Effect of Endodontic Irrigants on the Cyclic Fatigue Resistance of Nickel–Titanium Rotary Instruments: A Systematic Review

Abstract

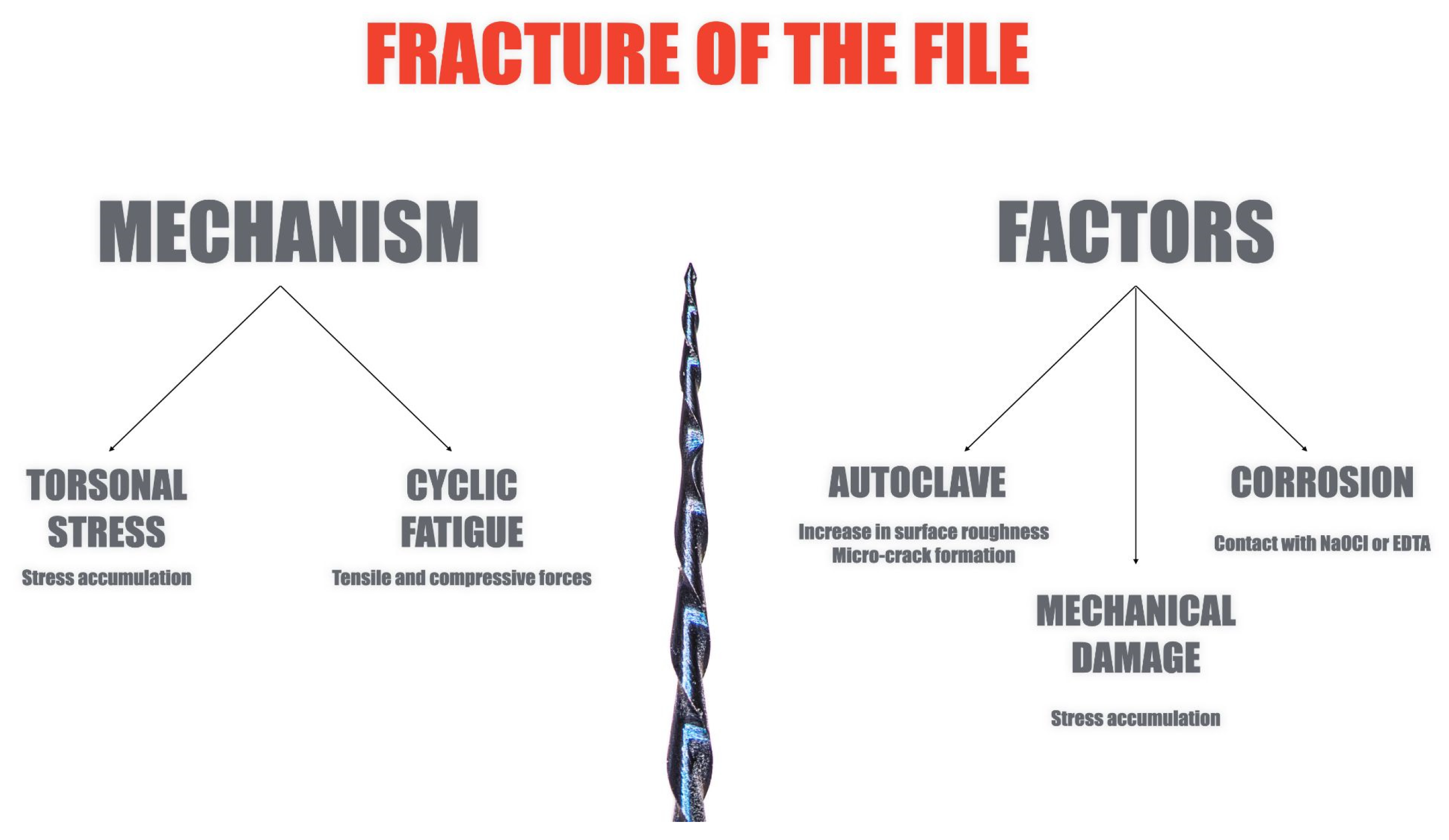

1. Introduction

2. Materials and Methods

2.1. Focused Question

2.2. Protocol

2.3. Eligibility Criteria

- Investigation of cyclic fatigue resistance of NiTi rotary instruments depending on irrigant solutions

- Changes in specified surfaces evaluated using optical microscope and/or Scanning Electron Microscope (SEM) and/or profilometers and/or Micro-Computed Tomography (Micro-CT);

- In vitro studies;

- Studies in English;

- Full-text articles;

- Not an investigation of irrigant solutions on cyclic fatigue resistance

- Non-English papers;

- Clinical reports;

- Opinions;

- Editorial papers;

- Review articles;

- No full-text accessible;

- Duplicated publications.

2.4. Information Sources, Search Strategy, and Study Selection

2.5. Data Collection Process and Data Items

2.6. Risk of Bias and Quality Assessment

2.7. Quality Assessment

- Is it clear in the study what is the ‘cause’ and what is the ‘effect’?

- Were the participants included in any similar comparisons?

- Were the participants included in any comparisons receiving similar treatment/care, other than the exposure or intervention of interest?

- Was there a control group?

- Were there multiple measurements of the outcome both before and after the intervention/exposure?

- Was a follow-up completed, and if not, were differences between groups in terms of their follow-up adequately described and analyzed?

- Were the outcomes of participants included in any comparisons measured in the same way?

- Were the outcomes measured in a reliable way?

- Was an appropriate statistical analysis used?

3. Results

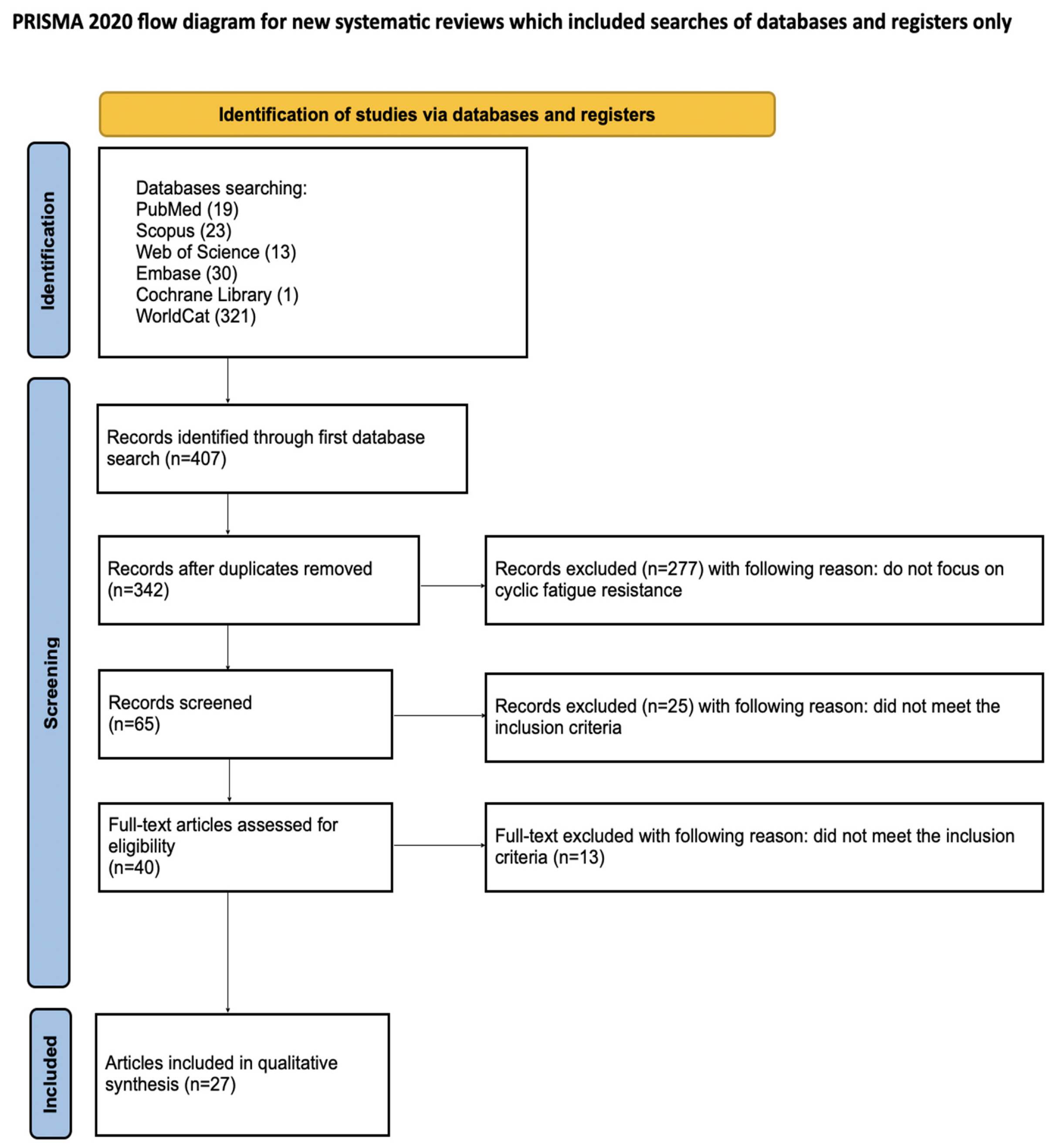

3.1. Study Selection

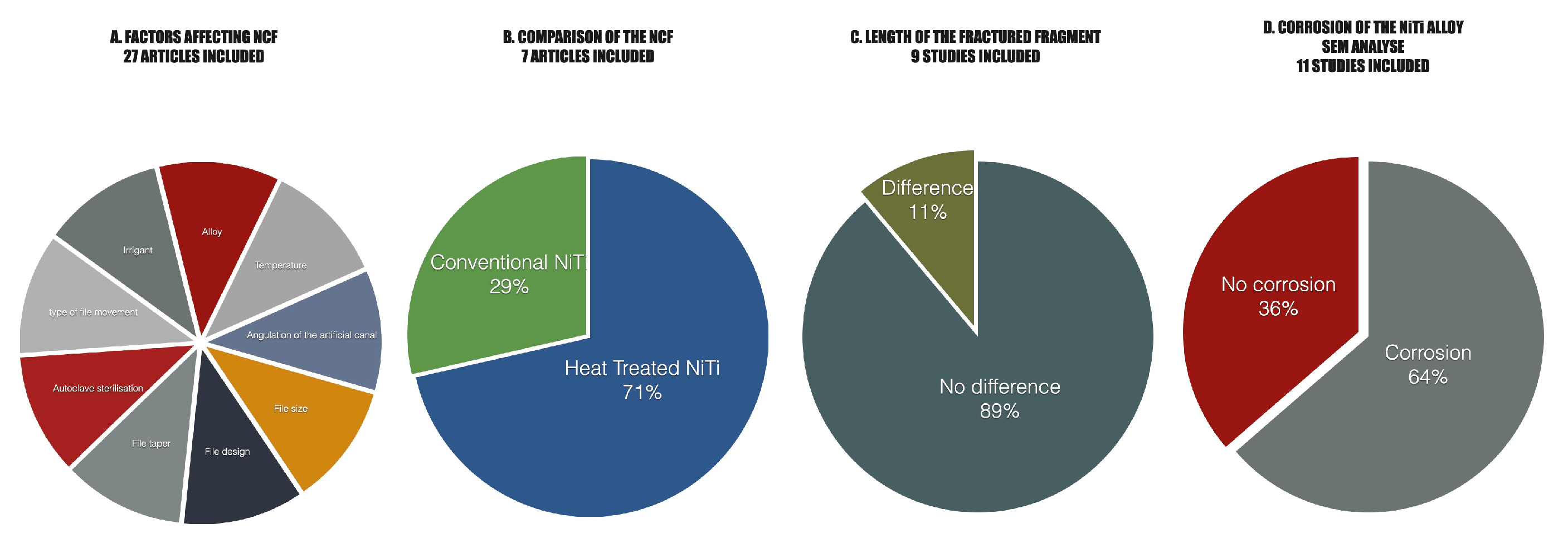

3.2. General Characteristics of the Included Studies

3.3. Main Study Outcomes

3.3.1. Number of Cycles to Fracture (NCF)

3.3.2. Fracture Fragment Length

3.3.3. Scanning Electron Microscopy (SEM) Analysis

| Author | Instrument Type, Alloy | Irrigant (Type + Conc. + Temp. + Exposure) | Parameters of Simulated Canal | Rotation, Speed | Fatigue Test Method | Fatigue Resistance Results | Surface Analysis (SEM) |

