Strength Characteristics of Straw-Containing Cemented Tailings Backfill Under Different Strain Rates

Abstract

1. Introduction

2. Materials and Methods

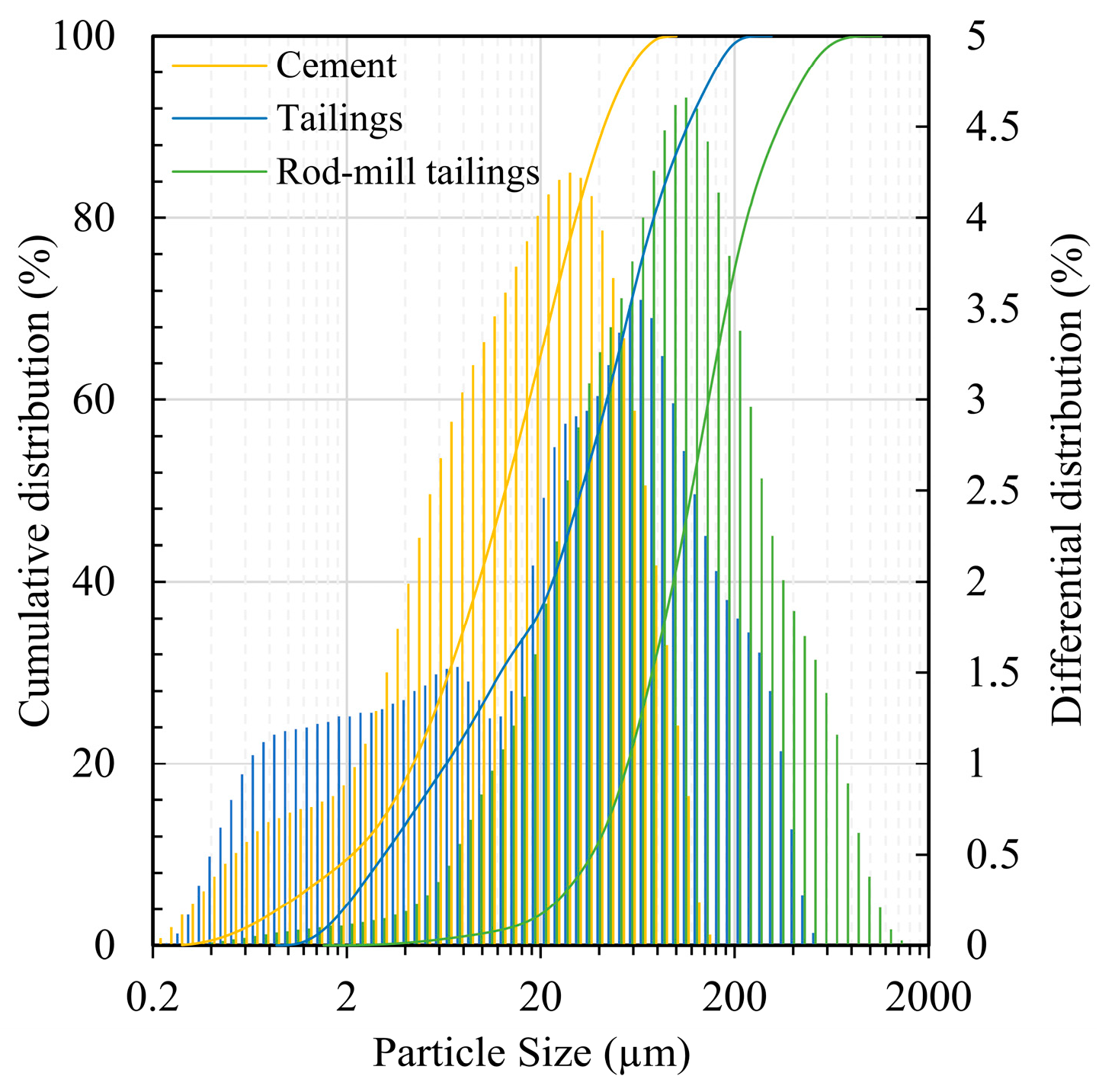

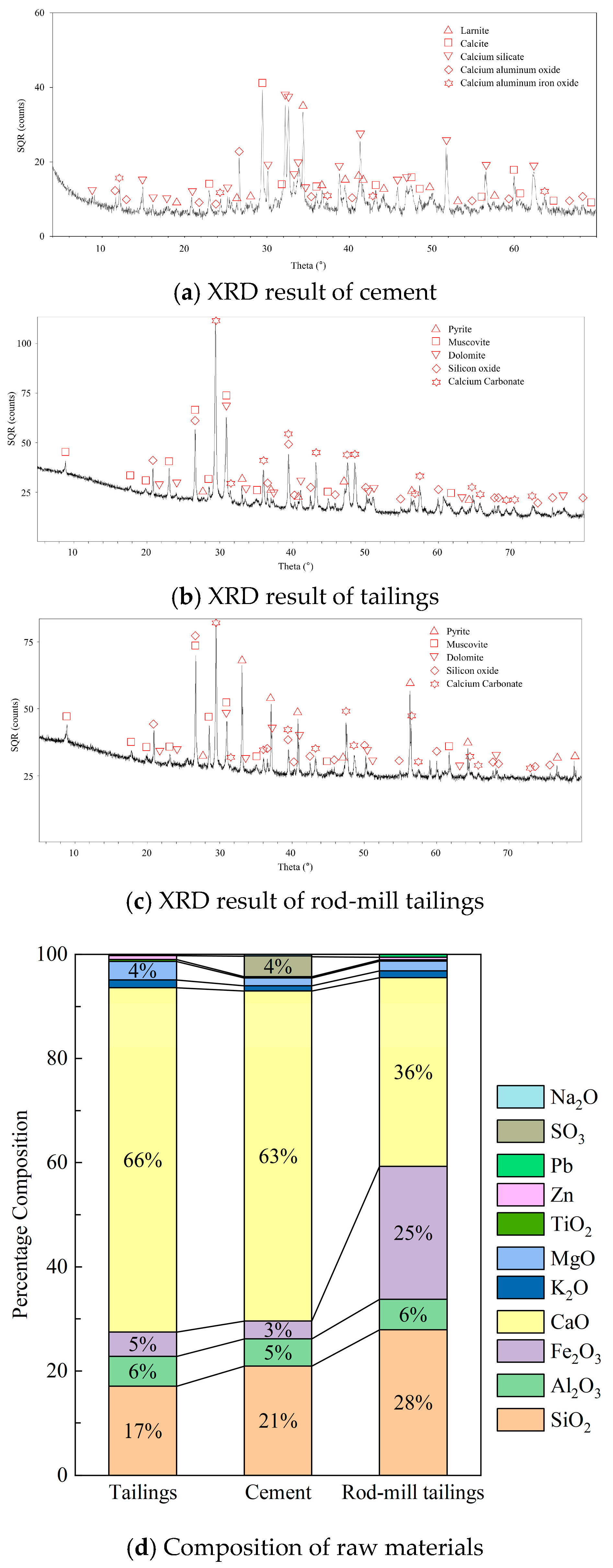

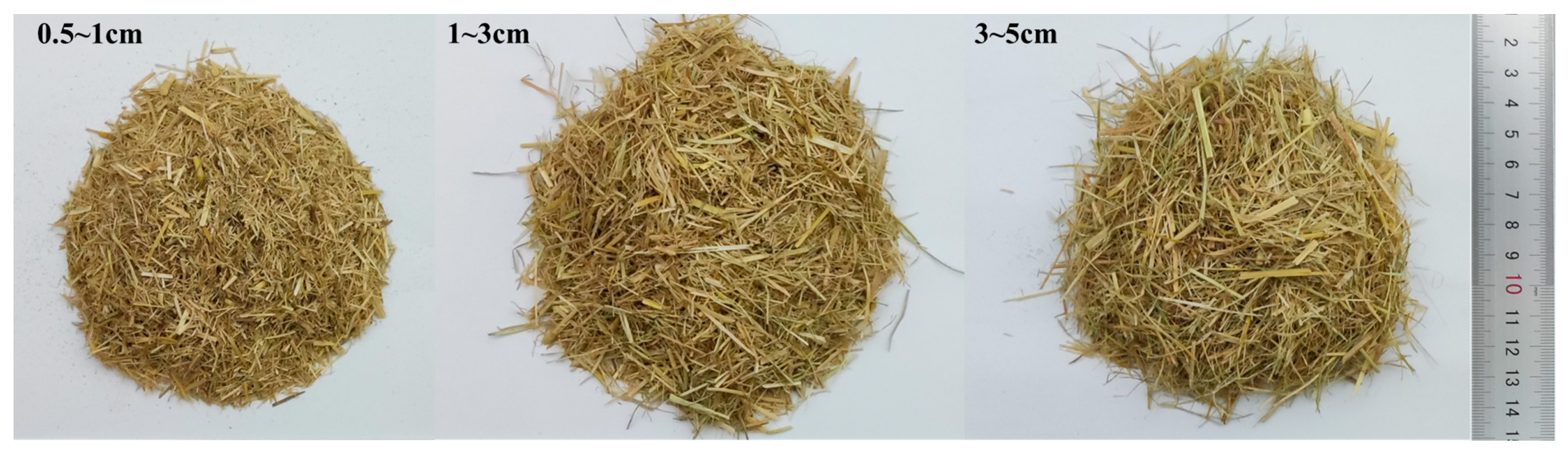

2.1. Materials

2.2. Specimen Preparation

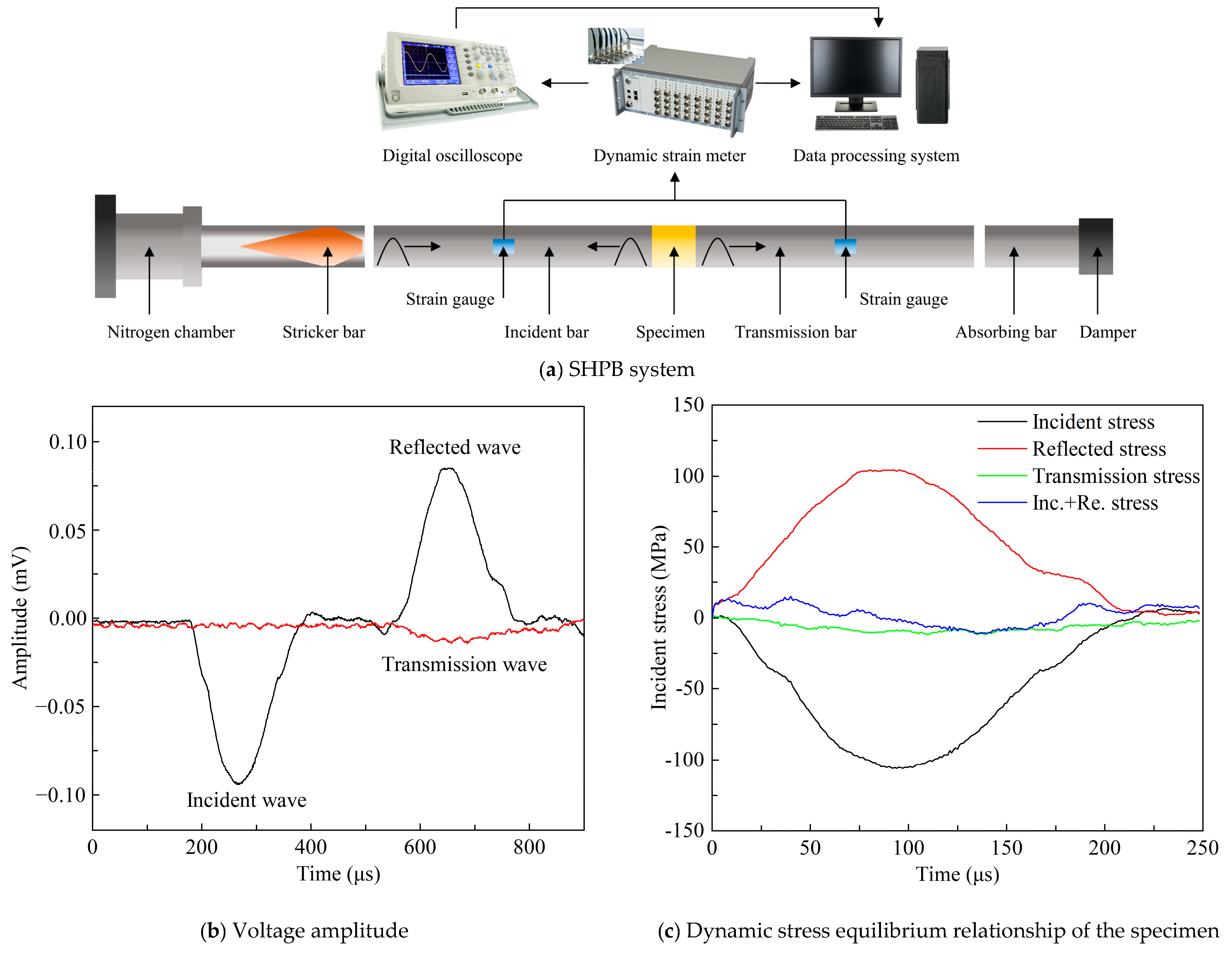

2.3. Experimental Methods

2.3.1. Diffusivity Test

2.3.2. Unconfined Compressive Strength Test

2.3.3. Dynamic Unconfined Compressive Strength Test

2.3.4. Microstructure and Elemental Analysis

3. Results and Discussion

3.1. Fluidity

3.1.1. Effect of RS Fiber on Backfill Slurry Fluidity

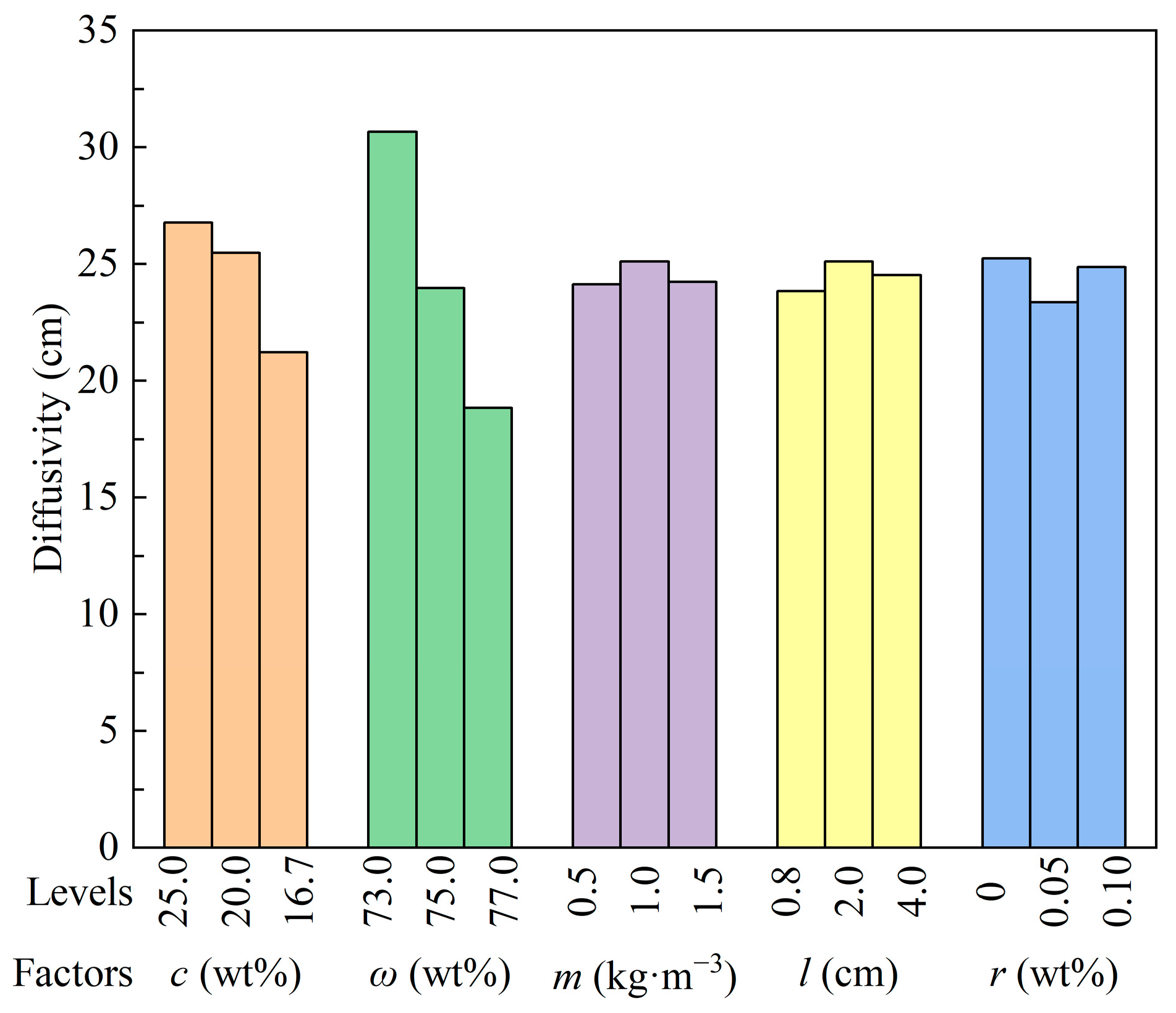

3.1.2. Univariate Analysis of Factors Affecting RSCTB Slurry Fluidity

3.2. Unconfined Compressive Strength

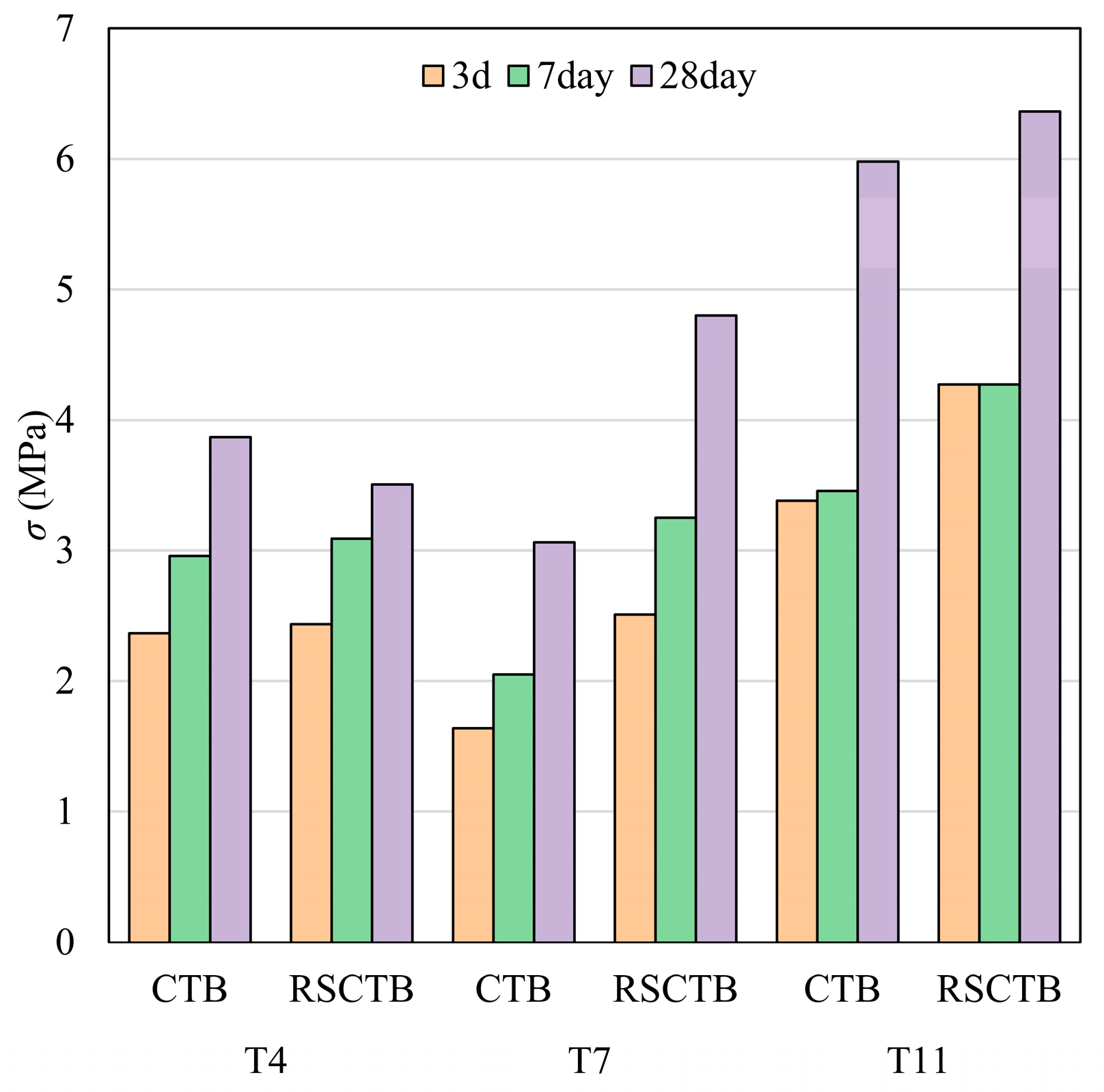

3.2.1. Enhancing Effect of RS Fiber on CTB

3.2.2. Univariate Analysis of Factors Affecting RSCTB UCS

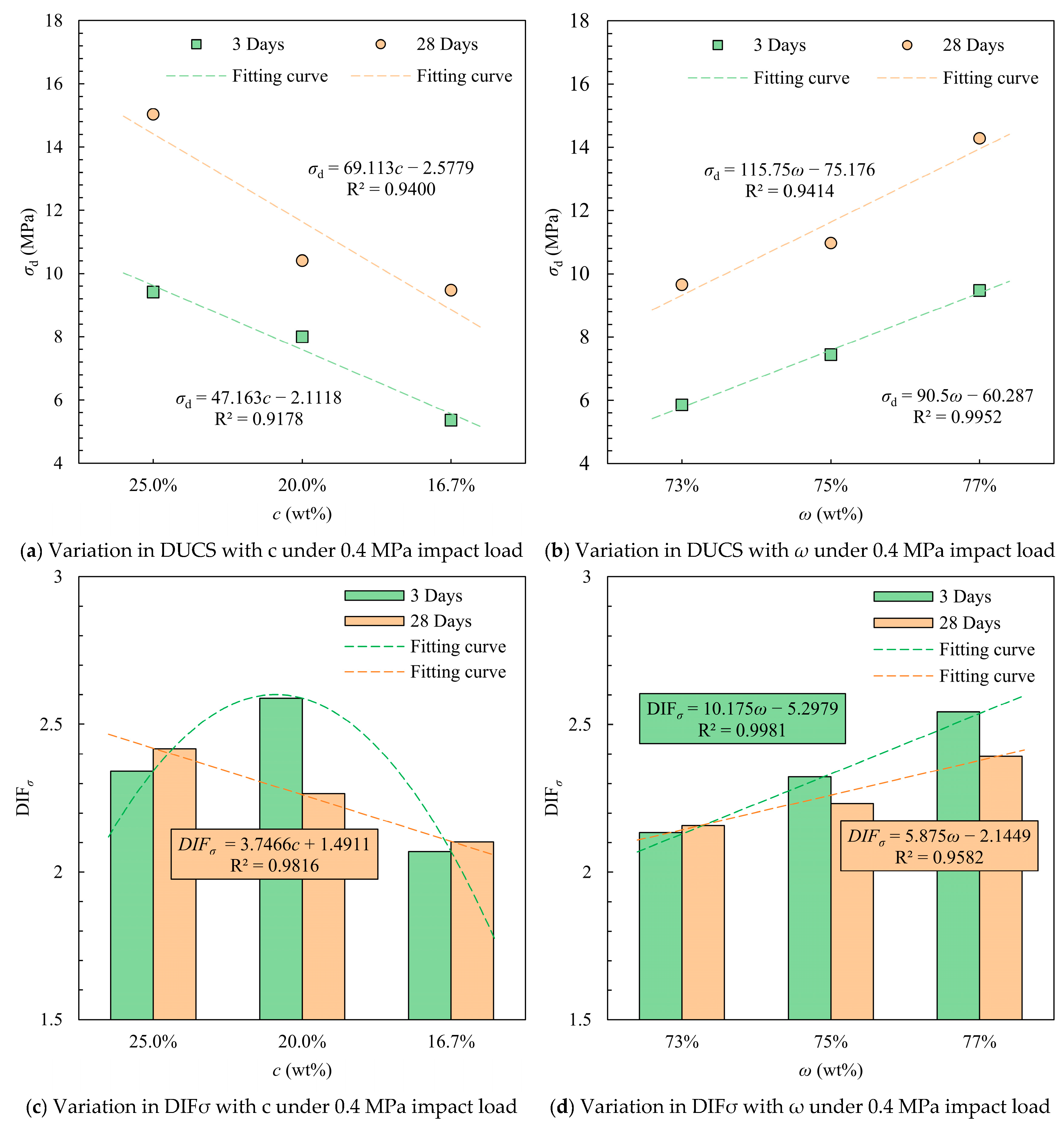

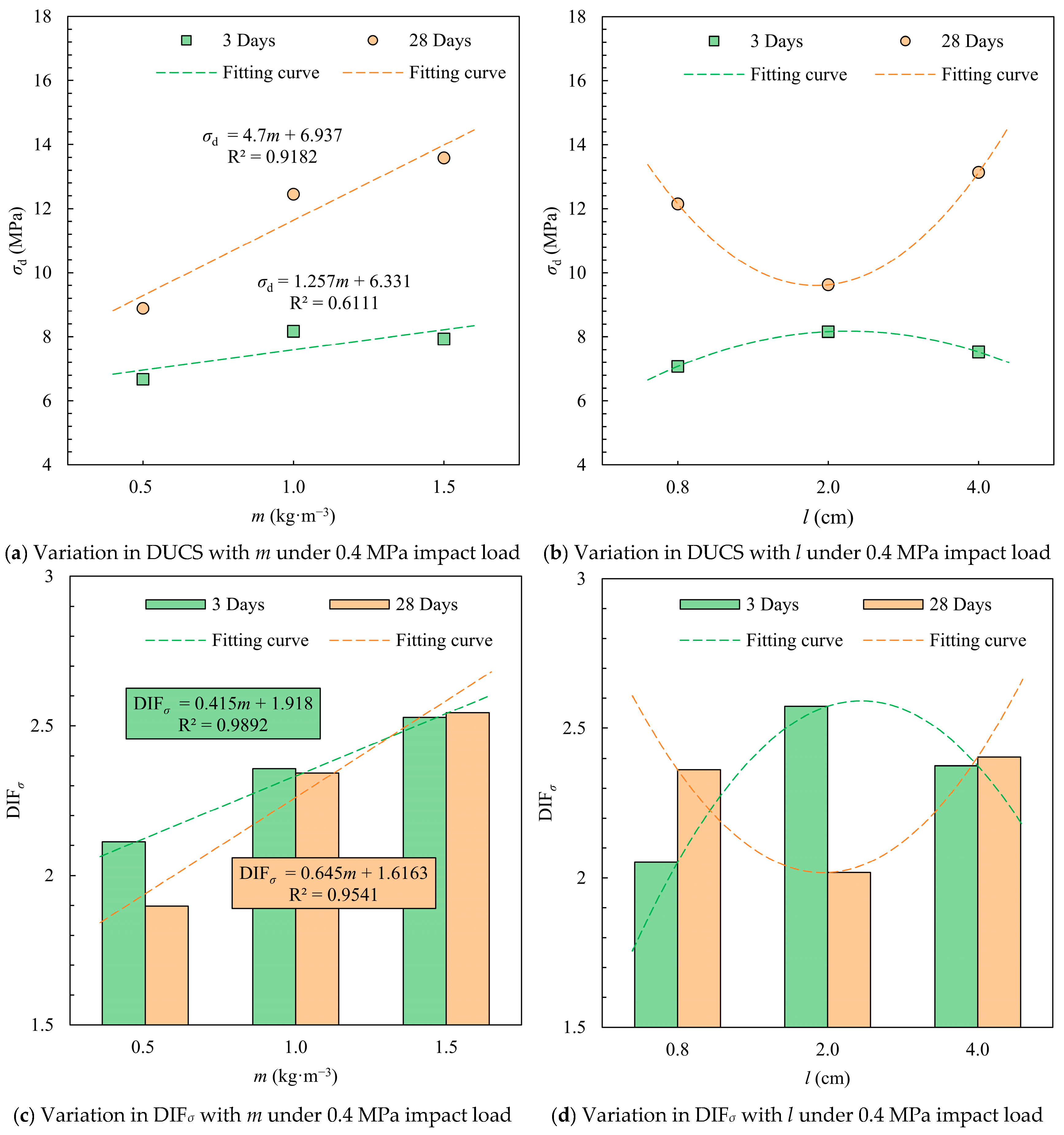

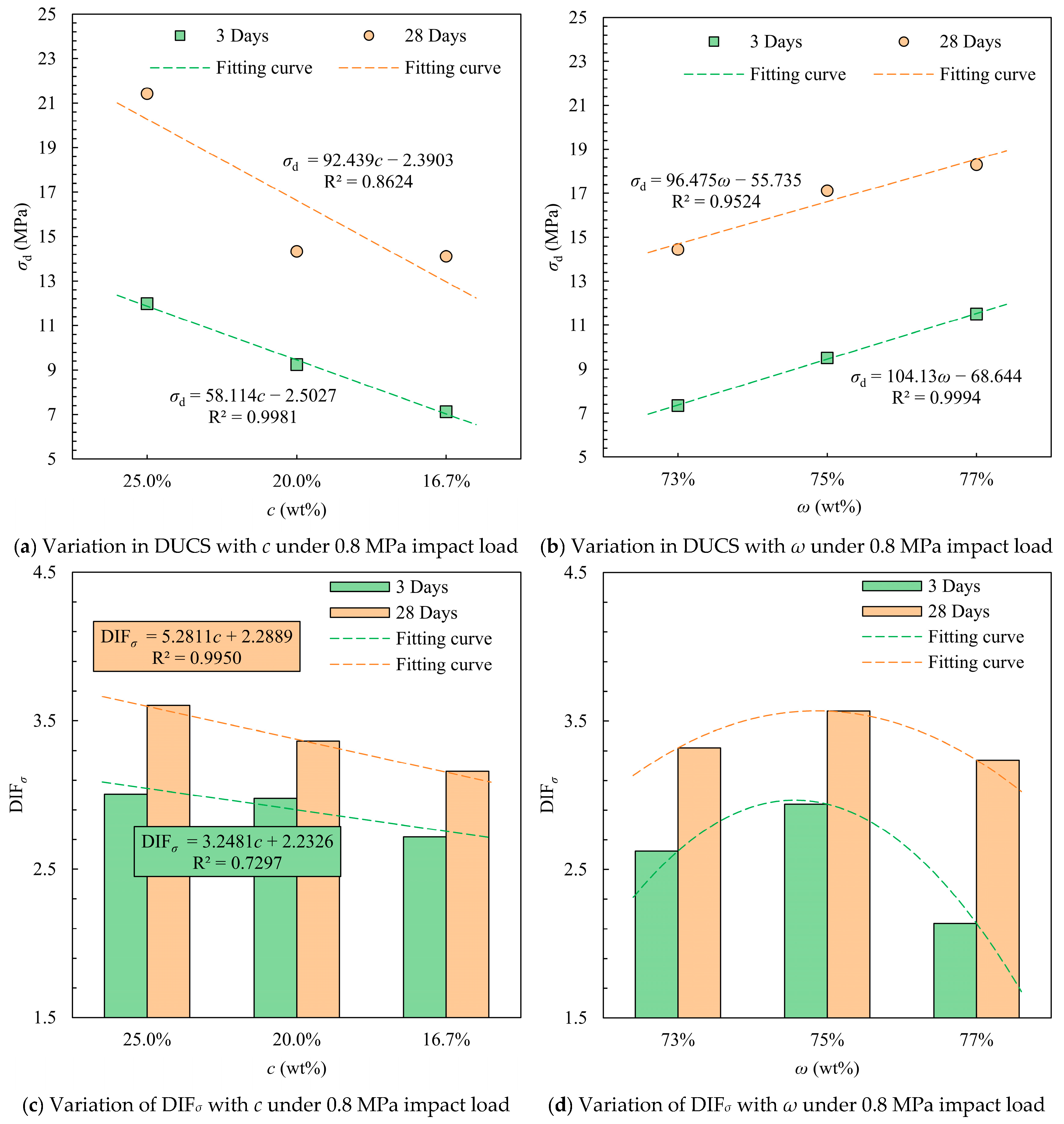

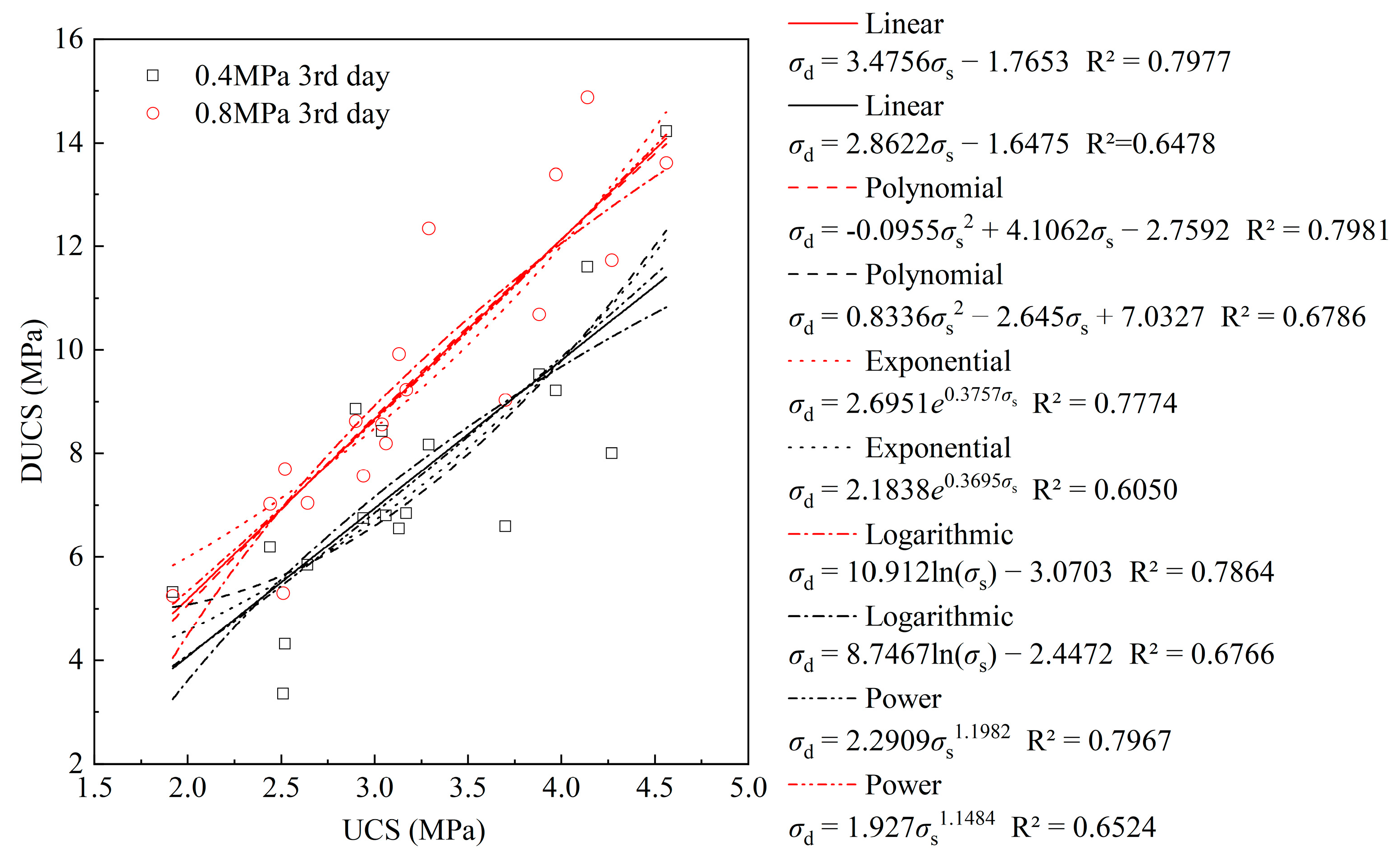

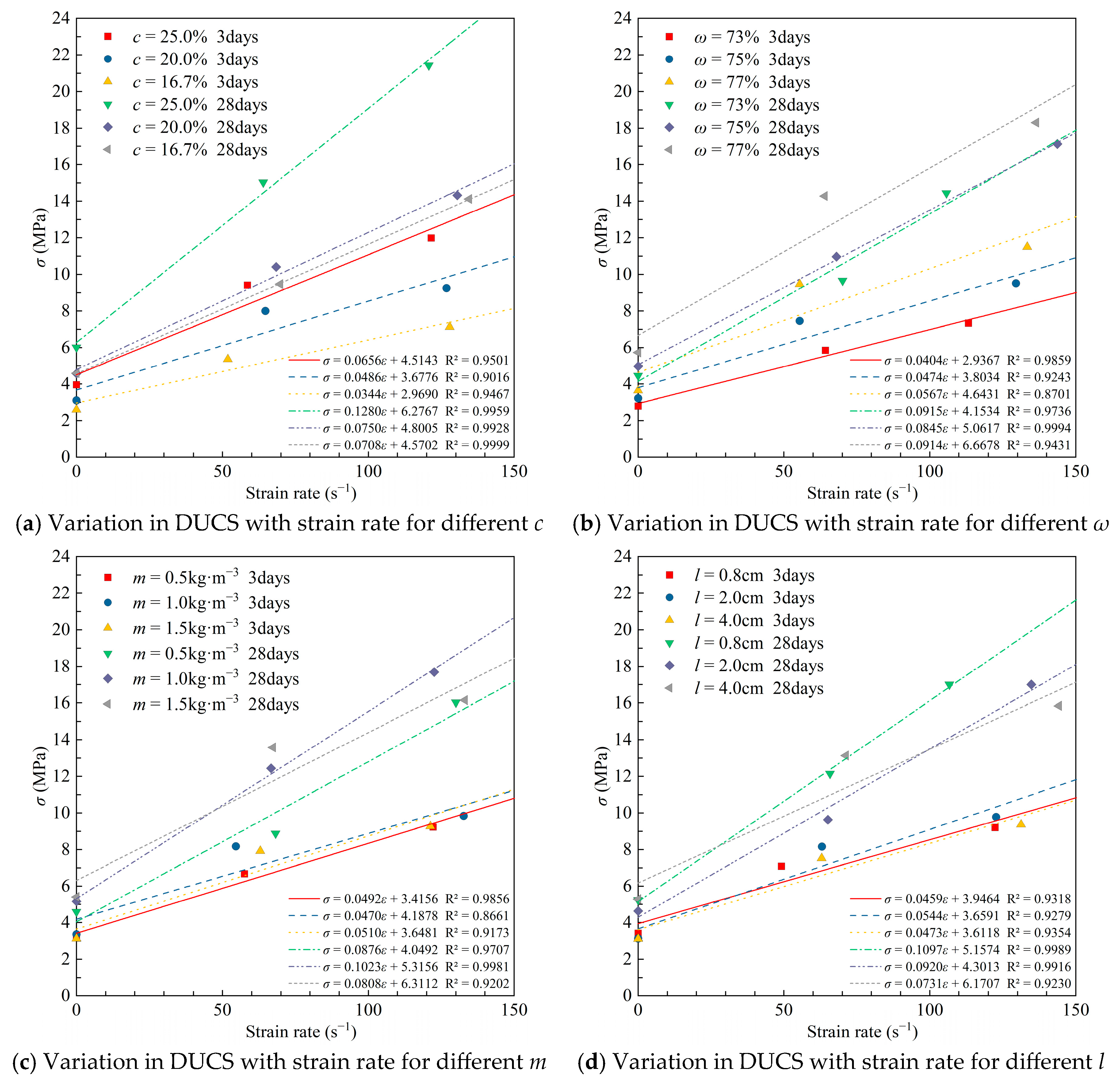

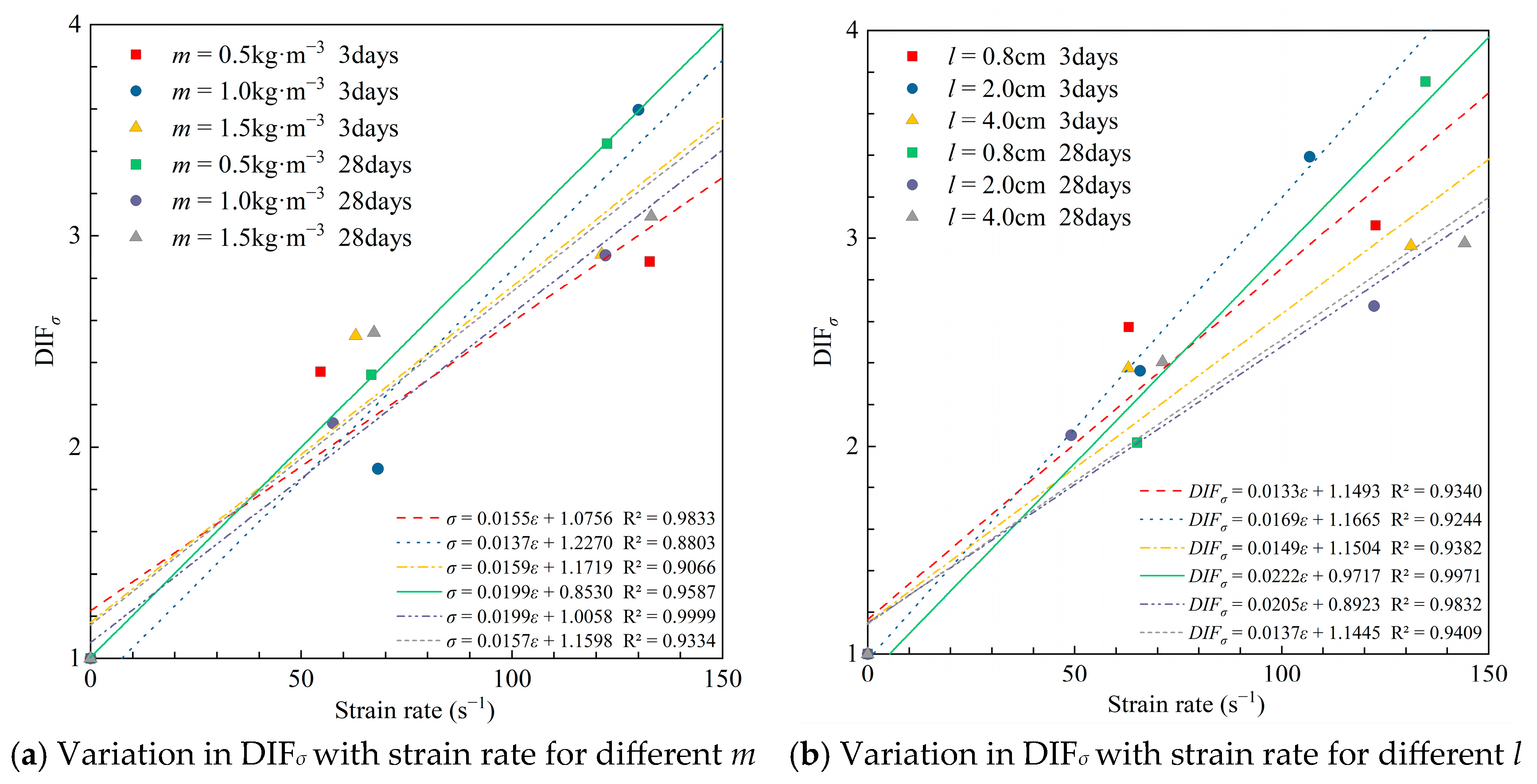

3.3. Compressive Response Under Dynamic Load

3.4. High Strain Rate Effect

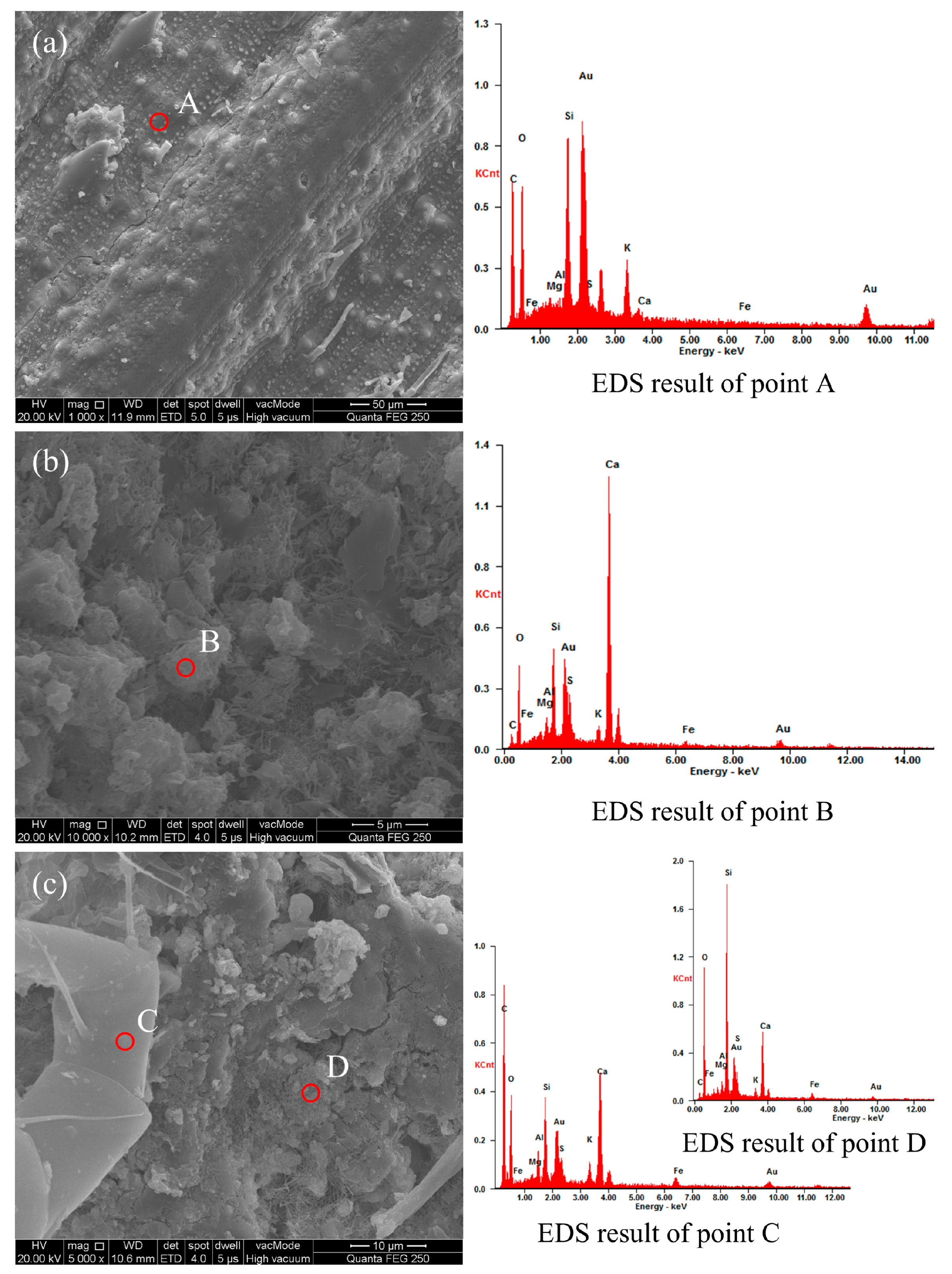

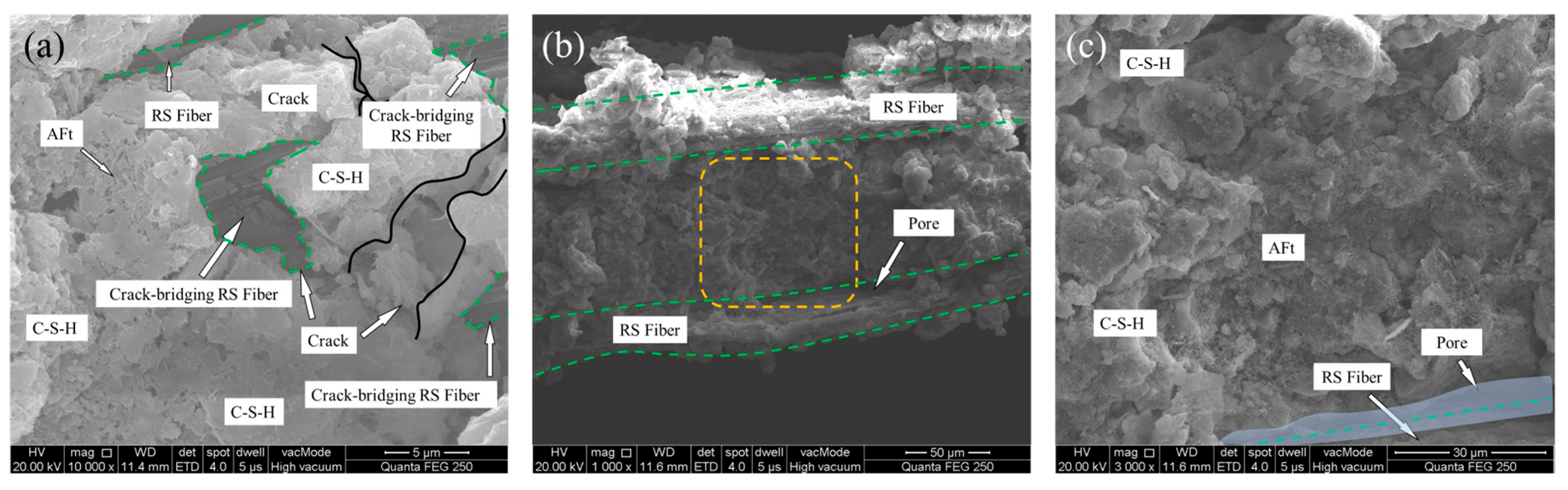

3.5. Microscopic Morphology of RSCTB and Macroscopic Roles of RS Fibers

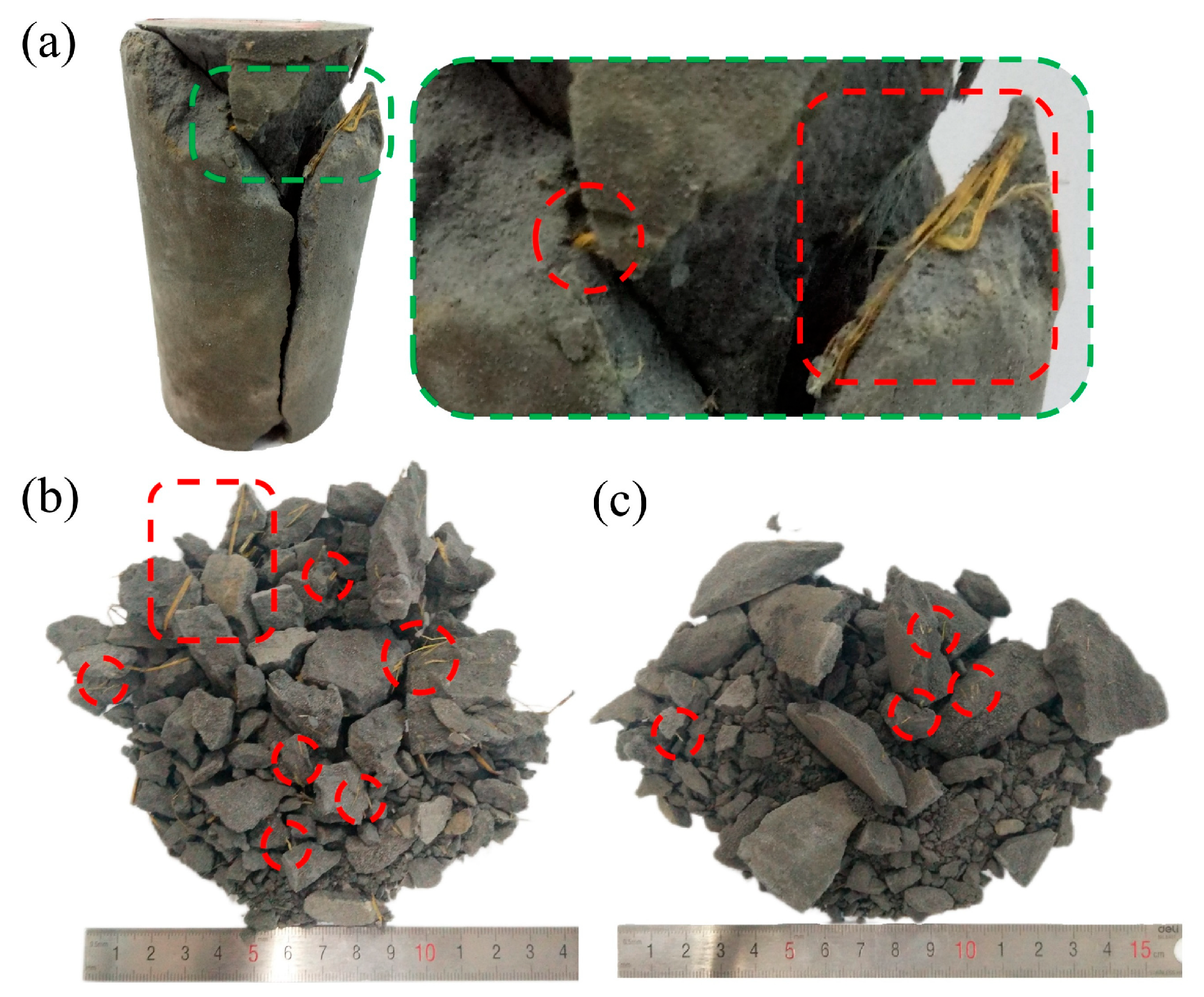

