Optimization of Casting Process Parameters for Solidification Structures in Complex Superalloy Castings

Abstract

1. Introduction

2. Materials and Methods

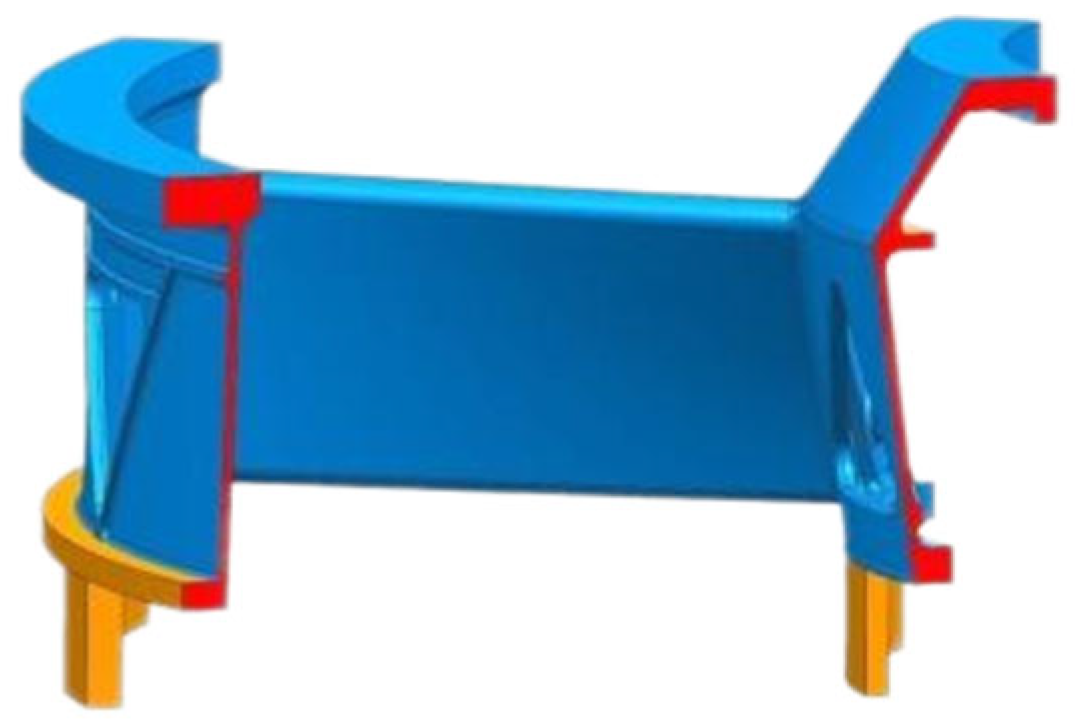

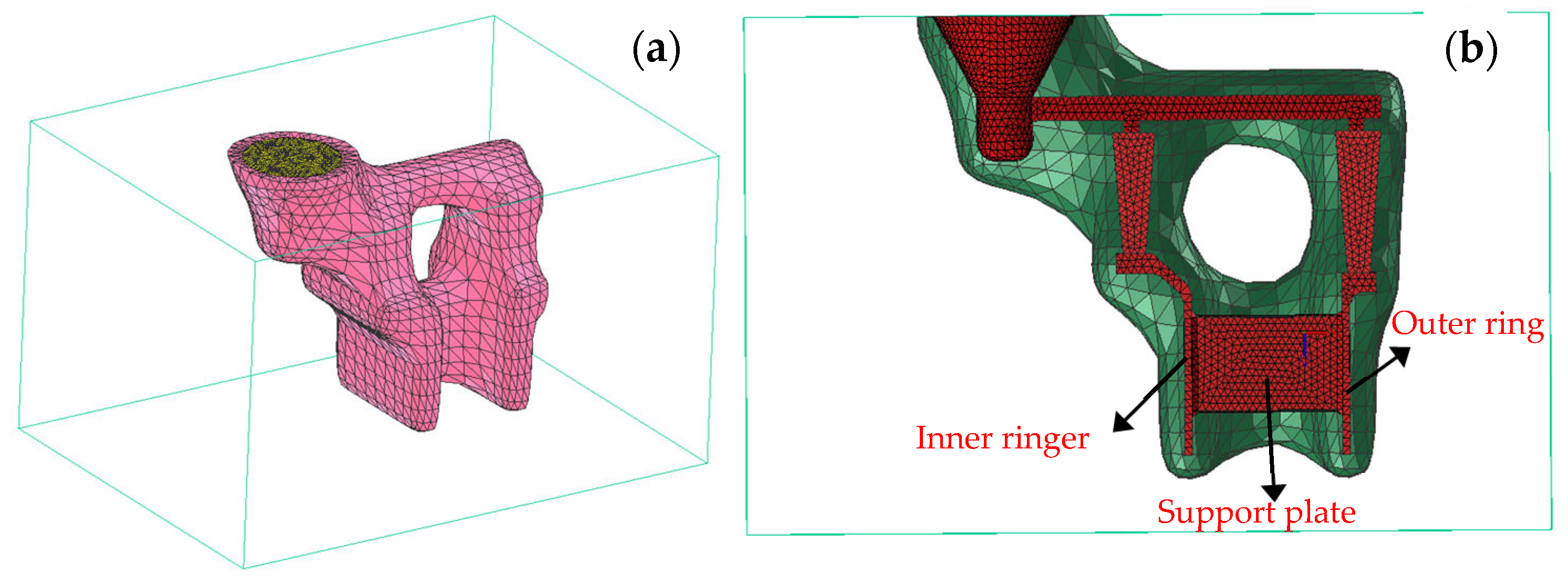

2.1. Design of the Structural Features of Casings

- (1)

- Left and right thin-walled plates (2 mm thick): These plates represent the inner and outer ring structures.

