Geometric Analysis and Experimental Studies of Hexachiral Structures

Abstract

1. Introduction

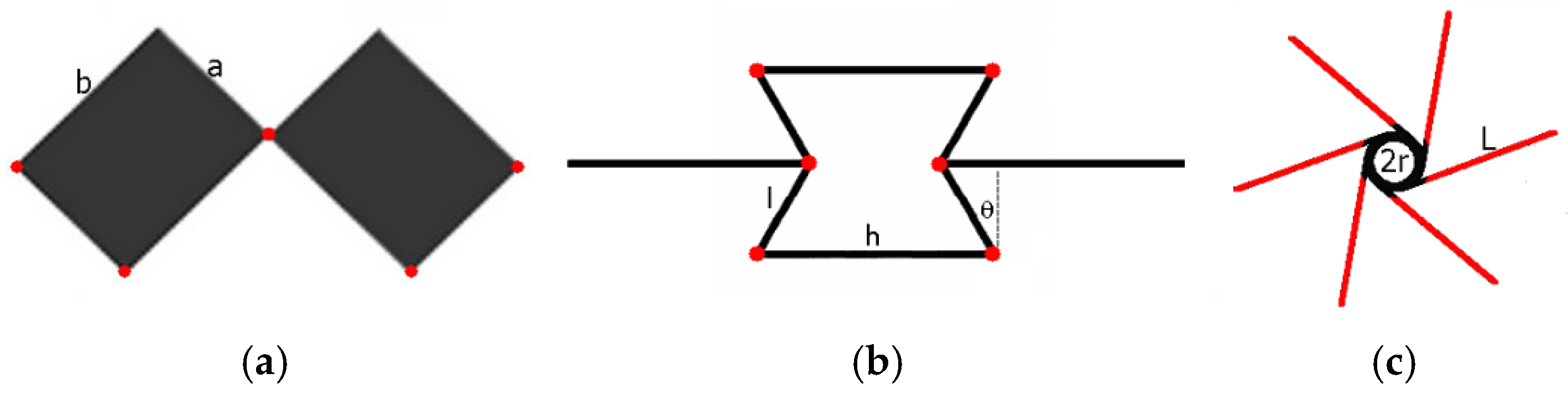

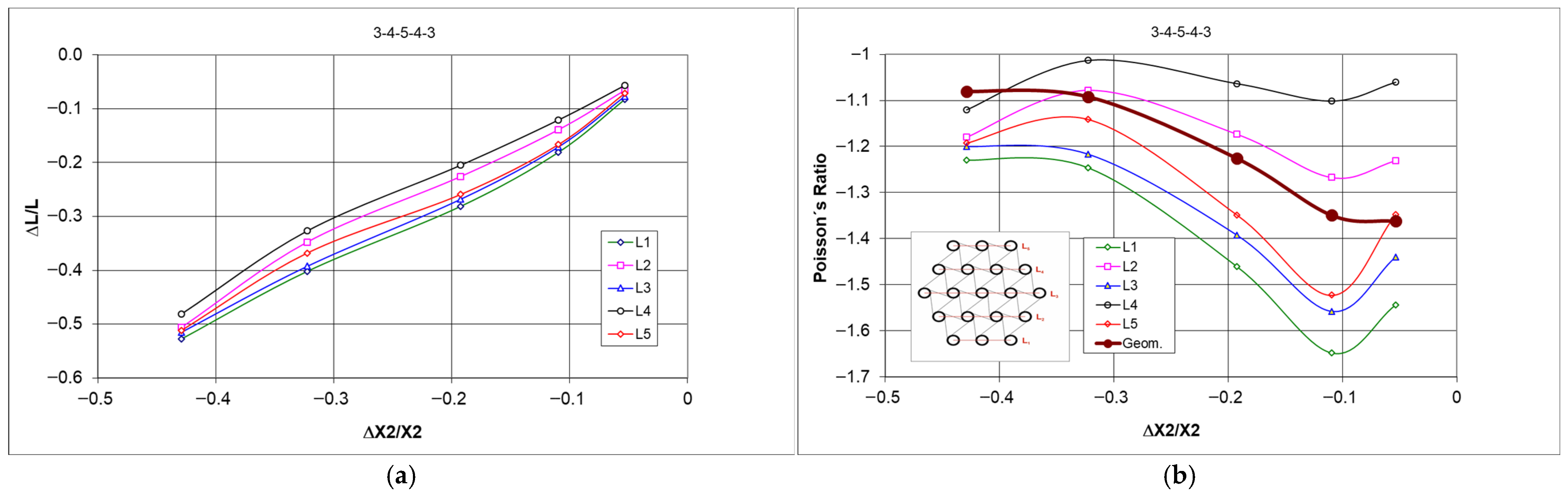

Geometrical Analysis of Hexachiral Structures

2. The Experiments

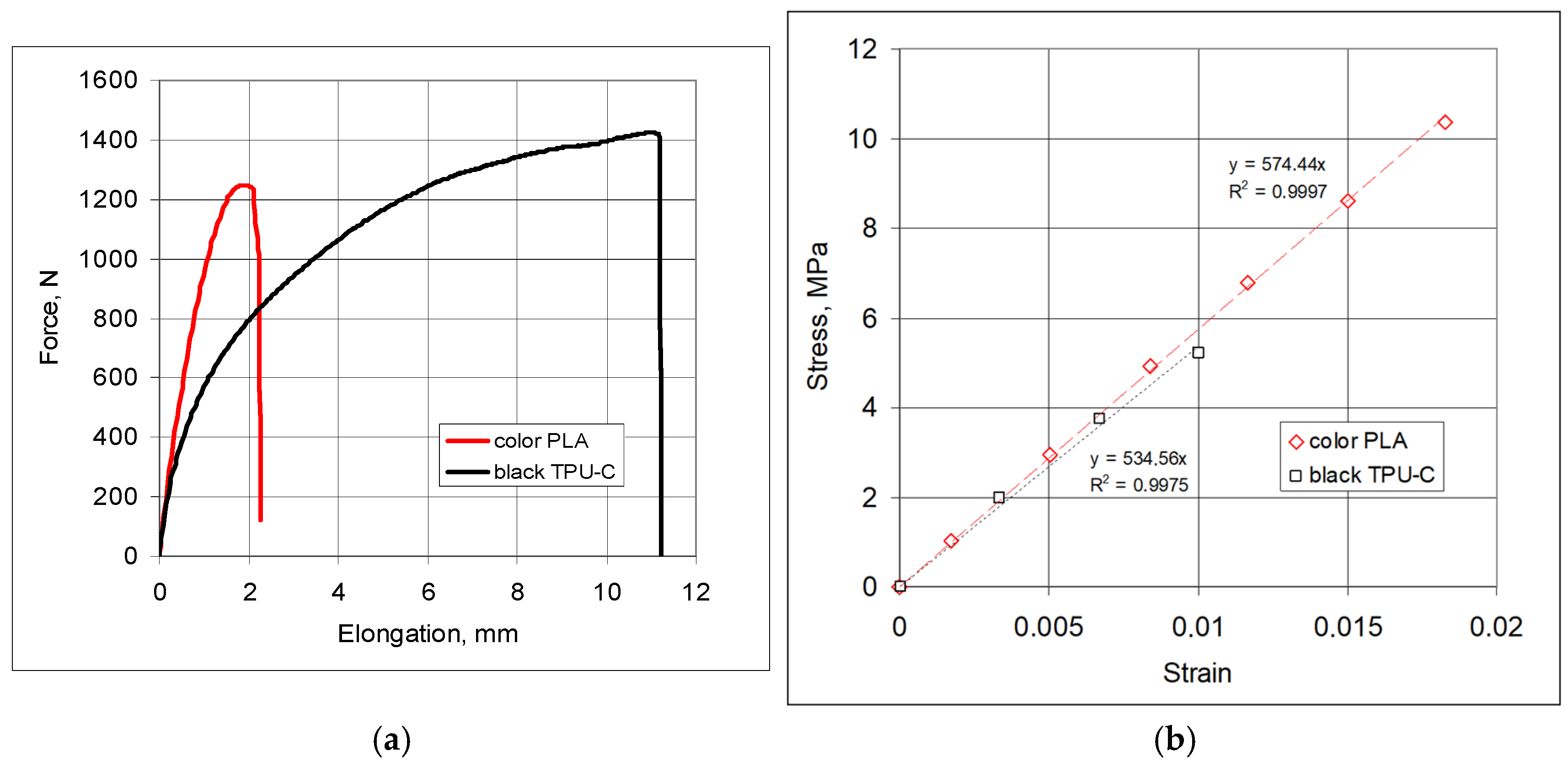

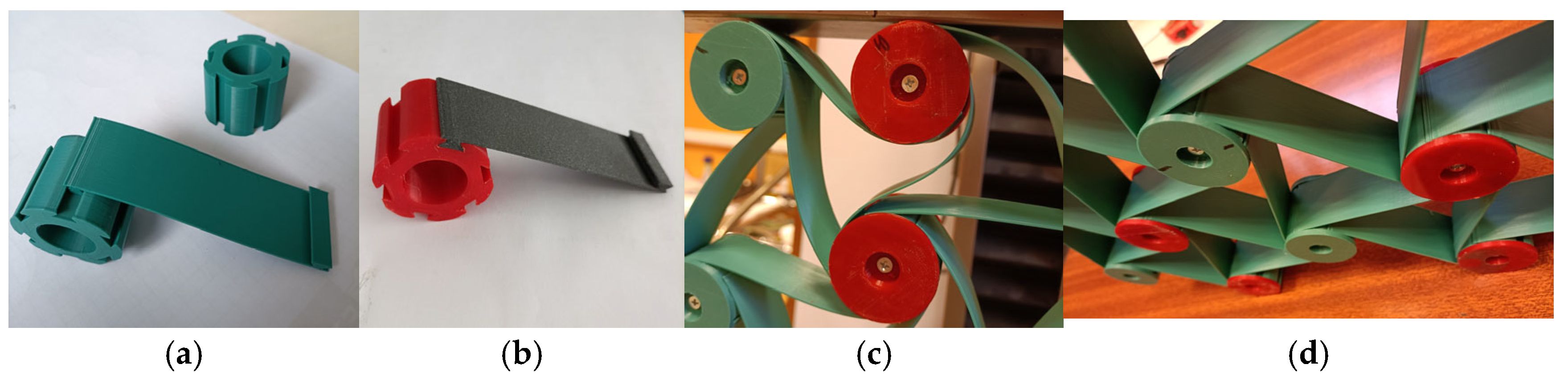

