Multi-Characterization of Rejuvenators’ Impact on Aged Asphalt Binder Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.1.1. Virgin Asphalt

2.1.2. The WBO and MO

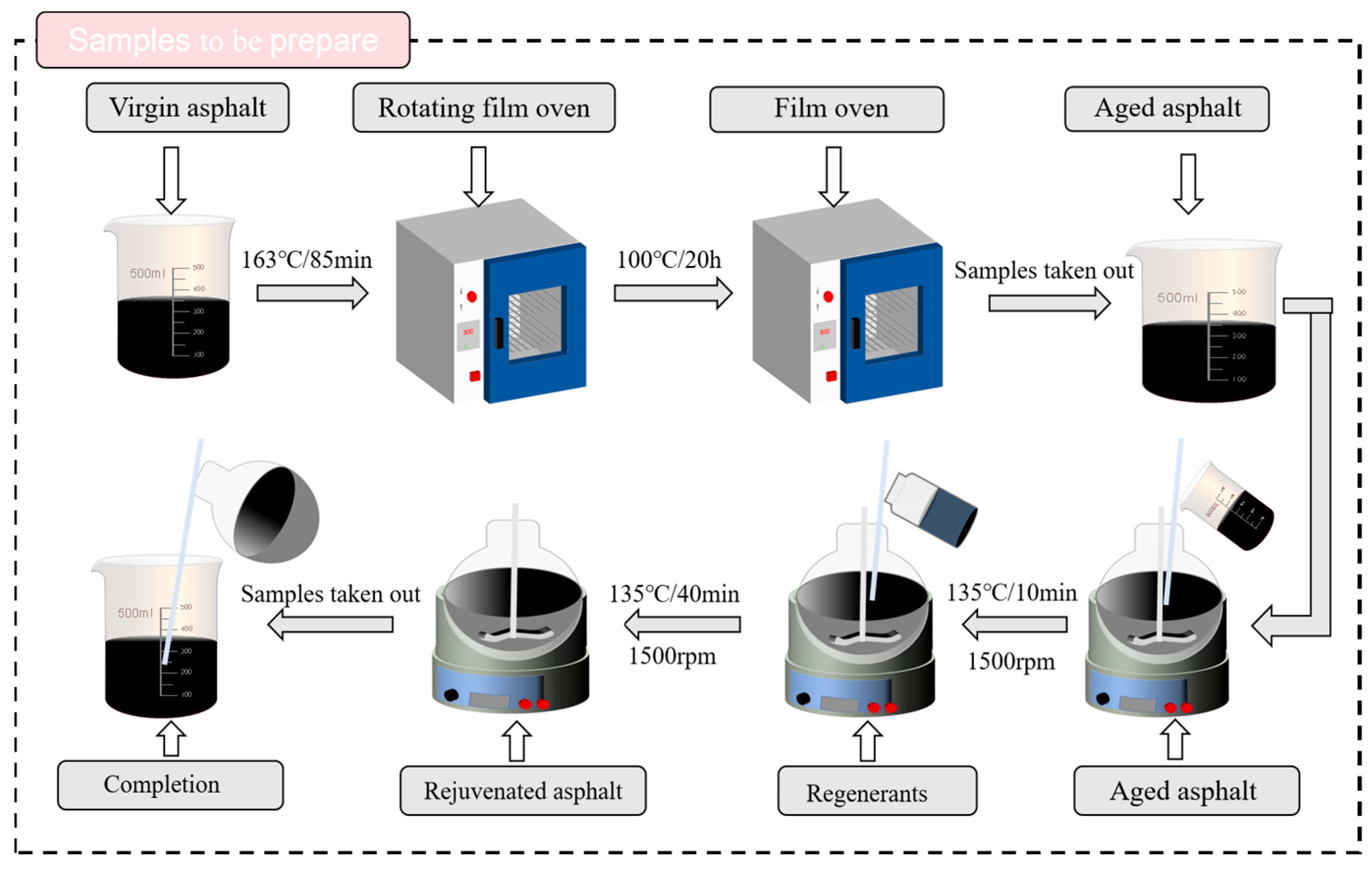

2.2. Preparation of Aged Asphalt and Rejuvenated Asphalt

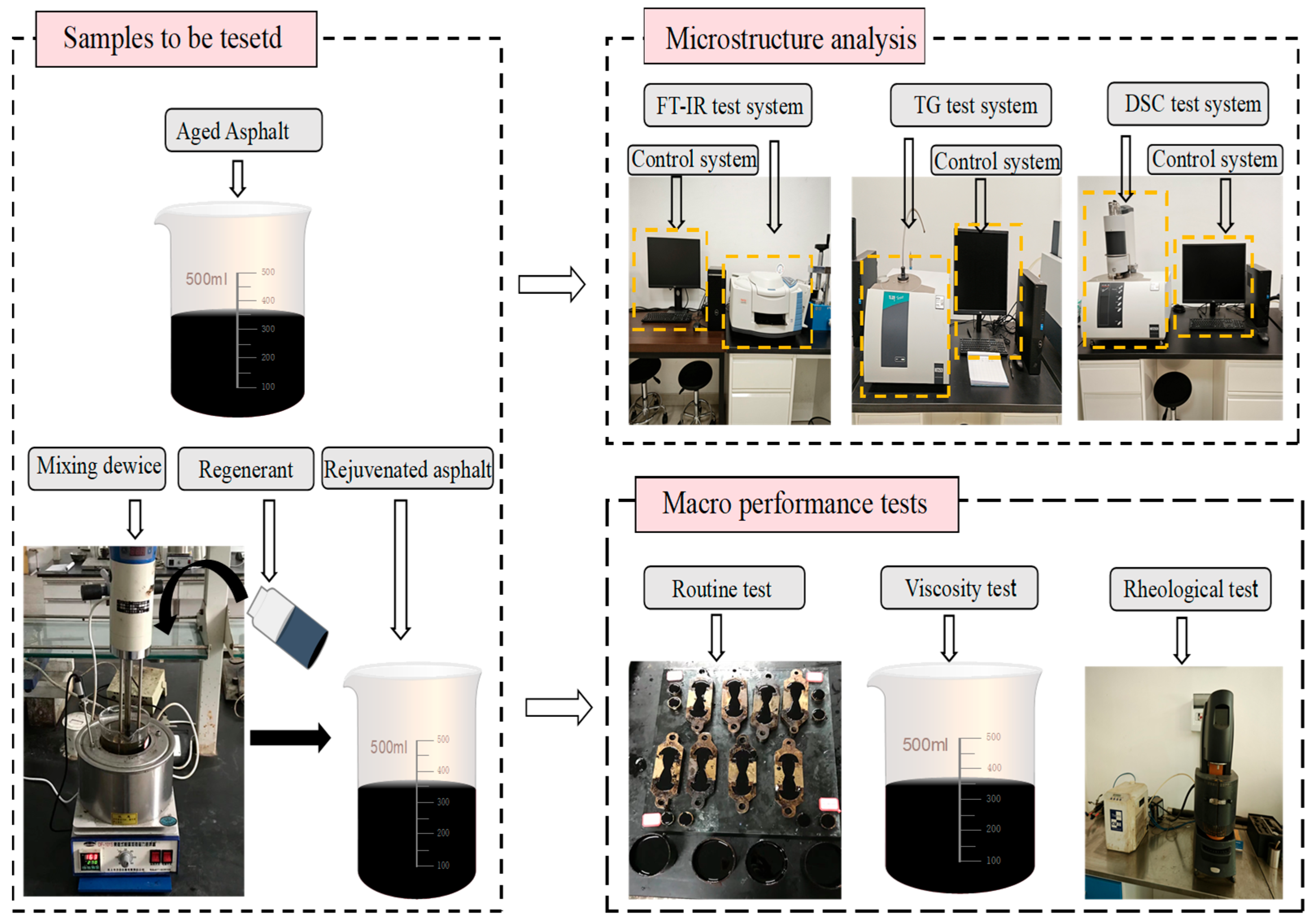

2.3. Test Methods for Asphalt Binder

2.3.1. Conventional Performance Tests

2.3.2. Viscosity Test

2.3.3. FT-IR (Fourier Transform Infrared Spectroscopy)

2.3.4. Thermogravimetric Analysis (TG)

2.3.5. Differential Scanning Calorimetry (DSC)

2.3.6. Dynamic Shear Rheometer (DSR) Test

3. Results

3.1. Conventional Properties of the Asphalt

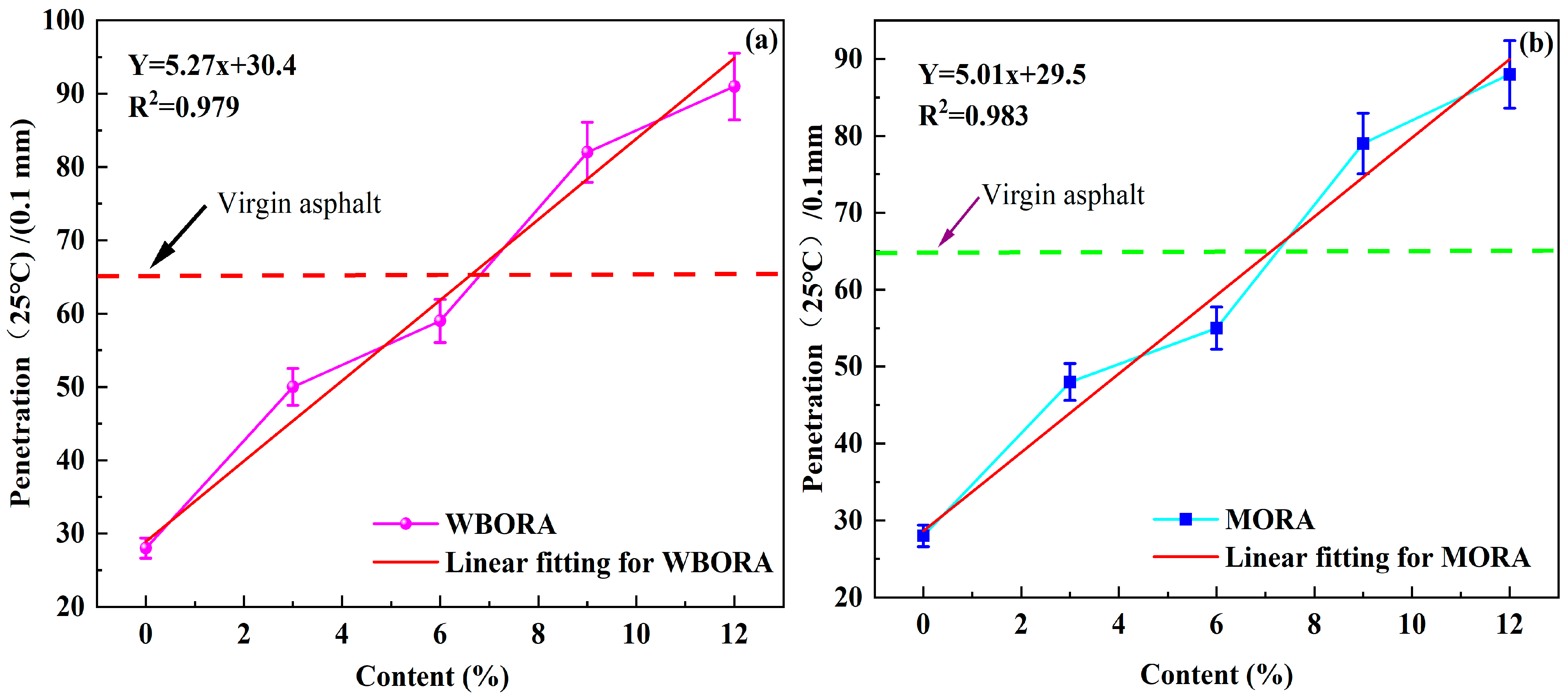

3.1.1. Optimization of Rejuvenator Dosage

3.1.2. Softening Point

