Highlights

- Bolt geometry significantly affects rock stress and crack initiation location.

- Cylindrical tips with chamfers promote deeper, more efficient crack paths.

- Numerical models show that a crack starts at the bolt–rock contact zone, not the anchor head.

- Design variations enable control over fracture volume and detachment zone.

- Findings support safer, non-explosive methods for selective rock fragmentation.

Abstract

This paper presents an analysis of the influence of the termination geometry of an undercutting anchor drive bolt and the shape of the bottom of the anchor hole on the initiation and progression of failure processes in a rock medium. The study employed the finite element method (FEM) to model various bolt termination configurations, including cylindrical terminations with a 2 × 2 mm chamfer, a rounded termination with radius R, and a conical termination. The interaction of these bolt geometries with both cylindrical and conical hole bottoms was analyzed. The numerical simulations enabled the identification of stress concentration zones and crack propagation paths, which are critical to understanding the efficiency and mechanism of rock failure. The results indicate that the geometry of the bolt termination significantly influences stress distribution within the contact zone, as well as the extent and morphology of the resulting failure zone. Specifically, employing a cylindrical termination with a 2 × 2 mm chamfer in combination with a conical hole bottom promotes the development of deep fractures, which may lead to the detachment of larger rock fragments. This mechanism may be useful in the development of non-explosive rock fragmentation technologies. The findings provide a foundation for further optimization of anchor designs and the development of targeted excavation methods in mining and geotechnical engineering.

1. Introduction

Engineering anchors represent a crucial component of fastening systems used across a broad spectrum of technical disciplines—from general construction and civil engineering to mining; geotechnics; and the offshore sector [1,2,3,4,5]. They serve as load-transferring elements between structural components and substrate materials such as concrete, masonry, or rock masses. Depending on design requirements and operating conditions, various types of anchors are employed, including bonded, mechanical, expansion, and undercut anchors [6,7,8]. The latter operate based on mechanical interlock within a specially prepared undercut in the substrate. The diversity in anchor design and the wide range of installation methods enable their effective application under static and dynamic loading conditions, as well as in aggressive environments [9,10,11].

A particularly important category of anchors includes systems designed for use in rock masses, which are characterized by significant structural heterogeneity and anisotropy of mechanical properties [12,13,14]. In such conditions, standard anchoring methods may fail to provide sufficient load-bearing capacity and reliability, prompting the development of advanced anchoring technologies employing components with specialized geometries—such as undercutting head bolts or expansion anchors with additional spreading mechanisms. Anchors are also used beyond the traditional scope of civil engineering [15,16,17,18,19,20], including in systems for stabilizing offshore drilling platforms [21,22,23], support structures for renewable energy installations, and innovative technologies for rock fragmentation and detachment of rock blocks [24,25,26].

In the context of research and development, particular attention is directed toward the load transfer mechanism of undercutting anchors and their influence on the initiation and propagation of the failure zone within the surrounding medium. These issues are critical both for the design of reliable fixings in concrete and rock and for the advancement of novel, non-explosive rock fragmentation methods under challenging mining conditions [27,28,29]. This study aims to analyze the effect of the drive bolt termination geometry of an undercutting anchor and the shape of the anchor hole bottom on stress distribution and crack propagation trajectories in a rock medium. The findings may serve as a basis for the optimization of advanced structural solutions in rock detachment technologies [30,31,32,33].

In recent years, the use of anchorage systems has attracted increasing attention, particularly in the context of retrofitting and structural reinforcement of historical buildings and existing foundations. These systems are widely recognized for their ability to enhance the structural integrity and prolong the lifespan of aging or deteriorated constructions, contributing significantly to their preservation and stability [21,22,23,34,35].

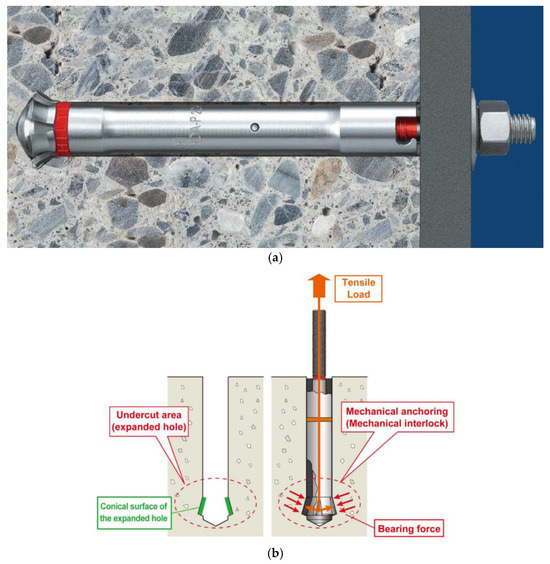

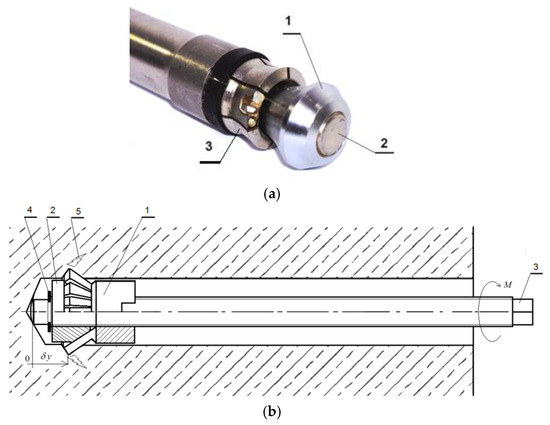

In typical applications, steel anchors serve as essential structural components for securing infrastructure elements to concrete structures, masonry, or rock masses. Various structural types and installation methods are available, including cast-in-place anchors (e.g., headed bolts) embedded during concrete pouring, mechanically installed post-installed anchors [36], and bonded anchors using appropriate polymer adhesives [37,38]. The installation principle of a typical mechanically installed undercut anchor is illustrated in Figure 1 [39,40].

Figure 1.

(a) HDA-P type undercut anchor; (b) Principles of anchoring of an ANZEX bolt.

Anchor fastening systems in concrete typically fail due to concrete-related damage. Depending on the type of loading (tensile or shear), several failure modes can be distinguished, including anchor pull-out, steel rod failure, side-face blowout, concrete cone breakout, splitting failure, or a combination of concrete and anchor failure under shear loads [37,38]. Transitions between these failure modes are governed by several parameters, such as concrete strength and embedment depth [41,42,43].

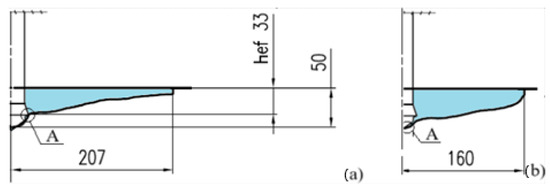

Concrete failure in the vicinity of the anchor is commonly characterized by a fracture resembling a conical breakout shape [44,45,46,47] (Figure 2). The crack initiation point (point A) of the surface fissure leading to the formation of the failure cone is typically located at the outer edge of the anchor head (at the base of the conical portion). Such a failure mechanism is observed in the majority of cases involving mechanically installed anchors.

Figure 2.

Simplified model of the failure zone in the medium under the action of an undercutting anchor: A—location of the crack initiation point.

Fracture is considered a brittle failure, characterized by a sudden drop in the load–displacement curve after the peak load, caused by rapid and unstable crack propagation in concrete. Eligehausen et al. [48,49] reported that circumferential cracking during the failure of the concrete cone primarily depends on the effective embedment depth (hef) of the anchor. To date, numerous studies [44,45,46,50,51] have been conducted on anchors subjected to tensile loads, as it is essential to investigate the influence of various design and technological parameters on the behavior of the anchor–concrete system, its evaluation, and design procedures [47]. Detailed investigations on the influence of geometric parameters of cast-in-place anchors, including headed bolts, can be found in [52].

Recently, particular research attention has focused on the development of anchor load-bearing capacity under variable (cyclic or dynamic) loading conditions [53], which pose a serious threat to the long-term performance of anchorage systems, especially in regions affected by increased tectonic activity.

In contrast, issues related to anchor installation in rock masses are highly complex [37], primarily due to the significant heterogeneity of the rock structure [54].

In such conditions, chemically bonded anchors may offer a viable solution [12,55]; however, given the scope of this study, they were not subjected to detailed analysis. Other application areas for mechanically installed anchors include, for example, anchoring systems used to stabilize offshore drilling platforms on the seabed [56,57].

The aspect of medium fracturing under tensile forces applied to the anchor [44,48,49,50] is closely related to the topic addressed in this article, as it pertains to the proposed use of undercutting anchors in rock detachment technologies [58,59]. This technology is currently being tested by members of the research team as an alternative to conventional excavation methods, particularly in challenging environments such as mining operations, where mechanical or explosive rock fragmentation is not feasible.

Typical mechanical excavation technologies [60,61,62] are based on the use of excavating machines equipped with cutting tools such as discs or rotary knives [63,64,65]. These technologies enable high-performance coal and rock excavation, as well as the tunneling of large-diameter or large-cross-section openings. Depending on the local excavation conditions, both the geometry of the tools and their arrangement on the cutting heads are optimized. These tasks are carried out using numerical methods such as the finite element method (FEM) [66,67,68] or the discrete element method (DEM) [69,70,71]. Reference [72] presents numerical approaches for modeling rock–tool interactions, including simulations using the discrete element method (DEM), smoothed particle hydrodynamics (SPH), and predictive models enhanced with machine learning (ML). The study evaluates cutting process optimization strategies that employ topology optimization to balance objectives such as energy efficiency, chip formation control, and tool lifespan.

The fracture mechanics of the medium—whether occurring during anchor installation in concrete structures or during the proposed rock block separation—share many fundamental characteristics. Therefore, the authors aim to apply existing knowledge of anchor–concrete interaction (with concrete considered a brittle material) to the development of the proposed rock detachment technique.

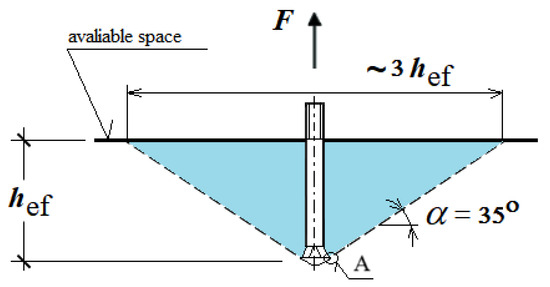

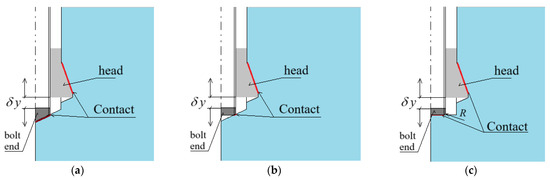

As previously mentioned, in typical undercut anchor systems, the failure process is initiated by the action of the anchor head, with the crack initiation zone typically located at the base of the undercutting head, as illustrated in Figure 3. The dominant failure mode involves debonding that originates in this region [73,74].