2.1. Sample Materials and Design

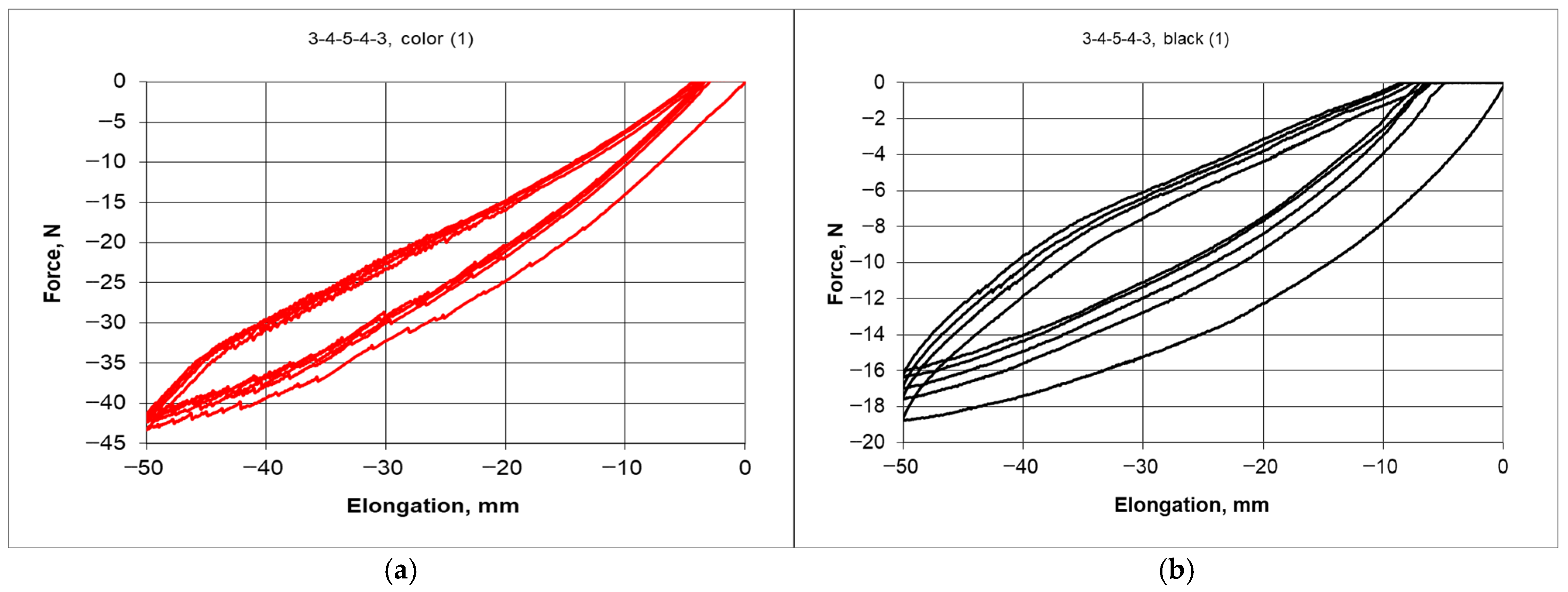

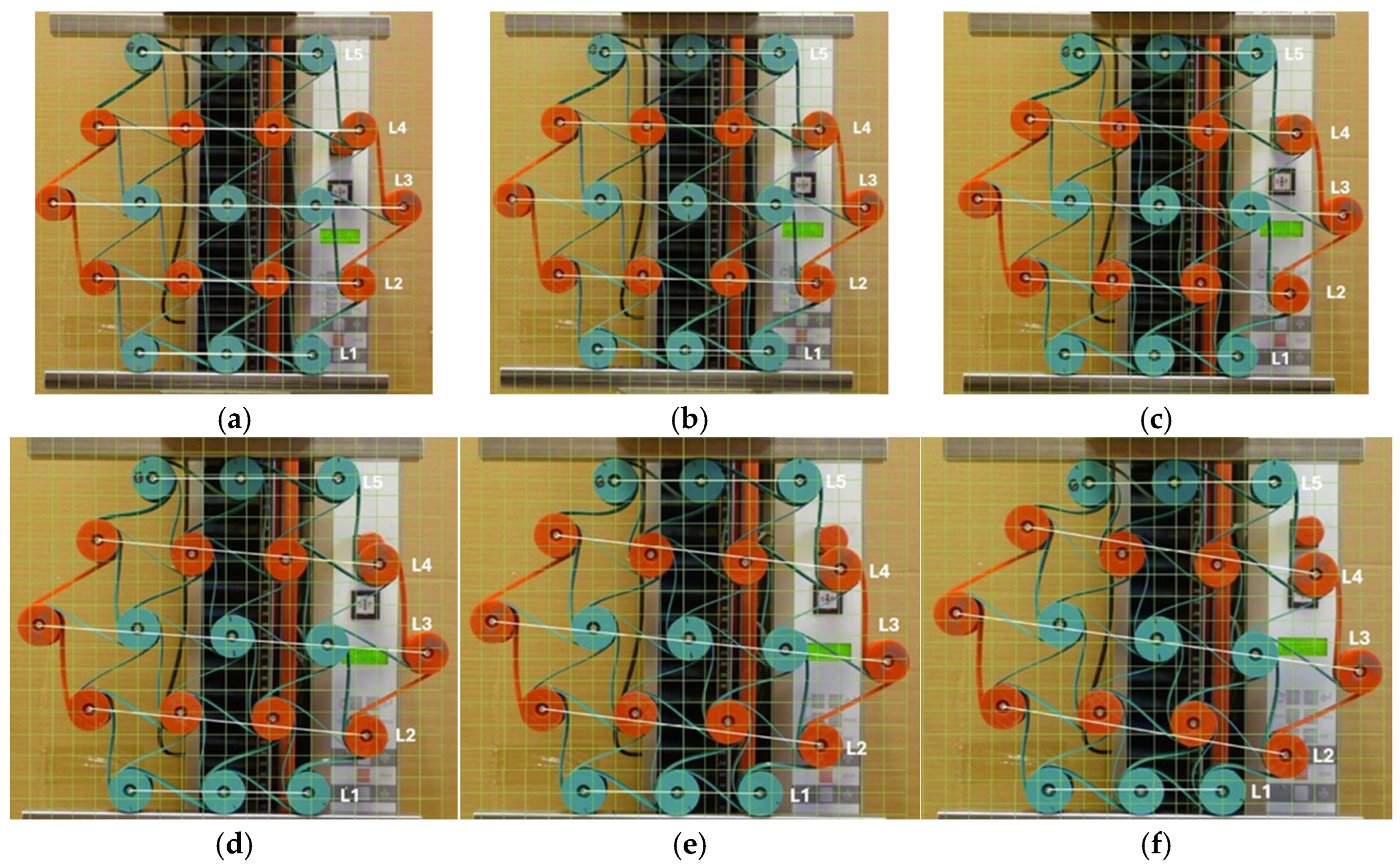

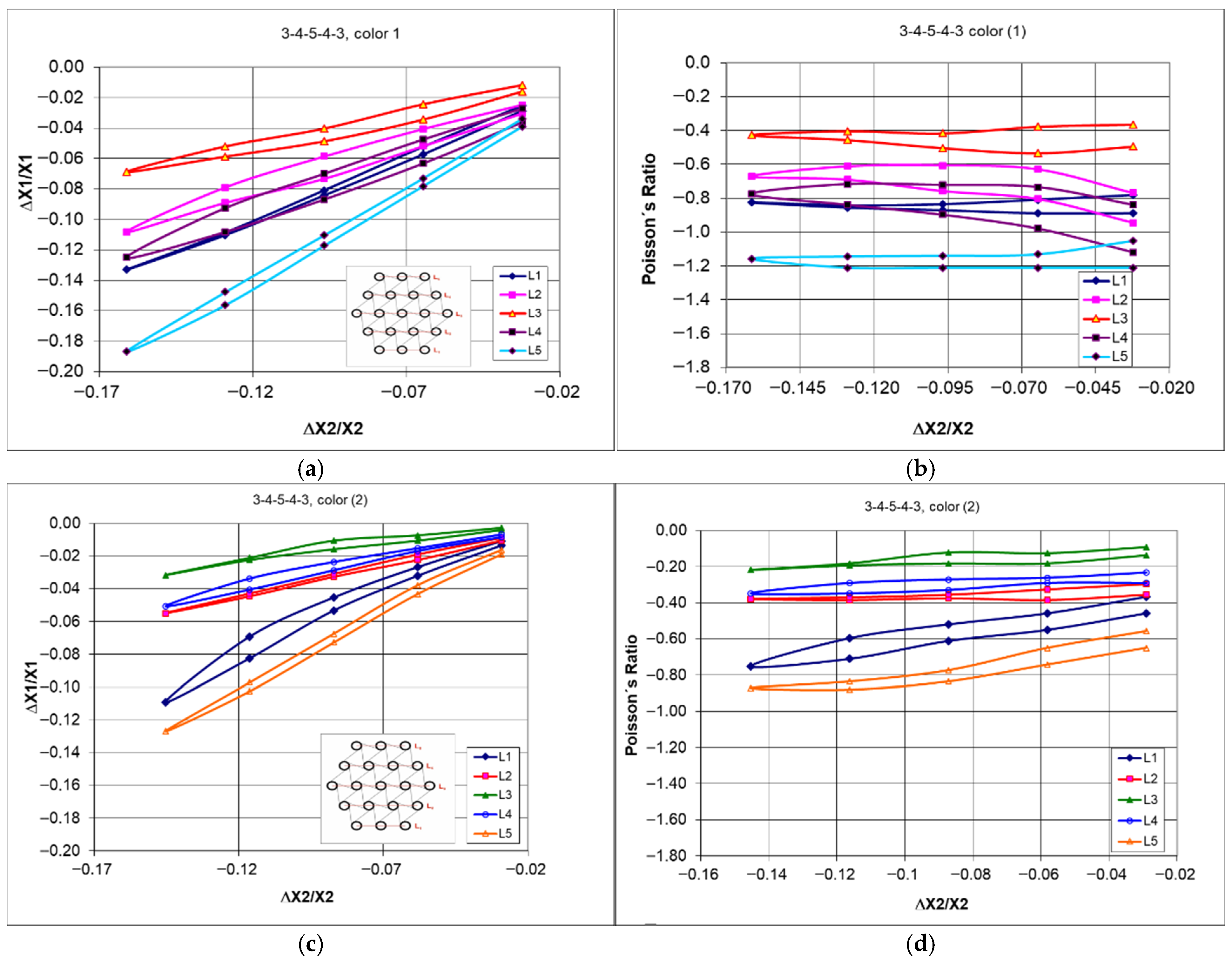

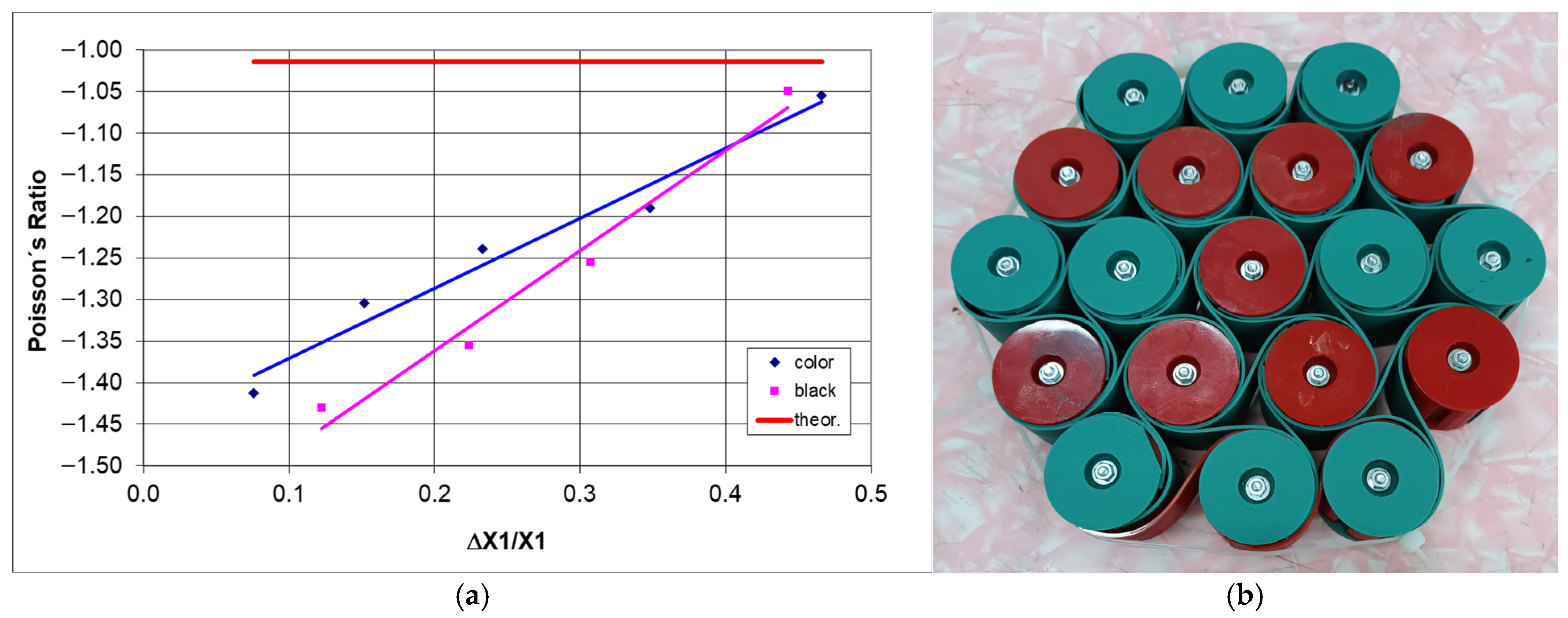

2.2. Experimental Testing, Uniaxial Compression of 3-4-5-4-3 Structures

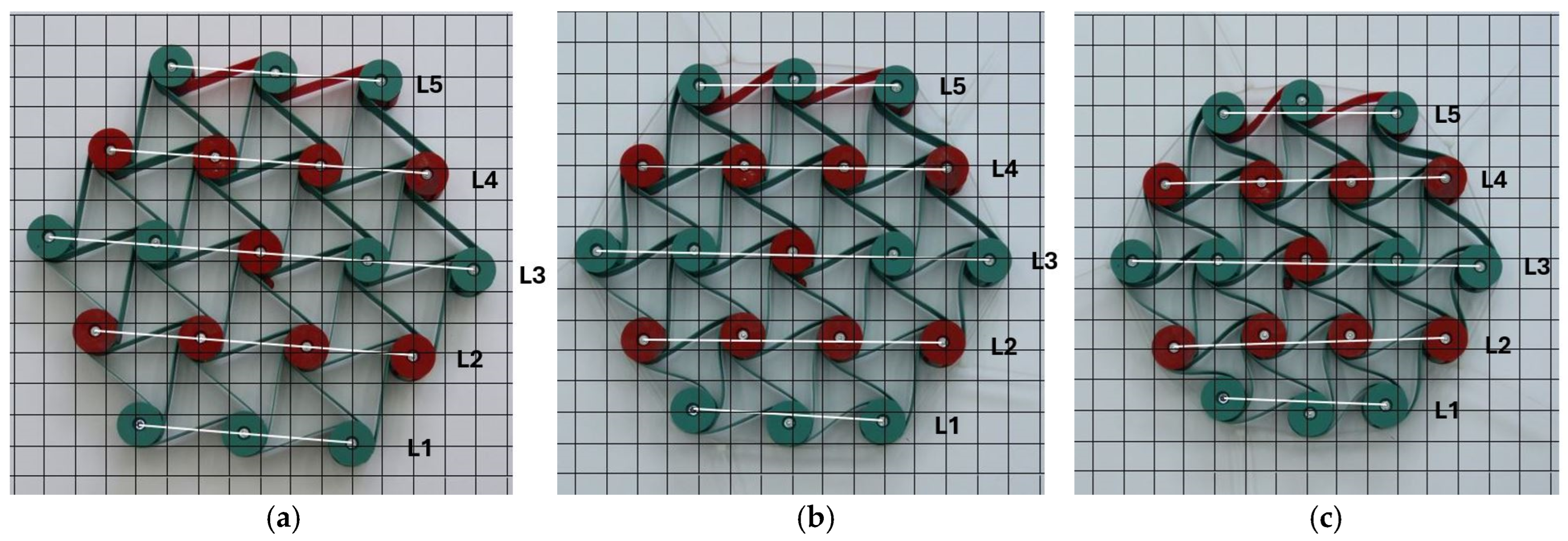

