Investigating the Thermal Properties of Structural Partitions Produced Using Additive Technology (3D Printing) from Biodegradable Materials for Use in Construction

Abstract

1. Introduction

2. Biodegradable Materials in Additive Manufacturing Technologies

Application of Thermoplastic Starch (TPS) in Thermal Insulation Materials Produced by Additive Manufacturing (3D Printing)

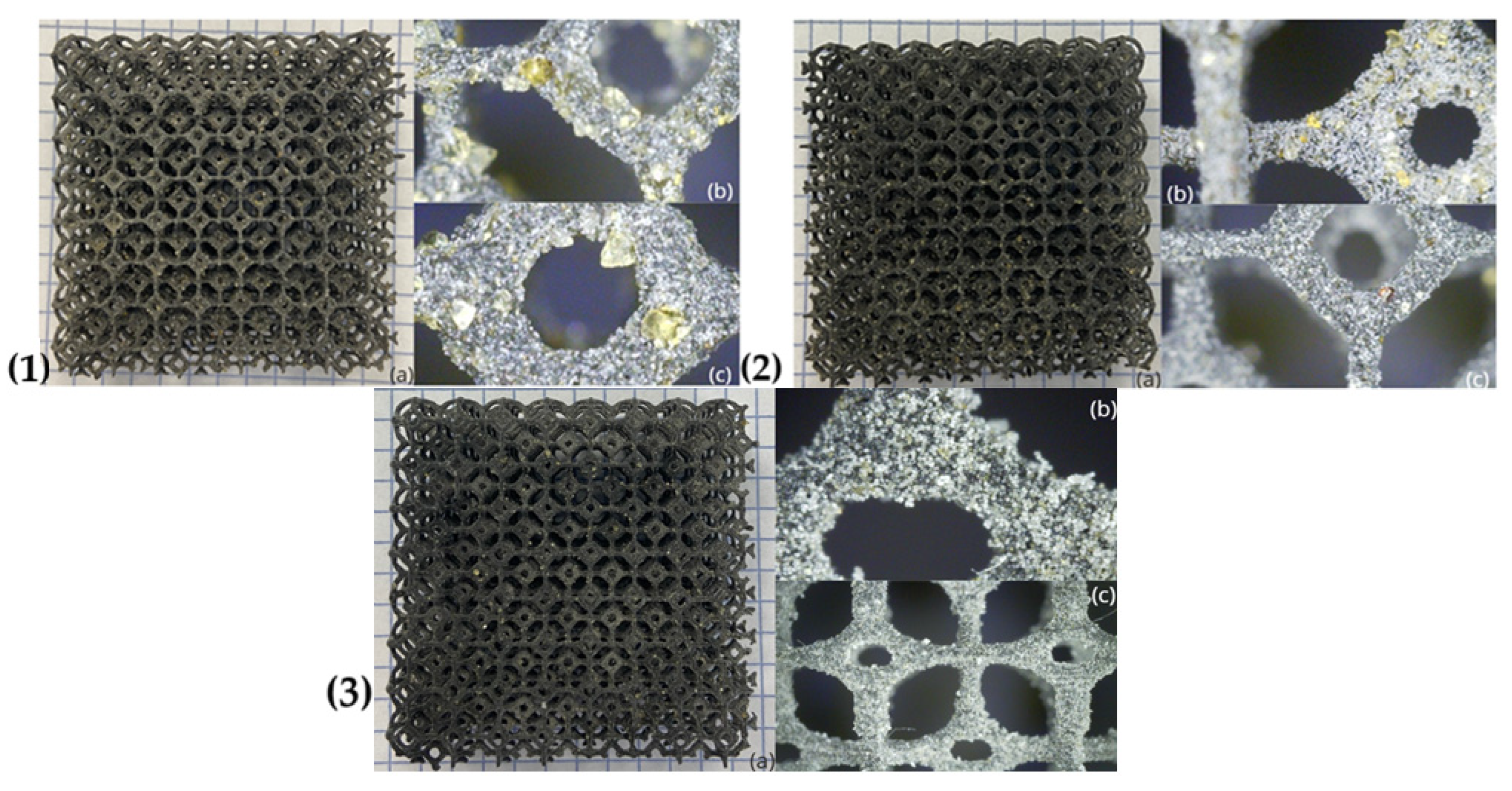

3. Materials and Methods

3.1. Material for Printing

3.2. Experimental Determination of the Thermal Transmittance Coefficient

3.3. Quantitative Method for Calculating Thermal Parameters

- q is the heat flux density, [W/m2];

- Uqc is the voltage of the flowing current, [mV].

- λ is the design thermal conductivity of the material, [W/m·K];

- d is the thickness of the test sample, [m];

- q is the heat flux density, [W/m2];

- Tg is the temperature of the upper surface of the sample, [°C];

- Td is the temperature of the lower surface of the sample, [°C].

- U is the thermal transmittance, [W/m2·K];

- Rsi is the internal surface resistance, [m2·K/W];

- Rse is the external surface resistance, [m2·K/W];

- di is the thickness of the material layer (i) in the component, [m];

- λi is the design thermal conductivity of the material layer (i), [W/m·K].

