Effect of Short Carbon Fiber Volume Fraction on High-Temperature Tensile Properties of SCF/2A12 Composite

Highlights

- The SCF/2A12 composite achieves a 412 MPa yield strength at room temperature.

- The 6 vol.% SCF offers peak hardness and strength via effective fiber load transfer.

- At 220 °C, the best yield strength meets drilling pipe requirements at room temperature.

Abstract

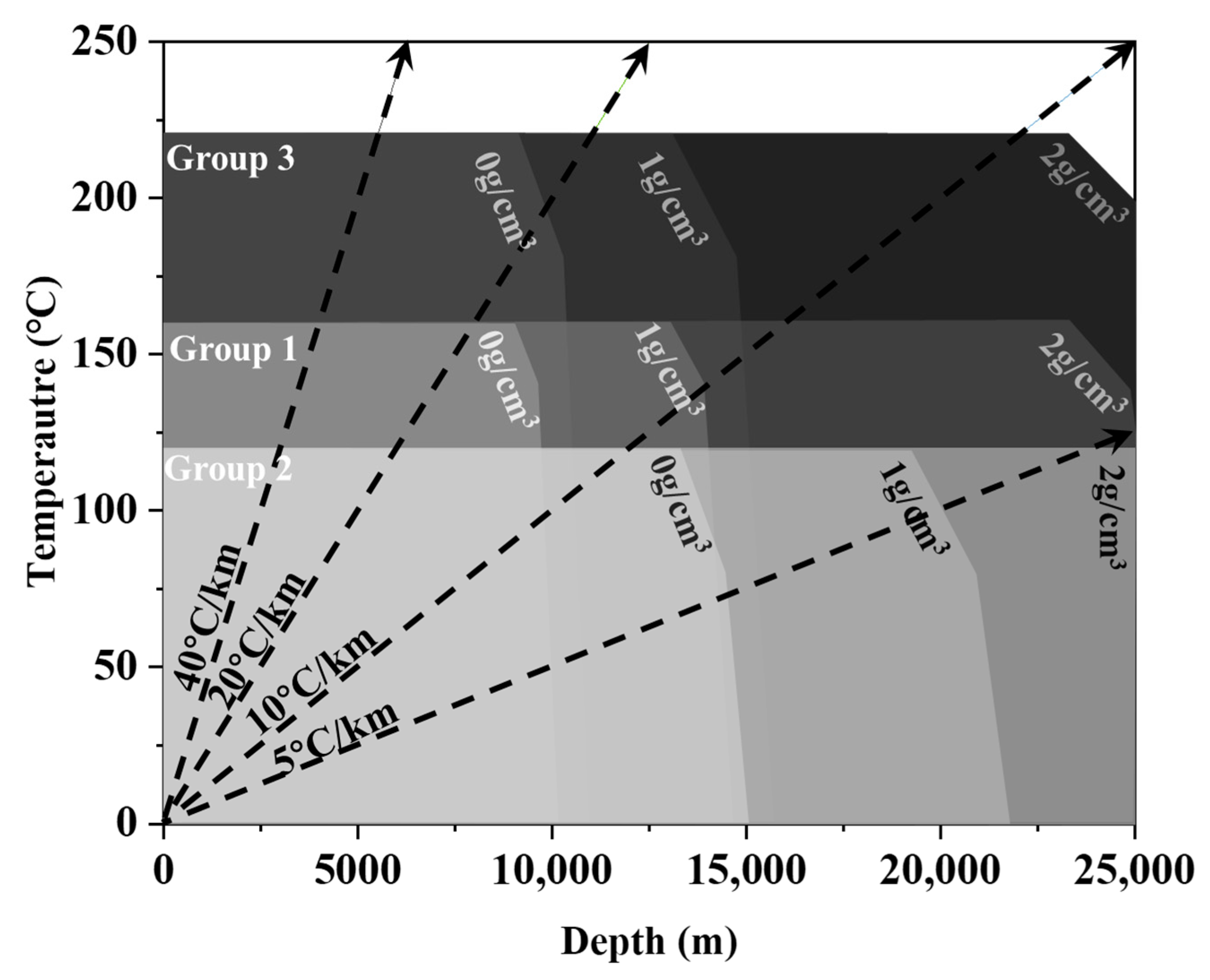

1. Introduction

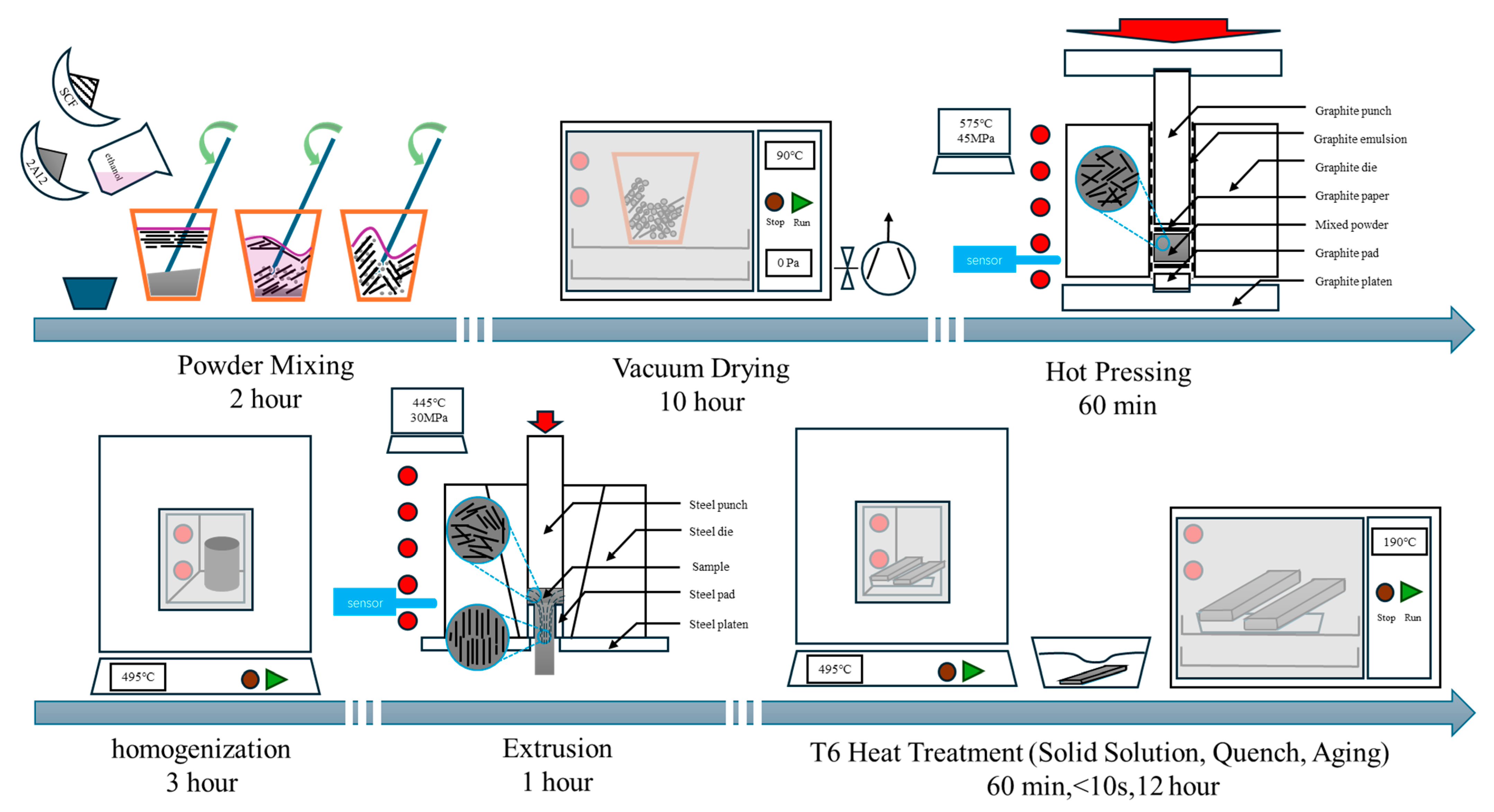

2. Materials and Methods

3. Results and Discussion

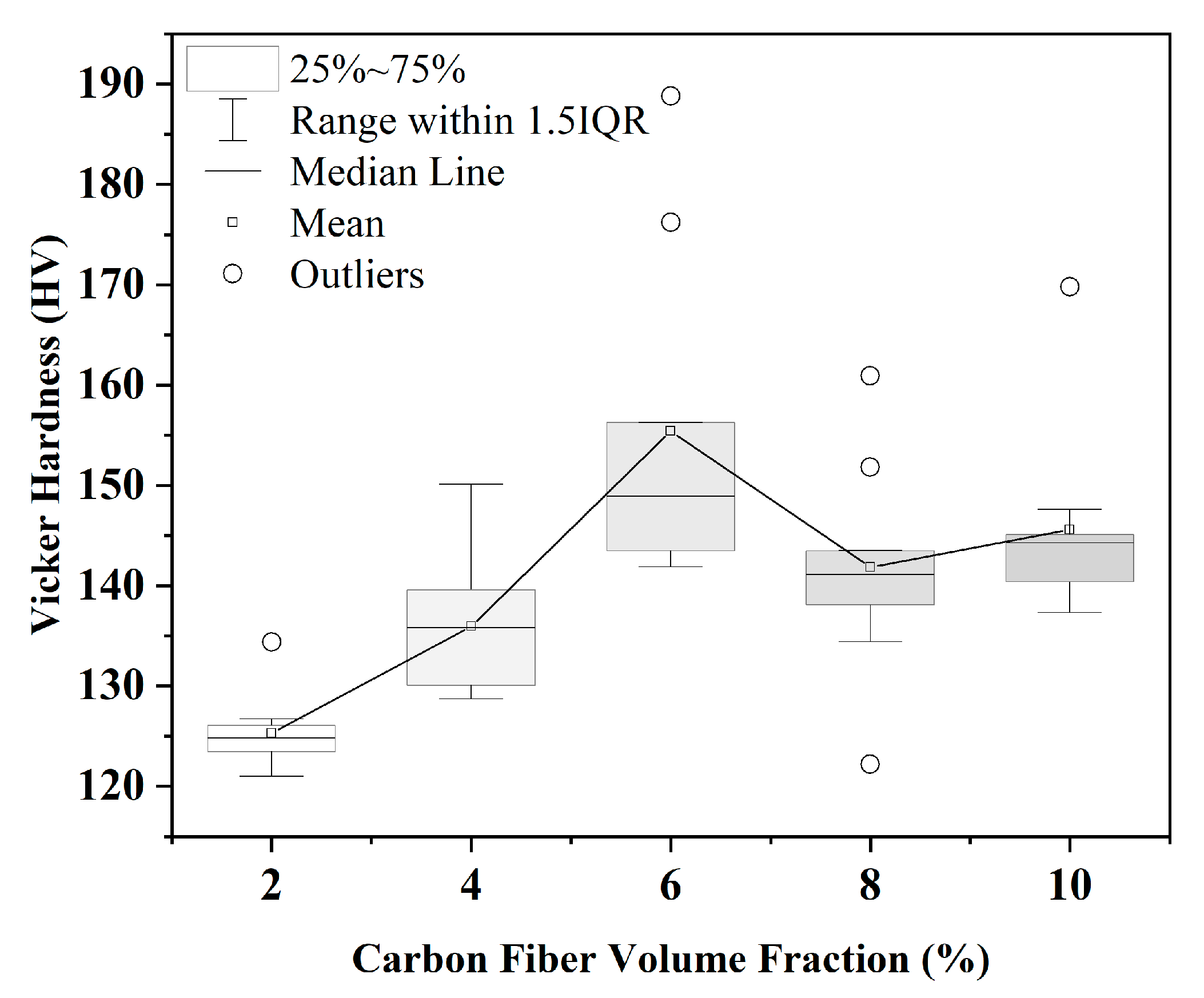

