Effect of Nano-AlN Particles on the Microstructure and Mechanical Properties of Mg-Al-Nd-Mn Alloy

Abstract

1. Introduction

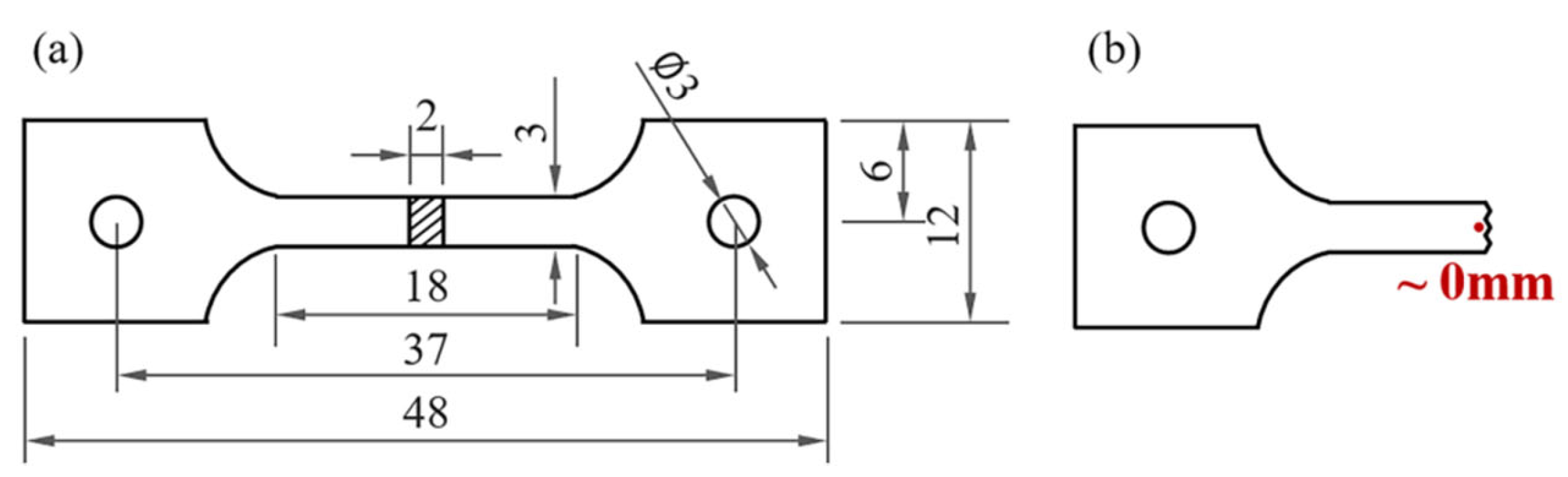

2. Materials and Methods

3. Results

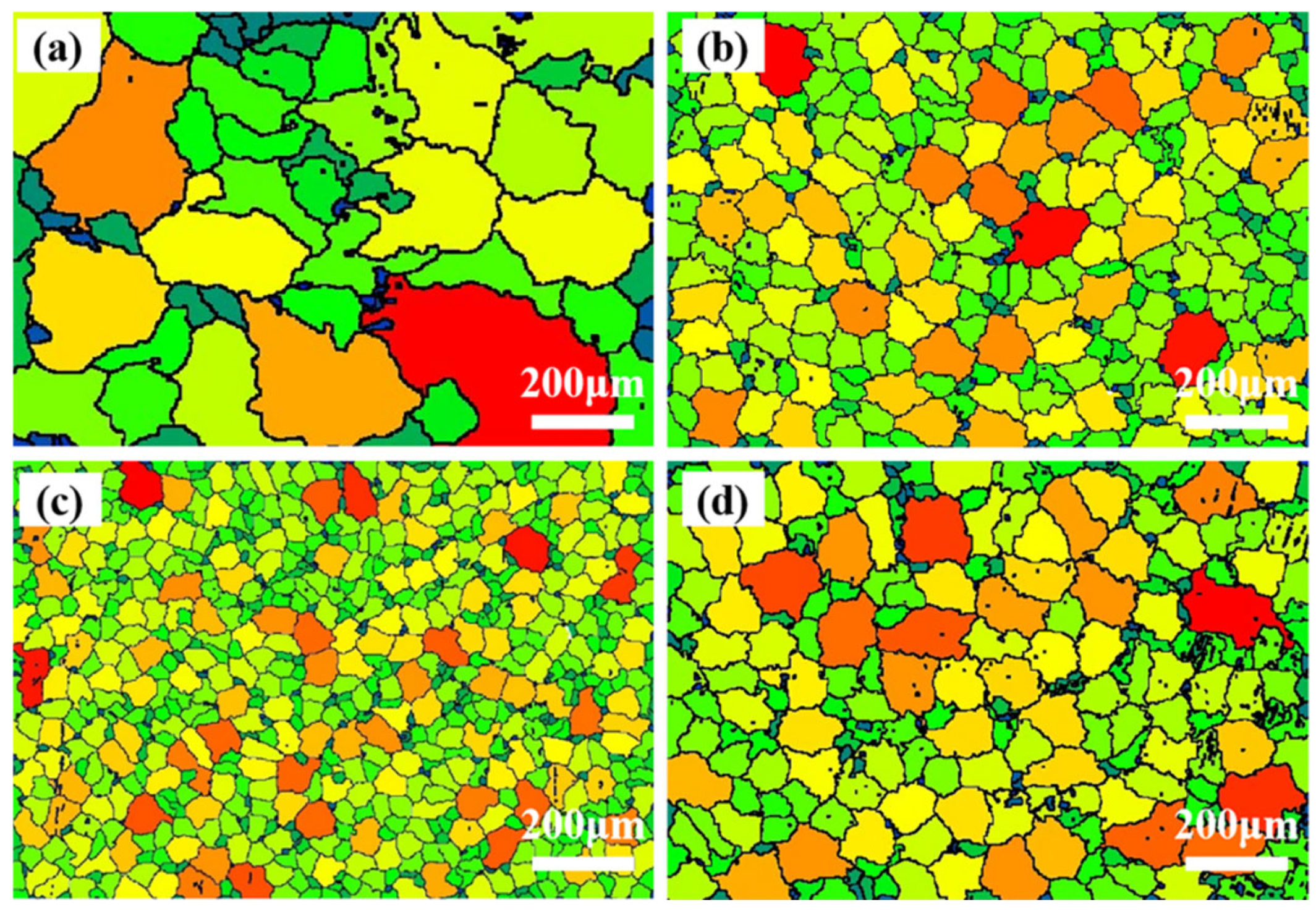