Figure 3.

(a) Crack propagation trajectory in the medium under the action of a pulled-out undercutting anchor (displacement induced by the pull-out force); (b) Crack path during anchor extraction. A—location of the crack initiation point (author’s own work).

The location of crack initiation and the trajectory of failure zone propagation are of particular interest to the research team, as they may serve as a key criterion for evaluating the effectiveness of the proposed rock block detachment technology based on anchor pull-out (i.e., maximizing the volume of detached material during anchor extraction).

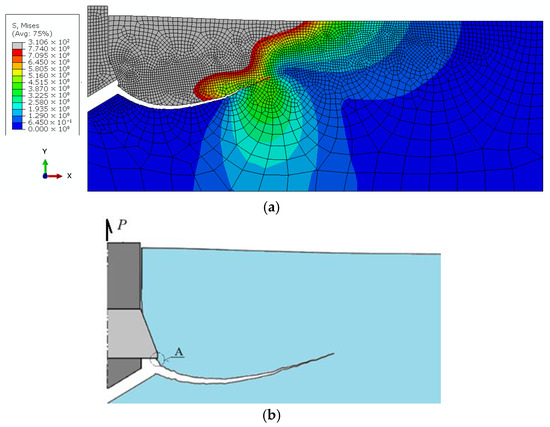

The effectiveness of the proposed detachment technology, in light of the conducted field tests, should be assessed as highly efficient (assuming the implementation of works as specified in the project assumptions). Proportionally to the effective anchoring depth, it is possible to detach blocks of considerable volume (Figure 4 [6,75]).

Figure 4.

(a) Example of applying the proposed technology for local rock detachment at an excavation site; (b) Typical rock blocks detached using the tested undercut anchors.

The design of the undercutting anchor has been repeatedly modified by the authors, along with the associated detachment technology—ranging from the use of standard undercutting anchors for pull-out applications [58,59,76,77] to a redesigned anchor system in which rock detachment is achieved through the expansion of the anchor assembly. In this system, the end of the drive bolt presses against the borehole bottom, while the undercutting head engages a dedicated recess located near the hole base [26,59,73,78,79].

One of the modified undercutting anchor variants developed specifically for rock block separation, along with the concept of its expansion within the borehole, is illustrated in Figure 5 [26,73].

Figure 5.

(a) Modified HDP-A undercutting anchor used in the initial phase of testing a novel rock detachment technology via tensile-induced fracturing near the borehole bottom: 1—anchor head; 2—drive screw; 3—elastic undercutting sleeve with six cutting segments; (b) Modified anchor design for rock mass detachment: 1—undercutting element of the anchor head; 2—conical expansion element; 3—drive screw (anchor core); 4—setting ring; 5—induced fracture in the rock mass; M—applied torque on the drive screw; δy—imposed linear displacement of the anchor head along the axis of the drive screw.

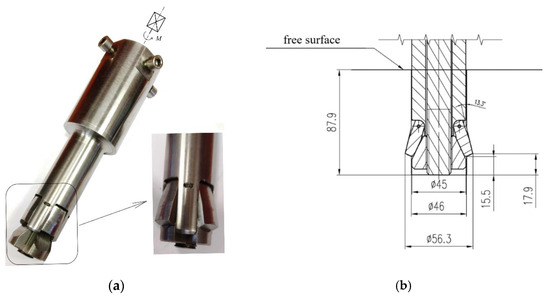

For the implementation of the novel rock detachment technology, the authors also proposed a dedicated structural solution in the form of a combined undercutting–detachment anchor, designed to enable potential automation of the detachment process (Figure 6, based on [26]).

Figure 6.

(a) Detachment head equipped with a drive torque multiplier; M—applied torque; (b) characteristic parameters of the anchor.

In the proposed structural solution, both the expansion of the anchor within the undercut borehole and the rock fracturing process leading to detachment are significantly facilitated.

The authors’ research [26,59,78,79] has indicated that, depending on factors such as the geometry of the anchor’s drive screw and the configuration of the borehole bottom in which the anchor is installed, different crack initiation points may occur (see Figure 7).

Figure 7.

Geometry of the failure zone during the pull-out of an undercutting anchor; A—crack initiation point. (a) Initiation located at the base of the conical undercutting head; (b) Initiation located at the base of the anchor’s drive screw.

From the perspective of the proposed rock detachment technology, a critical yet insufficiently explored aspect of using newly designed anchors is the understanding of the failure zone formation mechanism (i.e., the so-called failure cone), including the location of crack initiation and the potential extent of the failure zone (crack propagation trajectory).

The layering, fracturing, and variability in grain size and internal structure of rocks result in anisotropic properties and pose significant challenges for their mathematical description, necessitating the use of advanced computational algorithms to investigate the behavior of such materials under destructive loading [80]. Considering this, as well as the need to determine, for the purposes of the present project, the influence of anchor geometric parameters and process-related parameters on the potential volume of detachment and the extent of spalling (which, to date, has not been analyzed in the literature), the authors decided, at the current stage of research, to adopt the assumption of a homogeneous rock mass structure. This assumption enables a general estimation of the potential damage zone dimensions. In subsequent stages, the influence of rock mass heterogeneity on the investigated failure effects induced by the modified undercut anchor design will be analyzed.

In the present stage of the study, a simplified assumption of a homogeneous and isotropic rock mass was adopted to enable an assessment of the influence of the investigated geometric parameters on crack initiation and propagation mechanisms. The authors acknowledge that, under real geological conditions, sedimentary rocks such as grey sandstone are characterized by the presence of bedding planes, joint sets, and microcracks, which may significantly affect the fracture process [81,82,83,84]. In future research, the effects of rock anisotropy and heterogeneity will be addressed by implementing layered and stochastic models calibrated with field test results.

Despite numerous studies on the fracture mechanics of brittle media under the action of undercutting anchors, most analyses focus on conventional anchor–concrete systems, assuming standard head and drive screw geometries. However, there is a lack of detailed investigations into the influence of the drive screw termination geometry and the shape of the borehole bottom on the initiation and development of the failure zone. Existing numerical models rarely incorporate realistic contact conditions at the interface between the screw and the borehole bottom, nor do they account for the variability in screw termination geometry. This limits their applicability in designing innovative rock detachment technologies.

This research gap is particularly significant in the context of developing non-explosive rock fragmentation methods, where precise control over the location and extent of detachment is crucial for the efficiency and safety of the process.

Therefore, the aim of the present study was to investigate the influence of the drive screw termination geometry in a newly developed undercutting/detachment anchor, as well as the configuration of the borehole bottom, on the location of crack initiation and the potential extent of the failure zone. These factors directly affect the volume of the failure zone and, consequently, the volume of the detached rock mass.

2. Materials and Methods

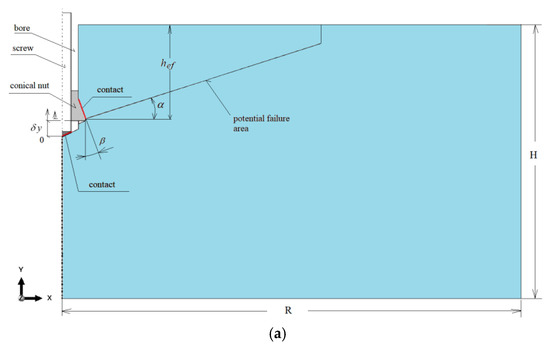

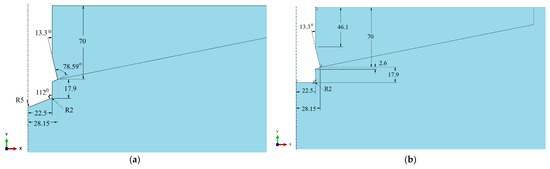

Typical drive screw termination geometries were considered, including a cylindrical end with a 2 × 2 mm chamfer (a common design in screw manufacturing)—see Figure 8a; and a conical end—see Figure 8b. These configurations are commonly used due to the relative simplicity of their manufacturing processes.

Figure 8.

Configurations of the undercutting anchor drive screw termination combined with borehole bottom geometry in rock: (a) conical screw end and conical borehole bottom; (b) cylindrical screw end with 2 × 2 mm chamfer and conical borehole bottom; (c) cylindrical screw end with rounded termination (R = 2 mm) and flat borehole bottom (cylindrical hole); δy—imposed displacement of the anchor head along the axis of the drive screw.

Similarly, the bottom of the borehole is most often conical in conventional applications, as it reflects the profile of the tip of a concrete or soft/medium rock drill bit. However, for the purpose of the present research project, an additional variant was introduced in which the borehole bottom is cylindrical—requiring a specially designed tool with a cylindrical cutting profile.

In one of the tested variants, the standard 2 × 2 mm chamfer was replaced with a rounded termination, featuring a radius of R = 2 mm. The combinations of screw termination and borehole bottom shapes considered in the analysis are illustrated in Figure 8.

In practical manufacturing, both the 2 × 2 mm chamfer and the R = 2 mm rounded termination can be produced using standard machining processes, such as CNC turning or milling, with tolerances typically within ±0.1 mm. These geometries are commonly achievable under field workshop conditions using portable machining tools, although ensuring repeatability requires appropriate quality control, e.g., with gauge templates. The selected dimensions were therefore chosen to balance their functional influence on stress distribution with the feasibility of production and installation in mining or geotechnical environments.

The anchor was subjected to a controlled upward displacement along its axis (Y-direction). The rock strength parameters used in the numerical simulations fall within the range of values obtained from field investigations and laboratory tests previously conducted by the research team [58,85,86].

The analysis was carried out using the finite element software ABAQUS 2019 [87] (Abaqus 2019, Dassault SystèmesSimulia Corp., Vélizy-Villacoublay, France), with the extended finite element method (XFEM) algorithm applied.

The following damage modeling strategy was implemented in ABAQUS:

Damage initiation criterion: Maximum principal stress

Crack propagation direction: Perpendicular to the maximum principal tensile stress

Damage evolution: Energy-based fracture propagation using a linear softening model

Material properties of the rock model were defined as follows:

Young’s modulus: 14,275 MPa

Poisson’s ratio: 0.247

Tensile strength threshold (ft): 7.74 MPa

Fracture energy (Gf): 0.355 N/m

A stabilization coefficient of 1 × 10−6 was introduced to ensure numerical convergence of the XFEM algorithm.

