Fatigue Damage of Aluminum Alloy Overhead Line Conductors Initiated by Fretting

Abstract

1. Introduction

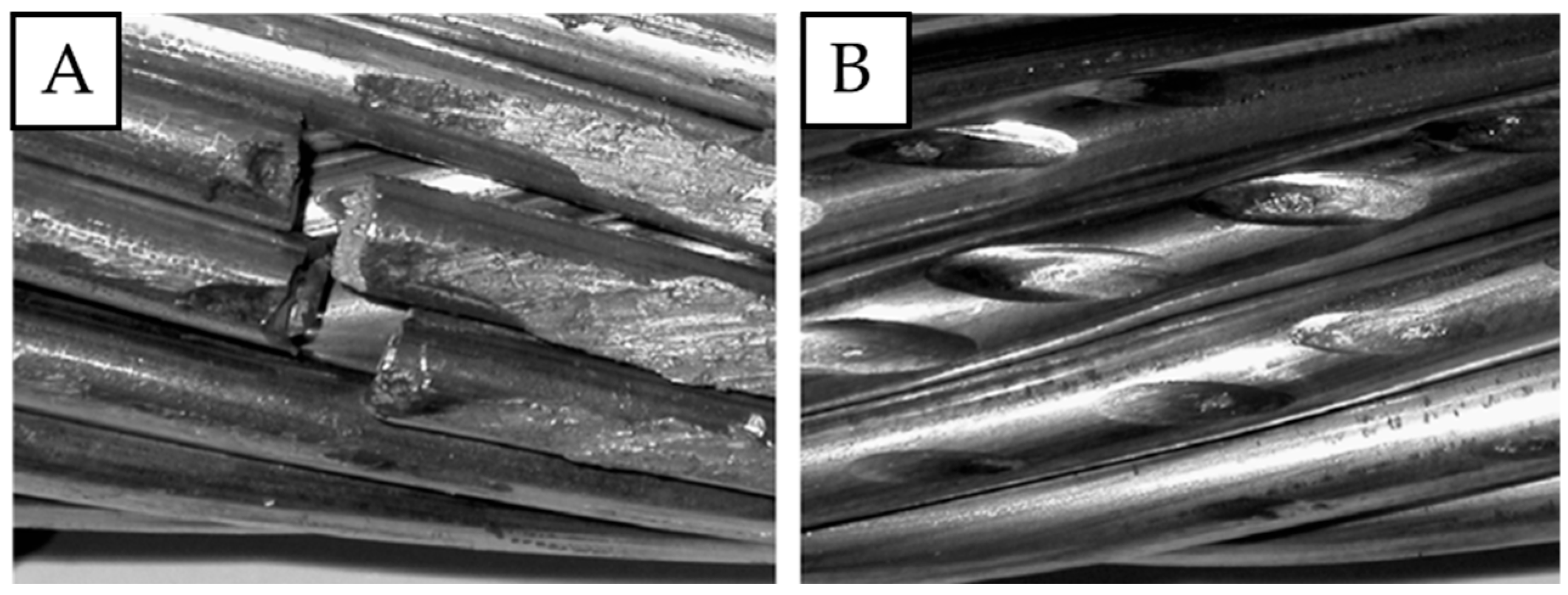

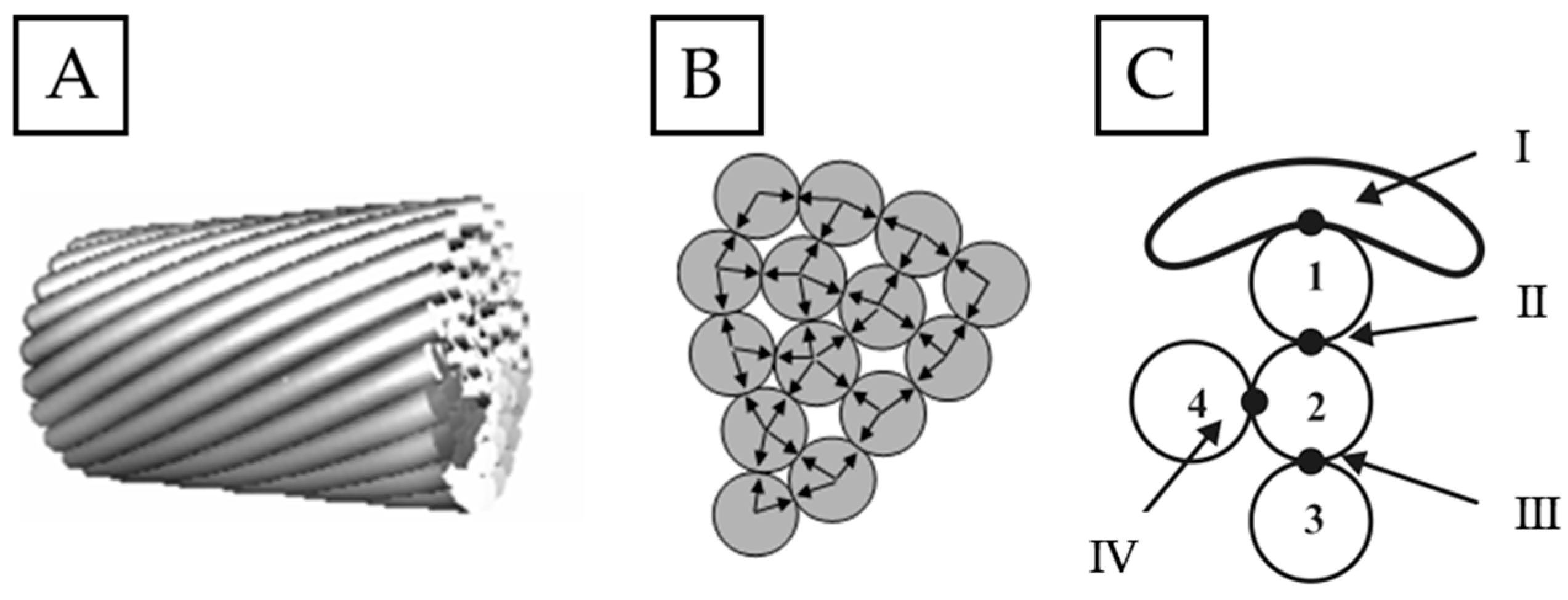