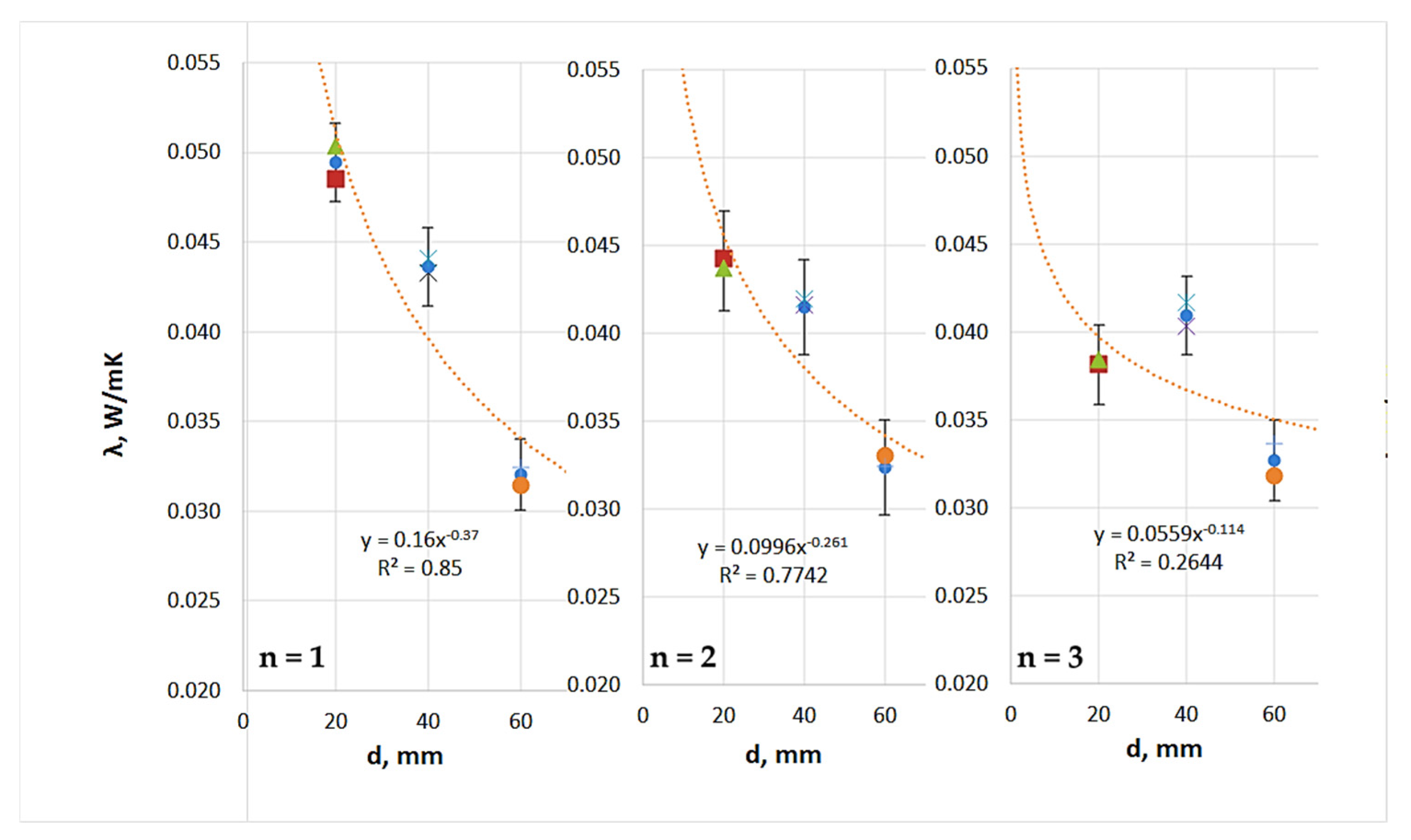

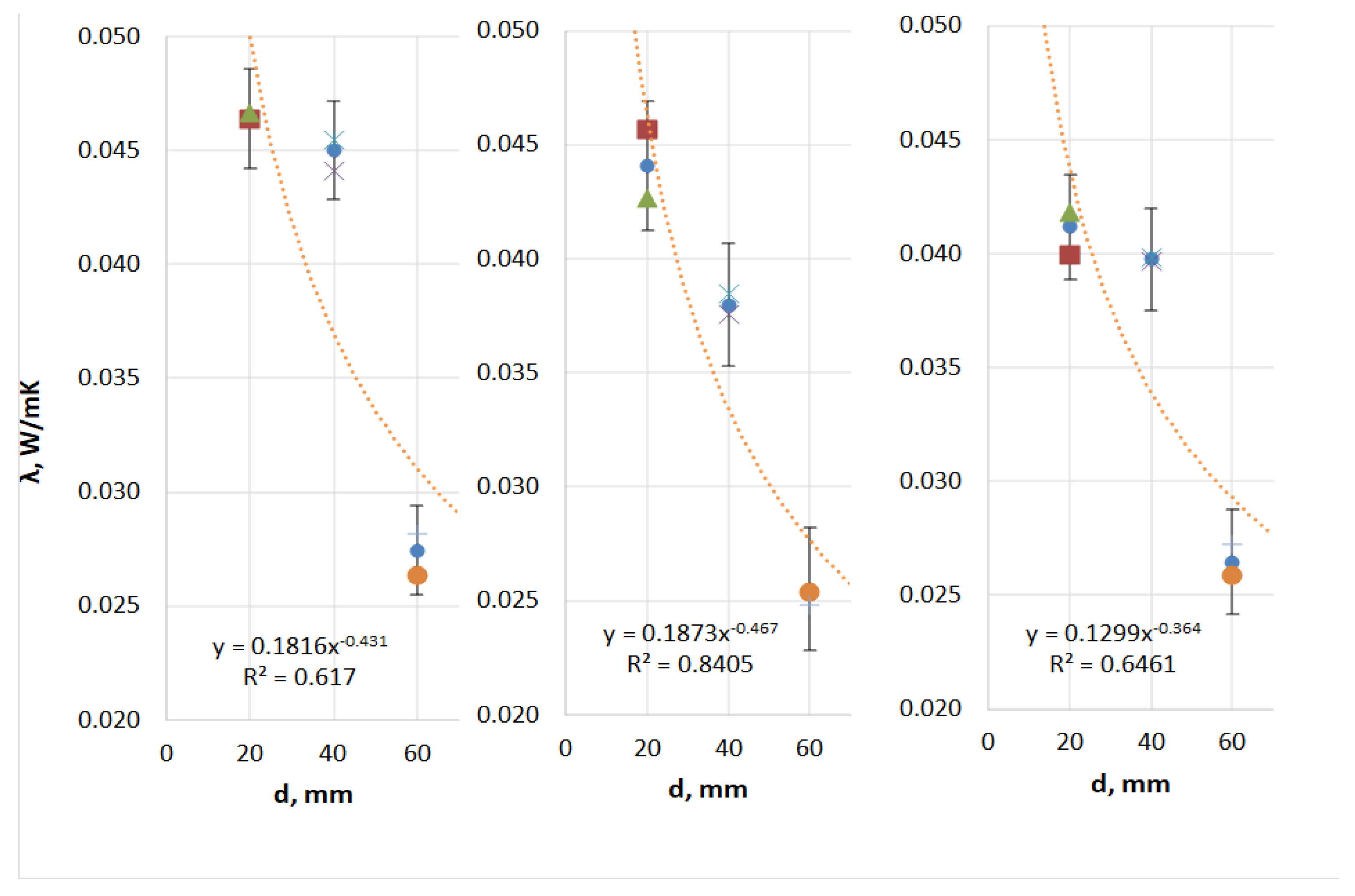

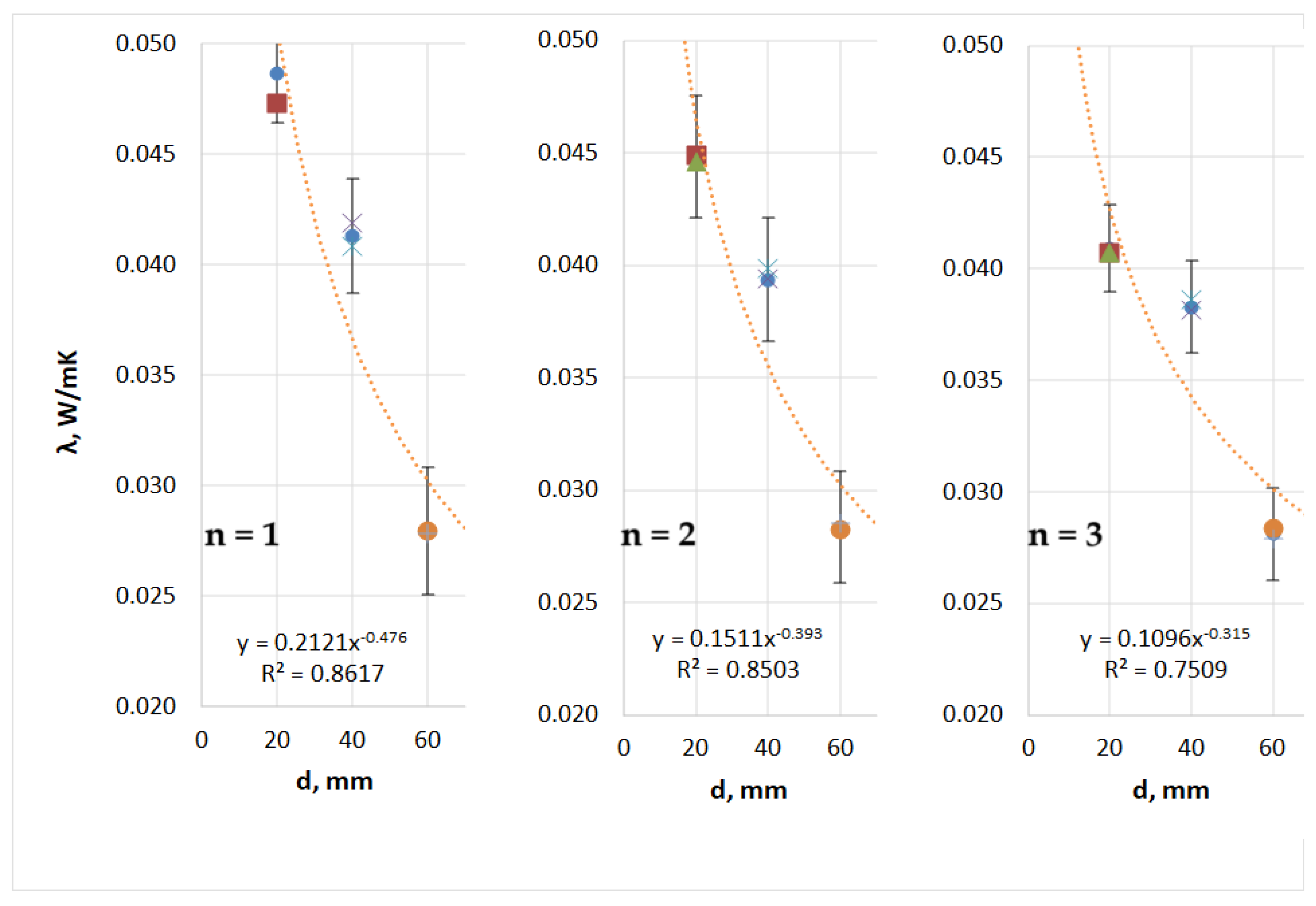

4. Results and Discussion

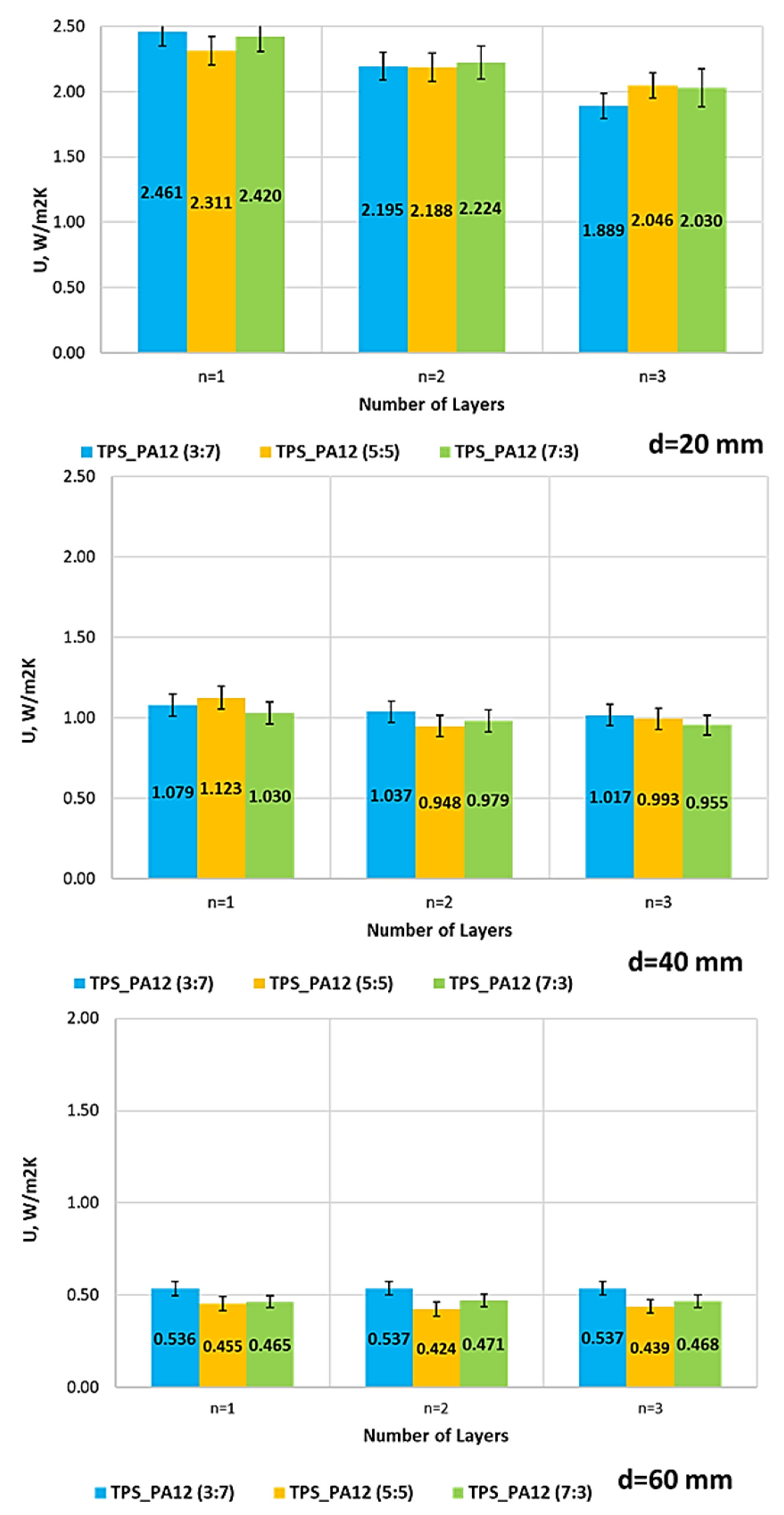

4.1. Analysis of the Test Results for the Thermal Properties of Thermal Insulation Materials

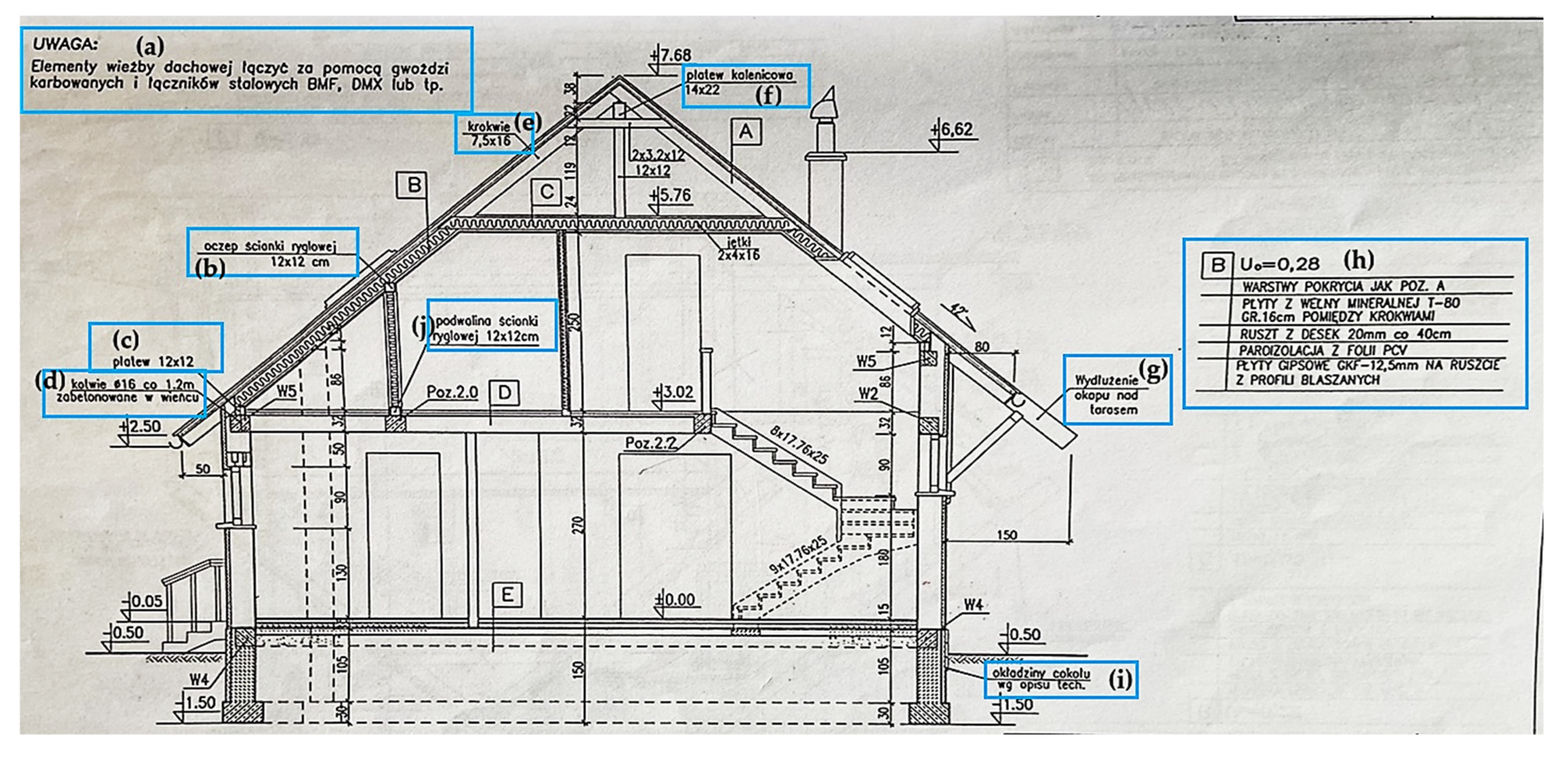

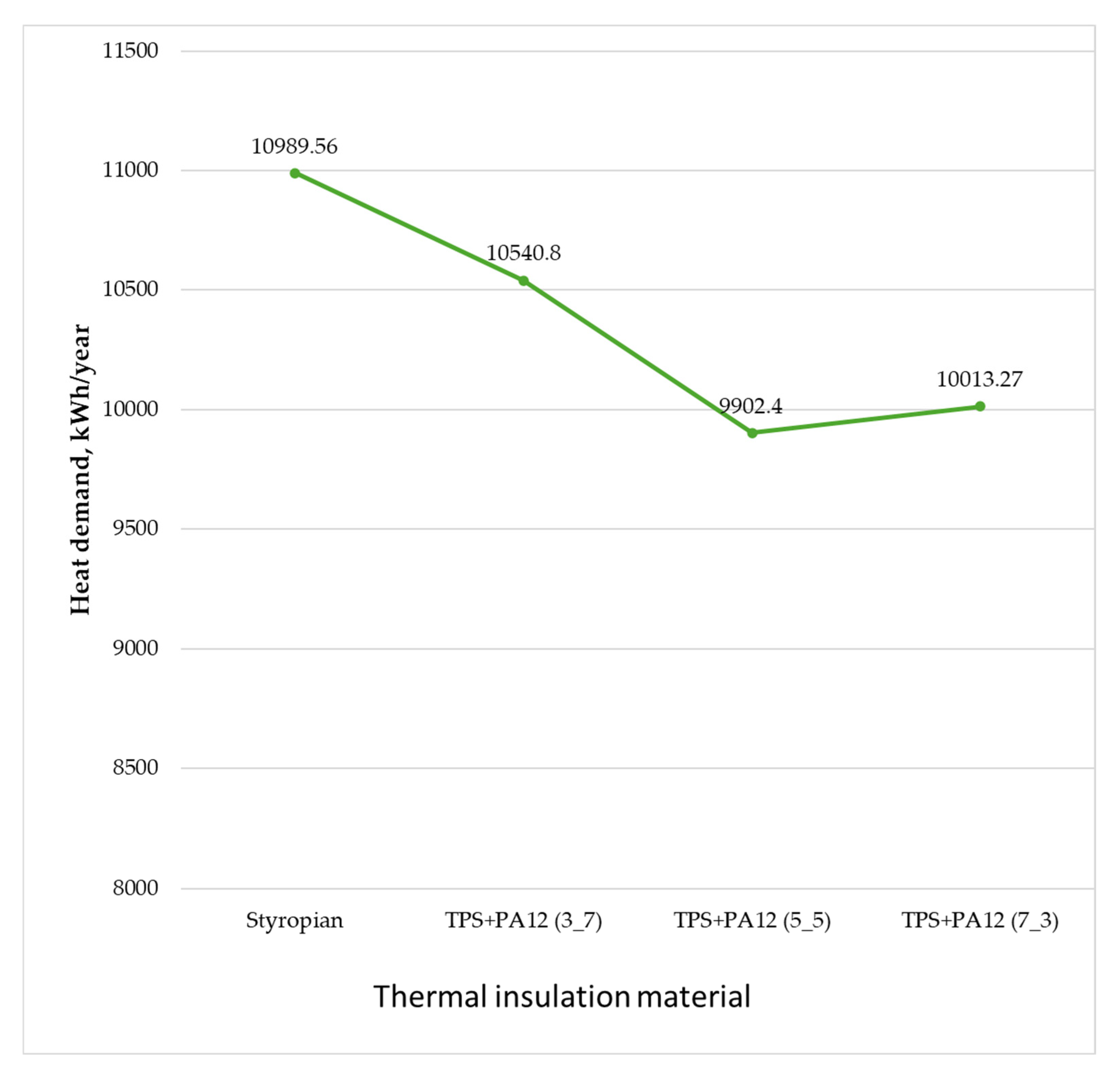

4.2. The Application of Prototype Thermal Insulation Materials in Energy-Efficient Construction Is Analyzed

- The existing building, where the external walls are insulated with 12 cm thick polystyrene;

- A building in which the polystyrene has been replaced with a three-layer prototype thermal insulation material with the same thickness (12 cm), made from TPS + PA12 at a 3:7 mass ratio;

- A building in which the polystyrene has been replaced with a three-layer prototype thermal insulation material consisting of TPS and PA12 at a 5:5 mass ratio and with a thickness of 12 cm;

- A building in which the polystyrene has been replaced with a three-layer prototype thermal insulation material of the same thickness (12 cm) consisting of TPS and PA12 at a mass ratio of 7:3.

Description of the Analyzed Building

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sandanayake, M.S. Environmental Impacts of Construction in Building Industry—A Review of Knowledge Advances, Gaps and Future Directions. Knowledge 2022, 2, 139–156. [Google Scholar] [CrossRef]

- Buildings-GSR. Available online: https://globalabc.org/Global-Status-Report?Utm_source=chatgpt.com (accessed on 31 May 2025).

- Global Status Report for Buildings and Construction. Available online: https://www.unep.org/Resources/Report/Global-Status-Report-Buildings-and-Construction-20242025?Utm_source=chatgpt.com (accessed on 31 May 2025).

- IEA. Available online: https://www.iea.org/ (accessed on 31 May 2025).

- PE/36/2023/REV/2 Directive (EU) 2023/2413 of the European Parliament and of the Council of 18 October 2023 Amending Directive (EU) 2018/2001, Regulation (EU) 2018/1999 and Directive 98/70/EC as Regards the Promotion of Energy from Renewable Sources, and Repealing Council Directive (EU) 2015/652. Off. J. Eur. Union 2023.

- PE/4/2018/REV/1 Directive (EU) 2018/844 of the European Parliament and of the Council of 30 May 2018 Amending Directive 2010/31/EU on the Energy Performance of Buildings and Directive 2012/27/EU on Energy Efficiency (Text with EEA Relevance). Off. J. Eur. Union, 2018.

- Naciążek, B.; Piotrowski, R. Jak Zbudować Dom Energooszczędny i Skorzystać z Dopłaty; Wydawnictwo Przewodnik Budowlany: Warszawa, Poland, 2023. [Google Scholar]

- Al-Homoud, M.S. Performance Characteristics and Practical Applications of Common Building Thermal Insulation Materials. Build. Environ. 2005, 40, 353–366. [Google Scholar] [CrossRef]

- Schiavoni, S.; D’Alessandro, F.; Bianchi, F.; Asdrubali, F. Insulation Materials for the Building Sector: A Review and Comparative Analysis. Renew. Sustain. Energy Rev. 2016, 62, 988–1011. [Google Scholar] [CrossRef]

- Anwajler, B.; Zdybel, E.; Tomaszewska-Ciosk, E. Innovative Polymer Composites with Natural Fillers Produced by Additive Manufacturing (3D Printing)—A Literature Review. Polymers 2023, 15, 3534. [Google Scholar] [CrossRef] [PubMed]

- Khan, N.R.; Sharmin, T.; Bin Rashid, A. Exploring the Versatility of Aerogels: Broad Applications in Biomedical Engineering, Astronautics, Energy Storage, Biosensing, and Current Progress. Heliyon 2024, 10, e23102. [Google Scholar] [CrossRef] [PubMed]

- Abu-Jdayil, B.; Mourad, A.-H.; Hittini, W.; Hassan, M.; Hameedi, S. Traditional, State-of-the-Art and Renewable Thermal Building Insulation Materials: An Overview. Constr. Build. Mater. 2019, 214, 709–735. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Castell, A.; Barreneche, C.; de Gracia, A.; Fernández, A.I. Materials Used as PCM in Thermal Energy Storage in Buildings: A Review. Renew. Sustain. Energy Rev. 2011, 15, 1675–1695. [Google Scholar] [CrossRef]

- Sharma, R.; Jang, J.-G.; Hu, J.-W. Phase-Change Materials in Concrete: Opportunities and Challenges for Sustainable Construction and Building Materials. Materials 2022, 15, 335. [Google Scholar] [CrossRef]

