Effects of Tensile Specimen Geometry and Gripping System on the Mechanical Stability of Ausferrite in Austempered Ductile Irons

Abstract

1. Introduction

2. Materials and Methods

2.1. ADI Production

2.2. Tensile Testing

2.3. DIC Measurements

2.4. XRD Measurements

2.5. FEM Simulations

3. Results

3.1. Tensile Test Results

3.2. DIC Results

3.3. XRD Results

3.4. FEM Results

4. Discussion

4.1. Austenite Evolution During Tensile Testing

4.2. Tensile Behavior and Ausferrite Instability

4.3. Ausferrite Instability and Stress Raisers

5. Conclusions

- In the deformed gauge of the flat tensile specimens, the austenite-to-martensite transformation was strain-induced, while at the fracture surface, the austenite disappeared completely with no recorded strain development, so that the austenite-to-martensite transformation at the fracture was explained as stress-induced because of the stress intensification and triaxiality at the advancing cracks.

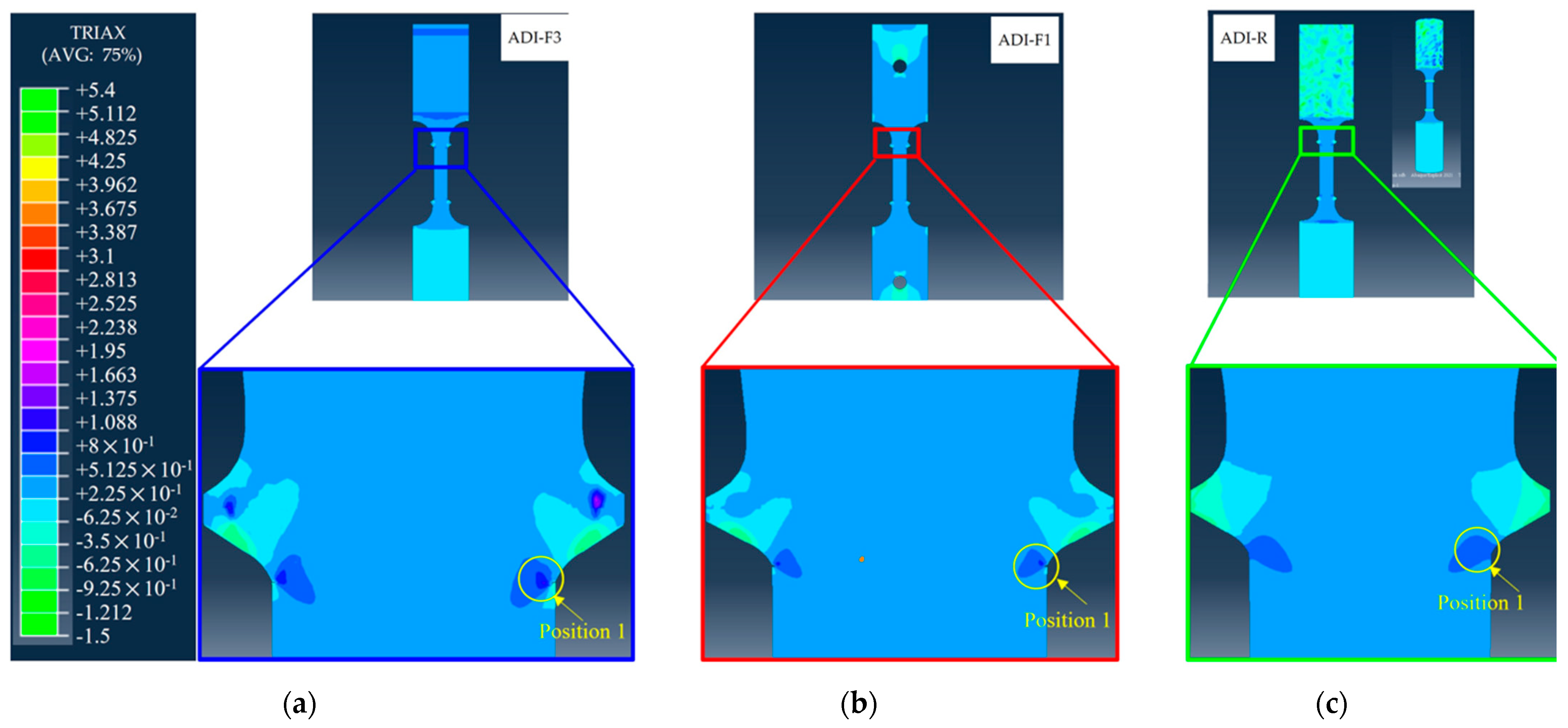

- FEM simulations found that the ridges limiting the tensile gauge and the wedge gripping system produced significant stress intensification and triaxiality, causing a substantial reduction in ductility, capturing the trend of ductility and the fracture locations for all the investigated pulling configurations.