- Effective bridging, contributing to structural integrity: When intersecting the natural pores of the backfill at a relatively large angle, straw fibers are capable of bridging across pore walls; this behavior is shown in Figure 17a, effectively linking the cemented matrix on both sides and mitigating overall failure. The corresponding macroscopic post-failure state is highlighted by the red circles in Figure 18a.

- Partial bridging during failure, insufficient to prevent structural breakdown: As shown in red circles in Figure 18b,c, the fibers provided a degree of connectivity during deformation but ultimately failed to prevent the material from disintegrating. This can be attributed to two primary factors: either the interfacial bonding strength was insufficient, resulting in fiber pull-out, or the tensile capacity of the fibers was exceeded, causing rupture.

- No observable reinforcement effect: In certain cases, straw fibers did not contribute to the structural reinforcement of the backfill. Such occurrences are more likely when the fibers are excessively long or densely clustered in localized regions. RSCTB T3 and T6 had the same straw content, while T3 had a longer straw fiber length, and these longer straws even become the starting points of crack development, as illustrated by the areas marked with rectangles in Figure 18a,b. At the microscopic level, these fibers are relatively independent, as shown in Figure 17b.

4. Conclusions

- Orthogonal test analysis showed that the effects of straw addition and straw fiber length on UCS, DUCS, and fluidity were much smaller than those of binder content and solid mass concentration.

- The strength of RSCTB under quasi-static loading was generally higher than that of CTB without RS, with a maximum lead of more than 50%.

- The straw absorbed water and weakened the mobility of fresh CTB by up to 15%.

- High fiber content (1.5 kg·m−3) promotes the highest dynamic strength and DIF under low impact, while medium fiber content (1.0 kg·m−3) favors maximum strength under high impact.

- A moderate fiber length (1.0 cm) slightly reduced long-term strength under impact pressures below 0.4 MPa, but in all other cases, it was beneficial for dynamic compressive strength and the dynamic increase factor.

- The compressive properties of RSCTB are positively correlated with strain rate and can be fitted well by a linear function.

- Straw can bridge the pores within hydration products, providing flexible connections. However, excessive amounts or overly long fibers may adversely affect the performance of RSCTB.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| RSCTB | Rice Straw Fiber-Reinforced Cemented Tailings Backfill |

| UCS | Unconfined Compressive Strength |

| DUCS | Dynamic Unconfined Compressive Strength |

| SHPB | Split Hopkinson Pressure Bar |

| CTB | Cemented Tailings Backfill |

| SEM | Scanning Electron Microscope |

| EDS | Energy-Dispersive X-ray Spectroscopy |