2.3. Experimental Testing, Uniaxial Compression of 3-4-3, 3-4-3-4-3, and 3-4-3-4-3-4-3 Structures

2.4. Experimental Testing, Multi-Directional Compression of 3-4-5-4-3 Structures

3. Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kramberger, J.; Necemer, B.; Glodez, S. Assessing the cracking behavior of auxetic cellular structures by using both a numerical and an experimental approach. Theor. Appl. Fract. Mech. 2019, 101, 17–24. [Google Scholar] [CrossRef]

- Beretta, L.; Bonfanti, S.; Fiocchi, J.; Font-Clos, F.; Guerra, R.; Tuissi, A.; Zapperi, S. Automatic design of chiral mechanical metamaterials. APL Mater. 2021, 9, 101112. [Google Scholar] [CrossRef]

- Gao, D.; Wang, S.; Zhang, M.; Zhang, C. Experimental and numerical investigation on in-plane impact behaviour of chiral auxetic structure. Comp. Struct. 2021, 267, 113922. [Google Scholar] [CrossRef]

- Gao, D.; Zhang, C.; Zhang, J. Compressive Behavior of a NovelHexagonal Nodes-Based 3D ChiralAuxetic Structure. Appl. Sci. 2023, 13, 8480. [Google Scholar] [CrossRef]

