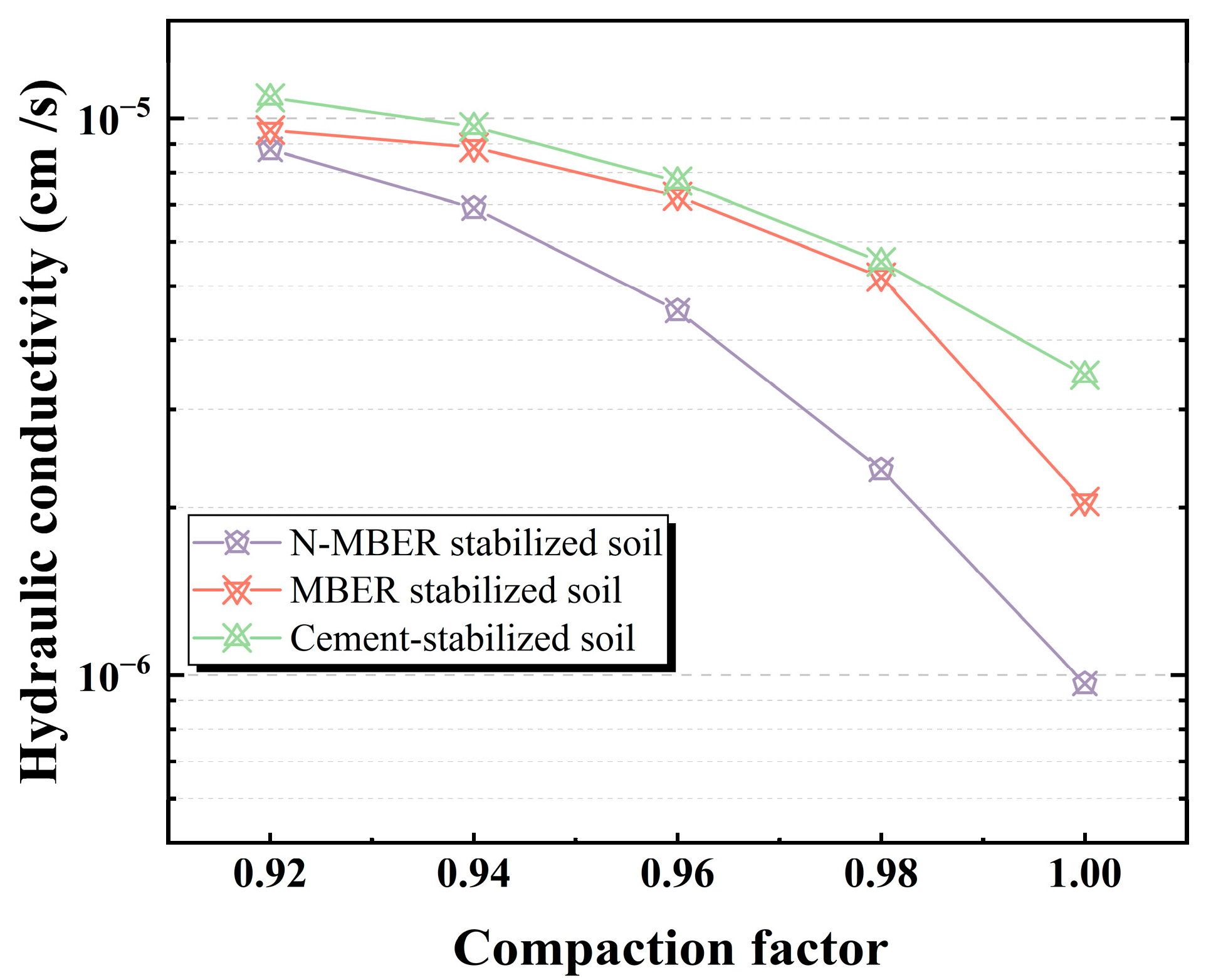

3.3. Falling-Head Permeability Test Results and Analysis

3.4. Wetting–Drying Cycle Test Results and Analysis

4. Microstructural Characteristics and Stabilization Mechanisms

4.1. XRD Results and Analysis

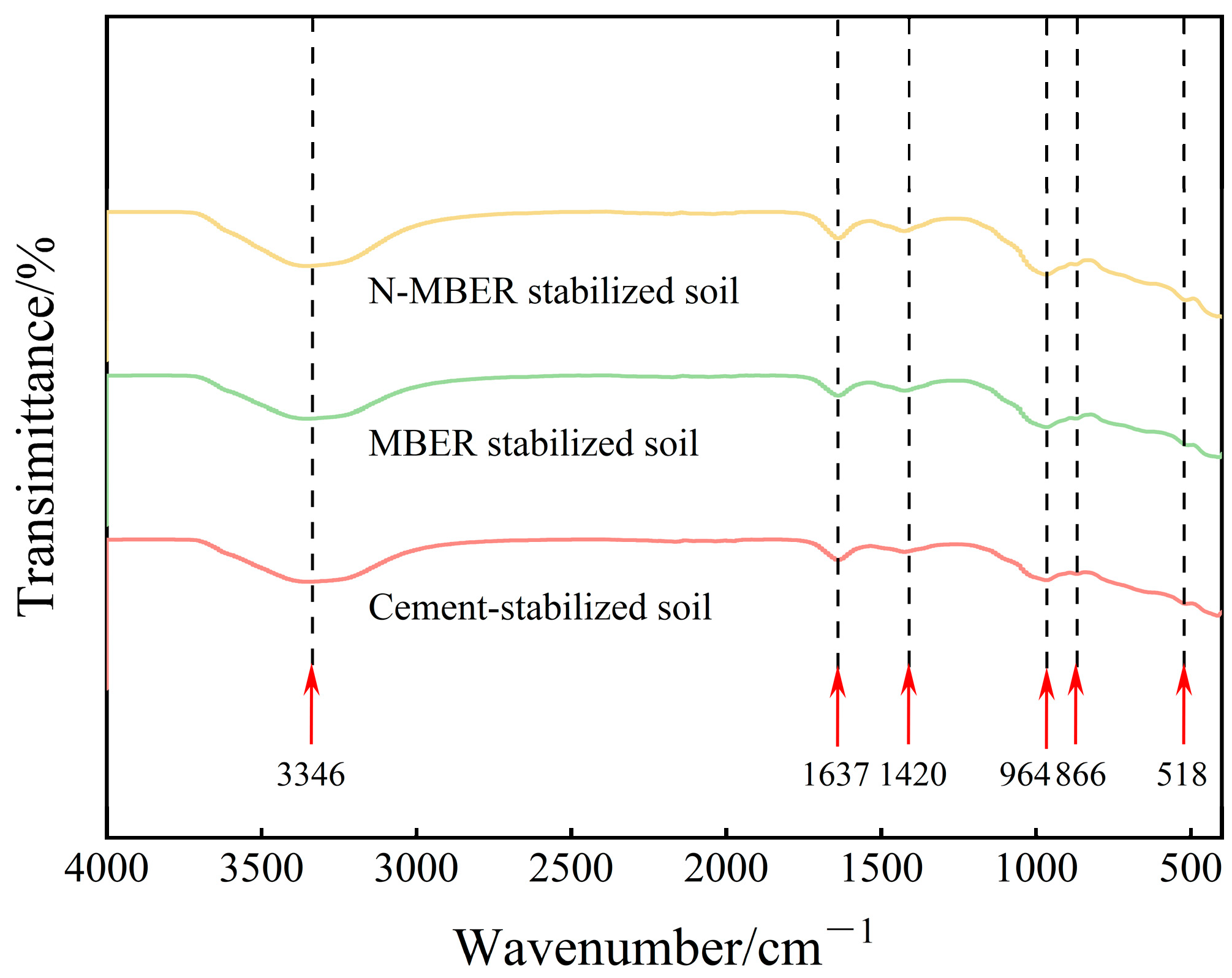

4.2. FT-IR Results and Analysis

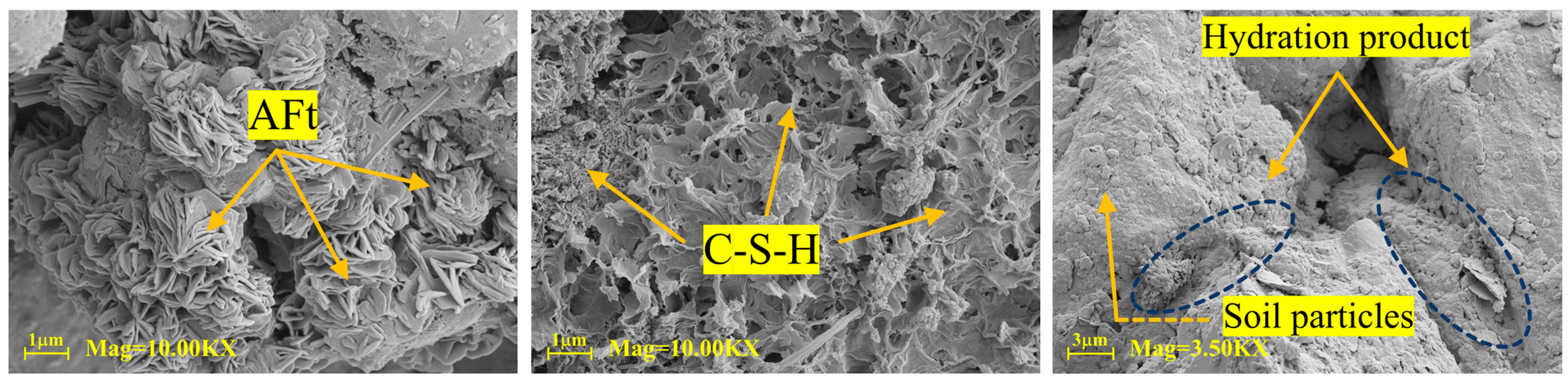

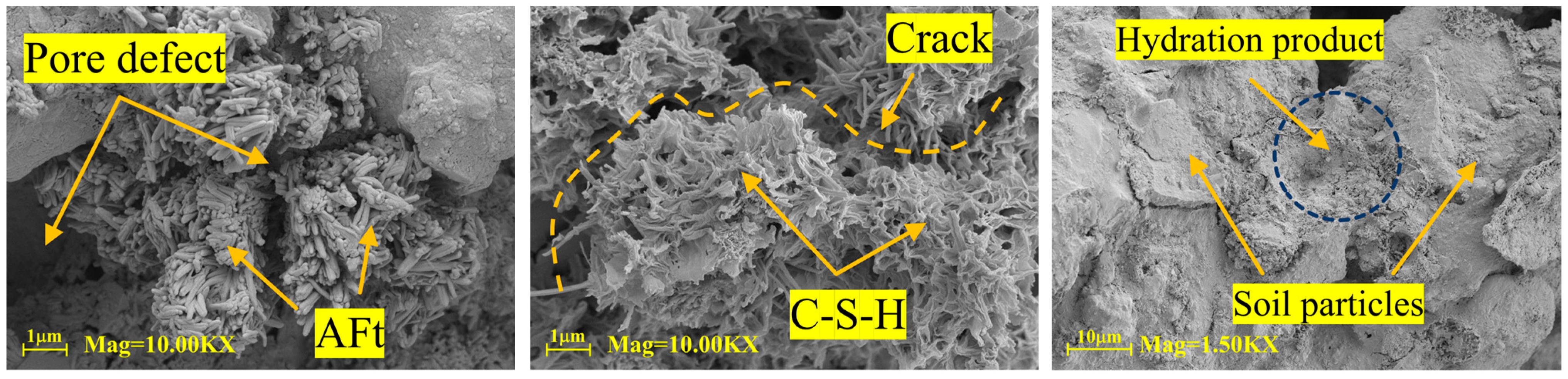

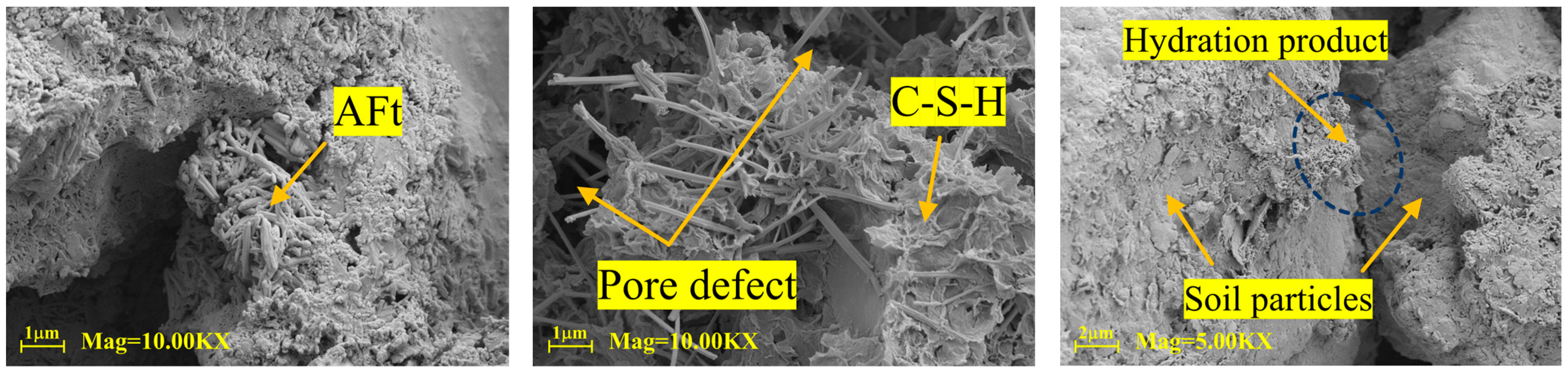

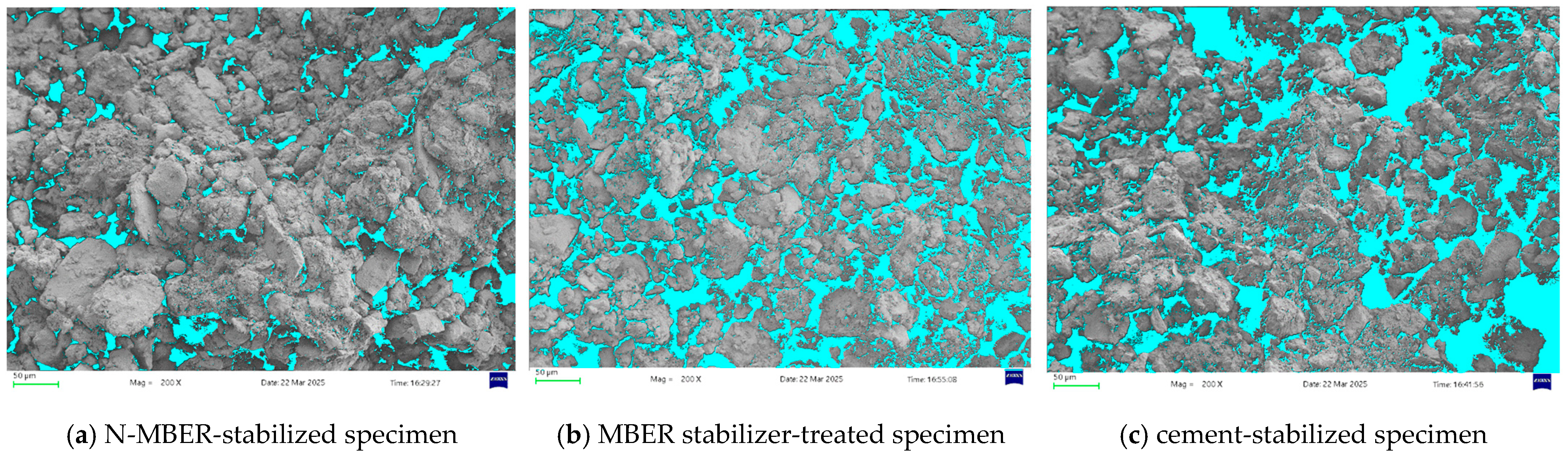

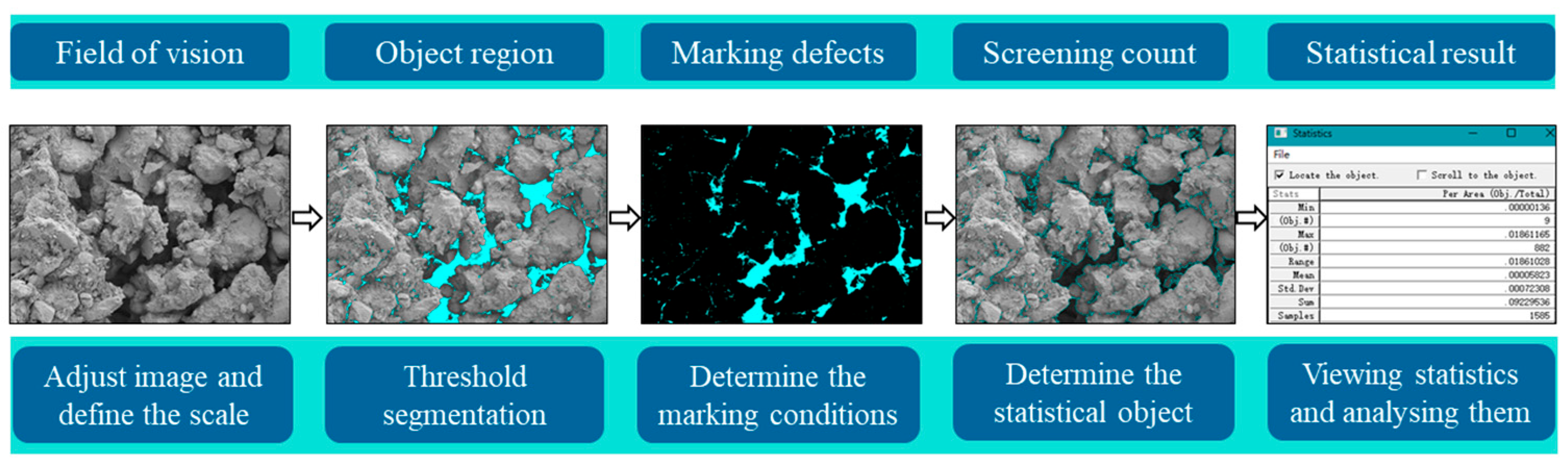

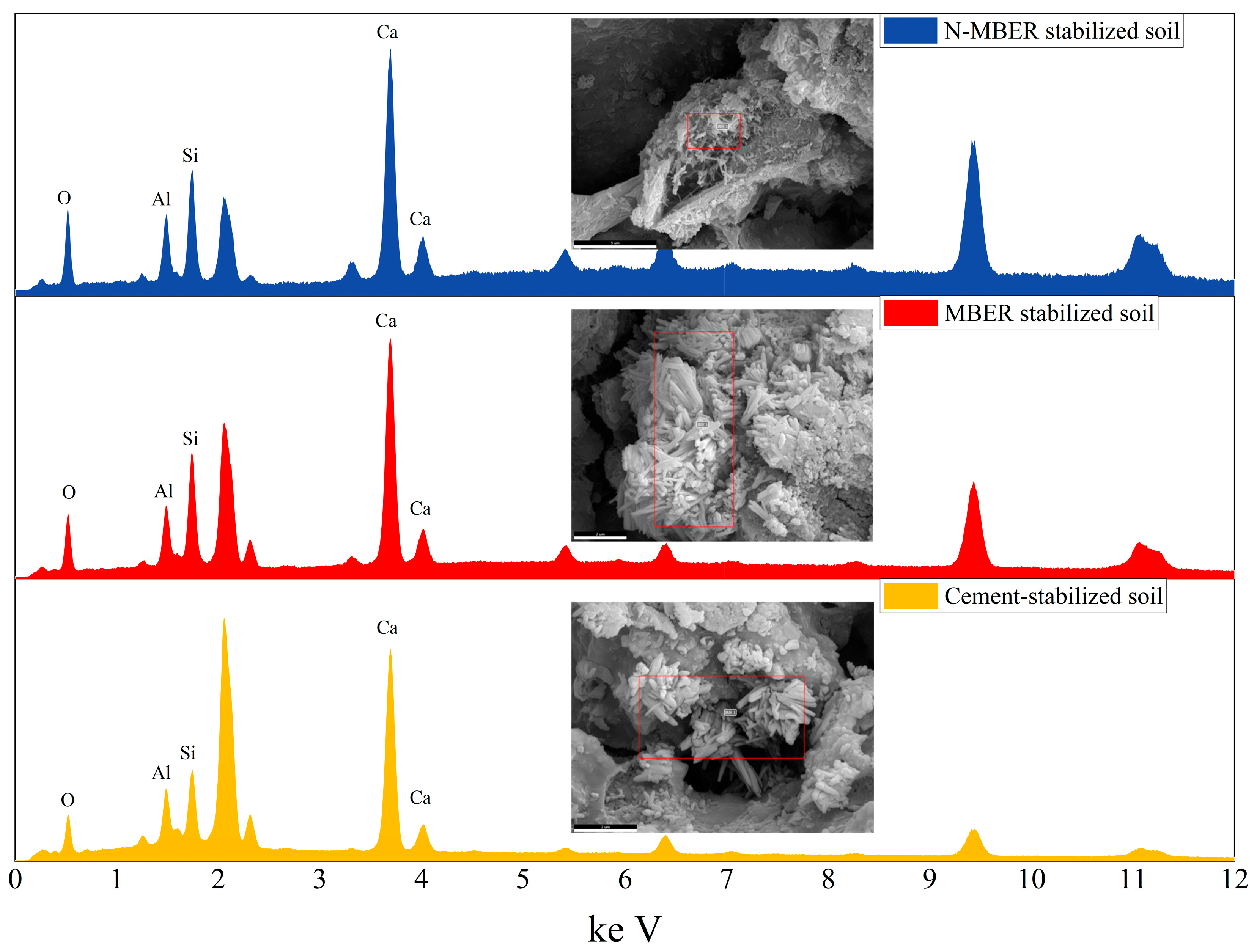

4.3. SEM Results and Analysis

4.4. NMR Results and Analysis

5. Cost

6. Conclusions

- (1)

- The compressive strength of N-MBER-stabilized soil initially increases then decreases with rising moisture content, while gradually increasing