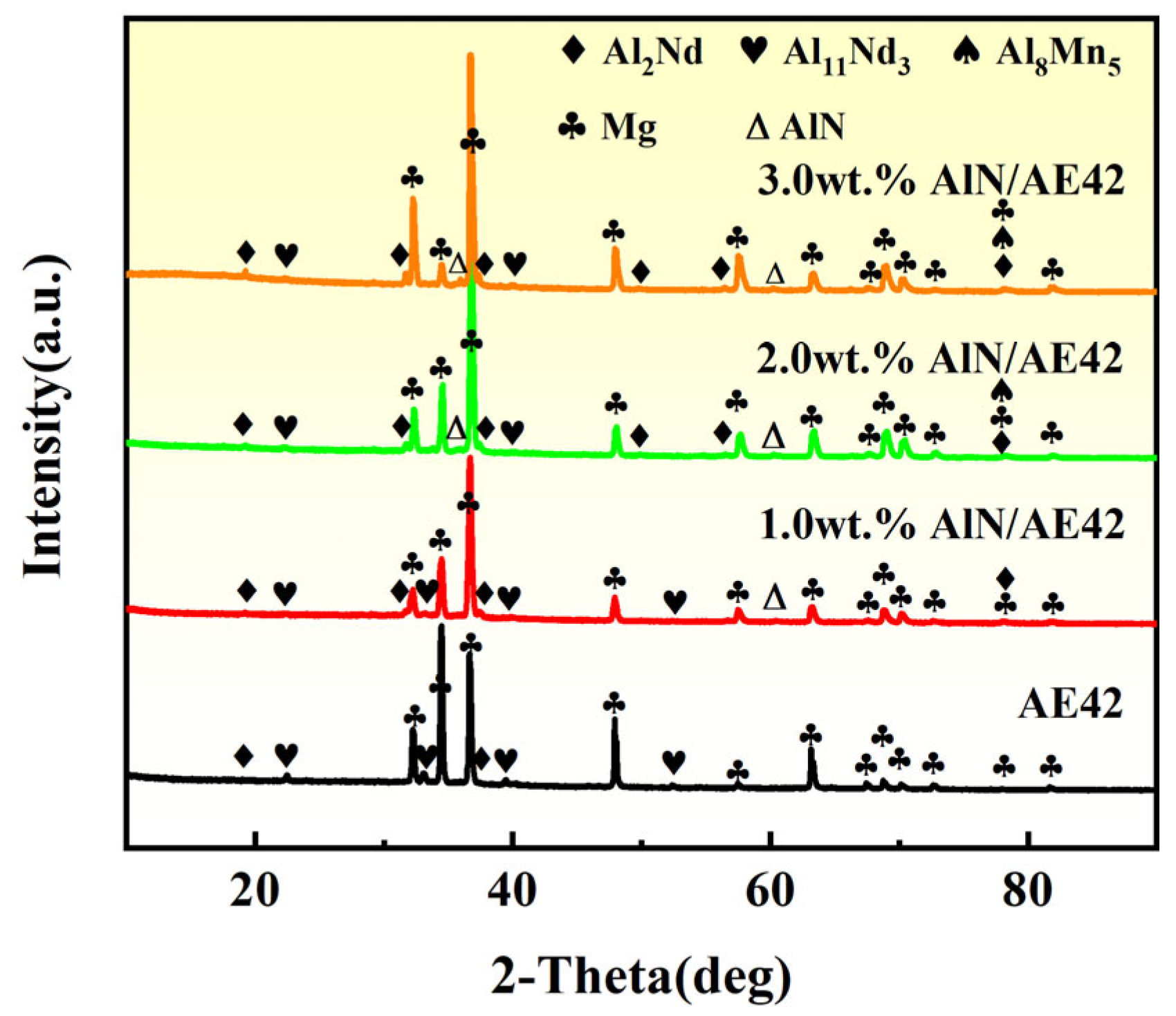

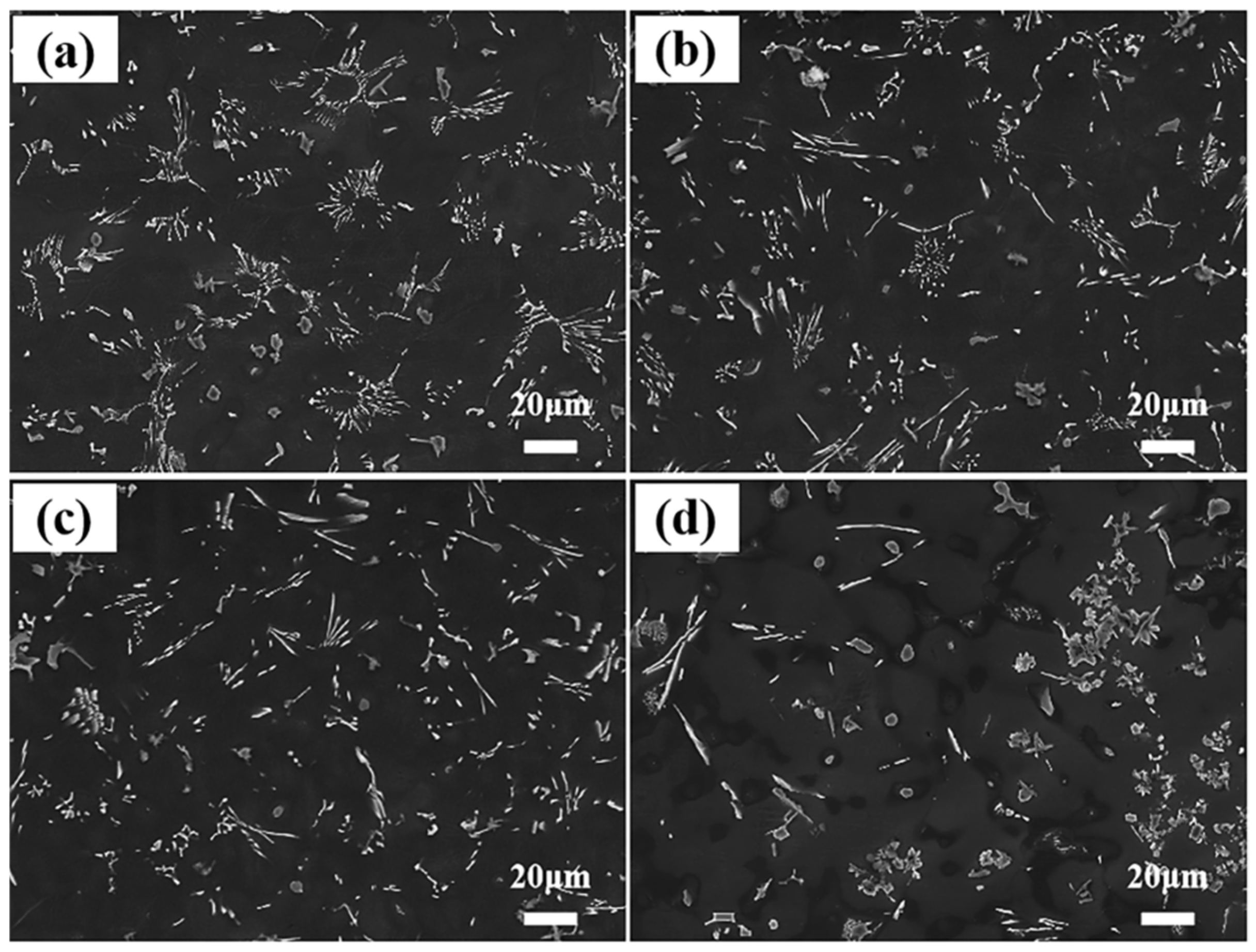

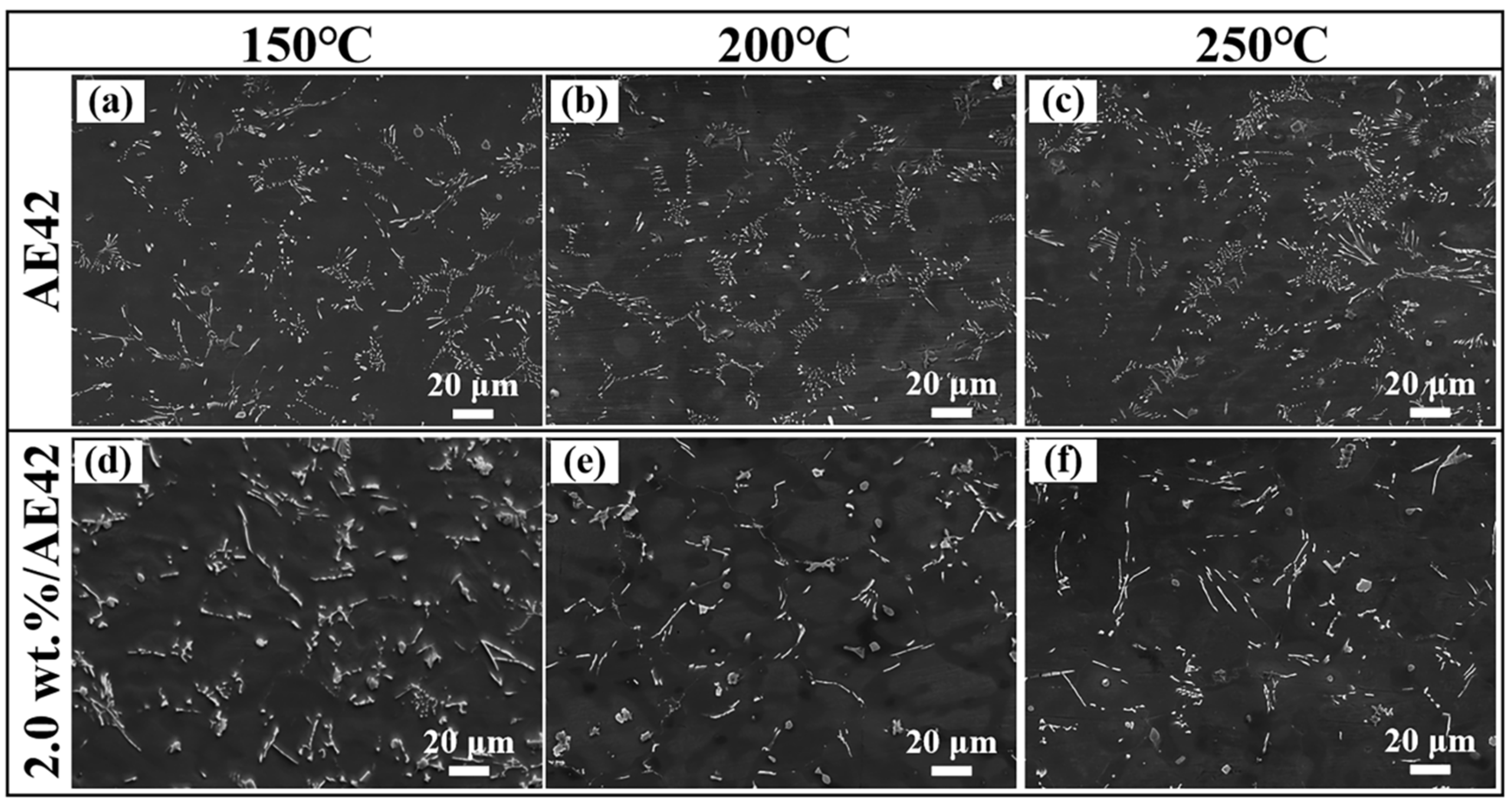

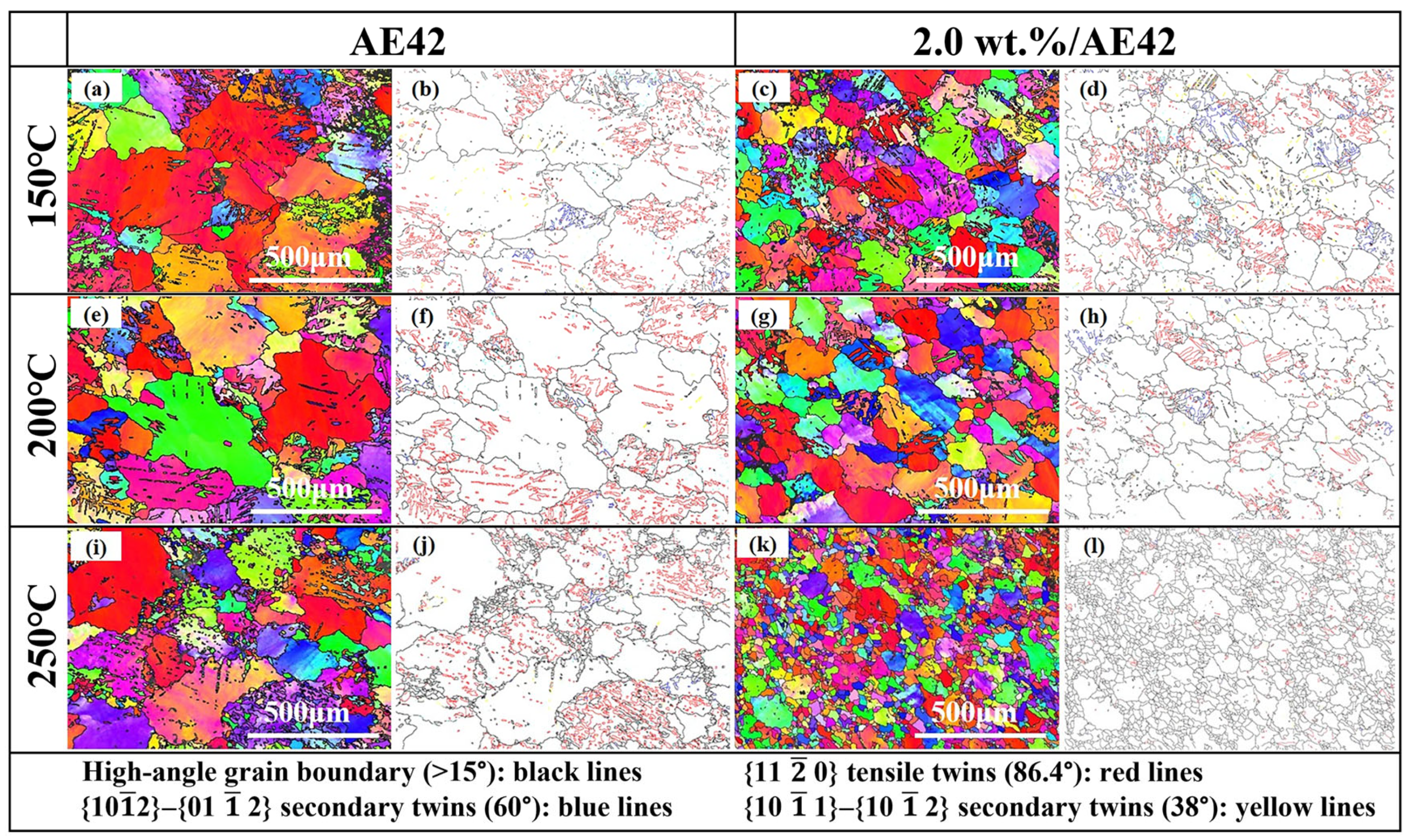

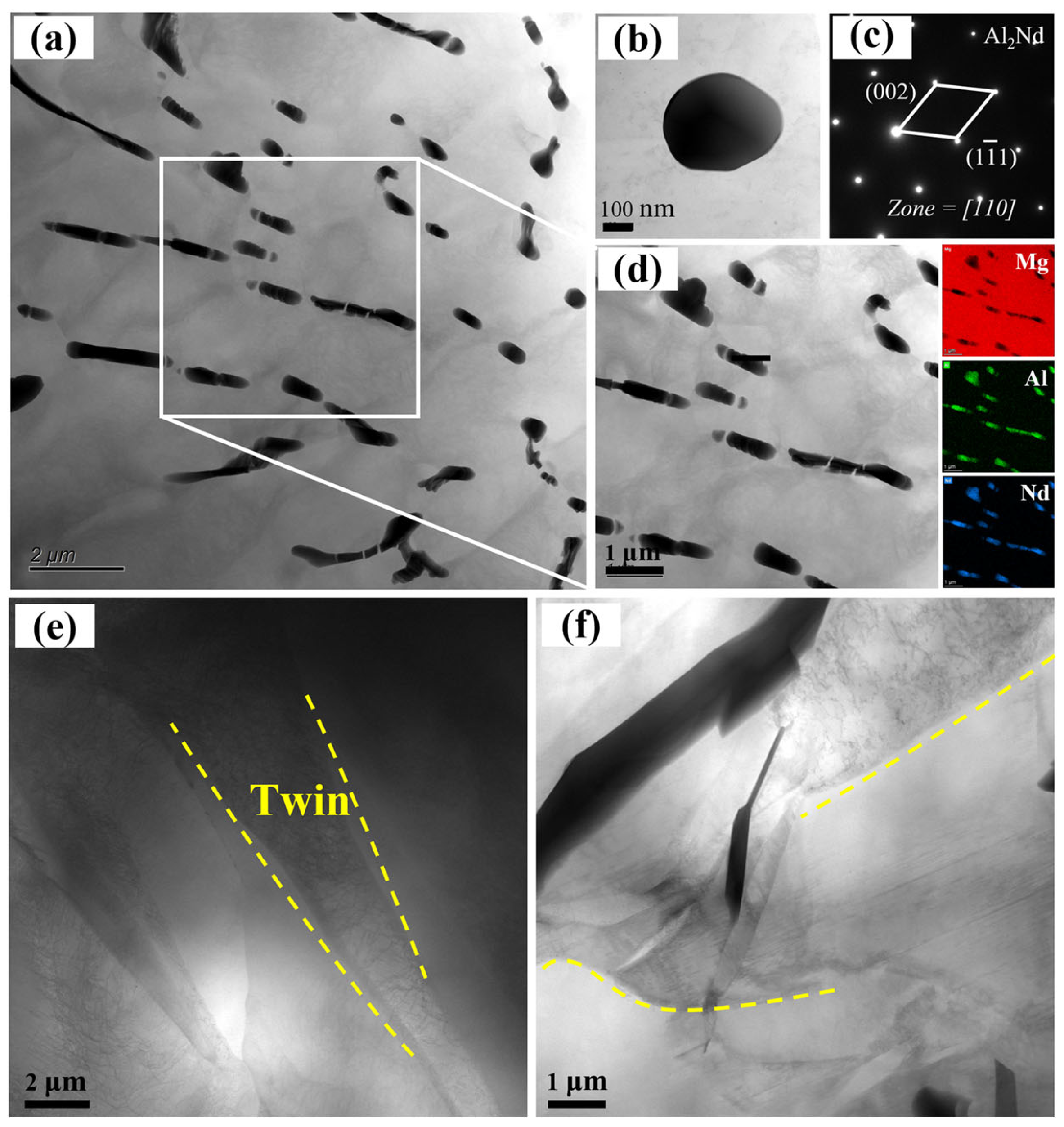