- Kose, R.; Novak, N.; Grednev, S.; Ren, Z.; Vesenjak, M.; Jung, A. Numerical Prediction of the Yield Surface of a Chiral Auxetic Structure. Adv. Eng. Mater. 2024, 26, 230091402. [Google Scholar] [CrossRef]

- Rossiter, J.; Takashima, K.; Scarpa, F.; Walters, P.; Mukai, T. Shape memory polymer hexachiral auxetic structures with tunable stiffness. Smart Mater. Struct. 2014, 23, 45007. [Google Scholar] [CrossRef]

- Xu, W.; Zhang, H.; Liu, Z.; Zhu, P. On the crashworthiness of aperiodic chiral mechanical metamaterials: Design and modeling method. J. Phys. Conf. Ser. 2023, 2639, 012029. [Google Scholar] [CrossRef]

- Bettini, P.; Airoldi, A.; Sala, G.; Di Landro, L.; Ruzzene, M.; Spadoni, A. Composite chiral structures for morphing airfoils: Numerical analyses and development of a manufacturing process. Compos. Part B Eng. 2010, 41, 133–147. [Google Scholar] [CrossRef]

- Chen, Y.J.; Scarpa, F.; Liu, Y.J.; Leng, J.S. Elasticity of anti-tetrachiral anisotropic lattices. Int. J. Solids Struct. 2013, 50, 996–1004. [Google Scholar] [CrossRef]

- Inan, C.Y.; Evis, Z.; Ozturk, B. Structural comparison of conventional and chiral auxetic morphed aircraft rib. Mater. Test. 2024, 66, 56–65. [Google Scholar] [CrossRef]

- Alderson, A.; Alderson, K.L.; Attard, D.; Evans, K.E.; Gatt, R.; Grima, J.N.; Miller, W.; Ravirala, N.; Smith, C.W.; Zied, K. Elastic constants of 3-, 4- and 6-connected chiral and anti-chiral honeycombs subject to uniaxial in-plane loading. Comp. Sci. Technol. 2010, 70, 1042–1048. [Google Scholar] [CrossRef]

- Kazemi, M.; Eghbalpoor, A.M. Types and application of auxetic cells: A review. Mech. Adv. Mater. Struct. 2024, 2, 413–431. [Google Scholar] [CrossRef]

- Chen, Y.; Lanzara, G. Auxetic Films with a Miniaturized Cellular Structure. Proceedings 2018, 2, 486. [Google Scholar] [CrossRef]

- Jiang, Y.; Yaning, L. 3D Printed Auxetic Mechanical Metamaterial with Chiral Cells and Re-entrant Cores. Sci. Rep. 2018, 8, 2397. [Google Scholar] [CrossRef] [PubMed]

- Agnese, F.; Remillat, C.; Scarpa, F.; Payne, C. Composite chiral shear vibration damper. Comp. Struct. 2015, 132, 215–225. [Google Scholar] [CrossRef]

- Wei, T.; Lu, F.; Zhang, C.; Huang, Y.; Rui, X.; Zhu, Y. Energy absorption of 3D assembled auxetic meta-structure with compression-twisting effect. Structures 2025, 73, 108482. [Google Scholar] [CrossRef]

- Ye, M.; Gao, L.; Wang, F.; Li, H. A Novel Design Method for Energy Absorption Property of Chiral Mechanical Metamaterials. Materials 2021, 14, 5386. [Google Scholar] [CrossRef]

- Alomarah, A.; Hamdoon, F.O.; Al-Ibraheemi, Z.A.; Ruan, D. Compressive properties of a modified re-entrant chiral auxetic structure (MRCA) under uniaxial quasi-static loading. Mater. Struct. 2024, 33, 055028. [Google Scholar] [CrossRef]

- Miller, W.; Smith, C.W.; Scarpa, F.L.; Abramovich, H.; Evans, K.E. Multifunctional Chiral Negative Poisson’s ratio (Auxetic) Honeycomb Cores with Embedded Piezo-ceramic Patches. In Proceedings of the ICCM International Conferences on Composite Materials, Edinburgh, Scotland, 27–31 July 2009. [Google Scholar]

- Wu, W.; Hu, W.; Qian, G.; Liao, H.; Xu, X.; Berto, F. Mechanical design and multifunctional applicationsof chiral mechanical metamaterials: A review. Mater. Design 2019, 180, 107950. [Google Scholar] [CrossRef]

- Liu, X.N.; Hu, G.K. Elastic metamaterials making use of chirality: A review. Stroj.-J. Mech. Eng. 2016, 62, 7–8. [Google Scholar] [CrossRef]

- Caporale, A.M.; Airoldi, A.; Novak, N. A novel body centered cubic 3D auxetic chiral geometry. Smart Mater. Struct. 2025, 34, 015050. [Google Scholar] [CrossRef]

- Ha, C.S.; Plesha, M.E.; Lakes, R.S. Chiral three-dimensional isotropic lattices with negative Poisson’s ratio. Phys. Status Solidi B 2016, 253, 1243–1251. [Google Scholar] [CrossRef]

- Duan, S.; Wen, W.; Fang, D. A predictive micropolarcontinuum model for a novel three-dimensional chiral lattice with size effect and tension-twist coupling behavior. J. Mech. Phys. Solids. 2018, 121, 23–46. [Google Scholar] [CrossRef]

- Li, J.; Ha, C.S.; Lakes, R.S. Observation of squeeze–twist coupling in a chiral 3D isotropic lattice. Phys. Status Solidi B 2020, 257, 1900140. [Google Scholar] [CrossRef]

