Laboratory Study of Dynamic Durability and Material Properties of Bio-Cemented Sand for Green Road Base Applications

Highlights

- Microbial-induced carbonate precipitation (MICP) technology can effectively improve the static and dynamic characteristics of desert aeolian sand.

- The unconfined compressive strength and splitting tensile strength of bio-cemented sand under its optimal curing condition can meet the strength design standards of the road base.

- There exists a threshold for the bio-cured solution content when mixing methods are utilized in the MICP process.

- Bio-cemented sand shows great potential for application in road base materials in desert areas.

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Materials

2.1.1. Bacterial Solution (BS) and Cementation Solution (CS)

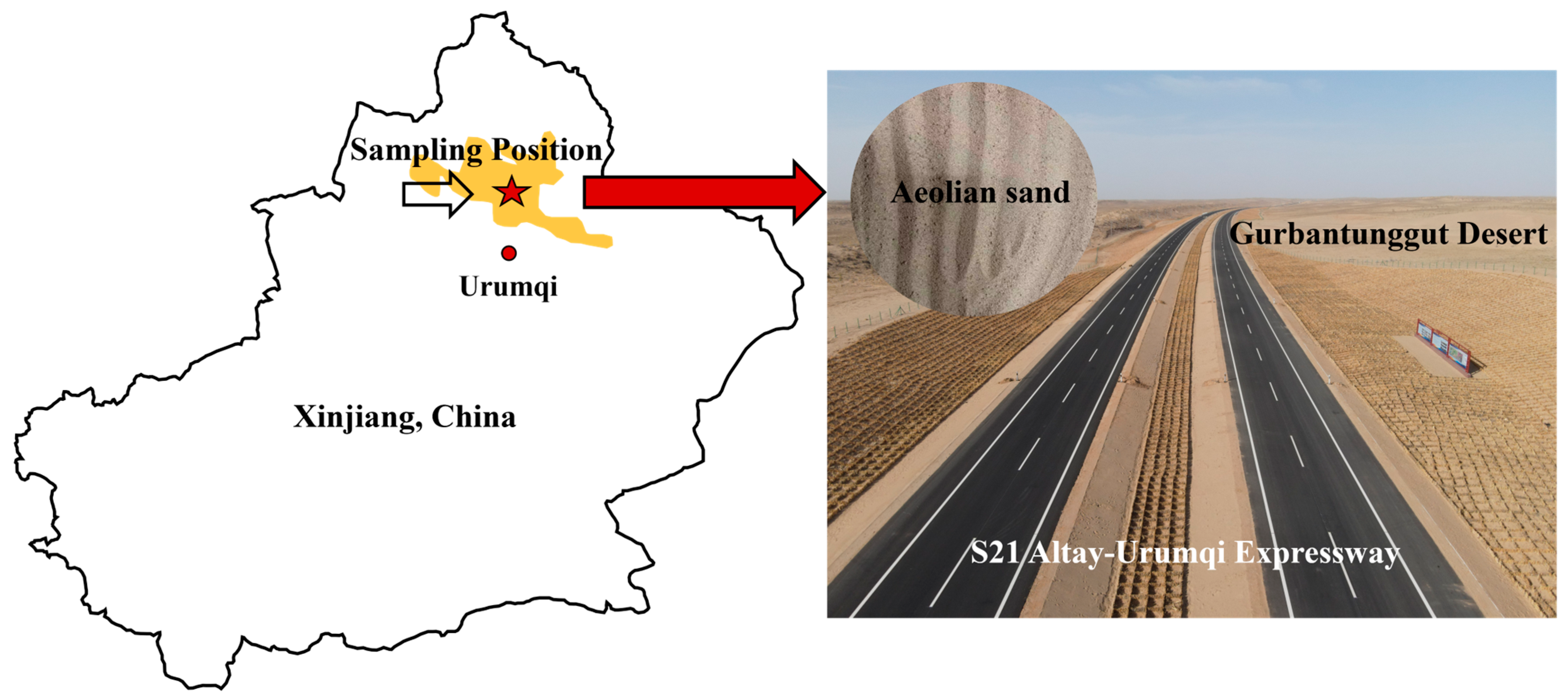

2.1.2. Aeolian Sand (AS)

2.2. Sample Preparation

2.3. Unconfined Compressive Strength (UCS) Test

2.4. Calcium Carbonate Content (CCC) Determination

2.5. Dynamic Triaxial Test

2.6. Road Performance Tests