3.1. Microstructural Evolution

3.2. Mechanical Properties

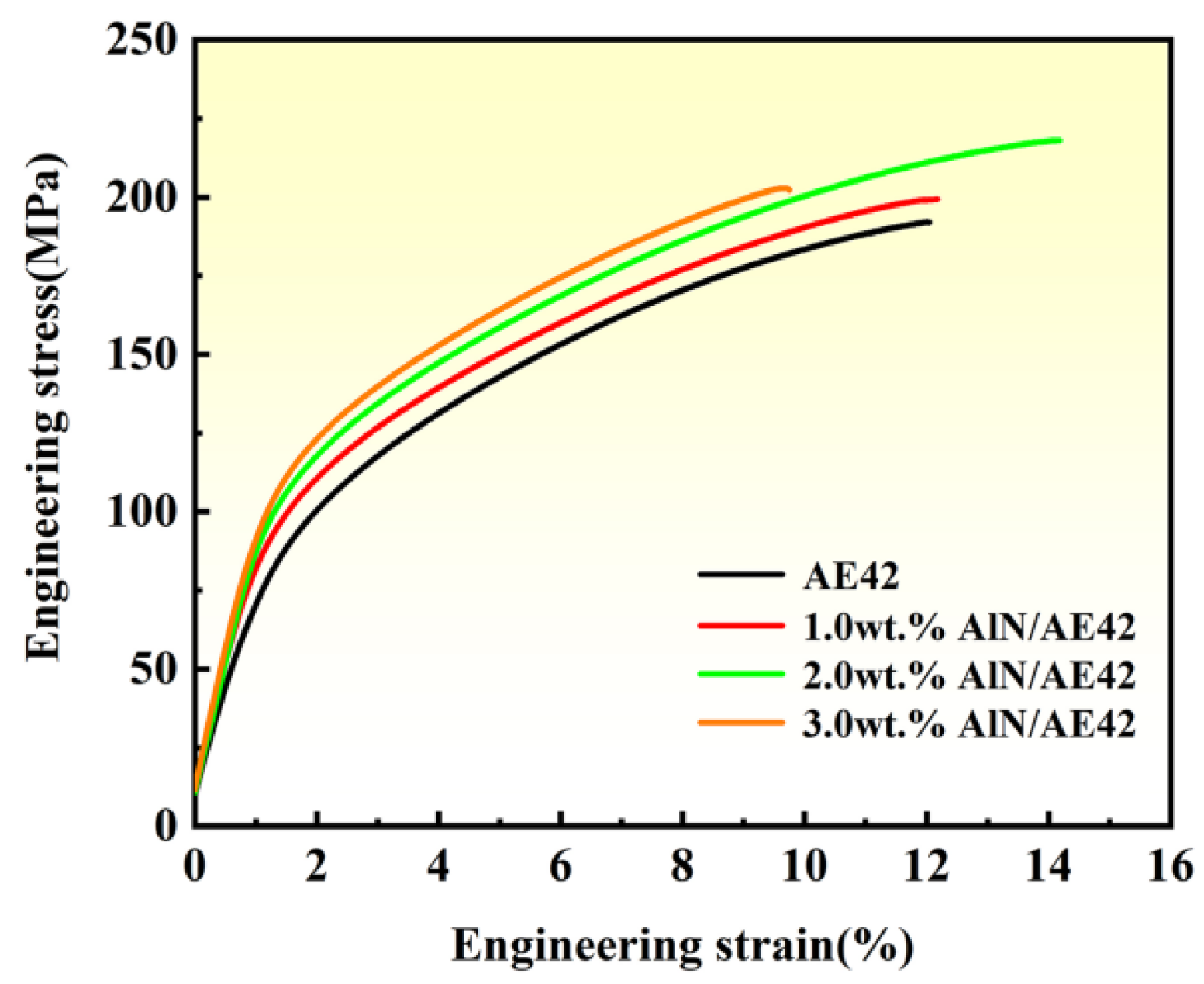

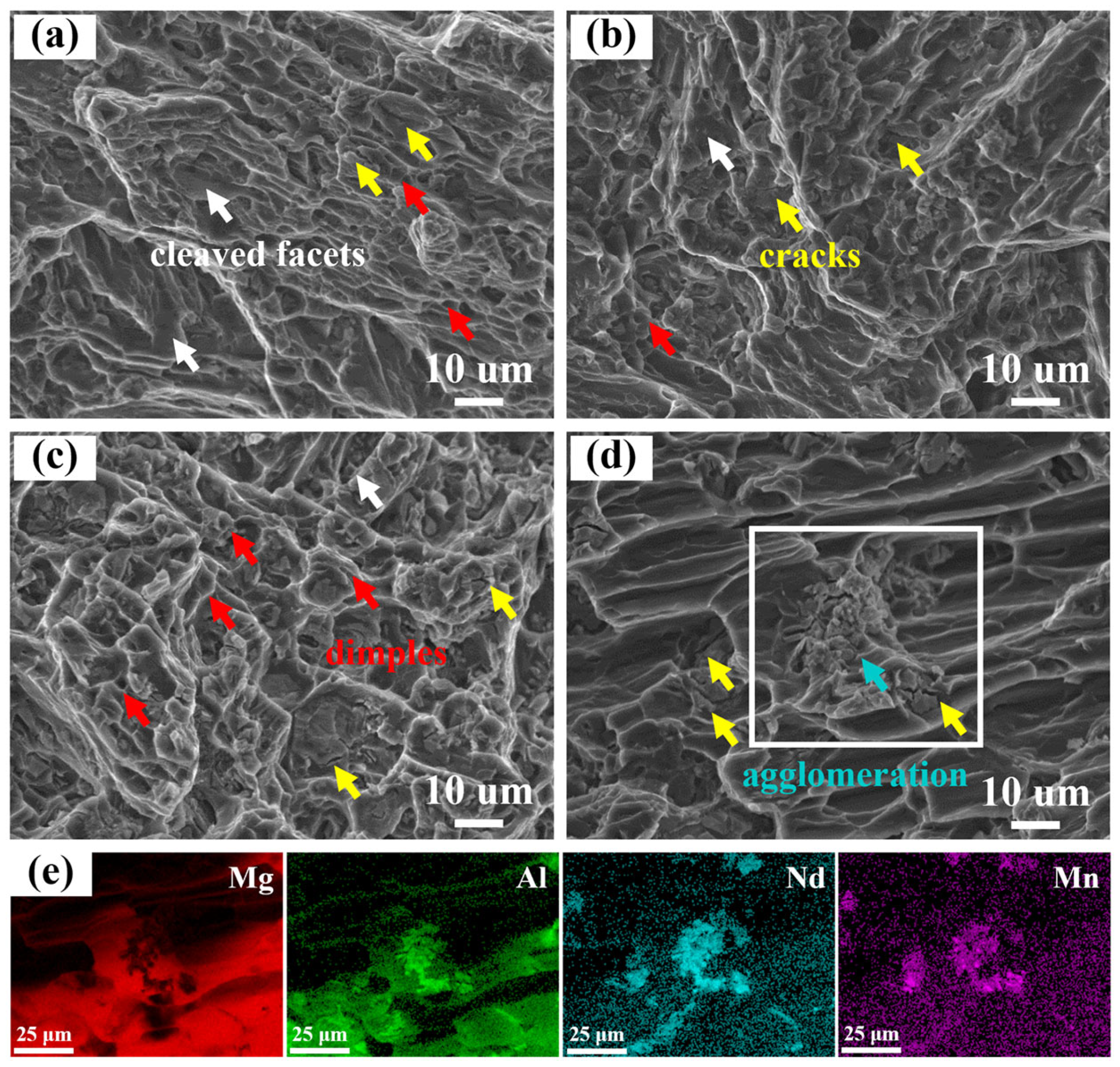

3.2.1. Room-Temperature Mechanical Properties

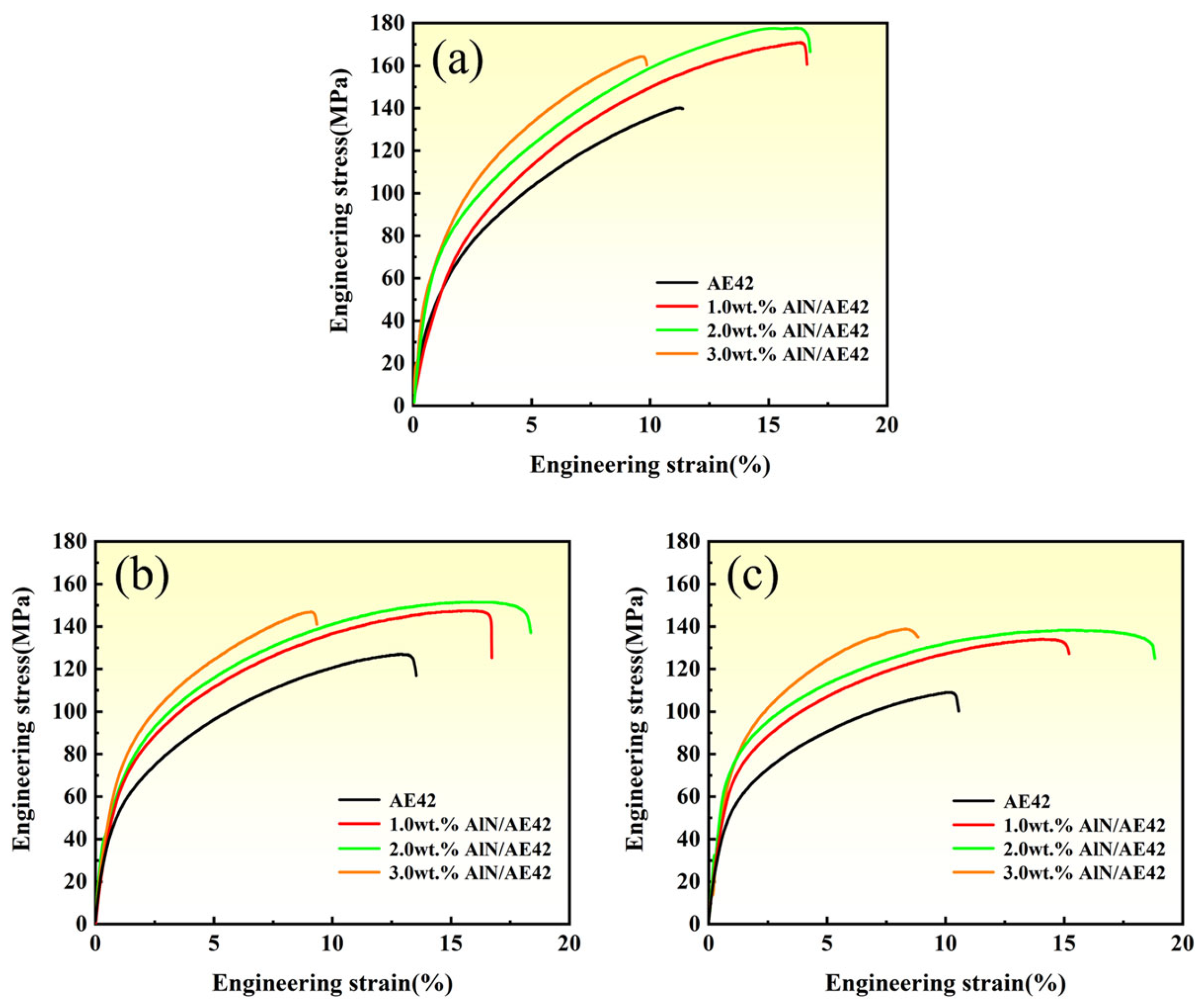

