Synergistic Deformation of Ferrite/Martensite Laminates Brings High Strength and Good Ductility in Dual-Phase Steel

Abstract

1. Introduction

2. Materials and Methods

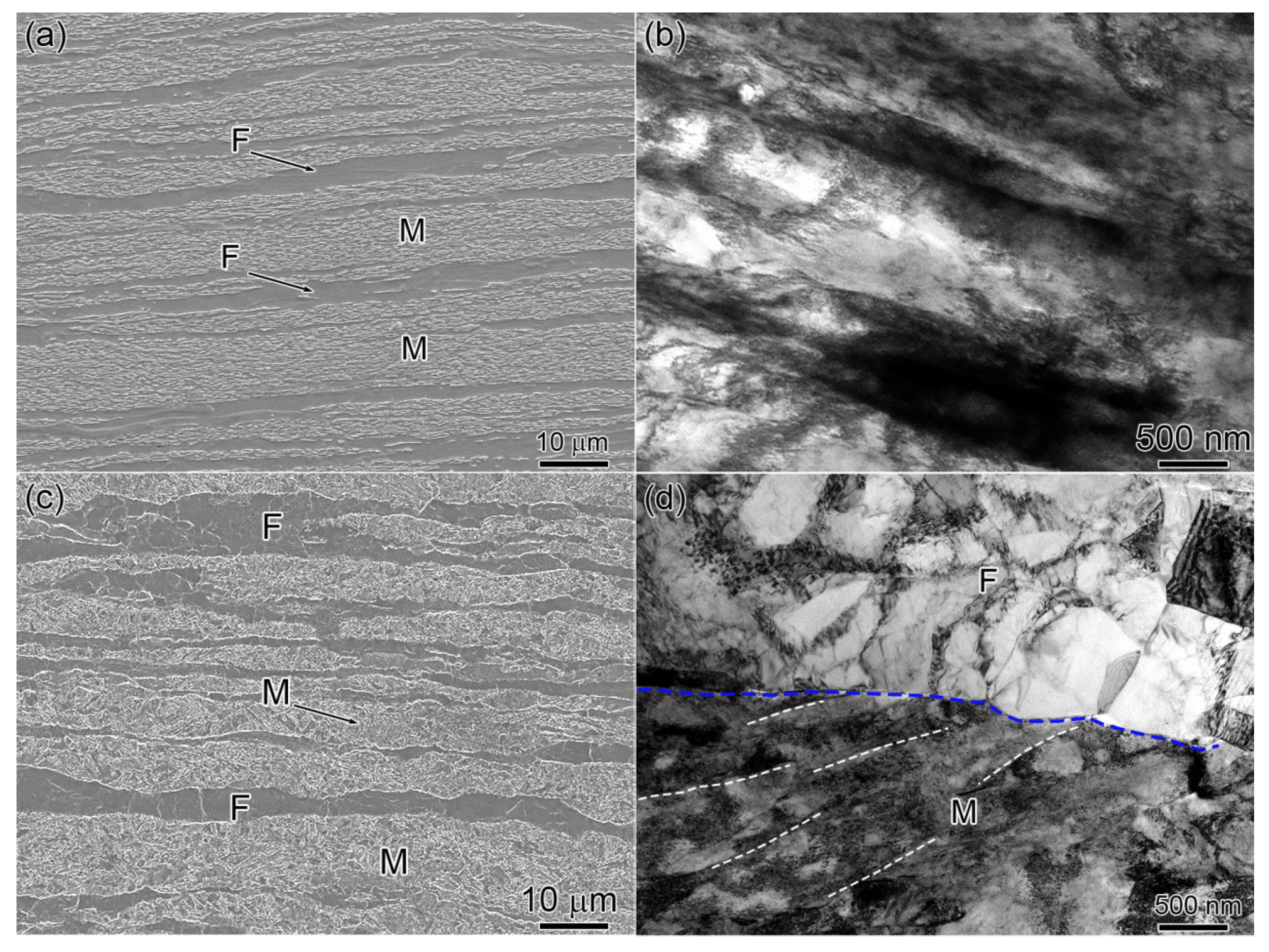