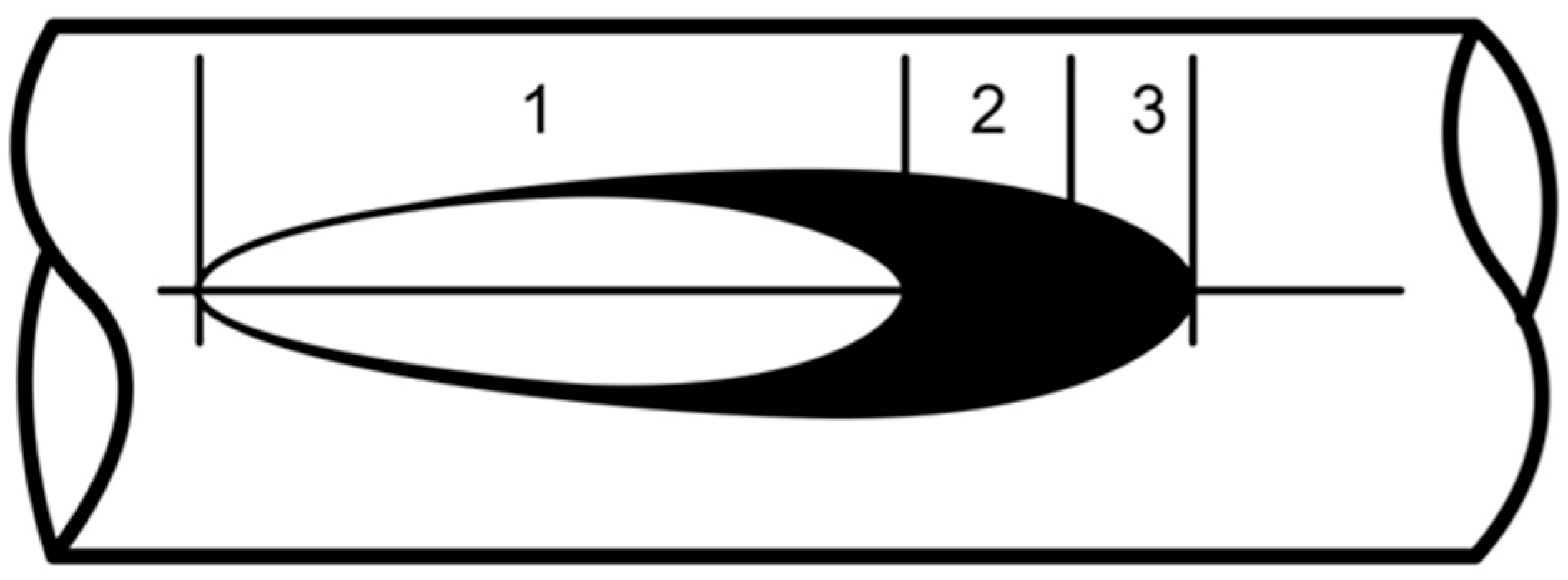

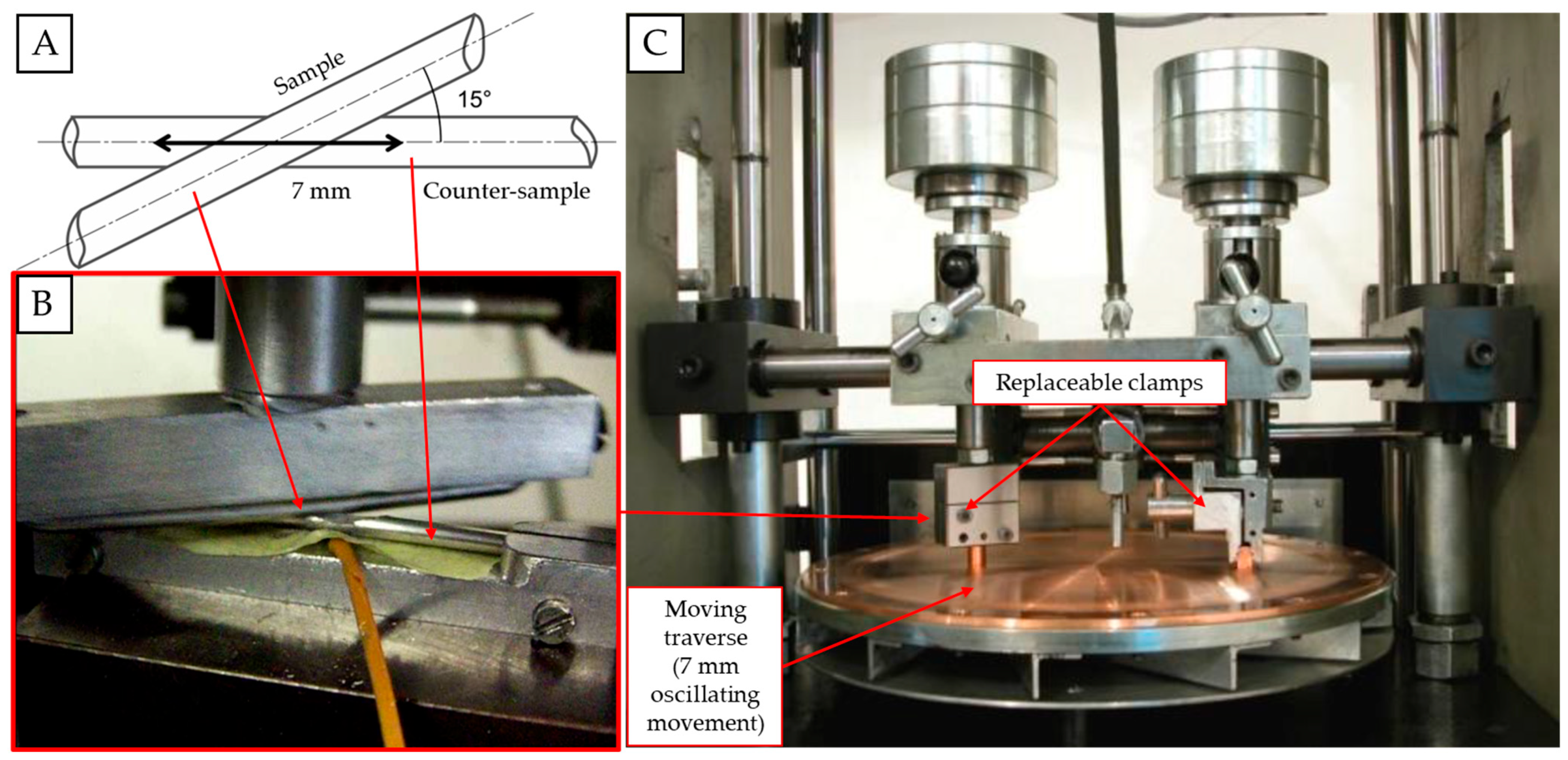

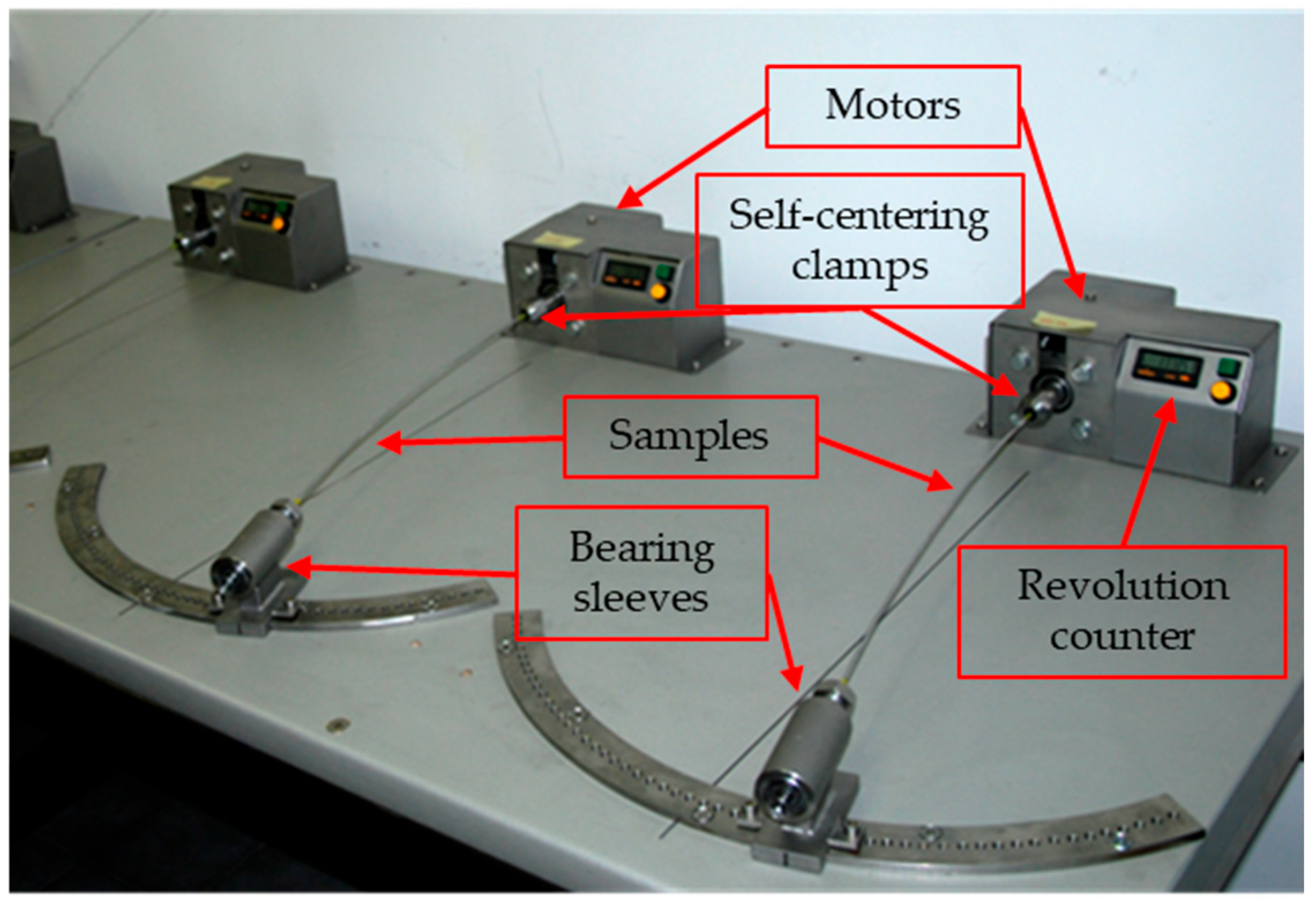

2. Mechanism of Fretting Formation

3. Materials and Methods