with higher compaction. At 28 days of curing under 16% moisture content and compaction degree of 1, the compressive strength reaches a local optimum of 3.68 MPa.

- (2)

- Extended curing time enhances soil strength, with growth rate decelerating beyond 28 days. Compared to MBER and cement-stabilized soils, N-MBER-stabilized loess demonstrates superior water resistance and microstructural density, exhibiting significantly reduced void defect ratios. After five wet–dry cycles at 28-day curing, strength loss rates reach 24.4% for MBER and 27.54% for cement-stabilized soils, versus 18.23% for N-MBER-stabilized soil. Additionally, N-MBER-stabilized soil shows 21.63% fewer total pores and 41.64% fewer macro-pores than cement-stabilized counterparts.

- (3)

- The nanomaterial’s ultra-fine particle size and high specific surface area facilitate enhanced interactions with soil particles, accelerating hydration reactions. Generated ettringite (AFt) and three-dimensional networked C-S-H gels intertwine tightly with soil particles, forming dense stabilization layers that reduce void defects and establish a stable cemented framework, thereby enhancing overall stability.

- (4)

- Compared to traditional concrete roads, nano-stabilized soil roads can utilize local soil as raw material, offering a significant cost advantage over traditional building materials.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, F.; Kong, R.; Peng, J. Effects of heating on compositional, structural, and physicochemical properties of loess under laboratory conditions. Appl. Clay Sci. 2018, 152, 259–266. [Google Scholar] [CrossRef]