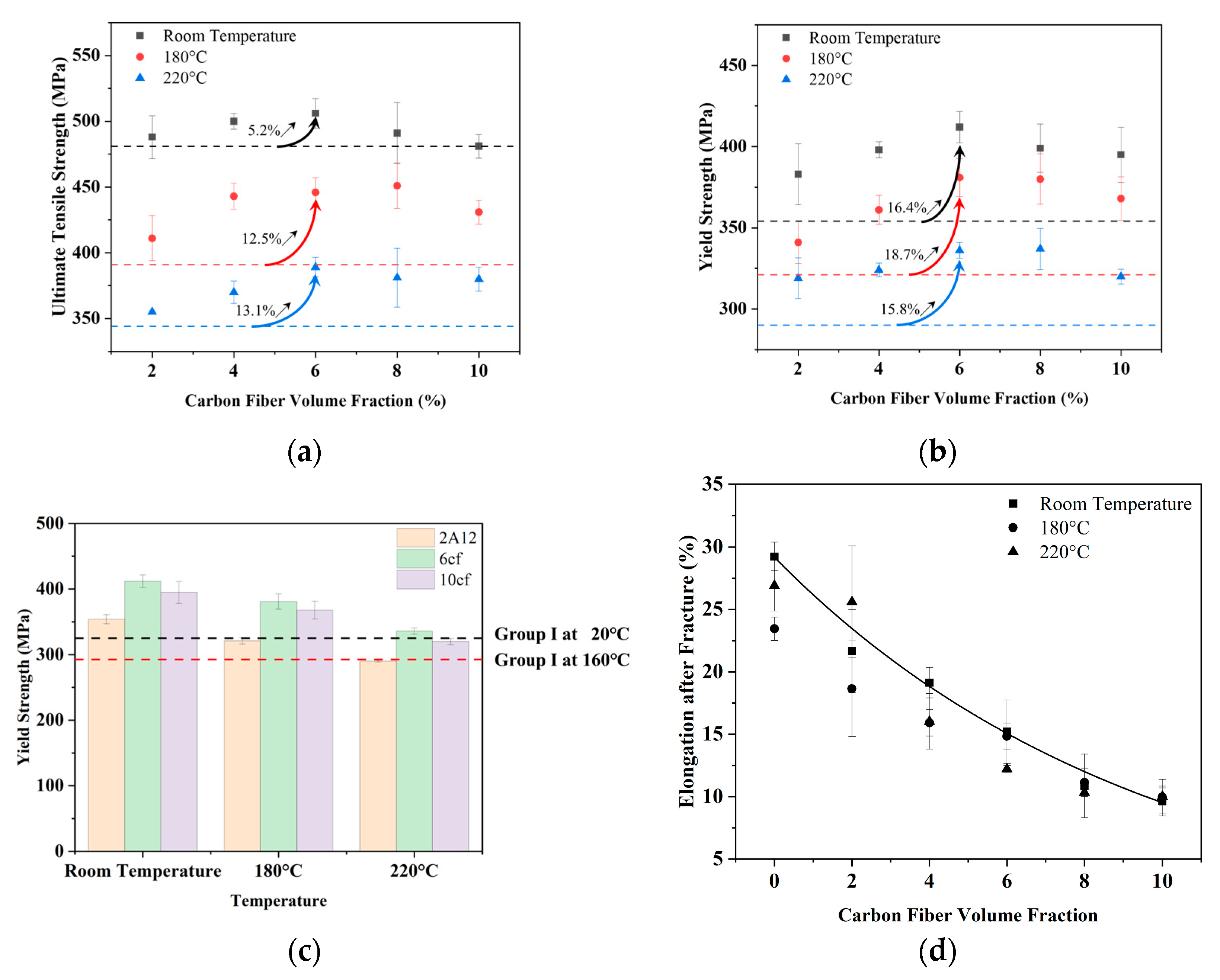

3.1. Mechanical Properties Enhanced by Addition of Carbon Fiber

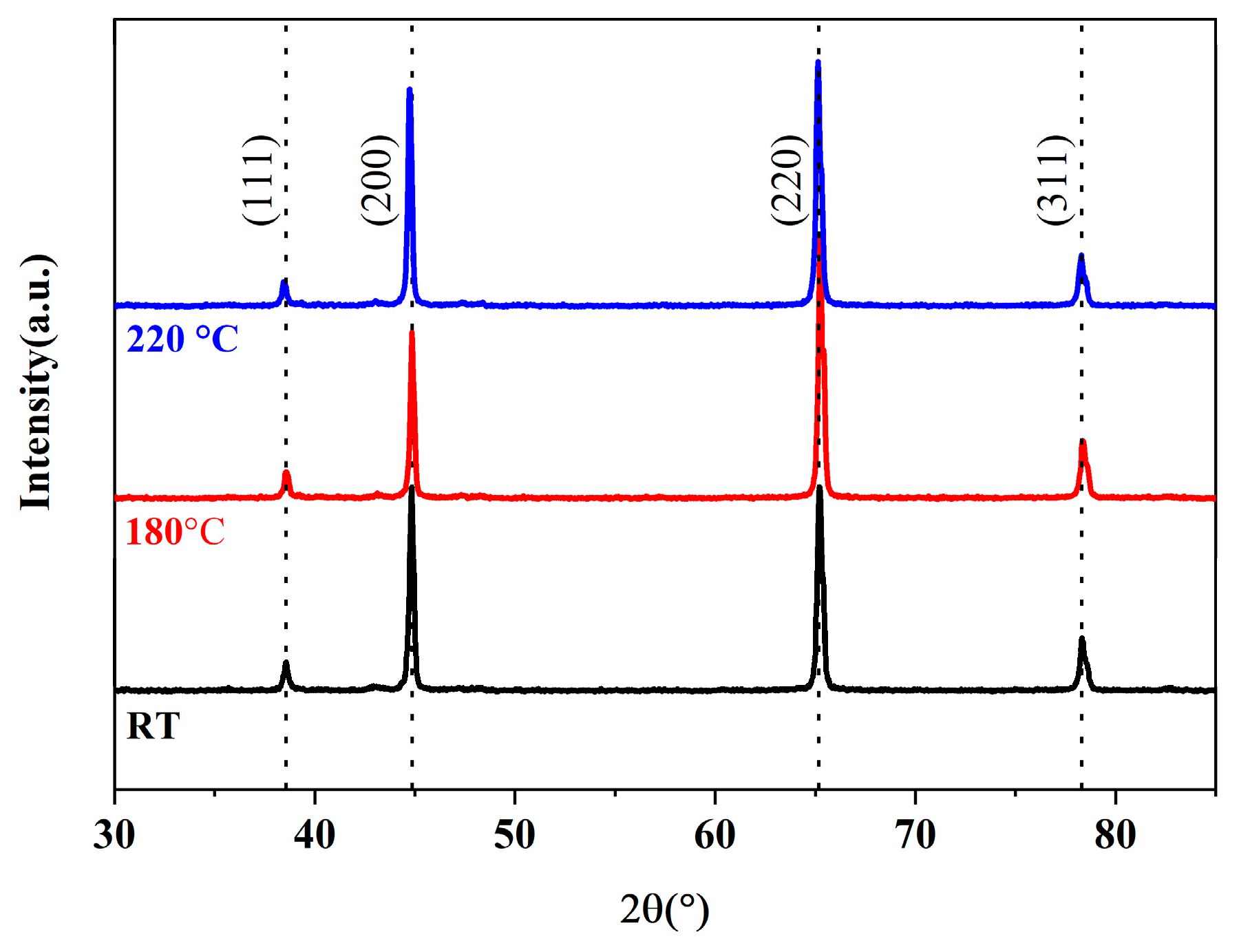

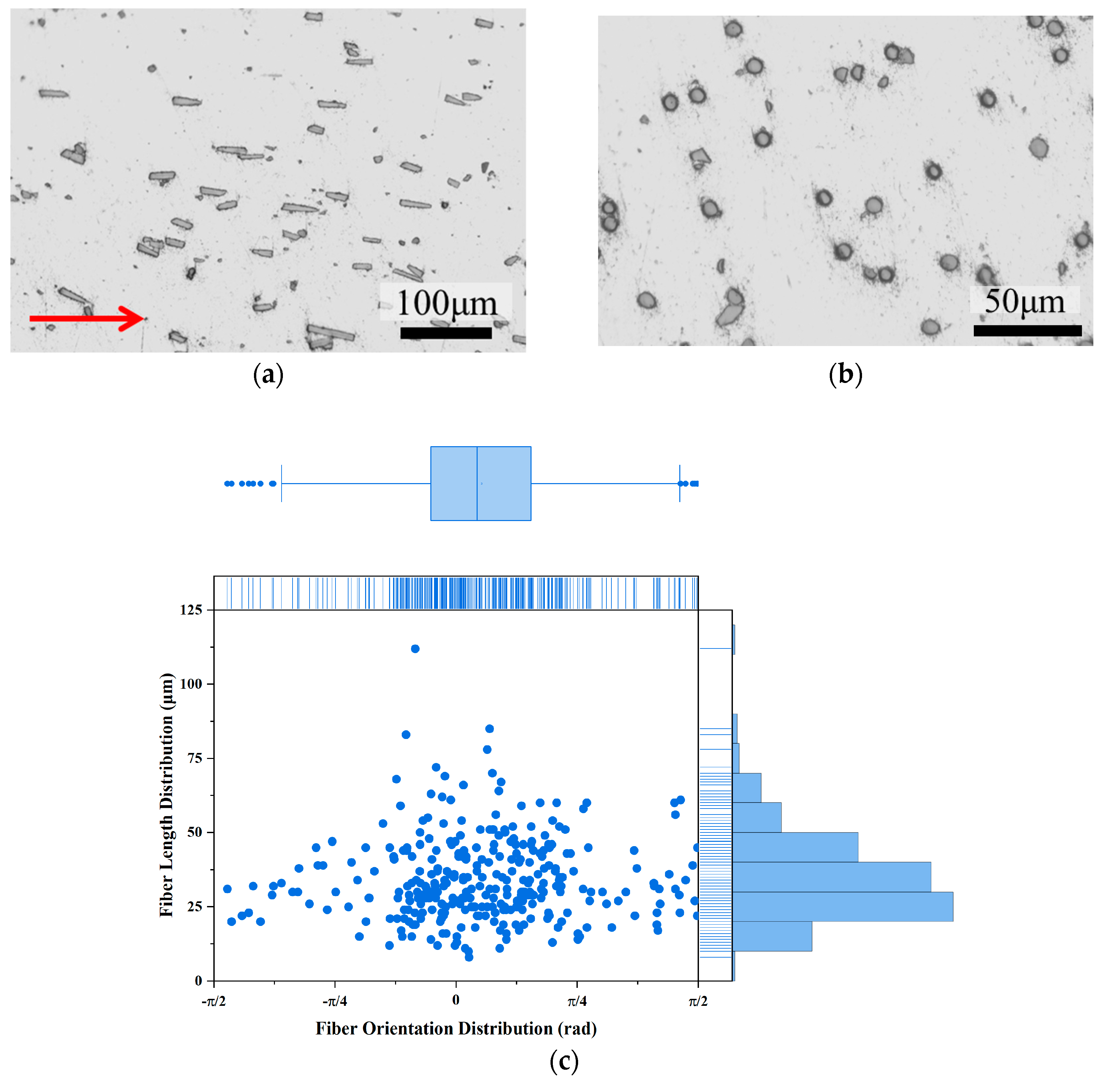