2.6.1. Splitting Tensile Strength Test

2.6.2. Freeze-Thaw Test

2.6.3. Temperature Shrinkage Test and Arch Expansion Test

3. Results and Discussion

3.1. Unconfined Compression Strength (UCS)

3.2. Calcium Carbonate Content (CCC)

3.3. Compressive Failure Pattern

3.4. Dynamic Characteristics

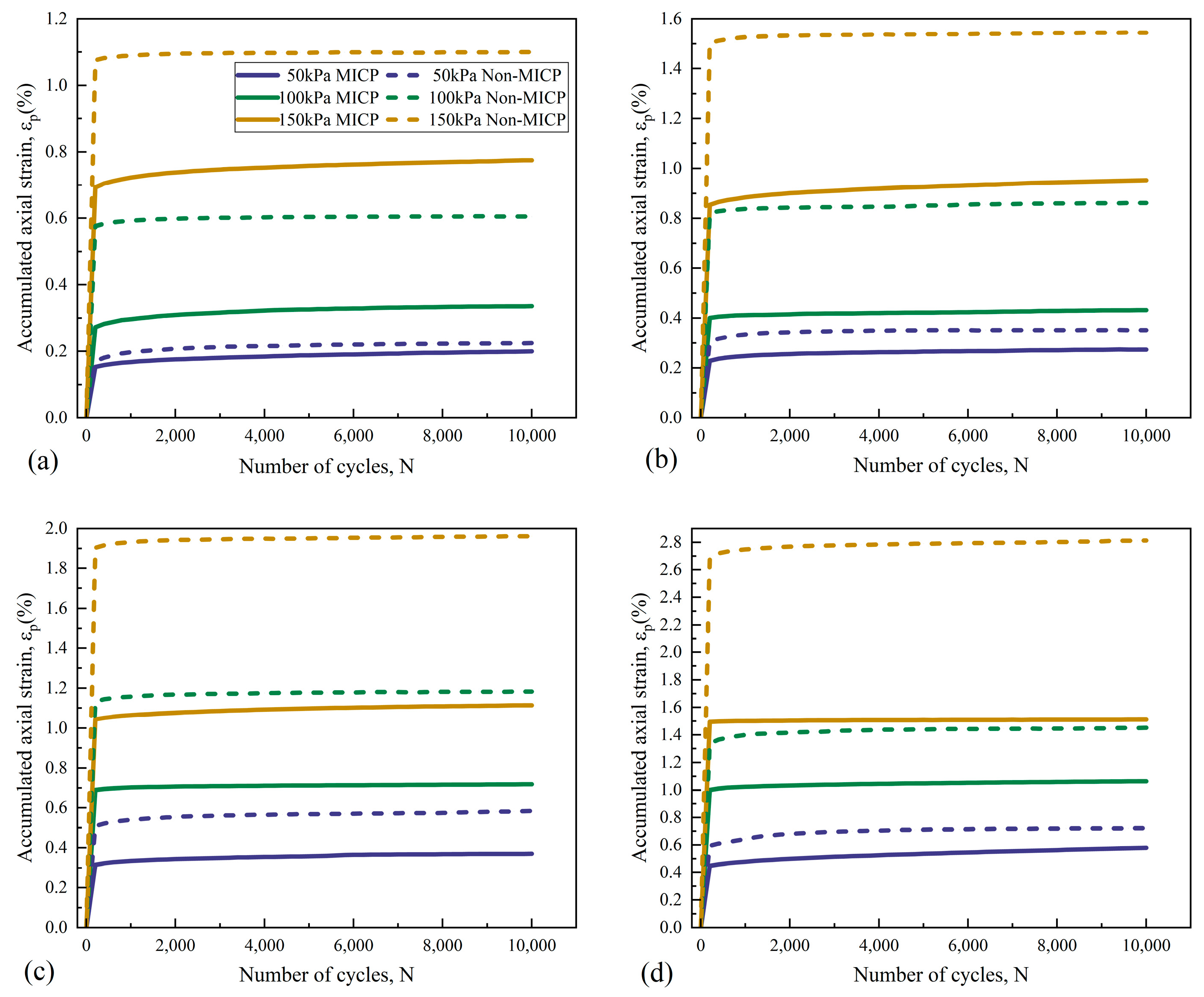

3.4.1. Cumulative Plastic Axial Strain (εp)

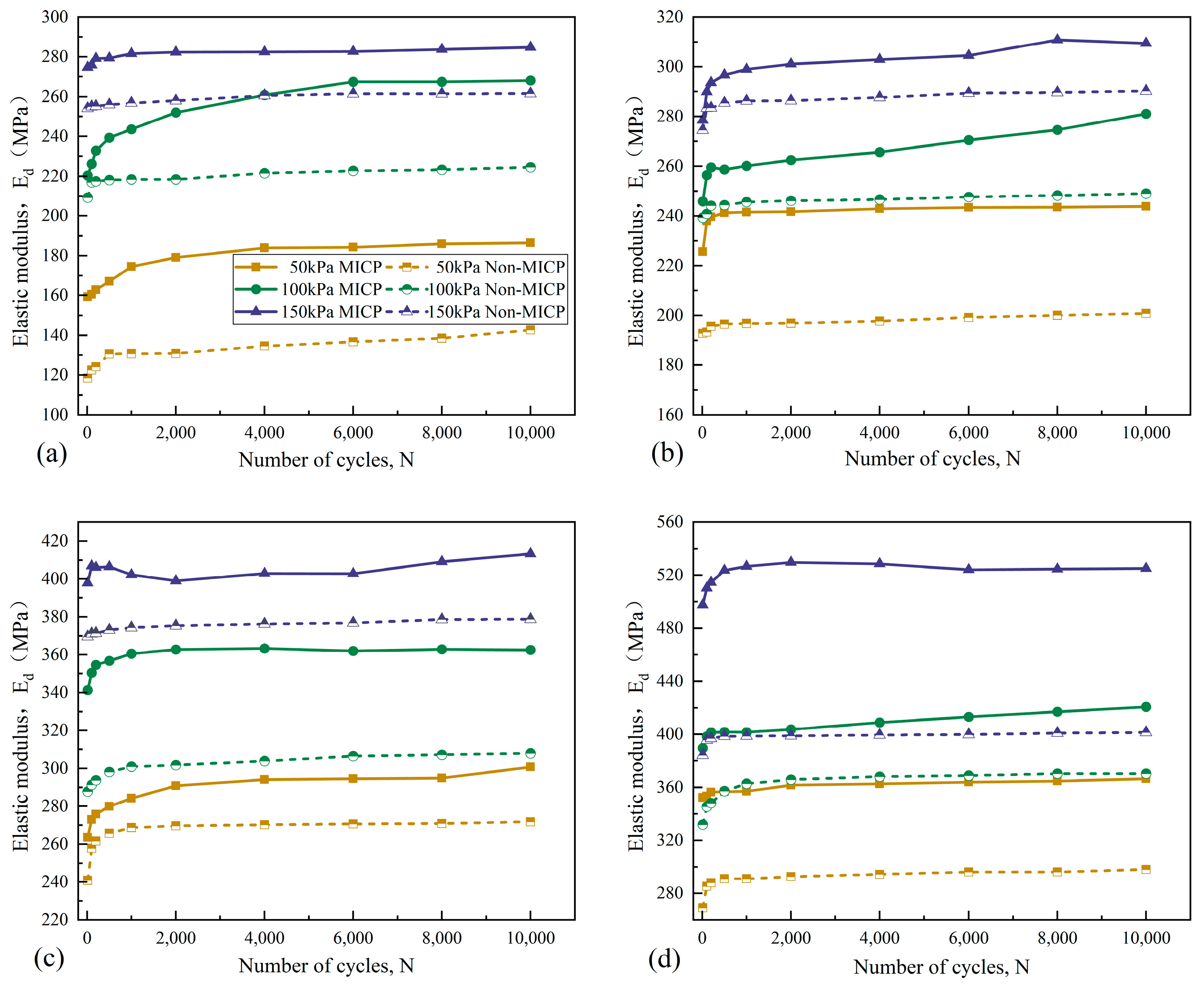

3.4.2. Dynamic Elastic Modulus (Ed)

3.5. Road Performance Indicators

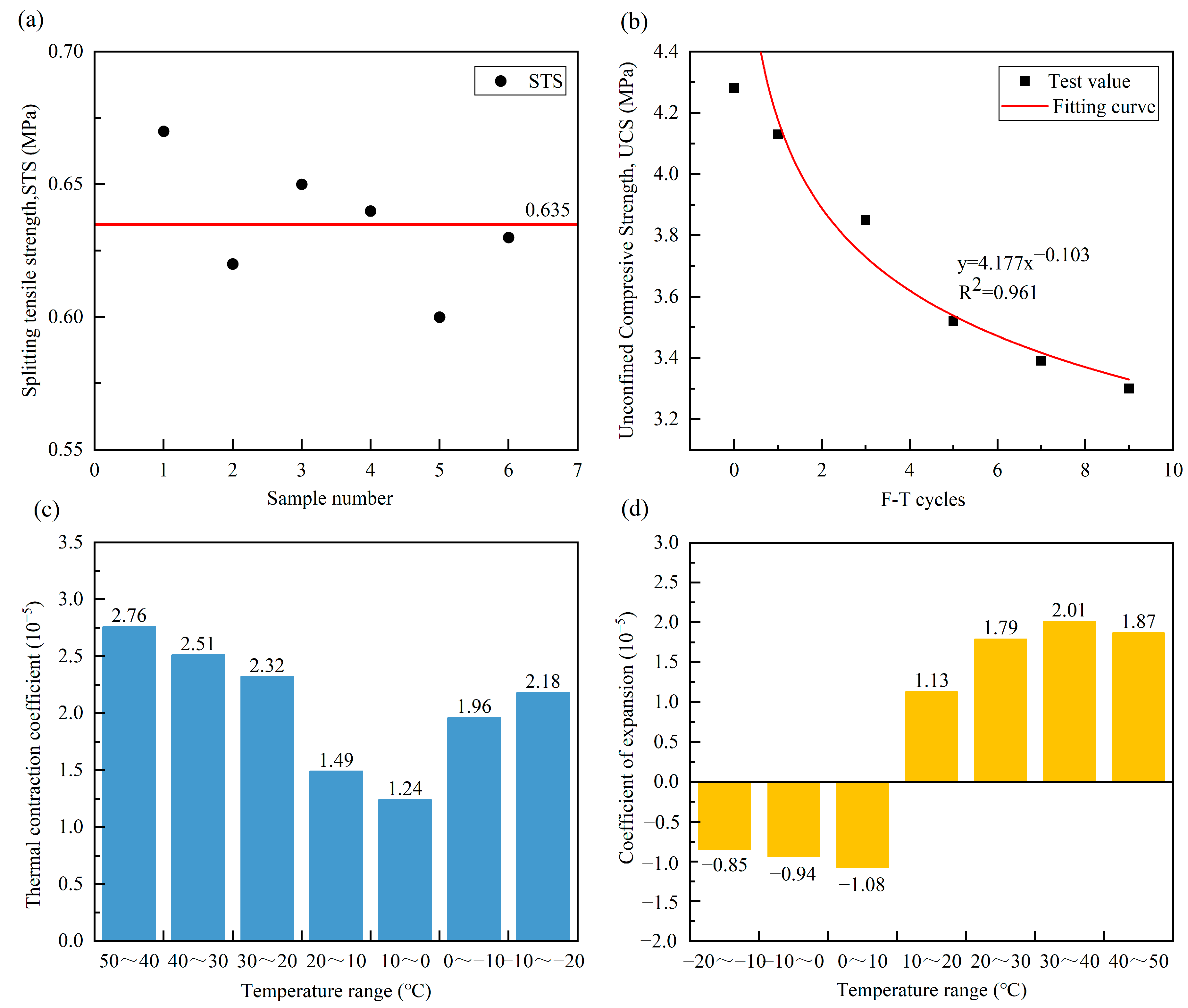

3.5.1. Splitting Tensile Strength

3.5.2. Frost Resistance

3.5.3. Temperature Shrinkage and Expansion Coefficient

3.6. Microstructural Characteristics

4. Discussions

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Aiban, S.A. A study of sand stabilization in Eastern Saudi Arabia. Eng. Geol. 1994, 38, 65–79. [Google Scholar] [CrossRef]

- Lopez-Querol, S.; Arias-Trujillo, J.; Gm-Elipe, M.; Matias-Sanchez, A.; Cantero, B. Improvement of the bearing capacity of confined and unconfined cement-stabilized aeolian sand. Constr. Build. Mater. 2017, 153, 374–384. [Google Scholar] [CrossRef]