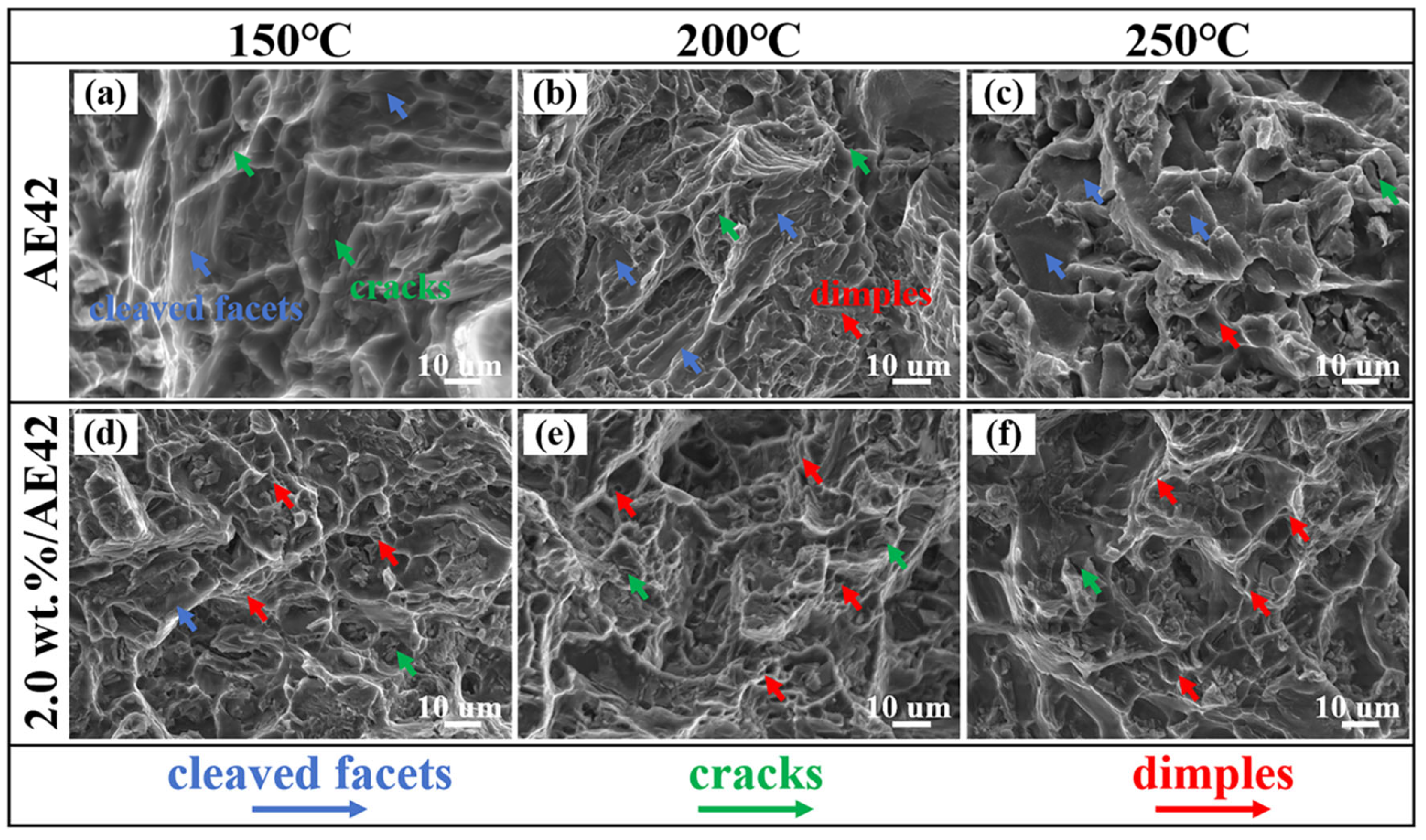

3.2.2. High-Temperature Mechanical Properties

4. Discussion

4.1. Room-Temperature Strengthening Mechanism

4.2. High-Temperature Strengthening Mechanism

5. Conclusions

- (1)