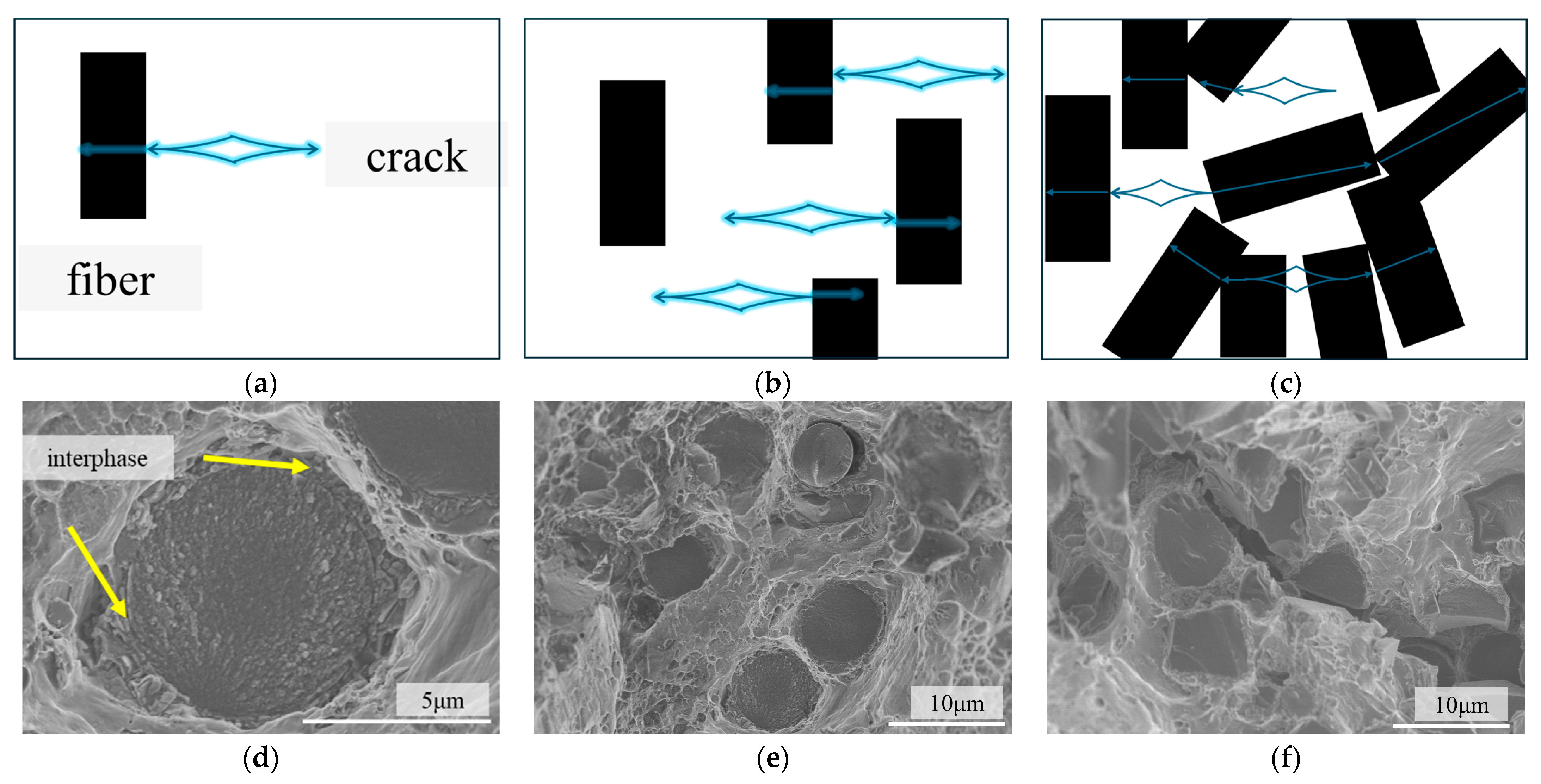

3.2. Analysis of Strength Enhancement Mechanisms

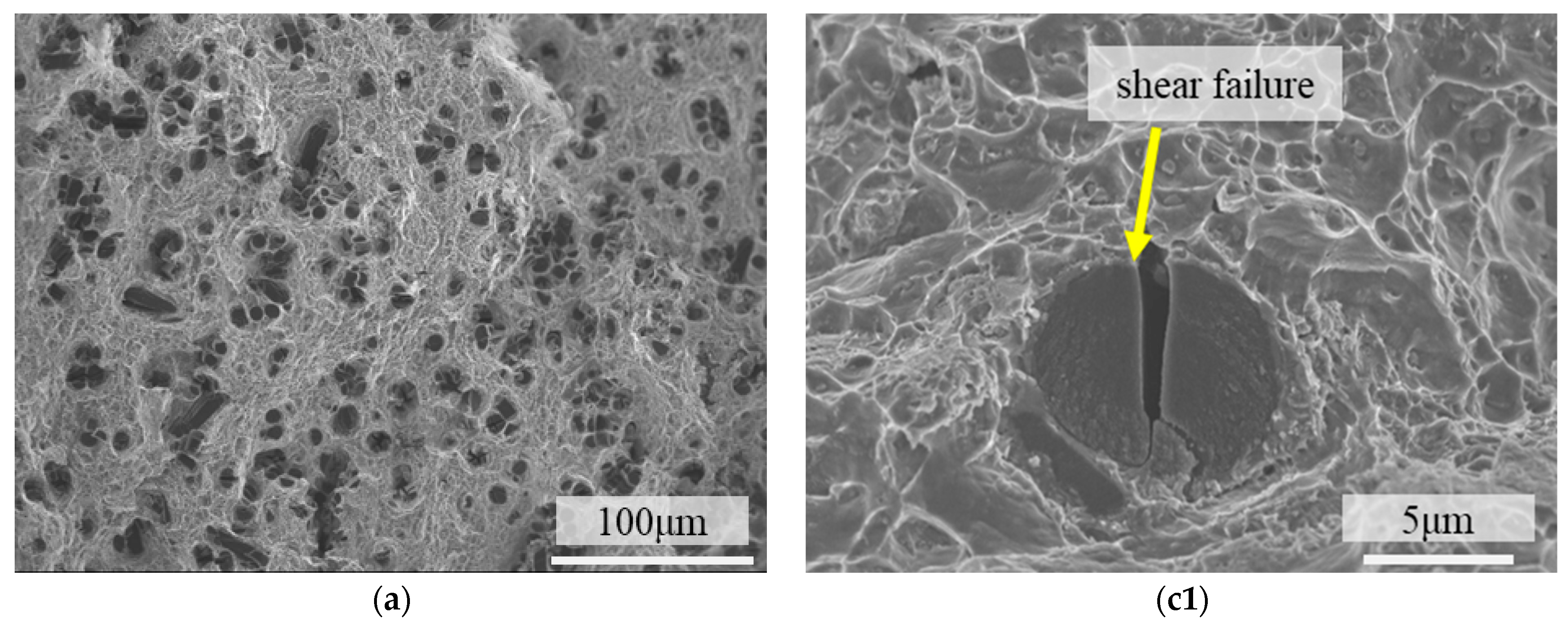

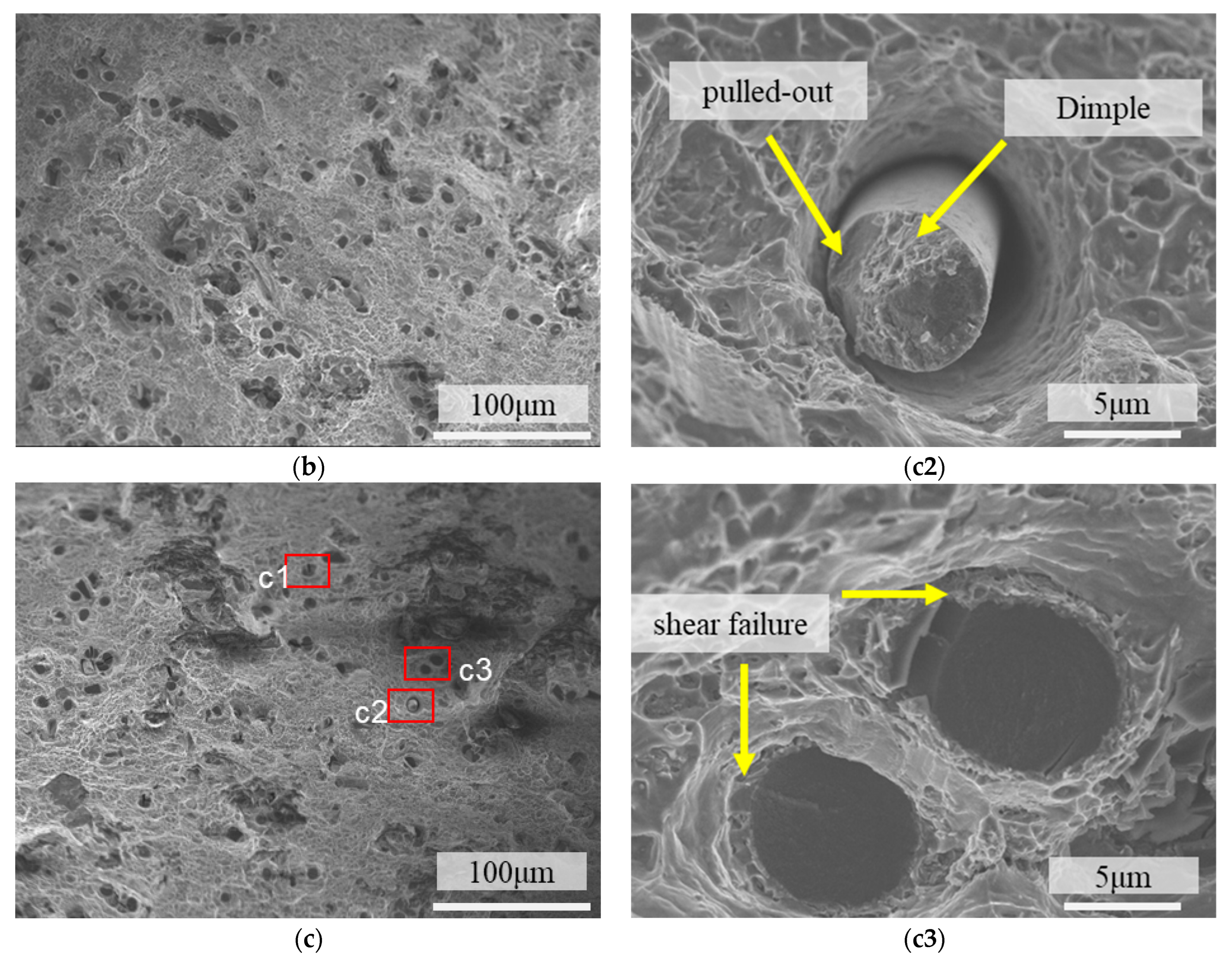