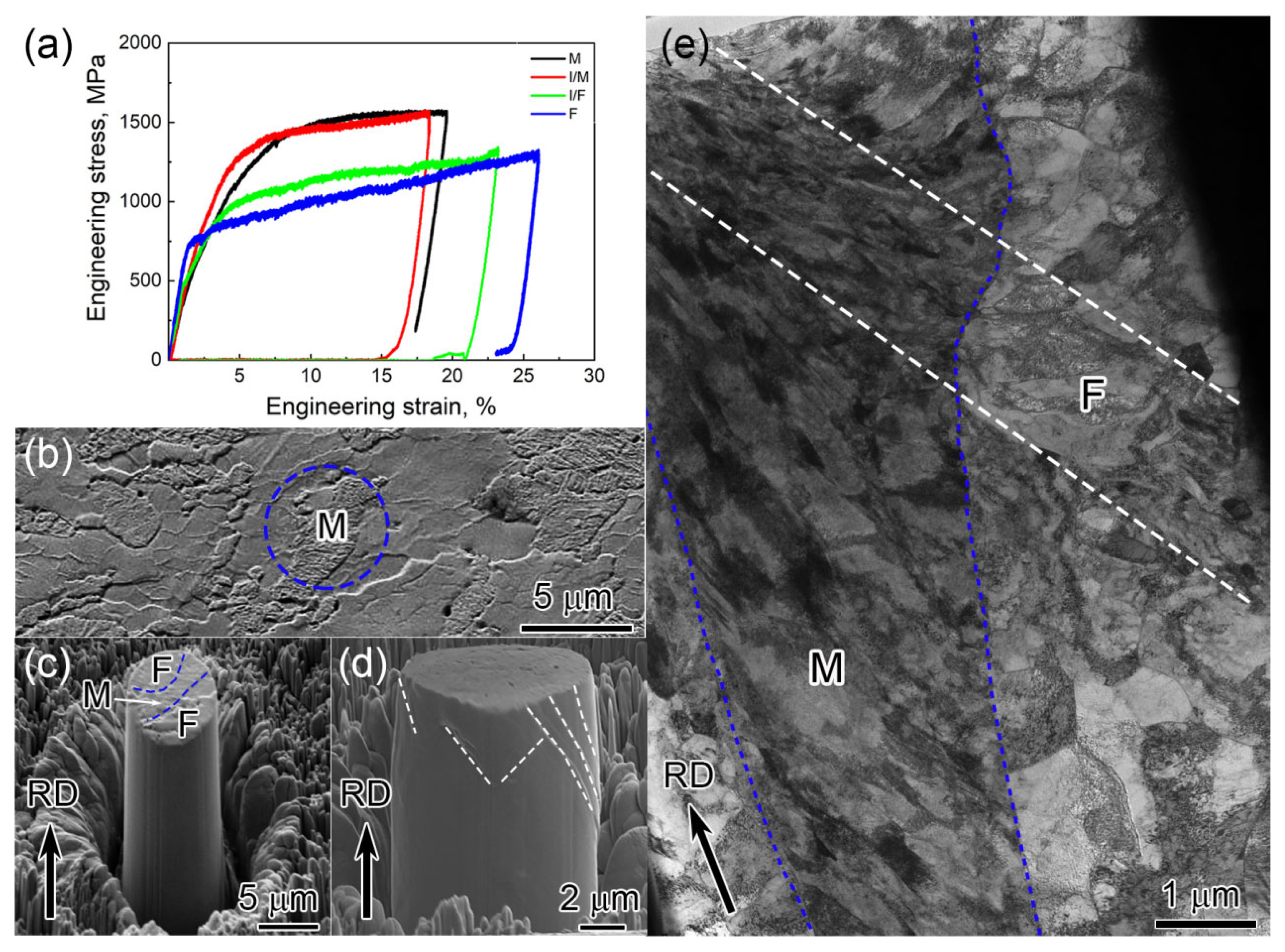

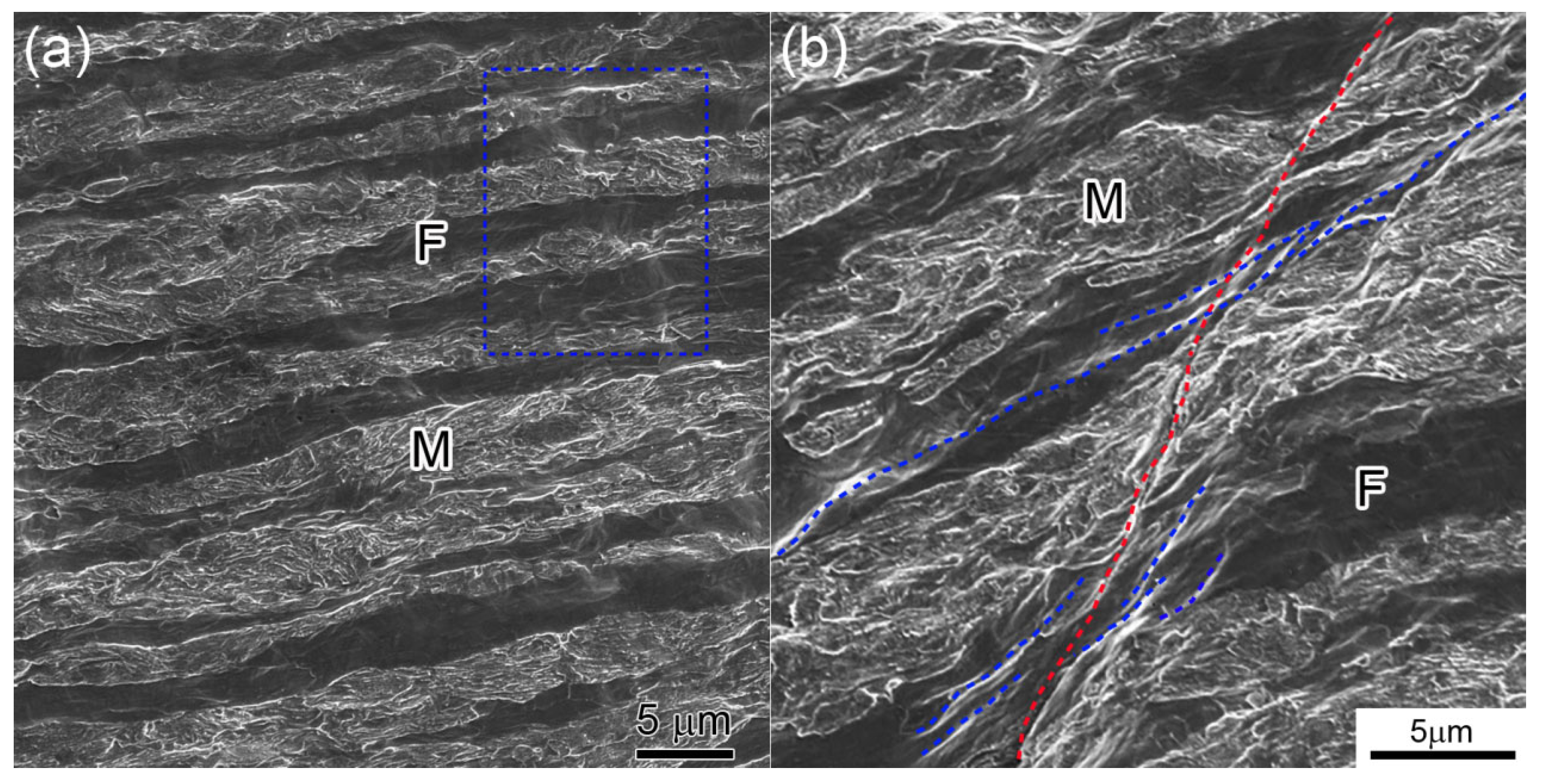

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhu, Y.; Ameyama, K.; Anderson, P.M.; Beyerlein, I.J.; Gao, H.; Kim, H.S.; Lavernia, E.; Mathaudhu, S.; Mughrabi, H.; Ritchie, R.O.; et al. Heterostructured materials: Superior properties from hetero-zone interaction. Mater. Res. Lett. 2020, 9, 1–31. [Google Scholar] [CrossRef]