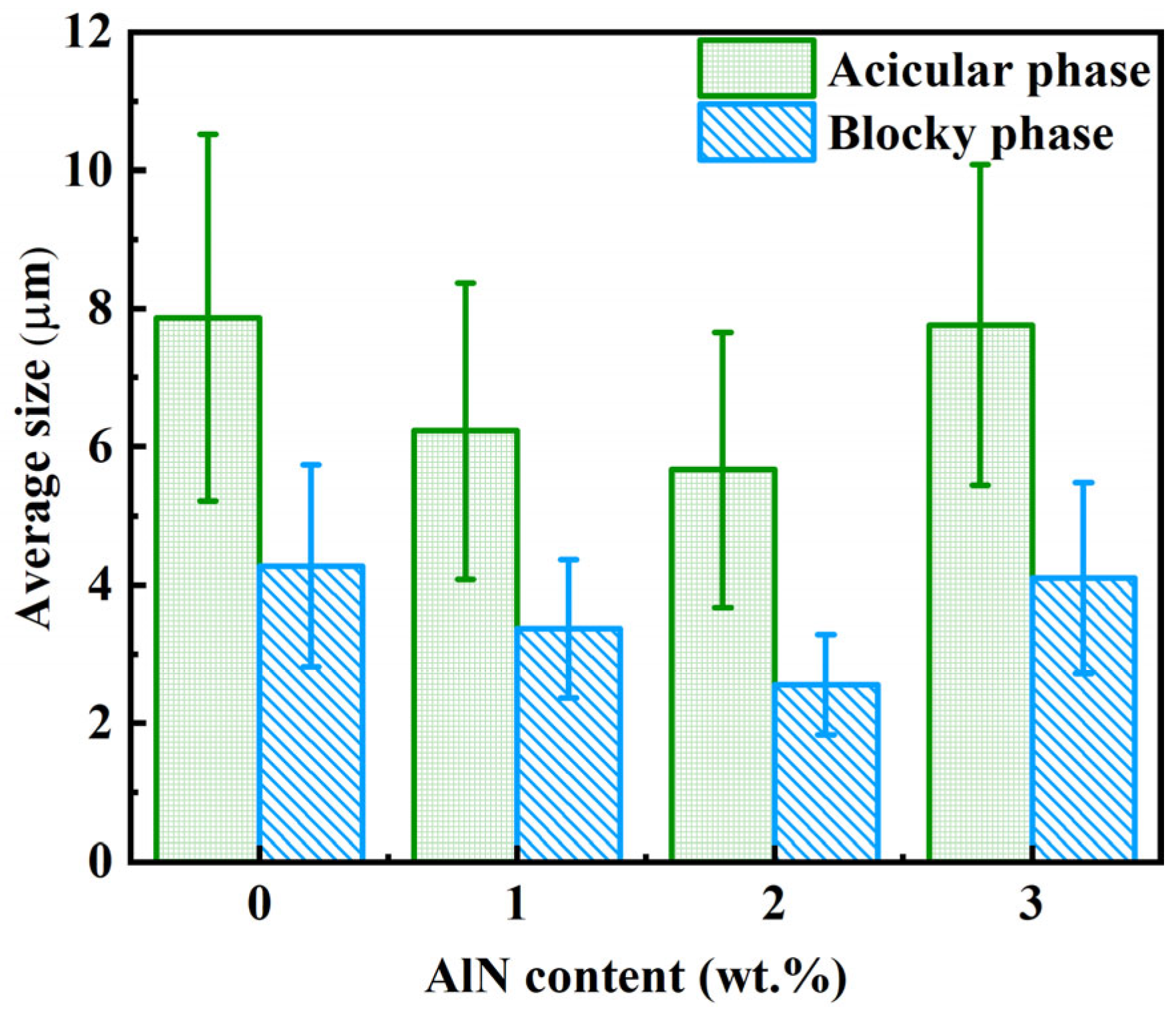

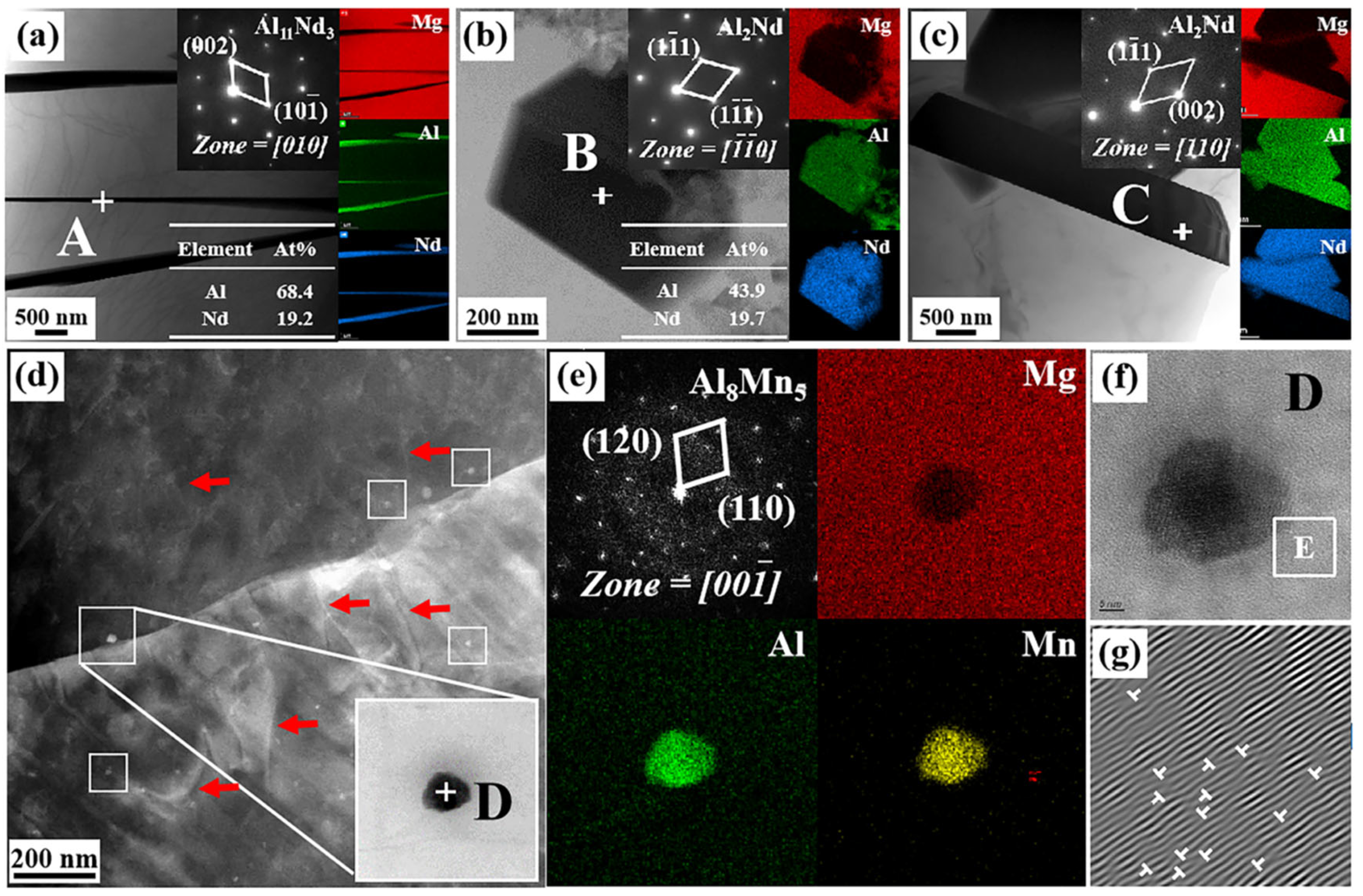

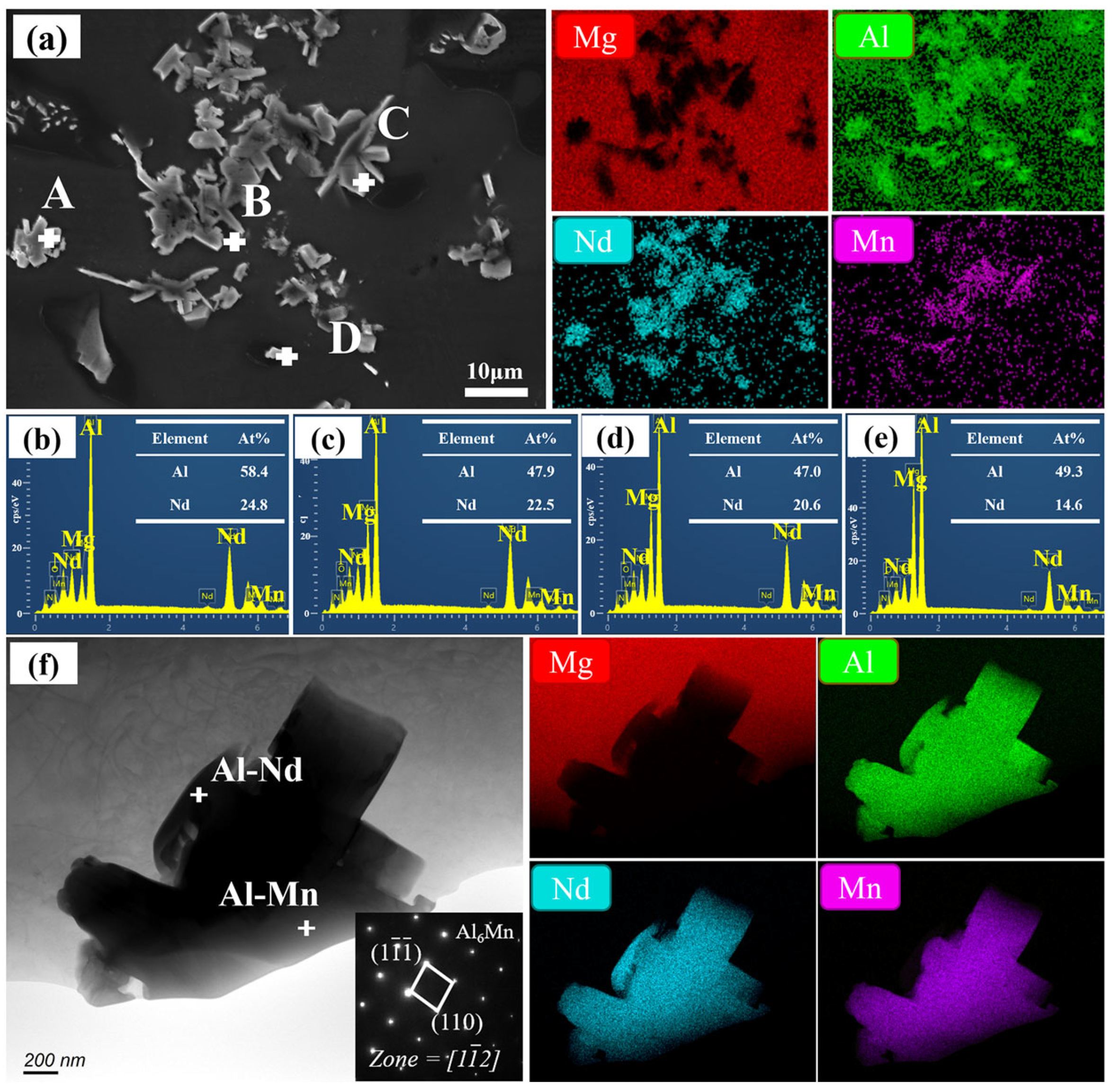

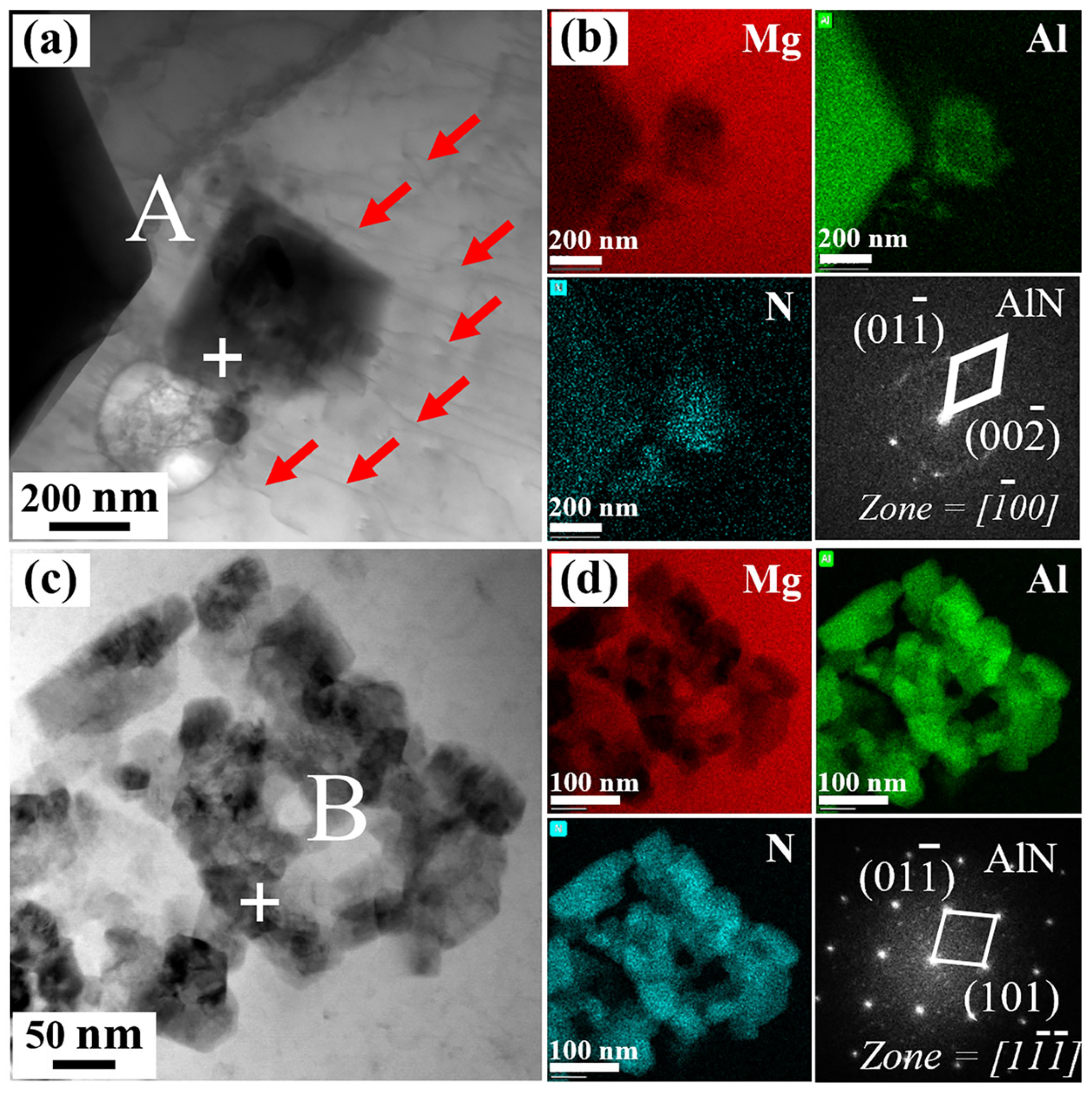

- With increasing AlN content, the average sizes of the α-Mg grains and acicular (Al11Nd3) and blocky (Al2Nd) second phases in the AE42 alloy first decreased and then increased while promoting the precipitation of the Al8Mn5 phase. Optimal refinement effects were achieved in the 2.0 wt.% AlN/AE42 composite, where average sizes of α-Mg, Al11Nd3, and Al2Nd phases in AE42 alloy were reduced from 116.0 μm, 7.9 μm, and 4.3 μm to 36.0 μm, 5.7 μm and 2.6 μm, respectively.

- (2)

- Benefiting from the refinement effects of nano-AlN particles on α-Mg grains and AlxNdy phases, coupled with their dislocation pinning effect, the 2.0 wt.% AlN/AE42 composite achieved enhanced room-temperature properties: YS, UTS, and ε reached 107 MPa, 219 MPa, and 13.8%, respectively.

- (3)

- The addition of nano-AlN particles promoted twin precipitation and DRX in AE42 alloy during high-temperature tensile deformation. Furthermore, the grain boundary pinning effect of AlN particles hindered the growth of DRXed grains while simultaneously enhancing grain boundary stability, effectively improving the high-temperature mechanical properties of AlN/AE42 composites. In the 2.0 wt.% AlN/AE42 composite, YS, UTS, and ε at 250 °C were 77 MPa, 139 MPa, and 18.8%, respectively, representing increases of 23 MPa, 30 MPa, and 8% over the AE42 alloy (54 MPa, 109 MPa, 10.8%).

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Su, Q.; Wang, R.; Yu, H.; Li, H.; Zhou, J.; Wang, D.; Hu, L. The effect of submicron SiC particles on the thermal stability of nanocrystalline AZ91 alloy. J. Mater. Res. Technol. 2023, 22, 519–530. [Google Scholar] [CrossRef]

- Ni, J.; Jin, L.; Zeng, J.; Li, J.; Wang, F.; Wang, F.; Dong, S.; Dong, J. Development of high-strength magnesium alloys with excellent ignition-proof performance based on the oxidation and ignition mechanisms: A review. J. Magnes. Alloys 2023, 11, 1–14. [Google Scholar] [CrossRef]

