Experimental Investigation of the Effect of Nano Silica Fume on Durability of Concrete with Close-Packing Aggregate

Abstract

1. Introduction

2. Materials and Methods

2.1. Characteristics of Experimental Materials

2.2. Mixing Procedure and Specimen Preparation

2.3. Experimental Test Details

- (1)

- At the testing age, specimens were submerged in water that was kept at (20 ± 2) °C. The lower portions of the specimens were raised so that the water surface was at least 25 mm over the tops of the specimens. Specimens were removed from the water after 24 h, their saturated surface-dry masses were weighed, and surface moisture was removed using a wrung-out damp cloth. After that, the specimens were submerged once more for 24 h, repeating the previous procedures. The immersion was stopped when the mass change between two consecutive 24 h immersion intervals was less than 0.2% of the bigger value, after it had been continuing for at least 48 h. It was noted that the final saturated surface-dry mass was ms.

- (2)

- The samples were put in a drying oven with forced air that was kept at (105 ± 5) °C. Following a 24 h drying period, the samples were removed and allowed to cool to ambient temperature in a desiccator, and their oven-dry masses were measured. Following that, the drying procedure was repeated for a further twenty-four hours. After at least 48 h, the drying process was stopped when the mass change between two 24 h drying intervals was less than 0.2% of the smaller value. It was noted that the final oven-dry mass was md.

- (1)

- After being cured for 26 days, the test specimens were taken out, the surface moisture was wiped off, and they were then kept in an oven set at (80 ± 5) °C for 48 h. They were then allowed to cool to ambient temperature in a dry setting after drying.

- (2)

- The cooled specimens were submerged in a 5% Na2SO4 solution that had been prepared, with the solution level at least 20 mm above the specimen surfaces. After 15 h of soaking, the specimens were taken out and allowed to air dry for one additional hour. After that, they were put in an oven that was set at (80 ± 5) °C and left there for six hours to dry. Following drying, the samples were taken out and allowed to cool for two hours before being submerged once again in the 5% Na2SO4 solution to finish a 24 h dry–wet cycle.