- Wang, K.; Niu, H. Research on the Strength Properties and Microscopic Mechanism of Loess Stabilized by the Combined Use of MICP Technology and Plant Straw. Materials 2025, 18, 992. [Google Scholar] [CrossRef]

- Lal, A.; Fronczyk, J. Stabilisation/Solidification of the Zn-Contaminated Loess Silt in View of the Mechanical Properties. Materials 2024, 17, 6266. [Google Scholar] [CrossRef] [PubMed]

- Wu, D.; Chen, M.; Chen, K.; Zhang, Z.; Cai, Q. An Experimental Study on the Effect of Desulfurized Gypsum on Geopolymer-Solidified Soil. Int. J. Geomech. 2025, 25, 04025091. [Google Scholar] [CrossRef]

- Ma, Q.; Wang, K.; Li, Q.; Zhang, Y. Alkali-Activated Dredged-Sediment-Based Fluidized Solidified Soil: Early-Age Engineering Performance and Microstructural Mechanisms. Materials 2025, 18, 3408. [Google Scholar] [CrossRef]

- Xiao, J.; Liu, J.; Xiang, J.J.; Liu, Z.H.; Liu, C.Z.; Rong, Y.P.; Liu, Z.Y.; Chang, J.; Zhang, H.R.; He, J.G. Optimization of stabilizer ratio and strength formation mechanism for fluidized multi-source solid waste-stabilized loess. China J. Highw. Transp. 2025, 38, 250–263. [Google Scholar] [CrossRef]

- Huang, J.; Deng, L.; Gao, H.; Wu, C.; Li, J.; Zhu, D. Enhancing Tensile Performance of Cemented Tailings Backfill Through 3D-Printed Polymer Lattices: Mechanical Properties and Microstructural Investigation. Materials 2025, 18, 3314. [Google Scholar] [CrossRef] [PubMed]

- Islam, M.S.; Elahi, T.E.; Shahriar, A.R.; Mumtaz, N. Effectiveness of fly ash and cement for compressed stabilized earth block construction. Constr. Build. Mater. 2020, 255, 119392. [Google Scholar] [CrossRef]