|---|---|---|---|---|---|---|---|

| de Castro Martins [22] | Total files = 80 Type: ProFile Sizes 20, 25, 30 with 0.04 taper Size 20 with 0.06 taper Alloy: NiTi | 5.25% NaOCl deionized water Temp.: Not specified Exposure: EG1: 24 h immersion in NaOCl EG2: Used deionized water for shaping canals EG3: Used NaOCl for shaping canals | Artificial canals—AISI H13 tool steel, 45° angle of curvature and 5 mm radius The area of max. tensile strain amplitude at about 4 mm from the tip of the instrument | Constant speed of 250 rpm, -low speed, -low torque. | Rotating bending fatigue test Conducted using a custom test bench with artificial canals | Fracture location: typically ~4 mm from the tip. CG: NCF –#20/0.04: ≈1000 –#25/0.04: ≈800 –#30/0.04: ≈650 –#20/0.06: ≈700 EG1: NCF –#20/0.04: ≈950 –#25/0.04: ≈750 –#30/0.04: ≈600 –#20/0.06: ≈680 EG2: NCF –#20/0.04: ≈600 –#25/0.04: ≈500 –#30/0.04: ≈450 #20/0.06: ≈400 EG3: –#20/0.04: ≈600 –#25/0.04: ≈500 –#30/0.04: ≈450 –#20/0.06: ≈420 EG2 and EG3 had significantly lower NCF than CG and EG1. EG1 showed no significant change from control. EG3 showed higher fatigue resistance than EG2, but not statistically significant | EG1: No signs of corrosion or surface alteration EG2 & EG3 (post use): Signs of fretting, scratched surfaces, metal flash loss but no corrosion visible under SEM. Presence of microcracks between 2.2 mm and 3.8 mm from tip. SEM of fractured surfaces showed fatigue striations and ductile fracture characteristics |

| Cheung [28] | Total files = 179 Type: ProFile, K3, HERO, Shaper, FlexMaster Size 25, 0.04 and 0.06 tapers Alloy: NiTi | 1.2% NaOCl Temp.: 23 °C ± 2 °C Exposure: Continuous immersion during the entire fatigue test (i.e., real-time exposure during rotation) | Custom-made device mimicking rotational instruments were pre-bent to a curvature (radius Rc measured from photo) Noexact canal length or curvature angle specified—just that curvatures varied and were controlled | -250 rpm -maximum torque | The Low-Cycle Fatigue test (LFC)—rotational-bending low cycle fatigue test Nf < 2000 cycles The test focused on the strain-life relationship, calculating surface strain amplitude using the instrument’s curvature and fracture cross-section diameter. This follows the Coffin–Manson equation, which is standard for LCF evaluation. | ProFile (PF) Number of samples: 30 Y-intercept: 2.2220 Fatigue-ductility exponent (c ± SE): −0.612 ± 0.070 Coefficient of determination (R²): 0.732 K3 Number of samples: 28 Y-intercept: 2.0577 Fatigue-ductility exponent (c ± SE): −0.583 ± 0.094 Coefficient of determination (R²): 0.594 HERO Shaper (HE) Number of samples: 49 Y-intercept: 2.0680 Fatigue-ductility exponent (c ± SE): −0.568 ± 0.049 Coefficient of determination (R²): 0.745 FlexMaster (FM) Number of samples: 29 Y-intercept: 2.2519 Fatigue-ductility exponent (c ± SE): −0.648 ± 0.141 Coefficient of determination (R²): 0.439 | SEM was used Corrosion pits were found in ~13% of all samples across all brands. These pits were usually located at or near the vertex of the cross-section. When present, pits were always the site of crack initiation. PF: 14% with pits K3: 13% HE: 13% FM: 13% Multiple crack origins were more common in some brands (e.g., K3: 48% of samples). Fractographic analysis showed that cracks initiated in high-strain areas and then grew inward. |

| Ormiga Galvão Barbosa [23] | Total files= 32 Type: K3 Size 25, taper 0.06 Alloy: NiTi | 5.25% NaOCl Temp.: not specified Exposure: immersion of files in 400 mL of 5.25% NaOCl for up to 8 h | Material: Small glass tube used to simulate canal curvature Angle: 45 degrees Curvature Radius: 5 mm Location of Curvature: Between 3 and 7 mm from the tip of the file | Flexural fatigue tests: 300 rpm Torsional resistance tests: 1 rpm clockwise | Flexural fatigue test: Files rotated in a simulated canal (glass tube with curvature) until fracture, monitored by electrical resistance changes Torsional resistance: Files were clamped and twisted until fracture using a torque meter, torque oscillated within the range of 2.5 to 4.5 Ncm. | Files as Received -Flexural Fatigue Test: Number of cycles: 7993.13 ± 2469.26 -Torsional Resistance Test: Angle (degrees): 481.50 ± 54.59 Torque (N·cm): 3.80 ± 0.59 Files Exposed to NaClO -Flexural Fatigue Test: Number of cycles: 8235.63 ± 1652.55 -Torsional Resistance Test: Angle (degrees): 477.75 ± 103.87 Torque (N·cm): 3.73 ± 0.35 | No evidence of localized corrosion or surface changes after exposure to NaClO. SEM images showed similar morphology between new and NaClO-exposed files |

| Berutti [24] | Total files = 120 Type: ProTaper (F2) Alloy: NiTi | 5% NaOCl Temp.: 50 °C Exposure Time: 5 min (EG1—20 mm, EG2—whole files) | Material: Stainless steel artificial canal Curvature: 60° Radius of Curvature: 10 mm Constant air cooling was applied to avoid overheating | Constant speed 300 rpm | Cyclic fatigue test using a motorized endodontic instrument in a stainless steel simulated canal. Instruments rotated until fracture; time to fracture was recorded. | Group 1 (control): Mean fracture time = 142.47 s Group 2 (20 mm immersed): Mean = 136.50 s Group 3 (fully immersed): Mean = 105.15 s Group 3 had significantly lower resistance (p < 0.001). Some instruments fractured after only 7 s. Groups 1 and 2 were not significantly different (p = 0.42) | SEM revealed corrosion damage in Group 3: localized pitting and cracks, especially near fracture areas. EDS spectra showed nickel and titanium in non-corroded zones; in corroded areas, oxides of Ni and Ti were present along with calcium carbonate (from tap water). Fractures showed intergranular propagation linked to corrosion sites. |

| Javadi [29] | Total files= 90 Type: M3 Pro Gold, SP1 (V-Taper Gold). M3 size 25, taper 0.06 SP1 size F2 Alloy: M3 Pro Gold: Gold-treated CM wire (Controlled Memory alloy), composed of martensite and austenite phases at room temperature. SP1: Manufactured using H-wire technology, exact alloy composition is not disclosed. | 5% NaOCl Deconex Temp.: Room temperature (~25 °C) Exposure: 5 min | Material: Stainless steel groove in chromium-cobalt block Shape: Corresponded to size #25/0.06 gutta-percha Curvature: 45° angle, 5 mm radius of curvature | SP1: 350 rpm, torque 2 N·cm M3 Pro Gold: 350 rpm, torque 3 N·cm | Cyclic fatigue test performed using a custom- made device. Files were rotated in an artificial canal until fracture. The setup included a motorized handpiece mounted on a fixed base. Tempered glass cover was used for visual monitoring. Lubricant spray (Hi-Clean) used to reduce friction. | NCF (M3)—Deconex: 79.67 ± 8.2 NCF (M3)—5% NaOCl: 72.93 ± 6.92 NCF (M3)—No immersion: 111.6 ± 7.02 NCF (M3)—Total: 88.07 ± 18.53 NCF (SP1)—Deconex: 158.53 ± 8.14 NCF (SP1)—5% NaOCl: 120.67 ± 19.7 NCF (SP1)—No immersion: 118 ± 19.08 NCF (SP1)—Total: 132.4 ± 23.46 NCF (Total)—Deconex: 119.1 ± 40.9 NCF (Total)—5% NaOCl: 96.8 ± 28.28 NCF (Total)—No immersion: 114.8 ± 10.82 NCF (Total)—Total: 110.23 ± 30.63 Highest resistance: SP1 in Deconex (158.53 ± 8.14) Lowest resistance: M3 in NaOCl (72.93 ± 6.92) SP1 files had significantly higher resistance than M3 files overall (p < 0.001). NaOCl immersion reduced fatigue resistance, especially for M3. Deconex either maintained or increased resistance, especially in SP1. | None |

| Palma [30] | Total files= 90 Type: ProTaper Next (PTN), Hyflex CM (CM), Hyflex EDM (EDM) Size 25, taper 0.06 (PTN, CM) Size 25, variable taper (EDM) Alloy: NiTi | 3% NaOCl Temp.: 37 °C Exposure: 1 min or 5 min of dynamic immersion (rotating in a glass container) | Cyclic fatigue testing inside a curved canal milled from stainless-steel blocks Length: 16 mm Curvature: 45° angle, Radius: 5 mm Width: 1.4 mm coronally, 0.5 mm apically The axial movement of the canal = 3.5 mm amplitude at ⅓ Hz | PTN: 300 rpm, torque 2.0 N·cm CM and EDM: 500 rpm, torque 2.5 N·cm | Dynamic cyclic fatigue model with axial movement. Performed in an artificial canal heated to 37 °C Number of cycles to fracture recorded by software | NCF: PTN: -Without immersion: 1237.50 ± 177.24 -After 1 min in NaOCl: 1193.00 ± 184.69 (3.6% reduction) -After 5 min in NaOCl: 1172.00 ± 186.31 (5.3% reduction) -p value: < 0.01 CM: -Without immersion: 2155.60 ± 372.25 -After 1 min in NaOCl: 1833.32 ± 346.33 (15% reduction) -After 5 min in NaOCl: 1859.17 ± 307.32 (14% reduction) -p value: < 0.01 EDM: -Without immersion: 6028.33 ± 1012.20 -After 1 min in NaOCl: 5182.32 ± 829.46 (14% reduction) -After 5 min in NaOCl: 5508.33 ± 480.89 (9% reduction) -p value: < 0.01 NaOCl reduced fatigue resistance in all systems, especially in CM and EDM. | SEM analysis was performed on two randomly selected samples from each group to examine: Fracture surfaces. All files showed features typical of cyclic fatigue: -Initiation zone, -Crack propagation zone, -Final fracture zone with visible dimples. Surface condition—After immersion in NaOCl (especially 5 min), corrosion was observed in the form of: -Craters -Pitting defects More evident on EDM instruments due to their rougher surfaces. |

| Devi Priya [31] | 320 files TruNatomy (NiTi wire that is used to manufacture most generic files, followed by a special heat treatment), Hyflex CM (controlled memory wire with a lower Nickel content), Hyflex EDM (controlled memory wire with electric discharge machining (EDM), EdgeFile X3 (Fire-Wire NiTi alloy) Size 25.06 20 files per subgroup | Subgroup1. Control group S2. NaOCl 5.25% for 3 min S3. Autoclave 3 cycles 121 °C S4. NaOCl 5.25% for 3 min and Autoclave 3 cycles 121 °C | 75° angle of curvature, a 5 mm radius of curvature to the center, overall length of 17 mm. Built with Schneider’s technique. | Continuous rotation 500 rpm | Fatigue test was performed after the immersion and autoclave. The tool allowed the instrument to revolve freely and under steady pressure inside the man-made canal. Till a fracture developed, all instruments were turned. The mechanical parts were lubricated with a synthetic oil (Turbo X Spray Plus (NSK, Tokyo, Japan)) | NCF TruNatomy S1. 271.11 ± 56.22 S2. 277.33 ± 34.22 S3. 185.00 ± 99.00 S4. 366.33 ± 74.22 HyflexCM S1. 433.99 ± 125.22 S2. 811.00 251.00 S3. 666.22 ± 266.00 S4. 700.22 ± 231.22 HyflexEDM S1. 768.88 ± 109.22 S2. 721.33 ± 93.22 S3. 725.00 ± 86.00 S4. 963.00 ± 221.96 EdgefileX3 S1. 803.28 ± 171.22 S2. 1222.31 ± 266.22 S3. 1355.00 ± 581.00 S4. 1495.00 ± 394.22 | None |

| Mousavi [25] | 45 files, 15 per subgroup ProTaper Gold S1 | NaOCl 5.25% at 22 °C in group 1, at 4 °C in group 2, and at 37 °C in group 3. ±1 °C | Stainless-steel metal block, a curvature angle of 60°, a curvature radius of 5 mm and a length of 25 mm | Rotated at 300 rpm | The block was fixed inside a recipient that was filled with 5.25% sodium hypochlorite. The block and handpiece were fixed in place with a clamp. | NCF Group 1 1248.50000 ±299.17526 4.42 ± 0.45 Group 2 1076.50000 ±190.93411 4.98 ± 0.56 Group 3 1119.50000 ±117.81174 4.48 ± 0.71 | None |