- Guan, S.; Wang, P.; Wang, T.; Wang, C.; Liu, G.; Zhu, Y. Microstructure and Mechanical Properties of High-Pressure Die-Casting Mg-Al-RE Alloys with Minor Ca Addition. Materials 2025, 18, 231. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.G.; Weiler, J.P. Recent developments in high-pressure die-cast magnesium alloys for automotive and future applications. J. Magnes. Alloys 2023, 11, 78–87. [Google Scholar] [CrossRef]

- Mo, N.; Tan, Q.; Bermingham, M.; Huang, Y.; Dieringa, H.; Hort, N.; Zhang, M.-X. Current development of creep-resistant magnesium cast alloys: A review. Mater. Des. 2018, 155, 422–442. [Google Scholar] [CrossRef]

- Yu, Z.P.; Yan, Y.H.; Yao, J.; Wang, C.; Zha, M.; Xu, X.Y.; Liu, Y.; Wang, H.Y.; Jiang, Q.C. Effect of tensile direction on mechanical properties and microstructural evolutions of rolled Mg-Al-Zn-Sn magnesium alloy sheets at room and elevated temperatures. J. Alloys Compd. 2018, 744, 211–219. [Google Scholar] [CrossRef]

- Mahmudi, R.; Kabirian, F.; Nematollahi, Z. Microstructural stability and high-temperature mechanical properties of AZ91 and AZ91+2RE magnesium alloys. Mater. Des. 2011, 32, 2583–2589. [Google Scholar] [CrossRef]

- Dong, X.; Feng, L.; Wang, S.; Nyberg, E.A.; Ji, S. A new die-cast magnesium alloy for applications at higher elevated temperatures of 200–300 °C. J. Magnes. Alloys 2021, 9, 90–101. [Google Scholar] [CrossRef]

- Ahmadian, H.; Zhou, T.; Alansari, A.; Kumar, A.S.; Fathy, A.; Elmahdy, M.; Yu, Q.; Weijia, G. Microstructure, mechanical properties and wear behavior of Mg matrix composites reinforced with Ti and nano SiC particles. J. Mater. Res. Technol. 2024, 31, 4088–4103. [Google Scholar] [CrossRef]

- Jiang, Q.; Li, X.; Wang, H. Fabrication of TiC particulate reinforced magnesium matrix composites Scr. Mater. 2003, 48, 713–717. [Google Scholar] [CrossRef]

- Liu, J.; Chen, X.; Wang, W.; Zhao, Y.; He, N. Effect of TiB(2) Nanoparticle Content on the Microstructure and Mechanical Properties of TiB(2)/Mg-4Al-1.5Si Composites. Materials 2023, 16, 2852. [Google Scholar] [CrossRef]

- Sun, Y.; Yang, C.; Zhang, B.; Fan, J.; Li, H.; Zhao, T.; Li, J. The aging behavior, microstructure and mechanical properties of AlN/AZ91 composite. J. Magnes. Alloys 2023, 11, 2458–2468. [Google Scholar] [CrossRef]