- The austenite instability, consistent with the rationalization of the triaxiality effect on the austenite-to-martensite transformation, was also supported by FEM simulations and rationalized as caused by high stress concentrations and triaxiality due to the presence of the ridges and wedge gripping systems, because the wedges produced some constraints to the elastic lateral contractions of the flat tensile specimen heads.

- The flat tensile specimen geometry affected the ductility, though it was less significant than the pulling configurations with ridges. Consistent with the fact that the structural specimens’ features (ridges and grips) caused the reduction in ductility and increased the ausferrite instability, this finding was explained as being caused by the surface imperfections that could act as stress raisers, and graphitic nodules at the surface of the specimens could be one of these.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Janowak, J.F.; Gundlach, R.B.; Eldis, G.T.; Rohrting, K. Technical advances in cast iron metallurgy. Int. Cast Met. J. 1982, 6, 28–42. [Google Scholar]

- Rouns, T.N.; Rundman, K.B.; Moore, D.M. The Relationship Between Microstructure and Tensile Properties in ADI. AFS Trans. 1984, 121, 815–840. [Google Scholar]

- Dubensky, W.; Rundman, K.B. An Electron Microscope Study of Carbide Formation in Austempered ductile Iron. AFS Trans. 1985, 93, 389–394. [Google Scholar]

- Janowak, J.F.; Norton, P.A. A guide to mechanical properties possible by austempering, 1 percent Ni, 0.3 percent Mo Iron. AFS Trans. 1985, 88, 123–135. [Google Scholar]

- Gundlach, R.B.; Janowak, J.F. Austempered ductile irons combine strength with toughness and ductility. Met. Prog. 1985, 12, 231–236. [Google Scholar]

- Moore, D.J.; Noun, T.B.; Rundman, K.B. The relationship between microstructure and tensile properties in austempered ductile cast iron. AFS Trans. 1987, 87, 165–174. [Google Scholar]

- Górny, M.; Stefanescu, D.M. Cast Iron Science and Technology. In ASM Handbook; ASM International: Almere, The Netherlands, 2017; Volume 1A, pp. 626–628. [Google Scholar]

- Górny, M.; Gondek, L.; Tyrała, E.; Angella, G.; Kawalec, M. Structure homogeneity and thermal stability of austempered ductile iron. Metall. Mater. Trans. 2021, 52, 2228–2237. [Google Scholar] [CrossRef]

- Dodd, J. High strength, high ductility ductile irons. Mod. Cast. 1978, 68, 60–66. [Google Scholar]

- Gundlach, R.B.; Janowak, J.F. Development of a ductile iron for commercial austempering. AFS Trans. 1983, 94, 377–388. [Google Scholar]

- Angella, G.; Zanardi, F.; Donnini, R. On the significance to use dislocation-density-related constitutive equations to correlate strain hardening with microstructure of metallic alloys: The case of conventional and austempered ductile irons. J. Alloys. Comp. 2016, 669, 262–271. [Google Scholar] [CrossRef]

- Donnini, R.; Fabrizi, A.; Bonollo, F.; Zanardi, F.; Angella, G. Assessment of the microstructure evolution of an austempered ductile iron during austempering process through strain hardening analysis. Metall. Mater. Int. 2020, 23, 855–864. [Google Scholar] [CrossRef]

- Angella, G.; Ripamonti, D.; Górny, M. Comparison between ductility examination and a new approach based on strain hardening analysis to support the determination of proper austempering times. Int. J. Cast Met. Res. 2020, 33, 50–60. [Google Scholar] [CrossRef]

- Tanaka, Y.; Kage, H. Development and application of austempered spheroidal graphite cast iron. Mater. Trans. JIM 1992, 33, 543–557. [Google Scholar] [CrossRef]

- Keough, J.R. Austempered ductile iron (ADI)—A green alternative. Trans. Am. F. 2011, 119, 591–599. [Google Scholar]