- (2)

- Central connecting plate (1 mm thick): This plate represents the support plate linking the inner and outer rings.

- (3)

- Mounting edge (5 mm thick): Incorporated at one end of the left and right thin-walled plates.

2.2. Numerical Simulation

Shell Material Selection and Mold Design

2.3. Examination of the Grain Structure of the Casing

3. Results

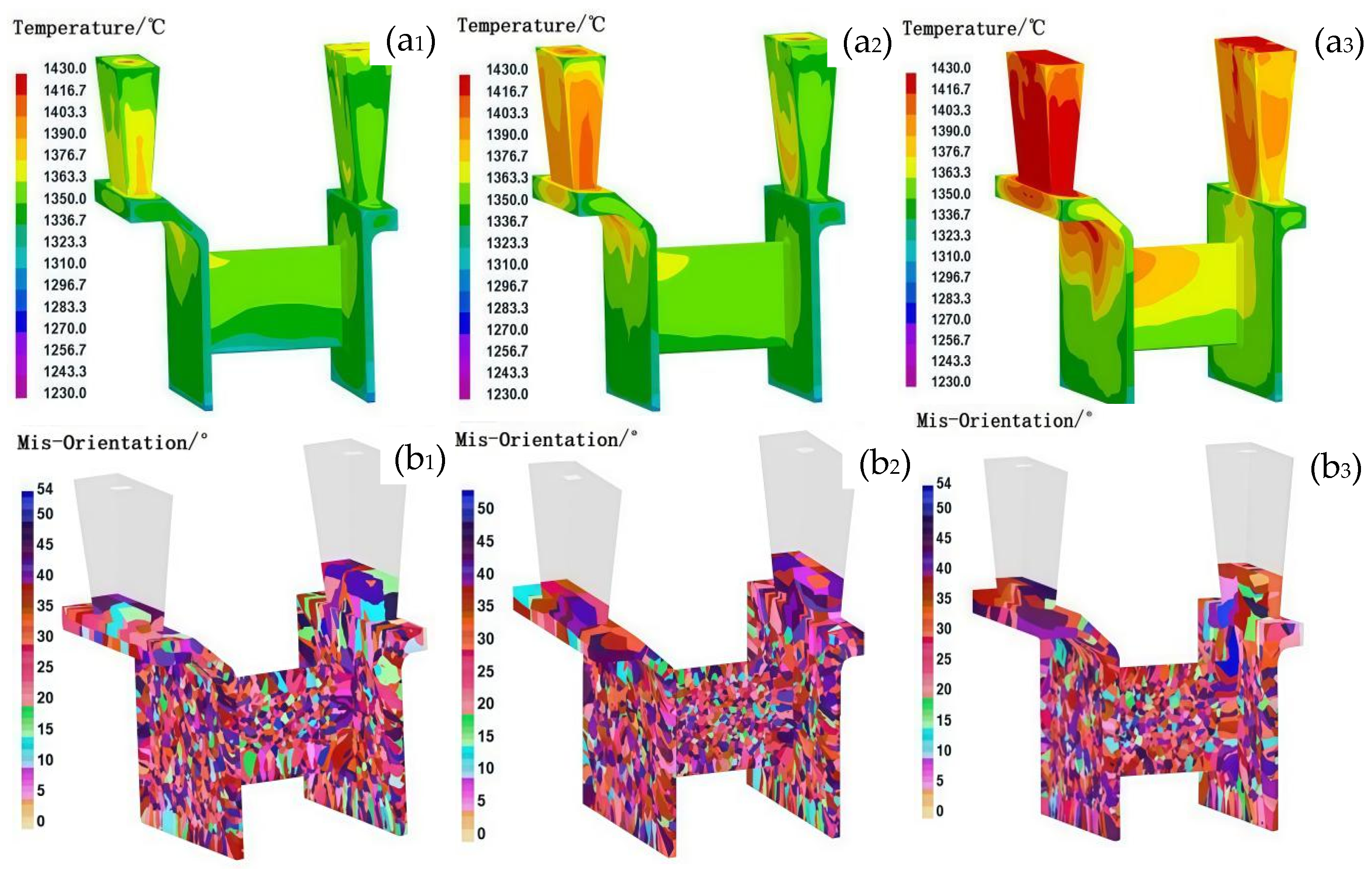

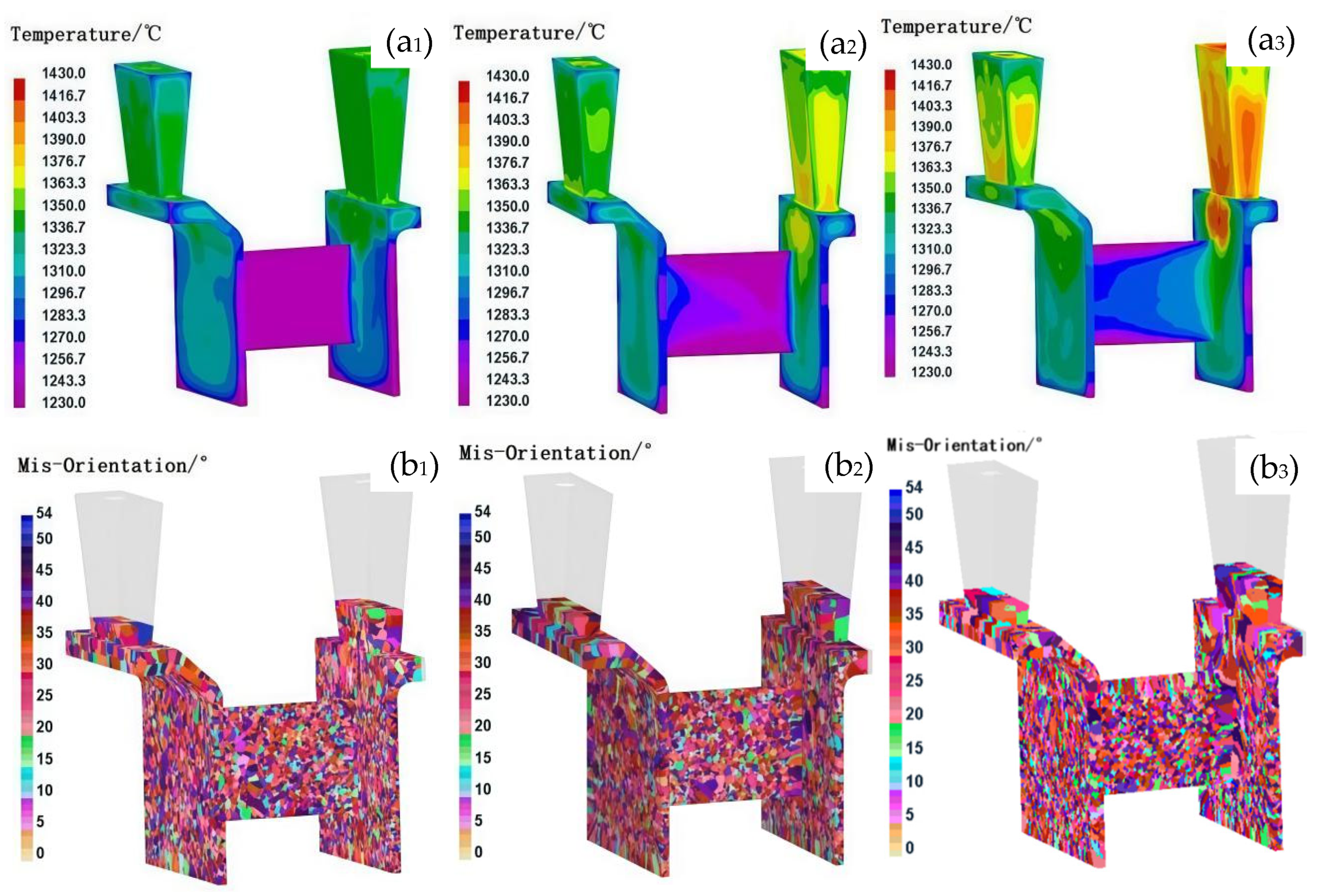

3.1. Effects of the Filling Flow Field on the Grain Structure

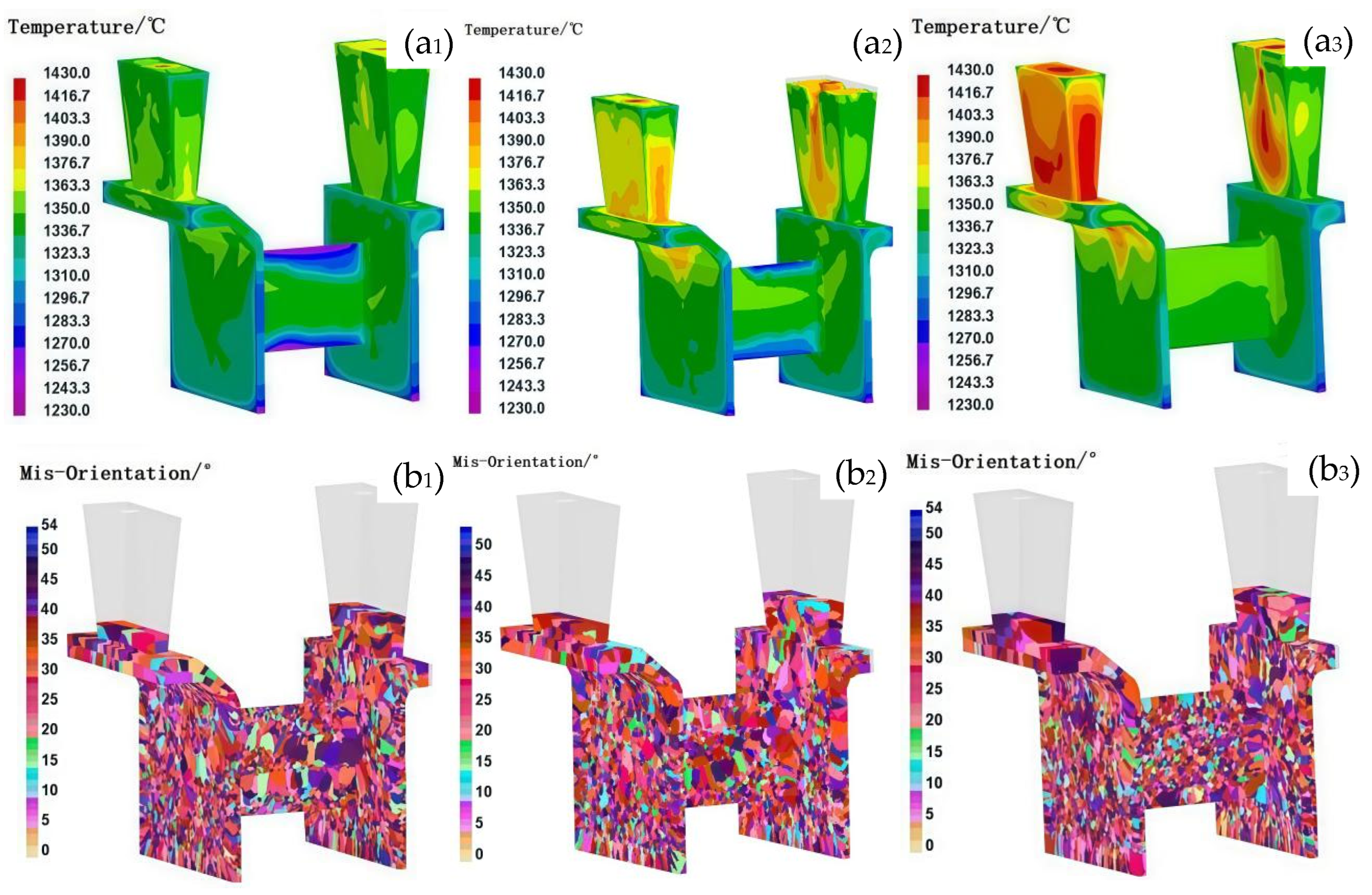

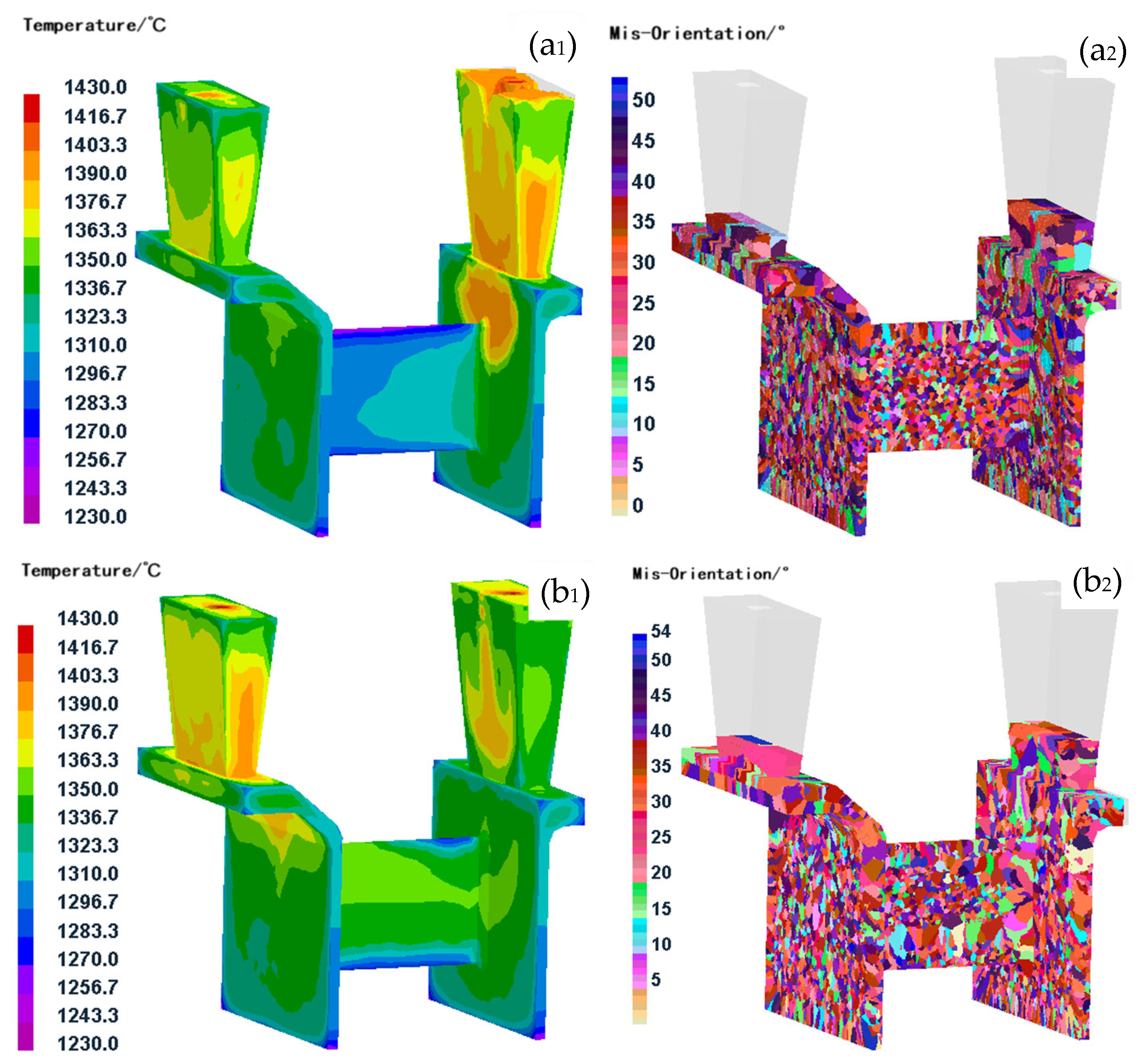

3.2. Influence of the Pouring/Shell Temperature on the Grain Structure

3.3. Influence of the Cooling Rate on the Grain Microstructure