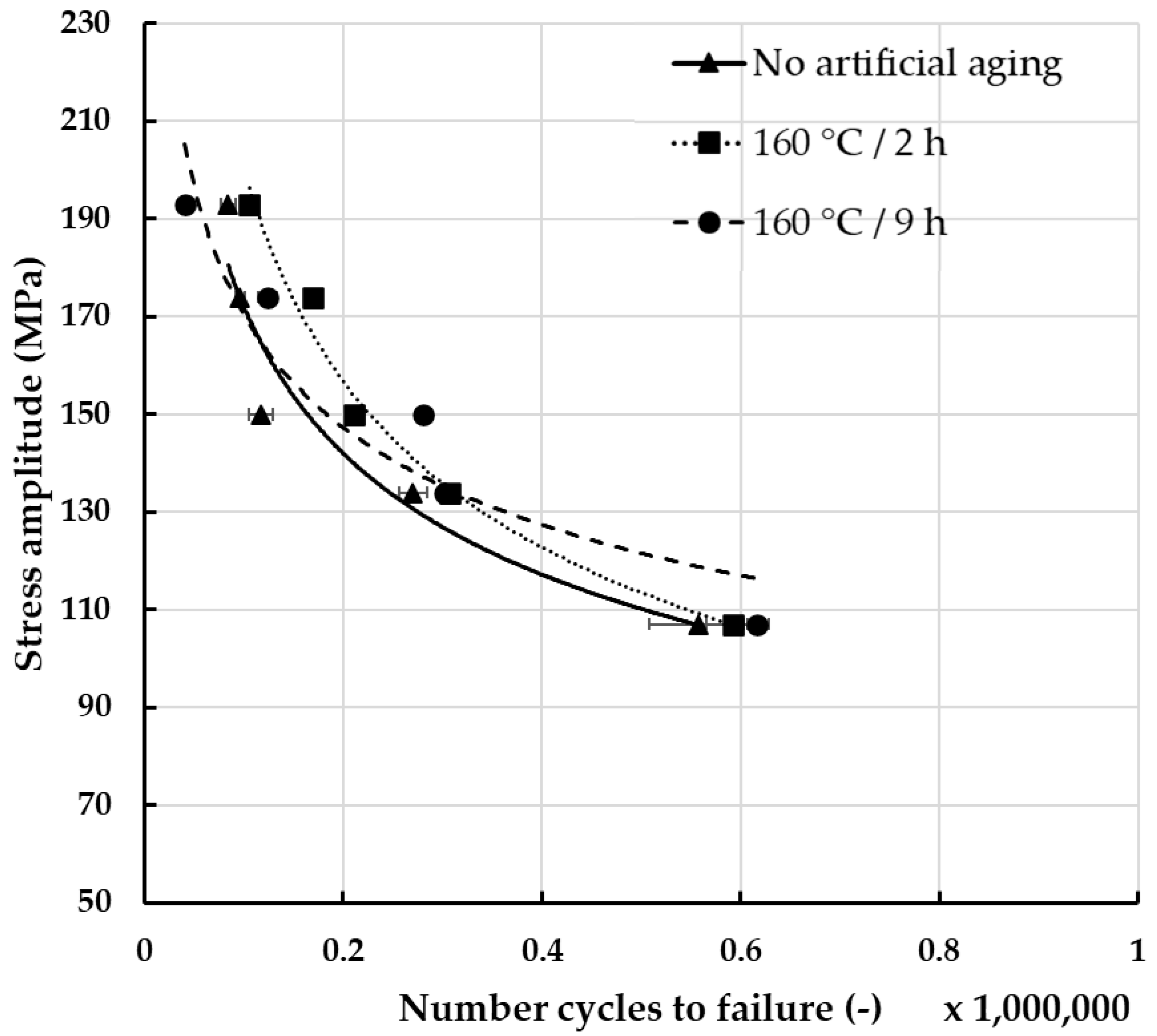

- Wires with no artificial aging;

- Wires subjected to artificial aging for 2 h in 160 °C;

- Wires subjected to artificial aging for 9 h in 160 °C.