- Fan, H.H.; Wu, P.T.; Gao, J.E.; Wang, G.Z.; Sun, S.L. Factors influencing unconfined compressive strength of solidified soil catchment surfaces. Trans. Chin. Soc. Agric. Eng. 2006, 9, 11–15. [Google Scholar]

- Fan, H.H.; Gao, J.E.; Wu, P.T.; Lou, Z.K. Analysis of factors affecting solidified soil strength based on physicochemical property variations of loess. Rock Soil Mech. 2011, 32, 1996–2000. [Google Scholar] [CrossRef]

- Fan, H.H.; Gao, J.E.; Wu, P.T.; Yang, S.W. Mechanical and water-harvesting performance of catchment surfaces using different structural soil stabilizers. J. Northwest A&F Univ. (Nat. Sci. Ed.) 2013, 41, 224–228+234. [Google Scholar] [CrossRef]

- Zhang, X.C.; Gao, J.E.; Fan, H.H.; Li, X.H.; Gao, Z.; Guo, Z.H.; Long, S.B.; Xue, L. Experimental study on mechanical properties of reconstructed loess with nano-soil stabilizer. Res. Soil Water Conserv. 2021, 28, 131–137+143. [Google Scholar] [CrossRef]

- Zhang, X.; Gao, J.; Fan, H.; Li, X.; Gao, Z.; Xue, L.; Sun, S. Study on the mechanism of nano-SiO2 for improving the properties of cement-based soil stabilizer. Nanomaterials 2020, 10, 405. [Google Scholar] [CrossRef] [PubMed]

- Kong, R.; Zhang, F.; Wang, G.; Peng, J. Stabilization of loess using nano-SiO2. Materials 2018, 11, 1014. [Google Scholar] [CrossRef] [PubMed]

- Thomas, G.; Rangaswamy, K. Strengthening of cement blended soft clay with nano-silica particles. Geomech. Eng. 2020, 20, 505–516. [Google Scholar] [CrossRef]

- Yong, L.L.; Namal Jayasanka Perera, S.V.A.D.; Syamsir, A.; Emmanuel, E.; Paul, S.C.; Anggraini, V. Stabilization of a residual soil using calcium and magnesium hydroxide nanoparticles: A quick precipitation method. Appl. Sci. 2019, 9, 4325. [Google Scholar] [CrossRef]

- Kani, E.N.; Rafiean, A.H.; Tavakolzadeh, M.; Ghaffar, S.H. Performance enhancement of cementitious soil stabilizers using incorporated nanosilica. Results Eng. 2022, 16, 100713. [Google Scholar] [CrossRef]

- Pandey, G.; Jain, P. Assessing the nanotechnology on the grounds of costs, benefits, and risks. Beni-Suef Univ. J. Basic Appl. Sci. 2020, 9, 63. [Google Scholar] [CrossRef]

- GB/T 50123-2019; Standard for Geotechnical Testing Method—Part 53: Strongly Soluble Salt Test. MOHURD (Ministry of Housing and Urban-Rural Development): Beijing, China, 2019.

- Gao, J.E.; Sun, S.L.; Wu, P.T. A New Type of Soil Stabilizer: China Patent No. 200410073273.5. P. Northwest Sci.-Technol. Univ. Agric. For. 2005, 6, 29. [Google Scholar]

- Zhang, X.C. Development of Nano-Stabilizer Materials and Their Soil Stabilization Performance. Ph.D. Dissertation, University of Chinese Academy of Sciences (Research Center for Soil and Water Conservation and Ecological Environment, Ministry of Education), Xianyang, China, 2021. [Google Scholar] [CrossRef]

- Lei, B.; Zhang, X.; Fan, H.; Gao, J.; Du, Y.; Ji, Y.; Gao, Z. Effects of Nano-SiO2 and Nano-CaCO3 on Mechanical Properties and Microstructure of Cement-Based Soil Stabilizer. Nanomaterials 2025, 15, 785. [Google Scholar] [CrossRef]

- Xu, Z.L. Elastic Mechanics; Higher Education Press: Beijing, China, 2008. [Google Scholar]

- Guo, H.W. Application of Cement-Based Stabilized Soil in High-Standard Farmland Road Construction. Master’s Dissertation, Northwest A&F University, Xianyang, China, 2024. [Google Scholar] [CrossRef]

- Han, X.B.; Chen, Z.M.; Ye, F.; Liang, X.M.; Feng, H.L.; Xia, T.H. Model test study on disturbance characteristics of surrounding rock during loess shield tunnel excavation. Chin. J. Geotech. Eng. 2024, 46, 968–977. [Google Scholar] [CrossRef]

- Piplai, T.; Parsai, T.; Kumar, A.; Alappat, B.J. Understanding interactions of nanomaterials with soil: Issues and challenges ahead. In Environmental Nanotechnology Volume 3; Springer: Cham, Switzerland, 2019; pp. 117–141. [Google Scholar]

- Díaz-López, J.L.; Cabrera, M.; Agrela, F.; Rosales, J. Geotechnical and engineering properties of expansive clayey soil stabilized with biomass ash and nanomaterials for its application in structural road layers. Geomech. Energy Environ. 2023, 36, 100496. [Google Scholar] [CrossRef]