- Bui, M.; Adjiman, C.S.; Bardow, A.; Anthony, E.J.; Boston, A.; Brown, S.; Fennell, P.S.; Fuss, S.; Galindo, A.; Hackett, L.A.; et al. Carbon capture and storage (CCS): The way forward. Energy Environ. Sci. 2018, 11, 1062–1176. [Google Scholar] [CrossRef]

- Wu, T.; Ng, S.T.; Chen, J. Deciphering the CO2 emissions and emission intensity of cement sector in China through decomposition analysis. J. Clean. Prod. 2022, 352, 131627. [Google Scholar] [CrossRef]

- Garcia-Lodeiro, I.; Palomo, A.; Fernández-Jiménez, A. 2-An overview of the chemistry of alkali-activated cement-based binders. In Handbook of Alkali-Activated Cements, Mortars and Concretes; Pacheco-Torgal, F., Labrincha, J.A., Leonelli, C., Palomo, A., Chindaprasirt, P., Eds.; Woodhead Publishing: Oxford, UK, 2015; pp. 19–47. [Google Scholar]

- Provis, J.L. Geopolymers and other alkali activated materials: Why, how, and what? Mater. Struct. 2014, 47, 11–25. [Google Scholar] [CrossRef]

- Arias-Trujillo, J.; Matías-Sanchez, A.; Cantero, B.; López-Querol, S. Effect of polymer emulsion on the bearing capacity of aeolian sand under extreme confinement conditions. Constr. Build. Mater. 2020, 236, 117473. [Google Scholar] [CrossRef]

- Onyejekwe, S.; Ghataora, G.S. Soil stabilization using proprietary liquid chemical stabilizers: Sulphonated oil and a polymer. Bull. Eng. Geol. Environ. 2015, 74, 651–665. [Google Scholar] [CrossRef]

- Verma, H.; Ray, A.; Rai, R.; Gupta, T.; Mehta, N. Ground improvement using chemical methods: A review. Heliyon 2021, 7, e07678. [Google Scholar] [CrossRef]

- Zhang, X.; Geng, J.; Hu, G.; Su, L.; Li, T.; Wang, Y.; Zheng, C.; Li, W.; Zhang, X. Toughening characteristics of rubber granule-improved alkali-activated slag-stabilized aeolian sand. Constr. Build. Mater. 2024, 438, 137059. [Google Scholar] [CrossRef]

- Ruan, B.; Li, J.; Cheng, Y.; Nie, R.; Shan, F.; Teng, J. Orthogonal investigation of factors influencing the splitting tensile strength of cemented aeolian sand reinforced with hybrid fibers. Case Stud. Constr. Mater. 2025, 22, e04596. [Google Scholar] [CrossRef]