| Tanomaru [47] | 30 files, 10 per subgroup XP-Endo Finisher | Group 1: XPF instruments using 2% chlorhexidine gel as an irrigation solution; Group 2: XPF using 6% sodium hypochlo- rite as an irrigation solution; Group 3 (control group): XPF instruments using lubricating oil (WD-40, Milton Keynes, UK). | Artificial groove measuring 1.5 mm wide, 20 mm long and 3.5 mm deep with a straight cervical segment measuring 14.29 mm, with an arc length of curvature of 4.71 mm, with a radius of curvature of 3 mm angle 90 degree, and ending in a linear apical segment of 1 mm simulating root canals | The speed is 900 RPM and torque 1N·cm. | The irrigant was taken to the artificial canal with Navi tip plastic needles, with a 21 mm long flexible tip penetrating 1 mm into the cervical region of the simulated canal with the needle tip without touching the moving file, maintaining the canal filled with the solution. The files were inserted in the simulated canals until the length of 20 mm, using a stop to register this length. | Time and NCF CHX T-4.99 (1.62) NCF 4558.5 (1495.33) NaOCl T-0.92 (0.91) NCF 1014.00 (795.34) Oil T-0.67 (0.41) NCF 832.50 (354.42) Fragment length CHX 3.90 (0.188) NaOCl 4.05 (0.236) LO 3.82 (0.187) | Analyzed under SEM. Absence of plastic deformation in the helical shaft of all instruments |

| Abuhulaibah [32] | 90 files 15 per subgroup One Curve (OC) iso25 (heat-treated C-wire technology ) and ProTaper Gold (PTG) F2 | S1. No immersion (control), S2. 1 min immersion, S3. 5 min immersion in 2.5%NaOCl at 37 °C. | 25 mm length, with a single curvature of 60° and a 5 mm radius that was engraved into the block to a depth of 1.5 mm. | Clockwise rotation with individual manufacturer’s recommended speed for each system. | Immersion in sodium hypo was performed before the fatigue test. Test of the files was conducted in a water bath machine, filled with water maintained at 37 °C. A lubrication spray (Pegasus Hand Piece Lubrication Spray, UK) was introduced within the canal space to reduce frictional heat. | NCF PTG-control 752.00 ± 165.37 PTG-1 min NaOCl 651.00 ± 165.64 PTG-5 min NaOCl 490.33 ± 120.65 OC-control 1325.00 ± 334.0 OC-1 min NaOCl 1038.33 ± 204.12 OC-5-min NaOCl 962.33 ± 145.80 | None |

| Svec [26] | 75 files, 25 per group, 5 per subroup ProFile 0.04 taper rotary files 25 mm long in ISO sizes 25, 30, and 35 | Group A control (no rotation, no autoclave, no sodium hypo) Group B Saline, no autoclave Group C Saline, autoclave between cycycles Group D Sodium hypo 5.25%, no autoclave Group E Sodium Hypo 5.25% autoclave between cycles | The tube had a 90° curve with a 5 mm radius of curvature. | 150 rpm | Groups B, C, D, and E were exposed to cyclic fatigue three times for 30 s each time. The files were used in an axial motion with a range of ~6 mm. Group C and E was autoclaved 132C, 30 min between each cycle Torsional moment (N-cm) and angular deflection (degrees) at failure were measured on the Torsiometer/Memocouple | Torsional moment of rotary files Size 25 A 0.78 (0.04) B 0.84 (0.06) C 0.84 (0.07) D 0.81 (0.04) E 0.83 (0.08) Size 30 A 1.06 (0.10) B 1.15 (0.09) C 1.13 (0.10) D 1.10 (0.17 E 1.18 (0.05) Size 35 A 1.47 (0.15) B 1.30 (0.10) C 1.30 (0.13) D 1.38 (0.08) E 1.30 (0.19) Angular deflection of rotary files Size 25 A 500 (30) B 620 (60) C 690 (120) D 580 (70) E 570 (90) Size 30 A 480 (40) B 680 (70) C 620 (110) D 640 (120) E 620 (110) Size 35 A 810 (150) B 790 (60) C 820 (70) D 720 (80) E 610 (120) | None |

| Kermeoglu [33] | 210 files, 70 per type, 10 per subgroup (iso 25) Reciproc R25 file, ProTaper Universal F2 file and Wave One Gold Primary file | Subgroup 1 (control): no immersion Subgroup 2: immersion in 5.25% NaOCl at a temperature of 37 °C was performed for 5 min Subgroup 3: immersion in Irritrol at a temperature of 37 °C was carried out for 5 min. Subgroup 4: immersion in 5.25% NaOCl at a tempera- ture of 37 °C for 5 min with one-cycle autoclave steril- isation was performed. Subgroup 5: the procedure of subgroup 4 was repeated three times. Subgroup 6: immersion in Irritrol at a temperature of 37 °C for 5 min with one-cycle autoclave sterilization was performed. Subgroup 7: the procedure of subgroup 6 was repeated three times. | A stainless steel artificial canal was produced as a result of reproducing the size and taper of the instrument with an angle of curvature of 60°, a radius of curvature of 5 mm and the curvature center-positioned 5 mm from the artificial canal’s tip | Reciproc ALL PTU instruments were utilized with the identical endodontic motor at 500 rpm and the highest torque level WaveOne ALL | Immersion and autoclave was performed before the fatigue test. The dynamic cyclic fatigue test was conducted on the chosen instruments by utilizing a custom-made cyclic fatigue testing device. For the fatigue test in SS artificial block there was an application of synthetic oil (Super Oil; Singer Co Ltd., Elizabethport, NJ, USA) All instruments were rotated in a freeway within the artificial canal until occurring a fracture. | TF ProTaper Control: 29.94 ± 5.62 Subgroup 2: 22.65 ± 9.94 Subgroup 3: 28.31 ± 4.95 Subgroup 4: 19.29 ± 4.79 Subgroup 5: 14.09 ± 4.95 Subgroup 6: 18.75 ± 3.44 Subgroup 7: 13.22 ± 4.08 Total: 20.89 ± 8.16 WaveOne Gold Control: 51.38 ± 11.81 Subgroup 2: 47.90 ± 3.02 Subgroup 3: 47.82 ± 5.23 Subgroup 4: 45.15 ± 12.20 Subgroup 5: 42.65 ± 15.28 Subgroup 6: 45.54 ± 17.60 Subgroup 7: 40.00 ± 15.68 Total: 45.78 ± 12.51 Reciproc Control: 126.90 ± 20.50 Subgroup 2: 122.79 ± 21.85 Subgroup 3: 113.60 ± 23.71 Subgroup 4: 112.32 ± 20.68 Subgroup 5: 108.36 ± 30.96 Subgroup 6: 111.62 ± 21.86 Subgroup 7: 93.68 ± 18.61 Total: 112.75 ± 24.04 Total Control: 69.40 ± 44.41 Subgroup 2: 64.45 ± 45.30 Subgroup 3: 63.24 ± 39.59 Subgroup 4: 58.92 ± 42.15 Subgroup 5: 55.04 ± 44.60 Subgroup 6: 58.64 ± 42.68 Subgroup 7: 48.97 ± 36.70 Total: 59.81 ± 42.15 Length ProTaper Control: 3.37 ± 0.36 Subgroup 2: 2.97 ± 0.27 Subgroup 3: 3.04 ± 0.25 Subgroup 4: 2.81 ± 0.36 Subgroup 5: 3.20 ± 0.19 Subgroup 6: 3.19 ± 0.25 Subgroup 7: 3.42 ± 0.32 Total: 3.14 ± 0.35 WaveOne Gold Control: 2.28 ± 0.09 Subgroup 2: 2.31 ± 0.07 Subgroup 3: 2.28 ± 0.12 Subgroup 4: 2.63 ± 0.32 Subgroup 5: 3.18 ± 0.77 Subgroup 6: 3.46 ± 0.67 Subgroup 7: 2.44 ± 0.25 Total: 2.65 ± 0.60 Reciproc Control: 2.17 ± 0.22 Subgroup 2: 2.08 ± 0.15 Subgroup 3: 2.12 ± 0.17 Subgroup 4: 3.17 ± 1.00 Subgroup 5: 3.36 ± 0.93 Subgroup 6: 3.68 ± 0.29 Subgroup 7: 3.85 ± 0.73 Total: 2.92 ± 0.93 Total Control: 2.60 ± 0.60 Subgroup 2: 2.45 ± 0.40 Subgroup 3: 2.48 ± 0.44 Subgroup 4: 2.87 ± 0.66 Subgroup 5: 3.25 ± 0.69 Subgroup 6: 3.44 ± 0.48 Subgroup 7: 3.24 ± 0.76 Total: 2.90 ± 0.69 | The SEM images of the fractured surfaces of the Pro- Taper, WOG and Reciproc files after the cyclic fatigue test under 3009 and 30,009 magnifications showed the typical pattern of a cyclic fatigue fracture with a fatigue striation and circular abrasion mark. Similarly to previous studies, |

| Pedulla [34] | 210 files, 15 per subgroup per type (25/0.06) Twisted Files and Hyflex CM | Group 1 (control group) no autoclave, no sodium hypo Groups 2—1 time immersion in sodium hypo 5% for 3 min. Group3—3 times immersion in sodium hypo 5% for 3 min. Groups 4—1 time autoclave Group 5—3 times autoclave Group 6—immersion in sodium hypo and 1 time autoclave Group 7 immersion in NaOCl and 3 times autoclave. | Metal block with a suitable artificial canal with a 60 degree angle of curvature and a 5 mm radius of curvature to the center of the 1.5-mm-wide canal. | Continuous rotation at 500 rpm. | Dynamic immersion (1 or 3 min) was allowed, activating the endodontic instruments with a 500 rpm. Autoclave 134, 17 min. Immersion was before autoclaving | NCF Instrument: Hyflex CM Group 1: n = 15, NCF = 710.5, SD = 71.2 Group 2: n = 15, NCF = 792.6, SD = 55.8 Group 3: n = 15, NCF = 686.4, SD = 63.5 Group 4: n = 15, NCF = 750.0, SD = 51.5 Group 5: n = 15, NCF = 797.5, SD = 65.0 Group 6: n = 15, NCF = 681.4, SD = 42.6 Group 7: n = 15, NCF = 732.2, SD = 74.5 Instrument: Twisted File Group 1: n = 15, NCF = 705.8, SD = 75.8 Group 2: n = 15, NCF = 674.4, SD = 77.6 Group 3: n = 15, NCF = 661.4, SD = 81.5 Group 4: n = 15, NCF = 638.9, SD = 70.2 Group 5: n = 15, NCF = 484.9, SD = 74.4 Group 6: n = 15, NCF = 641.9, SD = 83.7 Group 7: n = 15, NCF = 548.8, SD = 68.2 | SEM analyses Clear crack initiation zones and overload fast fracture zones, both typical of cyclic fatigue failure, were evident on all samples. Surface Grooves: -HyFlex CM files exhibited grooves orthogonal (perpendicular) to their longitudinal axis. -Twisted Files (TFs) displayed grooves parallel to the longitudinal axis. |

| Huang [35] | K3, K3XF, Vortex 12 files per group (size 25/0.04), | Sodium hypochlorite 5.25% and distilled water in 3 temperatures: 2 °C, 37 °C, 60 °C. | Novel artificial ceramic canal with a curvature of 60 degree and a 5 mm radius. | K3 was rotated at 300 rpm, and K3XF and Vortex were allowed to rotate at 500 rpm as recommended by the manufacturer | Fixed in a glass container filled with 300 mL 5.25% NaOCl or distilled water that was placed on a hot plate | K3 -Distilled water 501.54 ± 70.46 at 22 °C, 413.75 ± 46.67 at 37 °C, and 328.75 ± 47.87 at 60 °C. -In 5.25% sodium hypochlorite 433.33 ± 57.98 at 22 °C, 348.33 ± 72.00 at 37 °C, and 284.17 ± 38.54 at 60 °C. K3XF -In distilled water: 914.58 ± 215.30 revolutions at 22 °C, 603.47 ± 112.45 at 37 °C, and 326.00 ± 39.07 at 60 °C. -In 5.25% NaOCl: 884.72 ± 242.96 at 22 °C, 505.56 ± 73.29 at 37 °C, and 293.06 ± 62.45 at 60 °C. Vortex -In distilled water: 1356.94 ± 126.87 revolutions at 22 °C, 1102.78 ± 84.93 at 37 °C, 638.89 ± 64.46 at 60 °C. -In 5.25% NaOCl: 1197.92 ± 64.76 at 22 °C, 1098.61 ± 90.65 at 37 °C, 609.72 ± 77.59 at 60 °C. | Typical fracture patterns were present in all 3 files including 1 or 2 crack initiation areas, the presence of fatigue striations, and a fast fracture zone with dimples. No pitting or crevice corrosion in water or 5.25% NaOCl was present |