- Chen, J.; Bao, C.-G.; Wang, Y.; Liu, J.-L.; Suryanarayana, C. Microstructure and Lattice Parameters of AlN Particle-Reinforced Magnesium Matrix Composites Fabricated by Powder Metallurgy. Acta Metall. Sin. 2015, 28, 1354–1363. [Google Scholar] [CrossRef]

- Fu, H.M.; Zhang, M.X.; Qiu, D.; Kelly, P.M.; Taylor, J.A. Grain refinement by AlN particles in Mg–Al based alloys. J. Alloys Compd. 2009, 478, 809–812. [Google Scholar] [CrossRef]

- Yang, C.; Zhang, B.; Zhao, D.; Lü, H.; Zhai, T.; Liu, F. Microstructure and mechanical properties of AlN particles in situ reinforced Mg matrix composites. Mater. Sci. Eng. A 2016, 674, 158–163. [Google Scholar] [CrossRef]

- Xie, W.; Gao, Y.; Yang, H.; Zhou, J.; Zhao, J.; Guo, X.; Song, J.; Huang, G.; Jiang, B.; Pan, F. Microstructural evolution and increased high-temperature tensile strength of extruded and aged AlN/Al reinforced Mg-10Gd-3Y-1Zn composites. J. Alloys Compd. 2025, 1010, 177152. [Google Scholar] [CrossRef]

- Cao, G.; Choi, H.; Oportus, J.; Konishi, H.; Li, X. Study on tensile properties and microstructure of cast AZ91D/AlN nanocomposites. Mater. Sci. Eng. A 2008, 494, 127–131. [Google Scholar] [CrossRef]

- Katsarou, L.; Mounib, M.; Lefebvre, W.; Vorozhtsov, S.; Pavese, M.; Badini, C.; Molina-Aldareguia, J.M.; Jimenez, C.C.; Pérez Prado, M.T.; Dieringa, H. Microstructure, mechanical properties and creep of magnesium alloy Elektron21 reinforced with AlN nanoparticles by ultrasound-assisted stirring. Mater. Sci. Eng. A 2016, 659, 84–92. [Google Scholar] [CrossRef]

- Li, Y.; Gao, Y.; Zhang, X.; Song, Y.; Dong, Z.; Zhang, A.; Li, T.; Jiang, B.; Pan, F. Microstructure and Mechanical Properties of Mg-Al-La-Mn Composites Reinforced by AlN Particles. Materials 2024, 17, 3497. [Google Scholar] [CrossRef]

- GB/T228.1-2021; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. Standardization Administration of the People’s Republic of China: Beijing, China, 2010.

- GB/T228.2-2015; Metallic Materials—Tensile Testing—Part 2: Method of Test at Elevated Temperature. Standardization Administration of the People’s Republic of China: Beijing, China, 2015.