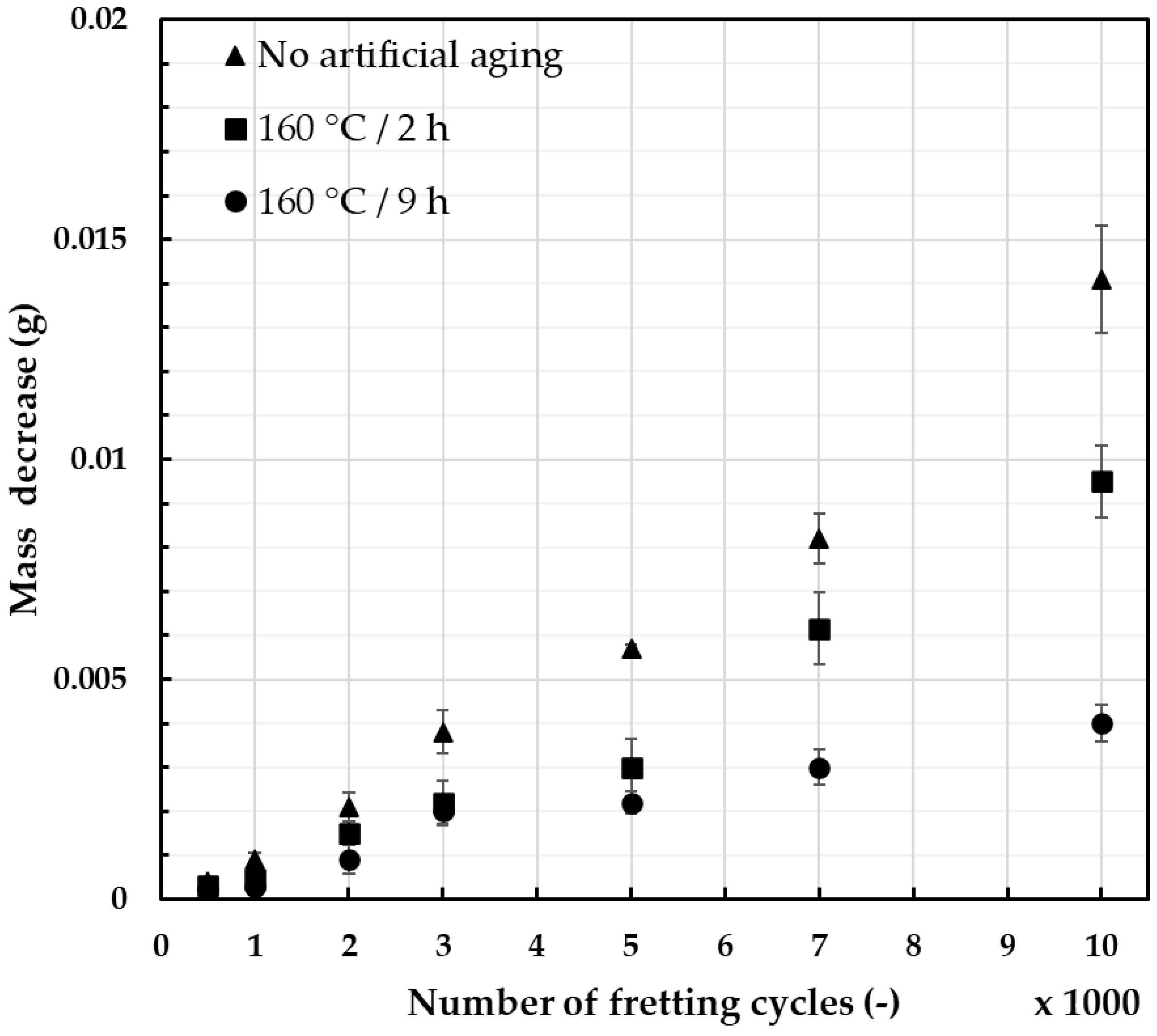

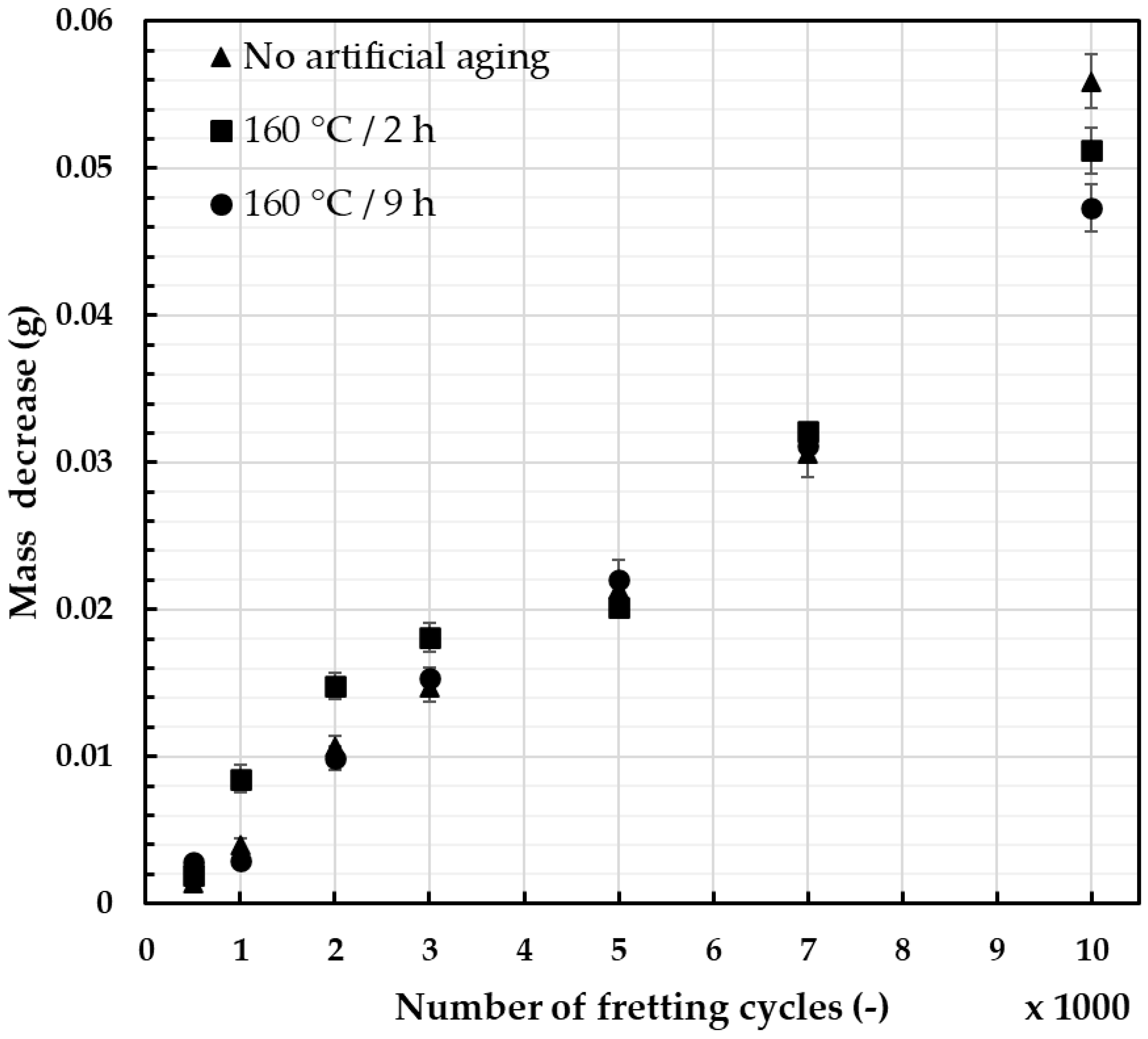

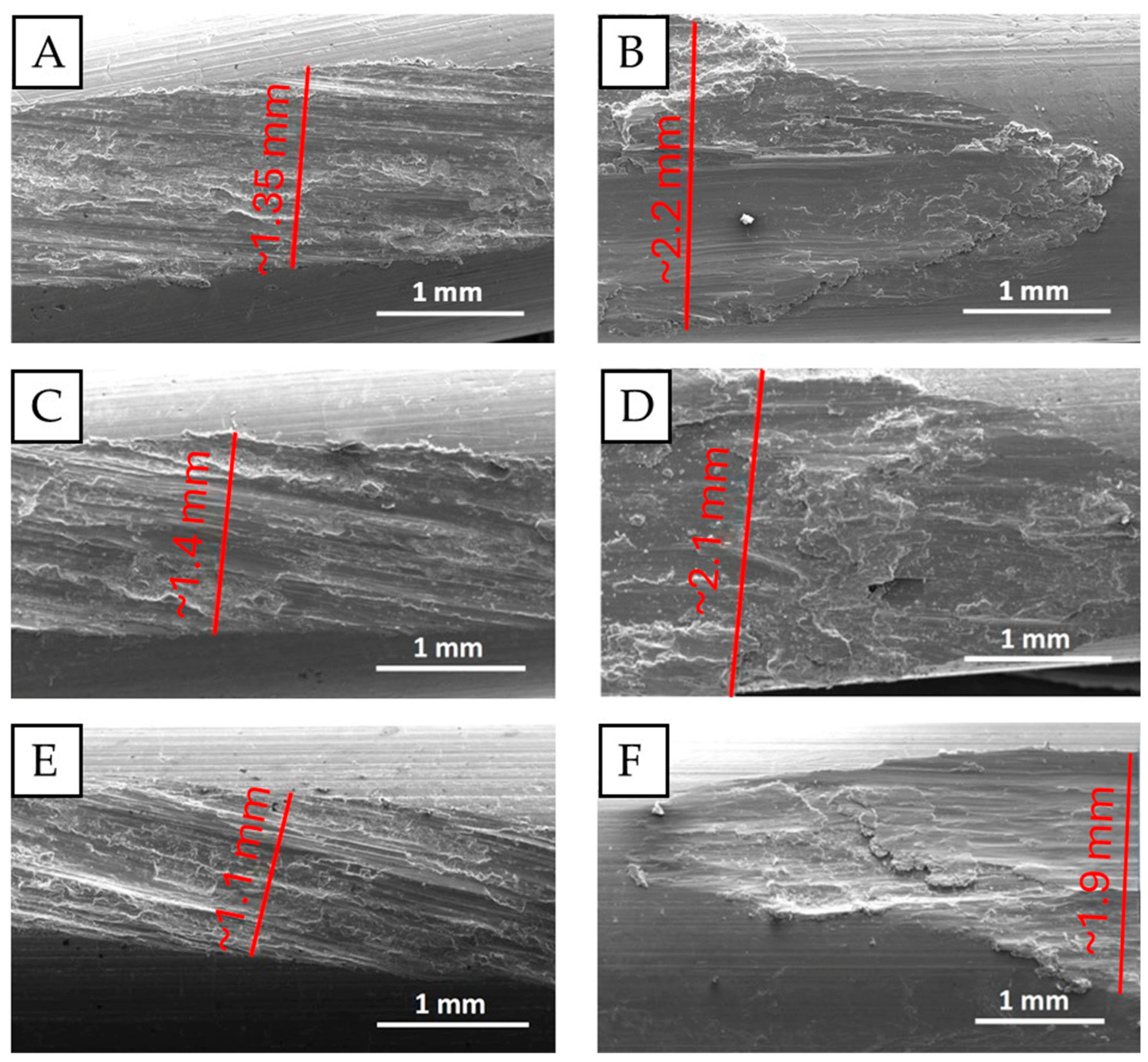

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Barani, M.; Loffler, K.; Crespo del Granado, P.; Moskalenko, N.; Panos, E.; Hoffart, F.M.; von Hirschhausen, C.; Kannavou, M.; Auer, H.; Hainsch, K.; et al. European energy vision 2050 and beyond: Designing scenarios for Europe’s energy transition. Renew. Sust. Energy Rev. 2026, 225, 116074. [Google Scholar] [CrossRef]