- Ashalley, E.; Ma, C.-P.; Zhu, Y.-S.; Xu, H.-X.; Yu, P.; Wang, Z.-M. Recent progress in chiral absorptive metamaterials. J. Electr. Sci. Technol. 2021, 19, 100098. [Google Scholar] [CrossRef]

- Fernandez-Corbaton, I.; Rockstuhl, C.; Ziemke, P.; Gumbsch, P.; Albiez, A.; Schwaiger, R.; Frenzel, T.; Kadic, M.; Wegener, M. New Twists of 3D Chiral Metamaterials. Adv. Mater. 2019, 31, 18077421. [Google Scholar] [CrossRef]

- Vergniory, M.G.; Kondo, T.; Kotov, N.A.; Balandin, A.A. Topological and chiral matter—Physics and applications. Appl. Phys. Lett. 2024, 125, 160401. [Google Scholar] [CrossRef]

- Kaushik, S.; Kharzeev, D.E. Quantum Oscillations in the Chiral Magnetic Conductivity. Phys. Rev. B 2017, 95, 235136. [Google Scholar] [CrossRef]

- Begum, W.; Mondal, M.H.; Mandal, U.; Saha, B. Chiral Metamaterials Chapter 2. In Electromagnetic Metamaterials: Properties and Applications; Tariq Altalhi, I., Ed.; Wiley: Hoboken, NJ, USA, 2023. [Google Scholar] [CrossRef]

- Tomita, S.; Kurosawa, H.; Ueda, T.; Sawada, K. Metamaterials with magnetism and chirality. J. Phys. D Appl. Phys. 2018, 51, 083001. [Google Scholar] [CrossRef]

- Xu, C.; Ren, Z.; Zhou, H.; Zhou, J.; Pei Ho, C.; Wang, N.; Lee, C. Expanding chiral metamaterials for retrieving fingerprints via vibrational circular dichroism. Light Sci. Appl. 2023, 12, 154. [Google Scholar] [CrossRef]

- Yoo, S.J.; Park, Q.-H. Metamaterials and chiral sensing: A review of fundamentals and applications. Nanophotonics 2019, 8, 249–261. [Google Scholar] [CrossRef]

- Niu, X.; Zhao, R.; Yan, S.; Pang, Z.; Li, H.; Yang, X.; Wang, K. Chiral Materials: Progress, Applications, and Prospects. Nano-Micro Swall 2023, 19, 2303059. [Google Scholar] [CrossRef]

- Liu, Q.; Zhang, Y.; Wu, L.; Jiang, X. Recent progress in fabrication and application of chiral interfaces. Chin. J. Anal. Chem. 2024, 52, 100391. [Google Scholar] [CrossRef]

- Wu, W.; Qi, D.; Liao, H.; Qian, G.; Geng, L.; Niu, Y.; Liang, J. Deformation mechanism of innovative 3D chiral metamaterials. Sci. Rep. 2018, 8, 12575. [Google Scholar] [CrossRef]

- Moein, M.M.; Tran, T.A. Application of chiral chromatography in radiopharmaceutical fields: A review. J. Chromatogr. A 2020, 22, 461611. [Google Scholar] [CrossRef]

- The Nobel Prize in Chemistry 2001 Was Divided, One Half Jointly to William S. Knowles and Ryoji Noyori “for Their Work on Chirally Catalysed Hydrogenation Reactions” and the Other Half to K. Barry Sharpless “for His Work on Chirally Catalysed Oxidation Reactions” The Nobel Prize in Chemistry 2001. Available online: https://www.nobelprize.org/prizes/chemistry/2001/summary/ (accessed on 1 June 2025).

- Akhmetshin, L.; Smolin, I. Characterization of a chiral metamaterial depending on the type of connection between unit cells. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2022, 236, 10214–10220. [Google Scholar] [CrossRef]

- Wojciechowski, K.W. Two-dimensional isotropic system with a negative poisson ratio. Phys. Lett. A 1989, 137, 60–64. [Google Scholar] [CrossRef]

- Prall, D.; Lakes, R. Properties of a chiral honeycomb with a poisson’s ratio of −1. (longer version). Int. J. Mech. Sci. 1997, 39, 305–314. [Google Scholar] [CrossRef]

- Mizzi, L.; Simonetti, A.; Spaggiari, A. Mechanical properties and failure modes of additively-manufactured chiral metamaterials based on Euclidean tessellations: An experimental and finite element study. Rapid Prototyp. J. 2024, 30, 59–71. [Google Scholar] [CrossRef]

- Zhang, C.; Lu, F.; Lin, B.; Ling, X.; Zhu, Y. Analysis on the collapse stress of auxetic tubular anti-tetrachiral structures. Eur. J. Mech.-A/Solids 2024, 103, 105167. [Google Scholar] [CrossRef]

- Montazeri, A.; Mahnama, M. Twisting chiral mechanical metamaterials: A review. Mater. Today Comm. 2025, 44, 112070. [Google Scholar] [CrossRef]

- Spadoni, A.; Ruzzene, M. Numerical and experimental analysis of the static compliance of chiral truss-core airfoils. J. Mech. Mater. Struct. 2007, 2, 965–981. [Google Scholar] [CrossRef]

- Spadoni, A.; Ruzzene, M. Elasto-static micropolar behavior of a chiral auxetic lattice. J. Mech. Phys. Solids 2012, 60, 156–171. [Google Scholar] [CrossRef]

- Subramani, P.; Rana, S.; Ghiassi, B.; Fangueiro, R.; Oliveira, D.V.; Lourenco, P.B.; Xavier, J. Development and characterization of novel auxetic structures based on re-entrant hexagon design produced from braided composites. Comp. B Eng. 2016, 93, 132–142. [Google Scholar] [CrossRef]

- Grima, J.N.; Gatt, R.; Farrugia, P.S. On the properties of auxetic meta-tetrachiral structures. Phys. Status Solidi B 2008, 245, 511–520. [Google Scholar] [CrossRef]