| DIF | Dynamic Increase Factor |

References

- Qi, C.; Chen, Q.; Fourie, A.; Tang, X.; Zhang, Q.; Dong, X.; Feng, Y. Constitutive modelling of cemented paste backfill: A data-mining approach. Constr. Build. Mater. 2019, 197, 262–270. [Google Scholar] [CrossRef]

- Fall, M.; Célestin, J.C.; Pokharel, M.; Touré, M. A contribution to understanding the effects of curing temperature on the mechanical properties of mine cemented tailings backfill. Eng. Geol. 2010, 114, 397–413. [Google Scholar] [CrossRef]

- Behera, S.K.; Mishra, D.P.; Singh, P.; Mishra, K.; Mandal, S.K.; Ghosh, C.N.; Kumar, R.; Mandal, P.K. Utilization of mill tailings, fly ash and slag as mine paste backfill material: Review and future perspective. Constr. Build. Mater. 2021, 309, 125120. [Google Scholar] [CrossRef]

- Wang, S.; Song, X.; Wei, M.; Liu, W.; Wang, X.; Ke, Y.; Tao, T. Strength characteristics and microstructure evolution of cemented tailings backfill with rice straw ash as an alternative binder. Constr. Build. Mater. 2021, 297, 123780. [Google Scholar] [CrossRef]

- Zhou, X.; Hu, S.; Zhang, G.; Li, J.; Xuan, D.; Gao, W. Experimental investigation and mathematical strength model study on the mechanical properties of cemented paste backfill. Constr. Build. Mater. 2019, 226, 524–533. [Google Scholar] [CrossRef]

- Zhang, S.; Zhao, Y.; Ding, H.; Qiu, J.; Hou, C. Effect of sodium chloride concentration and pre-curing time on the properties of cemented paste backfill in a sub-zero environment. J. Clean. Prod. 2021, 283, 125310. [Google Scholar] [CrossRef]