3. Results and Discussion

3.1. Long-Term Mechanical Properties

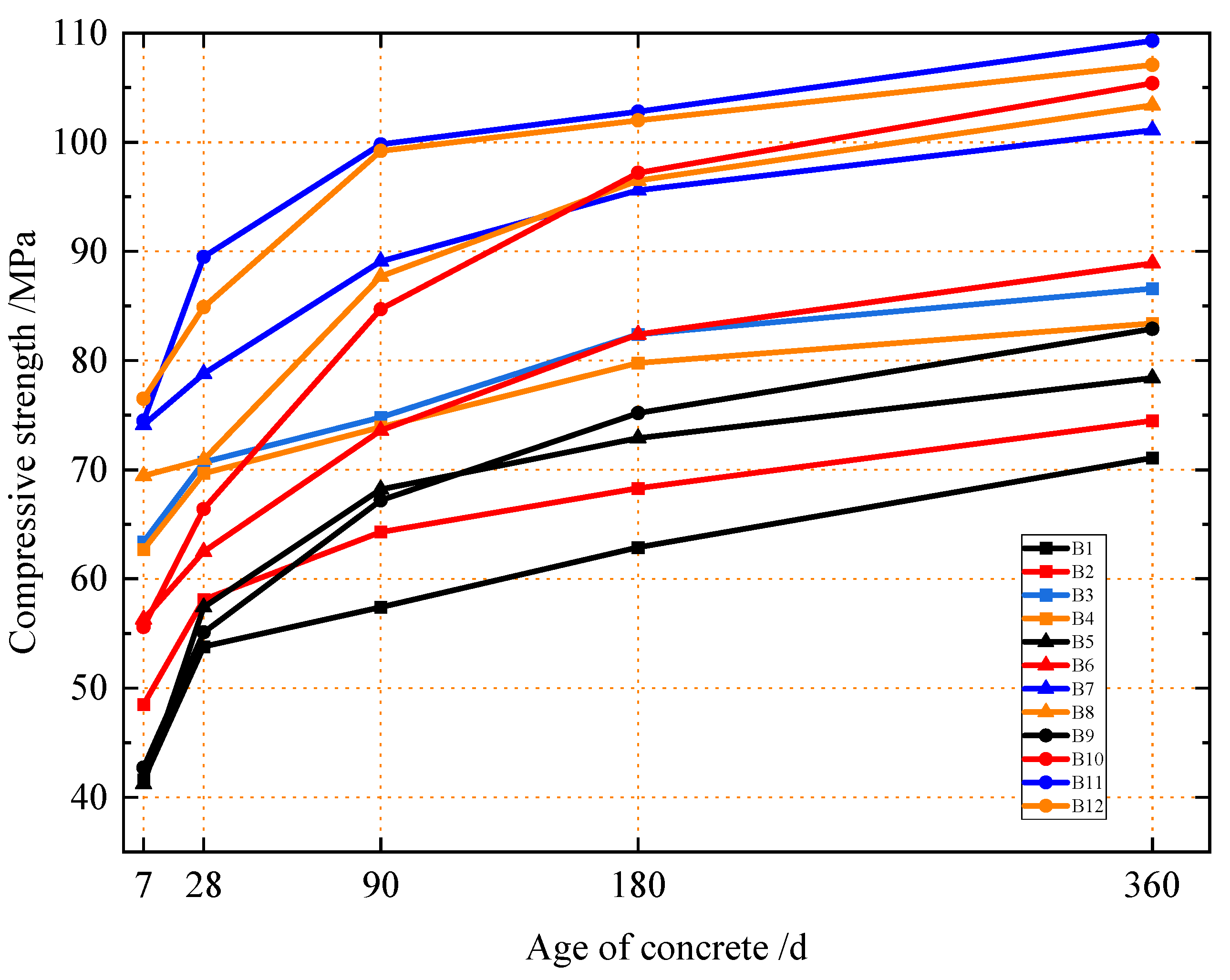

3.1.1. Long-Term Compressive Strength

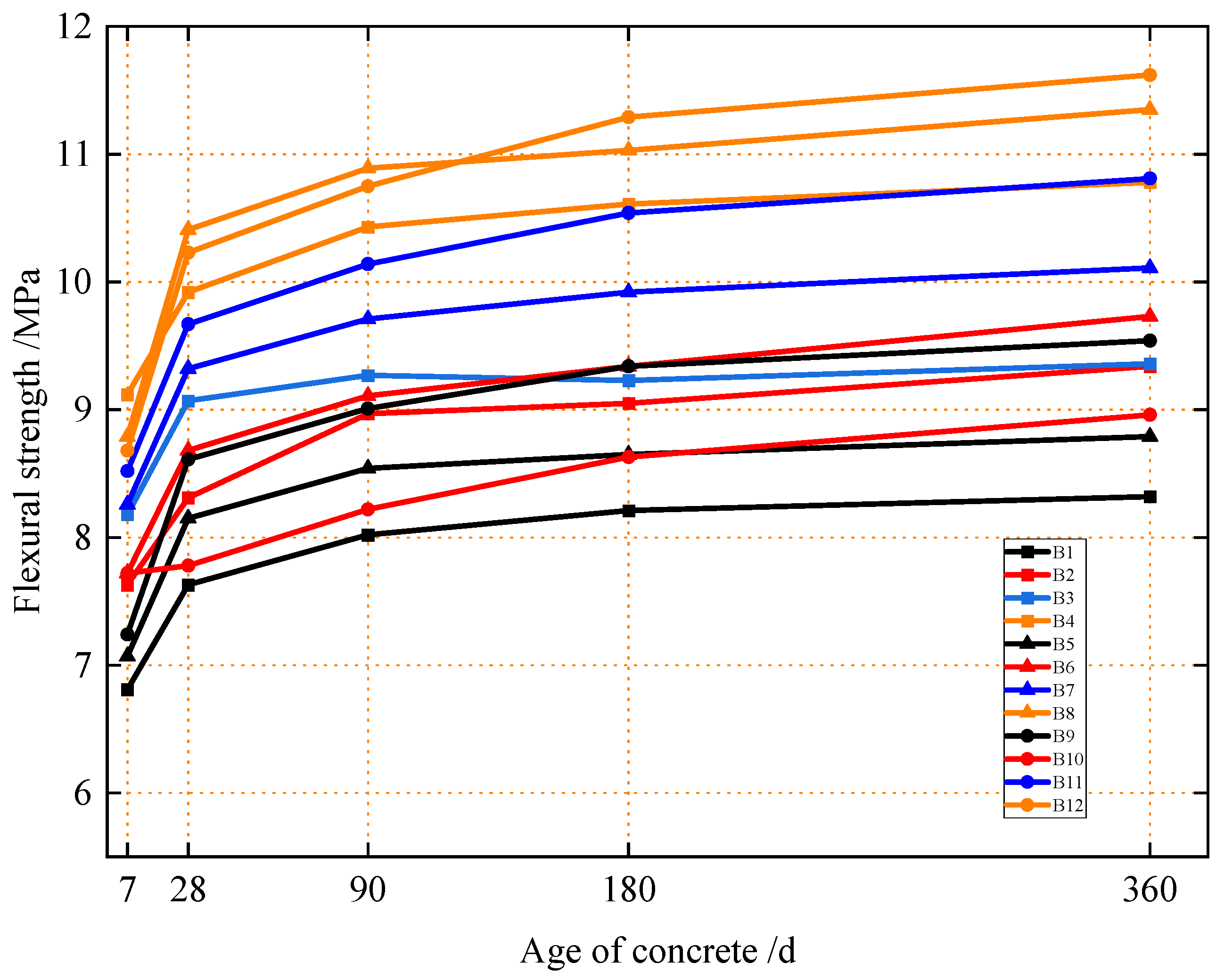

3.1.2. Long-Term Flexural Strength

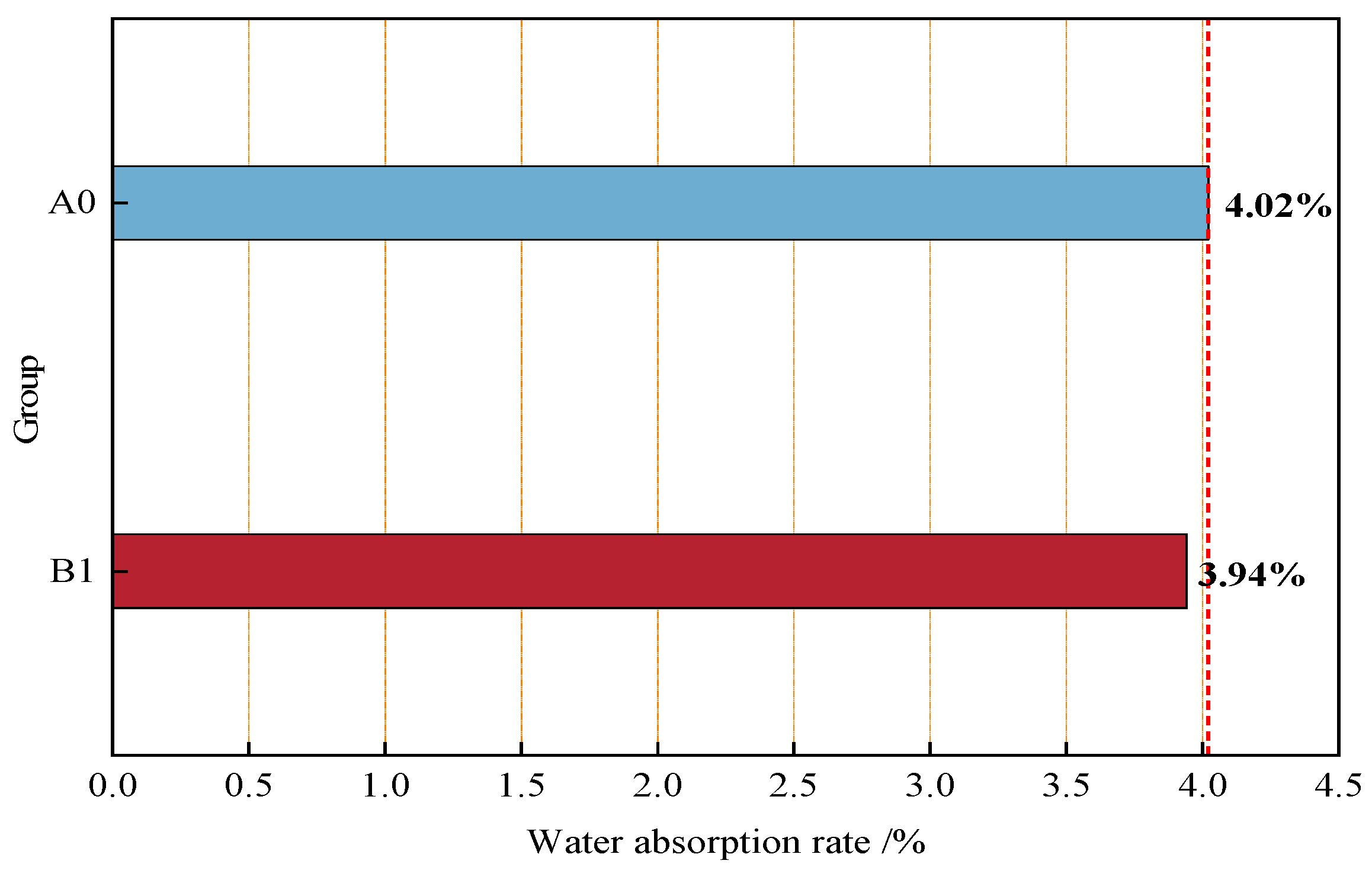

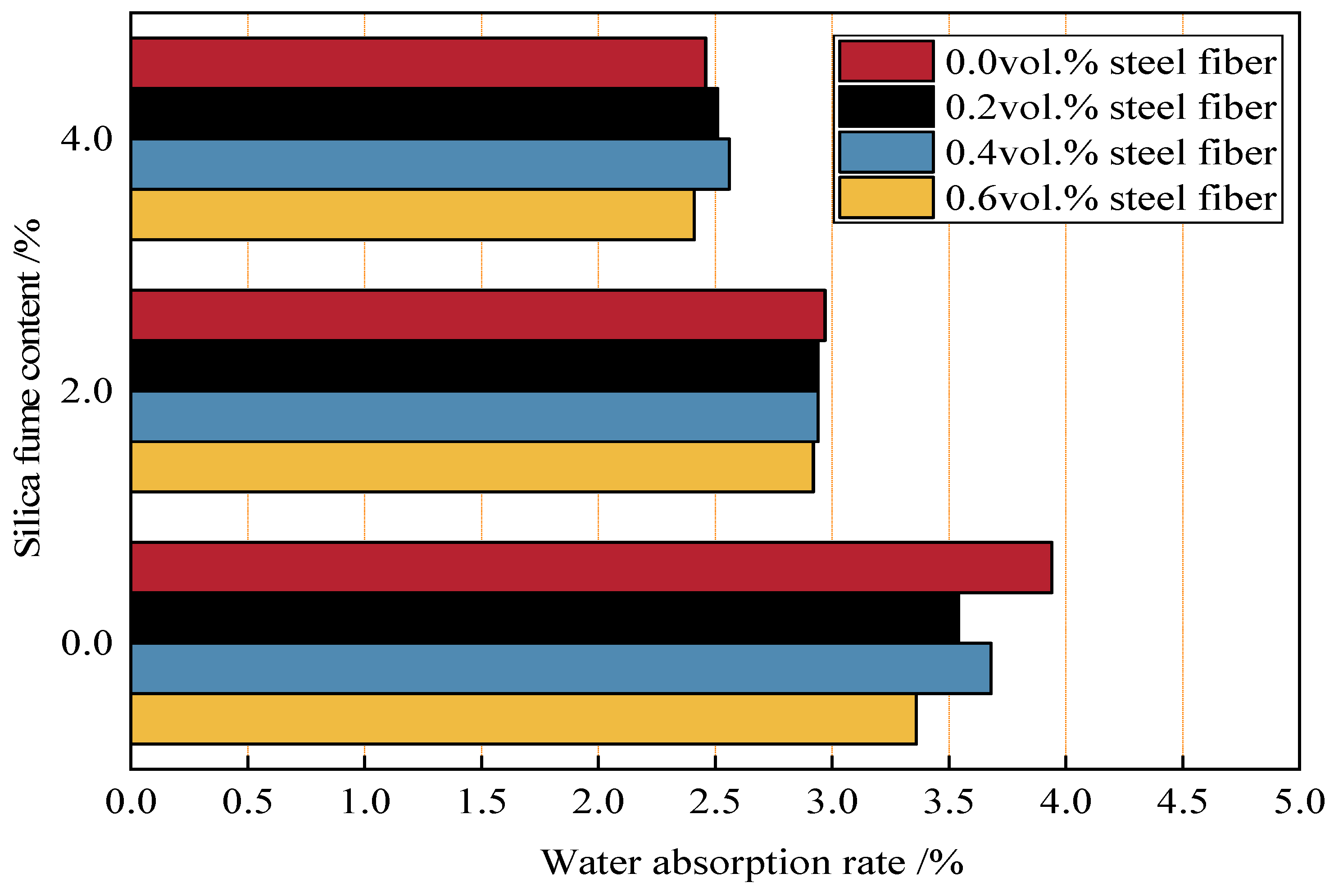

3.2. Water Absorption Rate

3.3. Sulfate Erosion Resistance Under Wet and Dry Cycles

4. Conclusions

- (1)

- In the state of tight aggregate accumulation, silica fume can give full play to its pozzolanic effect and micro-aggregate effect in concrete, and increasing the silica fume content can improve the long-term compressive strength and flexural strength of concrete; the 360-day long-term compressive strength of concrete is up to 109.3 MPa, and the 360-day long-term flexural strength is up to 11.62 MPa. At the same time, when compared to other concrete materials of comparable performance, the concrete with close-packing aggregate enables an effective reduction in manufacturing costs.

- (2)

- The 28d water absorption rate of concrete with close-packing aggregate is between 2.4% and 4.0%, the improvement in the concrete water absorption rate is not obvious with the tight packing of aggregate, and the water absorption rate of concrete can be slightly reduced by fine steel fiber; the incorporation of silica fume and the promotion of its content can effectively refine the internal structure of concrete, reduce the internal defects of the concrete and the water permeability path, and reduce the water absorption rate of the concrete.

- (3)