- Xu, P.; Zhang, Q.; Qian, H.; Li, M.; Yang, F. An investigation into the relationship between saturated permeability and microstructure of remolded loess: A case study from Chinese Loess Plateau. Geoderma 2021, 382, 114774. [Google Scholar] [CrossRef]

- Akbari, H.R.; Sharafi, H.; Goodarzi, A.R. Effect of polypropylene fiber and nano-zeolite on stabilized soft soil under wet-dry cycles. Geotext. Geomembr. 2021, 49, 1470–1482. [Google Scholar] [CrossRef]

- Arabani, M.; Shalchian, M.M.; Rahimabadi, M.M. The influence of rice fiber and nanoclay on mechanical properties and mechanisms of clayey soil stabilization. Constr. Build. Mater. 2023, 407, 133542. [Google Scholar] [CrossRef]

- Althoey, F.; Zaid, O.; Martínez-García, R.; Alsharari, F.; Ahmed, M.; Arbili, M.M. Impact of Nano-silica on the hydration, strength, durability, and microstructural properties of concrete: A state-of-the-art review. Case Stud. Constr. Mater. 2023, 18, e01997. [Google Scholar] [CrossRef]

- Kong, D.; Du, X.; Wei, S.; Zhang, H.; Yang, Y.; Shah, S.P. Influence of nano-silica agglomeration on microstructure and properties of the hardened cement-based materials. Constr. Build. Mater. 2012, 37, 707–715. [Google Scholar] [CrossRef]

- Wang, C.C. Experimental Study and Mechanism Analysis on Composite Solidification of Liquid Soil with Red Mud-Steel Slag Powder-Cement. Master’s Dissertation, Taiyuan University of Technology, Taiyuan, China, 2023. [Google Scholar] [CrossRef]

- Pang, S.; Li, J.; Xie, F.; Wang, G.; Fan, H.; Zhu, K. Research on improving the flexural performance of alkali-activated geopolymer cemented coal gangue through layered addition of fibers. J. Build. Eng. 2024, 96, 110549. [Google Scholar] [CrossRef]

- Cao, R.; Li, B.; You, N.; Zhang, Y.; Zhang, Z. Properties of alkali-activated ground granulated blast furnace slag blended with ferronickel slag. Constr. Build. Mater. 2018, 192, 123–132. [Google Scholar] [CrossRef]

- Mohsen, A.; Ramadan, M.; Gharieb, M.; Yahya, A.; Soltan, A.; Hazem, M.M. Rheological behaviour, mechanical performance, and anti-fungal activity of OPC-granite waste composite modified with zinc oxide dust. J. Clean. Prod. 2022, 341, 130877. [Google Scholar] [CrossRef]

- Ghari, H.S.; Jalali-Arani, A. Nanocomposites based on natural rubber, organoclay and nano-calcium carbonate: Study on the structure, cure behavior, static and dynamic-mechanical properties. Appl. Clay Sci. 2016, 119, 348–357. [Google Scholar] [CrossRef]

- Lang, L.; Chen, B. Strength properties of cement-stabilized dredged sludge incorporating nano-SiO2 and straw fiber. Int. J. Geomech. 2021, 21, 04021119. [Google Scholar] [CrossRef]

- Marik, S.; Ransinchung, G.D.; Singh, A.; Khot, P. Investigation on use of silica based additive for sustainable subgrade construction. Case Stud. Constr. Mater. 2022, 17, e01229. [Google Scholar] [CrossRef]

- Wang, J.; Cheng, Y.; Yuan, L.; Xu, D.; Du, P.; Hou, P.; Zhou, Z.; Cheng, X.; Liu, S.; Wang, Y. Effect of nano-silica on chemical and volume shrinkage of cement-based composites. Constr. Build. Mater. 2020, 247, 118529. [Google Scholar] [CrossRef]

- Karumanchi, M.; Nerella, R. Shear strength parameters from digital tri-axial test and soils stabilization with extracted nanosilica. Nanotechnol. Environ. Eng. 2022, 7, 307–318. [Google Scholar] [CrossRef]

| Properties | Test Result |

|---|---|

| Classification | CL |

| Specific gravity, GS | 2.68 |

| Maximum dry density, ρmax (g/cm3) | 1.76 |

| Optimum moisture content, wopt (%) | 16.8 |

| Liquid limit, WL (%) | 31.3 |

| Plastic limit, WP (%) | 18.2 |

| Grain-size distribution | |

| Clay content (%) | 27.6 |

| Silt content (%) | 66.1 |

| Sand content (%) | 6.3 |

| Ingredients | Cement Clinker | Fly Ash | Gypsum | Active Agent | Nano-SiO2 | N-MBER Stabilizer |

|---|---|---|---|---|---|---|

| Content % | 82.5 | 11 | 3 | 1 | 2.5 | 100 |

| SO3 content | 2.01 | 0.26 | 1.40 | 0 | 0 | 3.67 |

| Purity (%) | APS (nm) | SSA (m2/g) | Morphology | Bulk Density (g/cm3) | True Density (g/cm3) |