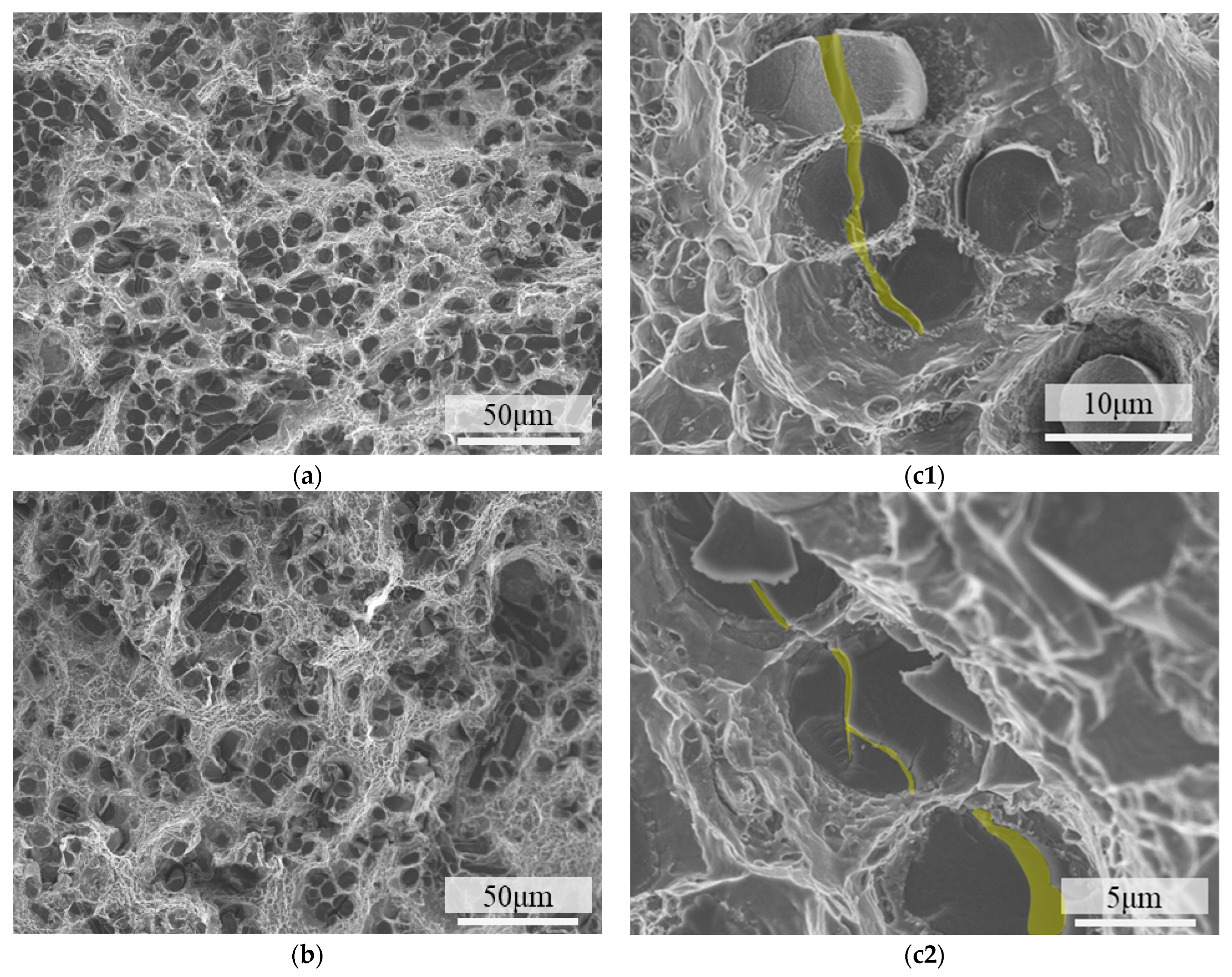

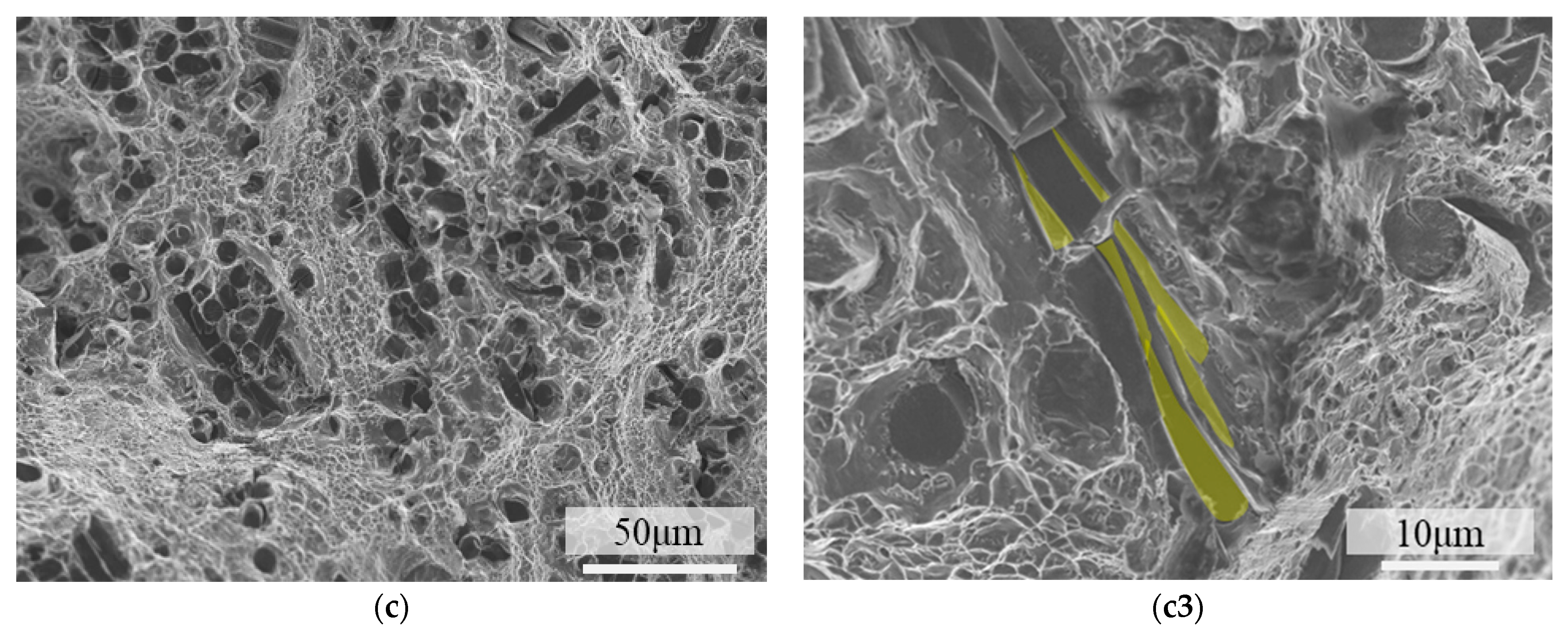

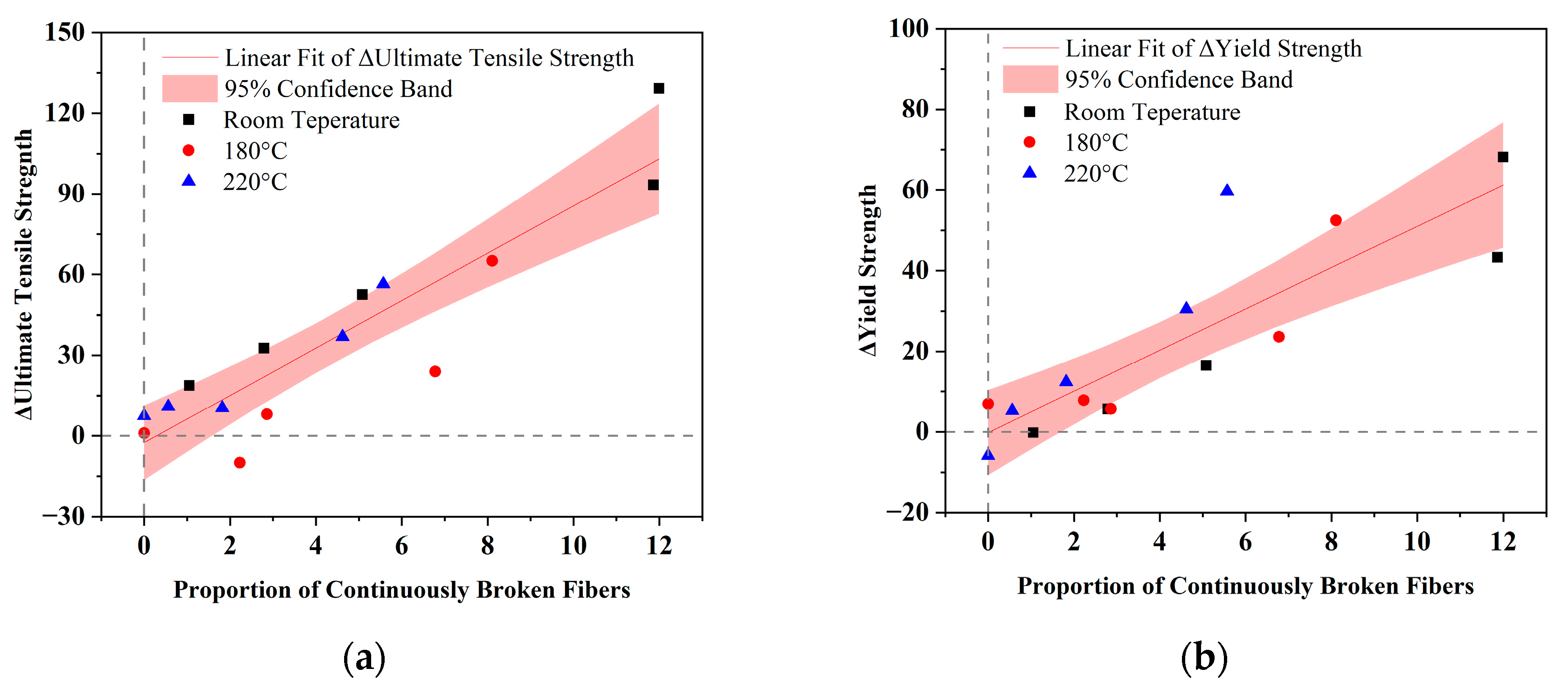

3.3. Strength Reduction by Excess Carbon Fiber Addition

4. Conclusions

- (1)