The steel used for the anchor components was modeled as a linear, elastic, and isotropic material, with deformation assumed to remain within the elastic range. The mechanical properties were defined as follows:

Young’s modulus: 210,000 MPa

Poisson’s ratio: 0.3

For the considered anchor termination variants (Figure 8), axisymmetric models of the rock medium with an undercut for the anchor head were developed, as shown in Figure 9. In all cases, the geometry of the undercutting head was identical. Likewise, the effective embedment depth was constant and set to hef = 70 mm.

Figure 9.

Interaction models of the anchor head with the rock medium: (a) conical screw termination with a conical borehole bottom; (b) cylindrical screw termination with a 2 × 2 mm chamfer and a conical borehole bottom; (c) cylindrical screw termination with a rounded end (R = 2 mm) and a flat-bottomed cylindrical borehole.

The dimensions of the model were R = 500 mm and H = 300 mm. These values were selected to eliminate the influence of boundary constraints on the stress distribution in the rock medium and on the extent of detachment measured on the free surface. The selection of these parameters was based on previous field investigations [58] and numerical analyses [26,59].

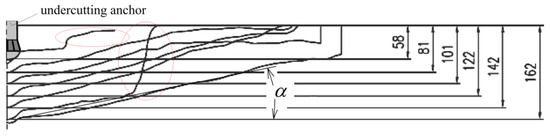

The angle α (Figure 9) was defined for auxiliary purposes only, to determine the potential distribution of finite element mesh density used in tracing the fracture trajectory. In existing standards, this angle is typically assumed to be around 35°. However, based on our field studies, it ranges from 13° to 17° for grey sandstones and up to 25° for porphyry [75]. According to our 3D FEM analyses, it can reach values between approximately 27° and 29° [88]. For the purpose of this modeling, an average value of 20° was adopted. In typical anchoring of rock masses, this angle has been observed in the range of 20–27° [54].

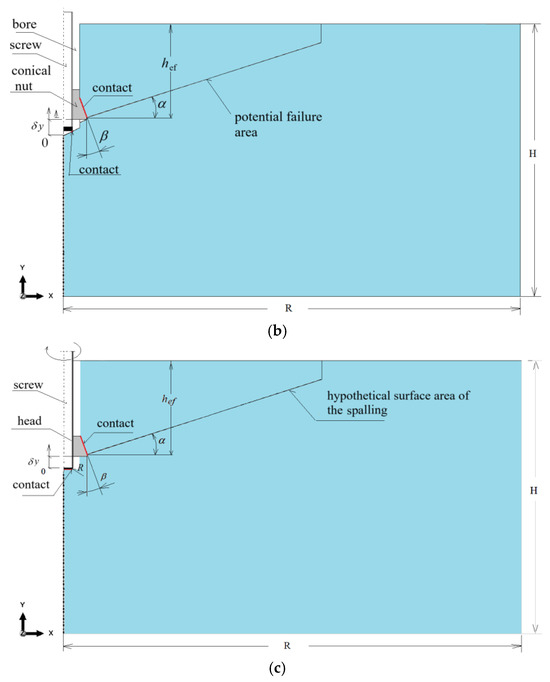

The interaction between the anchor head and the rock was modeled as an axisymmetric contact problem. Contact was assumed between the conical anchor head and the rock, as well as in the support zone between the termination of the drive screw and the bottom of the borehole (see Figure 9 and Figure 10). In all cases, a constant contact friction coefficient of μ = 0.2 was applied. This value falls within the range of estimates reported in the literature for various steel–concrete and steel–rock interactions [26,59,77,85,89]. For this coefficient value, the project team members obtained good agreement between the crack propagation trajectories recorded during field tests [58] and those from numerical simulations performed using a plane model of the rock medium [90]. Therefore, this value was adopted as the reference point for further numerical simulations. The range of values considered was 0.2–0.6 [26]. Literature data indicate that, for the steel head–rock interface, good agreement between simulation and experimental results is achieved for μ = 0.35–0.4 [91].

Figure 10.

Modeling of the displacement-driven loading of the anchor head using a “Connector” element from the ABAQUS element library; (a) conical screw termination with a conical borehole bottom; (b) cylindrical screw termination with a 2 × 2 mm chamfer and a conical borehole bottom; (c) cylindrical screw termination with a rounded end (R = 2 mm) and a flat-bottomed cylindrical borehole. A, B—node of the connector element.

As in previous analyses of this problem [78], a displacement-controlled loading condition was assumed. This was realized through the imposed movement of the nut relative to the screw axis and the borehole bottom, achieved by applying a driving torque (M, as shown in Figure 5 and Figure 6) to the opposite end of the screw.

The maximum imposed displacement was set to δy= 10 mm (as indicated in Figure 9), applied incrementally in discrete steps of 0.01 mm per increment until either mechanical failure occurred or convergence of the computational algorithm was achieved.

To implement this boundary condition, the “Connector Displacement” elements available in the ABAQUS software were used (see Figure 10).

For the analyzed design variants, node A of the connector element was linked to the predefined nodes of the conical anchor head, while node B was connected to the nodes at the end of the drive screw, as shown in Figure 10. By iteratively adjusting the distance between nodes A and B, the vertical separation between the anchor head and the borehole bottom (δy, see Figure 8 and Figure 9) was increased along the OY axis. This resulted in a progressive deformation of the rock in the anchor contact zone, ultimately leading to fracture initiation and propagation within the rock medium.

The boundary conditions for each rock model were defined as illustrated in Figure 10c. Here, U denotes translational degrees of freedom, and UR denotes rotational degrees of freedom. The applied constraints were as follows:

Right edge: U1 = 0, allowing displacement only in the vertical direction (Y-axis)

Bottom edge: U2 = 0, allowing displacement only in the horizontal direction (X-axis)

Left edge of the rock domain, left edge of the screw, and connector nodes: U1 = U3 = UR2 = 0, enforcing axisymmetry with respect to the model’s central axis and allowing displacement only along the Y-axis.

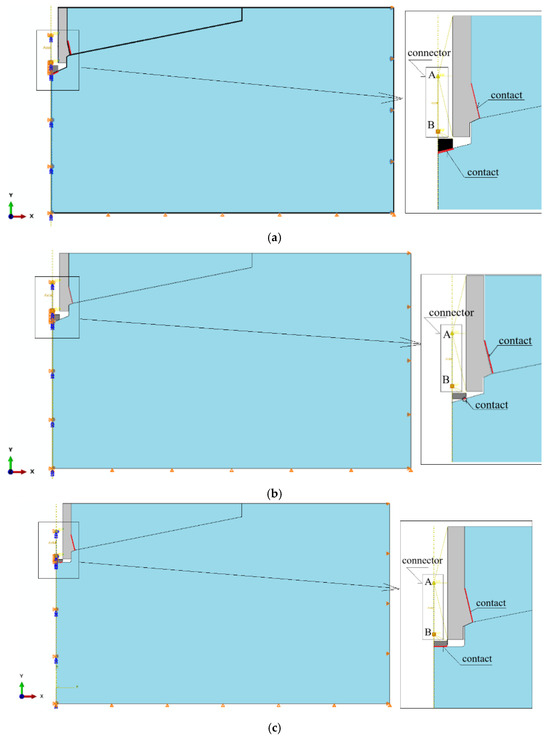

Figure 11 presents the characteristic dimensions of the undercut profiles in the rock corresponding to the studied borehole bottom configurations.

Figure 11.

Characteristic dimensions of boreholes corresponding to the investigated variants of the undercutting anchor drive screw: (a) conical bottom of the hole, (b) flat bottom cylindrical hole.

The rock models with boreholes corresponding to conical and cylindrical screw terminations were assumed to be geometrically identical (Figure 11a), except for the configuration involving a cylindrical screw termination combined with a flat borehole bottom (cylindrical hole), as illustrated in Figure 11b.

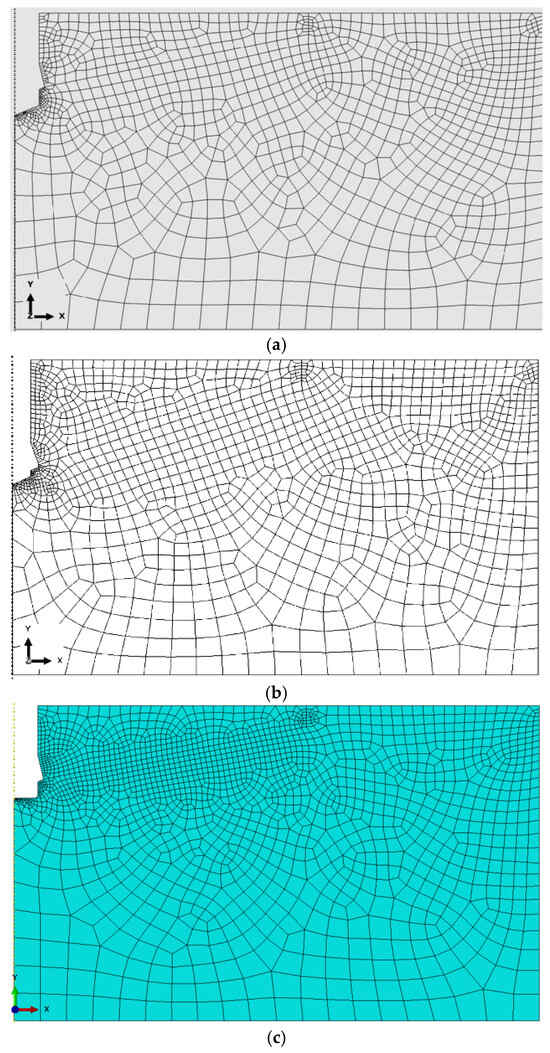

For each of the developed rock domain models, finite element meshes were generated and are presented in Figure 12. These meshes were obtained based on a mesh sensitivity analysis performed to assess the influence of element size. As this procedure has been repeatedly presented in the authors’ previous publications [73,78,92], only the final mesh configurations are shown here (Figure 12), representing the most efficient solutions in terms of computational time and smoothness of crack surfaces.

Figure 12.

Optimal finite element mesh structures of the rock domain models used in numerical analysis: (a,b)—conical bottom of the hole, (c) flat bottom cylindrical hole.

The models were discretized using 4-node axisymmetric finite elements of type CAX4R (Continuum, Axisymmetric, 4-node, Reduced integration), generating the finite element mesh shown in Figure 12. This meshing strategy provided an effective compromise between computational efficiency and the accuracy required for predicting stress concentrations and crack initiation in critical regions.