| Topcuoglu [36] | 90 files, 30 per brand, 15 per group, ProTaper D3 (size 20, 0.07 taper), D-RaCe DR2 (size 25, 0.04 taper), and Mtwo R2 (size 25, 0.05 taper). | Group 1—no immersion (control group) Group 2 immersion in 5% NaOCl at 37 °C for 5 min. (16 mm of the working part). | 60° angle of curvature 5 mm radius of curvature. Measuring method of Schneider. curvature center 5 mm from the instrument tip | Manufacturer’s recommendation (ProTaper D3; 400 rpm, D-RaCe DR2; 600 rpm, Mtwo R2, 280 rpm) | Immersion before the fatigue test, special oil (WD-40 Company, Milton Keynes, UK) was used for lubrication. The diameter of the simulated canal was higher than the instruments allowing free rotation. Instrument rotated freely at a constant pressure | NCF: NaOCl: PT 703.07 ± 212.14 Mtwo 728.33 ± 189.74 D-race 832.67 ± 257.38 No immersion: PT 744.93 ± 283.21 Mtwo 785.07 ± 164.43 D-race—949.87 ± 266.94 Fragment length: NaOCl: PT 4.69 ± 0.2 Mtwo 5.08 ± 0.4 D-race 5.06 ± 0.3 No immersion: PT—4.30 ± 0.3 Mtwo—4.91 ± 0.5 D-race—5.00 ± 0.4 | None |

| Alfawaz [27] | 135 files 15 files per group ProTaper Gold F2 | Three liquids—distilled water, Sodium hypochlorite 2.5%, Sodium Hypochlorite 5.25% All in three temperatures 25, 37, 60 Celsius degree. | curvature angle of 60 degree, a curvature radius of 5 mm, and a curvature center 5 mm from the instrument tip | Rotation at 300 rpm until fracturing occurred. | The block was fixed inside a recipient that was filled with tested liquids. endodontic rotary motor was mounted on a device that allowed reproducible and fixed positioning | NCF Fragment length At 25 °C, the number of cycles to fracture (NCF) for ProTaper Gold F2 was: 1239.1 ± 388.2 in distilled water, 761.3 ± 270.9 in 2.5% NaOCl 877.8 ± 298.0 in 5.25% NaOCl At 37 °C, the NCF values were: 962.9 ± 276.0 in distilled water, 662.3 ± 227.9 in 2.5% NaOCl, 571.1 ± 172.3 in 5.25% NaOCl. At 60 °C, the NCF values were: 418.8 ± 114.8 in distilled water, 325.9 ± 116.9 in 2.5% NaOCl, 305.6 ± 90.6 in 5.25% NaOCl. The length of the fractured fragments was in the range between 4.1 ± 0.77 and 5.2 ± 0.78 mm. | The fracture surfaces of PTG F2 instruments observed under scanning electron microscopy (SEM) at various temperatures and irrigation conditions exhibited characteristic features of cyclic fatigue. These included one or two crack initiation sites, the presence of fatigue striations, and a fast-fracture zone marked by dimples. Examination of the fracture cross-sections revealed that cracks consistently initiated at the cutting edges, with microscopic dimples evident on the fracture surfaces. Notably, none of the tested instruments showed signs of pitting or crevice corrosion when exposed to water or 5.25% NaOCl, as confirmed by SEM analysis. |

| Bulem [37] | 160 files, 40 per brand, 10 per group—25.06 ProFile FlexMaster Mtwo Twisted File | Group 1—Sodium Hypo 2.5%, 5 min, room temperature Group 2—Sodium Hypo 2.5%, 5 min, room temperature and 1 autoclave cycle 135 °C, 32.5 minutes Group 3—5 full cycles of Group 2 protocol 5× (sodium hypo-autoclave) Group 4—control group—no sodium hypo, no autoclave | 60° angle, 2.5 mm radius, curvature beginning 2 mm from the tip of the file | 300 rpm for Profile, FlexMasrter, Mtwo 500 rpm for Twisted File | Immersion and autoclave was performed before fatigue test Endodontic motor was fixed, with no movement | ProFile (n = 40): Control: NCF = 396.5 (SD = 77.46), Fragment length = 2.6 mm (SD = 0.4) 5 min 2.5% NaOCl: NCF = 385.5 (SD = 76.03), Fragment length = 2.4 mm (SD = 0.5) 5 min 2.5% NaOCl + sterilization: NCF = 359 (SD = 73.25), Fragment length = 2.5 mm (SD = 0.6) 5× (5 min 2.5% NaOCl + sterilization): NCF = 320 (SD = 61.55), Fragment length = 2.6 mm (SD = 0.2) FlexMaster (n = 40): Control: NCF = 379 (SD = 70.54), Fragment length = 3 mm (SD = 0.4) 5 min 2.5% NaOCl: NCF = 378 (SD = 53.39), Fragment length = 2.5 mm (SD = 0.4) 5 min 2.5% NaOCl + sterilization: NCF = 374 (SD = 70.82), Fragment length = 2.7 mm (SD = 0.3) 5× (5 min 2.5% NaOCl + sterilization): NCF = 373.5 (SD = 67.37), Fragment length = 2.5 mm (SD = 0.4) Twisted File (n = 40): Control: NCF = 551.2 (SD = 118.78), Fragment length = 2.4 mm (SD = 0.4) 5 min 2.5% NaOCl: NCF = 526.5 (SD = 105.8), Fragment length = 2.4 mm (SD = 0.2) 5 min 2.5% NaOCl + sterilization: NCF = 439 (SD = 148.16), Fragment length = 2.6 mm (SD = 0.4) 5× (5 min 2.5% NaOCl + sterilization): NCF = 415.7 (SD = 126.21), Fragment length = 2.5 mm (SD = 0.2) Mtwo (n = 40): Control: NCF = 599.5 (SD = 79.46), Fragment length = 2.8 mm (SD = 0.2) 5 min 2.5% NaOCl: NCF = 560 (SD = 56.81), Fragment length = 2.7 mm (SD = 0.2) 5 min 2.5% NaOCl + sterilization: NCF = 553 (SD = 87.94), Fragment length = 2.6 mm (SD = 0.2) 5× (5 min 2.5% NaOCl + sterilization): NCF = 514.5 (SD = 73.76), Fragment length = 2.6 mm (SD = 0.2) | None |

| Pedulla [38] | 90 files 45 per brand 15 per group Reciproc R25 and WaveOne Primary | Group 1 (control) new instruments Group 2 immersion in sodium hypo 5%, 37 °C, 1 min Group 3 immersion in sodium hypo 5%, 37 °C, 5 min | The artifi- cial canal was manufactured by reproducing an instrument’s size and taper. It provided the instrument with a suitable simulated root canal with a 60° angle of curvature and 5 mm radius of curvature measured according to the method of Schneider The center of the curvature was 6 mm from the tip of the instrument, | RECIPROC ALL and WAVEONE ALL | dynamic immersion, with a 6:1 reduction endodontic motor After rinsing and drying all three groups of each brand were tested in fatigue test | Time to fracture (in seconds) RECIPROC, Group 1: Mean TtF was 119.7 s. Median = 121 s. Standard deviation = 17.72. Group 2: Mean TtF = 107.0 s. Median = 106 s. Standard deviation = 18.94. Group 3: Mean TtF = 108.8 s. Median = 111 s. Standard deviation = 17.27. WAVEONE, Group 1: Mean TtF = 74.8 s. Median = 74 s. Standard deviation = 14.59. Group 2: Mean TtF = 70.5 s. Median = 68 s. Standard deviation = 13.60. Group 3: Mean TtF = 71.0 s. Median = 73 s. Standard deviation = 14.92. | None |

| Cai [39] | 25.06 HyFlex and M3 AFM testing: 4 files 2 per brand Fatigue test 72 files 36 files per brand 12 er subgroup | AFM test dynamic immersion in 5.25% sodium hypochlorite or 17% (EDTA) solution for 10 min Fatigue test 5.25% NaOCl Group 1—no immersion, Group 2—dynamic immersion in 5.25% sodium hypochlorite for 10 min Group 3—17% (EDTA) solution for 10 min | curvature of 45° with a 3 mm radius | 400 or 500 rpm | Dynamic immersion in 5.25% NaOCl for 10 min and Groups 3 were dynamic Immersion in 17% EDTA for 10 min. Fatigue test synthetic oil was sprayed into the simulated canal. Test performed at room temperature. | HyFlex Mean Roughness Ra (nm) New, Mean (Ra): 1441, SD: 373 5.25% NaOCl, Mean (Ra): 1412, SD: 324 17% EDTA, Mean (Ra): 1566, SD: 405 M3 New, Mean (Ra): 1203, SD: 155 5.25% NaOCl, Mean (Ra): 1235, SD: 295 17% EDTA, Mean (Ra): 1269, SD: 258 | AFM atomic force microscopy Significant differences in surface roughness after immersion were observed between the two files. |

| Cheung [15] | ProFile—NiTi engine-file (size 25, 0.04 and 0.06 taper) | Sodium hypochlorite: 1.2% aqueous solution, 23 °C ± 2 °C Deionized water: 23 °C ± 2 °C Air: relative humidity 65%, 23 °C ± 2 °C Silicone oil: “for oil bath”, 23 °C ± 2 °C Exposure: Only the curved portion of the instrument was immersed during testing to avoid galvanic action | Static model using 3 rigid stainless steel pins. Various curvatures tested. Variable radius of curvature (Rc) determined. | 250 rpm, continuous rotational motion | Custom-made rotational-bending fatigue testing machine. The test employed a strain-life approach with continuous rotation at 250 rpm until fracture, with electronic monitoring via optical counter and break-detection circuit. Pecking motion not tested. | air (106 total, 95 failed in LCF), water (106 total, 87 failed in LCF), hypochlorite (39 total, 30 failed in LCF), and silicone oil (40 total, 36 failed in LCF). In the low-cycle fatigue (LCF) region, fatigue life ranged from approximately 100–10,000 cycles before transitioning to high-cycle fatigue at ~1.2% strain amplitude around 2000–10,000 cycles. The regression line slopes for LCF lives were: air (−1.603 ± 0.104), water (−1.190 ± 0.127), hypochlorite (−1.196 ± 0.137), and silicone oil (−1.555 ± 0.128). | Crack origins, fatigue striations, and dimple rupture regions on all specimens. Corrosion assessment: Only 1 specimen in hypochlorite group showed corrosion pits; no corrosion pits found in water, air, or silicone oil groups Crack initiation sites: almost all specimens showed crack initiation at cutting edge or “radial land” region. |

| Elnaghy [40] | WaveOne Gold size 25, 0.07 taper (Gold wire thermal treatment alloy) Reciproc size 25, 0.08 taper (M-Wire NiTi) | Sodium hypochlorite: 5% NaOCl, 37 °C ± 1 °C Saline: 37 °C ± 1 °C Air: control group at room temperature 20 °C ± 1 °C Exposure: Instruments were immersed in test solutions during reciprocation until fracture | Static model using custom-made device with 3 stainless steel pins Curvature angle: 60° Radius: 5 mm radius of curvature Position: Center of curvature was 5 mm from instrument tip Working length: 19 mm for each instrument | Reciprocating motion, WaveOne ALL for WaveOne Gold and Reciproc ALL for Reciproc | Custom-made device with three stainless steel pins (6 mm diameter, 4 cm long) attached to a Teflon base with 0.5 mm wide V-shaped notches to preserve instrument location during rotation, placed inside a glass container and stabilized with clamps. Instruments were reciprocated in test solutions until fracture, with time to failure recorded in seconds and converted to cycles by multiplying by rotational speed. | WaveOne Gold achieved 1505.9 ± 163.75 cycles in air, 1066.0 ± 113.93 cycles in saline, and 990.83 ± 106.93 cycles in NaOCl. Reciproc achieved 1251.03 ± 103.29 cycles in air, 912.83 ± 100.69 cycles in saline, and 880.27 ± 50.79 cycles in NaOCl. WaveOne Gold had 1027 predicted cycles for 99% survival in air, while Reciproc in NaOCl had the lowest predicted cycles (613 cycles). Fragment lengths were consistent around 5 mm from tip across all groups with no significant differences. | Crack origins, fatigue zones, and overload fast fracture zones in all specimens. Crack initiation occurred at the cutting edge in all instruments. Multiple fatigue-crack initiation locations were found in Reciproc fractured fragments, WaveOne Gold had improved resistance to fatigue-crack initiation. No pitting corrosion was observed. |