- The composite achieves its optimal performance in hardness, ultimate tensile strength, and yield strength with the addition of 6 vol.% short carbon fibers. The yield strength increases by 16.4% from 354 MPa to 412 MPa at room temperature, by 18.7% from 321 MPa to 381 MPa at 180 °C, and by 15.8% from 290 MPa to 336 MPa.

- (2)

- Grain refinement can characterize the trend in mechanical properties of the composite at room temperature, while the load transfer mechanism can describe its behavior across different testing temperatures. The performance of composite materials decreases after the volume fraction of carbon fibers exceeds 6%, due to continuous breaking. The discrepancy observed between theoretical predictions and measured composite strengths appears to be influenced by the extent of continuous fiber fragmentation.

- (3)

- Adding short carbon fiber successfully extends the service condition of the 2A12 aluminum alloy by approximately 40°C. The yield strength of the 6 vol.% short-carbon-fiber-reinforced 2A12 aluminum alloy at 220 °C is comparable to that of the unreinforced 2A12 aluminum alloy at 180 °C, even higher than the minimum value of the material at 20 °C in the ISO standard.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zamani, S.M.; Hassanzadeh-Tabrizi, S.A.; Sharifi, H. Failure Analysis of Drill Pipe: A Review. Eng. Fail. Anal. 2016, 59, 605–623. [Google Scholar] [CrossRef]

- Liu, W.; Li, J.; Zhong, Y.; Shi, T.; Zhang, J.; Li, S. Failure Analysis on Aluminum Alloy Drill Pipe with Pits and Parallel Transverse Cracks. Eng. Fail. Anal. 2022, 131, 13. [Google Scholar] [CrossRef]

- Kondrat’eV, S.Y.; Shvetsov, O.V. Technological and Operational Features of Drill Pipes from Aluminum Alloys 2024 and 1953. Met. Sci. Heat Treat. 2018, 60, 32–38. [Google Scholar] [CrossRef]

- Kondrat’eV, S.Y.; Ermakov, B.S.; Shvetsov, O.V.; Alfimov, A.D. Potential Use of 1953t1 Aluminum Alloy Drill Pipes Instead of G-105-Strength Steel Pipes. Met. Sci. Heat Treat. 2024, 66, 423–428. [Google Scholar] [CrossRef]

- Jian, L.; Jianhua, S.; Xinmiao, L.; Yongqin, Z.; Li, P. Development and Application of Aluminum Alloy Drill Rod in Geologic Drilling. Procedia Eng. 2014, 73, 84–90. [Google Scholar] [CrossRef]

- ISO 20312:2011; Petroleum and Natural Gas Industries—Design and Operating Limits of Drill Strings with Aluminium Alloy Components. ISO: Geneva, Switzerland, 2011.

- Shvecov, O.V. Improving the Operational Reliability of Drill Pipes of Aluminium Alloys D16t and 1953t1. Metall. Mater. 2017, 23, 236–246. [Google Scholar]

- Ajima, K.; Naganawa, S.; Bjarkason, E. Application of Insulated Drill Pipe to Supercritical/Super-Hot Geothermal Well Drilling. In Proceedings of the ASME 42nd International Conference on Ocean, Offshore and Arctic Engineering (OMAE), Melbourne, Australia, 11–16 June 2023. [Google Scholar]

- Akbarzadeh, E.; Picas, J.A.; Baile, M.T. Microstructure and Properties of Aluminum Silicon/Short Fibre Carbon Composites Fabricated by Semi-Solid Thixomixing. Mater. Des. 2015, 88, 683–692. [Google Scholar] [CrossRef]

- Li, G.; Qu, Y.; Yang, Y.; Zhou, Q.; Liu, X.; Li, R. Improved Multi-Orientation Dispersion of Short Carbon Fibers in Aluminum Matrix Composites Prepared with Square Crucible by Mechanical Stirring. J. Mater. Sci. Technol. 2020, 40, 81–87. [Google Scholar] [CrossRef]

- Choi, Y.; Meng, X.; Xu, Z. Manufacturing Process of Short Carbon Fiber Reinforced Al Matrix with Preformless and Their Properties. Sci. Rep. 2021, 11, 23385. [Google Scholar] [CrossRef]

- Jia, C.; Zhang, P.; Xu, W.; Wang, W. Neutron Shielding and Mechanical Properties of Short Carbon Fiber Reinforced Aluminium 6061-Boron Carbide Hybrid Composite. Ceram. Int. 2021, 47, 10193–10196. [Google Scholar] [CrossRef]

- Zhou, X.; Gao, Y.; Wang, Y.; Xiao, P. Effect of Short Carbon Fibers Orientation on the Tensile Property and Wear Behavior of Cf(Ni)-Zrc/2024al Composite. J. Alloys Compd. 2023, 943, 168895. [Google Scholar] [CrossRef]

- Jang, J.M.; Ko, S.-H.; Lee, W. Effects of Sic Coating of Carbon Fiber on Mechanical Properties in Short Carbon Fiber Reinforced Al Matrix Composite. Arch. Met. Mater. 2021, 66, 941–946. [Google Scholar] [CrossRef]

- Szymański, P. Manufacturing of Composite Castings by the Method of Fused Models Reinforced with Carbon Fibers Based on the Aluminum Matrix. Arch. Foundry Eng. 2023, 23, 118–123. [Google Scholar] [CrossRef]

- Lv, Z.; Sha, J.; Lin, G.; Wang, J.; Guo, Y.; Dong, S. Mechanical and Thermal Expansion Behavior of Hybrid Aluminum Matrix Composites Reinforced with Sic Particles and Short Carbon Fibers. J. Alloys Compd. 2023, 947, 169550. [Google Scholar] [CrossRef]

- Zhang, C.; Wu, J.; Meng, Q.; Sun, Y.; Wen, M. The Evolution of Interfacial Microstructure and Fracture Behavior of Short Carbon Fiber Reinforced 2024 Al Composites at High Temperature. Appl. Sci. 2019, 9, 3477. [Google Scholar] [CrossRef]

- Yuan, M.; Wu, J.; Meng, Q.; Zhang, C.; Mao, X.; Huang, S.; Wang, S. The Role of Al4C3 Morphology in Tensile Properties of Carbon Fiber Reinforced 2024 Aluminum Alloy During Thermal Exposure. Materials 2022, 15, 8828. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.H.; Zhang, C.; Meng, Q.; Liu, B. Study on Tensile Properties of Carbon Fiber Reinforced Aa7075 Composite at High Temperatures. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2021, 825, 11. [Google Scholar] [CrossRef]