In key regions of the model, a non-uniform mesh density was applied using the automatic mesh generator available in ABAQUS, supplemented by manually defined element seed sizes in selected areas. As a result:

The global element size (edge length) was set to 25 mm;

In the contact zone between the conical anchor head and the rock, the element size was refined to 2 mm;

In the contact region between the screw tip and the borehole bottom, a finer mesh with element sizes ranging from 0.4 mm to 1 mm was used;

Along the anticipated crack propagation path, the mesh was refined to 5 mm to enhance fracture resolution;

Along the upper boundary of the rock domain, the element size varied between 3 mm and 10 mm, depending on the local geometry and loading conditions.

The mesh sensitivity analysis and convergence studies for the XFEM models have been thoroughly presented in the authors’ previous publications [73,78,92]. These studies demonstrated no significant changes in stress distribution or crack propagation trajectories with further mesh refinement, confirming the numerical stability of the adopted approach. Due to the already substantial length of the present paper, the graphical results of these analyses are not repeated here.

The assumptions adopted in the numerical modeling are based on the research team’s prior experience and on literature concerning fracture mechanics of brittle materials and anchor–rock contact behavior. To ensure a proper balance between computational accuracy and efficiency, axisymmetric models were employed using CAX4R-type elements, which enabled precise representation of the contact zone and localization of failure initiation.

The model implemented the extended finite element method (XFEM), allowing for the simulation of crack initiation and propagation without the need to predefine crack paths [93,94]. The damage model was based on the maximum principal stress criterion and energy-based crack evolution, which is suitable for capturing brittle fracture mechanisms characteristic of grey sandstone used in experimental investigations.

Material parameters such as Young’s modulus, tensile strength, and fracture energy were defined based on previous field studies and the authors’ earlier publications, ensuring consistency between the numerical model and experimental observations.

The applied boundary conditions and contact formulation, including a friction coefficient of μ = 0.2 at the interface between the screw and the rock, closely replicate real-world anchor installation conditions. The best correspondence with experimental observations—both in terms of maximum force and fracture pattern—was obtained in the simulation using an anchor with a friction coefficient of 0.2 between the anchor and the rock. However, it was noted that in reality, this coefficient may vary due to changes occurring in the rock during testing [95]. This modeling approach enabled a realistic analysis of the influence of drive screw termination geometry and borehole bottom shape on stress distribution and crack propagation behavior, while substantially reducing the need for costly experimental testing.

3. Results and Discussion

This section presents the results of numerical simulations conducted to analyze the influence of the drive screw termination geometry and the borehole bottom shape on the stress distribution and crack propagation trajectory in a rock medium. For each of the investigated model variants, characteristic stress states and failure propagation paths were analyzed under identical loading and material conditions. Particular attention was focused on the contact zone between the anchor screw and the borehole bottom, where the failure mechanism is typically initiated. This analysis is crucial for optimizing the geometric parameters of anchors used in non-explosive rock fragmentation technologies.

To ensure clarity and readability of the results, the data are presented in the form of stress distribution maps and crack propagation visualizations for each geometric configuration. Comparisons were made between drive screw termination types—flat and conical—and borehole bottom shapes—cylindrical and conical. This approach enables a detailed evaluation of the effect of each geometric parameter on the mechanical response of the anchoring system and allows the identification of configurations that promote controlled and efficient fracture propagation.

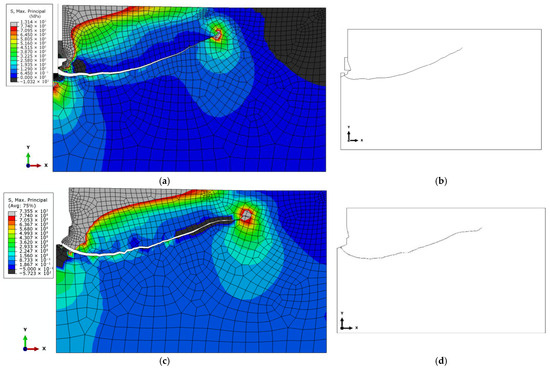

As the displacement parameter δy (Figure 9) increases, the deformation of the rock under the anchor head also intensifies, eventually leading to the initiation and propagation of a crack at the base of the drive screw, as illustrated in Figure 13.

Figure 13.

Distribution of maximum tensile stresses (σ_max) and crack propagation trajectories under the action of an undercutting anchor for the analyzed design variants: (a) conical screw termination with conical borehole bottom; (c) cylindrical screw termination with a 2 × 2 mm chamfer and conical borehole bottom; (e) cylindrical screw termination with a rounded end (R = 2 mm) and flat-bottomed cylindrical borehole; (g) A—location of the crack initiation point under the action of a cylindrical screw termination (as in the Hertz problem), (b,d,f)—cracking trajectory according to the analyzed model (according to the case of model—(a,c,e)).

The results of the analysis demonstrated that, regardless of the drive screw termination geometry, the location of the crack initiation point leading to rock detachment may differ from that observed in conventional pull-out anchor systems (see Figure 3a). For the investigated design variants, fracture was initiated at the base of the drive screw (Figure 13b,d,e). This has direct implications for the volume of the potentially detached rock block, which assumes the form of a so-called pseudo-conical failure zone. The term “pseudo-failure cone” is intentionally used here, as in the case of rocks, the actual shape of the detached fragment deviates significantly from an ideal cone, as discussed in detail in [92].

Analysis of stress distribution and crack propagation trajectories indicates a significant influence of both the drive screw termination geometry and the borehole bottom shape on the initiation and development of the failure zone in the rock medium. In the case of a flat screw termination with a 2 × 2 mm chamfer combined with a conical borehole bottom, strong stress concentrations were observed in the contact zone, leading to the formation of a single dominant crack path. This trajectory penetrates deepest into the material, favoring the detachment of a larger rock volume.

In contrast, the remaining configurations resulted in shallower crack paths that reached the free surface of the rock more quickly. The simulation results suggest that it is potentially feasible to control the stress distribution by appropriately selecting the shape of the drive screw termination in the detachment anchor. Consequently, it becomes possible to control, to some extent, the extent and volume of the detached rock mass.

The analysis results also confirmed the premises of preliminary investigations [26,79], in which a deviation from typical crack propagation modes was observed during the failure of rock structure using one of the newly developed detachment anchor variants. Specifically, an alternative initiation and propagation pattern of the fracture was noted, differing from that observed in conventional anchoring systems.

These findings are of significant importance for the advancement of rock detachment technologies utilizing undercutting anchors. In particular, the use of drive screws with specially designed terminations may enable the generation of failure with a controlled character by enforcing specific crack propagation paths within the rock medium. This is especially relevant in underground excavation environments, where control over fracture direction directly affects both the safety and efficiency of the process.

The results suggest that a properly designed anchor termination geometry can reduce the need for explosives, thus contributing to the development of more environmentally friendly and selective rock fragmentation methods.

The qualitative analysis performed in this study confirmed the presence of all three primary fracture modes (I–III) during the rock detachment process. In future research stages, the numerical model will be extended to include a quantitative decomposition of the fracture energy into individual modes, enabling a mode mixity analysis and a more precise assessment of the influence of the screw termination geometry on the dominant failure mechanism. This approach will facilitate better tailoring of the anchor design to achieve the desired crack propagation direction and character.

Although the present study primarily focused on the influence of drive screw termination geometry and borehole bottom shape on crack initiation and propagation, the numerical results indirectly provide insight into the characteristics of the damage zone preceding visible fracture formation. The observed stress concentration patterns and early-stage crack initiation points correspond to the onset of a localized fracture process zone (FPZ), the extent of which can be qualitatively inferred from the XFEM stress–strain fields. Future work will incorporate a continuum damage mechanics (CDM) approach to quantitatively capture FPZ evolution and its role in determining the size and morphology of the detached rock fragment.

It should be emphasized; however, that the presented analyses are based on a numerical model that—despite incorporating realistic boundary conditions and material properties—does not account for all factors present in real operating environments; such as natural fractures; structural heterogeneity of the rock; or localized material damage. Future research should include model calibration using extended experimental datasets, including field trials and destructive testing, to validate the performance of different screw termination geometries under actual working conditions.

It is also recommended to consider the application of nonlinear fracture mechanics methods and heterogeneous material models for further optimization of undercutting anchor designs.

In light of the obtained results, the growing role of advanced computational methods—such as the Finite Element Method (FEM) [96,97,98,99]; the Boundary Element Method (BEM) [100,101,102,103,104,105]; and artificial neural network (ANN)-based models [106,107,108,109,110,111]—should be highlighted in engineering analysis of complex contact problems. The use of such tools enables a deeper understanding of the mechanisms governing crack initiation and propagation in brittle materials while also significantly reducing the need for costly and time-consuming experimental testing in the early design phase.

Properly calibrated numerical models allow for extensive parametric studies that support the optimization of anchor geometry and their adaptation to variable operating conditions. Moreover, the integration of machine learning algorithms may, in the future, contribute to the automation of identifying key geometric and material features that influence rock detachment effectiveness—representing an important step toward the development of intelligent anchoring system design.

In this study, the numerical analyses were conducted under the assumption of a homogeneous, isotropic rock medium without pre-existing fractures. These simplifications allowed for a clearer evaluation of the influence of anchor geometry and load distribution but represent an idealized scenario. In real rock masses, heterogeneity of lithology, variable joint patterns, and the presence of natural discontinuities can significantly affect load transfer mechanisms and failure propagation. Therefore, the direct applicability of the presented results to insitu conditions should be approached with caution. Future research will include models incorporating spatial variability of material properties and pre-existing fracture networks to better reflect the complexity of natural rock masses.

3.1. Experimental Validation

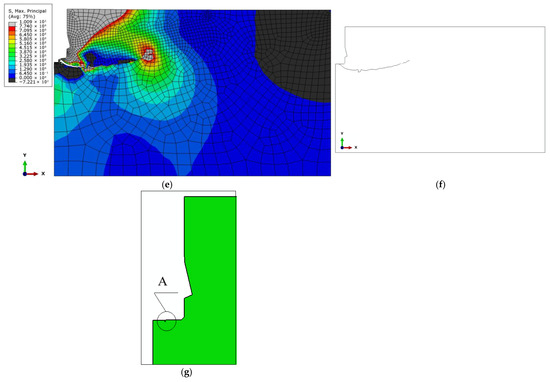

Experimental studies on rock block detachment using undercutting anchors—both with the modified HDP-A anchor variant (as shown in Figure 3a) and with the newly developed anchor design [78]—were conducted either in the Brenna sandstone quarry (OPUS 10 competition No. 2015/19/B/ST10/02817, financed by the Polish National Science Centre)or at the test facility located at ITG KOMAG. In the latter case, tests were performed on sandstone blocks originating from the Brenna quarry, as illustrated in Figure 14.