- Farshadi, A.; Mehrnahad, H.; Abdoli, M. Effects of glass fibers and nanoclay on the strength parameters of aeolian sand: An experimental study. Bull. Eng. Geol. Environ. 2023, 82, 278. [Google Scholar] [CrossRef]

- Al-Mahbashi, A.M.; Almajed, A. The Role of Biopolymers on the Water Retention Capacity of Stabilized Sand. Sustainability 2024, 16, 8612. [Google Scholar] [CrossRef]

- Lemboye, K.; Almajed, A. Effect of Varying Curing Conditions on the Strength of Biopolymer Modified Sand. Polymers 2023, 15, 1678. [Google Scholar] [CrossRef]

- Xiao, Y.; Fan, W.; Cui, H.; Wu, B.; Zhao, H.; Fu, G. Drained shear strength and dilatancy of biocemented soil by biostimulation. Acta Geotech. 2025, 20, 2683–2693. [Google Scholar] [CrossRef]

- Dong, C.; Guo, Z.; Zhu, Y.; Rui, S.; Li, Y. Effect of water glass-enhanced biocementation in sand: Early strength enhancement and mechanistic insights. Constr. Build. Mater. 2025, 479, 141516. [Google Scholar] [CrossRef]

- Zi, J.; Liu, T.; Zhang, W.; Pan, X.; Ji, H.; Zhu, H. Quantitatively characterizing sandy soil structure altered by MICP using multi-level thresholding segmentation algorithm. J. Rock Mech. Geotech. Eng. 2024, 16, 4285–4299. [Google Scholar] [CrossRef]

- Tang, C.; Yao, J.; Liu, X.; K, M.; Lv, Y.; Liu, J.; Cao, Y. Research progress in utilization of microbial immobilization technology in microbially induced mineralization of heavy metals. J. Environ. Chem. Eng. 2024, 12, 114086. [Google Scholar] [CrossRef]

- Wang, L.; Yao, J.; Liu, X.; Liu, J.; Ma, Z.; Chen, X.; Cao, C.; Li, R.; Jiang, J. Ureolytic Nocardia tenerifensis-driven carbonate precipitation for enhanced La3+ adsorption and immobilization. J. Clean. Prod. 2024, 482, 144193. [Google Scholar] [CrossRef]

- Zhou, G.; Jia, X.; Xu, Y.; Gao, X.; Zhao, Z.; Li, L. Efficient remediation of cadmium and lead contaminated soil in coal mining areas by MICP application in hydrothermal carbon-based bacterial agents: Nucleation pathways and mineralization mechanisms. J. Environ. Manag. 2024, 370, 122744. [Google Scholar] [CrossRef]

- Zhang, G.-Z.; Liu, Z.-H.; Zhang, J.; Zhao, H.; Xia, Y.; Su, Y.; Wang, H.; Wang, L. Algae-bacteria symbiosis for cracks active repair in cement mortar: A novel strategy to enhance microbial self-healing efficacy. Constr. Build. Mater. 2025, 483, 141815. [Google Scholar] [CrossRef]

- Zhang, M.; Zhang, Y.; Zhang, R.; Zhang, L. Effect of MICP-recycled GFRP fiber on the self-repairing properties of concrete. J. Build. Eng. 2024, 96, 110513. [Google Scholar] [CrossRef]

- Zheng, Y.; Li, R.; Wang, J.; Pan, H.; Zhang, G.; Cheng, L. Innovative and environmentally friendly MICP surface curing: Enhancing mechanical and durability properties of concrete. J. Clean. Prod. 2024, 478, 143962. [Google Scholar] [CrossRef]

- Liu, B.; Xie, Y.-H.; Tang, C.-S.; Pan, X.-H.; Jiang, N.-J.; Singh, D.N.; Cheng, Y.-J.; Shi, B. Bio-mediated method for improving surface erosion resistance of clayey soils. Eng. Geol. 2021, 293, 106295. [Google Scholar] [CrossRef]

- Xiao, Y.; Ma, G.; Wu, H.; Lu, H.; Zaman, M. Rainfall-Induced Erosion of Biocemented Graded Slopes. Int. J. Geomech. 2022, 22, 04021256. [Google Scholar] [CrossRef]

- Cheng, L.; Kobayashi, T.; Shahin, M.A. Microbially induced calcite precipitation for production of “bio-bricks” treated at partial saturation condition. Constr. Build. Mater. 2020, 231, 117095. [Google Scholar] [CrossRef]

- Ghalandarzadeh, S.; Maghoul, P.; Ghalandarzadeh, A.; Courcelles, B. Effect of nanoparticle-enhanced biocementation in kaolinite clay by microbially induced calcium carbonate precipitation. Constr. Build. Mater. 2024, 414, 134939. [Google Scholar] [CrossRef]

- Cheng, L.; Shahin, M.A.; Chu, J. Soil bio-cementation using a new one-phase low-pH injection method. Acta Geotech. 2019, 14, 615–626. [Google Scholar] [CrossRef]