3.1.3. Ductility

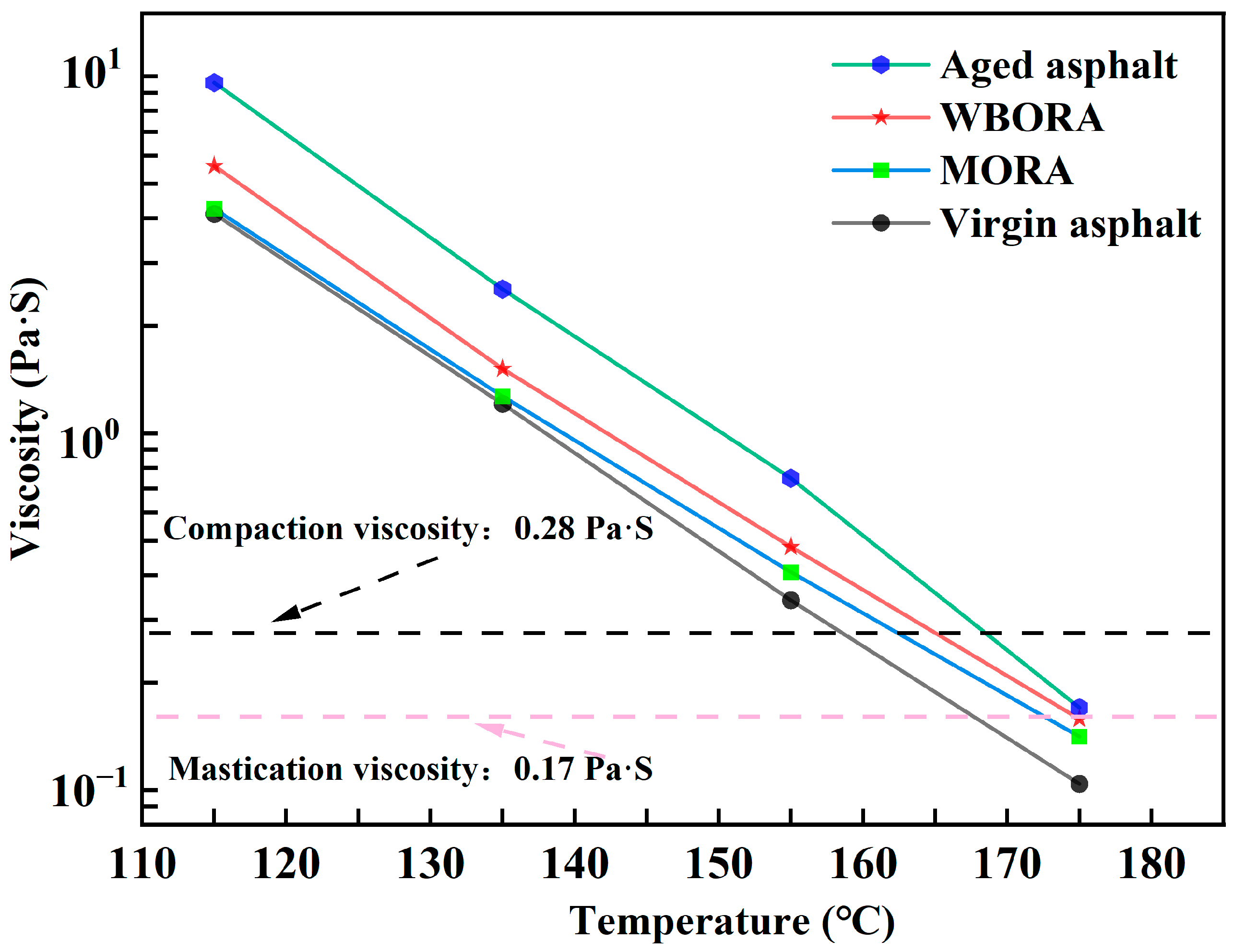

3.2. Rotational Viscosity

3.3. Fourier Transform Infrared (FT-IR)

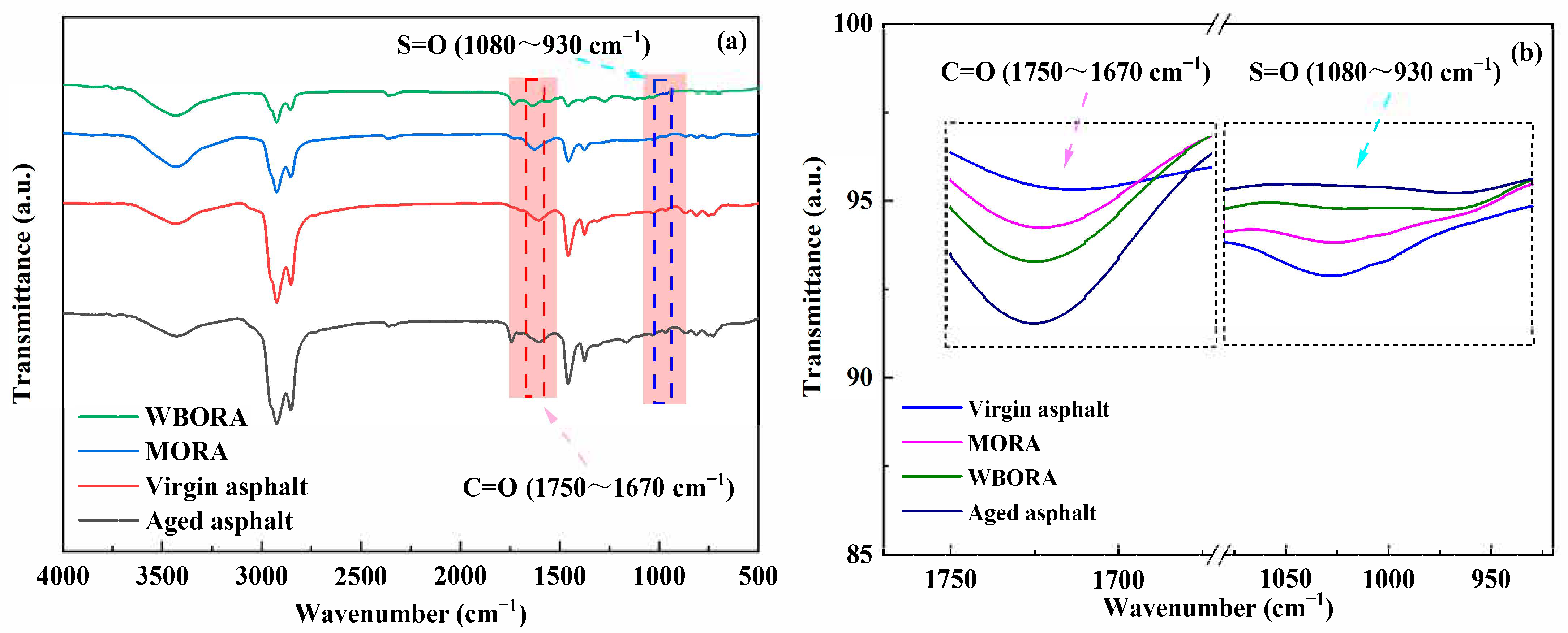

3.4. Thermogravimetric Test (TG)

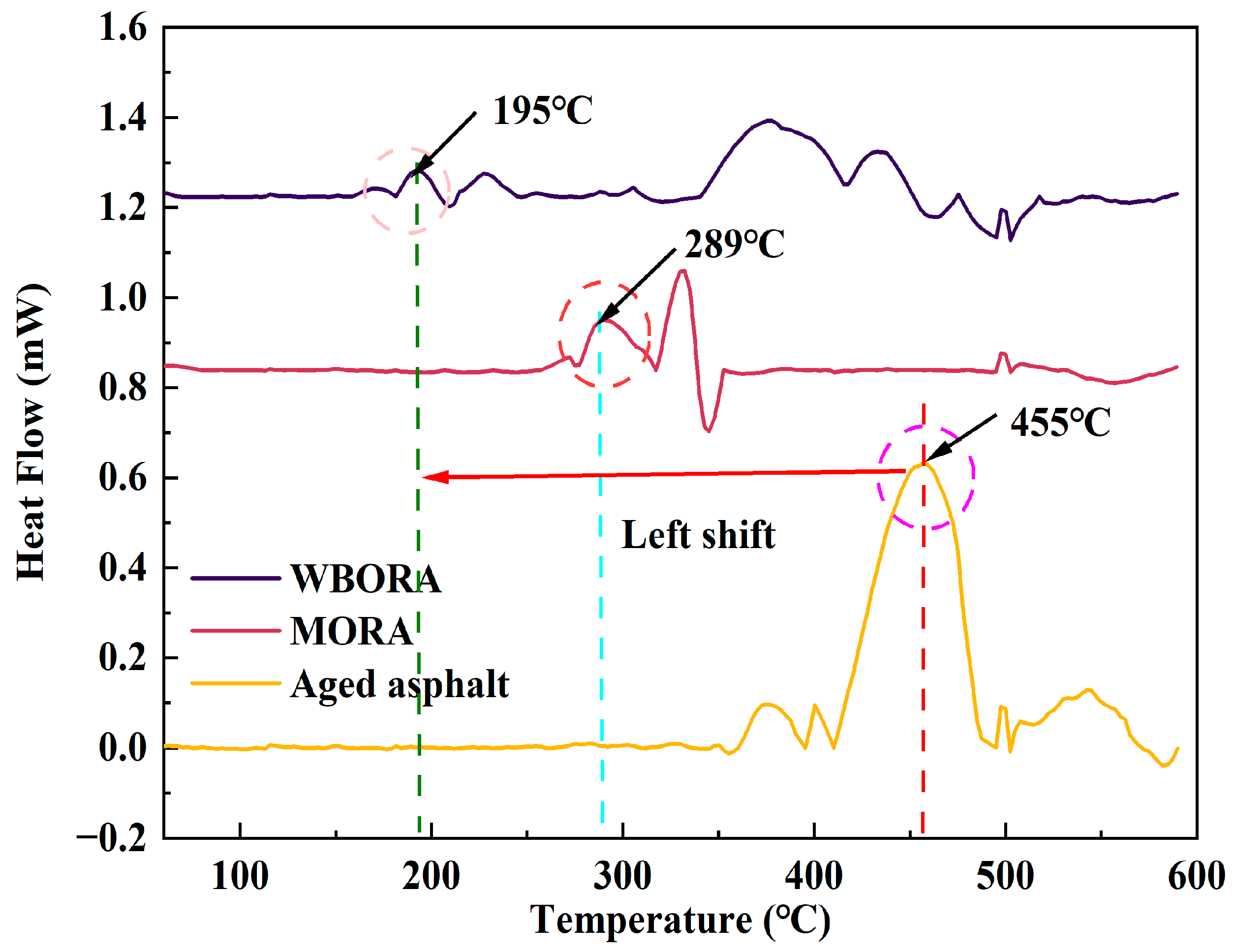

3.5. Differential Scanning Calorimetry (DSC)

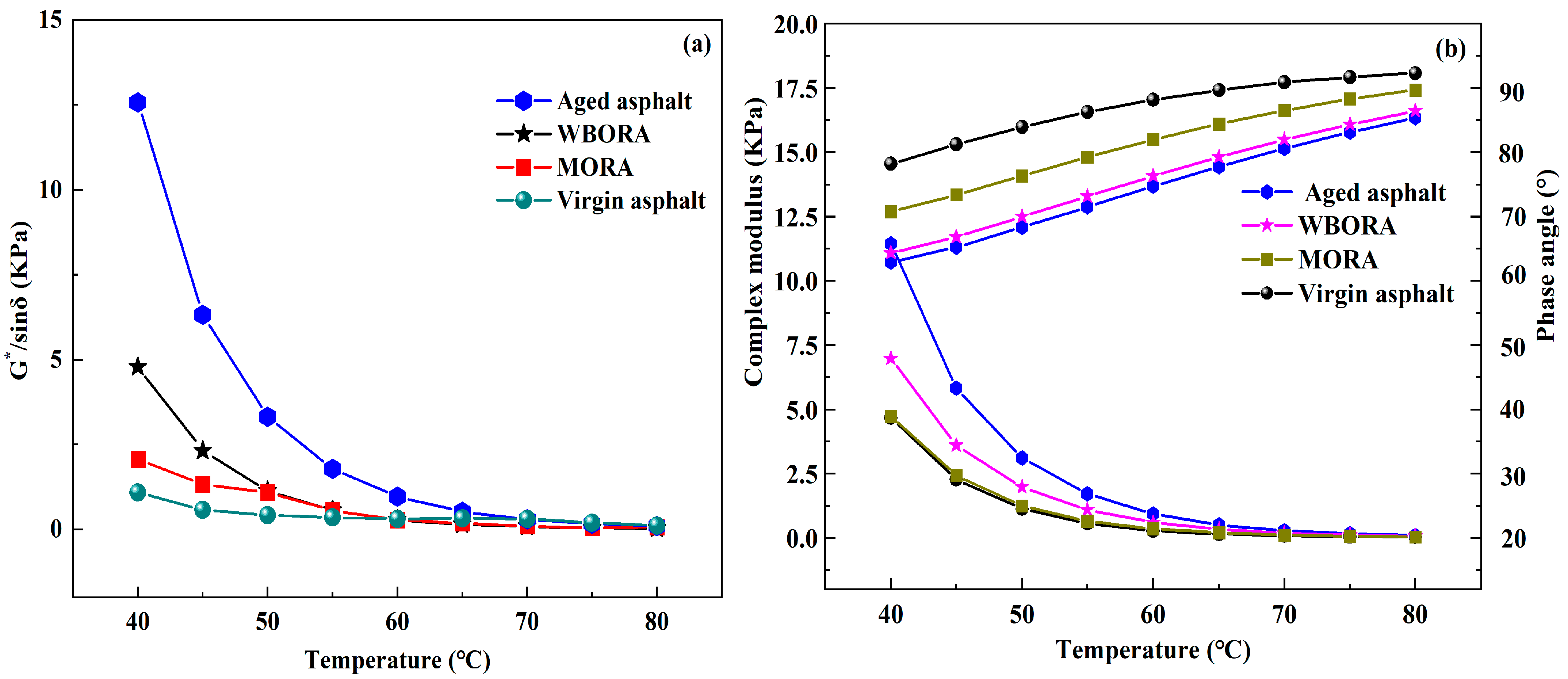

3.6. Rheological Properties (DSR)

3.6.1. Temperature Sweep

3.6.2. Frequency Sweep

4. Conclusions

- (1)

- Conventional performance tests confirm that both rejuvenated asphalts exhibit softening effects. Viscosity of aged asphalt decreases progressively with rejuvenator incorporation, ensuring adequate workability during construction operations.

- (2)

