Effect of Intercritical Quenching Temperature on Microstructure and Mechanical Performance of Cr-Ni-Mo-V Steel with Banded Structure

Abstract

1. Introduction

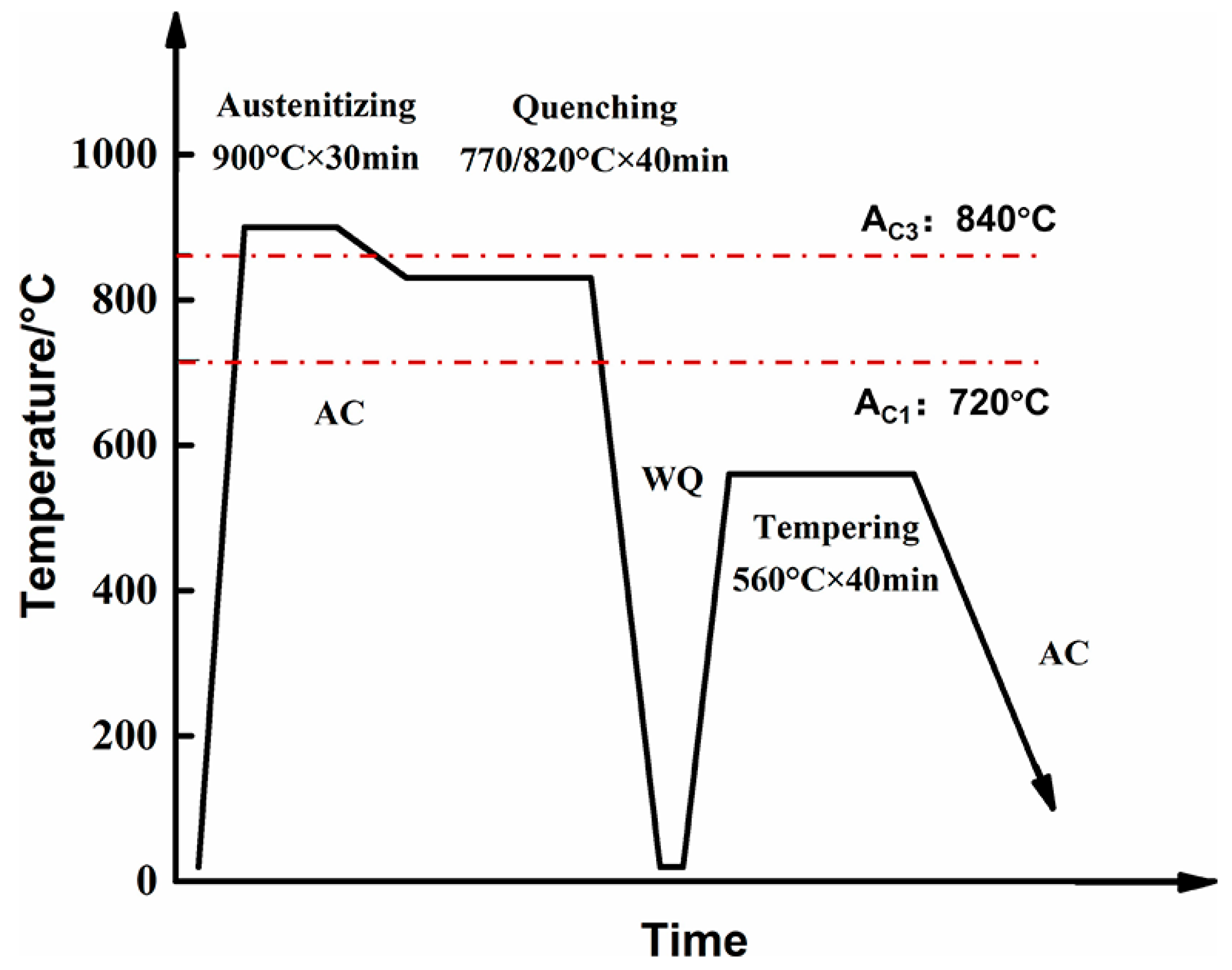

2. Materials and Methods

3. Results and Discussion