- Jiang, H.; Qi, Z.; Yilmaz, E.; Han, J.; Qiu, J.; Dong, C. Effectiveness of alkali-activated slag as alternative binder on workability and early age compressive strength of cemented paste backfills. Constr. Build. Mater. 2019, 218, 689–700. [Google Scholar] [CrossRef]

- Cihangir, F.; Ercikdi, B.; Kesimal, A.; Turan, A.; Deveci, H. Utilisation of alkali-activated blast furnace slag in paste backfill of high-sulphide mill tailings: Effect of binder type and dosage. Miner. Eng. 2012, 30, 33–43. [Google Scholar] [CrossRef]

- Chen, X.; Shi, X.; Zhou, J.; Chen, Q.; Li, E.; Du, X. Compressive behavior and microstructural properties of tailings polypropylene fibre-reinforced cemented paste backfill. Constr. Build. Mater. 2018, 190, 211–221. [Google Scholar] [CrossRef]

- Chen, X.; Shi, X.; Zhou, J.; Yu, Z. Influence of Polypropylene Fiber Reinforcement on Tensile Behavior and Failure Mode of Tailings Cemented Paste Backfill. IEEE Access 2019, 7, 69015–69026. [Google Scholar] [CrossRef]

- Cristelo, N.; Cunha, V.M.C.F.; Topa Gomes, A.; Araújo, N.; Miranda, T.; Lurdes Lopes, M.d. Influence of fibre reinforcement on the post-cracking behaviour of a cement-stabilised sandy-clay subjected to indirect tensile stress. Constr. Build. Mater. 2017, 138, 163–173. [Google Scholar] [CrossRef]