- FT-IR spectroscopy reveals increased carbonyl (C=O) and sulfoxide (S=O) indices in aged asphalt versus virgin binder. These indices attenuate upon rejuvenator addition, with WBORA demonstrating superior carbonyl peak reduction. MORA shows no chemical interactions—only physical blending with aged asphalt constituents.

- (3)

- Thermogravimetric analysis indicates rejuvenators compromise high-temperature stability but enhance low-temperature performance. The left-shifted oxidation onset peaks (WBORA: 190–210 °C; MORA: 280–300 °C) evidence WBORA asphalt’s superior rheological restorative efficacy, concurrently preserving high-temperature stability and low-temperature ductility.

- (4)

- Combined temperature-frequency sweeps show neither rejuvenated asphalt nor fully restored virgin asphalt’s rheological complex modulus (G*) or phase angle (δ). This stems from fundamentally distinct regeneration mechanisms: MORA primarily achieves physical restoration, whereas WBORA facilitates chemical reconstruction—as validated via Cole–Cole plot divergence.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Guo, M.; Yin, X.-M.; Liang, M.; Du, X. Study on effect of thermal, oxidative and ultraviolet coupled aging on rheological properties of asphalt binder and their contribution rates. Int. J. Pavement Eng. 2023, 24, 2239426. [Google Scholar] [CrossRef]

- Abouelsaad, A.; White, G. Comparing the Effect of Thermal-Oxidation and Photo-Oxidation of Asphalt Mixtures on the Rheological and Chemical Properties of Extracted Bituminous Binder. Materials 2022, 15, 6793. [Google Scholar] [CrossRef] [PubMed]