- Hou, X.; Wang, L.; Feng, Y.; Fu, Y.; Fan, R.; Guo, E. Effect of Al2Nd intermetallic phase on the microstructure and properties of Mg-Al-Nd alloys. J. Mater. Sci. 2023, 58, 11788–11803. [Google Scholar] [CrossRef]

- Su, M.; Zhang, J.; Feng, Y.; Bai, Y.; Wang, W.; Zhang, Z.; Jiang, F. Al-Nd intermetallic phase stability and its effects on mechanical properties and corrosion resistance of HPDC Mg-4Al-4Nd-0.2Mn alloy. J. Alloys Compd. 2017, 691, 634–643. [Google Scholar] [CrossRef]

- Wang, M.; Zhou, Y.; Chen, T.; Yang, H.; Tan, J.; Chen, X.; Pan, F. Tailoring the structure, mechanical, electronic, and thermodynamic properties of Al8Mn5 by doping Ti atom with different atomic site configurations. J. Mater. Res. Technol. 2023, 26, 4469–4482. [Google Scholar] [CrossRef]

- Wang, Y.; Freiberg, D.; Huo, Y.; Zhu, W.; Williams, R.; Li, M.; Wang, Y. Shapes of nano Al6Mn precipitates in Mn-containing Al-alloys. Acta Mater. 2023, 249, 118819. [Google Scholar] [CrossRef]

- Chen, J.; Bao, C.; Chen, F. Evolutions of microstructure and mechanical properties for Mg-Al/AlN composites under hot extrusion. Mater. Sci. Eng. A 2016, 667, 426–434. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, Y.; Peng, L.; Fu, P.; Huang, F.; Ding, W. Microstructure evolution and mechanical properties of an ultra-high strength casting Mg–15.6Gd–1.8Ag–0.4Zr alloy. J. Alloys Compd. 2014, 615, 703–711. [Google Scholar] [CrossRef]

- Penghuai, F.; Liming, P.; Haiyan, J.; Zhenyan, Z.; Chunquan, Z. Fracture behavior and mechanical properties of Mg–4Y–2Nd–1Gd–0.4Zr (wt.%) alloy at room temperature. Mater. Sci. Eng. A 2008, 486, 572–579. [Google Scholar] [CrossRef]

- Gao, L.; Chen, R.-S.; Han, E.-H. Fracture behavior of high strength Mg-Gd-Y-Zr magnesium alloy. T. Nonferr. Metal. Soc. 2010, 20, 1217–1221. [Google Scholar] [CrossRef]

- Cui, X.; Yu, Z.; Liu, F.; Du, Z.; Bai, P. Influence of secondary phases on crack initiation and propagation during fracture process of as-cast Mg-Al-Zn-Nd alloy. Mater. Sci. Eng. A 2019, 759, 708–714. [Google Scholar] [CrossRef]

- Wang, D.; Hu, M.; Sugiyama, S.; Ji, Z.; Xu, H.; Wang, Y. Microstructure evolution and hot extrusion behavior of AZ31-Nd magnesium alloy adopting AZ31 chips and Mg-Nd chips. Results Phys. 2019, 15, 102622. [Google Scholar] [CrossRef]

- He, S.M.; Zeng, X.Q.; Peng, L.M.; Gao, X.; Nie, J.F.; Ding, W.J. Microstructure and strengthening mechanism of high strength Mg–10Gd–2Y–0.5Zr alloy. J. Alloys Compd. 2007, 427, 316–323. [Google Scholar] [CrossRef]

- Maghzi, M.; Mirzadeh, H.; Mahmudi, R. Grain refinement and improved mechanical properties of as-cast Mg-3Gd alloy by Zr addition. J. Mater. Res. Technol. 2025, 35, 2346–2353. [Google Scholar] [CrossRef]

- Yang, H.; Zander, D.; Huang, Y.; Kainer, K.U.; Dieringa, H. Individual/synergistic effects of Al and AlN on the microstructural evolution and creep resistance of Elektron21 alloy. Mater. Sci. Eng. A 2020, 777, 139072. [Google Scholar] [CrossRef]

- Yang, B.; Wang, J.; Li, Y.; Barnett, M.; Llorca, J. Suppressed transformation of compression twins to double twins in Mg by activation of <a> non-basal slip. Scripta Mater. 2023, 235, 115620. [Google Scholar] [CrossRef]

- Jiang, L.; Jonas, J.J.; Luo, A.A.; Sachdev, A.K.; Godet, S. Twinning-induced softening in polycrystalline AM30 Mg alloy at moderate temperatures. Scr. Mater. 2006, 54, 771–775. [Google Scholar] [CrossRef]

- Wang, X.J.; Hu, X.S.; Nie, K.B.; Deng, K.K.; Wu, K.; Zheng, M.Y. Dynamic recrystallization behavior of particle reinforced Mg matrix composites fabricated by stir casting. Mater. Sci. Eng. A 2012, 545, 38–43. [Google Scholar] [CrossRef]

- Liang, S.; Ren, Q.; Li, X.; Luan, S.; Li, X.; Jin, P.; Wang, J. The dynamic recrystallization induced by Al2Nd and promoted by Al2RE in a hot compressed Mg–1Al-1.5Nd-1.5Y-0.5Gd alloy. J. Mater. Res. Technol. 2024, 33, 8232–8245. [Google Scholar] [CrossRef]

- Zhang, K.; Gao, Y.; Zhang, A.; Chen, Z.; Dong, Z.; Yang, Y.; Song, J.; Jiang, B.; Pan, F. Effects of nano-micron TiB2-Al2Y particles on the microstructural evolution and mechanical properties of extruded Mg-9Y-0.6La composites. Mater. Sci. Eng. A 2024, 913, 147016. [Google Scholar] [CrossRef]

- Wang, X.J.; Hu, X.S.; Wang, Y.Q.; Nie, K.B.; Wu, K.; Zheng, M.Y. Microstructure evolutions of SiCp/AZ91 Mg matrix composites during hot compression. Mater. Sci. Eng. A 2013, 559, 139–146. [Google Scholar] [CrossRef]

| Samples | YS/MPa | UTS/MPa | ε/% |

|---|---|---|---|

| AE42 | 86 ± 1 | 191 ± 2 | 12.1 ± 0.2 |

| 1.0 wt.% AlN/AE42 | 100 ± 2 | 199 ± 2 | 13.2 ± 0.2 |

| 2.0 wt.% AlN/AE42 | 107 ± 2 | 219 ± 1 | 13.8 ± 0.3 |

| 3.0 wt.% AlN/AE42 | 111 ± 4 | 203 ± 3 | 9.8 ± 0.3 |

| Temperature | Alloys | YS (MPa) | UTS (MPa) | ε (%) |

|---|---|---|---|---|

| 150 °C | AE42 | 70 ± 3 | 140 ± 2 | 11.4 ± 0.3 |

| 1.0 wt.% AlN/AE42 | 81 ± 3 | 171 ± 3 | 16.5 ± 0.4 | |

| 2.0 wt.% AlN/AE42 | 84 ± 2 | 178 ± 3 | 16.7 ± 0.3 | |

| 3.0 wt.% AlN/AE42 | 90 ± 3 | 164 ± 4 | 9.8 ± 0.5 | |

| 200 °C | AE42 | 62 ± 3 | 127 ± 3 | 13.0 ± 0.4 |

| 1.0 wt.% AlN/AE42 | 71 ± 2 | 147 ± 3 | 16.1 ± 0.3 | |

| 2.0 wt.% AlN/AE42 | 74 ± 2 | 152 ± 3 | 18.3 ± 0.4 | |

| 3.0 wt.% AlN/AE42 | 83 ± 4 | 147 ± 5 | 9.3 ± 0.5 | |

| 250 °C | AE42 | 54 ± 3 | 109 ± 2 | 10.8 ± 0.2 |

| 1.0 wt.% AlN/AE42 | 71 ± 2 | 134 ± 3 | 15.1 ± 0.4 | |

| 2.0 wt.% AlN/AE42 | 77 ± 3 | 139 ± 2 | 18.8 ± 0.3 | |

| 3.0 wt.% AlN/AE42 | 79 ± 5 | 139 ± 3 | 8.7 ± 0.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Zhang, K.; Gao, Y.; Zhang, A.; Zhao, J.; Li, Y.; Dong, Z.; Song, Y.; Li, T.; Jiang, B. Effect of Nano-AlN Particles on the Microstructure and Mechanical Properties of Mg-Al-Nd-Mn Alloy. Materials 2025, 18, 4104. https://doi.org/10.3390/ma18174104

Zhang X, Zhang K, Gao Y, Zhang A, Zhao J, Li Y, Dong Z, Song Y, Li T, Jiang B. Effect of Nano-AlN Particles on the Microstructure and Mechanical Properties of Mg-Al-Nd-Mn Alloy. Materials. 2025; 18(17):4104. https://doi.org/10.3390/ma18174104

Chicago/Turabian StyleZhang, Xiang, Kun Zhang, Yuyang Gao, Ang Zhang, Jing Zhao, Yuanlin Li, Zhihua Dong, Yan Song, Tian Li, and Bin Jiang. 2025. "Effect of Nano-AlN Particles on the Microstructure and Mechanical Properties of Mg-Al-Nd-Mn Alloy" Materials 18, no. 17: 4104. https://doi.org/10.3390/ma18174104

APA StyleZhang, X., Zhang, K., Gao, Y., Zhang, A., Zhao, J., Li, Y., Dong, Z., Song, Y., Li, T., & Jiang, B. (2025). Effect of Nano-AlN Particles on the Microstructure and Mechanical Properties of Mg-Al-Nd-Mn Alloy. Materials, 18(17), 4104. https://doi.org/10.3390/ma18174104