- Koga, N.; Suzuki, M.; Umezawa, O. Influence of layer thickness on tensile deformation and fracture in the ferrite + martensite fine multi-layered steel sheets. Mater. Sci. Eng. A 2021, 806, 140599. [Google Scholar] [CrossRef]

- Ma, X.; Huang, C.; Moering, J.; Ruppert, M.; Höppel, H.W.; Göken, M.; Narayan, J.; Zhu, Y. Mechanical properties of copper/bronze laminates: Role of interfaces. Acta Mater. 2016, 116, 43–52. [Google Scholar] [CrossRef]

- Chen, A.; Li, Y.; Zhang, J.; Pan, D.; Lu, J. The influence of interface structure on nanocrystalline deformation of a layered and nanostructured steel. Mater. Des. 2013, 47, 316–322. [Google Scholar] [CrossRef]

- Yu, W.; Qian, L.; Wei, C.; Li, K.; Ding, Y.; Yu, P.; Jia, Z.; Zhang, F.; Meng, J. Enhancing the ductility and yield strength of 2.7 Mn steel via two-step partitioning heat treatment. Int. J. Plast. 2024, 183, 104148. [Google Scholar] [CrossRef]

- Bai, R.; Du, Y.; Zhang, Y.; He, X. The influence of Al content and heat treatment on the microstructure and properties of austenite-ferrite duplex Fe-Mn-Al-C lightweight steels. J. Alloy. Met. Syst. 2025, 9, 100162. [Google Scholar] [CrossRef]

- Zhang, M.; Cao, W.; Dong, H.; Zhu, J. Element partitioning effect on microstructure and mechanical property of the micro-laminated Fe–Mn–Al–C dual phase steel. Mater. Sci. Eng. A 2016, 654, 193–202. [Google Scholar] [CrossRef]

- Cao, W.; Huang, C.; Wang, C.; Dong, H.; Weng, Y. Dynamic reverse phase transformation induced high-strain-rate superplasticity in low carbon low alloy steels with commercial potential. Sci. Rep. 2017, 7, 9199. [Google Scholar] [CrossRef]

- Liu, T.; Cao, Z.; Wang, H.; Wu, G.; Jin, J.; Cao, W. A new 2.4 GPa extra-high strength steel with good ductility and high toughness designed by synergistic strengthening of nano-particles and high-density dislocations. Scr. Mater. 2020, 178, 285–289. [Google Scholar] [CrossRef]

- Zhang, L.; Liang, M.; Feng, Z.; Zhang, L.; Cao, W.; Wu, G. Nanoindentation characterization of strengthening mechanism in a high strength ferrite/martensite steel. Mater. Sci. Eng. A 2019, 745, 144–148. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, Z.; Wang, Y.; Ma, G.; Huang, T.; Wu, G.; Jensen, D.J. Fabricating interstitial-free steel with simultaneous high strength and good ductility with homogeneous layer and lamella structure. Scr. Mater. 2017, 141, 111–114. [Google Scholar] [CrossRef]

- Wang, Y.-R.; Hou, Z.-Y.; Yang, H.; Zhao, J.; Chang, Z.-Y.; Meng, F.-M.; Zhang, L.; Wu, G.-L.; Huang, X.-X. Effect of initial microstructure on microstructure evolution and mechanical properties of 0.12C martensitic steels during quenching and tempering. J. Iron Steel Res. Int. 2024, 32, 260–269. [Google Scholar] [CrossRef]

- Ma, X.; Chu, X.; Yang, Y.; Lu, H.; Wang, W.; Zhao, Z. Influence of Annealing and Aging Parameters on the Microstructure and Properties of 1200 MPa Grade Cold-Rolled Dual-Phase Steel. Materials 2024, 17, 4933. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Wu, X. Heterostructured materials. Prog. Mater. Sci. 2023, 131, 101019. [Google Scholar] [CrossRef]