- Polo-Mendoza, R.; Martinez-Arguelles, G.; Walubita, L.F.; Moreno-Navarro, F.; Giustozzi, F.; Fuentes, L.; Navarro-Donado, T. Ultraviolet ageing of bituminous materials: A comprehensive literature review from 2011 to 2022. Constr. Build. Mater. 2022, 350, 128889. [Google Scholar] [CrossRef]

- Diouri, K.; De, A.; Dave, E.V.; Sias, J.; Mallick, R.B. Effect of aging and temperature on milling-induced stresses and cracks in Hot Mix Asphalt (HMA) pavements. Constr. Build. Mater. 2021, 313, 125493. [Google Scholar] [CrossRef]

- Kaseer, F.; Martin, A.E.; Arámbula-Mercado, E. Use of recycling agents in asphalt mixtures with high recycled materials contents in the United States: A literature review. Constr. Build. Mater. 2019, 211, 974–987. [Google Scholar] [CrossRef]

- Gou, J.; Guo, M.; Xie, X.; Du, X. Unravelling the adhesion mechanism of recycled SBS-modified asphalt: Integrating surface free energy, atomic force microscopy and molecular dynamics. Constr. Build. Mater. 2025, 483, 141672. [Google Scholar] [CrossRef]

- Ma, Y.; Hu, W.; Polaczyk, P.A.; Han, B.; Xiao, R.; Zhang, M.; Huang, B. Rheological and aging characteristics of the recycled asphalt binders with different rejuenator incorporation methods. J. Clean. Prod. 2025, 262, 121249. [Google Scholar] [CrossRef]

- Chai, F.; Cao, F.; Zhai, F.; Chen, Y.; Wang, X.; Su, Z. Transesterification of Vegetable Oil to Biodiesel using a Heteropolyacid Solid Catalyst. Adv. Synth. Catal. 2007, 349, 1057–1065. [Google Scholar] [CrossRef]