- Colin, G.E.; Cruz, R.A.; Reyes, C.G.; Romero, S.J.A.; Sanchez, A.R.G.; Hernández, C.M. Influence of nickel addition and casting modulus on the properties of hypo-eutectic ductile cast iron. J. Min. Metall. Sect. B Metall. 2019, 55, 115–124. [Google Scholar]

- Bakhshinezhad, H.; Honarbakhshraouf, A.; Abdollah, P.H. A study of effect of vanadium on microstructure and mechanical properties of as-cast and austempered ductile iron. Phys. Met. Metallogr. 2019, 120, 441–446. [Google Scholar]

- Haydarzadeh, S.M.; Nili, A.A.; Bahrami, V.A. The role of austempering parameters on the structure and mechanical properties of heavy section ADI. J. Mater. Process. Technol. 2004, 153, 203–208. [Google Scholar]

- Kim, Y.J.; Shin, H.; Park, H.; Lim, J.D. Investigation into mechanical properties of austempered ductile cast iron (ADI) in accordance with austempering temperature. Mat. Lett. 2008, 62, 357–360. [Google Scholar] [CrossRef]

- Hegde, A.; Sharma, S.; Vikas Sadanand, R. Mechanical characterization and optimization of heat treatment parameters of manganese alloyed austempered ductile iron. J. Mech. Eng. Sci. 2019, 13, 4356–4367. [Google Scholar] [CrossRef]

- Cakir, M.C.; Isik, Y. Investigating the machinability of austempered ductile irons having different austempering temperatures and times. Mater. Des. 2008, 29, 937–942. [Google Scholar] [CrossRef]

- Hegde, A.; Sharma, S.; Shankar, M.C. Machinability and related properties of austempered ductile iron: A review. J. Mech. Eng. Sci. 2018, 12, 4180–4190. [Google Scholar] [CrossRef]

- Putatunda, S.K.; Bartosiewicz, L.; Krause, A.R.; Alberts, F.A.; Singh, I. Influence of microstructure on high cycle fatigue behavior of austempered ductile cast iron. Mater. Char. 1993, 30, 221–234. [Google Scholar]

- Shanmugam, P.; Rao, P.P.; Udupa, K.R.; Venkataraman, N. Effect of microstructure on the fatigue strength of an austempered ductile iron. J. Mater. Sci. 1994, 29, 4933–4940. [Google Scholar] [CrossRef]

- Zhang, H.; Wu, Y.; Li, Q.; Hong, X. Mechanical properties and rolling-sliding wear performance of dual phase austempered ductile iron as potential metro wheel material. Wear 2018, 406, 156–165. [Google Scholar] [CrossRef]

- Putatunda, S.K.; Singh, I. Fracture toughness of unalloyed austempered ductile cast iron. J. Test. Eval. 1995, 23, 325–332. [Google Scholar] [CrossRef]

- Panneerselvam, S.; Martis, C.J.; Putatunda, S.K.; Boileau, J.M. An investigation on the stability of austenite in Austempered Ductile Cast Iron (ADI). Mat. Sci. Eng. 2015, 626, 237–246. [Google Scholar]

- Nelson, E. Why ADI? Four applications where ADI is the material of choice and process considerations. In Proceedings of the World Conference on ADI, Barcelona, Spain, 27–28 October 2016; Ductile Iron Society: Germantown, WI, USA, 2016; pp. 1–6. [Google Scholar]

- Bamberger, M. Encyclopedia of Iron, Steel, Their Alloy, 5th ed.; Taylor and Francis: New York, NY, USA, 2016; pp. 196–216. [Google Scholar]

- Darwish, N.; Elliott, R. Austempering of low manganese ductile irons. Mater. Sci. Technol. 1993, 9, 572–585. [Google Scholar] [CrossRef]

- Darwish, N.; Elliott, R. Austempering of low manganese ductile irons Part 3 Variation of mechanical properties with heat treatment conditions. Mater. Sci. Technol. 1993, 9, 882–889. [Google Scholar] [CrossRef]

- Boccardo, A.D.; Dardati, P.M.; Godoy, L.A.; Celentano, D.J. Sensitivity of Austempering Heat Treatment of Ductile Irons to Changes in Process Parameters. Metall. Mater. Trans. B 2018, 49, 1522–1536. [Google Scholar] [CrossRef]