- Jegan, J.; Anitha, P.; Logaraja, R. Comprehensive Study on Thermal Properties and Application of Phase Change Materials in Construction. J. Build. Pathol. Rehabil. 2025, 10, 31. [Google Scholar] [CrossRef]

- Jha, S.K.; Sankar, A.; Zhou, Y.; Ghosh, A. Incorporation of Phase Change Materials in Buildings. Constr. Mater. 2024, 4, 676–703. [Google Scholar] [CrossRef]

- Kurańska, M.; Malewska, E.; Ożóg, H.; Sędzimir, J.; Put, A.; Kowalik, N.; Michałowski, S.; Zemła, M.; Kucała, M.; Prociak, A. Open-Cell Spray Polyurethane Foams Based on Biopolyols from Fruit Seed Oils. Polymers 2024, 16, 1145. [Google Scholar] [CrossRef] [PubMed]

- Gavrilović-Grmuša, I.; Rančić, M.; Tešić, T.; Stupar, S.; Milošević, M.; Gržetić, J. Bio-Epoxy Resins Based on Lignin and Tannic Acids as Wood Adhesives—Characterization and Bonding Properties. Polymers 2024, 16, 2602. [Google Scholar] [CrossRef]

- Mohan, S.; Thilagavathi, G.; Rajkhowa, R. Composite Panels Utilizing Microdust and Coir Pith for Eco-Friendly Construction Solutions. J. Text. Inst. 2025, 116, 175–182. [Google Scholar] [CrossRef]

- Varamesh, A.; Zhu, Y.; Hu, G.; Wang, H.; Rezania, H.; Li, Y.; Lu, Q.; Ren, X.; Jiang, F.; Bryant, S.L.; et al. Fully Biobased Thermal Insulating Aerogels with Superior Fire-Retardant and Mechanical Properties. Chem. Eng. J. 2024, 495, 153587. [Google Scholar] [CrossRef]

- Hilal, N.; Hamah Sor, N.; Hadzima-Nyarko, M.; Radu, D.; Tawfik, T.A. The Influence of Nanosunflower Ash and Nanowalnut Shell Ash on Sustainable Lightweight Self-Compacting Concrete Characteristics. Sci. Rep. 2024, 14, 9450. [Google Scholar] [CrossRef] [PubMed]

- Anwajler, B. Modern Insulation Materials for Sustainability Based on Natural Fibers: Experimental Characterization of Thermal Properties. Fibers 2024, 12, 76. [Google Scholar] [CrossRef]

- Ibraheem, E.K.; Bdaiwi, W. Enhancing Mechanical and Thermal Properties of Unsaturated Polyester Composites Through Sidr Leaves’ Particle Reinforcement. Rev. Compos. Matériaux Avancés 2024, 34, 269–275. [Google Scholar] [CrossRef]

- Cigarruista Solís, L.; Chen Austin, M.; Deago, E.; López, G.; Marin-Calvo, N. Rice Husk-Based Insulators: Manufacturing Process and Thermal Potential Assessment. Materials 2024, 17, 2589. [Google Scholar] [CrossRef]

- Raja, T.; Mohanavel, V.; Kannan, S.; Vekariya, V.; Paul, D.; Velmurugan, P.; Chinnathambi, A.; Ali Alharbi, S.; Sivakumar, S. Rice Bran Particulates Reinforced Ipomoea carnea Fiber Epoxy Composite for Engineering Application. J. Nat. Fibers 2024, 21, 2364253. [Google Scholar] [CrossRef]

- Aguillón, B.; Cabrera, D.; Lazo, M.; Adrián, E.; Carrasco, M.; Medina-Perilla, J.; Vera-Villalobos, J.; Rigail-Cedeño, A. Sorbitol Glycidyl Ether Epoxy/Brewer’s Spent Grain Biocomposite for Fiberboard Applications. Case Stud. Chem. Environ. Eng. 2024, 9, 100705. [Google Scholar] [CrossRef]

- Wan, D.; Tian, C.; Cai, Q.; Zhang, X. Investigating the Characteristics and Thermal Performance of Plaster Composites Enhanced with Paddy Husk for Sustainable Residential Construction. Case Stud. Therm. Eng. 2024, 60, 104638. [Google Scholar] [CrossRef]

- Sergi, C.; Bavasso, I.; Frighetto, G.; Tirillò, J.; Sarasini, F.; Casalini, S. Linoleum Waste as PLA Filler for Components Cost Reduction: Effects on the Thermal and Mechanical Behavior. Polym. Test. 2024, 138, 108548. [Google Scholar] [CrossRef]

- Fernandes, F.A.d.S.; Fernandes, T.F.d.S.; Rossignolo, J.A. Production of Glass Foam in a Microwave Oven Using Agro-Industrial Waste as Raw Material. Buildings 2024, 14, 1643. [Google Scholar] [CrossRef]

- Pop, M.A.; Croitoru, C.; Matei, S.; Zaharia, S.-M.; Coșniță, M.; Spîrchez, C. Thermal and Sound Insulation Properties of Organic Biocomposite Mixtures. Polymers 2024, 16, 672. [Google Scholar] [CrossRef]

- Fayzullin, I.; Gorbachev, A.; Volfson, S.; Serikbayev, Y.; Nakyp, A.; Akylbekov, N. Composite Material Based on Polypropylene and Modified Natural Fillers. Polymers 2024, 16, 1703. [Google Scholar] [CrossRef]

- Jamal, I.I.; Marsi, N.; Rus, A.Z.M.; Bahri, A.H.S.; Md-Said, A.; Hashim, M.M.; Ariffin, I.A. Mechanical Characteristics Rice Husk Fiber (RHF) Blended Recycled Polyethylene (RPE) for RHF/RPE Polymer Composite. J. Adv. Res. Appl. Mech. 2024, 118, 144–156. [Google Scholar] [CrossRef]