- Qiu, Q.; Zhang, J.; Yang, L.; Du, D.; Tang, C. Differences analysis of water molecular diffusion behaviors in vegetable oil and mineral oil under temperature field. J. Mol. Liq. 2021, 323, 115030. [Google Scholar] [CrossRef]

- Chang, J.Y. Effects of different waste oils on the rheological properties of aging SBS asphalt. Highw. Traffic Sci. Technol. 2023, 40, 33–40. [Google Scholar] [CrossRef]

- Zhao, Y.; Guo, R.; Li, J.; Wen, L. Research on rheological properties and road performance of cold recycled high-RAP binder and mixtures with asphalt light fractions as rejuvenators. Constr. Build. Mater. 2025, 490, 142545. [Google Scholar] [CrossRef]

- Ahmad, M.; Khedmati, M.; Mensching, D.; Hofko, B.; Haghshenas, H.F. Aging characterization of asphalt binders through multi—Aspect analyses: A critical review. Fuel 2024, 376, 132679. [Google Scholar] [CrossRef]

- Zhao, Y.; Chen, M.; Shen, J.; Shi, P.; Wu, S.; Chen, D.; Zhang, J.; Zhao, Z. Aging behaviors of asphalt binders rejuvenated by different chemical fractions from waste cooking oil. Constr. Build. Mater. 2024, 435, 136867. [Google Scholar] [CrossRef]

- Qin, Y.; Dong, R.; Li, Y. Characterization of light components in rubber—Oil mixtures reclaimed asphalt and their effect on the self-healing performance of asphalt. Constr. Build. Mater. 2024, 444, 137866. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, M.; Zhao, Y.; Wu, S.; Chen, D.; Sun, Y. Influence of macromolecular substances in waste cooking oil on rejuvenation properties of asphalt with different aging degrees. Constr. Build. Mater. 2022, 361, 129522. [Google Scholar] [CrossRef]

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. National Standard of the People’s Republic of China: Beijing, China, 2011.

- Girimath, S.; Singh, D. Effects of bio-oil on performance characteristics of base and recycled asphalt pavement binders. Constr. Build. Mater. 2019, 227, 116684. [Google Scholar] [CrossRef]

- ASTM D2872-21; Standard Test Method for Effect of Heat and Air on a Moving Film of Asphalt (Rolling Thin-Film Oven Test). ASTM International: West Conshohocken, PA, USA.

- ASTM D4402/D4402M-15; Standard Test Method for Viscosity Determination of Asphalt at Elevated Temperatures Using a Rotational Viscometer. ASTM International: West Conshohocken, PA, USA, 2015.

- Joohari, I.; Giustozzi, F. Oscillatory shear rheometry of hybrid polymer-modified bitumen using multiple stress creep and recovery and linear amplitude sweep tests. Constr. Build. Mater. 2022, 315, 125791. [Google Scholar] [CrossRef]

- Lei, Y.; Wang, H.; Chen, X.; Yang, X.; You, Z.; Dong, S.; Gao, J. Shear property, high-temperature rheological performance and low-temperature flexibility of asphalt mastics modified with bio-oil. Constr. Build. Mater. 2018, 174, 30–37. [Google Scholar] [CrossRef]

- Vigneswaran, S.; Yun, J.; Lee, M.-S.; Kim, H.; Lee, S.-J. Enhancing Asphalt Performance: The Combined Influence of Trinidad Lake Asphalt (TLA) and Styrene–Isoprene–Styrene (SIS) on PG 64-22 Binder. Appl. Sci. 2024, 14, 8939. [Google Scholar] [CrossRef]

- Deef-Allah, E.; Abdelrahman, M. Effect of used motor oil as a rejuvenator on crumb rubber modifier’s released components to asphalt binder. Prog. Rubber Plast. Recycl. Technol. 2020, 37, 87–114. [Google Scholar] [CrossRef]

- Gao, X.; Kong, F.; Cheng, H.; Zhang, Y.; Xue, C.; Cheng, Z. Effect of Waste Palm Oil Reclaiming Agent on Viscoelastic and Mechanical Properties of Hot-in-Place Recycled Mixture. Appl. Sci. 2025, 15, 4156. [Google Scholar] [CrossRef]

- Fan, X.; Shang, H.; Li, J.; Zhang, W.; Duan, A. Effects of microwave electric field on the structure and association behaviour of asphaltenes: MD and DFT study. Chem. Eng. Sci. 2023, 265, 118245. [Google Scholar] [CrossRef]

- Siddiqui, M.N. Infrared Study of Hydrogen Bond Types in Asphaltenes. Liq. Fuels Technol. 2003, 21, 1601–1615. [Google Scholar] [CrossRef]

- Akkenzheyeva, A.; Haritonovs, V.; Bussurmanova, A.; Merijs-Meri, R.; Imanbayev, Y.; Riekstins, A.; Serikbayeva, A.; Sydykov, S.; Aimova, M.; Mustapayeva, G. Study of the Viscoelastic and Rheological Properties of Rubber-Bitumen Binders Obtained from Rubber Waste. Polymers 2024, 16, 20734360. [Google Scholar] [CrossRef]