Figure 14.

(a) Rock detachment using the newly developed undercutting anchor (2), assisted by a torque multiplier (1); (b) Detached sandstone block in the form of a pseudo-failure cone; A—location of the crack initiation point at the base of the drive screw.

To enhance the reliability of the numerical model, preliminary experimental tests were repeated three times for each configuration, ensuring result repeatability within ±7% of peak load values. The measurement system uncertainty was determined for the applied force and displacement sensors. Although full stress–strain curves were not recorded for all trials, representative results illustrating the load–displacement relationship and the corresponding crack initiation and propagation sequences were obtained. Additionally, high-resolution photographs captured during testing document the onset and development of fractures, enabling direct visual verification of numerical predictions.

The tested rock was grey sandstone (a sedimentary rock), with mechanical properties summarized in Table 1.

Table 1.

Mechanical properties of grey Brenna sandstone.

The sandstone exhibited a layered structure, with individual strata approximately 0.7–1.0 m thick, as described in detail in [112]. The tests were conducted in a homogeneous section of the rock mass, free from fractures or structural disturbances.

For the newly developed anchor design (item 2 in Figure 14a), the experiments were performed using a torque multiplier (item 1 in Figure 14a).

The field tests generally confirmed that the initiation point of the detachment-inducing crack is located at the base (termination) of the drive screw (point A, Figure 14b). This location corresponds to the contact zone between the drive screw and the bottom of the borehole in which the anchor is installed.

3.2. Model Limitations and Future Research Perspectives

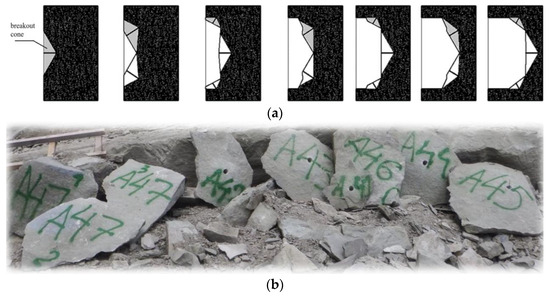

It should be noted that the premises of the present analysis involve several limitations, arising from the following factors:

- The use of a homogeneous rock medium model, selected to best represent the mechanical properties of grey sandstone from the Brenna quarry. This represents an idealized case, as natural rocks often exhibit fracturing, moisture presence, or internal heterogeneity [37,54,58];

- The application of a linear elastic material model, which is a significant simplification considering the wide variability in internal structure and deformation behavior across different rock types [80]. Disturbances in crack propagation trajectories (Figure 15) were observed even in hypothetically homogeneous grey sandstone from the “Zalas” mine (based on [59]).

Figure 15. Disturbances in crack propagation trajectories in a hypothetically homogeneous grey sandstone.

Figure 15. Disturbances in crack propagation trajectories in a hypothetically homogeneous grey sandstone.

- The use of an undercutting anchor with a conical head, which introduces a load transfer mechanism that differs significantly from that of bonded or cast-in-place anchors [12,55,78,92];

- The assumed installation method, including anchor expansion and interaction with the rock medium, differs from the conventional behavior of pull-out-type undercutting anchors.

Moreover, there are indications that the outcomes of the numerical simulation may also be significantly influenced by the following factors:

- Substantial variability in the mechanical properties of rock media, including Young’s modulus, Poisson’s ratio, Coulomb friction coefficient at the anchor–rock interface, moisture content, stratification, and natural fracturing of the rock mass;

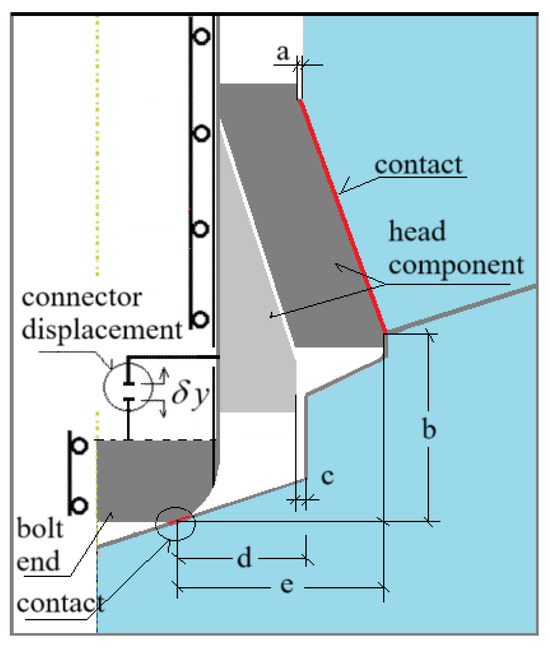

- The combination of geometric parameters of the mechanical model of the rock medium (Figure 16) and the anchor head geometry—particularly the clearance dimensions (a and c)—as these may alter the direction and distribution of force transmission from the anchor to the rock [113];

Figure 16. Geometric relationships relevant to the simulation outcome in the model of detachment anchor interaction with the rock medium.

Figure 16. Geometric relationships relevant to the simulation outcome in the model of detachment anchor interaction with the rock medium. - The detachment process in grey sandstone, being a sedimentary rock, may depend on the orientation of the bedding planes. In the present study, the borehole axis was oriented predominantly perpendicular to the sedimentation/bedding planes.

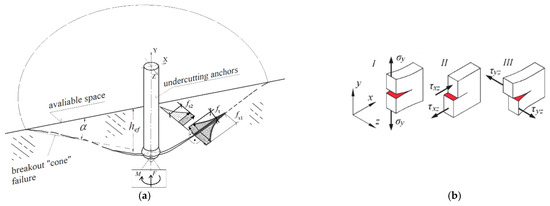

It should also be noted that in the proposed anchor design, the rotational motion of the drive screw within the conical head introduces tangential (circumferential) friction forces acting on the conical surface (in a full 3D interaction model). This significantly alters the mechanical conditions compared to simplified assumptions commonly used in planar models (e.g., cohesive zone models) or axisymmetric models. A third fracture mode emerges (see Figure 17), more complex than those considered in previous studies [26,79], particularly in models developed for pull-out failure of installation-type anchors (flat 2D models [90,114]).

Figure 17.

(a) Complex fracture model of the rock medium under the action of a conical anchor head, accounting for torsional friction between the rotating head and the rock; (b) Fundamental fracture modes in continuous media. M—friction torque; F—applied load/force.

Although the present study applied a maximum principal stress criterion with linear softening—suitable for modeling brittle fracture initiation in homogeneous sandstone—the authors acknowledge that complex mixed-mode (I/II/III) fracture mechanisms may occur under the combined tensile; shear; and torsional loading conditions generated by the novel anchor design. Future work will therefore incorporate more advanced fracture modeling approaches, such as cohesive zone models (CZM) with traction–separation laws, J-integral-based fracture parameter evaluation, and crack tip stress intensity factor (SIF) analysis, to more accurately capture multi-mode crack propagation in heterogeneous rock masses. These developments will allow for improved calibration of numerical results against experimental field data.

The contact between two surfaces in relative rotational motion is a well-known phenomenon in many engineering applications [115,116], and the resulting torsional friction contact is a critical aspect in this case.

The action of the pull-out force F (Figure 17a) induces Mode I fracture (opening/tensile failure). The conical shape of the anchor head introduces deformations in the X-direction of the model and leads to Mode II fracture (in-plane shear along the XZ plane). Additionally, the torque M applied to the drive screw causes rotational movement of the head under friction, potentially generating Mode III fracture (out-of-plane shear in the YZ plane).

Most existing models are based on classical pull-out tests of foundation-type anchors with cylindrical heads, for which cohesive zone modeling is justified. However, in the case of the pull-out behavior of the anchor configuration considered in this study, such simplification is insufficient and may not capture the full complexity of the failure mechanism.

Although the axisymmetric modelling approach adopted in this study enabled a detailed analysis of the interaction between the anchor head and the rock medium, it inherently cannot capture asymmetric fracture patterns or complex 3D crack propagation, particularly under the influence of torsional forces that may induce Mode III shear. In real operating conditions, such effects can result in non-axisymmetric crack trajectories, especially in heterogeneous rock masses with natural discontinuities. Therefore, future work will involve the development of fully 3D numerical models to account for these additional fracture modes and to provide a more comprehensive representation of the rock detachment process.

4. Conclusions

Given the number of potentially influential factors, it is essential to conduct more extensive field investigations encompassing a broader diversity of rock structures, as well as an in-depth parametric analysis. This should include key geometric parameters of both the anchor and the undercut borehole—extending beyond the scope of previous studies [26,75,78,79].

Although the present study focuses on macroscopic FEM-based simulations using XFEM to capture crack initiation and propagation, it does not explicitly model the micro-to-macro transition of fracture development. Future work will address this gap by integrating approaches from damage mechanics and discrete fracture network (DFN) modelling, which enable the explicit representation of micro-crack nucleation, coalescence, and their evolution into macro-scale fractures. Such integration is expected to provide deeper mechanistic insight into the fracture process and improve the predictive capability of the numerical models.

5. Summary and Conclusions

Field investigations confirmed that, for the tested rock type (medium-strength grey sandstone), the location of the crack initiation point during detachment with anchors expanded near the borehole bottom is consistently found in the contact zone between the screw tip and the borehole bottom—regardless of the screw termination variant. This differs from typical undercutting anchors pulled out from the substrate, where fracture initiation commonly occurs at the base of the conical head (as shown in Figure 3).

The conducted analyses demonstrate that the geometry of the screw termination and the shape of the borehole bottom play a critical role in the initiation and progression of failure in the rock medium. Cylindrical terminations with a chamfer (as shown in Figure 8) generate deeper crack penetration compared to conical or cylindrical terminations combined with flat-bottomed boreholes. This may be advantageous in the context of detaching larger volumes of rock material under lower axial loading forces.

These findings provide a foundation for the design of new types of undercutting anchors dedicated to rock detachment applications. Such designs could be optimized for directional crack propagation and efficient fragmentation without the use of explosives.

The developed anchor configurations may find direct application in a variety of engineering scenarios where controlled, non-explosive rock detachment is required. Potential use cases include tunneling in urban or environmentally sensitive areas, selective rock removal in mining operations to minimize dilution, and stabilization of rock slopes or excavation fronts in geotechnical engineering. In such contexts, the ability to control crack initiation and propagation through optimized anchor geometry could significantly improve both operational safety and process efficiency.