- Huang, Z.; Cao, S.; Yilmaz, E. Investigation on the flexural strength, failure pattern and microstructural characteristics of combined fibers reinforced cemented tailings backfill. Constr. Build. Mater. 2021, 300, 124005. [Google Scholar] [CrossRef]

- Juradin, S.; Boko, I.; Netinger Grubeša, I.; Jozić, D.; Mrakovčić, S. Influence of different treatment and amount of Spanish broom and hemp fibres on the mechanical properties of reinforced cement mortars. Constr. Build. Mater. 2021, 273, 121702. [Google Scholar] [CrossRef]

- Festugato, L.; Fourie, A.; Consoli, N.C. Cyclic shear response of fibre-reinforced cemented paste backfill. Géotechnique Lett. 2013, 3, 5–12. [Google Scholar] [CrossRef]

- Chen, X.; Shi, X.; Zhou, J.; Yu, Z.; Huang, P. Determination of mechanical, flowability, and microstructural properties of cemented tailings backfill containing rice straw. Constr. Build. Mater. 2020, 246, 118520. [Google Scholar] [CrossRef]

- Li, Z.; Shi, X.; Chen, X. Effect of Rice Straw on Tensile Properties of Tailings Cemented Paste Backfill. Appl. Sci. 2022, 12, 526. [Google Scholar] [CrossRef]

- Quintana-Gallardo, A.; Romero Clausell, J.; Guillén-Guillamón, I.; Mendiguchia, F.A. Waste valorization of rice straw as a building material in Valencia and its implications for local and global ecosystems. J. Clean. Prod. 2021, 318, 128507. [Google Scholar] [CrossRef]

- Shang, X.; Yang, J.; Song, Q.; Wang, L. Efficacy of modified rice straw fibre on properties of cementitious composites. J. Clean. Prod. 2020, 276, 124184. [Google Scholar] [CrossRef]