|---|---|---|---|---|---|

| 99.9 | 30 | 600 | spherical | 0.08 | 2.2~2.6 |

| Factors | Levels |

|---|---|

| Water content/% | 12, 14, 16, 18, 20 |

| Degree of compaction | 0.92, 0.94, 0.96, 0.98, 1.0 |

| Curing period/d | 28 |

| Specimen Number | Water Content/% | Degree of Compaction | 28 d UCS /MPa | Specimen Number | Water Content/% | Degree of Compaction | 28 d UCS /MPa |

|---|---|---|---|---|---|---|---|

| S1 | 12 | 0.92 | 1.42 | S14 | 16 | 0.98 | 3.26 |

| S2 | 12 | 0.94 | 1.83 | S15 | 16 | 1.00 | 3.68 |

| S3 | 12 | 0.96 | 2.03 | S16 | 18 | 0.92 | 2.17 |

| S4 | 12 | 0.98 | 2.21 | S17 | 18 | 0.94 | 2.34 |

| S5 | 12 | 1.00 | 2.37 | S18 | 18 | 0.96 | 2.51 |

| S6 | 14 | 0.92 | 1.51 | S19 | 18 | 0.98 | 2.61 |

| S7 | 14 | 0.94 | 1.92 | S20 | 18 | 1.00 | 3.42 |

| S8 | 14 | 0.96 | 2.34 | S21 | 20 | 0.92 | 2.14 |

| S9 | 14 | 0.98 | 2.75 | S22 | 20 | 0.94 | 2.55 |

| S10 | 14 | 1.00 | 3.17 | S23 | 20 | 0.96 | 2.58 |

| S11 | 16 | 0.92 | 2.04 | S24 | 20 | 0.98 | 2.89 |

| S12 | 16 | 0.94 | 2.65 | S25 | 20 | 1.00 | 3.37 |

| S13 | 16 | 0.96 | 3.06 |

| Type of Stabilizer | Stabilizer Content/% | Moisture Content/% | Compaction Degree | Curing Age/d |

|---|---|---|---|---|

| N-MBER stabilizer | 12% | 16% | 1 | 3, 7, 28, 60, 90 |

| MBER stabilizer | ||||

| Cement-based stabilizer |

| Type of Stabilizer | Softened Strength/MPa | Dry Strength/MPa | Softening Coefficient |

|---|---|---|---|

| N-MBER stabilizer | 3.60 | 10.62 | 0.339 |

| MBER stabilizer | 2.77 | 9.37 | 0.296 |

| Cement-based stabilizer | 2.53 | 8.86 | 0.286 |

| Type of Stabilizer | Average Pore Defect Area/μm2 | Average Proportion of Pore Defect Area/% |

|---|---|---|

| N-MBER stabilizer | 21,295.23 | 8.86 |

| MBER stabilizer | 59,546.19 | 24.05 |

| Cement-based stabilizer | 100,594.71 | 40.62 |

| Stabilizer Type | Total Pores | CV | Micropores | CV | Medium-Pores | CV | Macro-Pores | CV |

|---|---|---|---|---|---|---|---|---|

| N-MBER stabilizer | 21,859.548 | 0.058 | 19,864.154 | 0.059 | 1919.204 | 0.069 | 76.190 | 0.096 |

| MBER stabilizer | 27,468.048 | 0.075 | 23,677.536 | 0.078 | 3714.286 | 0.062 | 76.226 | 0.072 |

| Cement-based stabilizer | 27,892.730 | 0.060 | 23,358.953 | 0.056 | 4403.230 | 0.083 | 130.547 | 0.066 |

| Project | Unit Price/RMB | Cured Soil Road | Concrete Road | ||

|---|---|---|---|---|---|

| Quantity/ton | Price/RMB | Quantity/ton | Price/RMB | ||

| Nano-curing agent | 480 | 15 | 7200 | 0 | 0 |

| Red soil | 0 | 85 | 0 | 0 | 0 |

| Aggregate | 250 | 0 | 0 | 100 | 25,000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lei, B.; Zhang, X.; Fan, H.; Wu, S.; Zhao, C.; Ni, W.; Liu, C. A Strategy to Optimize the Mechanical Properties and Microstructure of Loess by Nano-Modified Soil Stabilizer. Materials 2025, 18, 4435. https://doi.org/10.3390/ma18194435

Lei B, Zhang X, Fan H, Wu S, Zhao C, Ni W, Liu C. A Strategy to Optimize the Mechanical Properties and Microstructure of Loess by Nano-Modified Soil Stabilizer. Materials. 2025; 18(19):4435. https://doi.org/10.3390/ma18194435

Chicago/Turabian StyleLei, Baofeng, Xingchen Zhang, Henghui Fan, Shijian Wu, Changzhi Zhao, Wenbo Ni, and Changhao Liu. 2025. "A Strategy to Optimize the Mechanical Properties and Microstructure of Loess by Nano-Modified Soil Stabilizer" Materials 18, no. 19: 4435. https://doi.org/10.3390/ma18194435

APA StyleLei, B., Zhang, X., Fan, H., Wu, S., Zhao, C., Ni, W., & Liu, C. (2025). A Strategy to Optimize the Mechanical Properties and Microstructure of Loess by Nano-Modified Soil Stabilizer. Materials, 18(19), 4435. https://doi.org/10.3390/ma18194435