- Grzybek, J.; Nazari, M.; Jebrane, M.; Terziev, N.; Petutschnigg, A.; Schnabel, T. Enhancing Fire Safety and Thermal Performance: Wood Composites with Bio-based Phase Change Materials and Fire Retardants for Building Applications. Fire Mater. 2024, 48, 838–846. [Google Scholar] [CrossRef]

- Bonifacio, A.L.; Archbold, P. Exploring Oat Husks as Aggregates in Limestone-Based Composites: Effects of Surface Treatments and Binder Selection on Mechanical Performance. Materials 2024, 17, 2588. [Google Scholar] [CrossRef] [PubMed]

- Buda, R.; Pucinotti, R. Natural Lime–Cork Mortar for the Seismic and Energetic Retrofit of Infill Walls: Design, Materials, and Method. Appl. Sci. 2024, 14, 7503. [Google Scholar] [CrossRef]

- Dymek, M.; Ptak, M.; Kaczyński, P.; Fernandes, F.A.O.; Alves de Sousa, R.J.; Serra, G.F.; Kurańska, M. Eco-Friendly Cork–Polyurethane Biocomposites for Enhanced Impact Performance: Experimental and Numerical Analysis. Polymers 2024, 16, 887. [Google Scholar] [CrossRef]

- Sergi, C.; Sarasini, F.; Bracciale, M.P.; Russo, P.; Tirillò, J. Cork Consolidated by Hot Compression as a Viable Bio-Based Alternative to Polyolefines in Decking Boards: A Preliminary Study. Constr. Build. Mater. 2024, 420, 135541. [Google Scholar] [CrossRef]

- Krumins, J.A.; Vamza, I.; Dzalbs, A.; Blumberga, D. Particle Boards from Forest Residues and Bio-Based Adhesive. Buildings 2024, 14, 462. [Google Scholar] [CrossRef]

- Bendaikha, O.; Yaseri, A.Z.H. Thermal Performance and Feasibility Study Using a Straw-Based Thermal Insulation in Geothermal Systems. J. Renew. Energ. 2024, 1, 173–180. [Google Scholar] [CrossRef]

- Mucsi, Z.M.; Hasan, K.M.F.; Horváth, P.G.; Bak, M.; Hung Anh, L.D.; Kóczán, Z.; Bejó, L.; Alpár, T. Fabrication and Characterization of Lignocellulosic Coconut and Energy Reed Straw-Reinforced Methylene Diphenyl Diisocyanate-Bonded Sustainable Insulation Panels. Constr. Build. Mater. 2024, 414, 134992. [Google Scholar] [CrossRef]

- Glenn, G.M.; Tonoli, G.H.D.; Silva, L.E.; Klamczynski, A.P.; Wood, D.; Chiou, B.-S.; Lee, C.; Hart-Cooper, W.; McCaffrey, Z.; Orts, W. Effect of Starch and Paperboard Reinforcing Structures on Insulative Fiber Foam Composites. Polymers 2024, 16, 911. [Google Scholar] [CrossRef]

- Rodríguez Neira, K.; Cárdenas-Ramírez, J.P.; Rojas-Herrera, C.J.; Haurie, L.; Lacasta, A.M.; Torres Ramo, J.; Sánchez-Ostiz, A. Assessment of Elaboration and Performance of Rice Husk-Based Thermal Insulation Material for Building Applications. Buildings 2024, 14, 1720. [Google Scholar] [CrossRef]

- Mohammed, W.; Osman, Z.; Elarabi, S.; Mehats, J.; Charrier, B. Mechanical and Physical Properties of Biocomposites for Furniture and Thermal Insulation. Cellul. Chem. Technol. 2024, 58, 331–338. [Google Scholar] [CrossRef]

- Kamalizad, M.; Morshed, R. Seismic Performance of Compressed Earth Block Walls Reinforced with Common Reeds. Case Stud. Constr. Mater. 2024, 21, e03388. [Google Scholar] [CrossRef]

- Tasgin, Y.; Demircan, G.; Kandemir, S.; Acikgoz, A. Mechanical, Wear and Thermal Properties of Natural Fiber-Reinforced Epoxy Composite: Cotton, Sisal, Coir and Wool Fibers. J. Mater. Sci. 2024, 59, 10844–10857. [Google Scholar] [CrossRef]

- Spyridonos, E.; Witt, M.-U.; Dippon, K.; Milwich, M.; Gresser, G.T.; Dahy, H. Natural Fibre Pultruded Profiles: Illustration of Optimisation Processes to Develop High-Performance Biocomposites for Architectural and Structural Applications. Compos. Part C Open Access 2024, 14, 100492. [Google Scholar] [CrossRef]

- Han, S.; Zhao, X.; Li, X.; Ye, H.; Wang, G. Synergistic In-Situ Reinforcement of Lignin and Adhesive for High-Performance Aligned Bamboo Fibers Composites. J. Mater. Res. Technol. 2024, 28, 879–890. [Google Scholar] [CrossRef]

- Urdanpilleta, M.; del Rey, R.; Leceta, I.; Rodríguez, J.C.; Alba, J.; Guerrero, P. Empirical Modelling of the Acoustic Behavior of Sheep Wool/Soy Protein Biocomposites. J. Build. Eng. 2024, 89, 109290. [Google Scholar] [CrossRef]

- Segura, J.; Montava, I.; Juliá, E.; Gadea, J.M. Acoustic and Thermal Properties of Panels Made of Fruit Stones Waste with Coconut Fibre. Constr. Build. Mater. 2024, 426, 136054. [Google Scholar] [CrossRef]

- Ali, M.; Al-Suhaibani, Z.; Almuzaiqer, R.; Albahbooh, A.; Al-Salem, K.; Nuhait, A. New Composites Derived from the Natural Fiber Polymers of Discarded Date Palm Surface and Pineapple Leaf Fibers for Thermal Insulation and Sound Absorption. Polymers 2024, 16, 1002. [Google Scholar] [CrossRef]

- Kharshiduzzaman, M.; Haque, M.R.; Bhuiyan, M.S.; Alam, S.; Mashuk, M.; Ahmed, S.K.N.; Afgani, S.H.; Gafur, M.A. Evaluation of the Mechanical Properties of a Novel Hybrid Composite Composed of Rattan and Date Palm Fiber: An Experimental Study. Adv. Polym. Technol. 2024, 2024. [Google Scholar] [CrossRef]

- Krishnasamy, B.; Shanmugam, N.; Subramanian, A.; Selvaraj, S.K.; Sakthivel, S.; Guru, R.; Admassu, Y. Sound-Absorbing and Thermal Insulating Properties of Natural Coir/Jute Hybrid Composites for Functional Materials. J. Eng. Fibers Fabr. 2024, 19. [Google Scholar] [CrossRef]

- Alazzawi, S.; Mahmood, W.A.; Shihab, S.K. Comparative Study of Natural Fiber-Reinforced Composites for Sustainable Thermal Insulation in Construction. Int. J. Thermofluids 2024, 24, 100839. [Google Scholar] [CrossRef]

- Ariharasudhan, S.; Sundaresan, S.; Selvaraj, S.K.; Ramratan; Worku, A.; Santhanam, S. Studies on Sugarcane Bagasse/Jute Fibers Reinforced Bio-Composites for Functional Thermal Insulation Materials. J. Eng. Fiber Fabr. 2024, 19. [Google Scholar] [CrossRef]

- Trociński, A.; Wieruszewski, M.; Bartkowiak, M.; Dziurka, D.; Mirski, R. The Influence of Hemp Fibers (Cannabis sativa L.) on the Mechanical Properties of Fiber–Gypsum Boards Reinforcing the Gypsum Matrix. Polymers 2024, 16, 2644. [Google Scholar] [CrossRef] [PubMed]

- Greco, P.F.; Pepi, C.; Gioffré, M. A Novel Biocomposite Material for Sustainable Constructions: Metakaolin Lime Mortar and Spanish Broom Fibers. J. Build. Eng. 2024, 83, 108425. [Google Scholar] [CrossRef]

- Jové-Sandoval, F.; García-Baños, E.M.; Barbero-Barrera, M.M. Characterisation and Thermal Improvement of Adobe Walls from Earth-Straw Lightweight Panels. MRS Adv. 2023, 9, 71–77. [Google Scholar] [CrossRef]

- Jadhav, P.S.; Sarkar, A.; Zhu, L.; Ren, S. Flame Retardant Biogenic Building Insulation Materials from Hemp Fiber. J. Appl. Polym. Sci. 2024, 141, e55137. [Google Scholar] [CrossRef]

- Kabore, A.; Ouellet-Plamondon, C.M. The Impact of Vegetable Fibres on the Shrinkage and Mechanical Properties of Cob Materials. Materials 2024, 17, 736. [Google Scholar] [CrossRef]

- Kebede, M.S.; Ayaliew, T.G.; Demlie, S.M. Experimental Characterizing Mechanical and Physical Properties of Water Lily Polyester Matrix Composite Materials. Adv. Mater. Sci. Eng. 2024, 2024. [Google Scholar] [CrossRef]

- Bąk, A.; Mikuła, J.; Oliinyk, I.; Łach, M. Basic Research on Layered Geopolymer Composites with Insulating Materials of Natural Origin. Sci. Rep. 2024, 14, 12576. [Google Scholar] [CrossRef] [PubMed]

- Varma, D.A.; Joseph, L.; Madhavan, M.K.; Jayanarayanan, K.; Pegoretti, A. Strength, Durability and Finite Element Analysis of Hybrid Jute/Basalt Fiber Reinforced Polymer Confined Concrete Column under Axial Compression. Results Eng. 2024, 22, 102281. [Google Scholar] [CrossRef]

- Abu-Saleem, M.; Gattas, J.M. Eccentric Compression Behaviour of Hybrid Timber-Cardboard Sandwich Columns. Constr. Build. Mater. 2024, 440, 137365. [Google Scholar] [CrossRef]

- Abu-Saleem, M.; Gattas, J.M. Fabrication and Structural Characterisation of Hybrid Timber-Cardboard Sandwich Beams. Eng. Struct. 2024, 305, 117678. [Google Scholar] [CrossRef]

- Anwajler, B. Application of Voronoi Tessellation to the Additive Manufacturing of Thermal Barriers of Irregular Porous Materials—Experimental Determination of Thermal Properties. Materials 2025, 18, 1873. [Google Scholar] [CrossRef] [PubMed]

- Balazs, D.M.; Ibáñez, M. Widening the Use of 3D Printing. Science 2023, 381, 1413–1414. [Google Scholar] [CrossRef]

- Anwajler, B. The Thermal Properties of a Prototype Insulation with a Gyroid Structure—Optimization of the Structure of a Cellular Composite Made Using SLS Printing Technology. Materials 2022, 15, 1352. [Google Scholar] [CrossRef]

- Anwajler, B.; Szulc, P. The Impact of 3D Printing Technology on the Improvement of External Wall Thermal Efficiency—An Experimental Study. J. Compos. Sci. 2024, 8, 389. [Google Scholar] [CrossRef]

- Anwajler, B.; Szołomicki, J.; Noszczyk, P. Application of a Gyroid Structure for Thermal Insulation in Building Construction. Materials 2024, 17, 6301. [Google Scholar] [CrossRef]

- Anwajler, B.; Szołomicki, J.; Noszczyk, P.; Baryś, M. The Potential of 3D Printing in Thermal Insulating Composite Materials—Experimental Determination of the Impact of the Geometry on Thermal Resistance. Materials 2024, 17, 1202. [Google Scholar] [CrossRef]

- Anwajler, B.; Zielińska, S.; Witek-Krowiak, A. Innovative Cellular Insulation Barrier on the Basis of Voronoi Tessellation—Influence of Internal Structure Optimization on Thermal Performance. Materials 2024, 17, 1578. [Google Scholar] [CrossRef]

- Grabowska, B.; Kasperski, J. The Thermal Conductivity of 3D Printed Plastic Insulation Materials—The Effect of Optimizing the Regular Structure of Closures. Materials 2020, 13, 4400. [Google Scholar] [CrossRef] [PubMed]

- de Rubeis, T. 3D-Printed Blocks: Thermal Performance Analysis and Opportunities for Insulating Materials. Sustainability 2022, 14, 1077. [Google Scholar] [CrossRef]

- de Rubeis, T.; Ciccozzi, A.; Giusti, L.; Ambrosini, D. The 3D Printing Potential for Heat Flow Optimization: Influence of Block Geometries on Heat Transfer Processes. Sustainability 2022, 14, 15830. [Google Scholar] [CrossRef]

