Controlling Residual Stress and Microstructure Distribution in an Invar Alloy Joint Fabricated by Oscillating Laser Welding

Abstract

1. Introduction

2. Experimental Procedures and Analytical Methods

2.1. Experimental Setup and Characterization

2.2. Finite Element Simulation Modeling

3. Results and Discussion

3.1. Weld Morphology

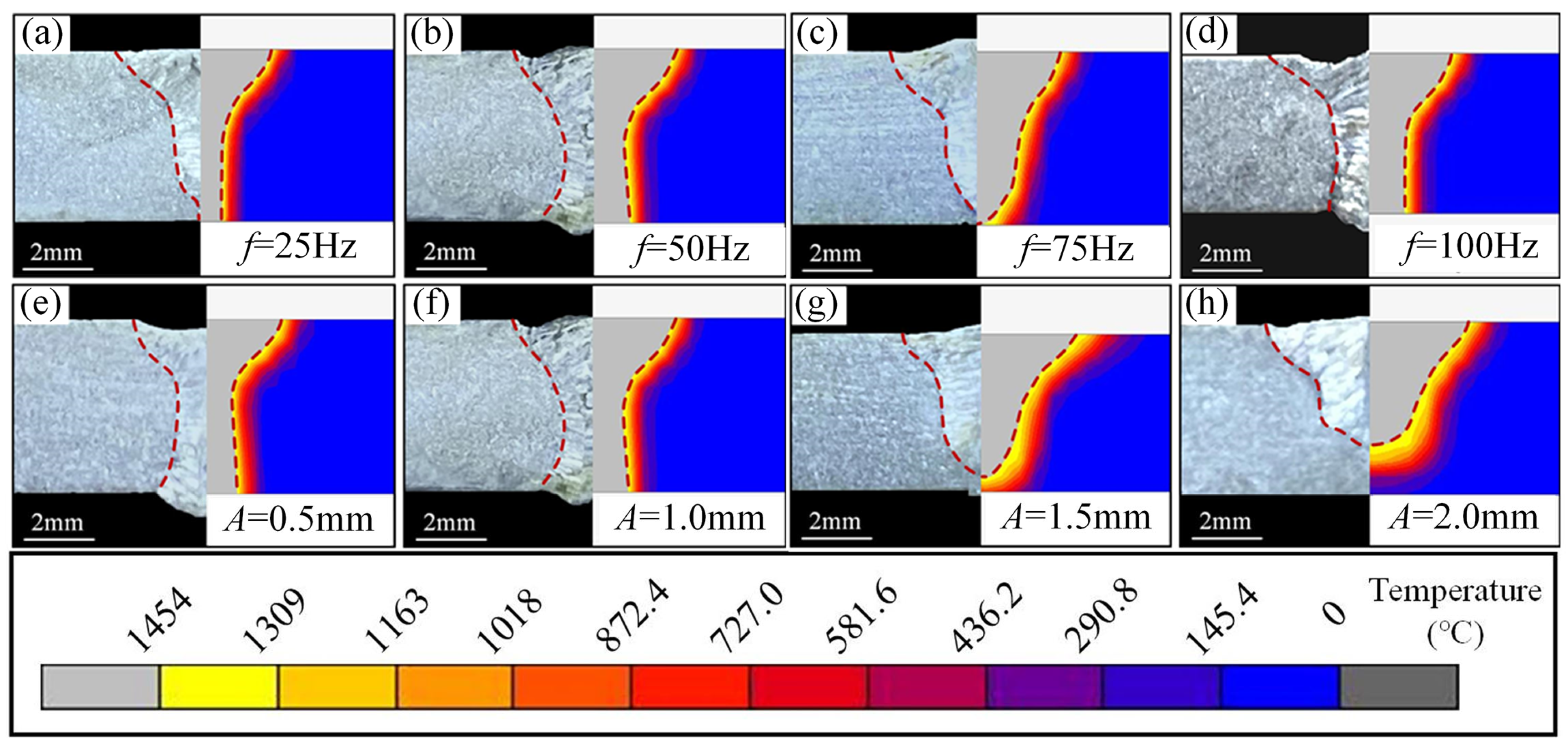

3.2. Temperature Field Distribution

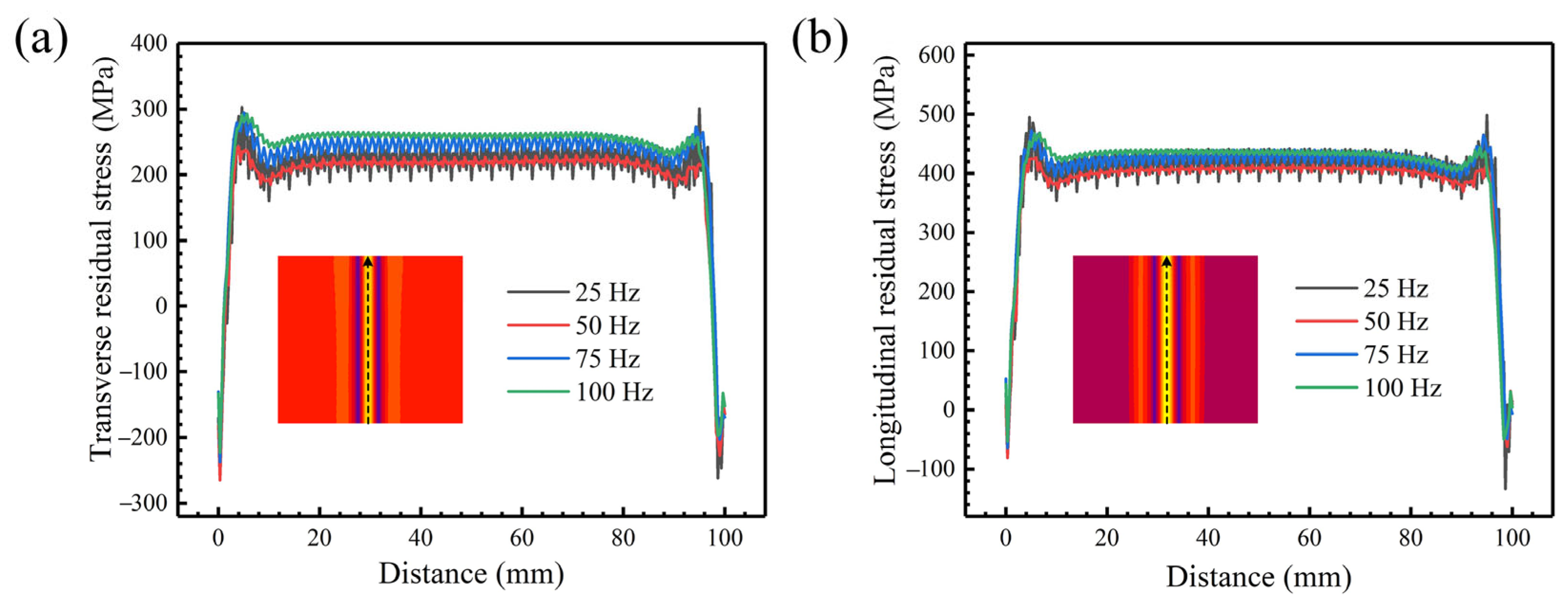

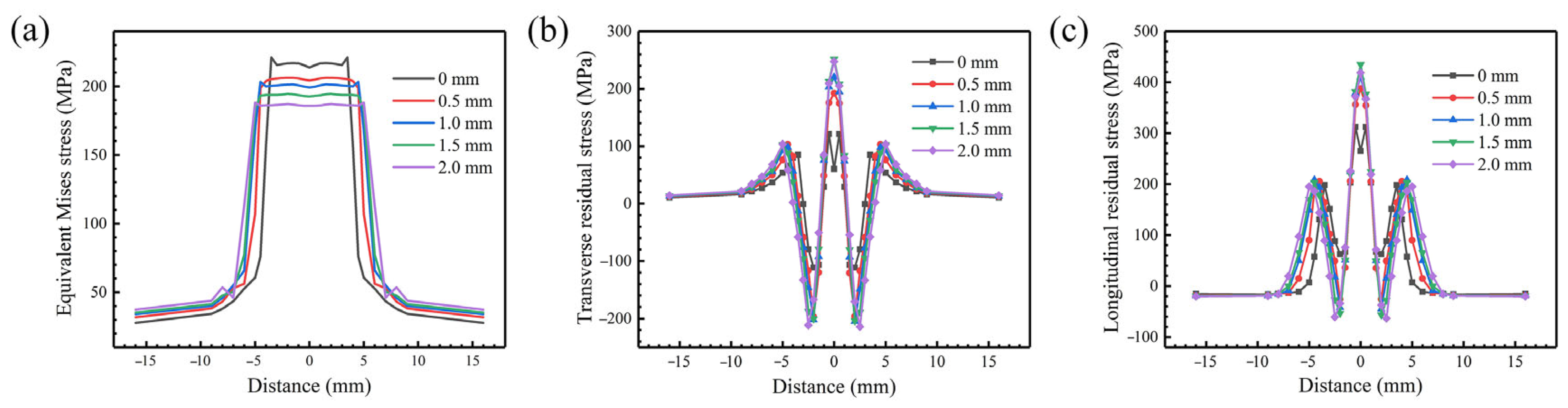

3.3. Residual Stress Field Distribution

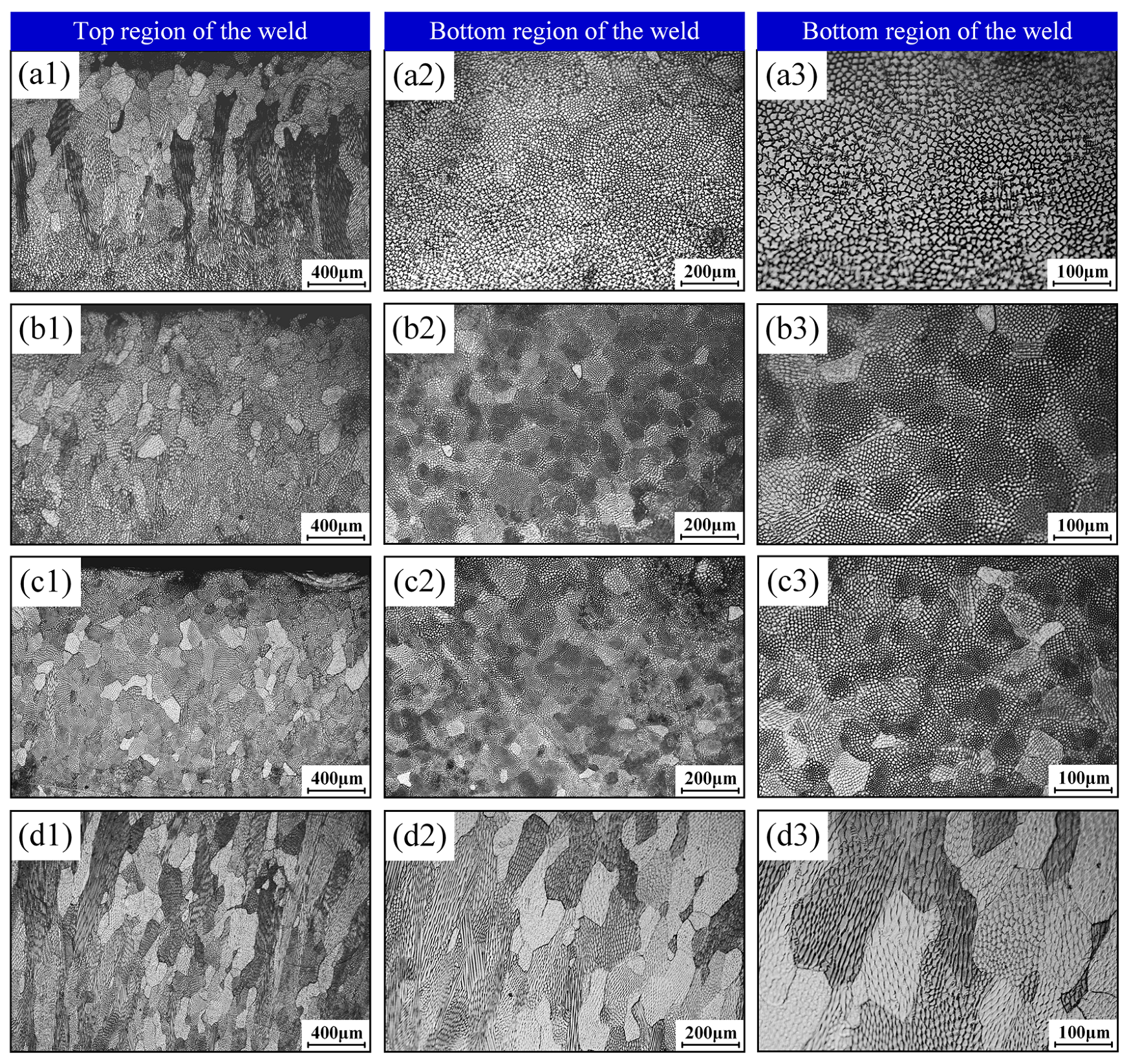

3.4. Microstructure and Tensile Property

4. Conclusions

- (1)

- The increasing of the oscillating frequency enhances the homogeneity of the temperature field. Concomitantly, the thermal