The presented numerical models—once properly calibrated with experimental data—may serve as valuable tools for supporting the development of selective rock detachment technologies in underground mining and geotechnical engineering.

Author Contributions

Conceptualization, J.J. and R.K.; methodology, A.W. and J.J.; software, A.W.; validation, J.J. and R.K.; formal analysis, J.J. and R.K.; investigation, J.J. and R.K.; resources, J.J. and R.K.; data curation, A.W.; writing—original draft preparation, J.J. and R.K.; writing—review and editing, J.J. and R.K.; visualization, J.J.; supervision, J.J. and R.K.; project administration, J.J. and R.K.; funding acquisition, J.J. and R.K. All authors have read and agreed to the published version of the manuscript.

Funding

This project was financed by the Polish National Center for Research and Development under the TANGO IV program under the title “Technology for unconventional falling off the rock fragments”, project number: TANGO-IV-A/0058/2019. The research performed by RK was funded under Grant No. FD-20/IM-5/052 of the Lublin University of Technology.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Brown, E.T. Rock Engineering Design of Post-Tensioned Anchors for Dams—A Review. J. Rock Mech. Geotech. Eng. 2015, 7, 1–13. [Google Scholar] [CrossRef]

- Zou, W.-L.; Wang, X.-Q.; Vanapalli, S.K. Experimental Evaluation of Engineering Properties of GFRP Screw Anchors for Anchoring Applications. J. Mater. Civ. Eng. 2016, 28, 04016029. [Google Scholar] [CrossRef]

- Wils, L.; Wils, T.; Tremblay, M. Toward a Career Anchor Structure: An Empirical Investigation of Engineers. Relat. Ind. 2010, 65, 236–256. [Google Scholar] [CrossRef]

- Zheng, J.-J.; Dai, J.-G. Prediction of the Nonlinear Pull-out Response of FRPG round Anchors Using an Analytical Transfer Matrix Method. Eng. Struct. 2014, 81, 377–385. [Google Scholar] [CrossRef]

- Jonak, J.; Karpiński, R.; Siegmund, M.; Wójcik, A.; Jonak, K. Analysis of the Rock Failure Cone Size Relative to the Group Effect from a Triangular Anchorage System. Materials 2020, 13, 4657. [Google Scholar] [CrossRef]

- Jonak, K.; Karpiński, R.; Wójcik, A.; Jonak, J. Simulation of Rock Failure Cone Development Using a Modified Load-Transferring Anchor Design. Appl. Sci. 2025, 15, 7653. [Google Scholar] [CrossRef]

- Yilmaz, S.; Özen, M.A.; Yardim, Y. Tensile Behavior of Post-Installed Chemical Anchors Embedded to Low Strength Concrete. Constr. Build. Mater. 2013, 47, 861–866. [Google Scholar] [CrossRef]

- Contrafatto, L.; Cosenza, R. Predictionofthe Pull-out Strength of Chemical Anchors in Natural Stone. Fract. Struct. Integr. 2014, 8, 196–208. [Google Scholar] [CrossRef]

- Shaqour, F. Ground Anchors in an Aggressive Hydro-Environment. Bull. Eng. Geol. Environ. 2006, 65, 43–56. [Google Scholar] [CrossRef]

- Mottl, M.; Reiterman, P.; Pazderka, J. The Influence of Aggressive Environmental Conditions on the Adhesion of Applied Crystalline Materials. J. Compos. Sci. 2023, 8, 5. [Google Scholar] [CrossRef]

- Gruttadauria, A.; Barella, S.; Gerosa, R. An Overview of Austenitic Stainless-Steel Rock Anchors Damage in an Environment Rich with Chlorides. Eng. Fail. Anal. 2019, 100, 88–102. [Google Scholar] [CrossRef]

- Lamplmair-Irsigler, S.; Zeman, O.; Stierschneider, E.; Voit, K. Fastening in Rock Mass—Structural Design of Shallow Embedded Anchors in Inhomogeneous Substrate. Materials 2024, 17, 6044. [Google Scholar] [CrossRef]

- Cai, M. Rock Mass Characterization and Rock Property Variability Considerations for Tunneland Cavern Design. Rock Mech. Rock Eng. 2011, 44, 379–399. [Google Scholar] [CrossRef]

- Kong, P.; Jiang, L.; Shu, J.; Sainoki, A.; Wang, Q. Effect of Fracture Heterogeneity on Rock Mass Stability in a Highly Heterogeneous Underground Roadway. Rock Mech. Rock Eng. 2019, 52, 4547–4564. [Google Scholar] [CrossRef]

- Bokor, B.; Tóth, M.; Sharma, A. Fasteners in Steel Fiber Reinforced Concrete Subjected to Increased Loading Rates. Fibers 2018, 6, 93. [Google Scholar] [CrossRef]

- Tóth, M.; Bokor, B.; Sharma, A. Befestigungen Im Stahlfaserverstärkten Beton Bei Betonbruch—Stand Der Technik Und Bemessungsansatz/Anchorages in Steel Fiber Reinforced Concrete in the Case of Concrete Break out Failure—State of the Art and Design Concept. Bauingenieur 2021, 96, 254–265. [Google Scholar] [CrossRef]

- Tóth, M.; Bokor, B.; Sharma, A. Anchorage in Steel Fiber Reinforced Concrete–Concept, Experimental Evidence and Design Recommendations for Concrete Cone and Concrete Edge Break out Failure Modes. Eng. Struct. 2019, 181, 60–75. [Google Scholar] [CrossRef]

- Bokor, B.; Sharma, A.; Hofmann, J. Experimental Investigations on Concrete Cone Failure of Rectangular and Non-Rectangular Anchor Groups. Eng. Struct. 2019, 188, 202–217. [Google Scholar] [CrossRef]

- Bokor, B.; Sharma, A.; Pregartner, T. An Assessment Method to Ensure Applicability of Concrete Capacity Method for Design of Anchorages: Linear Force Distribution Approach. Struct. Concr. 2023, 24, 7249–7271. [Google Scholar] [CrossRef]

- Zheng, H.; Wu, X.; Jiang, Y.; Wang, G.; Wang, Z. Shear Behavior of Rock Joints Reinforced with Fully-Grouted and Energy-Absorbing Bolts Subjected to Shear Cycles. J. Rock Mech. Geotech. Eng. 2024, 17, 4314–4328. [Google Scholar] [CrossRef]

- Gkournelos, P.D.; Triantafillou, T.C.; Bournas, D.A. Seismic Upgrading of Existing Reinforced Concrete Buildings: A State-of-the-Art Review. Eng. Struct. 2021, 240, 112273. [Google Scholar] [CrossRef]

- Zhong, C.; Christopoulos, C. Self-Centering Seismic-Resistant Structures: Historical Overview and State-of-the-Art. Earthq. Spectra 2022, 38, 1321–1356. [Google Scholar] [CrossRef]

- Cao, X.-Y.; Shen, D.; Feng, D.-C.; Wang, C.-L.; Qu, Z.; Wu, G. Seismic Retrofitting of Existing Frame Buildings through Externally Attached Sub-Structures: State of the Art Review and Future Perspectives. J. Build. Eng. 2022, 57, 104904. [Google Scholar] [CrossRef]

- Jing, H.W.; Yang, S.Q.; Zhang, M.L.; Xu, G.A.; Chen, K.F. An Experimental Study on Anchorage Strength and Deformation Behavior of Large-Scale Jointed Rock Mass. Tunn. Undergr. Space Technol. 2014, 43, 184–197. [Google Scholar] [CrossRef]

- Wang, Y.; Li, C.; Cai, Z.; Zhu, G.; Zhou, J.; Yao, W. Mechanical Behaviors of Anchorage Interfaces in Layered Rocks with Fractures under Axial Loads. J. Earth Sci. 2023, 34, 354–368. [Google Scholar] [CrossRef]

- Wójcik, A.; Jonak, K.; Karpiński, R.; Jonak, J.; Kalita, M.; Prostański, D. Mechanism of Rock Mass Detachment Using Undercutting Anchors: A Numerical Finite Element Method (FEM) Analysis. Materials 2024, 17, 4468. [Google Scholar] [CrossRef]

- Caldwell, T. A Comparison of Non-Explosive Rock Breaking Techniques. In Proceedings of the 12th Australian Tunnelling Conference, Brisbane, Australia, 17–20 April 2005. [Google Scholar]

- Singh, S.P. Non-Explosive Applications of the PCF Concept for Underground Excavation. Tunn. Undergr. Space Technol. 1998, 13, 305–311. [Google Scholar] [CrossRef]

- Xu, K. Rock Fragmentation. In The ECPH Encyclopedia of Mining and Metallurgy; Springer Nature Singapore: Singapore, 2023; pp. 1–2. ISBN 978-981-19-0740-1. [Google Scholar]

- Zhu, C.; Huang, M.; Cai, Q.; Zuo, Y.; Tang, S.; Yin, Q. Complex Rock Mechanics Problems and Risk Prevention Solutions. Appl. Sci. 2025, 15, 755. [Google Scholar] [CrossRef]

- Li, G.; Ma, W.; Yu, C.; Tao, Z.; Wang, F. Optimization of Anchorage Support Parameters for Soft Rock Tunnel Based on Displacement Control Theory. J. Mt. Sci. 2023, 20, 2076–2092. [Google Scholar] [CrossRef]

- Li, M.; Ye, L.; Feng, J.; Fang, Y.; Wen, H.; Wu, X. Failure Mechanism and Control Technology of Soft-Rock Roadways Subjected to High Structural Stress. Front. Earth Sci. 2024, 12, 1473108. [Google Scholar] [CrossRef]

- Wang, D.; He, F.; Chen, D.; Bascompta, M.; Wang, X.; Xu, C.; Liu, B.; Tian, W. Mechanism of Enhanced Control and Technological Application of Surrounding Rock Anchoring in Fully Mechanized Caving Face of Extra-Thick Coal Seams. Processes 2025, 13, 1216. [Google Scholar] [CrossRef]

- Zheng, H.; Wu, X.; Jiang, Y.; Wang, G.; Li, B. Insights into Velocity-Dependent Shear Characteristics of Bolted Rock Joints: A Comparative Study of Fully-Grouted and Energy-Absorbing Bolts. Int. J. Rock Mech. Min. Sci. 2024, 183, 105910. [Google Scholar] [CrossRef]

- Wang, Z.; Liao, L.; Guo, S.; Zheng, H.; Wu, X. Numerical Investigation of Bolted Rock Joints under Varying Normal Stressand Joint Roughness Coefficient Conditions. Front. Earth Sci. 2024, 12, 1402708. [Google Scholar] [CrossRef]