- Xiao, Y.; Wang, Y.; Wang, S.; Evans, T.M.; Stuedlein, A.W.; Chu, J.; Zhao, C.; Wu, H.; Liu, H. Homogeneity and mechanical behaviors of sands improved by a temperature-controlled one-phase MICP method. Acta Geotech. 2021, 16, 1417–1427. [Google Scholar] [CrossRef]

- Tanyıldızı, M.; Uz, V.E.; Gökalp, İ. Utilization of waste materials in the stabilization of expansive pavement subgrade: An extensive review. Constr. Build. Mater. 2023, 398, 132435. [Google Scholar] [CrossRef]

- Sun, X.; Miao, L.; Chen, R.; Wang, H.; Xia, J. Surface rainfall erosion resistance and freeze-thaw durability of bio-cemented and polymer-modified loess slopes. J. Environ. Manag. 2022, 301, 113883. [Google Scholar] [CrossRef]

- Sun, X.; Miao, L.; Wang, H.; Chen, R.; Wu, L. Bio-cementation for the mitigation of surface erosion in loess slopes based on simulation experiment. J. Soils Sediments 2022, 22, 1804–1818. [Google Scholar] [CrossRef]

- Hamdan, N.; Kavazanjian, E. Enzyme-induced carbonate mineral precipitation for fugitive dust control. Géotechnique 2016, 66, 546–555. [Google Scholar] [CrossRef]

- Maleki, M.; Ebrahimi, S.; Asadzadeh, F.; Emami Tabrizi, M. Performance of microbial-induced carbonate precipitation on wind erosion control of sandy soil. Int. J. Environ. Sci. Technol. 2016, 13, 937–944. [Google Scholar] [CrossRef]

- Renjith, R.; Robert, D.J.; Gunasekara, C.; Setunge, S.; O’Donnell, B. Optimization of Enzyme-Based Soil Stabilization. J. Mater. Civ. Eng. 2020, 32, 04020091. [Google Scholar] [CrossRef]

- Rawat, V.; Satyam, N. Innovative premix treatment for enhancing the efficacy of microbial-induced calcite precipitation in improving shear strength of fly ash-mixed sand. Soil Use Manag. 2025, 41, e70034. [Google Scholar] [CrossRef]

- Tian, K.; Wu, Y.; Zhang, H.; Li, D.; Nie, K.; Zhang, S. Increasing Wind Erosion Resistance of Aeolian Sandy Soil by Microbially Induced Calcium Carbonate Precipitation. Land Degrad. Dev. 2018, 29, 4271–4281. [Google Scholar] [CrossRef]

- Cao, H.; Gao, G.; Rao, L.; Zhang, Y.; Sun, Z.; Zhang, J.; Wang, T.; Ding, G.; Zhao, H. Microbially induced calcium carbonate precipitation to combat desertification: A field application experiment. J. Clean. Prod. 2024, 468, 143085. [Google Scholar] [CrossRef]

- Duo, L.; Kan-liang, T.; Hui-li, Z.; Yu-yao, W.; Kang-yi, N.; Shi-can, Z. Experimental investigation of solidifying desert aeolian sand using microbially induced calcite precipitation. Constr. Build. Mater. 2018, 172, 251–262. [Google Scholar] [CrossRef]

- Wang, H.-L.; Yin, Z.-Y. Unconfined compressive strength of bio-cemented sand: State-of-the-art review and MEP-MC-based model development. J. Clean. Prod. 2021, 315, 128205. [Google Scholar] [CrossRef]

- Jhuo, Y.-S.; Wong, H.-E.; Tung, H.-H.; Ge, L. Effectiveness of microbial induced carbonate precipitation treatment strategies for sand. Environ. Technol. Innov. 2025, 38, 104132. [Google Scholar] [CrossRef]

- Chen, R.; Chen, H.; Kang, Z.; Bao, W. Experimental study on cyclic behavior of aeolian sand stabilized with geopolymer and fines. Acta Geotech. 2024, 19, 669–683. [Google Scholar] [CrossRef]

- Wu, T.; Jin, H.; Guo, L.; Sun, H.; Tong, J.; Jiang, Y.; Wei, P. Predicting method on settlement of soft subgrade soil caused by traffic loading involving principal stress rotation and loading frequency. Soil Dyn. Earthq. Eng. 2022, 152, 107023. [Google Scholar] [CrossRef]

- Karimian, A.; Hassanlourad, M. Mechanical behaviour of MICP-treated silty sand. Bull. Eng. Geol. Environ. 2022, 81, 285. [Google Scholar] [CrossRef]

- Whiffin, V.S. Microbial CaCO3 Precipitation for the Production of Biocement. Doctoral Dissertation, Murdoch University, Murdoch, Australia.

- GB/T 50123-2019; Standard for Geotechnical Testing Method. China Planning Press: Beijing, China, 2019.

- GB/T 50145-2007; Standard for Engineering Classification of Soil. China Planning Press: Beijing, China, 2007.