- Graabak, I.; Bakken, B.H. Scenarios for integration of large shares of renewable energy in Europe up to 2050. In Proceedings of the IEEE Trondheim PowerTech, Trondheim, Norway, 19–23 June 2011; pp. 1–8. [Google Scholar] [CrossRef]

- Ansari, D.; Holz, F. Anticipating global energy, climate and policy in 2055: Constructing qualitative and quantitative narratives. Energy Res. Soc. Sci. 2019, 58, 101250. [Google Scholar] [CrossRef]

- Gaillet, L.; Rondineau, A.; Langlois, S.; Demers, M.; Dieng, L. Microstructural and Mechanical Characterization of Corroded Aluminum Wires from ACSR Strand. Corros. Mater. Degrad. 2025, 6, 25. [Google Scholar] [CrossRef]

- Chen, X.; Han, M.; Yang, X.; Wang, B. Stability Analysis of Parametric Vibration in Overhead Conductors Under Time-Varying Tension. Symmetry 2025, 17, 464. [Google Scholar] [CrossRef]

- Ahsan, M.; Baharom, M.N.R.; Khalil, I.U.; Zainal, Z. Analysis of high-ampacity and low-sag conductors of 275 kV overhead transmission lines using reconductoring technique. Electr. Power Syst. Res. 2025, 246, 111719. [Google Scholar] [CrossRef]

- Yang, W.; Zheng, Z.; Huang, W.; Chen, D.; Yuan, J.; Yue, Y.; Sun, Z.; Sun, Q. Thermal analysis for multi-conductor bundle in high voltage overhead transmission lines under the effect of strong wind. Electr. Power Syst. Res. 2024, 231, 110308. [Google Scholar] [CrossRef]

- Zasadzińska, M. Fragmentation of Cu2O Oxides Caused by Various States of Stress Resulting from Extreme Plastic Deformation. Materials 2025, 18, 1736. [Google Scholar] [CrossRef]

- Zasadzińska, M.; Knych, T. The morphology of eutectic copper oxides I(Cu2O) in the processing of wire rod and wires made from ETP grade copper. Arch. Metall. Mater. 2019, 64, 1611–1616. [Google Scholar] [CrossRef]

- Walsh, F.C. Electrode Reactions in Metal Finishing. Trans. IMF 1991, 69, 107–110. [Google Scholar] [CrossRef]

- Davis, J.R. ASM Specialty Handbook: Copper and Copper Alloys; ASM International: Novelty, OH, USA, 2001; ISBN 978-087170-726-0. [Google Scholar]

- London Metal Exchange Official Website. Available online: https://www.lme.com/en/ (accessed on 6 August 2025).

- Strzępek, P.; Zasadzińska, M. Prospective cold metal working and analysis of deformation susceptibility of CuMg alloys with high magnesium content. Sci. Rep. 2024, 14, 6447. [Google Scholar] [CrossRef] [PubMed]

- Lunn, K.F.; Apelian, D. Thermal and Electrical Conductivity of Aluminum Alloys: Fundamentals, structure-property relationships, and pathways to enhance conductivity. Mater. Sci. Eng. A. 2025, 924, 147766. [Google Scholar] [CrossRef]

- Margita, F.; Beňa, Ľ.; Malska, W.; Pijarski, P. Possibilities of Increasing the Ampacity of Overhead Lines Using High-Temperature Low-Sag Conductors in the Electric Power System of the Slovak Republic. Appl. Sci. 2024, 14, 7846. [Google Scholar] [CrossRef]

- Jurkiewicz, B.; Smyrak, B.; Zasadzińska, M.; Franczak, K.; Strzępek, P. The researches of influence of strengthening on fatigue strength of aluminium wires for OHL conductors. Arch. Civ. Mech. Eng. 2019, 19, 862–870. [Google Scholar] [CrossRef]

- Martinova, Z.; Damagaliev, D.; Hirsh, M. The effect of room temperature pre-aging on tensile and electrical properties of thermomechanical treated AlMgSi alloy. J. Min. Metall. Sect. B. 2002, 38, 61–73. [Google Scholar] [CrossRef]

- Kalombo, R.B.; Martinez, J.M.G.; Ferreira, J.L.A.; da Silva, C.R.M.; Araujo, J.A. Comparative Fatigue Resistance of Overhead Conductors Made of Aluminium and Aluminium Alloy: Tests and Analysis. Procedia Eng. 2015, 133, 223–232. [Google Scholar] [CrossRef]

- Smyrak, B.; Jurkiewicz, B.; Zasadzińska, M.; Gniełczyk, M.; Jałowy, P. The Effect of Al-Mg-Si Wire Rod Heat Treatment on Its Electrical Conductivity and Strength. Metals 2020, 10, 1027. [Google Scholar] [CrossRef]

- Nowak, A. Wpływ Drgań Eolskich na Własności Eksploatacyjne Napowietrznych Przewodów Elektroenergetycznych ze Stopów AlMgSi. Ph.D. Thesis, AGH University of Krakow, Krakow, Poland, 2015. [Google Scholar]

- Kalombo, R.B.; Miranda, T.B.; Rocha, P.H.C.; Ferreira, J.L.A.; da Silva, C.R.M.; Araujo, J.A. Fatigue performance of overhead conductors tested under the same value of H/w parameter. Procedia Eng. 2018, 213, 346–358. [Google Scholar] [CrossRef]

- Knych, T. Elektroenergetyczne Przewody Napowietrzne Teoria—Materiały—Aplikacje; Wydawnictwa AGH: Kraków, Poland, 2010; ISBN 978-83-7464-250-7. [Google Scholar]

- Matos, I.M.; Araujo, J.A.; Castro, F.C. Fretting fatigue performance and life prediction of 1120 aluminum alloy wires of overhead conductors. Theor. Appl. Fract. Mech. 2022, 121, 103521. [Google Scholar] [CrossRef]

- Matos, I.M.; Araujo, J.A.; Castro, F.C. Life prediction of 6201-T81 aluminum alloy wires under fretting fatigue and variable amplitude loading. Tribol. Int. 2023, 183, 108407. [Google Scholar] [CrossRef]