- Walubita, L.F.; Martinez-Arguelles, G.; Chunduri, H.R.; Gonzalez Hernandez, J.G.; Fuentes, L. Statistical Evaluation of the Material-Source Effect on the Ductility and Elastic Recovery (ER) of Plant-Mix Extracted Asphalt-Binders. Adv. Civ. Eng. 2020, 2020, 8851691. [Google Scholar] [CrossRef]

- Margellou, A.G.; Zormpa, F.F.; Karfaridis, D.; Karakoulia, S.A.; Triantafyllidis, K.S. Hydrodeoxygenation of Phenolic Compounds and Lignin Bio-Oil Surrogate Mixture over Ni/BEA Zeolite Catalyst and Investigation of Its Deactivation. Catalysts 2025, 15, 48. [Google Scholar] [CrossRef]

- Darabi, M.K.; Rahmani, E.; Masad, E.A.; Little, D.N. A coupled aging–viscoelastic–viscodamage model for predicting fatigue behavior in aged asphalt pavements. Mech. Time-Depend. Mater. 2025, 29, 50. [Google Scholar] [CrossRef]

- Li, Y.W.W. Relationship between chemical and physical or rheological properties of asphalt binders during aging. Pet. Sci. Technol. 2020, 38, 19a24. [Google Scholar] [CrossRef]

- Cavalli, M.C.; Griffa, M.; Bressi, S.; Partl, M.N.; Tebaldi, G.; Poulikakos, L.D. Multiscale imaging and characterization of the effect of mixing temperature on asphalt concrete containing recycled components. J. Microsc. 2016, 264, 22–23. [Google Scholar] [CrossRef]

- Wahhab, H.A.; Dalhat, M.A.; Habib, M.A. Storage stability and high-temperature performance of asphalt binder modified with recycled plastic. Road Mater. Pavement Des. 2016, 18, 1117–1134. [Google Scholar] [CrossRef]

- Wang, R.; Xiong, Y.; Yue, M.; Hao, M.; Yue, J. Investigating the effectiveness of carbon nanomaterials on asphalt binders from hot storage stability, thermodynamics, and mechanism perspectives. J. Clean. Prod. 2020, 276, 124180. [Google Scholar] [CrossRef]

- Yao, Z.; Yang, R.; Sirin, Z.O. Study on the Applicability of Elastic Recovery (Resilience) Experiment for Asphalt-Rubber. Adv. Civ. Eng. 2022, 2022, 2286794. [Google Scholar] [CrossRef]

- Sofiah, A.G.N.; Pasupuleti, J.; Samykano, M.; Sulaiman, N.F.; Ramli, Z.A.C.; Kumar, R.R.; Shahabuddin, S.; Pandey, A.K.; Tiong, S.K.; Koh, S.P. Multi-objective optimization and price performance factor evaluation of polyaniline nanofibers-palm oil nanofluids for thermal energy storage application. Case Stud. Therm. Eng. 2023, 52, 103673. [Google Scholar] [CrossRef]

| Test | Result | Specification |

|---|---|---|

| Penetration (25 °C)/(0.1 mm) | 65 | 60–80 |

| Softening point (≥)/°C | 49 | 45 |

| Ductility (10 °C)/cm | 25 | ≥20 |

| Indexes | Viscosity (60 °C, mPa·s) | Density (g/cm3) | Flash Point (°C) | Mass Fraction of Saturates /% | Mass Fraction of Aromatics/% |

|---|---|---|---|---|---|

| WBO | 60 | 0.893 | 209 | 4.32 | 85.51 |

| MO | 57 | 0.876 | 318 | 4.91 | 83.32 |

| Specification | 50–500 | 0.8–1.05 | ≥200 | ≤30 | Measured |

| Test | Result | Specification |

|---|---|---|

| Penetration (25 °C)/(0.1 mm) | 29 | 60–80 |

| Softening point (≥)/°C | 81 | ≥45 |

| Ductility(10 °C)/cm | 10 | ≥20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, S.; Bu, W.; Niu, K.; Wang, H. Multi-Characterization of Rejuvenators’ Impact on Aged Asphalt Binder Properties. Materials 2025, 18, 4060. https://doi.org/10.3390/ma18174060

Hu S, Bu W, Niu K, Wang H. Multi-Characterization of Rejuvenators’ Impact on Aged Asphalt Binder Properties. Materials. 2025; 18(17):4060. https://doi.org/10.3390/ma18174060

Chicago/Turabian StyleHu, Sen, Wentao Bu, Kaimin Niu, and Haowu Wang. 2025. "Multi-Characterization of Rejuvenators’ Impact on Aged Asphalt Binder Properties" Materials 18, no. 17: 4060. https://doi.org/10.3390/ma18174060

APA StyleHu, S., Bu, W., Niu, K., & Wang, H. (2025). Multi-Characterization of Rejuvenators’ Impact on Aged Asphalt Binder Properties. Materials, 18(17), 4060. https://doi.org/10.3390/ma18174060