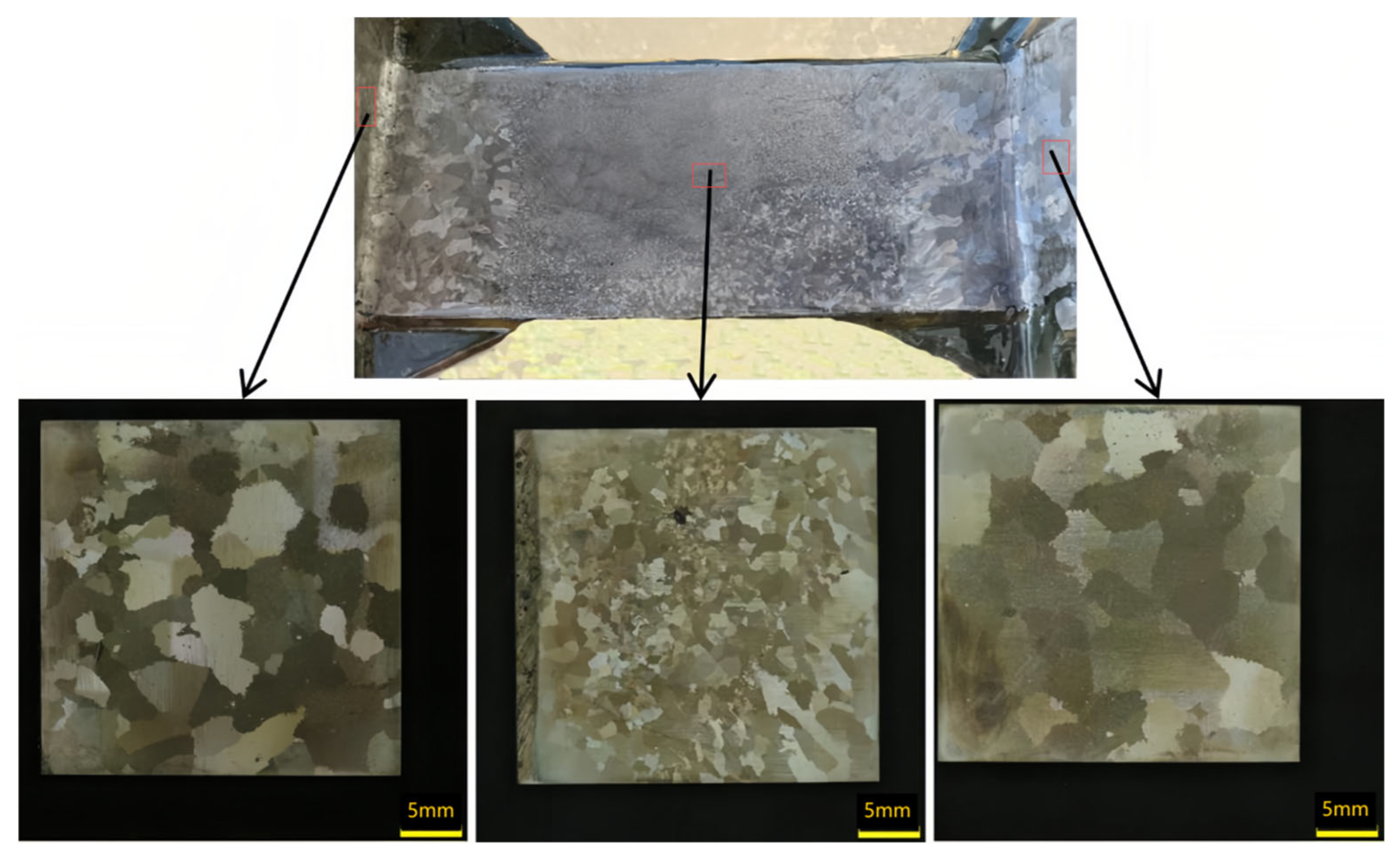

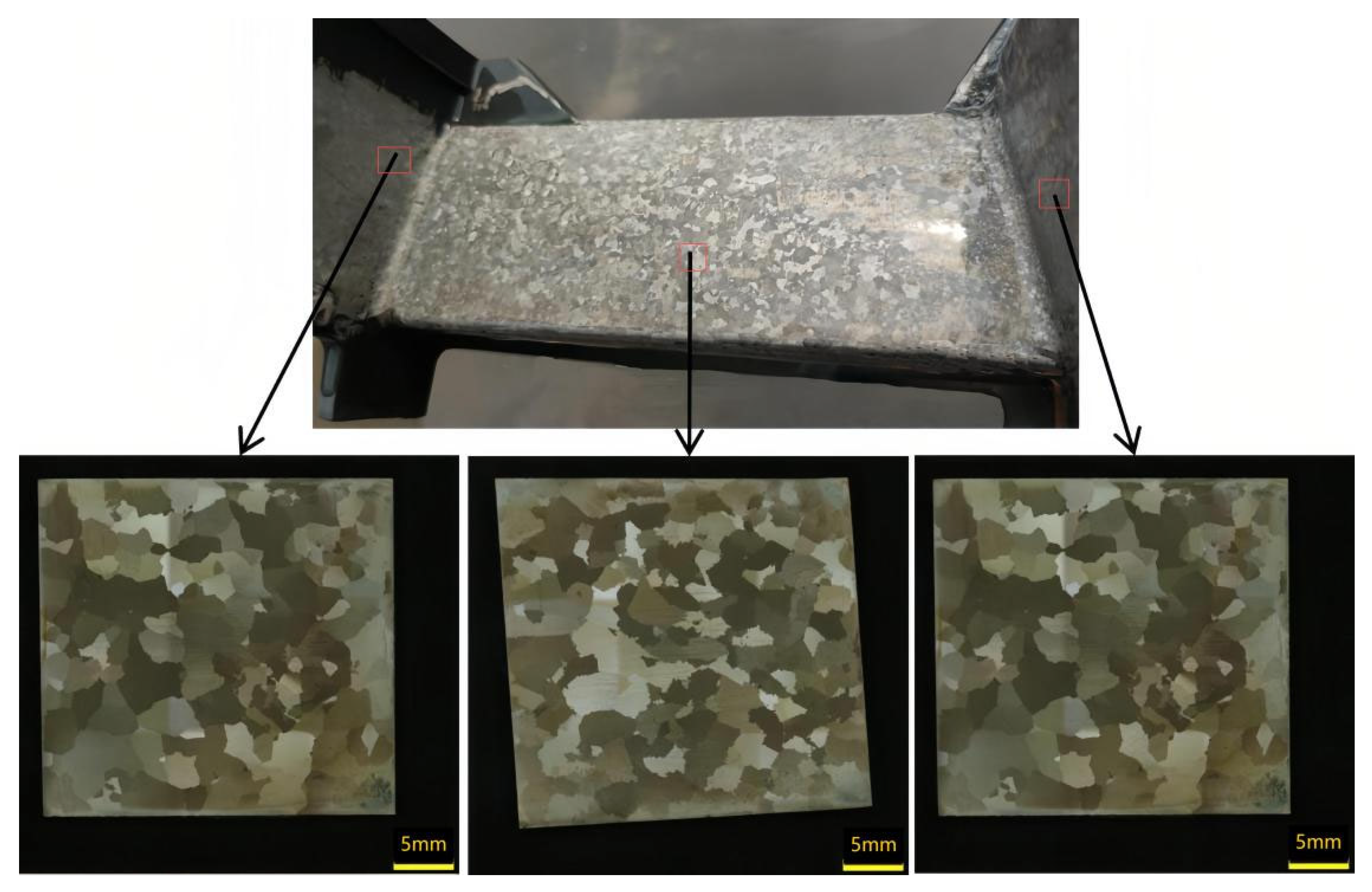

3.4. Comparison Experiment Analysis of the Solidification Grain Structure for Casings

3.5. Sensitivity Analysis of Key Simulation Parameters

4. Conclusions

- (1)

- The filling flow field plays a critical role in achieving uniform grain distribution within casing structural components. Concurrent filling from both the interior and exterior, as opposed to unilateral filling, facilitates a more consistent solidification temperature gradient across casing features, thereby reducing the occurrence of abnormally coarse columnar grains at L-shaped corners. However, the convergence of two molten alloy streams may introduce turbulence, which can result in irregular grain distribution and localized regions of coarser grains. Consequently, for the casting of large, complex thin-walled components, a multi-gate, rapid filling flow field control strategy should be employed to improve grain structure uniformity across various regions of the casting.