- de Rubeis, T.; Ciccozzi, A.; Paoletti, D.; Ambrosini, D. 3D Printing for Energy Optimization of Building Envelope—Experimental Results. Heliyon 2024, 10, e31107. [Google Scholar] [CrossRef] [PubMed]

- de Rubeis, T.; Ciccozzi, A.; Giusti, L.; Ambrosini, D. On the Use of 3D Printing to Enhance the Thermal Performance of Building Envelope—A Review. J. Build. Eng. 2024, 95, 110284. [Google Scholar] [CrossRef]

- Li, H.; Huneault, M.A. Comparison of Sorbitol and Glycerol as Plasticizers for Thermoplastic Starch in TPS/PLA Blends. J. Appl. Polym. Sci. 2011, 119, 2439–2448. [Google Scholar] [CrossRef]

- Souri Rudabadi, M.; Ashenai Ghasemi, F.; Fasihi, M.; Rajaee, P. An Experimental Study on the Microstructural, Tensile, and Fracture Properties of Biodegradable Polylactic Acid Blended with Thermoplastic Corn Starch Filled with Halloysite Nanotubes. Ind. Crops Prod. 2023, 201, 116922. [Google Scholar] [CrossRef]

- Haryńska, A.; Janik, H.; Sienkiewicz, M.; Mikolaszek, B.; Kucińska-Lipka, J. PLA–Potato Thermoplastic Starch Filament as a Sustainable Alternative to the Conventional PLA Filament: Processing, Characterization, and FFF 3D Printing. ACS Sustain. Chem. Eng. 2021, 9, 6923–6938. [Google Scholar] [CrossRef]

- Ju, Q.; Tang, Z.; Shi, H.; Zhu, Y.; Shen, Y.; Wang, T. Thermoplastic Starch Based Blends as a Highly Renewable Filament for Fused Deposition Modeling 3D Printing. Int. J. Biol. Macromol. 2022, 219, 175–184. [Google Scholar] [CrossRef]

- Qin, W.; Qiu, Y.; He, H.; Guo, B.; Li, P. Pyrogallic Acid–Compatibilized Polylactic Acid/Thermoplastic Starch Blend Produced via One-Step Twin-Screw Extrusion. Int. J. Biol. Macromol. 2024, 276, 133758. [Google Scholar] [CrossRef] [PubMed]

- Cai, K.; Liu, X.; Ma, X.; Zhang, J.; Tu, S.; Feng, J. Preparation of Biodegradable PLA/PBAT Blends with Balanced Toughness and Strength by Dynamic Vulcanization Process. Polymer 2024, 291, 126587. [Google Scholar] [CrossRef]

- Foret, S.; Mazian, B.; Bekas, V.; Martins, F.C.B.; Campanella, O.H.; Perré, P.; Augusto, P.E.D. Thermoplastic Starch Biocomposites Reinforced with Hemp Shives Obtained via Extrusion. Ind. Crops Prod. 2023, 206, 117707. [Google Scholar] [CrossRef]

- Miao, Z.; Li, L.; Xie, Y.; Feng, D.; Wu, F.; Xie, D.; Liu, Y.; Mei, Y. Revisiting Maleic Anhydride-Grafted Biopolymers for Improved Compatibility and Toughening of PLA/PBAT Blends: Effects of Molecular Weight and Grafting Ratio. Polymer 2025, 320, 128055. [Google Scholar] [CrossRef]

- Hamidi, M.N.; Abdullah, J.; Mahmud, A.S.; Hassan, M.H.; Zainoddin, A.Y. Influence of Thermoplastic Polyurethane (TPU) and Printing Parameters on the Thermal and Mechanical Performance of Polylactic Acid (PLA)/Thermoplastic Polyurethane (TPU) Polymer. Polym. Test. 2025, 143, 108697. [Google Scholar] [CrossRef]

- Hamidi, M.N.; Abdullah, J.; Shuib, R.K.; Aziz, I.; Namazi, H. 4D Printing of Polylactic Acid (PLA)/Thermoplastic Polyurethane (TPU) Shape Memory Polymer—A Review. Eng. Res. Express 2024, 6, 012402. [Google Scholar] [CrossRef]

- Williams, J.M.; Adewunmi, A.; Schek, R.M.; Flanagan, C.L.; Krebsbach, P.H.; Feinberg, S.E.; Hollister, S.J.; Das, S. Bone Tissue Engineering Using Polycaprolactone Scaffolds Fabricated via Selective Laser Sintering. Biomaterials 2005, 26, 4817–4827. [Google Scholar] [CrossRef]

- Wiria, F.E.; Leong, K.F.; Chua, C.K.; Liu, Y. Poly-ε-Caprolactone/Hydroxyapatite for Tissue Engineering Scaffold Fabrication via Selective Laser Sintering. Acta Biomater. 2007, 3, 1–12. [Google Scholar] [CrossRef]

- Eosoly, S.; Brabazon, D.; Lohfeld, S.; Looney, L. Selective Laser Sintering of Hydroxyapatite/Poly-ε-Caprolactone Scaffolds. Acta Biomater. 2010, 6, 2511–2517. [Google Scholar] [CrossRef]

- Simpson, R.L.; Wiria, F.E.; Amis, A.A.; Chua, C.K.; Leong, K.F.; Hansen, U.N.; Chandrasekaran, M.; Lee, M.W. Development of a 95/5 Poly(L-lactide-co-glycolide)/Hydroxylapatite and β-tricalcium Phosphate Scaffold as Bone Replacement Material via Selective Laser Sintering. J. Biomed. Mater. Res. B Appl. Biomater. 2008, 84B, 17–25. [Google Scholar] [CrossRef]

- Rodzeń, K.; Sharma, P.K.; McIlhagger, A.; Mokhtari, M.; Dave, F.; Tormey, D.; Sherlock, R.; Meenan, B.J.; Boyd, A. The Direct 3D Printing of Functional PEEK/Hydroxyapatite Composites via a Fused Filament Fabrication Approach. Polymers 2021, 13, 545. [Google Scholar] [CrossRef] [PubMed]

- Savalani, M.M.; Hao, L.; Zhang, Y.; Tanner, K.E.; Harris, R.A. Fabrication of Porous Bioactive Structures Using the Selective Laser Sintering Technique. Proc. Inst. Mech. Eng. H 2007, 221, 873–886. [Google Scholar] [CrossRef]

- Wiria, F.E.; Chua, C.K.; Leong, K.F.; Quah, Z.Y.; Chandrasekaran, M.; Lee, M.W. Improved Biocomposite Development of Poly(Vinyl Alcohol) and Hydroxyapatite for Tissue Engineering Scaffold Fabrication Using Selective Laser Sintering. J. Mater. Sci. Mater. Med. 2008, 19, 989–996. [Google Scholar] [CrossRef]

- Jiang, G.; Zhang, W.; Fan, L.; Luo, C.; Leng, P.; Tao, D. One-Step Strategy for Preparing Renewable Polylactic Acid (PLA)/Thermoplastic Starch (TPS) Composite Filaments for 3D Printing. Ind. Crops Prod. 2025, 233, 121444. [Google Scholar] [CrossRef]

- Chang, C.C.; Trinh, B.M.; Mekonnen, T.H. Robust Multiphase and Multilayer Starch/Polymer (TPS/PBAT) Film with Simultaneous Oxygen/Moisture Barrier Properties. J. Colloid Interface Sci. 2021, 593, 290–303. [Google Scholar] [CrossRef]

- Müller, P.; Bere, J.; Fekete, E.; Móczó, J.; Nagy, B.; Kállay, M.; Gyarmati, B.; Pukánszky, B. Interactions, Structure and Properties in PLA/Plasticized Starch Blends. Polymer 2016, 103, 9–18. [Google Scholar] [CrossRef]

- Xiong, Z.; Yang, Y.; Feng, J.; Zhang, X.; Zhang, C.; Tang, Z.; Zhu, J. Preparation and Characterization of Poly(Lactic Acid)/Starch Composites Toughened with Epoxidized Soybean Oil. Carbohydr. Polym. 2013, 92, 810–816. [Google Scholar] [CrossRef] [PubMed]

- PA12 Smooth, Sinterit—Manufacturer of Compact and Industrial SLS 3D Printers. Available online: https://sinterit.com/pl/ (accessed on 5 May 2025).

- EN ISO 9869-1:2014; Thermal Insulation—Building Elements—In Situ Measurement of Thermal Resistance and Thermal Transmittance. Part 1: Heat Flow Meter Method. International Organization for Standardization: Geneva, Switzerland, 2014.

- ISO 6946:2017; Building Components and Building Elements—Thermal Resistance and Thermal Transmittance—Calculation Methods. International Organization for Standardization: Geneva, Switzerland, 2017.

- PN-EN ISO 9229:2020-12; Thermal insulation—Dictionary. International Organization for Standardization: Geneva, Switzerland, 2020.

| Authors | Research Material | Composite Type | Application | Key Properties | Technology | Sustainability Notes |

|---|---|---|---|---|---|---|

| Kurańska et al. [17] | Polyurethane foams from bio-polyols (fruit seed oils) | Particle-reinforced (dispersion) | Thermal insulation | λ = 0.035–0.043 W/(m·K) | Oil transesterification, foaming | Renewable resources, seed waste |

| Gavrilović-Grmuša et al. [18] | Bio-epoxies based on lignin and tannic acid | Particle-reinforced (dispersion) | Wood adhesives | τt = 5.64–10.87 MPa (shear strength) | Resin chemical modification | Natural polyphenols, reduced synthetic hardeners |

| Mohan et al. [19] | Panels from cotton microdust + coir dust | Particle-reinforced (dispersion) | Thermal insulation | λ = 0.02–0.09 W/(m·K) | Panel forming, dust composition | Use of textile waste |

| Varamesh et al. [20] | Bio-aerogel (phytic acid + chitosan, cellulose) | Particle-reinforced (dispersion) | Thermal insulation | λ = 0.036–0.038 W/(m·K) | Layered assembly, crosslinking | Fully bio-based raw materials |

| Hilal et al. [21] | Self-compacting concrete with sunflower and walnut ash | Particle-reinforced (dispersion) | Structural (lightweight concrete) | σc = 14–33 MPa; σf = 1.9–5.2 MPa; σt = 1.1–3.0 MPa | Conventional concrete mixing | Partial cement replacement with ash, lower density |

| Anwajler [22] | 3D-printed insulation composites (soybean oil + wastepaper ash) | Particle-reinforced (dispersion) | Thermal insulation | U = 0.016 W/m·K; LOI = 56–63% | 3D printing (Voronoi, Rhino/Grasshopper) | Waste utilization, bio-based resin |

| Ibraheem & Bdaiwi [23] | Polyester composites with sidr leaf powder | Particle-reinforced (dispersion) | Thermal + mechanical insulation | σc = 34.5–48.7 MPa; λ = 0.101–0.190 W/(m·K) | Hand layup forming | Plant-based powder, regional waste |

| Cigarruista Solís et al. [24] | Insulation panels from rice husk + rice flour | Particle-reinforced (dispersion) | Thermal insulation | λ = 0.073 W/(m·K) | Mold forming, drying | Local raw materials, agro-waste |

| Raja et al. [25] | Epoxy with Ipomoea carnea fibers + bran filler | Particle/fiber-reinforced (dispersion) | Wall panels (antibacterial) | σt = 16.4–25.0 MPa; σf = 17.0–27.4 MPa | Hand layup | Natural fibers, hygienic properties |

| Aguillón et al. [26] | Boards from brewers’ spent grain + sorbitol epoxy | Particle-reinforced (dispersion) | Furniture/construction boards | σf = 33.3–51.5 MPa | Thermopressing | Brewery waste, wood-like material |

| Wan et al. [27] | Plasters with rice husk addition (800 μm granules) | Particle-reinforced (dispersion) | Thermal insulation | λ = 0.67–0.83 W/(m·K) | Mixing with plaster | Bio-additive in traditional plasters |

| Sergi et al. [28] | PLA reinforced with linoleum dust (wood flour, cork, jute) | Particle-reinforced (dispersion) | Decorative elements, lightweight panels | σt = 49–69 MPa; σf = 75–98 MPa | PLA molding, extrusion | Linoleum waste, biodegradable PLA |

| Fernandes et al. [29] | Glass foams with sugarcane bagasse ash | Particle-reinforced (dispersion) | Insulation, lightweight aggregate | σc = 0.48–0.58 MPa; λ = 0.05–0.07 W/(m·K) | Sintering at 750–850 °C | Bagasse ash, agro-waste, glass |