| Keles [41] | Reciproc 25- traditional NiTi Reciproc Blue R25-heat-treated NiTi WaveOne Primary-traditional NiTi WaveOne Gold Primary—heat-treated NiTi One Shape (25.06)—traditional NiTi | Sodium hypochlorite (5.25% NaOCl) Distilled water (DW) Temperature: 37 °C ± 1 °C and 60 °C ± 1 °C Exposure: 5 min immersion period | Dynamic model (with axial motion) Angle of curvature: 60° Radius: 5 mm Material: Stainless steel artificial canal | Reciproc and Reciproc Blue: Preset “Reciproc” program on X-Smart Plus motor WaveOne and WaveOne Gold: Preset “WaveOne” program on X-Smart Plus motor One Shape: 350 rpm and 2.5 N/cm torque Axial motion: 3 mm amplitude approximately every 2 s (pecking motion) | Dynamic cyclic fatigue test using a specialized cyclic fatigue testing device. Instruments rotated freely until fracture occurred. | TtF (in sec) WaveOne: -Control (no immersion): 157 ± 32 s -Distilled water at 37 °C: 161 ± 6 s -Distilled water at 60 °C: 198 ± 24 s -NaOCl at 37 °C: 164 ± 39 s -NaOCl at 60 °C: 21 ± 10 s WaveOne Gold: -Control (no immersion): 256 ± 63 s -Distilled water at 37 °C: 266 ± 33 s -Distilled water at 60 °C: 208 ± 47 s -NaOCl at 37 °C: 222 ± 42 s -NaOCl at 60 °C: 139 ± 81 s Reciproc: -Control (no immersion): 241 ± 67 s -Distilled water at 37 °C: 277 ± 44 s -Distilled water at 60°C: 312 ± 65 s -NaOCl at 37 °C: 91 ± 27 s -NaOCl at 60 °C: 50 ± 20 s Reciproc Blue: -Control (no immersion): 259 ± 99 s -Distilled water at 37 °C: 314 ± 98 s -Distilled water at 60 °C: 536 ± 106 s -NaOCl at 37 °C: 316 ± 65 s -NaOCl at 60 °C: 301 ± 78 s OneShape: -Control (no immersion): 153 ± 32 s -Distilled water at 37 °C: 142 ± 14 s -Distilled water at 60 °C: 163 ± 31 s -NaOCl at 37 °C: 112 ± 11 s -NaOCl at 60 °C: 85 s | Typical cyclic fatigue failure patterns in all tested instruments. Clear corrosion areas were visible, especially on OneShape instruments after 5 min of immersion in NaOCl at 60 °C. All fractures were consistent with cyclic fatigue failure mechanisms across all test conditions. |

| Alfawaz [42] | F2 size (#25) with 8% taper, 25 mm ProTaper Gold (PTG)—heat-treated NiTi EdgeTaper Platinum (ETP)—heat-treated NiTi | 17% EDTA, 5.25% NaOCl, and Distilled water (control) Temperature: 37 °C ± 1 °C Exposure: Continuous immersion during testing (instruments rotated within the solution-filled canal) | Static artificial canals milled in stainless steel blocks. Angle of curvature: 60° Radius: 5 mm Curvature center: 5 mm from instrument tip | 300 rpm, continuous rotation until fracture. Insertion depth: 19 mm from instrument tip. | Dynamic cyclic fatigue test using artificial canals. Instruments rotated continuously until fracture occurred. Glass bar used to cover canal and prevent slippage. Fracture detected audibly and visually with video recording assistance. | NCF: ProTaper Gold: EDTA: 979.0 ± 184.9 cycles NaOCl: 659.4 ± 111.8 cycles Distilled water: 939.4 ± 176.9 cycles EdgeTaper Platinum: EDTA: 1862.3 ± 365.7 cycles NaOCl: 1422.8 ± 246.6 cycles Distilled water: 1664.5 ± 285.9 cycles | Typical cyclic fatigue failure patterns in all tested instruments. Presence of fatigue striations and crack initiation areas. Fast fracture zone with dimples visible. No indication of corrosion observed in any of the tested solutions (17% EDTA, 5.25% NaOCl, or water). |

| Tyagi [43] | 25 mm length GenEndo—heat-treated NiTi T-wire ProTaper Gold (Dentsply Sirona, New Delhi, India)—heat-treated NiTi Hero Gold—NiTi EdgeFile X3—heat-treated NiTi with annealing treatment | Distilled water (control), 2.5% NaOCl, and 5.25% NaOCl Temperature: 25 °C, 37 °C, and 60 °C Exposure: Continuous immersion during testing (instruments rotated within the solution-filled canal) | Static artificial canals prepared in stainless steel blocks. Angle of curvature: 60° Radius: 5 mm Curvature center: 5 mm from instrument tip | 300 rpm, continuous rotation. Insertion depth: 19 mm from instrument tip | Dynamic cyclic fatigue test using artificial canals. Fixed and reproducible positioning using a mounted handpiece. Glass cover used to prevent instrument slippage and visualize fracture timing. | NCF GenEndo: -Distilled water: 1245.2 ± 382.3 (25 °C), 951.8 ± 289.1 (37 °C), 721.6 ± 112.6 (60 °C) -2.5% NaOCl: 1123.4 ± 265.7 (25 °C), 874.6 ± 227.9 (37 °C), 689.8 ± 117.8 (60 °C) -5.25% NaOCl: 1045.6 ± 287.1 (25 °C), 766.2 ± 192.8 (37 °C), 542.7 ± 91.9 (60 °C) ProTaper Gold: -Distilled water: 1139.1 ± 277.3 (25 °C), 912.9 ± 276.0 (37 °C), 367.7 ± 116.9 (60 °C) -2.5% NaOCl: 721.3 ± 270.9 (25 °C), 602.3 ± 225.6 (37 °C), 305.7 ± 116.7 (60 °C) -5.25% NaOCl: 817.7 ± 296.1 (25 °C), 551.1 ± 174.4 (37 °C), 285.4 ± 90.8 (60 °C) Hero Gold: -Distilled water: 1106.2 ± 266.3 (25 °C), 862.9 ± 276.0 (37 °C), 329.3 ± 121.7 (60 °C) -2.5% NaOCl: 693.2 ± 260.6 (25 °C), 552.3 ± 207.9 (37 °C), 275.9 ± 116.9 (60 °C) -5.25% NaOCl: 786.5 ± 281.1 (25 °C), 518.1 ± 172.3 (37 °C), 254.6 ± 90.6 (60 °C) EdgeFile X3: -Distilled water: 1058.6 ± 277.1 (25 °C), 822.7 ± 243.1 (37 °C), 278.7 ± 115.9 (60 °C) -2.5% NaOCl: 641.2 ± 169.8 (25 °C), 513.7 ± 216.8 (37 °C), 214.8 ± 147.6 (60 °C) -5.25% NaOCl: 744.4 ± 298.0 (25 °C), 476.6 ± 141.4 (37 °C), 194.8 ± 96.7 (60 °C) | Typical cyclic fatigue failure patterns in all tested instruments. Crack initiation areas identified. Consistent fracture morphology across all testing conditions. Evidence of micropitting due to NaOCl corrosive effects, particularly with higher concentrations and temperatures. |

| Erik [44] | -Reciproc blue -Wave One Gold -HyFlex EDM | Temperature of solutions—37 ± 1 °C. Irrigants: -distilled water (control) -6% NaOCl -17% EDTA -+8% HEBP; -3% NaOCl + 9% HEBP | The size of the artificial canals: -25/0.08(RPC Blue and HEDM),—25/0.07 (WO Gold) Curvature: 60°; 5 mm radius. | Reciproc GOLD endodontic motor, -“WaveOne ALL” program for WOG (reciprocal movement, 350 rpm) Reciproc ALL” program for “RPC Blue”(reciprocal movement, 300 rpm) −500 rpm and 2.5 N·cm torque values for HEDM | The files were rotated in the custom-made artificial canals according to manufacturer’s recommendations, until fracture occurred. | Number of cycles to failure (NCF) and fracture length (FL) of instruments 1. Reciproc Blue: (a) Distilled water NCF: 1543.9 ± 185.1 ax FL: 5.2 ± 0.5 (b) 6% NaOCl NCF: 1449.1 ± 202.8 ax FL5.2 ± 0.5 (c) 17% EDTA NCF: 1468.5 ± 190.8 ax FL: 5.1 ± 0.4 (d) 18% HEBP NCF: 1409.2 ± 225.4 ax FL:4.9 ± 0.4 (e) 18% HEBP + 6% NaOCl NCF: 1289.9 ± 141.7 ay FL: 5.2 ± 0.4 p value < 0.05 (for NCF) > 0.05 (for FL) 2. WaveOneGold (a) Distilled water NCF: 1489.8 ± 208.4 ax FL: 5.2 ± 0.3 (b) 6% NaOCl NCF: 1441.5 ± 172.9 ax FL: 5.1 ± 0.4 (c) 17% EDTA NCF: 1444.4 ± 173.2 ax FL: 4.9 ± 0.5 (d) 18% HEBP NCF: 1367.1 ± 177.7 ax FL: 5.3 ± 0.5 (e) 18% HEBP + 6% NaOCl NCF: 1015.1 ± 152.2 ay FL: 5.2 ± 0.4 p value < 0.05 (for NCF) > 0.05 (for FL) 3. HyFlex EDM (a) Distilled water NCF: 1712.3 ± 188.3 bx FL: 5.3 ± 0.4 (b) 6% NaOCl NCF: 1662.1 ± 249.3 bx FL: 5.1 ± 0.4 (c) 17% EDTA NCF: 1672.7 ± 217.3 bx FL: 5.1 ± 0.6 (d) 18% HEBP NCF: 1655.2 ± 198.6 bxFL: 5.2 ± 0.5 (e) 18% HEBP + 6% NaOCl NCF: 1412.3 ± 169.4 by FL: 5.2 ± 0.4 p value < 0.05 (for NCF) > 0.05 (for FL) | The SEM analysis showed typical features of the fractured cross-sectionssurfaces, (fatigue zones, crack origins, overload zones). |

| Pedulla [45] | 150 new Twisted Files (SybronEndo, Orange, CA, USA), Revo S SU files (Micro Mega, Besancon, France), Mtwo files (Sweden & Martina, Padova, Italy), Size 25.06 | 5% NaOCl (Niclor, OGNA Laboratory, Milan, Italy), 37 °C | 60 degree angle of curvature and a 5 mm radius of curvature. The center of the curvature was 6 mm from the tip of the instrument, and the curved segment of the canal was approximately 6 mm in length. | Constant speed of 300 rpm. 6:1 reduction handpiece (Sirona Dental Systems GmbH, Ensheim, Germany) powered by a torque-controlled electric motor (VDW Silver, VDW GmbH–Dentsply International Inc, Munich, Germany). Torque was set at 2 N·cm. | High-flow synthetic oil (Super Oil; Singer Co Ltd., Elizabethport, NJ, USA) was applied. TtF was recorded with a chronometer to an accuracy of 0.1 s. NCF were calculated to the nearest full number ultiplying the seconds by 5 (number of cycles for second using 300 rpm). | Twisted File Group 1 (n = 10): (a) Mean (seconds)-742.5 (b) Median-750 (c) Standard deviation-87.38 (d) Standard error of mean-27.63 (e) Min-555 (f) Max-865 Group 2 (n = 10): (a) Mean (seconds)-729.5 (b) Median-750 (c) Standard deviation-121.7 (d) Standard (error of mean-38.5 (e) Min-575 (f) Max-915 Group 3 (n = 10): (a) Mean (seconds)-703 (b) Median-735 (c) Standard deviation-92.26 (d) Standard error of mean-29.18 (e) Min-520 (f) Max-795 Group 4 (n = 10): (a) Mean (seconds)-802.5 (b) Median-807.5 (c) Standard deviation-84.73 (d) Standard error of mean-26.79 (e) Min-710 (f) Max-975 Group 5 (n = 10): (a) Mean (seconds)-755 (b) Median-767.5 (c) Standard deviation-138.9 (d) Standard error of mean-43.92 (e) Min-450 (f) Max-915 Revo S SU Group 1 (n = 10): (a) Mean (seconds)-395.5 (b) Median-375 (c) Standard deviation-72.17 (d) Standard error of mean-22.82 (e) Min-315 (f) Max-565 Group 2 (n = 10): (a) Mean (seconds)-417.5 (b) Median-452.5 (c) Standard deviation-124.3 (d) Standard error of mean-39.32 (e) Min-155 (f) Max-540 Group 3 (n = 10): (a) Mean (seconds)-392 (b) Median-390 (c) Standard deviation-92.14 (d) Standard error of mean-29.14 (e) Min-275 (f) Max-545 Group 4 (n = 10): (a) Mean (seconds)-390 (b) Median- 367.5 (c) Standard deviation-92,33 (d) Standard error of mean-29.2 (e) Min-260 (f) Max-530 Group 5 (n = 10): (a) Mean (seconds)-382 (b) Median- 390 (c) Standard deviation-35.76 (d) Standard error of mean-11.31 (e) Min-305 (f) Max-420 Mtwo Group 1 (n = 10): (a) Mean (seconds)-560 (b) Median-540 (c) Standard deviation-107.5 (d) Standard error of mean-33.99 (e) Min-450 (f) Max-730 Group 2 (n = 10): (a) Mean (seconds)-533 (b) Median-480 (c) Standard deviation-122 (d) Standard error of mean-38.59 (e) Min-380 (f) Max-700 Group 3 (n = 10): (a) Mean (seconds)-563 (b) Median-515.5 (c) Standard deviation-145.5 (d) Standard error of mean-46.01 (e) Min-435 (f) Max-905 Group 4 (n = 10): (a) Mean (seconds)-579.5 (b) Median-552.5 (c) Standard deviation-113 (d) Standard error of mean-35.73 (e) Min-450 (f) Max-800 Group 5 (n = 10): (a) Mean (seconds)-571.5 (b) Median-572.5 (c) Standard deviation-145.8 (d) Standard error of mean-46.12 (e) Min-415 (f) Max-840 | There was no SEM analysis |

| Dosanjh [46] | 30 files per subgroup EdgeEndo, Vortex Blue; ESX size 25 with a 0.04 | 4 subgroups 1—water at 3 °C, 2—water at 22 °C, 3—water at 37 °C, 4—water at 60 °C. | canal curvature of 60 degree and a 5 mm radius curvature. | Rotation at 500 rpm | The block was submerged in a water bath. Immersion during fatigue test. | NCF: -Edge Endo 3—6185 22—7243 37—1675 60—901 -Vortex 3—4842 22—2062 37—1233 60—651 -ESX 2—932 22—466 37—271 60—218 | No data |