- Liu, W.; Huang, X.; Yin, W.; Liu, G. Static and dynamic characteristics of cement-treated and untreated aeolian sand from the Tengger desert hinterland: Laboratory tests and prediction models. Constr. Build. Mater. 2025, 458, 139733. [Google Scholar] [CrossRef]

- Shu, S.; Zhang, F.; Wang, D.; Ge, B.; Jiang, Y. Dynamic behavior and characteristics of geogrid-reinforced sand under cyclic loading. Soil Dyn. Earthq. Eng. 2024, 180, 108630. [Google Scholar] [CrossRef]

- Wei, W.; Erlu, W.; Shuaishuai, H.; Xingjiang, S.; Na, L.; Ping, J. Experimental investigation on static and dynamic properties of nanosilica modified cement soil. Constr. Build. Mater. 2024, 412, 134746. [Google Scholar] [CrossRef]

- JTG 3441-2024; Test Methods of Materials Stabilized with Inorganic Binders for Engineering. People’s Communications Publishing House Co., Ltd.: Beijing, China, 2024.

- Bu, S.-z.; Zheng, Y.-l.; Lu, C.-h.; Cheng, L. Efficient inhibition of ASR by microbially induced calcium carbonate precipitation on aggregates at a low degree of saturation. J. Build. Eng. 2024, 84, 108516. [Google Scholar] [CrossRef]

- Cheng, L.; Cord-Ruwisch, R.; Shahin, M.A. Cementation of sand soil by microbially induced calcite precipitation at various degrees of saturation. Can. Geotech. J. 2013, 50, 81–90. [Google Scholar] [CrossRef]

- Cao, Z.; Zhang, Q.; Cai, Y.; Cui, Y.; Gu, C.; Wang, J. Impact of fines on the accumulated strain of unsaturated road base aggregate under cyclic loadings. Can. Geotech. J. 2022, 59, 2022–2029. [Google Scholar] [CrossRef]

- Yang, X.; Hu, Z.; Wang, Y.; Wang, X. Aeolian sand stabilized by using fiber- and silt-reinforced cement: Mechanical properties, microstructure evolution, and reinforcement mechanism. Constr. Build. Mater. 2024, 411, 134750. [Google Scholar] [CrossRef]

- Liu, J.; Wang, B.; Hu, C.; Chen, J.; Zhu, S.; Xu, X. Multiscale study of the road performance of cement and fly ash stabilized aeolian sand gravel base. Constr. Build. Mater. 2023, 397, 131842. [Google Scholar] [CrossRef]

- JTG/T F20-2015; Technical Guidelines for Construction of Highway Roadbases. People’s Communications Publishing House Co., Ltd.: Beijing, China, 2015.

- Ma, S.; Huang, H.; Tian, F.; Duan, Z.; Gong, J.; Zhang, J. Investigation of dynamic characteristics and cumulative plastic strain prediction model of clay-fouled round gravel under cyclic subway loading. Soil Dyn. Earthq. Eng. 2023, 174, 108173. [Google Scholar] [CrossRef]

- Tang, L.; Cong, S.; Geng, L.; Ling, X.; Gan, F. The effect of freeze-thaw cycling on the mechanical properties of expansive soils. Cold Reg. Sci. Technol. 2018, 145, 197–207. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Jamsawang, P.; Sukontasukkul, P.; Jongpradist, P.; Likitlersuang, S. Comparative mechanical performances of cement-treated sand reinforced with fiber for road and pavement applications. Transp. Geotech. 2021, 30, 100626. [Google Scholar] [CrossRef]

- Gao, M.; Dai, J.; Jing, H.; Ye, W.; Sesay, T. Investigation of the performance of cement-stabilized magnesium slag as a road base material. Constr. Build. Mater. 2023, 403, 133065. [Google Scholar] [CrossRef]

- Sharma, M.; Satyam, N.; Reddy, K.R. Effect of freeze-thaw cycles on engineering properties of biocemented sand under different treatment conditions. Eng. Geol. 2021, 284, 106022. [Google Scholar] [CrossRef]

- Abbasi, M.; Hosseinpour, I.; Barari, A.; Mirmoradi, S.H. Mechanical Properties of Silty Sand Treated with MICP Technique Subjected to Freeze-Thaw Cycles. Transp. Infrastruct. Geotechnol. 2024, 12, 34. [Google Scholar] [CrossRef]

- Chakrabarti, S.; Kodikara, J. Basaltic Crushed Rock Stabilized with Cementitious Additives: Compressive Strength and Stiffness, Drying Shrinkage, and Capillary Flow Characteristics. Transp. Res. Rec. 2003, 1819, 18–26. [Google Scholar] [CrossRef]

- Fedrigo, W.; Kleinert, T.R.; Núñez, W.P.; Graeff, Â.G.; Pinto da Silva Filho, L.C.; Brito, L.A.T. Shrinkage of Cold Recycled Cement-Treated Mixtures of Asphalt Pavement Materials. J. Test. Eval. 2023, 51, 2230–2244. [Google Scholar] [CrossRef]

- Cheng, L.; Shahin, M.A.; Mujah, D. Influence of Key Environmental Conditions on Microbially Induced Cementation for Soil Stabilization. J. Geotech. Geoenviron. Eng. 2017, 143, 04016083. [Google Scholar] [CrossRef]