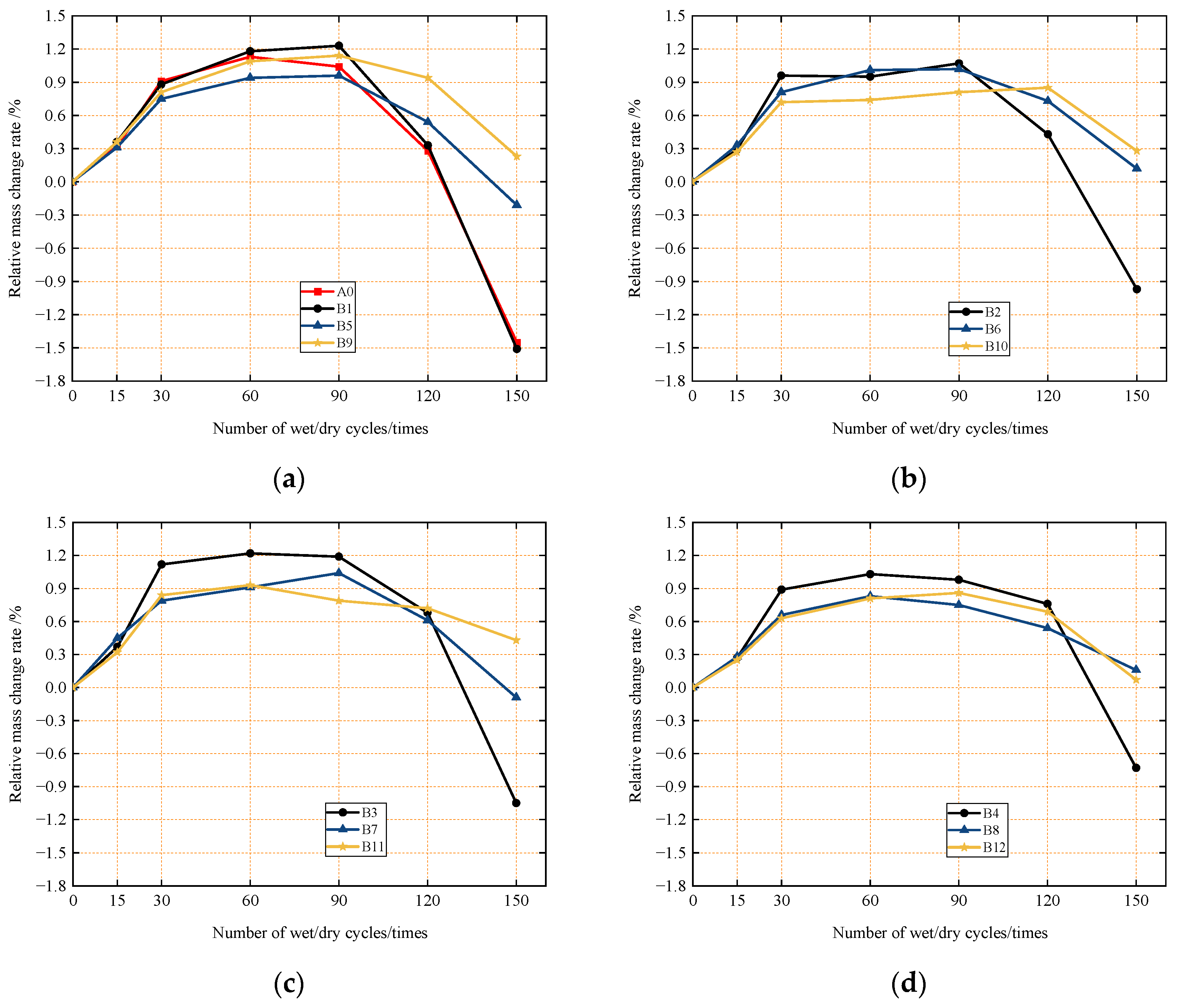

- Under the conditions of dry–wet cycling, the relative mass change of concrete with close-packing aggregate is eroded by sulfate, and then increases first, slows down, and then decreases with an increase in the number of dry–wet cycles. The tight packing of aggregate cannot improve the relative quality change trend of concrete, and the incorporation of fine steel fiber and silica fume can alleviate the mass loss of concrete in the early, middle, and late stages of sulfate erosion, respectively.

- (4)

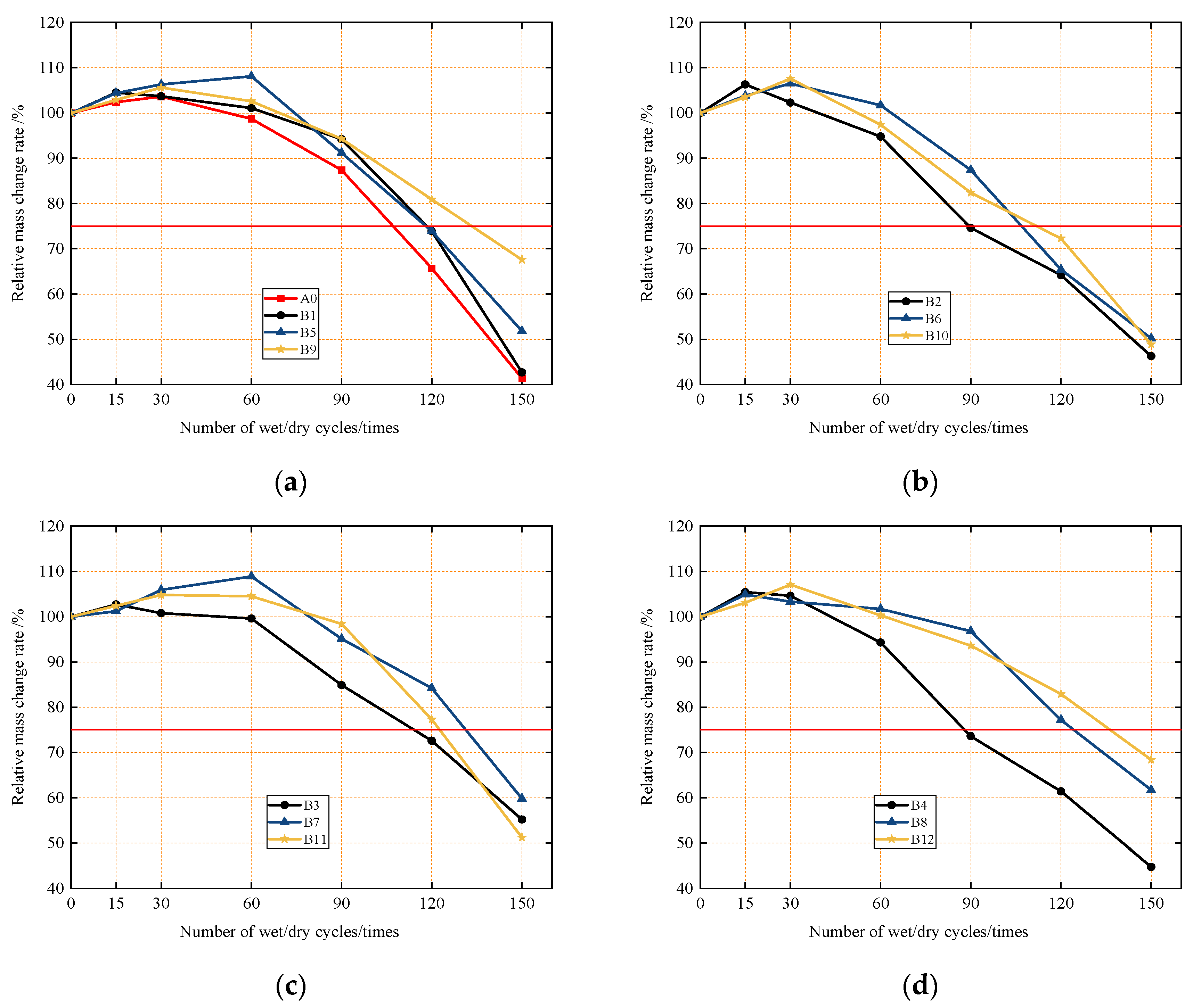

- Under the influence of sulfate erosion under the action of dry–wet cycles, the compressive strength and corrosion resistance coefficient of concrete with close-packing aggregate first increased and then decreased rapidly with an increase in the number of dry–wet cycles. The tight packing of aggregate can maintain the compressive strength of concrete slightly in the early and middle stages of sulfate erosion, but the tight packing of aggregate and the fine steel fiber cannot hinder the strength attenuation process of concrete eroded by sulfate; silica fume improves the microscopic structure of concrete because of its volcanic ash effect and micro-aggregate effect, reduces the ionic permeation path of concrete. enhances the mechanical properties of the base body, effectively improves the compressive strength corrosion resistance coefficient of the concrete, especially the corrosion resistance coefficient of the late stage of erosion, and the highest sulfuric acid salt resistance grade of concrete with close-packing aggregate reaches KS120. The concrete can withstand normal use of 100 years in a very serious sulfate erosion environment and normal use of 30~50 years in an extremely serious sulfate erosion environment, and the concrete has good sulfate erosion resistance as a whole. When the material achieves a high-performance state, this can not only significantly extend its service life but also effectively reduce long-term operation and maintenance costs, providing dual support for the long-term service and economic efficiency improvement of engineering structures.