- Guan, X.-K.; Wei, L.; Turner, N.C.; Ma, S.-C.; Yang, M.-D.; Wang, T.-C. Improved straw management practices promote in situ straw decomposition and nutrient release, and increase crop production. J. Clean. Prod. 2020, 250, 119514. [Google Scholar] [CrossRef]

- Chen, X.; Shi, X.; Zhou, J.; Li, E.; Qiu, P.; Gou, Y. High strain rate compressive strength behavior of cemented paste backfill using split Hopkinson pressure bar. Int. J. Min. Sci. Technol. 2021, 31, 387–399. [Google Scholar] [CrossRef]

- Jiang, H.; Yi, H.; Yilmaz, E.; Liu, S.; Qiu, J. Ultrasonic evaluation of strength properties of cemented paste backfill: Effects of mineral admixture and curing temperature. Ultrasonics 2020, 100, 105983. [Google Scholar] [CrossRef]

- Zhang, Y.-h.; Wang, X.-m.; Wei, C.; Zhang, Q.-l. Dynamic mechanical properties and instability behavior of layered backfill under intermediate strain rates. Trans. Nonferrous Met. Soc. China 2017, 27, 1608–1617. [Google Scholar] [CrossRef]

- Sun, Q.; Li, B.; Tian, S.; Cai, C.; Xia, Y. Creep properties of geopolymer cemented coal gangue-fly ash backfill under dynamic disturbance. Constr. Build. Mater. 2018, 191, 644–654. [Google Scholar] [CrossRef]

- Xu, D.; Zhang, Z.; Qin, Y.; Liu, T.; Cheng, Z. Effect of particle size distribution on dynamic properties of cemented coral sand under SHPB impact loading. Soil. Dyn. Earthq. Eng. 2022, 162, 107438. [Google Scholar] [CrossRef]

- Ma, Q.; Gao, C. Effect of Basalt Fiber on the Dynamic Mechanical Properties of Cement-Soil in SHPB Test. J. Mater. Civ. Eng. 2018, 30, 04018185. [Google Scholar] [CrossRef]

- Zhou, Z.-L.; Zhao, Y.; Jiang, Y.-H.; Zou, Y.; Cai, X.; Li, D.-Y. Dynamic behavior of rock during its post failure stage in SHPB tests. Trans. Nonferrous Met. Soc. China 2017, 27, 184–196. [Google Scholar] [CrossRef]

- Zhou, Z.; Li, X.; Ye, Z.; Liu, K. Obtaining Constitutive Relationship for Rate-Dependent Rock in SHPB Tests. Rock. Mech. Rock. Eng. 2010, 43, 697–706. [Google Scholar] [CrossRef]

- Wang, Z.; Li, P. Dynamic failure and fracture mechanism in alumina ceramics: Experimental observations and finite element modelling. Ceram. Int. 2015, 41, 12763–12772. [Google Scholar] [CrossRef]

- Wang, Z.; Li, P. Characterisation of dynamic behaviour of alumina ceramics: Evaluation of stress uniformity. AIP Adv. 2015, 5, 107224. [Google Scholar] [CrossRef]

- Zheng, D.; Song, W.; Cao, S.; Li, J.; Sun, L. Investigation on Dynamical Mechanics, Energy Dissipation, and Microstructural Characteristics of Cemented Tailings Backfill under SHPB Tests. Minerals 2021, 11, 542. [Google Scholar] [CrossRef]

- Tan, Y.-Y.; Yu, X.; Elmo, D.; Xu, L.-H.; Song, W.-D. Experimental study on dynamic mechanical property of cemented tailings backfill under SHPB impact loading. Int. J. Miner. Metall. Mater. 2019, 26, 404–416. [Google Scholar] [CrossRef]

- Huang, S.; Xia, K.; Qiao, L. Dynamic tests of cemented paste backfill: Effects of strain rate, curing time, and cement content on compressive strength. J. Mater. Sci. 2011, 46, 5165–5170. [Google Scholar] [CrossRef]

- Cao, S.; Xue, G.; Song, W.; Teng, Q. Strain rate effect on dynamic mechanical properties and microstructure of cemented tailings composites. Constr. Build. Mater. 2020, 247, 118537. [Google Scholar] [CrossRef]

- Belem, T.; Benzaazoua, M. Design and application of underground mine paste backfill technology. Geotech. Geol. Eng. 2008, 26, 147–174. [Google Scholar] [CrossRef]

- Cao, S.; Song, W.; Yilmaz, E. Influence of structural factors on uniaxial compressive strength of cemented tailings backfill. Constr. Build. Mater. 2018, 174, 190–201. [Google Scholar] [CrossRef]

- Xie, X.; Gou, G.; Wei, X.; Zhou, Z.; Jiang, M.; Xu, X.; Wang, Z.; Hui, D. Influence of pretreatment of rice straw on hydration of straw fiber filled cement based composites. Constr. Build. Mater. 2016, 113, 449–455. [Google Scholar] [CrossRef]

- Wei, L.; Chai, S.X.; Zhang, H.; Shi, Q. Mechanical properties of soil reinforced with both lime and four kinds of fiber. Constr. Build. Mater. 2018, 172, 300–308. [Google Scholar] [CrossRef]

- Wang, S.; Song, X.; Wei, M.; Liu, W.; Wang, X.; Ke, Y.; Tao, T. Effect of the Alkalized Rice Straw Content on Strength Properties and Microstructure of Cemented Tailings Backfill. Front. Mater. 2021, 8, 727925. [Google Scholar] [CrossRef]

| Physical Property | Tailings | Rod-Mill Tailings | Cement |

|---|---|---|---|

| Bulk density ρ (t/m3) | 1.93 | 1.86 | |

| Particle density ρs (t/m3) | 3.18 | 2.80 | 3.11 |

| Porosity n (%) 1 | 39.31 | 33.57 | |

| Osmotic coefficient K (cm/s) | 8.70 × 10−4 | 3.80 × 10−3 | |

| D10 (μm) | 3.21 | 39.78 | 2.00 |

| D30 (μm) | 12.99 | 76.43 | 6.54 |

| D50 (μm) | 33.01 | 121.8 | 13.65 |

| D60 (μm) | 47.94 | 146.8 | 17.82 |

| Uniformity coefficient Cu 2 | 14.93 | 3.69 | 8.90 |

| Curvature coefficient Cc 3 | 1.10 | 1.00 | 1.20 |

| Specific surface area S (m2/g) | 1.25 |

| Specimen Number | Cement Content c (wt%) | Solid Mass Concentration ω (wt%) | Fiber Content m (kg·m−3) | Fiber Length l (cm) | Rod-Mill Tailings r (wt%) |

|---|---|---|---|---|---|

| T1 | 25.0 | 73 | 0.5 | 0.8 | 0 |

| T2 | 25.0 | 75 | 1.0 | 2.0 | 0.05 |

| T3 | 25.0 | 77 | 1.5 | 4.0 | 0.10 |

| T4 | 20.0 | 73 | 0.5 | 2.0 | 0.05 |

| T5 | 20.0 | 75 | 1.0 | 4.0 | 0.10 |

| T6 | 20.0 | 77 | 1.5 | 0.8 | 0 |

| T7 | 16.7 | 73 | 1.0 | 0.8 | 0.10 |

| T8 | 16.7 | 75 | 1.5 | 2.0 | 0 |

| T9 | 16.7 | 77 | 0.5 | 4.0 | 0.05 |

| T10 | 25.0 | 73 | 1.5 | 4.0 | 0.05 |

| T11 | 25.0 | 75 | 0.5 | 0.8 | 0.10 |

| T12 | 25.0 | 77 | 1.0 | 2.0 | 0 |

| T13 | 20.0 | 73 | 1.0 | 4.0 | 0 |

| T14 | 20.0 | 75 | 1.5 | 0.8 | 0.05 |

| T15 | 20.0 | 77 | 0.5 | 2.0 | 0.10 |

| T16 | 16.7 | 73 | 1.5 | 2.0 | 0.10 |

| T17 | 16.7 | 75 | 0.5 | 4.0 | 0 |

| T18 | 16.7 | 77 | 1.0 | 0.8 | 0.05 |

| Number | Diffusion Diameter (cm) | Number | Diffusion Diameter (cm) | ||||

|---|---|---|---|---|---|---|---|

| X Direction | Y Direction | Average Value | X Direction | Y Direction | Average Value | ||

| T1 | 35.00 | 34.00 | 34.50 | T10 | 28.70 | 28.90 | 28.80 |

| T2 | 23.80 | 26.20 | 25.00 | T11 | 23.30 | 23.80 | 23.55 |

| T3 | 23.00 | 24.70 | 23.85 | T12 | 25.30 | 24.60 | 24.95 |

| T4 | 33.80 | 35.40 | 34.60 | T13 | 30.20 | 29.30 | 29.75 |

| T5 | 28.50 | 29.60 | 29.05 | T14 | 23.50 | 23.50 | 23.50 |

| T6 | 19.30 | 19.80 | 19.55 | T15 | 16.00 | 16.90 | 16.45 |

| T7 | 27.00 | 27.70 | 27.35 | T16 | 28.90 | 29.10 | 29.00 |

| T8 | 21.60 | 19.80 | 20.70 | T17 | 22.10 | 22.00 | 22.05 |

| T9 | 13.30 | 13.90 | 13.60 | T18 | 14.60 | 14.60 | 14.60 |

| Cement Content c | Average | Solid Mass Concentration ω | Average | Fiber Content m | Average | Fiber Length l | Average | Rod-Mill Tailings Content r | Average |