histories at symmetrically positioned nodes converge, while the peak temperature at the molten pool center exhibits an initial decrease followed by an increase. Elevating the oscillating amplitude induces significant expansion of the molten pool. Furthermore, as the amplitude increases from 0.5 mm to 2.0 mm, the temperature gradient across the molten pool surface undergoes a continuous reduction, accompanied by a 29.0% decrease in the peak temperature at the monitored internal node.

- (2)

- An augmentation in either the oscillating frequency or amplitude demonstrably enhances the homogeneity of the equivalent stress distribution across the weld surface, concomitantly mitigating the maximum stress intensity observed. Specifically, along the centerline of the weld surface, pronounced fluctuations are observed in both transverse and longitudinal residual stresses. The range of these stress fluctuations diminishes with increasing oscillating frequency. Furthermore, the average stress level along this path is relatively low at an oscillating frequency of 50 Hz. Increasing the oscillating amplitude also contributes to a reduction in internal stress within the weldment.

- (3)

- The higher oscillation frequencies promote homogenized laser energy distribution and welding thermal fields, thereby improving microstructural uniformity throughout the weld. With increasing oscillation amplitude, a significant reduction in molten pool temperature gradient expands the constitutional supercooling zone, providing favorable conditions for equiaxed dendrite nucleation and growth. Consequently, isotropic near-equiaxed grains develop at the weld center, exhibiting homogeneous equiaxed dendritic structures internally. The tensile strength and elongation of the oscillating welded joint exhibit respective enhancements of 15.0% and 36.6% compared to the non-oscillating condition.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sahoo, A.; Medicherla, V.R.R. Fe-Ni Invar alloys: A review. Mater. Today Proc. 2021, 43, 2242–2244. [Google Scholar] [CrossRef]

- Wang, Q.; Dong, Y.W.; Jiang, Z.H.; Jiang, Z.H.; Huang, J. Enhancing low thermal expansion behavior and strength via induced Zr-rich intermetallic phase in Fe-36Ni Invar alloy. Mater. Des. 2023, 226, 111644. [Google Scholar] [CrossRef]