| Pop et al. [30] | Acoustic insulation from cellulose + beeswax, fir resin, natural fillers | Particle-reinforced (dispersion) | Acoustic insulation | SAC = 0.15–0.78; λ = 0.05–0.08 (W/m·K) | Panel forming | Fully natural materials |

| Authors | Research Material | Composite Type | Application | Key Properties | Technology | Sustainability Notes |

|---|---|---|---|---|---|---|

| Fayzullin et al. [31] | Polypropylene composite with wood flour, rice husk, sunflower husk (enzymatically modified) | Large-particle-reinforced (0.1–1 mm) | Structural applications | σt = 21.0–31.9 MPa | Surface enzymatic modification | Improved filler–matrix bonding, renewable fillers |

| Jamal et al. [32] | Rice husk fiber + recycled polyethylene | Large-particle-reinforced (0.1–1 mm) | Partition panels | σt = 0.52–0.60 MPa; σf = 19.0–27.2 MPa | Blending RPE + RHF | Waste reuse, recycled PE |

| Grzybek et al. [33] | Pine wood particleboard with ethyl palmitate (PCM) + fire retardants | Large-particle-reinforced (0.1–1 mm) | Wall panels with PCM storage | Latent heat ≈ 50 J/g; PHRR = 348–548 kW/m2; THR = 82–213 MJ/m2 | Hot pressing with additives | Thermal storage, fire safety, paper/clay waste |

| Bonifacio & Archbold [34] | Limestone-based composites with oat/rice husks | Large-particle-reinforced (0.1–1 mm) | Binder composites | - | Binder mixing, surface coating (linseed oil) | Delayed degradation, renewable aggregates |

| Buda & Pucinotti [35] | Natural hydraulic lime mortar + cork (15–30%) | Large-particle-reinforced (1–2 mm) | Mortar (binder/insulation) | σc = 2.16–3.35 MPa; σf = 2.34–3.87 MPa; λ = 0.39–0.45 W/(m·K) | Mixing, curing | Local cork, renewable resource |

| Dymek et al. [36] | Bio-based polyurethane foams + cork granules (from cooking oil) | Large-particle-reinforced (1–2 mm) | Foams (insulation, cushioning) | σc = 0.283–0.344 MPa; λ = 0.04–0.07 W/(m·K) | Foam forming with cork | Reused cooking oil, cork waste |

| Sergi et al. [37] | Hot-compressed cork planks | Large-particle-reinforced (1–2 mm) | Deck boards, interior elements | σt = 7.98–9.27 MPa; σf = 12.8–16.4 MPa; λ = 0.24–0.68 W/(m·K) | Hot compression | Agglomerated cork, renewable |

| Krumins et al. [38] | Bio-based particleboards (branches, needles, bark) + carbohydrate binder | Large-particle-reinforced (2–5 mm) | Boards | σf = 2.13–9.99 MPa | Hot pressing (140–160 °C) | Forest waste as reinforcement and binder |

| Bendaikha & Yaseri [39] | Straw-based bio-insulation (straw + aloe vera + sodium bicarbonate) | Large-particle-reinforced (2–5 mm) | Pipe insulation (geothermal) | Thermal gradient ~9 °C | Mold forming + coating | Straw waste, natural additives |

| Mucsi et al. [40] | Coconut coir + reed straw panels (with MDI binder) | Large-particle-reinforced (2–5 mm) | Insulation panels | λ = 0.08–0.10 W/(m·K); σf = 2.41–6.33 MPa | Hot pressing with MDI | Agro-fibers, renewable |

| Glenn et al. [41] | Cellulose fiber foams + paperboard reinforcements | Large-particle-reinforced (2–5 mm) | Packaging/insulation foams | λ = 0.039–0.049 W/(m·K); σf = 0.038–0.460 MPa; σc = 0.001–0.305 MPa | Foaming, starch binding | Paper waste, biodegradable |

| Rodríguez et al. [42] | Rice husk panels (pulping + NaOH) | Large-particle-reinforced (5–10 mm) | Thermal + acoustic insulation | λ = 0.037–0.042 W/(m·K); NRC = 0.77–0.98 | Pulping, molding | Agro-waste, high acoustic absorption |

| Mohammed et al. [43] | Particleboards (bagasse, kenaf, cotton stalk) + casein/tannin adhesives | Large-particle-reinforced (>10 mm) | Furniture, wall panels, insulation | σf = 1.6–15.6 MPa; λ = 0.050–0.089 W/(m·K) | Hot pressing with bio-adhesives | Agro-residues, bio-adhesives |

| Kamalizad & Morshed [44] | Compressed earth blocks + sand-coated reed reinforcement | Large-particle-reinforced (>10 mm) | Structural blocks | σt = 40.9 MPa (reinforced); lateral displacement +76% | Manual pressing + reed reinforcement | Local earth, low-energy, seismic improvement |

| Authors | Research Material | Composite Type | Application | Key Properties | Technology | Sustainability Notes |

|---|---|---|---|---|---|---|

| Tasgin et al. [45]. | Epoxy composites with cotton and sisal fibers | Continuous fiber-reinforced | Semi-structural panels | σt = 15.3–52.8 MPa; λ = 0.70–1.02 W/(m·K) | VARTM (vacuum-assisted resin transfer molding) | Natural fibers, renewable |

| Spyridonos et al. [46] | Pultruded hemp fiber profiles + bio-resin | Continuous fiber-reinforced | Cylindrical profiles (bending loads) | σf = 247–311 MPa; bending modulus = 21 GPa | Pultrusion | Hemp fibers, renewable |

| Tasgin et al. [45] | Discontinuous fiber composites (sisal, coir) | Discontinuous aligned fiber | Thermal insulation | λ = 0.187 W/(m·K) (coir); moderate tensile strength | Compression molding | Plant fibers |

| Han et al. [47] | Densified bamboo fiber composite (aligned) | Discontinuous aligned fiber | Structural (wood-like material) | σt = 421.5 MPa; σf = 211.1 MPa | Hot pressing with resin | High strength, renewable bamboo |

| Urdanpilleta et al. [48] | Soy protein + Latxa sheep wool (porous biocomposites) | Random cut fiber composite | Acoustic insulation | SAC ≈ 0.95 at 4000 Hz; λ = 0.04–0.07 W/(m·K) | Freeze-drying | Sheep wool waste, biodegradable |

| Segura et al. [49] | Fruit stone particles + coconut fiber panels | Random cut fiber composite | Acoustic/thermal insulation | λ = 0.145–0.159 W/(m·K); SAC = 0.7–0.95 | Panel pressing | Agro-waste, natural fibers |

| Ali et al. [50] | Date palm fibers + pineapple leaf fibers + PVAc resin | Random cut fiber composite | Thermal/acoustic insulation | λ = 0.054–0.075 W/(m·K); SAC = 0.43–0.85 | Compression molding | Agro-waste fibers |

| Kharshiduzzaman et al. [51] | Rattan + date palm fibers (NaOH treated) | Random cut fiber composite | Interior partitions, panels | σt = 4.6–12.5 MPa; σf = 14.3–39.1 MPa | Mold pressing | Renewable agro-fibers |

| Krishnasamy et al. [52] | Epoxy composites reinforced with coir/jute fibers | Random cut fiber composite | Light insulation panels | λ = 0.11–0.156 W/(m·K); SAC = 0.1–0.44 | Compression molding | Natural coir/jute |

| Alazzawi et al. [53] | Epoxy composites with hemp, jute, date palm fibers | Random cut fiber composite | Insulation + structural panels | λ = 0.051–0.084 W/(m·K); σc = 64–70 MPa | ISO-179 cutting, resin molding | Plant fibers, renewable |

| Ariharasudhan et al. [54] | Bagasse + jute fiber composites with PVA | Random cut fiber composite | Load-bearing applications | σt = 6.7–7.0 MPa; σf = 12–14.6 MPa; λ = 0.112–0.156 W/(m·K) | Hand layup/compression | Agro-waste fibers |

| Trocinski et al. [55] | Gypsum + hemp fibers (Poland) | Random cut fiber composite | Lightweight gypsum boards | σf = 2.9–5.2 MPa; σt = 0.64–1.02 MPa | Casting with gypsum | Hemp fibers, renewable |

| Greco et al. [56] | Metakaolin–lime mortar + Spartium junceum fibers | Random cut fiber composite | Masonry reinforcement | σc = 6.7–12.5 MPa; σf = 0.8–2.8 MPa | Mortar mixing | Natural textile fibers |

| Jové-Sandoval et al. [57]. | Adobe clay + wheat straw/sawdust fibers | Random cut fiber composite | Thermal insulation panels | λ = 0.05–0.15 W/(m·K) | Mixing clay slurry | Agro-waste fibers, local |

| Jadhav et al. [58] | Hemp fiber + silica xerogel composites | Random cut fiber composite | Thermal insulation (fire retardant) | λ = 0.031–0.036 W/(m·K) | Xerogel preparation, pressing | Recycled hemp fibers |

| Kabore & Ouellet-Plamondon [59] | Cob (clay + fibers) samples | Random cut fiber composite | Non-load-bearing, insulating filler | σc = 1.8–4.6 MPa; λ = 0.2–0.5 W/(m·K) | Handcrafted cob drying | Local clay, plant fibers |

| Kebede et al. [60] | Polyester composites with water lily fibers | Random cut fiber composite | Structural applications | σt = 43.8–95.7 MPa; σf = 57.9–110.7 MPa | Polyester resin pressing | Invasive aquatic plants reused |

| Authors | Research Material | Composite Type | Application | Key Properties | Technology | Sustainability Notes |

|---|---|---|---|---|---|---|

| Bąk et al. [61] | Multilayer geopolymer composites with coconut/jute/hemp/flax felt/wool | Layer-reinforced (laminates) | Building envelopes (insulation panels) | λ = 0.805–1.177 W/(m·K) | Lamination + fiberglass reinforcement | Natural insulating mats, renewable |

| Varma et al. [62] | Concrete cylinders wrapped with jute + basalt fibers | Layer-reinforced (laminates) | Structural strengthening (columns) | σf = 73.6–110.7 MPa (flexural strength); compressive axial stress = 40.2 MPa | Hand layup wrapping | Basalt + jute natural fibers |

| Abu-Saleem & Gattas [63] | Timber–cardboard sandwich columns (plywood + waste cardboard) | Layer-reinforced (sandwich) | Lightweight structural columns | σc = 23.4–25.4 MPa; ultimate load = 34–84 kN | Sandwich panel assembly | Recycled cardboard core, plywood facings |

| Abu-Saleem & Gattas [64] | Timber–cardboard sandwich beams | Layer-reinforced (sandwich) | Lightweight beams | σf = 26.7–28.6 MPa; ultimate load ≈ 13 kN | Sandwich beam assembly | Recycled cardboard, plywood skins |

| Material/System | Three-Dimensional Printing Technique | Key Results/Observations | Source |

|---|---|---|---|

| PLA/TPS | FDM | Classical two-step approach; compatibility issues, improved properties with additives. | Li & Huneault [77] |

| PLA + 60% TPS | FDM | Elongation at break increased by 77%; greater ductility but lower stiffness. | Souri Rudabadi et al. [78] |

| PLA/TPS bio-based filament | FDM | Successful printing of porous structures and anatomical models; high printability. | Haryńska et al. [79] |

| PLA/TPS/PBAT | FDM | Low-cost filaments; stable and repeatable printing, good mechanical properties. | Ju et al. [80] |

| PLA/TPS + pyrogallol | Extrusion (no 3D printing) | One-step strategy; improved phase compatibility; no 3D printing test. | Qin et al. [81] |

| PLA/PBS | FDM | Elongation increased by 150–300% with compatibilisers; ↑ costs. | Cai et al. [82] |

| TPS z hemp shives | - | Plasticization of starch with hemp shives and glycerol; a description of methods and the properties of TPS (thermoplastic starch) as a base for composites. | Foret et al. [83] |

| PLA/PBAT | FDM | Flexible composites; improved deformability, compatibilizers required. | Miao et al. [84] |

| PLA + elastomers (NR/PU) | FDM | Impact strength ↑ 2–5×; reduced biodegradability. | Hamidi et al. [85,86] |

| PCL | SLS | Tissue/bone scaffolds, controlled porosity and geometry; good cell colonization. | Williams et al. [87] |

| PCL/HA | SLS | Bioactive bone composites. Porous 70/30% structures; bioactivity; modulus 0.6–2.3 MPa; σᵧ 0.1–0.6 MPa; effect of laser power and orientation. | Wiria et al. [88]; Eosoly et al. [89] |

| PLLA/PLGA + HA, β-TCP | SLS | Resorbable scaffolds. SLS-sintered composites; suitable sintering window; potential as bone substitute. | Simpson et al. [90] |

| PEEK/HA | SLS | Load-bearing implants; bioactivity; mechanical properties tailored for orthopedic applications. | Rodzen et al. [91] |

| PLA (modified) | - | Biocomposites. Narrow SLS window; modifications (e.g., nanoclay, wood fibers) improve powder stability and processability. | Hao, Savalani et al. [92] |

| PVA/HA | - | Bioactive composites. Sintered PVA/HA powders produce porous bioactive structures; quality dependent on powder morphology. | Wiria et al. [93] |