- (2)

- Both pouring temperature and shell temperature positively correlate with grain size, with shell temperature exerting a more significant influence. For fine and homogeneous grain structures, a lower pouring temperature is advisable at low shell temperatures. Conversely, at elevated shell temperatures, a moderate increase in pouring temperature can enhance heterogeneous nucleation, resulting in slightly coarser yet more uniformly distributed grains. Compared to slow cooling, rapid cooling more effectively promotes uniform grain nucleation within the thin-walled regions of casting features.

- (3)

- During the casting process of the nickel-based superalloy casing, the fiilling flow field control with simultaneous filling of the inner and outer rings, combined with the optimal casting parameters—a pouring temperature of 1430 °C and a shell temperature of 950 °C—results in a uniformly fine grain structure distribution, with grain sizes ranging between 2 and 4 mm. At the L-shaped corner of the support plate, no coarse columnar grain structures are observed; similarly, the central region of the support plate does not exhibit abnormally fine grain structures.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, L. The progress of investment casting of nickel-based superalloys. China Foundry 2012, 61, 1273–1285. [Google Scholar]

- Shi, C.X.; Zhong, Z.Y. Fifty Years of Superalloy in China; Metallurgical Industry Press: Beijing, China, 2006; Volume 72. [Google Scholar]

- Sun, B.D.; Wang, J.; Kang, M.D.; Wang, D.h.; Dong, A.P.; Wang, F.; Gao, H.Y.; Wang, G.X.; Du, D.F. Investment casting technology and development trend of superalloy ultra limit components. Acta Metall. Sin. 2022, 58, 412–427. [Google Scholar] [CrossRef]

- Xiong, Y.C. Basic research of precision forming technology of aviation complex components. Aero. Manuf. Technol. 2010, 53, 54–57. [Google Scholar] [CrossRef]

- Jiang, H.F. Requirements and forecast of turbine disk materials. Gas Turb. Exp. Res. 2002, 15, 1–6. [Google Scholar] [CrossRef]

- Zhang, J.; Jie, Z.Q.; Huang, T.W.; Yang, W.C.; Liu, L.; Fu, H.Z. Research and development of equiaxed grain solidification and forming technology for nickel-based cast superalloys. Acta Metall. Sin. 2019, 55, 1145–1159. [Google Scholar] [CrossRef]

- Li, Y. Research on investment precision casting process of large thin wall complex Ti-6Al-4V Allo. Titanium Ind. Prog. 2012, 29, 22–25. [Google Scholar]

- Jia, H.Z.; Fu, H.; Zhang, Y.G.; Xie, D.C.; Jing, W.X.; Li, C.Y.; Zhang, Z.K.; Lian, Y.D. Numeriacal Simulation and Optimization of Investment Casting Process of Auto Turbo-charger Turbine. Foundry 2022, 71, 760–765. [Google Scholar]

- Li, Z.F.; Wang, D.H.; Wu, W.Y. Numerical Simulation Study of Thermal Stress Field of Ni-base Superalloy Partsin In-vestment Casting. Hot Work. Technol. 2020, 49, 63–67. [Google Scholar]

- Han, D.P.; Yang, W.; Peng, Z.J.; Feng, W.G. Process Optimization of Whole Investment Casting of Large Thin-Wall Cartridge Re-ceiver Based on ProCAST Software. Foundry 2013, 62, 979–982. [Google Scholar] [CrossRef]

- Pequet, C.; Gremaud, M.; Rappaz, M. Modeling of microporosity, macroporosity, and pipe-shrinkage formation during the solidification of alloys using a mushy-zone refinement method: Applications to aluminum alloys. Metall. Mater. Trans. A 2002, 33, 2095–2106. [Google Scholar] [CrossRef]

- Wu, M.; Ahmadein, M.; Kharicha, A.; Ludwig, A.; Li, J. Multiphase and multiscale modeling of dendrite growth in solidification processes. JOM 2019, 71, 1095–1106. [Google Scholar]

- Jaafar, M.A.; Rousse, D.R.; Gibout, S.; Bédécarrats, J.P. A review of dendritic growth during solidification: Mathematical modeling and numerical simulations. Renew. Sust. Energ. Rev 2017, 74, 1064–1079. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, L.; Bao, L. Phase-field simulation of dendrite growth in Al-Cu alloy during directional solidification. Trans-Actions Nonferrous Met. Soc. China 2019, 29, 1868–1877. [Google Scholar]

- Yan, X.W.; Guo, X.; Liu, Y.L.; Song, X.F.; Xu, Q.Y.; Liu, B.C. Numerical simulation of dendrite growth in Ni-based superalloy casting during dirctional solidifi-cation process. Trans. Nonferrous Met. Soc. China 2019, 29, 338–348. [Google Scholar] [CrossRef]

- Yang, Y.F.; Xie, M.; Cheng, Y. Rearch Status of Numerical Simulation of Solidification Microstructure. Mater. Guide A Overv. 2014, 28, 24–29. [Google Scholar]

- Balliel, M.; Ma, D.; Hediger, F. Solidification & grain structure simulation of an equiaxed superalloy investment casting. Intermet. Superalloys 2000, 10, 115–120. [Google Scholar] [CrossRef]