- (5)

- In the concrete in which aggregate is tightly packed, silica fume and fine steel fiber are concrete-modifying materials with different functions, and the two compounds blended can synergistically modify and strengthen concrete; especially, they can synergistically enhance the mechanical properties of concrete. This is mainly due to the fact that silica fume not only improves the microstructure of concrete to improve the concrete’s performance, but also can improve the interface properties between the fine steel fiber and the concrete matrix, effectively improves the interfacial adhesion between the steel fiber and the matrix, and further improves the enhancement effect of the steel fiber on the concrete’s performance. Meanwhile, a high elastic modulus can reduce the amount of steel reinforcement required in the early construction stage, thereby lowering the initial construction costs.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Amirtharaj, J.; Rose, A.L. A state-of-the-art review on the structural behavior of concrete structures reinforced with various rebars as alternative to steel rebars. J. Build. Eng. 2025, 111, 113387. [Google Scholar] [CrossRef]

- Jia, S.; Han, B.; Ji, W.; Xie, H. Bayesian inference for predicting the long-term deflection of prestressed concrete bridges by on-site measurements. Constr. Build. Mater. 2022, 320, 126189. [Google Scholar] [CrossRef]

- Chapain, S.; Aly, A.M. Vibration attenuation in high-rise buildings to achieve system-level performance under multiple hazards. Eng. Struct. 2019, 197, 109352. [Google Scholar] [CrossRef]

- Wang, Y.; Zhu, J.; Jia, S.; Akiyama, M. Time-dependent deflection prediction of long-span prestressed concrete bridges considering the environmental effects. Eng. Struct. 2025, 322, 119163. [Google Scholar] [CrossRef]

- Jin, Y.; Sun, C.; Liu, H.; Xu, D. Analysis on the causes of cracking and excessive deflection of long span box girder bridges based on space frame lattice models. Structures 2023, 50, 464–481. [Google Scholar] [CrossRef]

- Ouyang, X.; Shi, C.; Wu, Z.; Li, K.; Shan, B.; Shi, J. Experimental investigation and prediction of elastic modulus of ultra-high performance concrete (UHPC) based on its composition. Cem. Concr. Res. 2020, 138, 106241. [Google Scholar] [CrossRef]

- Sun, Q.; Gupta, R.; Zhu, Z.; Sharma, A.; Qiang, S. A new mathematical model for elastic modulus prediction in mortar and concrete. J. Build. Eng. 2025, 100, 111761. [Google Scholar] [CrossRef]

- Liang, C.; Bao, J.; Gu, F.; Lu, J.; Ma, Z.; Hou, S.; Duan, Z. Determining the importance of recycled aggregate characteristics affecting the elastic modulus of concrete by modeled recycled aggregate concrete: Experiment and numerical simulation. Cem. Concr. Compos. 2025, 162, 106118. [Google Scholar] [CrossRef]

- Alfonso, D.; Dugarte, M.; Carrillo, J.; Arteta, C.A. Effect of aggregate type on the elastic modulus and compressive behavior of concrete: A case study in Colombia. Constr. Build. Mater. 2024, 411, 134131. [Google Scholar] [CrossRef]

- Wang, Q.; Li, Z.; Zhang, Y.; Zhang, H.; Zhou, M.; Fang, Y. Influence of coarse coal gangue aggregates on elastic modulus and drying shrinkage behaviour of concrete. J. Build. Eng. 2020, 32, 101748. [Google Scholar] [CrossRef]

- Poudyal, L.; Adhikari, K.; Won, M. Mechanical and Durability Properties of Portland Limestone Cement (PLC) Incorporated with Nano Calcium Carbonate (CaCO3). Materials 2021, 14, 905. [Google Scholar] [CrossRef]

- Konsta-Gdoutos, M.S.; Danoglidis, P.A.; Shah, S.P. High modulus concrete: Effects of low carbon nanotube and nanofiber additions. Theor. Appl. Fract. Mech. 2019, 103, 102295. [Google Scholar] [CrossRef]

- Tang, Y.; Chen, Z.; Feng, W.; Nong, Y.; Li, C.; Chen, J. Combined effects of nano-silica and silica fume on the mechanical behavior of recycled aggregate concrete. Nanotechnol. Rev. 2021, 10, 819–838. [Google Scholar] [CrossRef]

- Gao, S.; Ji, Y.; Qin, Z.; Zhang, H.; Xing, F.; Liu, A. A comprehensive analysis of pore structures and performances of mineral admixtures modified recycled aggregate concrete based on experiment and theory. Constr. Build. Mater. 2022, 358, 129451. [Google Scholar] [CrossRef]

- Ahmad, J.; Majdi, A.; Arbili, M.M.; Deifalla, A.F.; Naqash, M.T. Mechanical, Durability and Microstructure Analysis Overview of Concrete Made with Metakaolin (MTK). Buildings 2022, 12, 1401. [Google Scholar] [CrossRef]