- Deutsches Institut für Bautechnik. European Technical Assessment ETA-18/0629 of 4 September 2018; Deutsches Institut für Bautechnik: Berlin, Germany, 2018. [Google Scholar]

- American Certification Institute. Building Code Requirements for Structural Concrete (ACI 318–19) Commentary on Building Code Requirements for Structural Concrete: ACI 318M ERTA—2020; HISMarkit: New York, NY, USA, 2020. [Google Scholar]

- Hilti. Technical Datasheet Update: Dec-17, HDA Undercut Anchor; Hilti: Schaan, Liechtenstein, 2017. [Google Scholar]

- Hilti. Hilti Mechanical Anchors Catalog; Hilti: Schaan, Liechtenstein, 2025. [Google Scholar]

- MIYANAGA Co., Ltd. ANZEX Undercut Anchor System Installation Manual (ANZEX-D); MIYANAGA Co., Ltd.: Miki, Japan, 2020. [Google Scholar]

- Jonak, J.; Karpiński, R.; Wójcik, A. Numerical Analysis of the Effect of Embedment Depth on the Geometry of the Cone Failure. J. Phys. Conf. Ser. 2021, 2130, 012012. [Google Scholar] [CrossRef]

- Jonak, J.; Karpiński, R.; Wójcik, A. Numerical Analysis of Under cut Anchor Effect on Rock. J. Phys. Conf. Ser. 2021, 2130, 012011. [Google Scholar] [CrossRef]

- Zhang, B.; Chen, Z. Numerical Simulation and Parametric Study of Pull out Behavior of Anchor Studs in Normal-strength and High-strength Concrete. Struct. Concr. 2025, suco.70278. [Google Scholar] [CrossRef]

- Fuchs, W.; Eligehausen, R.; Breen, J.E. Concrete Capacity Design (CCD) Approach for Fastening to Concrete. Struct. J. 1995, 92, 73–94. [Google Scholar] [CrossRef]

- Di Nunzio, G. A Literature Review about the Head-Size Effect on the Capacity of Cast-in Anchors. In Proceedings of the 10th International Conference on Fracture Mechanics of Concrete and Concrete Structures, Bayonne, France, 23–26 June 2019. [Google Scholar]

- Hariyadi; Munemoto, S.; Sonoda, Y. Experimental Analysis of Anchor Bolt in Concrete under the Pull-Out Loading. Procedia Eng. 2017, 171, 926–933. [Google Scholar] [CrossRef]

- Kadima Lukanu Lwa Nzambi, A.; Bule Ntuku, J.; De Oliveira, D.R.C. Effect of Adhesive through Pilot Pull-Out Tests on Handcrafted Headed Studs Postinstalled in Steel Fiber Concrete. Pract. Period. Struct. Des. Constr. 2021, 26, 05021005. [Google Scholar] [CrossRef]

- Elgehausen, R.; Sawade, G. A Fracture Mechanics Based Description of the Pull-out Behavior of Headed Studs Embedded in Concrete. Communities Collect. 1989. [Google Scholar] [CrossRef]

- Eligehausen, R.; Mallée, R.; Silva, J.F. Anchorage in Concrete Construction; Wiley Library: Hoboken, NJ, USA, 2006; Volume 10. [Google Scholar]

- Henriques, J.; Raposo, J.M.; da Silva, L.S.; Neves, L.C. Tensile Resistance of Steel-Reinforced Anchorages: Experimental Evaluation. ACI Struct. J. 2013, 110, 2. [Google Scholar] [CrossRef]

- Zhuang, L.-D.; Chen, H.-B.; Ma, Y.; Ding, R. Research on Whole-Process Tensile Behavior of Headed Studs inSteel–Concrete Composite Structures. Int. J. Concr. Struct. Mater. 2021, 15, 24. [Google Scholar] [CrossRef]

- Malikova, L.; Miarka, P. Parametric Study on the Effect of Anchor’s Geometry on the Stress Distribution and Crack Initiation Direction in a Concrete Body. Fract. Struct. Integr. 2025, 19, 131–138. [Google Scholar] [CrossRef]

- Mahrenholtz, P. Experimental Performance and Recommendations for Qualification of Post-Installed Anchors for Seismic Applications; Inst. für Werkstoffe im Bauwesen: Stuttgart, Germany, 2013; ISBN 3-9811682-7-5. [Google Scholar]

- Grindheim, B.; Li, C.C.; Høien, A.H.; Lia, L. Behavior of a Rock Mass in Uplift Field Tests of Rock Anchors. Rock Mech. Rock Eng. 2024, 57, 2339–2364. [Google Scholar] [CrossRef]

- Lamplmair, S.; Zeman, O.; Voit, K. Factors Influencing the Load-Bearing Capacity of Rock as Base Material forPost-Installed Anchors. Materials 2021, 14, 5130. [Google Scholar] [CrossRef]

- Genco, A.; Ciantia, M.O.; Previtali, M.; Brown, M.; Ivanovic, A.; Cresswell, N.; Twomey, V. Large Deformation Numerical Assessment of Rock Anchor Response under Axial Loading for Offshore Renewable Energy Applications. Comput. Geotech. 2024, 173, 106563. [Google Scholar] [CrossRef]

- Ferrari, A.; Rosone, M.; Ziccarelli, M.; Gottardi, G. (Eds.) Geotechnical Engineering in the Digital and Technological Innovation Era; Springer Series in Geomechanics and Geoengineering; Springer: Cham, Switzerland, 2023; ISBN 978-3-031-34760-3. [Google Scholar]

- Jonak, J.; Karpiński, R.; Siegmund, M.; Machrowska, A.; Prostański, D. Experimental Verification of Standard Recommendations for Estimating the Load-Carrying Capacity of Undercut Anchorsin Rock Material. Adv. Sci. Technol. Res. J. 2021, 15, 230–244. [Google Scholar] [CrossRef]

- Jonak, J.; Wójcik, A.; Karpiński, R.; Jonak, K. Effect of Under cut Bolt Anchor Depth on Failure Cone Geometry: A Numerical FEM Analysis and Experimental Verification. Materials 2025, 18, 686. [Google Scholar] [CrossRef]

- Krzysztof, K.; Piotr, M. Methods of Mechanical Mining of Compact-Rock—A Comparison of Efficiency and Energy Consumption. Energies 2019, 12, 3562. [Google Scholar] [CrossRef]

- Hasilová, K.; Gajewski, J. The Use of Kernel Density Estimates for Classification of Ripping Tool Wear. Tunn. Undergr. Space Technol. 2019, 88, 29–34. [Google Scholar] [CrossRef]

- Gajewski, J.; Jonak, J. Utilisation of Neural Networks to Identify the Status of the Cutting Tool Point. Tunn. Undergr. Space Technol. 2006, 21, 180–184. [Google Scholar] [CrossRef]

- Jedliński, Ł.; Gajewski, J. Optimal Selection of Signal Features in the Diagnostics of Mining Head Tools Condition. Tunn. Undergr. Space Technol. 2019, 84, 451–460. [Google Scholar] [CrossRef]

- Liang, F.; Pei, C.; Luo, W.; You, M.; Tan, F. Numerical Simulation Analysis of Different Excavation Parameters for TBM3DDisc Cutters Based on the Discrete Element Method. Appl. Sci. 2024, 15, 38. [Google Scholar] [CrossRef]

- Vališ, D.; Forbelská, M.; Vintr, Z.; Gajewski, J. Degradation Process and Failure Estimation of Drilling System Based on RealDataand Diffusion Process Supported by State Space Models. Measurement 2020, 164, 108076. [Google Scholar] [CrossRef]

- Wang, Y.-T.; Zhou, X.-P.; Kou, M.-M. Three-Dimensional Numerical Study on the Failure Characteristics of Intermittent Fissures under Compressive-Shear Loads. Acta Geotech. 2019, 14, 1161–1193. [Google Scholar] [CrossRef]

- Zhou, X.; Wang, Y.; Qian, Q. Numerical Simulation of Crack Curving and Branching in Brittle Materials under Dynamic Loads Using the Extended Non-Ordinary State-Based Peridynamics. Eur. J. Mech. A Solids 2016, 60, 277–299. [Google Scholar] [CrossRef]

- Zhou, X.-P.; Gu, X.-B.; Wang, Y.-T. Numerical Simulations of Propagation, Bifurcation and Coalescence of Cracks in Rocks. Int. J. Rock Mech. Min. Sci. 2015, 80, 241–254. [Google Scholar] [CrossRef]

- Morshedlou, A.; Rostami, J.; Moradian, O. Introducing a New Model for Prediction of Mean Cutting Forces Acting on Conical Pick Cutters. Rock Mech. Rock Eng. 2024, 57, 1695–1716. [Google Scholar] [CrossRef]

- Deng, L.-C.; Zhang, F.-B.; Li, X.-Z.; Zhang, C.; Ji, Y.-K.; Wu, Y. Experimental and Numerical Investigations on Rock Breaking of TBM Disc Cutter Based on a Novel Platform with Rotational Cutting. Rock Mech. Rock Eng. 2023, 56, 1415–1436. [Google Scholar] [CrossRef]

- Vališ, D.; Gajewski, J.; Forbelská, M.; Vintr, Z.; Jonak, J. Drilling Head Knives Degradation Modelling Based on Stochastic Diffusion Processes Backed upby State Space Models. Mech. Syst. Signal Process. 2022, 166, 108448. [Google Scholar] [CrossRef]

- Cao, Y.; Zhang, Q.; Zhang, S.; Tian, Y.; Dong, X.; Song, X.; Wang, D. Optimization of Rock-Cutting Tools: Improvements in Structural Design and Process Efficiency. Computation 2025, 13, 152. [Google Scholar] [CrossRef]

- Jonak, J.; Karpiński, R.; Wójcik, A. Influence of the Undercut Anchor Head Angle on the Propagation of the Failure Zone of the Rock Medium—Part II. Materials 2021, 14, 3880. [Google Scholar] [CrossRef] [PubMed]

- Jonak, J.; Karpiński, R.; Wójcik, A. Influence of the Undercut Anchor Head Angle on the Propagation of the Failure Zone of the Rock Medium. Materials 2021, 14, 2371. [Google Scholar] [CrossRef] [PubMed]

- Siegmund, M.; Jonak, J. Analysis of the Process of Loosening the Rocks with Different Strength Properties Using the Undercutting Bolts. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 679, p. 012014. [Google Scholar] [CrossRef]

- Jonak, J.; Siegmund, M. FEM 3D Analysis of Rock Cone Failure Range during Pull-out of Undercut Anchors. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 710, p. 012046. [Google Scholar] [CrossRef]