- Pang, R.P.; Wang, F.M.; Zhang, G.Q.; Li, C.Y. Study of Solifification Thermal Parameters of 430 Ferrite Stainless Steel Based on 3D-CAFE Method. Acta Metall. Sin. 2013, 49, 1234–1242. [Google Scholar] [CrossRef]

- Wang, J.L.; Wang, F.M.; Zhao, Y.Y.; Zhang, J.M.; Ren, W. Numerical simulation of 3D-microstructures in solidification processes based on the CAFE method. Int. J. Miner. Met. Mater. 2009, 16, 640–645. [Google Scholar] [CrossRef]

- Hu, J.; Wang, Q.; Wang, K.; Wang, W.; Qiang, F.; Li, L. Coupled Temperature–Flow Field and Microstructure Numerical Simulation of the Solidification Process for Cu-3Ti-0.2Fe Alloy. Materials 2025, 18, 2478. [Google Scholar] [CrossRef]

- Sims, C.T.; Stoloff, N.S.; Hagel, W.C. (Eds.) Superalloy II: High-Temperature Materials for Aerospace and Industrial Power, 2nd ed.; Wiley-Interscience: New York, NY, USA, 1987; ISBN 978-0-471-01147-7. [Google Scholar]

- Kingery, W.D.; Bowen, H.K.; Uhlmann, D.R. Introduction to Ceramics, 2nd ed.; Wiley-Interscience: New York, NY, USA, 1976; ISBN 978-0-471-47860-7. [Google Scholar]

- Shackelford, J.F. Introduction to Materials Science for Engineers, 6th ed.; Pearson/Prentice Hall: Upper Saddle River, NJ, USA, 2004; ISBN 0131424866. [Google Scholar]

- Jin, D.Q. Computer modelling of thermal, deformation and microstructural evolution during hot rolling of steel. In Proceedings of the Proceeding 5th ICTP, Columbus, OH, USA, 7–10 October 1996; pp. 171–182. [Google Scholar]

- Gao, J.; Zhang, Y.; Wei, B. Rapid solidification of deeply undercooled Cu-Ni alloys. J. Alloys Compd. 2019, 785, 1160–1168. [Google Scholar]

- Zhu, B.W.; Li, L.X.; Liu, X.; Zhang, L.Q.; Bu, X.B.; Xu, R. Flow characteristics and solidified microstructure during filling process of thin-wall aluminum alloy under high pressure die casting conditions. Chin. J. Nonferr. Metal. 2014, 24, 43–52. [Google Scholar]

- Matysiak, H.; Zagorska, M.; Balkowiec, A.; Adamczyk-Cieslak, B.; Dobkowski, K.; Koralnik, M.; Cygan, R.; Nawrocki, J.; Cwajna, J.; Kurzydlowski, K.J. The Influence of the Melt-Pouring Temperature and Inoculant Content on the Macro and Microstructure of the IN713C Ni-Based Superalloy. JOM 2016, 68, 185–197. [Google Scholar] [CrossRef]

- Liu, L. Grain structure control of nickel-base superalloys in casting processes: Effect of foundry variables. ACTA Aeronaut. Et Astronaut. Sin. 1994, 15, 1357–1361. [Google Scholar]

| Material Parameters | Density/ρ (g/cm3) | Thermal Conductivity/Cp (W/m·K) | Solidification Temperature/T (°C) | Melting Temperature (°C) | Enthalpy/H (J/g) | Viscosity/µ (MPa·s) |

|---|---|---|---|---|---|---|

| The nickel-based superalloy | 7.77–6.53 | 14.72–35.27 | 1246–1355 | 1320–1360 [21] | 0.97–1153.57 | 7.33–3.23 |

| Mold-Mullite | 3.15 | 3.8–7.1 | / | 1840–1850 [22] | 0.55–1.2 | / |

| Sand box-Silica | 1.52 | 0.7 | / | 1710 [23] | 0.68–1.23 | / |

| Casting Condition | Outer Ring | Support Plate | Inner Ring |

|---|---|---|---|

| condition 1 | 3–7 | 1–4 | 3–7 |

| condition 2 | 2–4 | 2–3 | 2–4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, S.; Luo, H.; Li, S.; Han, G. Optimization of Casting Process Parameters for Solidification Structures in Complex Superalloy Castings. Materials 2025, 18, 4205. https://doi.org/10.3390/ma18174205

Han S, Luo H, Li S, Han G. Optimization of Casting Process Parameters for Solidification Structures in Complex Superalloy Castings. Materials. 2025; 18(17):4205. https://doi.org/10.3390/ma18174205

Chicago/Turabian StyleHan, Shaoli, Heli Luo, Shangping Li, and Guangwei Han. 2025. "Optimization of Casting Process Parameters for Solidification Structures in Complex Superalloy Castings" Materials 18, no. 17: 4205. https://doi.org/10.3390/ma18174205

APA StyleHan, S., Luo, H., Li, S., & Han, G. (2025). Optimization of Casting Process Parameters for Solidification Structures in Complex Superalloy Castings. Materials, 18(17), 4205. https://doi.org/10.3390/ma18174205