3.4. Quality Assesment

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Janeczek, M.; Kosior, P.; Piesiak-Pańczyszyn, D.; Dudek, K.; Chrószcz, A.; Czajczyńska-Waszkiewicz, A.; Kowalczyk-Zając, M.; Gabren-Syller, A.; Kirstein, K.; Skalec, A.; et al. The Effect of File Size and Type and Irrigation Solutions on the Accuracy of Electronic Apex Locators: An In Vitro Study on Canine Teeth. BioMed Res. Int. 2016, 2016, 8594087. [Google Scholar] [CrossRef]

- Raducka, M.; Piszko, A.; Piszko, P.J.; Jawor, N.; Dobrzyński, M.; Grzebieluch, W.; Mikulewicz, M.; Skośkiewicz-Malinowska, K. Narrative Review on Methods of Activating Irrigation Liquids for Root Canal Treatment. Appl. Sci. 2023, 13, 7733. [Google Scholar] [CrossRef]

- Orozco-Ocampo, Y.M.; Escobar-Rincón, D.; Jiménez-García, F.N.; Álvarez-Vargas, C.A.; Jaramillo-Gil, P.X. Factors Influencing NiTi Endodontic File Separation: A Thematic Review. Dent. Med. Probl. 2024, 61, 269–278. [Google Scholar] [CrossRef] [PubMed]

- Kinjrawi, L.; Abdo, A.; Alnour, A.; Achour, H.; Rekab, M.S. Post-Endodontic Pain in Curved Canals Prepared with Different Rotary Instrumentation Techniques: A Randomized Controlled Trial. Dent. Med. Probl. 2024, 61, 191–196. [Google Scholar] [CrossRef]

- Lile, I.E.; Hajaj, T.; Veja, I.; Hosszu, T.; Vaida, L.L.; Todor, L.; Stana, O.; Popovici, R.-A.; Marian, D. Comparative Evaluation of Natural Mouthrinses and Chlorhexidine in Dental Plaque Management: A Pilot Randomized Clinical Trial. Healthcare 2025, 13, 1181. [Google Scholar] [CrossRef]

- Hajaj, T.; Lile, I.E.; Veja, I.; Titihazan, F.; Rominu, M.; Negruțiu, M.L.; Sinescu, C.; Novac, A.C.; Talpos Niculescu, S.; Zaharia, C. Ifluence of Pontic Length on the Structural Integrity of Zirconia Fixed Partial Dentures (FPDs). J. Funct. Biomater. 2025, 16, 116. [Google Scholar] [CrossRef] [PubMed]

- Rocha, A.R.; Limoeiro, A.G.; Seckler, I.N.; Alves, B.R.; Soares, A.J.; Lima, S.N.; Vieira, V.T.; Marceliano-Alves, M.F.V.; Nascimento, W.M.; Rasquin, L.C.; et al. Multimethod Analysis of a Novel NiTi Rotary System: Cyclic Fatigue, Buckling Resistance, and Bending Tests. Eur. J. Dent. 2025. Epub ahead of print. [Google Scholar] [CrossRef]

- Alzamanan, M.M.; Albassam, A.A.; Khattab, E.M.; Alghamdi, F.T. Micro-Computed Tomography Evaluation of Dentinal Cracks after Root Canal Preparation with Different Endodontic Rotary Files: An Ex Vivo Study. Dent. Med. Probl. 2025, 62, 89–98. [Google Scholar] [CrossRef]

- Karaś, B.; Pitułaj, A.; Szyba, M.; Matys, J.; Dobrzyński, M. Two-Step Endodontic and Surgical Treatment of Large Periapical Lesions in the Maxilla: A Case Report. Ann. Ital. Chir. 2025, 96, 286–295. [Google Scholar] [CrossRef]

- Zakrzewski, W.; Dobrzyński, M.; Zawadzka-Knefel, A.; Lubojański, A.; Dobrzyński, W.; Janecki, M.; Kurek, K.; Szymonowicz, M.; Wiglusz, R.J.; Rybak, Z. Nanomaterials Application in Endodontics. Materials 2021, 14, 5296. [Google Scholar] [CrossRef]

- Assaf, D.; El Seoud, M.A.; Kataia, M.; Saber, S. Impact of Angle of File Access and Location of Canal Curvature on the Dynamic Cyclic Fatigue of Nickel Titanium Rotary Instruments. Eur. Endod. J. 2024, 9, 133–138. [Google Scholar] [CrossRef]

- Jamleh, A.; Almedlej, R.; Alomar, R.; Almayouf, N.; Alfadley, A.; Alfouzan, K. Evidence for Reduced Torsional Resistance of Rotary Files under Curved Position. Saudi Dent. J. 2021, 33, 614–619. [Google Scholar] [CrossRef]

- Pai, A.R.V. Mechanism and Clinical Aspects of Sodium Hypochlorite Accidents: A Narrative Review. Dent. Med. Probl. 2025, 62, 173–185. [Google Scholar] [CrossRef] [PubMed]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 Statement: An Updated Guideline for Reporting Systematic Reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef]

- Cheung, G.S.P.; Shen, Y.; Darvell, B.W. Effect of Environment on Low-Cycle Fatigue of a Nickel-Titanium Instrument. J. Endod. 2007, 33, 1433–1437. [Google Scholar] [CrossRef]

- Kensy, J.; Dobrzyński, M.; Wiench, R.; Grzech-Leśniak, K.; Matys, J. Fibroblasts Adhesion to Laser-Modified Titanium Surfaces—A Systematic Review. Materials 2021, 14, 7305. [Google Scholar] [CrossRef]

- Rygas, J.; Matys, J.; Wawrzyńska, M.; Szymonowicz, M.; Dobrzyński, M. The Use of Graphene Oxide in Orthodontics—A Systematic Review. J. Funct. Biomater. 2023, 14, 500. [Google Scholar] [CrossRef] [PubMed]

- Rajewska, J.; Kowalski, J.; Matys, J.; Dobrzyński, M.; Wiglusz, R.J. The Use of Lactide Polymers in Bone Tissue Regeneration in Dentistry—A Systematic Review. J. Funct. Biomater. 2023, 14, 83. [Google Scholar] [CrossRef] [PubMed]

- Małyszek, A.; Kiryk, S.; Kensy, J.; Kotela, A.; Michalak, M.; Kiryk, J.; Janeczek, M.; Matys, J.; Dobrzyński, M. Identification of Factors Influencing Fluoride Content in Tea Infusions: A Systematic Review. Appl. Sci. 2025, 15, 5974. [Google Scholar] [CrossRef]

- Piszko, P.J.; Piszko, A.; Kiryk, J.; Lubojański, A.; Dobrzyński, W.; Wiglusz, R.J.; Matys, J.; Dobrzyński, M. The Influence of Fluoride Gels on the Physicochemical Properties of Tooth Tissues and Dental Materials—A Systematic Review. Gels 2024, 10, 98. [Google Scholar] [CrossRef]

- Kubiak-Mihkelsoo, Z.; Kostrzębska, A.; Błaszczyszyn, A.; Pitułaj, A.; Dominiak, M.; Gedrange, T.; Nawrot-Hadzik, I.; Matys, J.; Hadzik, J. Ionic Doping of Hydroxyapatite for Bone Regeneration: Advances in Structure and Properties over Two Decades—A Narrative Review. Appl. Sci. 2025, 15, 1108. [Google Scholar] [CrossRef]

- de Castro Martins, R.; Bahia, M.G.A.; Buono, V.T.L.; Horizonte, B. The Effect of Sodium Hypochlorite on the Surface Characteristics and Fatigue Resistance of ProFile Nickel-Titanium Instruments. Oral Surg. Oral Med. Oral Pathol. Oral Radiol. Endod. 2006, 102, e99–e105. [Google Scholar] [CrossRef]

- Ormiga Galvão Barbosa, F.; Antônio da Cunha Ponciano Gomes, J.; Pimenta de Araújo, M.C. Influence of Sodium Hypochlorite on Mechanical Properties of K3 Nickel-Titanium Rotary Instruments. J. Endod. 2007, 33, 982–985. [Google Scholar] [CrossRef]

- Berutti, E.; Angelini, E.; Rigolone, M.; Migliaretti, G.; Pasqualini, D. Influence of Sodium Hypochlorite on Fracture Properties and Corrosion of ProTaper Rotary Instruments. Int. Endod. J. 2006, 39, 693–699. [Google Scholar] [CrossRef] [PubMed]

- Mousavi, S.A.; Norouzi, N.; Memarzadeh, B.; Havaei, S.R.; Yousefshahi, H. Effect of the Temperature of Sodium Hypochlorite on the Cyclic Fatigue Resistance of ProTaper Gold Rotary Files. Dent. Med. Probl. 2021, 58, 533–537. [Google Scholar] [CrossRef] [PubMed]

- Svec, T.A.; Powers, J.M. Effects of Simulated Clinical Conditions on Nickel-Titanium Rotary Files. J. Endod. 1999, 25, 759–760. [Google Scholar] [CrossRef]

- Alfawaz, H.; Alqedairi, A.; Alsharekh, H.; Almuzaini, E.; Alzahrani, S.; Jamleh, A. Effects of Sodium Hypochlorite Concentration and Temperature on the Cyclic Fatigue Resistance of Heat-Treated Nickel-Titanium Rotary Instruments. J. Endod. 2018, 44, 1563–1566. [Google Scholar] [CrossRef]

- Cheung, G.S.P.; Darvell, B.W. Low-Cycle Fatigue of Rotary NiTi Endodontic Instruments in Hypochlorite Solution. Dent. Mater. 2008, 24, 753–759. [Google Scholar] [CrossRef]

- Javadi, A.A.; Jafarzadeh, M.; Tavakoli, N.; Karampour, M. Effect of Immersion in Disinfectants on Cyclic Fatigue Resistance of Nickel-Titanium Instruments: An in Vitro Study. Front. Dent. 2023, 20, 15. [Google Scholar] [CrossRef]

- Palma, P.J.; Messias, A.; Cerqueira, A.R.; Tavares, L.D.; Caramelo, F.; Roseiro, L.; Santos, J.M. Cyclic Fatigue Resistance of Three Rotary File Systems in a Dynamic Model after Immersion in Sodium Hypochlorite. Odontology 2019, 107, 324–332. [Google Scholar] [CrossRef]

- Priya, D. A Comparison of The Cyclic Fatigue Resistance of Various File Systems Following Sterilization or Immersion in Sodium Hypochlorite. J. Pharm. Negat. Results 2022, 13, 2529–2535. Available online: https://www.pnrjournal.com/index.php/home/article/view/9139 (accessed on 20 August 2025).