- Yuan, M.; Wu, J.; Meng, Q.; Zhang, C.; Mao, X.; Huang, S.; Wang, S. Influence of Carbon Fiber Failure Mode Caused by TiO2 Coating on the High Temperature Tensile Strength of Carbon Fiber Reinforced 7075 Al Alloy Composites. J. Mater. Res. Technol. 2023, 26, 4551–4562. [Google Scholar] [CrossRef]

- Wang, C.; Su, Y.; Ouyang, Q.; Zhang, D. Enhanced Mechanical Behavior and Fabrication of Graphite Flakes Covered by Aligned Graphene Nanoplatelets Reinforced 2a12 Aluminum Composites. Vacuum 2021, 188, 110150. [Google Scholar] [CrossRef]

- Jiang, H.; Wu, R.; Yuan, C.; Jiao, W.; Chen, L.; Zhou, X. Prediction of Recrystallization Structure of 2a12 Aluminum Alloy Pipe Extrusion Process Based on Bp Neural Network. Metals 2023, 13, 664. [Google Scholar] [CrossRef]

- Chen, K.; Zhao, X.; Wang, D.-K.; Guo, L.-F.; Zhang, Z.-M. Obtaining Uniform High-Strength and Ductility of 2a12 Aluminum Alloy Cabin Components via Predeformation and Annular Channel Angular Extrusion. Coatings 2022, 12, 477. [Google Scholar] [CrossRef]

- Eid, M.; Kaytbay, S.; Elkady, O.; El-Assal, A. Microstructure and Mechanical Properties of Cf/Al Composites Fabricated by Hot Coining Technique. Ceram. Int. 2021, 47, 21890–21904. [Google Scholar] [CrossRef]

- Hou, L.; Wu, R.; Wang, X.; Zhang, J.; Zhang, M.; Dong, A.; Sun, B. Microstructure, Mechanical Properties and Thermal Conductivity of the Short Carbon Fiber Reinforced Magnesium Matrix Composites. J. Alloys Compd. 2017, 695, 2820–2826. [Google Scholar] [CrossRef]

- Lu, Y.; Hao, L.; Pan, F.; Chen, J.; Hirohashi, M. A Study of the Residual Stress and its Influence on Tensile Behaviors of Fiber-Reinforced SiC/Al Composite. Adv. Compos. Mater. 2013, 22, 255–263. [Google Scholar] [CrossRef]

- Hall, E.O. The Deformation and Ageing of Mild Steel: Iii Discussion of Results. Proc. Phys. Soc. Sect. B 1951, 64, 747–753. [Google Scholar] [CrossRef]

- Nam, D.H.; Cha, S.I.; Lim, B.K.; Park, H.M.; Han, D.S.; Hong, S.H. Synergistic Strengthening by Load Transfer Mechanism and Grain Refinement of Cnt/Al–Cu Composites. Carbon 2012, 50, 2417–2423. [Google Scholar] [CrossRef]

- Kelly, A.; Tyson, W.R. Tensile Properties of Fibre-Reinforced Metals: Copper/Tungsten and Copper/Molybdenum. J. Mech. Phys. Solids 1965, 13, 329–350. [Google Scholar] [CrossRef]

- Lang, L.-H.; Yu, S.; Wang, G.; Huang, X.-N.; Xu, Q.-Y. Microstructure and Mechanical Properties of 2a12 Al Alloy Powder Reinforced with Continuous Carbon Fibers Manufactured by Hot Isostatic Pressing. In Proceedings of the 12th International Bhurban Conference on Applied Sciences & Technology (IBCAST), Islamabad, Pakistan, 13–17 January 2015. [Google Scholar]

- Zhou, W.W.; Dong, M.; Zhou, Z.; Sun, X.; Kikuchi, K.; Nomura, N.; Kawasaki, A. In Situ Formation of Uniformly Dispersed Al4C3 Nanorods During Additive Manufacturing of Graphene Oxide/Al Mixed Powders. Carbon 2019, 141, 67–75. [Google Scholar] [CrossRef]

- Lv, S.; Li, J.; Li, S.; Kang, N.; Chen, B. Room-/High-Temperature Mechanical Properties of Titanium Matrix Composites Reinforced with Discontinuous Carbon Fibers. Adv. Eng. Mater. 2022, 24, 2101026. [Google Scholar] [CrossRef]

- Liu, Q.; Jiang, W.; Gao, Y.; Wang, Z.; Shi, S.; Sun, Z. Micromechanical Modeling of Longitudinal Tensile Behavior and Failure Mechanism of Unidirectional Carbon Fiber/Aluminum Composites Involving Fiber Strength Dispersion. Chin. J. Aeronaut. 2024, 37, 312–327. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, D.; Wu, G.; Li, B.; Li, P. Effect of Mg Content on the Mechanical Properties and Microstructure of Gr(F)/Al Composite. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2008, 497, 31–36. [Google Scholar] [CrossRef]

| Element | Cu | Mg | Mn | Fe | Si | Zn | Cr | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| Content | 4.59 | 1.68 | 0.43 | 0.060 | 0.043 | <0.05 | <0.01 | <0.001 | Bal. |

| Abbreviation | Volume Fraction (%) | Measured Density (g/cm3) | Relative Density (%) | Hardness (HV) |

|---|---|---|---|---|

| 2A12 | 0 | 2.756 ± 0.006 | 99.4 | 122.5 ± 9.7 |

| 2cf | 2 | 2.742 ± 0.003 | 99.5 | 125.3 ± 3.8 |

| 4cf | 4 | 2.722 ± 0.004 | 99.5 | 136.0 ± 6.9 |

| 6cf | 6 | 2.704 ± 0.002 | 99.6 | 155.4 ± 16.4 |

| 8cf | 8 | 2.683 ± 0.008 | 99.5 | 141.8 ± 10.7 |

| 10cf | 10 | 2.665 ± 0.003 | 99.6 | 145.6 ± 9.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, J.; Huang, S.; Meng, Q.; Yuan, M.; Wang, S.; Mao, X.; Qiu, Y.; He, L. Effect of Short Carbon Fiber Volume Fraction on High-Temperature Tensile Properties of SCF/2A12 Composite. Materials 2025, 18, 4143. https://doi.org/10.3390/ma18174143

Wu J, Huang S, Meng Q, Yuan M, Wang S, Mao X, Qiu Y, He L. Effect of Short Carbon Fiber Volume Fraction on High-Temperature Tensile Properties of SCF/2A12 Composite. Materials. 2025; 18(17):4143. https://doi.org/10.3390/ma18174143

Chicago/Turabian StyleWu, Jinhao, Shiyin Huang, Qingnan Meng, Mu Yuan, Sifan Wang, Xinyue Mao, Yuting Qiu, and Linkai He. 2025. "Effect of Short Carbon Fiber Volume Fraction on High-Temperature Tensile Properties of SCF/2A12 Composite" Materials 18, no. 17: 4143. https://doi.org/10.3390/ma18174143

APA StyleWu, J., Huang, S., Meng, Q., Yuan, M., Wang, S., Mao, X., Qiu, Y., & He, L. (2025). Effect of Short Carbon Fiber Volume Fraction on High-Temperature Tensile Properties of SCF/2A12 Composite. Materials, 18(17), 4143. https://doi.org/10.3390/ma18174143