- Ambedkar, B.; Alex, J.; Dhanalakshmi, J. Enhancement of mechanical properties and durability of the cement concrete by RHA as cement replacement: Experiments and modeling. Constr. Build. Mater. 2017, 148, 167–175. [Google Scholar] [CrossRef]

- Zhang, Y.; Tang, Z.; Liu, X.; Zhou, X.; He, W.; Zhou, X. Study on the Resistance of Concrete to High-Concentration Sulfate Attack: A Case Study in Jinyan Bridge. Materials 2024, 17, 3388. [Google Scholar] [CrossRef]

- Fan, L.; Ren, G.; Yu, Y.; Sun, L.; Li, P.; Zhang, J.; Su, Z. Durability of a Metakaolin-Incorporated Cement-Based Grouting Material in High Geothermal Tunnels. ACS Omega 2024, 9, 44251–44261. [Google Scholar] [CrossRef]

- Liang, J.; Liao, H.; Wang, L.; Liu, C.; Rong, H.; Yang, X. Effect of mineral admixtures on the calcium leaching resistance of porous cement stabilized macadam. Constr. Build. Mater. 2024, 421, 135712. [Google Scholar] [CrossRef]

- Xu, Y.; Zhou, J.; Jin, S. Early Strength Evolution of Cement Grouts Adopted in Reinforced Concrete Subjected to Na2SO4 Corrosion. Buildings 2023, 13, 579. [Google Scholar] [CrossRef]

- China Ecological Environment Status Bulletin 2021 (Excerpt). Environ. Prot. 2022, 50, 61–74. [CrossRef]

- Wu, C.; Shi, Y.; Xu, J.; Luo, M.; Lu, Y.; Zhu, D. Experimental Study of Mechanical Properties and Theoretical Models for Recycled Fine and Coarse Aggregate Concrete with Steel Fibers. Materials 2024, 17, 2933. [Google Scholar] [CrossRef]

- JTG 3420-2020; Testing Methods of Cement and Concrete for Highway Engineering. Research Institute of Highway Ministry of Transport: Beijing, China, 2020.

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. China Planning Press: Beijing, China, 2019.

- GB/T 50082-2009; Standard for Test Methods of Long-term Performance and Durability of Ordinary Concrete. China Planning Press: Beijing, China, 2009.

- Zhang, Z.; Liu, Y.; Liu, J.; Xin, G.; Long, G.; Zhang, T. Experimental study and analysis for the long-term behavior of the steel–concrete composite girder bridge. Structures 2023, 51, 1305–1327. [Google Scholar] [CrossRef]

- Seo, J.; Park, S.; Jin, D.W.; Park, J.; Kil, T.; Jang, D.; Kim, G.M. Discrimination of the role of silica fume and nano-silica in alkali-activated slag paste. Constr. Build. Mater. 2024, 438, 137092. [Google Scholar] [CrossRef]

- Deng, Y.; Meng, L.; Zhang, M.; Li, L.; Yao, Z.; Zhao, H. Sulfate Corrosion Resistance of Reclaimed Coal Gangue Sand Concrete Reinforced with Silica Fume. Iran. J. Sci. Technol. Trans. Civ. Eng. 2024, 48, 4169–4181. [Google Scholar] [CrossRef]

- Liang, Q.; Huang, X.; Zhang, L.; Yang, H. A Review on Research Progress of Corrosion Resistance of Alkali-Activated Slag Cement Concrete. Materials 2024, 17, 5065. [Google Scholar] [CrossRef]

- Song, S.; Yu, H.; Ma, H. Influence of Drying Conditions on the Durability of Concrete Subjected to the Combined Action of Chemical Attack and Freeze–Thaw Cycles. Materials 2024, 17, 1131. [Google Scholar] [CrossRef]

- Ahmad, J.; Althoey, F.; Abuhussain, M.A.; Deifalla, A.F.; Özkılıç, Y.O.; Rahmawati, C. Durability and microstructure analysis of concrete made with volcanic ash: A review (Part II). Sci. Eng. Compos. Mater. 2023, 30, 20220211. [Google Scholar] [CrossRef]

- Zheng, S.; Chen, H.; Xiao, Y.; He, R.; Qiu, H. Water distribution characteristics of capillary absorption in internally cured concrete with superabsorbent polymers. Constr. Build. Mater. 2024, 418, 135446. [Google Scholar] [CrossRef]

- Zhang, D.; Li, J. Toughening of concrete with ductile cementitious matrix: Proof of concept. Theor. Appl. Fract. Mech. 2025, 136, 104847. [Google Scholar] [CrossRef]

- Yang, J.; Zhu, M.; He, X.; Su, Y.; Huang, T.; Wang, X.; Tang, D.; Zeng, J.; Dai, F. Converting Iron Mine Tailings into Composite Aggregates for Ultrahigh-Performance Mortar. J. Mater. Civ. Eng. 2025, 37, 04024460. [Google Scholar] [CrossRef]

- Yang, M.; Sun, J.; Yuan, J.; Li, H.; Xu, D.; Zhang, R.; Ma, X. Iron tailing powder in cement-based composites: Evaluating filling effect from particle-size distribution. Case Stud. Constr. Mater. 2025, 23, e04919. [Google Scholar] [CrossRef]

- Xiao, S.; Cheng, H.; Que, Z.; Liu, T.; Zou, D. Enhancing marine anti-washout concrete: Optimal silica fume usage for improved compressive strength and abrasion resistance. Constr. Build. Mater. 2024, 428, 136262. [Google Scholar] [CrossRef]