- Abuhulaibah, H.F.; AbuMostafa, A. Resistance to Cyclic Fatigue of Nickel-Titanium Files Immersed in Sodium Hypochlorite at Body Temperature. Int. J. Dent. 2020, 2020, 8830163. [Google Scholar] [CrossRef] [PubMed]

- Kermeoglu, F.; Abduljalil, M. Impacts of NaOCl and Irritrol Irrigation Solutions with/without Autoclave Sterilisation on the Cyclic Fatigue Resistance of Different Nickel-Titanium Files. Aust. Endod. J. 2022, 48, 392–399. [Google Scholar] [CrossRef]

- Pedullà, E.; Benites, A.; La Rosa, G.M.; Plotino, G.; Grande, N.M.; Rapisarda, E.; Generali, L. Cyclic Fatigue Resistance of Heat-Treated Nickel-Titanium Instruments after Immersion in Sodium Hypochlorite and/or Sterilization. J. Endod. 2018, 44, 648–653. [Google Scholar] [CrossRef]

- Huang, X.; Shen, Y.; Wei, X.; Haapasalo, M. Fatigue Resistance of Nickel-Titanium Instruments Exposed to High-Concentration Hypochlorite. J. Endod. 2017, 43, 1847–1851. [Google Scholar] [CrossRef] [PubMed]

- Topçuoğlu, H.S.; Pala, K.; Aktı, A.; Düzgün, S.; Topçuoğlu, G. Cyclic Fatigue Resistance of D-RaCe, ProTaper, and Mtwo Nickel-Titanium Retreatment Instruments after Immersion in Sodium Hypochlorite. Clin. Oral Investig. 2016, 20, 1175–1179. [Google Scholar] [CrossRef]

- Bulem, Ü.K.; Kececi, A.D.; Guldas, H.E. Experimental Evaluation of Cyclic Fatigue Resistance of Four Different Nickel-Titanium Instruments after Immersion in Sodium Hypochlorite and/or Sterilization. J. Appl. Oral Sci. 2013, 21, 505–510. [Google Scholar] [CrossRef][Green Version]

- Pedullà, E.; Grande, N.M.; Plotino, G.; Palermo, F.; Gambarini, G.; Rapisarda, E. Cyclic Fatigue Resistance of Two Reciprocating Nickel-Titanium Instruments after Immersion in Sodium Hypochlorite. Int. Endod. J. 2013, 46, 155–159. [Google Scholar] [CrossRef]

- Cai, J.-J.; Tang, X.-N.; Ge, J.-Y. Effect of Irrigation on Surface Roughness and Fatigue Resistance of Controlled Memory Wire Nickel-Titanium Instruments. Int. Endod. J. 2017, 50, 718–724. [Google Scholar] [CrossRef] [PubMed]

- Elnaghy, A.M.; Elsaka, S.E. Effect of Sodium Hypochlorite and Saline on Cyclic Fatigue Resistance of WaveOne Gold and Reciproc Reciprocating Instruments. Int. Endod. J. 2017, 50, 991–998. [Google Scholar] [CrossRef]

- Keles, A.; Uzunoglu Ozyurek, E.; Uyanik, M.O.; Nagas, E. Effect of Temperature of Sodium Hypochlorite on Cyclic Fatigue Resistance of Heat-Treated Reciprocating Files. J. Endod. 2019, 45, 205–208. [Google Scholar] [CrossRef]

- Alfawaz, H.; Alqedairi, A.; Alhamdan, M.; Alkhzim, N.; Alfarraj, S.; Jamleh, A. Effect of NaOCl and EDTA Irrigating Solutions on the Cyclic Fatigue Resistance of EdgeTaper Platinum Instruments. BMC Oral Health 2022, 22, 195. [Google Scholar] [CrossRef]

- Tyagi, G.; Kumar, P.; Kumari, A.; Shakarwal, P.; Singh, A.; Kusum, P. Comparing the EdgeFile X3, GenEndo, HeroGold, and ProTaper Gold Rotary Instruments Regarding the Effect of Different Concentrations and Temperature of NaOCl on Cyclic Fatigue Resistance. J. Contemp. Dent. Pr. 2023, 24, 715–721. [Google Scholar] [CrossRef]

- Erik, C.E.; Özyürek, T. Effects of Etidronate, NaOCl, EDTA Irrigation Solutions and Their Combinations on Cyclic Fatigue Resistance of Nickel-Titanium Single-File Rotary and Reciprocating Instruments at Body Temperature. Odontology 2019, 107, 190–195. [Google Scholar] [CrossRef] [PubMed]

- Pedullà, E.; Grande, N.M.; Plotino, G.; Pappalardo, A.; Rapisarda, E. Cyclic Fatigue Resistance of Three Different Nickel-Titanium Instruments after Immersion in Sodium Hypochlorite. J. Endod. 2011, 37, 1139–1142. [Google Scholar] [CrossRef] [PubMed]

- Dosanjh, A.; Paurazas, S.; Askar, M. The Effect of Temperature on Cyclic Fatigue of Nickel-Titanium Rotary Endodontic Instruments. J. Endod. 2017, 43, 823–826. [Google Scholar] [CrossRef] [PubMed]

- Tanomaru, A.A.; Limoeiro, A.G.; De Jesus Soares, A.; Junior, E.L.M.; Campos, G.R.; Hamasaki, S.K.; Nascimento, W.M.; Horta, L.M.; Goulart, P.A.D.S.R.; Do Couto, V.R.; et al. Influence of Sodium Hypochlorite and Chlorhexidine on the Dynamic Cyclic Fatigue Resistance of XP Endo Shaper Instruments. Eur. J. Dent. 2022, 16, 580–584. [Google Scholar] [CrossRef]

- Lubojanski, A.; Dobrzynski, M.; Nowak, N.; Rewak-Soroczynska, J.; Sztyler, K.; Zakrzewski, W.; Dobrzynski, W.; Szymonowicz, M.; Rybak, Z.; Wiglusz, K.; et al. Application of Selected Nanomaterials and Ozone in Modern Clinical Dentistry. Nanomaterials 2021, 11, 259. [Google Scholar] [CrossRef]

- Zupanc, J.; Vahdat-Pajouh, N.; Schäfer, E. New Thermomechanically Treated NiTi Alloys—A Review. Int. Endod. J. 2018, 51, 1088–1103. [Google Scholar] [CrossRef]

- Dos Reis-Prado, A.H.; Abreu, L.G.; De Arantes, L.C.; Paula, K.d.S.d.; Oliveira, S.d.C.; Goto, J.; Viana, A.C.D.; Benetti, F. Influence of Sodium Hypochlorite on Cyclic Fatigue Resistance of Nickel–Titanium Instruments: A Systematic Review and Meta-Analysis of in Vitro Studies. Clin. Oral Investig. 2023, 27, 6291–6319. [Google Scholar] [CrossRef]

- Abdellatif, D.; Iandolo, A.; Scorziello, M.; Sangiovanni, G.; Pisano, M. Cyclic Fatigue of Different Ni-Ti Endodontic Rotary File Alloys: A Comprehensive Review. Bioengineering 2024, 11, 499. [Google Scholar] [CrossRef] [PubMed]

- De Pedro-Muñoz, A.; Rico-Romano, C.; Sánchez-Llobet, P.; Montiel-Company, J.M.; Mena-Álvarez, J. Cyclic Fatigue Resistance of Rotary versus Reciprocating Endodontic Files: A Systematic Review and Meta-Analysis. JCM 2024, 13, 882. [Google Scholar] [CrossRef] [PubMed]

- Ahn, S.-Y.; Kim, H.-C.; Kim, E. Kinematic Effects of Nickel-Titanium Instruments with Reciprocating or Continuous Rotation Motion: A Systematic Review of In Vitro Studies. J. Endod. 2016, 42, 1009–1017. [Google Scholar] [CrossRef] [PubMed]

| Study | Aim of the Study | Materials and Methods | Results | Conclusions |

|---|---|---|---|---|

| de Castro Martins [22] | How 5.25% NaOCl impacts the surface conditions and fatigue resistance of Profile Ni-Ti instruments. | 80 instruments were split into one control group (CG) and three experimental groups (EG1,2,3). In the EG1 instruments were soaked in NaOCl for 24 h. In the EG2 and 3 instruments were used to prepare curved root canals—one with water and the other one with NaOCl during the procedure. | SEM analysis revealed surface wear (scratches, metal loss) without corrosion in used instruments. NaOCl-treated instruments (EG3) showed significantly faster performance than untreated ones (EG2). Both groups developed microcracks 2.2–3.8 mm from the tip. Canal-used instruments (EG2,3) demonstrated significantly reduced fatigue resistance versus unused controls (CG, EG1). Fractures typically occurred ~4 mm from the tip due to fatigue failure, confirmed by SEM. | Soaking in 5.25% NaOCl for 24 h did not change the instrument’s surface or fatigue resistance. The tools that were used in the simulated root canal procedures had reduced fatigue resistance. |

| Cheung [28] | Evaluation the low-cycle fatigue response of NiTi rotary instruments working with NaOCl solution. | 179 instruments from 4 different brands were tested by rotating them at 250 rpm in a 1.2% NaOCl solution until they fractured. Surface strain was calculated from instrument curvature and fracture diameter, then compared to the number of rotations until failure. | All groups showed a linear strain-life relationship. The fatigue-ductility was similar across brands, but the number of crack initiation points differed. A inverse linear correlation was found between crack growth and strain amplitude. | NiTi rotary instruments in NaOCl show both low- and high-cycle fatigue patterns. The instrument’s cross-sectional shape does not influence LCF behavior. A certain level of crack growth leads to sudden fracture depending on strain amplitude. |

| Ormiga Galvão Barbosa [23] | Effect of NaOCl on the Mechanical Behavior of K3 NiTi Rotary Files | Both new and NaOCl –treated files were evaluated for their resistance to flexural fatigue and torsional fracture. A t-test was applied to compare the groups in terms of the number of cycles, rotation angle, and peak torque leading to fracture. | There was no statistically significant variation among the groups. SEM analysis revealed no signs of localized corrosion on the files that had been exposed to NaOCl. | The findings indicate that contact with NaOCl does not affect the fracture resistance of K3 rotary files. |

| Berutti [24] | To assess how immersion in NaOCl affects the cyclic fatigue resistance and corrosion behavior of ProTaper NiTi rotary files. | 120 ProTaper NiTi F2 files were randomly allocated into three groups (n = 40 each). Group 1 served as control. Group 2 had 20 mm of each file (excluding shaft) immersed in 5% NaOCl at 50 °C for 5 min. Group 3 had complete file submersion under identical conditions. Prematurely fractured Group 3 instruments underwent field emission SEM for micromorphological and microchemical analysis. | The files from group 3 demonstrated notably reduced fracture resistance due to cyclic fatigue compared to those in groups 1 and 2 (p < 0.001). In certain cases, instruments in group 3 fractured within just a few seconds of fatigue testing. SEM analysis showed clear indications of corrosion on the broken instruments. | Group 3 instruments demonstrated significantly reduced cyclic fatigue resistance compared to Groups 1 and 2. Early fractures may result from galvanic corrosion caused by dissimilar metals, where one metal acts as the cathode in NaOCl solution while the NiTi alloy serves as the anode, increasing corrosion susceptibility. |

| Javadi [29] | To investigate the effect of immersion in 5% NaOCl and Deconex on the cyclic fatigue resistance of two NiTi rotary instruments. | 90 rotary files (M3 Pro Gold 25.06 and SP1 F2) were used, with 45 instruments per type randomly divided into three groups (n = 15). Groups underwent 5 min room temperature exposure to: no immersion (control), 5% NaOCl, or Deconex. Cyclic fatigue resistance was assessed using a custom testing device. | The two-way ANOVA showed a significant difference in average cyclic fatigue resistance between M3 and SP1 files. The M3 files treated with NaOCl had the lowest resistance, while SP1 files exposed to Deconex showed the highest. Both the type of disinfectant (p < 0.001) and the file type (p < 0.001) had a statistically significant impact on fatigue resistance. | Immersing NiTi rotary instruments in disinfectant solutions can influence their resistance to cyclic fatigue, and the degree of this effect depends on the file type and the type of disinfectant applied. |

| Palma [30] | To evaluate and compare the cyclic fatigue resistance of three different rotary file systems in a dynamic model after immersion in 3% NaOCl. | 90 from 3 NiTi systems (ProTaper Next, Hyflex CM, Hyflex EDM) were randomly assigned to nine groups based on file type and 3% NaOCl immersion time (0, 1, or 5 min). Cyclic fatigue testing was performed in a simulated root canal (45° curvature, 5 mm radius) until fracture. Instrument reliability was assessed using Weibull statistical method. | PTN instruments averaged 1200 ± 178 cycles to fracture, CM reached 1949 ± 362, and EDM achieved 5573 ± 853 cycles—a statistically significant difference (p < 0.01). Immersion in 3% NaOCl led to a significant decrease in the average number of cycles to fracture (p = 0.01). | EDM instruments showed the highest fatigue resistance, followed by CM. PTN had the shortest lifespan. Sodium hypochlorite reduced fatigue resistance in all files, especially in CM-wire instruments. |

| Priya [31] | Evaluation of the impact of the autoclave sterilisationand sodium hypochlorite immersion on the cyclic fatigue resistance of four different NiTi rotary instruments. | A total of 320 new instruments were divided into four subgroups: Control (no treatment); Immersion in 5.25% NaOCl for 3 min; Three autoclave sterilization cycles; Combined immersion in NaOCl + three sterilizations. Each instrument was testednfor cyclic fatigue in a simulated curved canal setup, and the number of cycles to failure (NCF) was recorded. | EdgeFile X3 consistently showed the highest fatigue resistance across all treatment types. It was followed by Hyflex EDM, Hyflex CM, and TruNatomy, which had the lowest resistance. Neither NaOCl immersion alone nor sterilization alone significantly reduced cyclic fatigue resistance. The combination of both treatments actually increased NCF, suggesting a possible strengthening effect under those conditions. | All four file systems showed some resilience to treatment-related stress. EdgeFile X3 was the most durable, while TruNatomy was the most susceptible to fatigue failure. Immersion in NaOCl and multiple sterilization cycles did not negatively affect, and in some cases improved, the fatigue resistance of these heat-treated instruments. |