- Lakes, R.S.; Lee, T.; Bersie, A.; Wang, Y.C. Extreme damping in composite materials with negative-stiffness inclusions. Nature 2001, 410, 565–567. [Google Scholar] [CrossRef]

- Afdhal; Jirousek, O.; Palar, P.S.; Falta, J.; Dwianto, Y.B. Design exploration of additively manufactured chiral auxetic structure using explainable machine learning. Mater. Des. 2023, 232, 112128. [Google Scholar] [CrossRef]

- Mo, K.; Lu, F.; Wei, T.; Zhang, C.; He, Y.; Liu, Y.; Ling, X.; Zhu, Y. A novel anti-tri-missing rib structure with a central ring for maintaining constant Poisson’s ratio under large deformations. Thin-Walled Struct. 2025, 209, 112916. [Google Scholar] [CrossRef]

- Schneider, J.; Rawte, P.; Upadhyaya, P.; Kumar, S. Tailorable deformation and crushing behavior of 3D printed multilayered tetra-chiral lattices: Experiments and finite element modeling. Mater. Today Comm. 2025, 43, 111463. [Google Scholar] [CrossRef]

- Lorato, A.; Innocenti, P.; Scarpa, F.; Alderson, A.; Alderson, K.L.; Zied, K.M.; Ravirala, N.; Miller, W.; Smith, C.W.; Evans, K.E. The transverse elastic properties of chiral honeycombs. Comp. Sci. Technol. 2010, 70, 1057–1063. [Google Scholar] [CrossRef]

- Liu, X.N.; Huang, G.L.; Hu, G.K. Chiral effect in plane isotropic micropolar elasticity and its application to chiral lattices. J. Mech. Phys. Solids 2012, 60, 1907–1921. [Google Scholar] [CrossRef]

- Kharzeev, D.E.; Chernodub, M.N. Chiral matter: Theory and applications. LE Stud. Multidis. J. 2020, 6, 55–57. [Google Scholar] [CrossRef]

- Zhang, C.; Lu, F.; Wei, T.; He, Y.; Huang, Y.; Zhu, Y. A novel windmill-shaped auxetic structure with enhanced mechanical properties and tunable elastic constants. Eng. Struct. 2025, 325, 119439. [Google Scholar] [CrossRef]

- Liu, C.; Tsang, H.-H.; Xu, S.; Ruan, D. Lateral dynamic crushing of skeletal muscle inspired hierarchical celled structures. Bioinspir. Biomim. 2025, 20, 046003. [Google Scholar] [CrossRef]

- Sun, Y.; Li, Q.M. Dynamic compressive behaviour of cellular materials: A review of phenomenon, mechanism and modelling. Int. J. Impact Eng. 2018, 112, 74–115. [Google Scholar] [CrossRef]

- Fíla, T.; Koudelka, P.; Zlámal, P.; Falta, J.; Adorna, M.; Neuhäuserová, M.; Luksch, J.; Jiroušek, O. Strain Dependency of Poisson’s Ratio of SLS Printed Auxetic Lattices Subjected to Quasi-Static and Dynamic Compressive Loading. Adv. Eng. Mater. 2019, 21, 1900204. [Google Scholar] [CrossRef]

- Liu, H.; Laflamme, S. Investigation of scalable chiral metamaterial beams for combined stiffness and supplemental energy dissipation. Smart Mater. Struct. 2024, 33, 115051. [Google Scholar] [CrossRef]

- Gunaydin, K.; Turkmen, H.S.; Airoldi, A.; Grasso, M.; Sala, G.; Grande, A.M. Compression Behavior of EBM Printed Auxetic Chiral Structures. Materials 2022, 15, 1520. [Google Scholar] [CrossRef]

- Mousanezhad, D.; Haghpanah, B.; Ghosh, R.; Hamouda, A.M.; Nayeb-Hashemi, H.; Vaziri, A. Elastic properties of chiral, anti-chiral, and hierarchical honeycombs: A simple energy-based approach. Theor. Appl. Mech. Lett. 2016, 6, 81–96. [Google Scholar] [CrossRef]

- Dudek, K.K.; Gatt, R.; Wojciechowski, K.W.; Grima, J.N. Self-induced global rotation of chiral and other mechanical metamaterials. Int. J. Solids Struct. 2020, 191–192, 212–219. [Google Scholar] [CrossRef]

- Ion, A.; Frohnhofen, J.; Wall, L.; Kovacs, R.; Alistar, M.; Lindsay, J.; Lopes, P.; Chen, H.-T.; Baudisch, P. Metamaterial mechanisms. In Proceedings of the 29th Annual ACM Symposium on User Interface Software and Technology, Tokyo, Japan, 16–19 October 2016; pp. 529–539. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Plewa, J.; Płońska, M.; Feliksik, K.; Junak, G. Geometric Analysis and Experimental Studies of Hexachiral Structures. Materials 2025, 18, 4344. https://doi.org/10.3390/ma18184344

Plewa J, Płońska M, Feliksik K, Junak G. Geometric Analysis and Experimental Studies of Hexachiral Structures. Materials. 2025; 18(18):4344. https://doi.org/10.3390/ma18184344

Chicago/Turabian StylePlewa, Julian, Małgorzata Płońska, Kamil Feliksik, and Grzegorz Junak. 2025. "Geometric Analysis and Experimental Studies of Hexachiral Structures" Materials 18, no. 18: 4344. https://doi.org/10.3390/ma18184344

APA StylePlewa, J., Płońska, M., Feliksik, K., & Junak, G. (2025). Geometric Analysis and Experimental Studies of Hexachiral Structures. Materials, 18(18), 4344. https://doi.org/10.3390/ma18184344