- Zhu, H.; Fu, Z.; Wen, S.; Chen, J.; Xiao, Y. Evolution of LWAC–OC interfacial properties during sulfate dry–wet cycles: Bonding strength and micro–properties. J. Build. Eng. 2024, 92, 109780. [Google Scholar] [CrossRef]

- Tian, J.; Zhu, W.; Wu, X.; Sun, C.; Zheng, Y.; Tang, S.; Yuan, J.; Zuo, Y. Deterioration test and damage model of FRP-ECC-concrete composite interface under sulfate-dry-wet cycles. Constr. Build. Mater. 2025, 471, 140723. [Google Scholar] [CrossRef]

- Wang, H.; Pang, J. Mechanical Properties and Microstructure of Rubber Concrete under Coupling Action of Sulfate Attack and Dry–Wet Cycle. Sustainability 2023, 15, 9569. [Google Scholar] [CrossRef]

- Salvador, R.P.; Serafini, R.; Rambo, D.A.S.; Sant’Anna, A.S.; Quarcioni, V.A.; de Figueiredo, A.D. Effect of external sulfate attack on the tensile properties of steel-fibre-reinforced sprayed concrete. Mag. Concr. Res. 2024, 76, 872–881. [Google Scholar] [CrossRef]

- Yuan, X.; Dai, M.; Li, M.; Liu, F. Study of the Freeze–Thaw Resistance for Composite Fiber Recycled Concrete with Sulphate Attack Exposure. Buildings 2023, 13, 1037. [Google Scholar] [CrossRef]

- Zhao, C.; Li, B.; Li, K.; Li, Z. Research on Mechanical Properties of Silica Fume Cementitious Materials Excited by Wet Grinding Methods. Buildings 2024, 14, 3757. [Google Scholar] [CrossRef]

- Zhao, Q.; Ma, C.; Lu, X.; Huang, B.; Chen, Z.; Lian, C. Effect of silica fume on the efflorescence, strength, and micro-properties of one-part geopolymer incorporating sewage sludge ash. Constr. Build. Mater. 2024, 436, 136840. [Google Scholar] [CrossRef]

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 |

|---|---|---|---|---|---|

| 20.3 | 5.26 | 3.38 | 64.2 | 1.27 | 2.88 |

| Number | Cement | Water | River Sand | 5~10 mm Coarse Aggregates | 10~25 mm Coarse Aggregates | Silica Fume | Water Reducer | Steel Fiber |

|---|---|---|---|---|---|---|---|---|

| A0 | 19.4 | 5.6 | 28.1 | 9.3 | 37.3 | 0 | 0.3 | 0 |

| B1 | 19.4 | 5.6 | 28.1 | 11.7 | 34.9 | 0 | 0.3 | 0 |

| B2 | 19.3 | 5.6 | 27.9 | 11.6 | 34.7 | 0 | 0.3 | 0.2 |

| B3 | 19.2 | 5.6 | 27.8 | 11.5 | 34.5 | 0 | 0.3 | 0.4 |

| B4 | 19.0 | 5.5 | 27.6 | 11.5 | 34.3 | 0 | 0.3 | 0.6 |

| B5 | 19.3 | 5.6 | 28.0 | 11.6 | 34.8 | 2.0 | 0.3 | 0 |

| B6 | 19.2 | 5.6 | 27.8 | 11.6 | 34.6 | 2.0 | 0.3 | 0.2 |

| B7 | 19.1 | 5.5 | 27.7 | 11.5 | 34.4 | 2.0 | 0.3 | 0.4 |

| B8 | 18.9 | 5.5 | 27.5 | 11.4 | 34.2 | 2.0 | 0.3 | 0.6 |

| B9 | 19.3 | 5.6 | 27.9 | 11.6 | 34.6 | 4.0 | 0.3 | 0 |

| B10 | 19.1 | 5.5 | 27.7 | 11.5 | 34.4 | 4.0 | 0.3 | 0.2 |

| B11 | 19.0 | 5.5 | 27.5 | 11.4 | 34.2 | 4.0 | 0.3 | 0.4 |

| B12 | 18.9 | 5.5 | 27.4 | 11.4 | 34.0 | 4.0 | 0.3 | 0.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ye, Z.; Qu, X.; Li, J.; Ye, T.; Li, G.; Wang, H. Experimental Investigation of the Effect of Nano Silica Fume on Durability of Concrete with Close-Packing Aggregate. Materials 2025, 18, 4061. https://doi.org/10.3390/ma18174061

Ye Z, Qu X, Li J, Ye T, Li G, Wang H. Experimental Investigation of the Effect of Nano Silica Fume on Durability of Concrete with Close-Packing Aggregate. Materials. 2025; 18(17):4061. https://doi.org/10.3390/ma18174061

Chicago/Turabian StyleYe, Zilong, Xin Qu, Jiajun Li, Tianhao Ye, Gengying Li, and Haiyang Wang. 2025. "Experimental Investigation of the Effect of Nano Silica Fume on Durability of Concrete with Close-Packing Aggregate" Materials 18, no. 17: 4061. https://doi.org/10.3390/ma18174061

APA StyleYe, Z., Qu, X., Li, J., Ye, T., Li, G., & Wang, H. (2025). Experimental Investigation of the Effect of Nano Silica Fume on Durability of Concrete with Close-Packing Aggregate. Materials, 18(17), 4061. https://doi.org/10.3390/ma18174061