|---|---|---|---|---|---|---|---|---|---|

| 25.0% | 26.775 | 73% | 30.667 | 0.5 | 24.125 | 0.8 | 23.842 | 0 | 25.250 |

| 20.0% | 25.483 | 75% | 23.975 | 1.0 | 25.117 | 2.0 | 25.117 | 0.05 | 23.350 |

| 16.7% | 21.217 | 77% | 18.833 | 1.5 | 24.233 | 4.0 | 24.517 | 0.10 | 24.875 |

| Range Rj | 5.558 | 11.834 | 0.992 | 1.275 | 1.900 |

| Number | Average UCS σs (MPa) | Average Static Elastic Modulus Es (MPa) | ||||

|---|---|---|---|---|---|---|

| 3 Days | 7 Days | 28 Days | 3 Days | 7 Days | 28 Days | |

| T1 | 3.70 | 4.19 | 5.03 | 691.53 | 414.36 | 375.33 |

| T2 | 3.97 | 4.48 | 4.68 | 586.42 | 551.95 | 750.34 |

| T3 | 4.14 | 5.66 | 7.38 | 576.45 | 696.75 | 644.52 |

| T4 | 2.44 | 3.09 | 3.51 | 268.05 | 360.89 | 420.56 |

| T5 | 2.90 | 3.54 | 5.16 | 424.33 | 359.50 | 605.60 |

| T6 | 3.88 | 4.14 | 6.52 | 618.58 | 560.53 | 1106.68 |

| T7 | 2.51 | 3.25 | 4.80 | 355.55 | 410.07 | 531.19 |

| T8 | 2.64 | 3.10 | 5.72 | 457.66 | 394.47 | 873.87 |

| T9 | 2.94 | 3.66 | 5.01 | 471.85 | 427.96 | 696.44 |

| T10 | 3.17 | 3.59 | 5.59 | 358.50 | 422.61 | 509.92 |

| T11 | 4.27 | 4.27 | 6.36 | 551.98 | 559.37 | 714.01 |

| T12 | 4.56 | 5.12 | 7.00 | 754.05 | 638.45 | 762.39 |

| T13 | 3.06 | 4.09 | 4.59 | 421.39 | 494.40 | 522.44 |

| T14 | 3.04 | 3.62 | 3.97 | 437.50 | 575.85 | 505.93 |

| T15 | 3.29 | 4.00 | 3.68 | 462.97 | 707.93 | 674.23 |

| T16 | 1.92 | 2.63 | 3.26 | 265.55 | 365.61 | 428.35 |

| T17 | 2.52 | 2.63 | 3.96 | 340.33 | 451.42 | 471.28 |

| T18 | 3.13 | 3.81 | 4.79 | 438.96 | 477.89 | 430.58 |

| Property | Curing Age | Level | c | ω | m | l | r | Significance |

|---|---|---|---|---|---|---|---|---|

| σs | 3 Days | k1 | 3.968 | 2.800 | 3.193 | 3.422 | 3.393 | c > ω > l > r > m |

| k2 | 3.102 | 3.223 | 3.355 | 3.137 | 3.115 | |||

| k3 | 2.610 | 3.657 | 3.132 | 3.122 | 3.172 | |||

| Rj | 1.358 | 0.857 | 0.223 | 0.300 | 0.278 | |||

| 7 Days | k1 | 4.552 | 3.473 | 3.640 | 3.880 | 3.878 | c > ω > m > r > l | |

| k2 | 3.747 | 3.607 | 4.048 | 3.737 | 3.708 | |||

| k3 | 3.180 | 4.398 | 3.790 | 3.862 | 3.892 | |||

| Rj | 1.372 | 0.925 | 0.408 | 0.143 | 0.184 | |||

| 28 Days | k1 | 6.007 | 4.463 | 4.592 | 5.245 | 5.470 | c > ω > r > m > l | |

| k2 | 4.572 | 4.975 | 5.170 | 4.642 | 4.592 | |||

| k3 | 4.590 | 5.730 | 5.407 | 5.282 | 5.107 | |||

| Rj | 1.435 | 1.267 | 0.815 | 0.640 | 0.878 | |||

| Es | 3 Days | k1 | 586.49 | 393.42 | 464.45 | 515.68 | 547.25 | c > ω > r > l > m |

| k2 | 438.80 | 466.37 | 496.78 | 465.78 | 426.88 | |||

| k3 | 388.31 | 553.81 | 452.37 | 432.14 | 439.47 | |||

| Rj | 198.17 | 160.38 | 44.41 | 83.54 | 120.38 | |||

| 7 Days | k1 | 547.25 | 411.32 | 486.99 | 499.68 | 492.27 | ω > c > r > l > m | |

| k2 | 509.85 | 482.09 | 488.71 | 503.21 | 469.52 | |||

| k3 | 421.23 | 584.92 | 502.63 | 475.44 | 516.54 | |||

| Rj | 126.01 | 173.59 | 15.65 | 27.78 | 47.01 | |||

| 28 Days | k1 | 626.08 | 464.63 | 558.64 | 610.62 | 685.33 | ω > r > m > l > c | |

| k2 | 639.24 | 653.50 | 600.42 | 651.62 | 552.29 | |||

| k3 | 571.95 | 719.14 | 678.21 | 575.03 | 599.65 | |||

| Rj | 67.29 | 254.51 | 119.57 | 76.59 | 133.04 |

| Number | 3 Days | 28 Days | ||||

|---|---|---|---|---|---|---|

| σd0.4MPa | DIFσ | σd0.4MPa | DIFσ | |||

| 1 | 6.59 | 49.95 | 1.78 | 7.88 | 60.57 | 1.57 |

| 2 | 9.21 | 51.90 | 2.32 | 7.55 | 54.21 | 1.61 |

| 3 | 11.60 | 64.36 | 2.80 | 21.88 | 48.87 | 2.96 |

| 4 | 6.19 | 69.08 | 2.54 | 7.16 | 58.19 | 2.04 |

| 5 | 8.86 | 59.17 | 3.06 | 14.94 | 64.87 | 2.90 |

| 6 | 9.53 | 52.46 | 2.46 | 13.82 | 58.04 | 2.12 |

| 7 | 3.36 | 48.53 | 1.34 | 10.42 | 72.87 | 2.17 |

| 8 | 5.84 | 44.24 | 2.21 | 7.94 | 69.87 | 1.39 |

| 9 | 6.75 | 44.01 | 2.30 | 10.61 | 78.46 | 2.12 |

| 10 | 6.84 | 75.16 | 2.16 | 16.41 | 82.07 | 2.94 |

| 11 | 8.00 | 43.73 | 1.87 | 15.05 | 67.91 | 2.37 |

| 12 | 14.22 | 66.24 | 3.12 | 21.43 | 69.98 | 3.06 |

| 13 | 6.80 | 68.47 | 2.22 | 7.84 | 80.18 | 1.71 |

| 14 | 8.43 | 66.89 | 2.77 | 13.22 | 77.96 | 3.33 |

| 15 | 8.17 | 72.12 | 2.48 | 5.47 | 71.17 | 1.49 |

| 16 | 5.32 | 74.42 | 2.77 | 8.22 | 67.02 | 2.52 |

| 17 | 4.32 | 66.41 | 1.71 | 7.12 | 73.01 | 1.80 |

| 18 | 6.55 | 39.22 | 2.09 | 12.50 | 57.47 | 2.61 |

| Number | 3 Days | 28 Days | ||||

|---|---|---|---|---|---|---|

| σd0.8MPa | DIFσ | σd0.8MPa | DIFσ | |||

| 1 | 9.03 | 84.55 | 2.44 | 22.83 | 34.07 | 4.54 |

| 2 | 13.39 | 117.79 | 3.37 | 21.60 | 122.61 | 4.62 |

| 3 | 14.88 | 132.47 | 3.59 | 30.63 | 140.02 | 4.15 |

| 4 | 7.03 | 114.94 | 2.88 | 14.12 | 142.82 | 4.02 |

| 5 | 8.62 | 131.94 | 2.97 | 12.56 | 131.37 | 2.43 |

| 6 | 10.69 | 116.11 | 2.76 | 9.96 | 87.02 | 1.53 |

| 7 | 5.30 | 130.78 | 2.11 | 11.23 | 48.64 | 2.34 |

| 8 | 7.04 | 142.03 | 2.67 | 15.17 | 139.02 | 2.65 |

| 9 | 7.57 | 147.06 | 2.57 | 8.92 | 149.96 | 1.78 |

| 10 | 9.23 | 116.75 | 2.91 | 10.85 | 146.50 | 1.94 |

| 11 | 11.73 | 138.35 | 2.75 | 18.68 | 147.86 | 2.94 |

| 12 | 13.61 | 139.21 | 2.98 | 23.95 | 133.23 | 3.42 |

| 13 | 8.19 | 140.35 | 2.68 | 15.70 | 129.95 | 3.42 |

| 14 | 8.56 | 127.98 | 2.82 | 18.33 | 153.45 | 4.62 |

| 15 | 12.35 | 129.48 | 3.75 | 15.30 | 138.20 | 4.16 |

| 16 | 5.25 | 92.57 | 2.73 | 11.93 | 132.46 | 3.66 |

| 17 | 7.70 | 118.87 | 3.06 | 16.38 | 167.43 | 4.14 |

| 18 | 9.92 | 135.99 | 3.17 | 21.05 | 169.69 | 4.39 |

| Element | Point A (wt%) | Point B (wt%) | Point C (wt%) | Point D (wt%) |

|---|---|---|---|---|

| C | 24.40 | 02.89 | 38.09 | 04.58 |

| O | 17.16 | 22.03 | 18.61 | 35.28 |

| Mg | 00.45 | 00.73 | 00.48 | 00.65 |

| Al | 00.12 | 01.55 | 01.65 | 01.23 |

| Si | 06.56 | 06.20 | 04.48 | 21.97 |

| S | 00.35 | 03.29 | 01.77 | 03.18 |

| K | 03.85 | 01.89 | 01.97 | 01.46 |

| Ca | 00.25 | 33.04 | 11.32 | 12.54 |

| Fe | 00.59 | 01.57 | 02.37 | 03.11 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Shi, X.; Chen, X.; Zhang, J.; Wang, W.; Li, X. Strength Characteristics of Straw-Containing Cemented Tailings Backfill Under Different Strain Rates. Materials 2025, 18, 4193. https://doi.org/10.3390/ma18174193

Li Z, Shi X, Chen X, Zhang J, Wang W, Li X. Strength Characteristics of Straw-Containing Cemented Tailings Backfill Under Different Strain Rates. Materials. 2025; 18(17):4193. https://doi.org/10.3390/ma18174193

Chicago/Turabian StyleLi, Zeyu, Xiuzhi Shi, Xin Chen, Jinzhong Zhang, Wenyang Wang, and Xiaoyuan Li. 2025. "Strength Characteristics of Straw-Containing Cemented Tailings Backfill Under Different Strain Rates" Materials 18, no. 17: 4193. https://doi.org/10.3390/ma18174193

APA StyleLi, Z., Shi, X., Chen, X., Zhang, J., Wang, W., & Li, X. (2025). Strength Characteristics of Straw-Containing Cemented Tailings Backfill Under Different Strain Rates. Materials, 18(17), 4193. https://doi.org/10.3390/ma18174193