- Górny, M.; Angella, G.; Tyrała, E.; Kawalec, M.; Paź, S.; Kmita, A. Role of Austenitization Temperature on Structure Homogeneity and Transformation Kinetics in Austempered Ductile Iron. Met. Mater. Int. 2019, 25, 956–965. [Google Scholar] [CrossRef]

- Aranzabal, J.; Gutierrez, I.; Rodriguez-Ibabe, J.M.; Urcola, J.J. Influence of the Amount and Morphology of Retained Austenite on the Mechanical Properties of an Austempered Ductile Iron. Metall. Mater. Trans. A 1997, 28, 1143–1156. [Google Scholar] [CrossRef]

- Nishiyama, Z. (Ed.) Martensitic Transformation; Academic Press: New York, NY, USA, 1978. [Google Scholar]

- Tamura, I. Deformation-induced martensitic transformation and transformation-induced plasticity in steels. Met. Sci. 1982, 11, 245–253. [Google Scholar] [CrossRef]

- Vuorinen, J.J. Strain-hardening mechanism and characteristics of austempered ductile iron. AFS Trans. 1983, 86, 577–588. [Google Scholar]

- Hayrynen, K.L.; Moore, D.J.; Rundman, K.B. Tensile properties and microstructure of a clean austempered ductile iron. AFS Trans. 1990, 98, 471–480. [Google Scholar]

- Stieler, F.; Tonn, B. XRD-analysis of the relationship of stacking fault formation and TRIP-effect in ADI. Int. J. Met. 2024, 18, 1926–1934. [Google Scholar] [CrossRef]

- Jianghuai, Y.; Putatunda, S.K. Influence of a novel two-step austempering process on the strain-hardening behavior of austempered ductile cast iron (ADI). Mater. Sci. Eng. A 2004, 382, 265–279. [Google Scholar]

- Olofsson, J.; Larsson, D.; Svensson, I.L. Effect of Austempering on Plastic Behavior of Some Austempered Ductile Iron Alloys. Metall. Mater. Trans. A 2011, 42, 3999–4007. [Google Scholar] [CrossRef]

- Angella, G.; Zanardi, F. Comparison among Different Constitutive Equations on Investigating Tensile Plastic Behavior and Microstructure in Austempered Ductile Iron. J. Cast. Mater. Eng. 2018, 2, 14–23. [Google Scholar] [CrossRef][Green Version]

- Angella, G.; Donnini, R.; Ripamonti, D.; Bonollo, F.; Cygan, B.; Gorny, M. On Ausferrite Produced in Thin Sections: Stability Assessment through Round and Flat Tensile Specimen Testing. Metals 2023, 13, 105. [Google Scholar] [CrossRef]

- Angella, G.; Govahi, P.; Schiralli, M.; Gorny, M.; Masagggia, S.; Zanardi, F. Section-Sensitivity Assessment of 4.2 Wt Pct Silicon Ductile Iron Based on New Material Integrity Index. Metall. Mater. Trans. A 2025, 56, 2473–2484. [Google Scholar] [CrossRef]

- ASTM A536–84(2019)e; Standard Specification for Ductile Iron Castings. ASTM International: West Conshohocken, PA, USA, 2019.

- Lacaze, J.; Sertucha, J.; Castro-Roman, M.J. From Atom Scale to Casting: A Contemporary Monograph on Cast Irons Microstructure; 2024, HAL Open Science Id: Hal-04447564; Available online: https://hal.science/hal-04447564v1 (accessed on 6 August 2025).

- ASTM E8/E8M-11; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2011.

- ASTM E975-13; Standard Practice for X-Ray Determination of Retained Austenite in Steel with Near Random Crystallographic Orientation. ASTM International: West Conshohocken, PA, USA, 2013.

- Gupta, S.K. Peak decomposition using Pearson type VII function. J. Appl. Crystall. 1998, 31, 474–476. [Google Scholar] [CrossRef]

- Available online: https://www.nde-ed.org/Physics/X-Ray/attenuationCoef.xhtml (accessed on 6 August 2025).