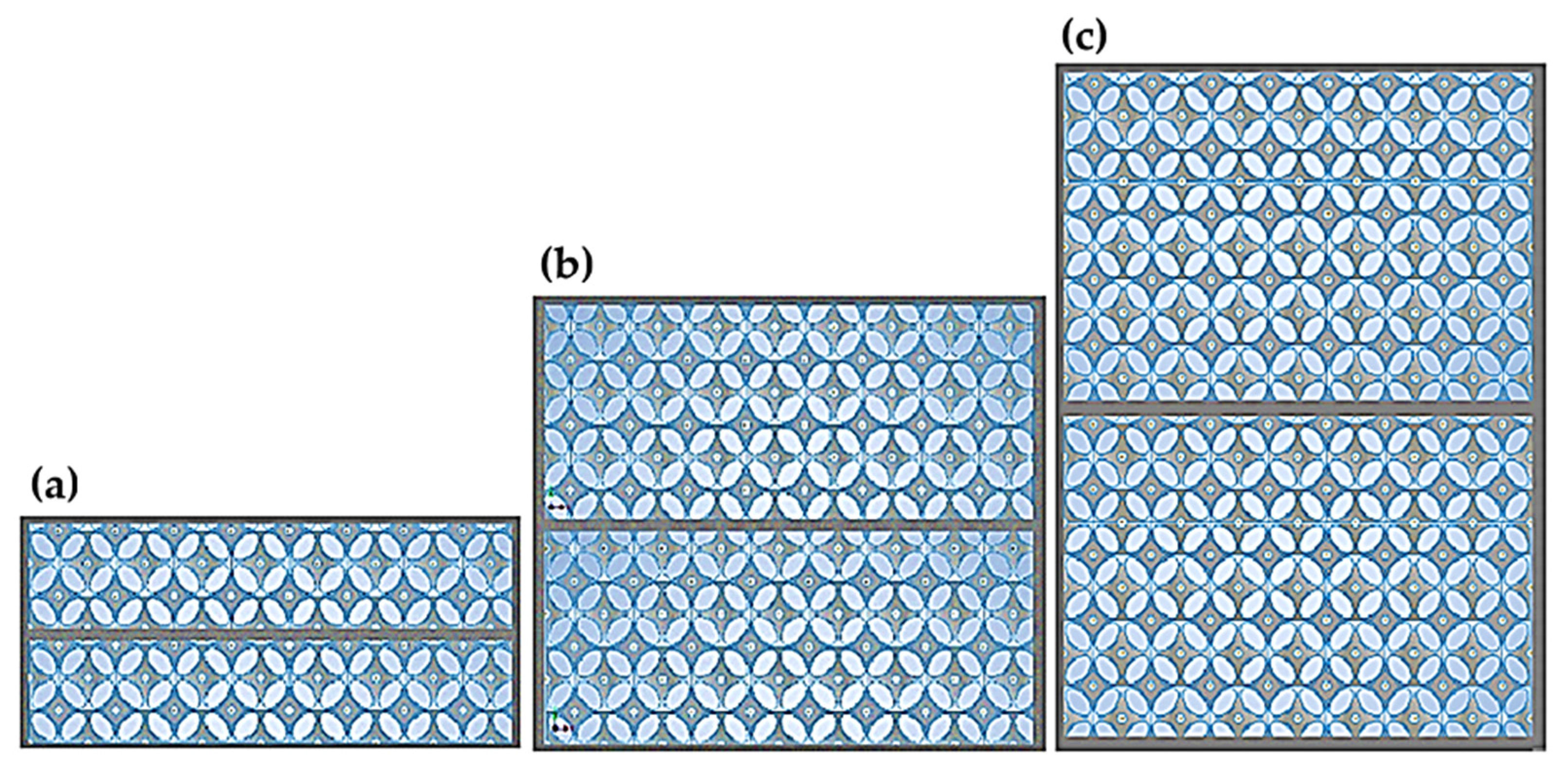

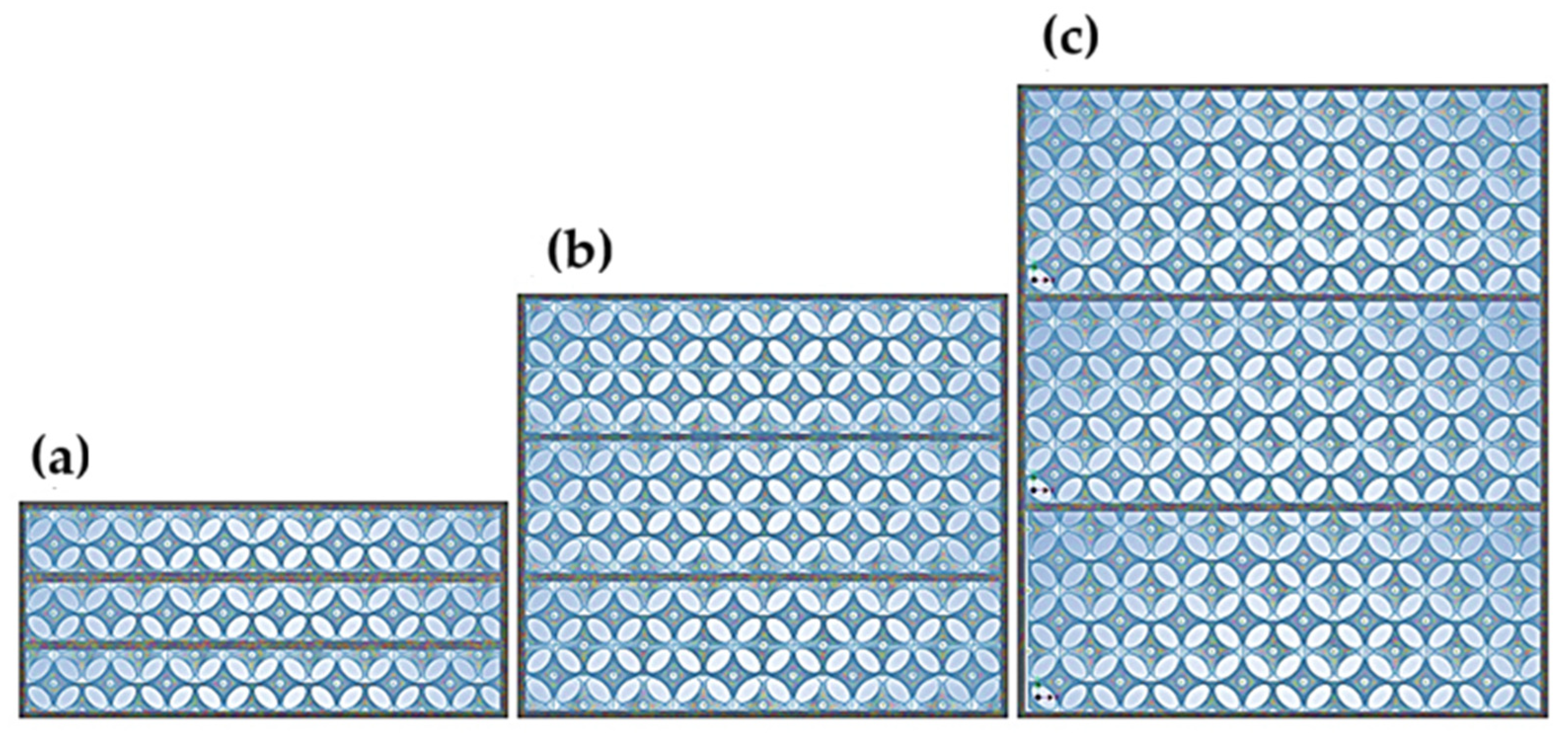

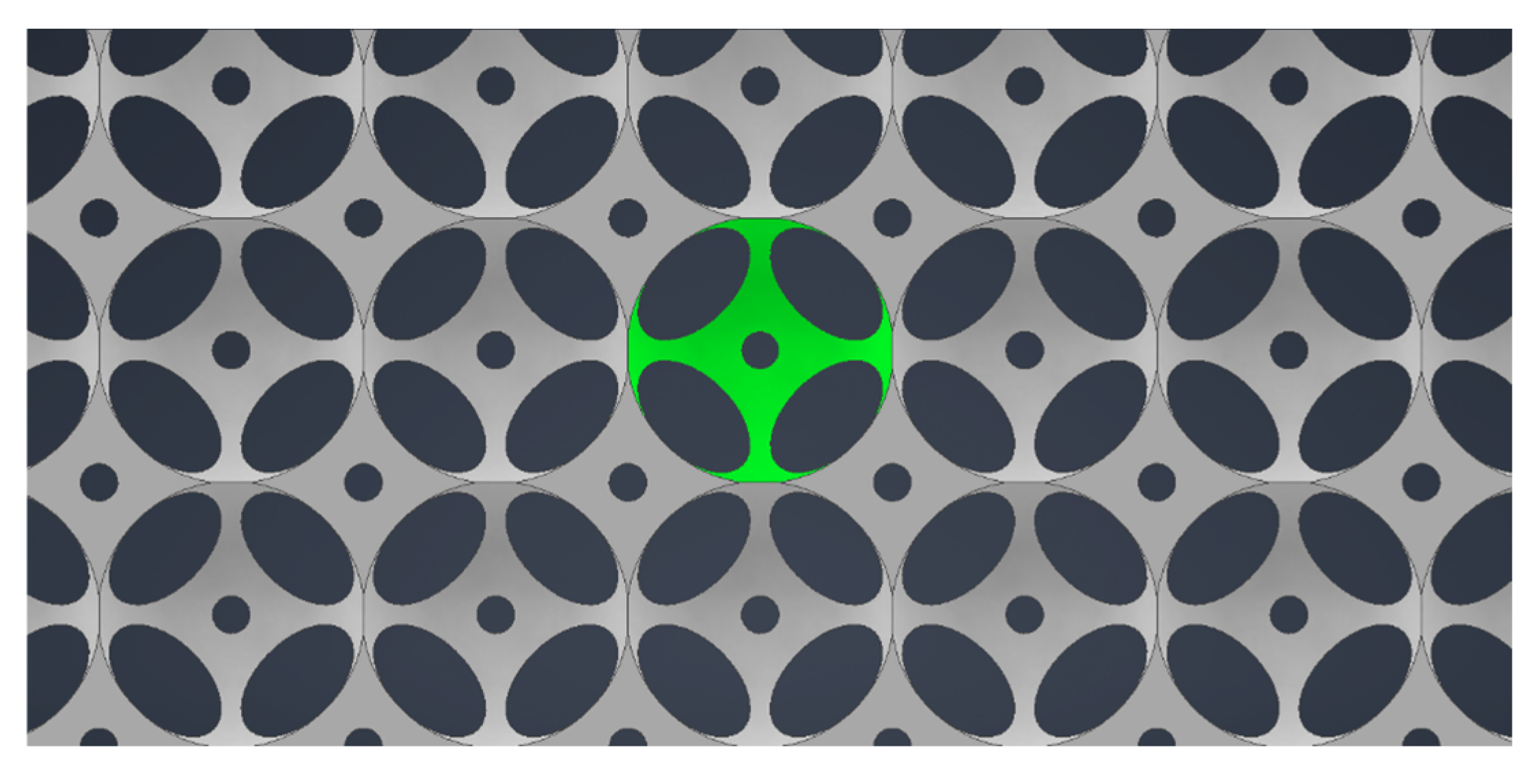

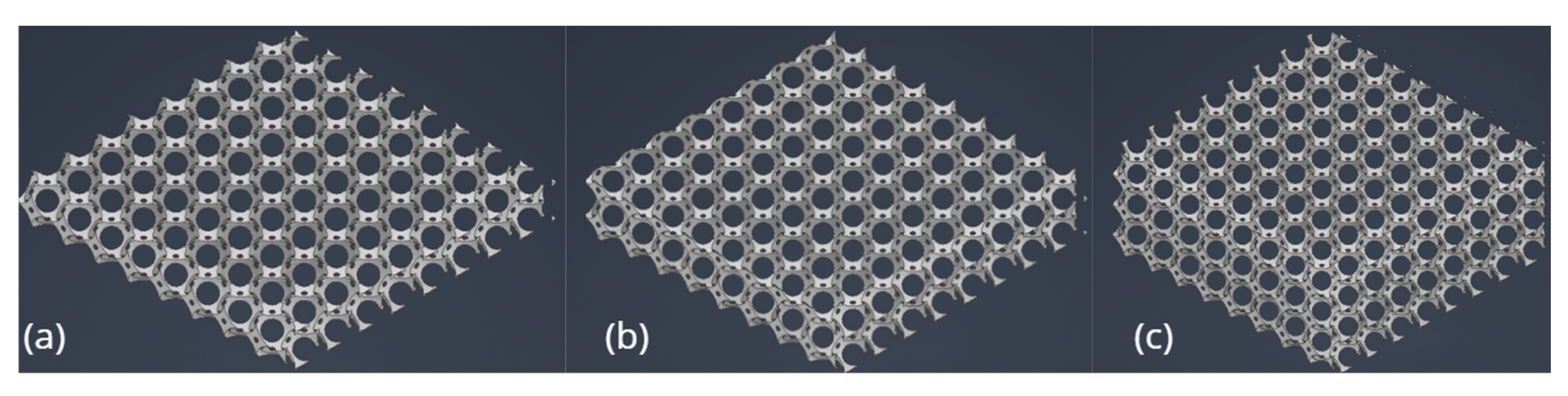

| No. | A, mm | d, mm | n, - |

|---|---|---|---|

| 1 | 50 | 20 | 1 |

| 2 | 50 | 20 | 2 |

| 3 | 50 | 20 | 3 |

| 4 | 50 | 40 | 1 |

| 5 | 50 | 40 | 2 |

| 6 | 50 | 40 | 3 |

| 7 | 50 | 60 | 1 |

| 8 | 50 | 60 | 2 |

| 9 | 50 | 60 | 3 |

| Variant | Material | Percent by Weight Concentration [wt.%] |

|---|---|---|

| 1 | PA12 + TPS | 70:30 |

| 2 | PA12 + TPS | 50:50 |

| 3 | PA12 + TPS | 30:70 |

| Measuring Device | Accuracy |

|---|---|

| K-type thermocouple (HELUKABEL Polska Sp. z o.o., Radziejowice, Poland) | 0.1 K |

| FHF04SC heat flux sensor | 11 μV/(W/m2) |

| Vernier caliper (GEKO SPÓŁKA Z OGRANICZNĄ ODPOWIEDZIALNOŚCIA SPÓŁKA KOMANDYTOWA, Kietlin, Poland) | 0.05 mm |

| Symbol That Identifies the Input Factors | SS | Degrees of Freedom | MS | F | p |

|---|---|---|---|---|---|

| Absolute term | 0.117051 | 1 | 0.117051 | 251351.7 | 0.00 |

| %_PA12 | 0.000084 | 2 | 0.000042 | 90.4 | 0.00 |

| d | 0.003446 | 2 | 0.001723 | 3700.4 | 0.00 |

| n | 0.000217 | 2 | 0.000108 | 232.8 | 0.00 |

| %_PA12*d | 0.000114 | 4 | 0.000028 | 61.0 | 0.00 |

| %_PA12*n | 0.000014 | 4 | 0.000004 | 7.7 | 0.00 |

| d*n | 0.000160 | 4 | 0.000040 | 85.9 | 0.00 |

| %_PA12*d*n | 0.000044 | 8 | 0.000006 | 11.8 | 0.00 |

| Error | 0.000025 | 54 | 0.000000 |

| d | 20 mm | 40 mm | 60 mm | ||||||

|---|---|---|---|---|---|---|---|---|---|

| n. - | 1 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 3 |

| λmean. W/mK | 0.049 | 0.044 | 0.038 | 0.044 | 0.041 | 0.041 | 0.032 | 0.032 | 0.033 |

| u (λmean) | 0.0022 | 0.0022 | 0.0020 | 0.0028 | 0.0027 | 0.0027 | 0.0023 | 0.0022 | 0.0023 |

| Rmean. m2K/W | 0.406 | 0.456 | 0.530 | 0.927 | 0.964 | 0.983 | 1.867 | 1.864 | 1.861 |

| u (Rmean) | 0.0180 | 0.0224 | 0.0271 | 0.0596 | 0.0627 | 0.0645 | 0.1330 | 0.1277 | 0.1289 |

| Umean. W/m2K | 2.461 | 2.195 | 1.889 | 1.079 | 1.037 | 1.017 | 0.536 | 0.537 | 0.537 |

| u (U Umean) | 0.1089 | 0.1077 | 0.0965 | 0.0694 | 0.0674 | 0.0667 | 0.0382 | 0.0368 | 0.0372 |

| d | 20 mm | 40 mm | 60 mm | ||||||

|---|---|---|---|---|---|---|---|---|---|

| n. - | 1 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 3 |

| λmean. W/mK | 0.046 | 0.044 | 0.041 | 0.045 | 0.038 | 0.040 | 0.027 | 0.026 | 0.026 |

| u (λmean) | 0.0022 | 0.0022 | 0.0020 | 0.0028 | 0.0027 | 0.0027 | 0.0023 | 0.0022 | 0.0023 |

| Rmean. m2K/W | 0.433 | 0.457 | 0.489 | 0.890 | 1.054 | 1.007 | 2.197 | 2.360 | 2.278 |

| u (Rmean) | 0.0204 | 0.0224 | 0.0232 | 0.0561 | 0.0748 | 0.0684 | 0.1815 | 0.2059 | 0.1967 |

| Umean. W/m2K | 2.311 | 2.188 | 2.046 | 1.123 | 0.948 | 0.993 | 0.455 | 0.424 | 0.439 |

| u (U Umean) | 0.1090 | 0.1074 | 0.0973 | 0.0708 | 0.0673 | 0.0674 | 0.0376 | 0.0370 | 0.0379 |

| d | 20 mm | 40 mm | 60 mm | ||||||

|---|---|---|---|---|---|---|---|---|---|

| n. - | 1 | 2 | 3 | 1 | 2 | 3 | 1 | 2y | 3 |

| λmean. W/mK | 0.049 | 0.045 | 0.041 | 0.041 | 0.039 | 0.038 | 0.028 | 0.028 | 0.028 |

| u (λmean) | 0.0023 | 0.0026 | 0.0029 | 0.0027 | 0.0028 | 0.0025 | 0.0019 | 0.0021 | 0.0021 |

| Rmean. m2K/W | 0.413 | 0.450 | 0.493 | 0.971 | 1.021 | 1.048 | 2.152 | 2.125 | 2.136 |

| u (Rmean) | 0.0193 | 0.0258 | 0.0348 | 0.0640 | 0.0712 | 0.0678 | 0.1488 | 0.1557 | 0.1571 |

| Umean. W/m2K | 2.420 | 2.224 | 2.030 | 1.030 | 0.979 | 0.955 | 0.465 | 0.471 | 0.468 |

| u (U Umean) | 0.1129 | 0.1275 | 0.1435 | 0.0679 | 0.0683 | 0.0618 | 0.0321 | 0.0345 | 0.0344 |

| Material | Trendline Function | Thermal Conductivity Coefficient (λ) for a Thickness of 12 cm (Three-Layer) |

|---|---|---|

| Polystyrene | Not applicable | 0.0400 |

| TPS + PA12 (30:70) | 0.0324 | |

| TPS + PA12 (50:50) | 0.0227 | |

| TPS + PA12 (70:30) | 0.0243 |