- Erden, F.; Akgul, B.; Dannaci l Oner, M. Thermoelectric and thermomechanical properties of invar 36: Comparison with common thermoelectric materials. J. Alloys Compd. 2023, 932, 167690. [Google Scholar] [CrossRef]

- Zhan, X.H.; Liu, X.B.; Wei, Y.H.; Chen, J.C.; Chen, J.; Liu, H.B. Microstructure and property characteristics of thick Invar alloy plate joints using weave bead welding. J. Mater. Process. Technol. 2017, 244, 97–105. [Google Scholar] [CrossRef]

- Otte, W.H.; O’Donnell, D.B.; Kiser, S.D.; Cox, C.W. Welding low thermal expansion alloys for aircraft composite tooling. Weld. J. 1996, 75, 51–55. [Google Scholar]

- Sood, A.; Schimmel, J.; Ferreira, V.M.; Bosman, M.; Goulas, C.; Popovich, V.; Hermans, M.J. Directed energy deposition of Invar 36 alloy using cold wire pulsed gas tungsten arc welding: Effect of heat input on the microstructure and functional behaviour. J. Mater. Res. Technol. 2022, 25, 6183–6197. [Google Scholar] [CrossRef]

- Su, Y.; Yang, X.W.; Wu, D.; Meng, T.X.; Li, W.Y.; Feng, W.Y.; Vairis, A. Optimizing welding sequence of TIG cross-joint of Invar steel using residual stresses and deformations. J. Manuf. Process. 2023, 105, 232–245. [Google Scholar] [CrossRef]

- Schultz, V.; Seefeld, T.; Vollertsen, F. Gap Bridging Ability in Laser Beam Welding of Thin Aluminum Sheets. Phys. Procedia 2014, 56, 545–553. [Google Scholar] [CrossRef]

- Fetzer, F.; Sommer, M.; Weber, R.; Weberpals, J.P.; Graf, T. Reduction of pores by means of laser beam oscillation during remote welding of AlMgSi. Opt. Lasers Eng. 2018, 108, 68–77. [Google Scholar] [CrossRef]

- Hagenlocher, C.; Sommer, M.; Fetzer, F.; Weber, R.; Graf, T. Optimization of the solidification conditions by means of beam oscillation during laser beam welding of aluminum. Mater. Des. 2018, 160, 1178–1185. [Google Scholar] [CrossRef]

- Zhou, J.F.; Zhou, D.W.; Liu, J.S. Effect of oscillating laser beam on the interface and mechanical properties of Ti/Al fusion welding joint. J. Mater. Res. Technol. 2022, 19, 1993–2007. [Google Scholar] [CrossRef]

- Gong, J.F.; Li, L.Q.; Meng, S.H.; Huang, R.S.; Zou, J.P.; Cao, H. Study on stability and microstructure properties of oscillating laser welded 5A06 alloy with narrow gap. Opt. Laser Technol. 2022, 155, 108360. [Google Scholar] [CrossRef]

- Wang, Z.M.; Oliveira, J.P.; Zeng, Z.; Bu, X.Z.; Peng, B.; Shao, X.Y. Laser beam oscillating welding of 5A06 aluminum alloys: Microstructure, porosity and mechanical properties. Opt. Laser Technol. 2019, 111, 58–65. [Google Scholar] [CrossRef]

- Choi, K.D.; Ahn, Y.N.; Kim, C. Weld strength improvement for Al alloy by using laser weaving method. J. Laser Appl. 2010, 22, 116–119. [Google Scholar] [CrossRef]

- Jin, J.; Geng, S.N.; Jiang, P.; Ren, L.Y.; Han, C.; Li, Y.T. Solidification cracking inhibition mechanism of 2024 Al alloy during oscillating laser-arc hybrid welding based on Zr-core-Al-shell wire. J. Mater. Sci. Technol. 2025, 217, 153–168. [Google Scholar] [CrossRef]