| Mousavi [25] | To investigate whether the temperature of sodium hypochlorite (NaOCl)—a common root canal irrigation solution—affects the cyclic fatigue resistance of ProTaper Gold (PTG) rotary endodontic files. | 45 PTG S1 rotary files were tested in an artificial canal (60° curvature, 5 mm radius) divided into three groups by NaOCl temperature: 22 °C (room temperature), 4 °C (cold), and 37 °C (body temperature). Files rotated at 300 rpm until fracture. Number of cycles to fracture (NCF) and fragment length were recorded. | There was no statistically significant difference in cyclic fatigue resistance or fragment length among the three groups. Thus, temperature variation between 4 °C and 37 °C did not significantly affect the performance of PTG files. | The cyclic fatigue resistance of heat-treated PTG rotary files is not significantly influenced by the temperature of the NaOCl solution within the tested range. Further clinical studies are recommended. |

| Tanomaru [47] | To evaluate the cyclic fatigue resistance of the XP-Endo Finisher (XPF) instrument in a dynamic model, using two different irrigation solutions: 2% chlorhexidine gel (CHX) and 6% sodium hypochlorite (NaOCl). | 30 new XPF files (25 mm long, 0.25 mm tip diameter) were divided into three groups (n = 10 each) based on irrigation solution: Group 1: 2% chlorhexidine gel (CHX), Group 2: 6% NaOCl, Group 3 (control): lubricating oil (WD-40). Stainless-steel artificial canal simulated severe apical curvature (3 mm, 90°). | CHX group demonstrated significantly higher cyclic fatigue resistance (4.99 min, 4558 cycles to fracture) compared to NaOCl group (0.92 min, 1014 cycles) and oil group (0.67 min, 832 cycles). CHX significantly outperformed both solutions (p < 0.001), with no significant difference between NaOCl and oil. | XP-Endo Finisher showed longest fatigue life with 2% CHX due to its lubricating and non-corrosive properties, unlike NaOCl which may corrode NiTi alloy and reduce fatigue resistance. While CHX improves resistance, it cannot dissolve organic tissue and thus cannot replace NaOCl. Further studies should explore alternative irrigants. |

| Abuhulaibah [32] | To evaluate cyclic fatigue (CF) resistance of two NiTi endodontic files (One Curve, ProTaper Gold) after immersion in 2.5% NaOCl at 37 °C for different time periods | 45 files of each type (OC, PTG) were divided into three groups: no immersion (control), 1 min NaOCl immersion, and 5 min NaOCl immersion. CF testing was performed in a simulated curved canal at 37 °C water bath. Number of cycles to fracture (NCF) was measured. | OC files significantly outperformed PTG files in all conditions. Both file types showed significant fatigue resistance reduction after 5 min NaOCl immersion. OC files maintained superior performance even after chemical exposure, suggesting better material resilience. PTG-1 min and PTG-5 min showed no significant difference but both were lower than PTG-control. | OC files demonstrated superior cyclic fatigue resistance compared to PTG files. Prolonged NaOCl exposure (5 min) significantly weakened both file types, though OC maintained greater resilience. These findings inform endodontic instrument selection and NaOCl irrigation timing decisions. |

| Svec [26] | To investigate how simulated clinical conditions (irrigant exposure to saline and NaOCl, sterilization, and cyclic fatigue) affect torsional moment and angular deflection of NiTi rotary endodontic files. | ProFile NiTi rotary files (ISO sizes 25, 30, 35; 25 mm long; 0.04 taper) were tested in saline or 5.25% NaOCl for up to three simulated uses in a 90° curved metal canal (5 mm radius, 1.5 mm diameter) at 150 rpm with ~6 mm axial movement. Five groups were tested: control, saline unsterilized, saline sterilized, NaOCl unsterilized, and NaOCl sterilized. | Torsional moment increased significantly with file size regardless of solution or sterilization. Cyclic fatigue, irrigants, or sterilization showed no consistent impact on torsional moment or angular deflection. | Sterilization and irrigation do not appear to significantly affect file failure behavior. |

| Kermeoglu [33] | To analyze cyclic fatigue resistance of NiTi rotary files after NaOCl and Irritol (EDTA + CHX final rinse) irrigation, with/without autoclaving. | 3 file systems: ProTaper (PTU F2), WaveOne Gold (primary), Reciproc (R25)—70 files per group (25, 0.08 ISO) divided into 7 subgroups (n = 10): control (no treatment), 5.25% NaOCl 5 min at 37 °C, Irritrol 5 min at 37 °C, subgroup 2 + 1-cycle autoclaving, subgroup 4 repeated 3×, subgroup 3 + 1-cycle autoclaving, subgroup 6 repeated 3×. Files tested using X-Smart Plus endomotor until fracture. Data: time to fracture (s), fragment lengths, SEM fracture surface analysis. | Reciproc showed highest cyclic fatigue resistance, ProTaper lowest. Only subgroups 5 and 7 differed significantly from control. Irrigation solutions and single sterilization cycle did not affect fracture time. No significant difference between subgroups 5 and 7. Subgroups 5,6,7 had significantly longer fractured segments versus others. | Immersion in irrigation solutions did not influence cyclic fatigue resistance. However, immersion combined with 3 sterilization cycles significantly decreased fatigue resistance of Reciproc, ProTaper, and WaveOne Gold files. |

| Pedulla [34] | This study investigates the effects of sodium hypochlorite (NaOCl) immersion and autoclave sterilization on the cyclic fatigue resistance of two types of heat. | 210 new NiTi instruments (TF and HyFlex CM) were divided into seven groups (n = 15 each). Groups were treated with combinations of: No treatment (control), Immersion in 5% NaOCl (1 or 3 times), Autoclave sterilization (1 or 3 times), Both treatments (1 or 3 cycles). Instruments were tested in a simulated curved canal for number of cycles to failure (NCF). Surface analysis was done via scanning electron microscopy (SEM) and energy-dispersive X-ray spectroscopy (EDS). | TF instruments showed a significant reduction in fatigue resistance after 3 cycles of sterilization, regardless of NaOCl immersion. HyFlex CM instruments maintained their cyclic fatigue resistance after all treatments. NaOCl immersion alone did not significantly reduce fatigue resistance in either instrument type. HyFlex CM files had a surface oxide layer that may contribute to greater corrosion resistance and durability. | Autoclave sterilization negatively affects TFs after repeated cycles but not HyFlex CM. NaOCl immersion (even repeatedly) has no significant detrimental effect on the cyclic fatigue resistance of the tested NiTi files. HyFlex CM is more resistant to fatigue and better suited for reuse compared to TF under the tested conditions. |

| Huang [35] | The study examined how high-concentration NaOCl (5.25%) and different temperatures affect cyclic fatigue resistance of 3 NiTi endodontic files: K3, K3XF, and Vortex. | A novel zirconium oxide ceramic canal model simulated clinical conditions. Files were tested in water and 5.25% NaOCl at three temperatures: 22 °C (room), 37 °C (body), and 60 °C (high). Fatigue resistance was measured by rotations until fracture (Nf). | Vortex files showed highest fatigue resistance, followed by K3XF and K3. All files demonstrated decreased resistance at higher temperatures, with lowest at 60 °C. NaOCl (5.25%) caused slightly shorter fatigue life than water (not statistically significant). No corrosion signs observed. Heat-treated files (Vortex, K3XF) performed better due to martensite phase flexibility at clinical temperatures. | High-concentration NaOCl slightly reduced fatigue life but not significantly. Temperature had greater impact on fatigue resistance. Vortex files with higher austenite finish temperature maintained better performance at body temperature (37 °C). Future designs should consider temperature-related NiTi phase transformation properties for improved clinical reliability. |

| Topcuoglu [36] | To assess how immersion in sodium hypochlorite (NaOCl) affects the cyclic fatigue resistance of 3 different nickel–titanium (NiTi) rotary retreatment instruments: D-RaCe, ProTaper, and Mtwo. | 90 new files (30 per brand) were divided into two groups: control (no immersion) and NaOCl immersion (5% NaOCl at 37 °C for 5 min). Cyclic fatigue testing rotated files in artificial canal (60° curvature, 5 mm radius) until fracture. Number of cycles to failure (NCF) was recorded and analyzed. | D-RaCe instruments showed highest cyclic fatigue resistance among the three brands. NaOCl immersion significantly reduced fatigue resistance for D-RaCe but not for ProTaper and Mtwo. No significant difference was observed between ProTaper and Mtwo fatigue resistance. ProTaper showed shorter fracture segments than other brands. | D-RaCe demonstrates superior cyclic fatigue resistance but decreases after NaOCl exposure. Clinicians should consider this when using D-RaCe instruments with NaOCl during retreatment. |

| Alfawaz [27] | To examine how different NaOCl concentrations and temperatures affect cyclic fatigue resistance of ProTaper Gold (PTG) rotary endodontic instruments made of heat-treated NiTi alloy. | 135 PTG instruments were divided into 9 groups exposed to different NaOCl concentrations (distilled water, 2.5%, 5.25%) and temperatures (25 °C, 37 °C, 60 °C). Instruments were rotated in artificial canal until fracture. Number of cycles to fracture (NCF) was measured and fracture surfaces examined using SEM. | Highest fatigue resistance: distilled water at 25 °C. Lowest: 5.25% NaOCl at 60 °C. Increasing NaOCl concentration and temperature both reduced fatigue resistance. Brief NaOCl exposure caused fatigue degradation, especially at higher concentrations. | NiTi instrument performance is significantly affected by irrigant environment, especially NaOCl concentration and temperature. High-temperature, high-concentration NaOCl may increase instrument fracture risk. |

| Bulem [37] | To investigate whether immersion in sodium hypochlorite (NaOCl) and/or autoclave sterilization affects the cyclic fatigue resistance of four types of nickel–titanium (NiTi) rotary endodontic instruments: ProFile, FlexMaster, Twisted File, Mtwo. | A total of 160 instruments (40 from each brand) were tested. A dynamic cyclic fatigue test was used to simulate clinical use in curved root canals. Instruments were divided into four treatment groups: Control (no treatment), Immersion in 2.5% NaOCl for 5 min, NaOCl + 1 sterilization cycle, NaOCl + 5 sterilization cycles | Mtwo had the highest fatigue resistance (NCF), followed by Twisted File, FlexMaster, and ProFile. Neither NaOCl immersion nor sterilization significantly affected the cyclic fatigue resistance of the instruments (p > 0.05). The length of fractured segments also showed no significant difference between groups. | NaOCl immersion and autoclave sterilization (up to 5 cycles) do not adversely affect the cyclic fatigue resistance of the tested NiTi instruments. Among the four brands, Mtwo showed the best resistance to fatigue under all conditions. |

| Pedulla [38] | To evaluate how NaOCl immersion affects cyclic fatigue resistance of two NiTi endodontic instruments: Reciproc R25 and WaveOne Primary. | Ninety new NiTi instruments (45 Reciproc, 45 WaveOne) were divided into 3 groups: no NaOCl immersion (control), 5% NaOCl immersion for 1 min, and 5% NaOCl immersion for 5 min. All instruments underwent cyclic fatigue testing in simulated curved canal until fracture. Time to fracture (TtF) was recorded. | NaOCl immersion (1–5 min) did not significantly reduce cyclic fatigue resistance. Reciproc R25 showed significantly greater fatigue resistance than WaveOne Primary across all groups. Differences attributed to instrument design and reciprocating mechanics, not alloy composition (both M-wire). | Short-term NaOCl exposure does not degrade cyclic fatigue resistance of M-wire NiTi files. Reciproc R25 shows greater durability than WaveOne Primary, likely due to cross-sectional geometry and mechanical operation. |

| Cai [39] | To evaluate how common endodontic irrigants (5.25% NaOCl and 17% EDTA) affect surface roughness and cyclic fatigue resistance of two NiTi rotary instruments made from controlled memory (CM) wire: HyFlex and M3. | HyFlex and M3 files were immersed for 10 min in 5.25% NaOCl or 17% EDTA at 37 °C. AFM analyzed surface changes before/after immersion. Fatigue resistance tested via rotational bending in simulated curved canal (45° curve, 3 mm radius). | Surface Roughness: M3 files showed significant roughness increase after both NaOCl and EDTA immersion. HyFlex files showed increased roughness only with EDTA, not NaOCl. Fatigue Resistance: No statistically significant reduction in fatigue resistance for either file type after irrigant immersion. HyFlex files demonstrated higher overall fatigue resistance than M3 files. | Surface damage (increased roughness) occurred in most files after irrigant exposure. Cyclic fatigue resistance was not significantly affected by 10 min irrigant exposure. CM wire instruments retain durability despite short-term exposure to common root canal irrigants. |