- Omrani, A.; Langlois, S.; van Dyke, P.; Lalonde, S.; Karganroudi, S.S.; Dieng, L. Fretting fatigue life assessment of overhead conductors using a clamp/conductor numerical model and biaxial fretting fatigue tests on individual wires. Fatigue Fract. Eng. Mater. Struct. 2021, 44, 1498–1514. [Google Scholar] [CrossRef]

- Azevedo, C.R.F.; Henriques, A.M.D.; Pulino Filho, A.R.; Ferreira, J.L.A.; Araujo, J.A. Fretting fatigue in overhead conductors: Rig design and failure analysis of a Grosbeak aluminium cable steel reinforced conductor. Eng. Fail. Anal. 2009, 16, 136–151. [Google Scholar] [CrossRef]

- Ding, J.; Yang, L.; Liu, W. Failure Mechanism Research on Bending Fretting Fatigue of 6061-T6 Aluminum Alloy by Experiment and Finite Element Method. Materials 2023, 16, 4161. [Google Scholar] [CrossRef] [PubMed]

- Vingsbo, O.; Soderberg, S. On fretting maps. Wear 1988, 126, 131–147. [Google Scholar] [CrossRef]

- Knych, T.; Mamala, A.; Nowak, A.; Ściężor, W. Analysis of the causes of overhead conductor damages caused by fretting of wires during wind vibrations. In original Polish language Analiza przyczyn uszkodzeń przewodów napowietrznych powodowanych przez wzajemne zacieranie drutów w warunkach drgań wiatrowych. Hut. Wiadomości Hut. 2013, 80, 54–56. [Google Scholar]

- Smyrak, B.; Knych, T.; Mamala, A. Selected issues of rheological behaviour of AlMgSi wires in conditions of variable stress and temperature. In original Polish language Wybrane zagadnienia reologicznego zachowania się drutów ze stopu AlMgSi w warunkach zmiennego naprężenia i temperatury. Rudy I Met. Nieżelazne 2005, 50, 183–192. [Google Scholar]

- Poffenberger, J.C.; Swart, R.L. Differential Displacement and Dynamic Conductor Strain. IEEE Trans. Power Appar. Syst. 1965, 84, 281–289. [Google Scholar] [CrossRef]

- Poon, C.T.; Barret, R.A.; Leen, S.B. Global and local modeling for inter-wire fretting in multi-wire copper conductors. Fatigue Fract. Eng. Mater. Struct. 2022, 45, 1618–1634. [Google Scholar] [CrossRef]

- Poon, C.; O’Halloran, S.M.; Connolly, A.; Barret, R.A.; Leen, S.B. Fretting wear and fatigue in submarine power cable conductors for floating offshore wind energy. Tribol. Int. 2023, 186, 108598. [Google Scholar] [CrossRef]

- Poon, C.; Mhurchadha, S.U.; Barrett, R.A.; Leen, S.B. Three-dimensional representative modelling for fretting wear and fatigue of submarine power cable conductors. Int. J. Fatigue 2024, 184, 108302. [Google Scholar] [CrossRef]

- Wang, Y.; Yan, Z.; Wu, Y. Numerical Simulation of Fretting Fatigue Damage Evolution of Cable Wires Considering Corrosion and Wear Effects. Comput. Model. Eng. Sci. 2023, 136, 1339–1370. [Google Scholar] [CrossRef]

- Thomas, O.O.; Chouinard, L.; Langlois, S. Probabilistic Fatigue Fragility Curves for Overhead Transmission Line Conductor-Clamp Assemblies. Front. Built Environ. 2022, 8, 833167. [Google Scholar] [CrossRef]

- Ouaki, B.; Goudreau, S.; Cardou, A.; Fiset, M. Fretting fatigue analysis of aluminium conductor wires near the suspension clamp: Metallurgical and fracture mechanics analysis. J. Strain Anal. Eng. Design. 2003, 38, 133–147. [Google Scholar] [CrossRef]

- Kong, Y.; Bennet, C.J.; Hyde, C.J. A review of non-destructive testing techniques for the in-situ investigation of fretting fatigue cracks. Mater. Des. 2020, 196, 109093. [Google Scholar] [CrossRef]

- Kaimkuriya, A.; Sethuraman, B.; Gupta, M. Effect of Physical Parameters on Fatigue Life of Materials and Alloys: A Critical Review. Technologies 2024, 12, 100. [Google Scholar] [CrossRef]

- Zhu, X.; Chen, X. Fretting Fatigue Behavior under Tension–Bending Mixed-Mode Loading. Appl. Sci. 2024, 14, 4969. [Google Scholar] [CrossRef]

- Garcia, M.A.; Badibanga, R.K.; Araujo, J.A.; Ferreira, J.L.A.; da Silva, C.R.M. Fretting fatigue tests on 6201-T81 aluminum alloy conductor wires at room temperature and 75 °C. Wear 2024, 548–549, 205321. [Google Scholar] [CrossRef]

- Report, T.F. Investigation and Evaluation of Lightning Protective Methods for Distribution Circuits Part II: Application and Evaluation. IEEE Trans. Power Appar. Syst. 1969, PAS-88, 1239–1247. [Google Scholar] [CrossRef]

- Lindley, T.C. Fretting Wear and Fatigue in Overhead Electrical Conductor Cables. In Fretting Fatigue: Advances in Basic Understanding and Applications; Mutoh, Y., Hoeppner, D.W., Kinyon, S.E., Eds.; ASTM International: West Conshohocken, PA, USA, 2003; pp. 403–422. [Google Scholar] [CrossRef]

- Zeng, L.R.; Song, Z.M.; Wu, X.M.; Li, C.H.; Zhang, G.P. Fatigue cracking behavior of 6063 aluminum alloy for fitting clamps of overhead conductor lines. Mater. Des. 2015, 88, 478–484. [Google Scholar] [CrossRef]

- International Standard IEC 61089:1991; Round Wire Concentric Lay Overhead Electrical Stranded Conductors. International Electrotechnical Commission: Geneva, Switzerland, 1991.

- Ma, X.; Gao, L.; Zhang, J.; Zhang, L.-C. Fretting Wear Behaviors of Aluminum Cable Steel Reinforced (ACSR) Conductors in High-Voltage Transmission Line. Metals 2017, 7, 373. [Google Scholar] [CrossRef]

- MatWeb Material Property Data. Available online: https://www.matweb.com/ (accessed on 11 August 2025).