- Boschen, R.; Bomas, H.; Mayr, P.; Vetters, H. Strength and fatigue of Austempered Ductile Iron(ADI). In Proceedings of the 2nd International Conference on Austempered Ductile Cast Iron, Ann Arbor, MI, USA, 17–19 March 1986; ASME, Gear Research Institute: Naperville, IL, USA, 1986; pp. 179–185. [Google Scholar]

- Mayr, P.; Vetters, H.; Walla, J. Investigations on the stress induced martensite formation in Austempered Ductlile Cast Iron (ADI). In Proceedings of the 2nd International Conference on Austempered Ductile Iron, Ann Arbor, MI, USA, 17–19 March 1986; pp. 171–178. [Google Scholar]

- Sidjanin, L.; Smallman, R.E.; Boutorabi, S.M. Metallography of bainitic transformation in austempered ductile iron. Mater. Sci. Technol. 1992, 8, 1095–2006. [Google Scholar] [CrossRef]

- Sidjanin, L.; Smallman, R.E.; Boutorabi, S.M. Microstructure and fracture of aluminum austempered ductile iron investigated using electron microscopy. Mater. Sci. Technol. 1994, 10, 711–723. [Google Scholar] [CrossRef]

- Garin, J.L.; Mannheim, R.L. Strain-induced martensite in ADI alloys. J. Mater. Process. Tech. 2003, 143–144, 347–351. [Google Scholar] [CrossRef]

- Li, X.; Soria, S.; Gan, W.; Hofmann, M.; Schulz, M.; Hoelzel, M.; Brokmeier, H.-G.; Petry, W. Multi-scale phase analyses of strain-induced martensite in Austempered ductile iron (ADI) using neutron diffraction and transmission techniques. J. Mater. Sci. 2021, 56, 5296–5306. [Google Scholar] [CrossRef]

- Oettel, H.; Martin, U. The nature of the TRIP-effect in metastable austenitic steels. Int. J. Mater. Res. 2006, 97, 1642–1647. [Google Scholar] [CrossRef]

- Oettel, H.; Glavatskikh, M.; Martin, U.; Nikulin, A. TRIP effect and deformation damaging of metastable austenitic steels. Mater. Sci. Forum 2007, 539, 4903–4908. [Google Scholar] [CrossRef]

- Soleimani, M.; Kalhor, A.; Mirzadeh, H. Transformation-induced plasticity (TRIP) in advanced steels: A review. Mater. Sci. Eng. A 2020, 795, 140023. [Google Scholar] [CrossRef]

- Giordani, T.; Theis Soares Diehl, C.A.; Diehl, I.L.; Rosauro Clarke, T.G. Induced Martensitic Transformation Effect on Residual Stress, Fatigue and Magnetic Permeability of Austenitic Stainless Steel. Mater. Res. 2024, 27, e20240050. [Google Scholar] [CrossRef]

- Alves, J.M.; dos Santos Paula, A.; Brandao, L.P. Residual Stress Analysis After the Induced Martensitic Transformation by Rolling and Tensile Test in the 304L TRIP Steel. Mater. Res. 2021, 24, e20210156. [Google Scholar] [CrossRef]

- Hou, P.; Li, Y.; Chae, D.; Ren, Y.; An, K.; Choo, H. Lean duplex TRIP steel: Role of ferrite in the texture development, plastic anisotropy, martensitic transformation kinetics, and stress partitioning. Materialia 2021, 15, 100952. [Google Scholar] [CrossRef]

- Chen, S.-C.; Huang, C.-Y.; Wang, Y.-T.; Huang, C.-Y.; Yen, H.-W. Role of the crystallographic texture in anisotropic mechanical properties of a newly-developed hot-rolled TRIP steel. Mater. Sci. Eng. A 2020, 790, 139683. [Google Scholar] [CrossRef]

- Wang, B.; Qiu, F.; Barber, G.C.; Pan, Y.; Cui, W.; Wang, R. Microstructure, wear behavior and surface hardening of austempered ductile iron. J. Mater Res Technol. 2020, 9, 9838–9855. [Google Scholar] [CrossRef]

- Wang, B.; He, M.; Barber, G.C.; Schall, J.D.; Tao, C.; Sun, X. Rolling contact fatigue resistance of austempered ductile iron processed at various austempering holding times. Wear 2018, 398–399, 41–46. [Google Scholar] [CrossRef]

- Batra, U.; Batra, N.; Sharma, J.D. Wear Performance of Cu-Alloyed Austempered Ductile Iron. J. Mater. Eng. Perform. 2013, 22, 1136–1142. [Google Scholar] [CrossRef]