- Jonak, J.; Karpiński, R.; Wójcik, A. Influence of Anchor Depth and Friction Coefficient Between Anchor and Rock on the Trajectory of Rock Masses Detachment. Adv. Sci. Technol. Res. J. 2023, 17, 290–298. [Google Scholar] [CrossRef]

- Jonak, J.; Karpiński, R.; Wójcik, A.; Siegmund, M.; Kalita, M. Determining the Effect of Rock Strength Parameters on the Breakout Area Utilizing the New Design of the Undercut/Breakout Anchor. Materials 2022, 15, 851. [Google Scholar] [CrossRef]

- Wójcik, A.; Jonak, J.; Karpiński, R.; Jonak, K.; Prostański, D.; Kaczyński, R. A Numerical Study of the Influence of Cone Angle of the Breakout Anchor Head on the Crack Trajectory of the Medium. Adv. Sci. Technol. Res. J. 2024, 18, 101–112. [Google Scholar] [CrossRef]

- Zhao, Z.; Zhou, X.-P. Digital Microscopic Multiphase Heterogeneity Representation and Its Effects on Micromechanics and Cracking Behaviors of Geomaterials. Rock Mech. Rock Eng. 2024, 57, 7443–7459. [Google Scholar] [CrossRef]

- Koca, M.Y.; Kincal, C.; Arslan, A.T.; Yilmaz, H.R. Anchor Application in Karatepe Andesite Rock Slope, Izmir—Türkiye. Int. J. Rock Mech. Min. Sci. 2011, 48, 245–258. [Google Scholar] [CrossRef]

- Zhao, Z.; Zhou, X.-P. A Comprehensive Review of Various AI-Based Segmentation Algorithms for Multiscale Rocks: Principles, Evaluations, Simple Applications and Future Directions. Rock Mech. Rock Eng. 2025, 2025, 1–36. [Google Scholar] [CrossRef]

- Zhou, X.-P.; Zhao, Z.; Li, Z. Cracking Behaviors and Hydraulic Properties Evaluation Based on Fractural Microstructure Models in Geomaterials. Int. J. Rock Mech. Min. Sci. 2020, 130, 104304. [Google Scholar] [CrossRef]

- Zhao, Z.; Zhou, X. Microscopic Characterizations of Heterogeneous Pores, ITZs, Multiple-Solids, and Their Impacts on Damage Property of Sandstone by Low-High Resolution 3D Reconstruction. Geophys. Res. Lett. 2021, 48, e2021GL095001. [Google Scholar] [CrossRef]

- Cook, R.A. Behavior and Design of Ductile Multiple-Anchor Steel-to-Concrete Connections; The University of Texas at Austin: Austin, TX, USA, 1989; ISBN 979-8-206-89520-9. [Google Scholar]

- Gontarz, J.; Podgórski, J. Numerical Analysis of Crack Propagation in a Pull-out Test. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2019; Volume 252, p. 08001. [Google Scholar] [CrossRef]

- ABAQUS, Version 2019; Dassault Systèmes Simulia Corporation: Vélizy-Villacoublay, France, 2019.

- Jnak, J.; Siegmund, M.; Karpiński, R.; Wójcik, A. Three-Dimensional Finite Element Analysis of the Undercut Anchor Group Effect in Rock Cone Failure. Materials 2020, 13, 1332. [Google Scholar] [CrossRef]

- Rabbat, B.G.; Russell, H.G. Friction Coefficient of Steel on Concrete or Grout. J. Struct. Eng. 1985, 111, 505–515. [Google Scholar] [CrossRef]

- Gotarz, J.; Podgórski, J.; Jonak, J.; Kalita, M.; Siegmund, M. Comparison Between Numerical Analysis and Actual Results for a Pull-Out Test. Eng. Trans. 2019, 67, 311–331. [Google Scholar] [CrossRef]

- Walter, H.; Baillet, L.; Brunet, M. Contact Analysis for the Modelling of Anchors in Concrete Structures. WIT Trans. Eng. Sci. 1997, 14, 341–349. [Google Scholar]

- Jonak, J.; Karpiński, R.; Wójcik, A.; Siegmund, M. The Influence of the Physical-Mechanical Parameters of Rock on the Extent of the Initial Failure Zone under the Action of an Undercut Anchor. Materials 2021, 14, 1841. [Google Scholar] [CrossRef]

- Wysmulski, P. Analysis of the Effect of an Open Hole on the Buckling of a Compressed Composite Plate. Materials 2024, 17, 1081. [Google Scholar] [CrossRef]

- Wysmulski, P. Failure Mechanism of Tensile CFRP Composite Plates with Variable Hole Diameter. Materials 2023, 16, 4714. [Google Scholar] [CrossRef]

- Gontarz, J.; Podgórski, J. Prediction of Crack Path in Concrete-like Composite using Extended Finite Element Method. Adv. Sci. Technol. Res. J. 2025, 19, 2. [Google Scholar] [CrossRef]

- Falkowicz, K. Numerical Investigations of Perforated CFRPZ-Cross-Section Profiles, under Axial Compression. Materials 2022, 15, 6874. [Google Scholar] [CrossRef]

- Falkowicz, K. Validation of Extension-Bending and Extension-Twisting Coupled Laminates in Elastic Element. Adv. Sci. Technol. Res. J. 2023, 17, 309–319. [Google Scholar] [CrossRef]

- Jing, L. A Review of Techniques, Advances and Outstanding Issues in Numerical Modelling for Rock Mechanics and Rock Engineering. Int. J. Rock Mech. Min. Sci. 2003, 40, 283–353. [Google Scholar] [CrossRef]

- Jing, L.; Hudson, J.A. Numerical Methods in Rock Mechanics. Int. J. Rock Mech. Min. Sci. 2002, 39, 409–427. [Google Scholar] [CrossRef]

- Romero, A.; Galvín, P.; Domínguez, J. 3D Non-Linear Time Domain FEM–BEM Approachto Soil–Structure Interaction Problems. Eng. Anal. Bound. Elem. 2013, 37, 501–512. [Google Scholar] [CrossRef]

- Romero, A.; Galvín, P.; Tadeu, A. An Accurate Treatment of Non-Homogeneous Boundary Conditions for Development of the BEM. Eng. Anal. Bound. Elem. 2020, 116, 93–101. [Google Scholar] [CrossRef]

- Min, K.B.; Park, B.; Kim, H.; Cho, J.W.; Jing, L. Experimental and Numerical Anisotropic Rock Mechanics. Rock Mech. Eng. 2017, 1, 108–138. [Google Scholar]

- Clouteau, D.; Elhabre, M.L.; Aubry, D. Periodic BEM and FEM-BEM Coupling. Comput. Mech. 2000, 25, 567–577. [Google Scholar] [CrossRef]

- Aimi, A.; Desiderio, L.; Fedeli, P.; Frangi, A. A Fast Boundary-Finite Element Approach for Estimating Anchor Losses in Micro-Electro-Mechanical System Resonators. Appl. Math. Model. 2021, 97, 741–753. [Google Scholar] [CrossRef]

- Saleh, A.L.; Aliabadi, M.H. Boundary Element Analysis of the Pullout Behaviour of an Anchor Bolt Embedded in Concrete. Mech. Cohesive-Frict. Mater. Int. J. Exp. Model. Comput. Mater. Struct. 1996, 1, 235–249. [Google Scholar] [CrossRef]

- Tang, C.A.; Yang, W.T.; Fu, Y.F.; Xu, X.H. A New Approach to Numerical Method of Modelling Geological Processes and Rock Engineering Problems—Continuum to Discontinuum and Linearity to Nonlinearity. Eng. Geol. 1998, 49, 207–214. [Google Scholar] [CrossRef]

- Stead, D.; Eberhardt, E.; Coggan, J.S. Developments in the Characterization of Complex Rock Slope Deformation and Failure Using Numerical Modelling Techniques. Eng. Geol. 2006, 83, 217–235. [Google Scholar] [CrossRef]

- Wei, X.; Li, Z.; Zhao, G. A Review of Multiscale Numerical Modeling of Rock Mechanics and Rock Engineering. Deep Undergr. Sci. Eng. 2024, dug2.12127. [Google Scholar] [CrossRef]

- Tan, X.; Konietzky, H.; Chen, W. Numerical Simulation of Heterogeneous Rock Using Discrete Element Model Based on Digital Image Processing. Rock Mech. Rock Eng. 2016, 49, 4957–4964. [Google Scholar] [CrossRef]

- Zhang, F.; Damjanac, B.; Maxwell, S. Investigating Hydraulic Fracturing Complexity in Naturally Fractured Rock Masses Using Fully Coupled Multiscale Numerical Modeling. Rock Mech. Rock Eng. 2019, 52, 5137–5160. [Google Scholar] [CrossRef]

- Szabelski, J.; Karpiński, R.; Machrowska, A. Application of an Artificial Neural Network in the Modelling of Heat Curing Effects on the Strength of Adhesive Joints at Elevated Temperature with Imprecise Adhesive Mix Ratios. Materials 2022, 15, 721. [Google Scholar] [CrossRef] [PubMed]

- Siegmund, M.; Kalita, M.; Bałaga, D.; Kaczmarczyk, K.; Józef, J. Testing the Rocks Loosening Process by Undercutting Anchors. Stud. Geotech. Mech. 2020, 42, 276–290. [Google Scholar] [CrossRef]

- Jonak, J.; Karpiński, R.; Wójcik, A.; Siegmund, M. The Effect of Undercut Anchor Diameter on the Rock Failure Cone Area in Pullout Tests. Adv. Sci. Technol. Res. J. 2022, 16, 261–270. [Google Scholar] [CrossRef]

- Gontarz, J.; Podgórski, J.; Siegmund, M. Comparison of Crack Propagation Analyses in a Pull-out Test. In AIP Conference Proceedings; Lublin, Poland, 13–16 September 2017, AIP Publishing: Lublin, Poland, 2018; Volume 1922, p. 130011. Available online: https://pubs.aip.org/aip/acp/article/1922/1/130011/608644/Comparison-of-crack-propagation-analyses-in-a-pull (accessed on 1 May 2025).

- Costagliola, G.; Bosia, F.; Pugno, N.M. Tuning of Frictional Properties in Torsional Contact by Means of Disk Grading. Friction 2022, 10, 787–802. [Google Scholar] [CrossRef]

- Chen, K.; Zhang, D.; Yang, X.; Cui, X.; Zhang, X.; Wang, Q. Research on Torsional Friction Behavior and Fluid Load Support of PVA/HA Composite Hydrogel. J. Mech. Behav. Biomed. Mater. 2016, 62, 182–194. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).