- Li, X.; Cui, X.; Liu, H.; Liu, J.; Cui, H.; Li, H.; Pan, Y.; Feng, R.; Man, Q. Influence of Mg and Si content and heat treatment on electrical conductivity and hardness of AA6101 Al alloy. J. Mater. Sci. 2023, 58, 8478–8488. [Google Scholar] [CrossRef]

- Sunde, J.K.; Marioara, C.D.; Wenner, S.; Holmestad, R. On the microstructural origins of improvements in conductivity by heavy deformation and ageing of Al-Mg-Si alloy 6101. Mater. Charact. 2021, 176, 111073. [Google Scholar] [CrossRef]

- Shaik, M.A.; Golla, B.R. Development of highly wear resistant Cu—Al alloys processed via powder metallurgy. Tribol. Int. 2019, 136, 127–139. [Google Scholar] [CrossRef]

- Yao, H.; Gong, J.; Cheng, S.; Liu, C.; Huang, H. Effects of Travel Speed on the Microstructure and Abrasion Resistance of Hardfacing Alloys Deposited with Composite Powder Particles and Solid Wire. Metals 2020, 10, 740. [Google Scholar] [CrossRef]

- Chao, L.; Jianxun, G.; Hongjiang, H. Effects of K2co3 Flux on the Microstructure and Abrasion Resistance of High-Chromium Hardfacing Alloys. Trans. Indian Inst. Met. 2022, 75, 3139–3148. [Google Scholar] [CrossRef]

- Medvedev, A.; Arutyunyan, A.; Lomakin, I.; Bondarenko, A.; Kazykhanov, V.; Enikeev, N.; Raab, G.; Murashkin, M. Fatigue Properties of Ultra-Fine Grained Al-Mg-Si Wires with Enhanced Mechanical Strength and Electrical Conductivity. Metals 2018, 8, 1034. [Google Scholar] [CrossRef]

- Jurkiewicz, B.; Smyrak, B. Studies on the Evolution of Fatigue Strength of Aluminium Wires for Overhead Line Conductors. Materials 2024, 17, 2537. [Google Scholar] [CrossRef] [PubMed]

- Rocha, P.H.C.; Langlois, S.; Lalonde, S.; Araujo, J.A.; Castro, F.C. Influence of 1350 and 6201 aluminum alloys on the fatigue life of overhead conductors—A finite element analysis. Tribol. Int. 2023, 186, 108661. [Google Scholar] [CrossRef]

- Sadaler, R.; Atasoy, S.; Arici, A.; Totik, Y. The Fretting Fatigue of Commercial Hard Anodized Aluminum Alloy. J. Mater. Eng. Perform. 2009, 18, 1280–1284. [Google Scholar] [CrossRef]

- Zhou, Z.; Liu, X.; He, G.; Liao, Y.; Liu, Y.; Li, Z.; Wang, Q. Fretting fatigue behavior and damage mechanism of cast Al-Si-Cu-T6 alloy under two surface roughness conditions. Int. J. Fatigue 2023, 175, 107765. [Google Scholar] [CrossRef]

- Ramakrishna Naiud, N.K.; Ganesh Sundara Raman, S. Effect of contact pressure on fretting fatigue behaviour of Al–Mg–Si alloy AA6061. Int. J. Fatigue 2005, 27, 283–291. [Google Scholar] [CrossRef]

- Zainuddin, N.M.; Rahman, M.A.; Kadir, M.A.; Ali, N.N.; Ali, Z.; Osman, M.; Mansor, M.; Ariffin, A.M.; Rahman, M.S.A.; Nor, S.F.M.; et al. Review of Thermal Stress and Condition Monitoring Technologies for Overhead Transmission Lines: Issues and Challenges. IEEE Access 2020, 8, 120053–120081. [Google Scholar] [CrossRef]

| Unit | Corresponding Values | ||||||

|---|---|---|---|---|---|---|---|

| Deflection arrow | mm | 125 | 112.5 | 100 | 87.5 | 75 | |

| Amplitude stress | MPa | 193 | 174 | 150 | 134 | 107 | |

| Element | Al | Mg | Si | Fe | Cu | Ti | Zn | Mn | Cr | V | B |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Nominal [47] | Min. 97.8 | 0.4–0.9 | 0.3–0.7 | Max. 0.4 | Max. 0.05 | Max. each 0.03; max. total 0.1 | |||||

| Measured | 98.66 | 0.57 | 0.58 | 0.19 | 0.001 | 0.002 | 0.002 | 0.002 | 0.001 | 0.004 | 0.009 |

| Source of Variation | SS | df | MS | F | p-Value | F Crit | |

|---|---|---|---|---|---|---|---|

| 2 N | Between Groups | 0.000036421 | 2 | 0.0000182 | 1.479438 | 0.25418 | 3.554557 |

| Within Groups | 0.000221563 | 18 | 0.0000123 | ||||

| Total | 0.000257984 | 20 | |||||

| 50 N | Between Groups | 0.000017172 | 2 | 0.0000086 | 0.029176 | 0.971292 | 3.554557 |

| Within Groups | 0.005297260 | 18 | 0.0002943 | ||||

| Total | 0.005314432 | 20 |

| Source of Variation | SS | df | MS | F | p-Value | F Crit | |

|---|---|---|---|---|---|---|---|

| No fretting | Between Groups | 647,575,506,551,821 | 2 | 323,787,753,275,911 | 1.006145 | 0.394487 | 3.885294 |

| Within Groups | 3,861,722,566,703,720 | 12 | 321,810,213,891,976 | ||||

| Total | 4,509,298,073,255,540 | 14 | |||||

| Fretting damage 50 N | Between Groups | 8,366,706,840 | 2 | 4,183,353,420 | 0.100261 | 0.905351 | 3.885294 |

| Within Groups | 500,696,114,340 | 12 | 41,724,676,195 | ||||

| Total | 509,062,821,180 | 14 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nowak, A.; Strzępek, P.; Korczak, P. Fatigue Damage of Aluminum Alloy Overhead Line Conductors Initiated by Fretting. Materials 2025, 18, 4103. https://doi.org/10.3390/ma18174103

Nowak A, Strzępek P, Korczak P. Fatigue Damage of Aluminum Alloy Overhead Line Conductors Initiated by Fretting. Materials. 2025; 18(17):4103. https://doi.org/10.3390/ma18174103

Chicago/Turabian StyleNowak, Andrzej, Paweł Strzępek, and Piotr Korczak. 2025. "Fatigue Damage of Aluminum Alloy Overhead Line Conductors Initiated by Fretting" Materials 18, no. 17: 4103. https://doi.org/10.3390/ma18174103

APA StyleNowak, A., Strzępek, P., & Korczak, P. (2025). Fatigue Damage of Aluminum Alloy Overhead Line Conductors Initiated by Fretting. Materials, 18(17), 4103. https://doi.org/10.3390/ma18174103