- Dolzhenko, A.; Yanushkevich, Z.; Nikulin, S.; Belyakov, A.; Kaibyshev, R. Impact toughness of an S700MC-type steel: Tempforming vs ausforming. Mater. Sci. Eng. A 2018, 723, 259–268. [Google Scholar] [CrossRef]

- Song, R.; Ponge, D.; Raabe, D. Mechanical properties of an ultrafine grained C–Mn steel processed by warm deformation and annealing. Acta Mater. 2005, 53, 4881–4892. [Google Scholar] [CrossRef]

- Dolzhenko, A.; Kaibyshev, R.; Belyakov, A. Outstanding impact toughness of low-alloyed steel with fine lamellar microstructure. Mater. Lett. 2021, 303, 130547. [Google Scholar] [CrossRef]

- Tian, C.; Ponge, D.; Christiansen, L.; Kirchlechner, C. On the mechanical heterogeneity in dual phase steel grades: Activation of slip systems and deformation of martensite in DP800. Acta Mater. 2020, 183, 274–284. [Google Scholar] [CrossRef]

- Choi, W.S.; De Cooman, B.C.; Sandlöbes, S.; Raabe, D. Size and orientation effects in partial dislocation-mediated deformation of twinning-induced plasticity steel micro-pillars. Acta Mater. 2015, 98, 391–404. [Google Scholar] [CrossRef]

- Cavusoglu, O.; Toros, S. Three-Dimensional Micromechanical Modeling of Martensite Particle Size Effects on the Deformation Behavior of Dual-Phase Steels. Materials 2024, 17, 5004. [Google Scholar] [CrossRef] [PubMed]

- HGhassemi-Armaki, H.; Maaß, R.; Bhat, S.; Sriram, S.; Greer, J.; Kumar, K. Deformation response of ferrite and martensite in a dual-phase steel. Acta Mater. 2014, 62, 197–211. [Google Scholar] [CrossRef]

- Li, Y.; Li, L.; Kang, J.; Niu, N.; Xi, H.; Liu, Y.; Yuan, G.; Wang, G. Achieving unprecedented yield strength of 2.2 GPa with high ductility in formed parts using strain-aging. Scr. Mater. 2023, 233, 115521. [Google Scholar] [CrossRef]

- Li, Y.; Yuan, G.; Li, L.; Kang, J.; Yan, F.; Du, P.; Raabe, D.; Wang, G. Ductile 2-GPa steels with hierarchical substructure. Science 2023, 379, 6228. [Google Scholar] [CrossRef] [PubMed]

- Chang, Z.; Li, Y.; Wu, D. Enhanced ductility and toughness in 2000 MPa grade press hardening steels by auto-tempering. Mater. Sci. Eng. A 2020, 784, 139342. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Cai, P.; Zhang, L.; Hou, Z.; Wu, G. Synergistic Deformation of Ferrite/Martensite Laminates Brings High Strength and Good Ductility in Dual-Phase Steel. Materials 2025, 18, 4198. https://doi.org/10.3390/ma18174198

Zhang L, Cai P, Zhang L, Hou Z, Wu G. Synergistic Deformation of Ferrite/Martensite Laminates Brings High Strength and Good Ductility in Dual-Phase Steel. Materials. 2025; 18(17):4198. https://doi.org/10.3390/ma18174198

Chicago/Turabian StyleZhang, Lijuan, Pengzhan Cai, Ling Zhang, Ziyong Hou, and Guilin Wu. 2025. "Synergistic Deformation of Ferrite/Martensite Laminates Brings High Strength and Good Ductility in Dual-Phase Steel" Materials 18, no. 17: 4198. https://doi.org/10.3390/ma18174198

APA StyleZhang, L., Cai, P., Zhang, L., Hou, Z., & Wu, G. (2025). Synergistic Deformation of Ferrite/Martensite Laminates Brings High Strength and Good Ductility in Dual-Phase Steel. Materials, 18(17), 4198. https://doi.org/10.3390/ma18174198