- Ghadr, S.; Assadi-Langroudi, A.; Hung, C.; O’Kelly, B.C.; Bahadori, H.; Ghodsi, T. Stabilization of Sand with Colloidal Nano-Silica Hydrosols. Appl. Sci. 2020, 10, 5192. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, J.; Chen, Y.; Dong, Y.; Liu, Z.; Song, Z.; Ma, X. Strength assessment of sand stabilized with synthetic polymer and natural fibers. Bull. Eng. Geol. Environ. 2024, 83, 214. [Google Scholar] [CrossRef]

- Soldo, A.; Miletić, M.; Auad, M.L. Biopolymers as a sustainable solution for the enhancement of soil mechanical properties. Sci. Rep. 2020, 10, 267. [Google Scholar] [CrossRef] [PubMed]

| Maximum Dry Density (g·cm−3) | Optimum Water Content (%) | Specific Gravity | Coefficient of Uniformity | Coefficient of Curvature |

|---|---|---|---|---|

| 1.91 | 12 | 2.60 | 2.75 | 0.92 |

| Bio-Cured Solution Content (%) | BCR | Curing Age (d) |

|---|---|---|

| 8, 12, 16 | 1:1, 1:2, 1:4 | 3, 5, 7 |

| Types of Samples | σ3 (kPa) | (kPa) | CSR | ƒ (Hz) | N |

|---|---|---|---|---|---|

| MICP/Non-MICP | 50 | 50 | 1 | 1 | 10,000 |

| 100 | 300 | 3 | 1 | 10,000 | |

| 150 | 750 | 5 | 1 | 10,000 | |

| 50 | 350 | 7 | 1 | 10,000 | |

| 100 | 100 | 1 | 1 | 10,000 | |

| 150 | 450 | 3 | 1 | 10,000 | |

| 50 | 250 | 5 | 1 | 10,000 | |

| 100 | 700 | 7 | 1 | 10,000 | |

| 150 | 150 | 1 | 1 | 10,000 | |

| 50 | 150 | 3 | 1 | 10,000 | |

| 100 | 500 | 5 | 1 | 10,000 | |

| 150 | 1050 | 7 | 1 | 10,000 |

| Sand Type | Stabilization Materials or Techniques | Interaction with Soils | Advantages | Disadvantages | References |

|---|---|---|---|---|---|

| Aeolian sand | MICP | CaCO3 cementation and filling | High strength, eco-friendly, good durability | High cost, by-product ammonia nitrogen may cause environmental pollution | This study |

| F161 sand | Colloidal nano-silica hydrosols | Gel cementation and filling | Good liquefaction resistance, eco-friendly | Limited cementation strength, high cost, long-term durability requires further validation | [67] |

| Aeolian sand | Cement | Cement hydration reaction | Technologically mature, high strength | Brittle failure prone to shrinkage cracking, high carbon emissions | [2] |

| Aeolian sand | Geopolymers | Geopolymerization reaction | Waste utilization, low heat of hydration, low shrinkage | High cost, the strong alkaline activator is corrosive | [42] |

| River sand | Fibers | Physical encapsulation and restraint | High toughness and tensile strength, simple construction process, eco-friendly | Low unconfined compressive strength, difficulty in ensuring uniform fiber distribution, long-term durability requires further validation | [68] |

| Silty Sand | Biopolymer | Physical encapsulation and hydrogen bonding | Improved eco-friendly, water retention capacity, simple application process | Poor water resistance and long-term durability, limited strength | [69] |

| Aeolian sand | Chemical emulsions | Physical adsorption and adhesion | Good water resistance and flexibility | Limited strength, high construction sensitivity, environmental pollution | [7] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ainiwaer, F.; Hou, T.; Huang, R.; Li, J.; Fan, L.; Bao, W. Laboratory Study of Dynamic Durability and Material Properties of Bio-Cemented Sand for Green Road Base Applications. Materials 2025, 18, 4178. https://doi.org/10.3390/ma18174178

Ainiwaer F, Hou T, Huang R, Li J, Fan L, Bao W. Laboratory Study of Dynamic Durability and Material Properties of Bio-Cemented Sand for Green Road Base Applications. Materials. 2025; 18(17):4178. https://doi.org/10.3390/ma18174178

Chicago/Turabian StyleAiniwaer, Fuerhaiti, Tianqi Hou, Rongsong Huang, Jie Li, Lin Fan, and Weixing Bao. 2025. "Laboratory Study of Dynamic Durability and Material Properties of Bio-Cemented Sand for Green Road Base Applications" Materials 18, no. 17: 4178. https://doi.org/10.3390/ma18174178

APA StyleAiniwaer, F., Hou, T., Huang, R., Li, J., Fan, L., & Bao, W. (2025). Laboratory Study of Dynamic Durability and Material Properties of Bio-Cemented Sand for Green Road Base Applications. Materials, 18(17), 4178. https://doi.org/10.3390/ma18174178