| Building Parameter | Jednostka | Styropian, Λ = 0.0400 | TPS + PA12 (30:70), Λ = 0.0324 | TPS + PA12 (50:50), Λ = 0.0227 | TPS + PA12 (70:30), Λ = 0.0243 |

|---|---|---|---|---|---|

| Design heat loss through transmission, ΦT | kW | 5.43 | 5.19 | 4.86 | 4.92 |

| Heat loss through external walls, Q | kW | 1.57 | 1.34 | 1.00 | 1.06 |

| Design ventilation heat loss, ΦV | kW | 3.52 | 3.52 | 3.52 | 3.52 |

| Total design heat load, ΦHL | kW | 8.95 | 8.72 | 8.38 | 8.44 |

| Design heat load per surface area, ΦA | W/m2 | 57.09 | 55.60 | 53.45 | 53.83 |

| Total heat loss through transmission, QH,tr | kWh/rok | 14,190.19 | 13,557.97 | 12,650.75 | 12,809.01 |

| Total heat loss through ventilation, QH,ve | kWh/rok | 7051.84 | 7051.84 | 7051.84 | 7051.84 |

| Annual useful heat demand for heating and ventilation, QH,nd | kWh/rok | 10,989.56 | 10,540.79 | 9902.41 | 10,013.27 |

| Annual energy demand index for heating and ventilation, EU | kWh/m2rok | 70.09 | 67.22 | 63.15 | 63.86 |

| Thermal Insulation Material d = 12 cm | Styropian, Λ = 0.0400 | TPS + PA12 (30:70), Λ = 0.0324 | TPS + PA12 (50:50), Λ = 0.0227 | TPS + PA12 (70:30), Λ = 0.0243 | |

|---|---|---|---|---|---|

| Zone name | A, m2 | Heat demand for heating and ventilation, kWh/rok | |||

| Garage (ground floor) 5 °C | 24.80 | 0.00 | 0.00 | 0.00 | 0.00 |

| Living rooms (ground floor) 20 °C | 59.90 | 3914.53 | 3728.32 | 3463.82 | 3509.72 |

| Bathroom (ground floor) 24 °C | 7.80 | 1639.06 | 1587.51 | 1513.84 | 1526.66 |

| Living rooms (first floor) 20 °C | 55.10 | 3961.04 | 3779.42 | 3521.21 | 3566.04 |

| Bathroom (first floor I) 24 °C | 9.20 | 1474.93 | 1445.55 | 1403.53 | 1410.85 |

| Total | 156.80 | 10,989.56 | 10,540.80 | 9902.40 | 10,013.27 |

| Thermal Insulation Material d = 12 cm | Styropian, Λ = 0.0400 | TPS + PA12 (30:70), Λ = 0.0324 | TPS + PA12 (50:50), Λ = 0.0227 | TPS + PA12 (70:30), Λ = 0.0243 | |

|---|---|---|---|---|---|

| Zone name | A, m2 | Heat loss through transmission, ΦTi, W | |||

| Garage (ground floor) 5 °C | 24.80 | 30.30 | 1.00 | −41.10 | −33.70 |

| Living rooms (ground floor) 20 °C | 59.90 | 2269.10 | 2178.40 | 2048.30 | 2071.00 |

| Bathroom (ground floor) 24 °C | 7.80 | 2227.60 | 2141.40 | 2017.60 | 2039.20 |

| Living rooms (first floor) 20 °C | 55.10 | 601.30 | 583.90 | 559.00 | 563.30 |

| Bathroom (first floor I) 24 °C | 9.20 | 577.90 | 567.60 | 552.80 | 555.40 |

| Total | 156.80 | 5706.20 | 5472.30 | 5136.60 | 5195.20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Anwajler, B.; Wieleżew, A.; Grabowski, K.; de Rubeis, T.; Ambrosini, D.; Zdybel, E.; Tomaszewska-Ciosk, E. Investigating the Thermal Properties of Structural Partitions Produced Using Additive Technology (3D Printing) from Biodegradable Materials for Use in Construction. Materials 2025, 18, 4379. https://doi.org/10.3390/ma18184379

Anwajler B, Wieleżew A, Grabowski K, de Rubeis T, Ambrosini D, Zdybel E, Tomaszewska-Ciosk E. Investigating the Thermal Properties of Structural Partitions Produced Using Additive Technology (3D Printing) from Biodegradable Materials for Use in Construction. Materials. 2025; 18(18):4379. https://doi.org/10.3390/ma18184379

Chicago/Turabian StyleAnwajler, Beata, Arkadiusz Wieleżew, Krystian Grabowski, Tullio de Rubeis, Dario Ambrosini, Ewa Zdybel, and Ewa Tomaszewska-Ciosk. 2025. "Investigating the Thermal Properties of Structural Partitions Produced Using Additive Technology (3D Printing) from Biodegradable Materials for Use in Construction" Materials 18, no. 18: 4379. https://doi.org/10.3390/ma18184379

APA StyleAnwajler, B., Wieleżew, A., Grabowski, K., de Rubeis, T., Ambrosini, D., Zdybel, E., & Tomaszewska-Ciosk, E. (2025). Investigating the Thermal Properties of Structural Partitions Produced Using Additive Technology (3D Printing) from Biodegradable Materials for Use in Construction. Materials, 18(18), 4379. https://doi.org/10.3390/ma18184379