- Yan, S.H.; Meng, Z.; Chen, B.; Tan, C.W.; Song, X.G.; Wang, G.D. Experimental study on the grain evolution induced by thermal characteristics during oscillation laser welding of IN718. Mater. Lett. 2022, 323, 132581. [Google Scholar] [CrossRef]

- Yang, L.F.; Chen, X. Effect of post-weld heat treatment methods on microstructure and fatigue behavior of Al-Mg-Si alloy oscillating laser welding. Mater. Today Commun. 2024, 39, 109078. [Google Scholar] [CrossRef]

- Cai, J.S.; Wei, Y.H.; Ouyang, Z.P.; Liu, X.; Jin, H.X.; Chen, J.C. Investigation on clockwise circular oscillating laser welding for the 5A06-H112 aluminum alloy: Energy distribution, seam appearance, microstructure, and mechanical properties. Opt. Laser Technol. 2024, 176, 111026. [Google Scholar] [CrossRef]

- Chen, L.; Mi, G.Y.; Zhang, X.; Wang, C.M. Effects of sinusoidal oscillating laser beam on weld formation, melt flow and grain structure during aluminum alloys lap welding. J. Mater. Process. Technol. 2021, 298, 117314. [Google Scholar] [CrossRef]

- Geng, S.N.; Yang, W.; Jiang, P.; Han, C.; Ren, L.Y. Numerical study of keyhole dynamics and porosity formation during high-power oscillating laser welding of medium-thick aluminum alloy plates. Int. J. Heat Mass Transf. 2022, 194, 123084. [Google Scholar] [CrossRef]

- Han, C.; Jiang, P.; Geng, S.N.; Kun, L. Nucleation mechanism in oscillating laser welds of 2024 aluminium alloy: A combined experimental and numerical study. Opt. Laser Technol. 2023, 158, 108812. [Google Scholar]

- Jiang, Z.G.; Chen, X.; Li, H.; Lei, Z.L.; Chen, Y.B.; Wu, S.B.; Wang, Y.H. Grain refinement and laser energy distribution during laser oscillating welding of Invar alloy. Mater. Des. 2020, 186, 108195. [Google Scholar] [CrossRef]

- Ke, W.C.; Bu, X.Z.; Oliveira, J.P.; Xu, W.G.; Wang, Z.M.; Zeng, Z. Modeling and numerical study of keyhole-induced porosity formation in laser beam oscillating welding of 5A06 aluminum alloy. Opt. Laser Technol. 2021, 133, 106540. [Google Scholar] [CrossRef]

- Ai, Y.W.; Yu, L.; Huang, Y.; Liu, X.Y. The investigation of molten pool dynamic behaviors during the “∞” shaped oscillating laser welding of aluminum alloy. Int. J. Therm. Sci. 2022, 173, 107350. [Google Scholar] [CrossRef]

- Cai, C.; Yu, J.; Chen, Z.L.; Li, Z.X.; Chen, H.; Tang, P.; Xiong, F.S. Welding process stability in narrow-gap oscillating laser-MIG hybrid welding of titanium alloys with various oscillating patterns. J. Manuf. Process. 2025, 133, 151–162. [Google Scholar] [CrossRef]

- Yan, S.H.; Meng, Z.; Chen, B.; Tan, C.W.; Song, X.G.; Wang, G.D. Prediction of temperature field and residual stress of oscillation laser welding of 316LN stainless steel. Opt. Laser Technol. 2022, 145, 107493. [Google Scholar] [CrossRef]

- Wang, Z.Y.; Yang, P.Q.; Liao, W.; Jiang, L.H.G.; Zhao, S.N.; Liu, Y.X.; Gao, M. Stresses numerical analysis of oscillating laser welding in aluminum alloys based on the equivalent fluid–structure interactions model. Opt. Laser Technol. 2025, 191, 113365. [Google Scholar] [CrossRef]