- Mohammed, A.D.; Kachit, M. Effects of Features of Graphite Nodules on Stress Concentration in Nodular Graphite Cast Iron Material under Multi-Axial Loading. Int. J. Appl. Eng. Res. 2017, 12, 656–663. [Google Scholar]

- Carpinteri, A.; de Freitas, M.; Spagnoli, A. Biaxial/Multiaxial Fatigue and Fracture; Elsevier: Amsterdam, The Netherlands, 2003. [Google Scholar]

- Reed, P.A.S.; Thompson, R.C.; James, J.S.; Putman, D.C.; Lee, K.K.; Gunn, S.R. Modelling of microstructural effects in the fatigue of austempered ductile iron. Mat. Sci. Engin. A 2003, 346, 273–286. [Google Scholar] [CrossRef]

- Kals, T.A.; Eckstein, R. Miniaturization in sheet metal working. J. Mater. Process. Technol. 2000, 103, 95–101. [Google Scholar] [CrossRef]

- Yang, L.; Lu, L. The influence of sample thickness on the tensile properties of pure Cu with different grain sizes. Scr. Mater. 2013, 69, 242–245. [Google Scholar] [CrossRef]

| Composition | C | Si | Mn | S | P | Mg | Cu | Ni | Fe | CEq |

|---|---|---|---|---|---|---|---|---|---|---|

| ADI_1 | 3.52 | 2.62 | 0.31 | 0.013 | 0.036 | 0.050 | 0.74 | 0.74 | Bal. | 4.32 1 |

| ADI_2 | 3.52 | 2.54 | 0.36 | 0.012 | 0.042 | 0.037 | 0.70 | 1.53 | Bal. | 4.30 1 |

| HSi | 3.54 | 4.20 | 0.13 | 0.006 | 0.014 | 0.045 | - | - | Bal. | 4.72 2 |

| Tensile Specimen Code | Description |

|---|---|

| ADI-R | ADI—Round geometry |

| ADI-F1 | ADI—Flat geometry with ridges and pin-hole grips |

| ADI-F2 | ADI—Flat geometry without ridges and pin-hole grips |

| ADI-F3 | ADI—Flat geometry with ridges and wedge grips |

| HSi-R | HSi 4.2%wt. of Si—Round geometry |

| HSi-F3 | HSi 4.2%wt. of Si—Flat geometry with ridges and wedge grips |

| Tensile Specimen Number | Total Plastic True Strain at the Gauge (Ext_1) | Localized Plastic True Strain (Ext_2) | Plastic True Strain at Fracture (Ext_3) |

|---|---|---|---|

| 1 | 0.037 | 0.074 | 0.034 |

| 2 | 0.039 | 0.081 | 0.033 |

| 3 | 0.048 | 0.067 | 0.034 |

| 4 | 0.044 | 0.076 | 0.028 |

| 5 | 0.036 | 0.064 | 0.029 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fu, L.; Schiralli, M.; Vedani, M.; Olofsson, J.; Górny, M.; Govahi, P.; Donnini, R.; Losurdo, M.; Angella, G. Effects of Tensile Specimen Geometry and Gripping System on the Mechanical Stability of Ausferrite in Austempered Ductile Irons. Materials 2025, 18, 4359. https://doi.org/10.3390/ma18184359

Fu L, Schiralli M, Vedani M, Olofsson J, Górny M, Govahi P, Donnini R, Losurdo M, Angella G. Effects of Tensile Specimen Geometry and Gripping System on the Mechanical Stability of Ausferrite in Austempered Ductile Irons. Materials. 2025; 18(18):4359. https://doi.org/10.3390/ma18184359

Chicago/Turabian StyleFu, Lun, Manuel Schiralli, Maurizio Vedani, Jakob Olofsson, Marcin Górny, Parnian Govahi, Riccardo Donnini, Maria Losurdo, and Giuliano Angella. 2025. "Effects of Tensile Specimen Geometry and Gripping System on the Mechanical Stability of Ausferrite in Austempered Ductile Irons" Materials 18, no. 18: 4359. https://doi.org/10.3390/ma18184359

APA StyleFu, L., Schiralli, M., Vedani, M., Olofsson, J., Górny, M., Govahi, P., Donnini, R., Losurdo, M., & Angella, G. (2025). Effects of Tensile Specimen Geometry and Gripping System on the Mechanical Stability of Ausferrite in Austempered Ductile Irons. Materials, 18(18), 4359. https://doi.org/10.3390/ma18184359