- Yi, Y.Z.; Wang, H.; Huang, Y.; Rong, Y.M.; Xu, J.J.; Jiang, W. Properties and deformation of 0.2 mm-thick TC4 overlap welded joint by laser oscillating welding. Opt. Laser Technol. 2025, 190, 113197. [Google Scholar] [CrossRef]

- Cai, C.; Liu, Y.H.; Wang, E.H.; Chen, H.; Chen, Z.L. Mechanisms of gap bridging and hump suppression in oscillating laser-arc hybrid welding of thick plate steel under variable gap conditions. J. Mater. Process. Technol. 2025, 339, 118819. [Google Scholar] [CrossRef]

- Sanati, S.; Nabavi, S.F.; Farshidianfar, A. Laser wobble welding modeling process: A comprehensive review of fundamentals, methods, heating, and solidification modes. J. Manuf. Process. 2024, 131, 1703–1739. [Google Scholar] [CrossRef]

- Wang, L.B.; Xu, T.Y.; Zhu, Z.W.; Zhang, L.; Mi, G.Y.; Ma, X.Q. Effects of a new dual-beam oscillating laser welding technique for aluminum alloy joints: Microstructure, properties, and formation mechanism. J. Mater. Process. Technol. 2025, 340, 118883. [Google Scholar] [CrossRef]

- Zhao, J.Y.; Wang, J.Y.; Kang, X.F.; Wang, X.M.; Zhan, X.H. Effect of beam oscillation and oscillating frequency induced heat accumulation on microstructure and mechanical property in laser welding of Invar alloy. Opt. Laser Technol. 2022, 158, 108831. [Google Scholar] [CrossRef]

- Pavan, A.R.; Arivazhagan, B.; Vasudevan, M.; Govind, K.S. Numerical simulation and validation of residual stresses and distortion in type 316L(N) stainless steel weld joints fabricated by advanced welding techniques. CIRP J. Manuf. Sci. Technol. 2022, 39, 294–307. [Google Scholar] [CrossRef]

| Material | C | P | S | Si | Mn | Ni | Fe |

| Invar36 | ≤0.05 | ≤0.02 | ≤0.02 | ≤0.3 | ≤0.6 | 35.0–37.0 | Bal. |

| Parameter | Value |

|---|---|

| Laser power (W) | 4500 |

| Welding speed (m/min) | 1.2 |

| Defocus amount (mm) | 0 |

| Oscillating frequency (Hz) | 25, 50, 75, 100 |

| Oscillating amplitude (mm) | 0.5, 1.0, 1.5, 2.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, Y.; Liu, X.; Chen, S.; Zhou, K.; Zhao, Y.; Zhan, X. Controlling Residual Stress and Microstructure Distribution in an Invar Alloy Joint Fabricated by Oscillating Laser Welding. Materials 2025, 18, 4099. https://doi.org/10.3390/ma18174099

Jiang Y, Liu X, Chen S, Zhou K, Zhao Y, Zhan X. Controlling Residual Stress and Microstructure Distribution in an Invar Alloy Joint Fabricated by Oscillating Laser Welding. Materials. 2025; 18(17):4099. https://doi.org/10.3390/ma18174099

Chicago/Turabian StyleJiang, Yi, Xing Liu, Suming Chen, Kun Zhou, Yanqiu Zhao, and Xiaohong Zhan. 2025. "Controlling Residual Stress and Microstructure Distribution in an Invar Alloy Joint Fabricated by Oscillating Laser Welding" Materials 18, no. 17: 4099. https://doi.org/10.3390/ma18174099

APA StyleJiang, Y., Liu, X., Chen, S., Zhou, K., Zhao, Y., & Zhan, X. (2025). Controlling Residual Stress and Microstructure Distribution in an Invar Alloy Joint Fabricated by Oscillating Laser Welding. Materials, 18(17), 4099. https://doi.org/10.3390/ma18174099