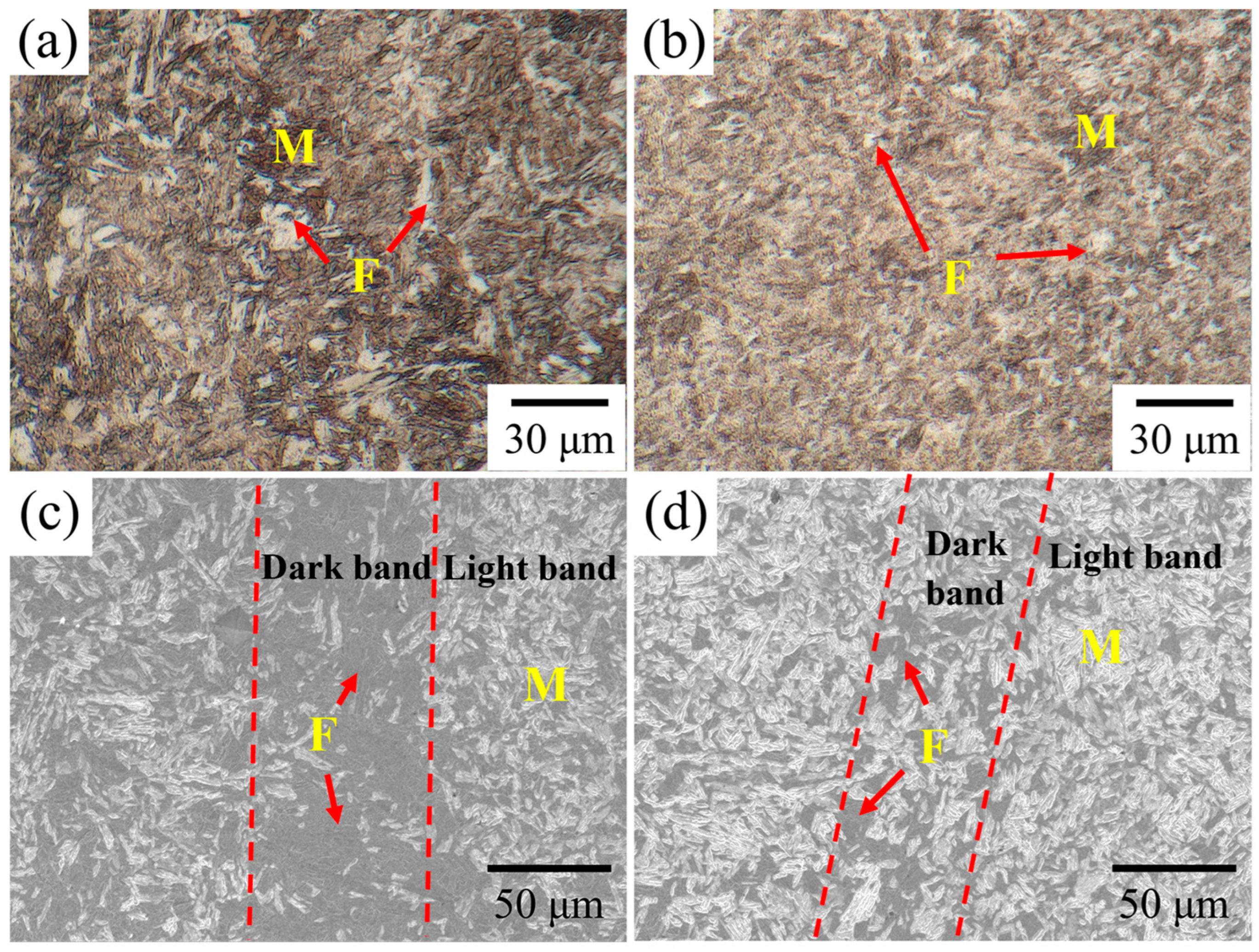

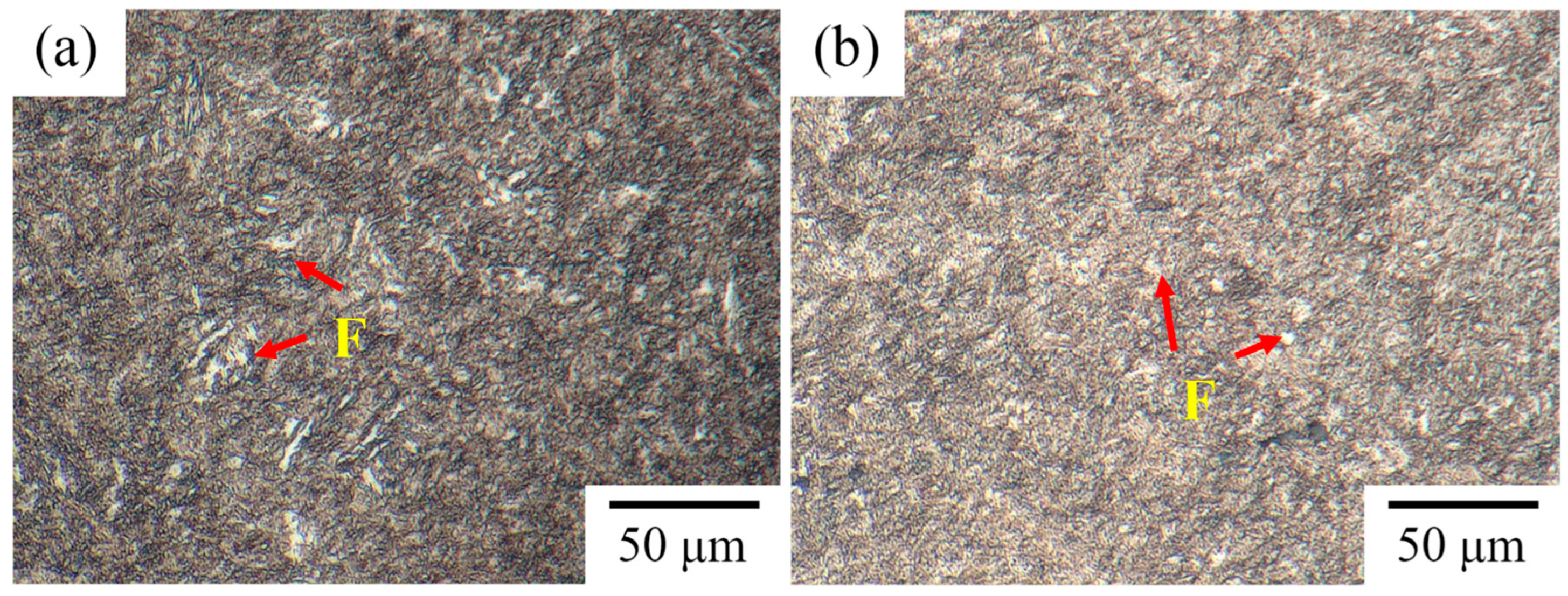

3.1. Quenched State

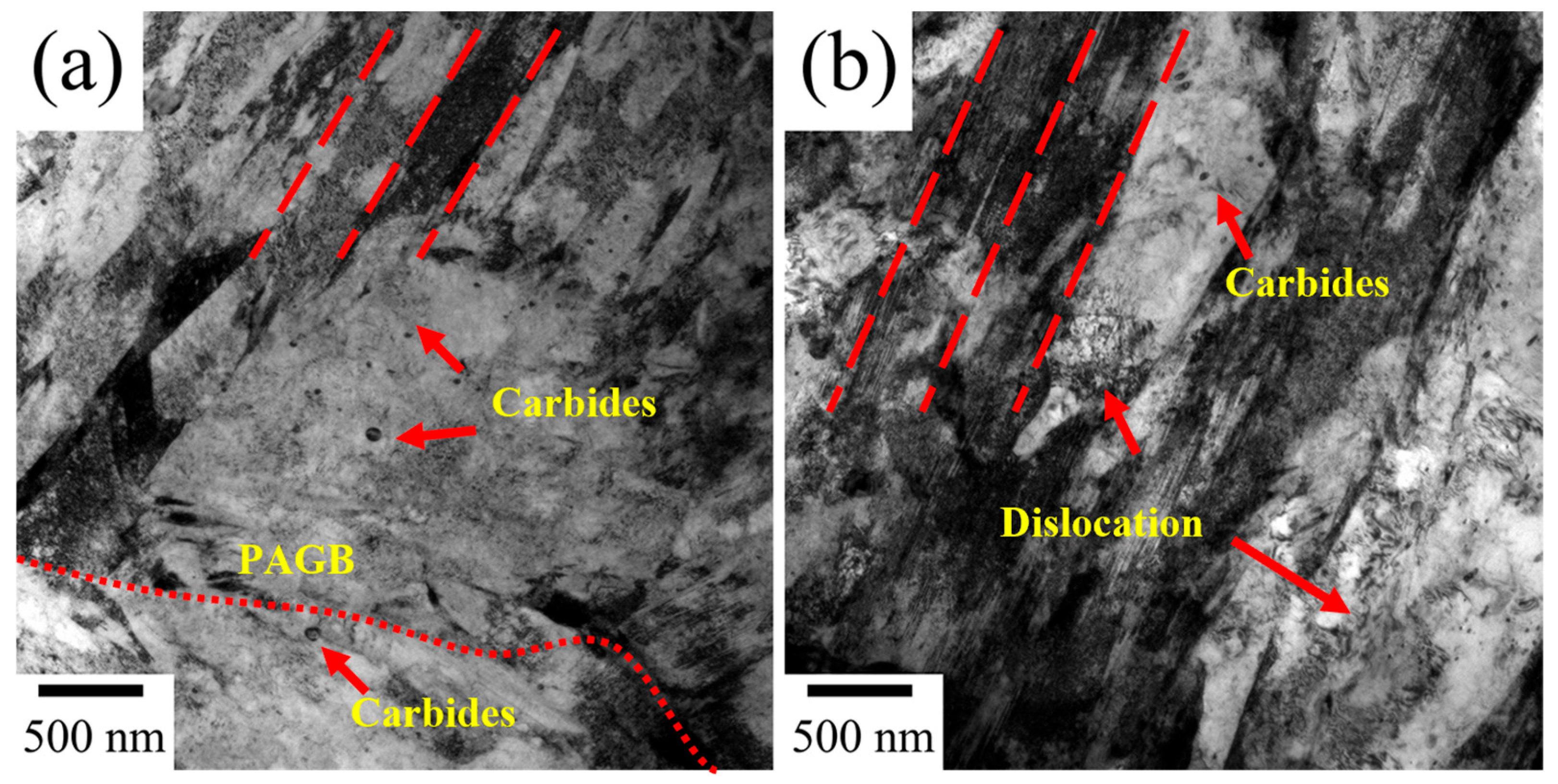

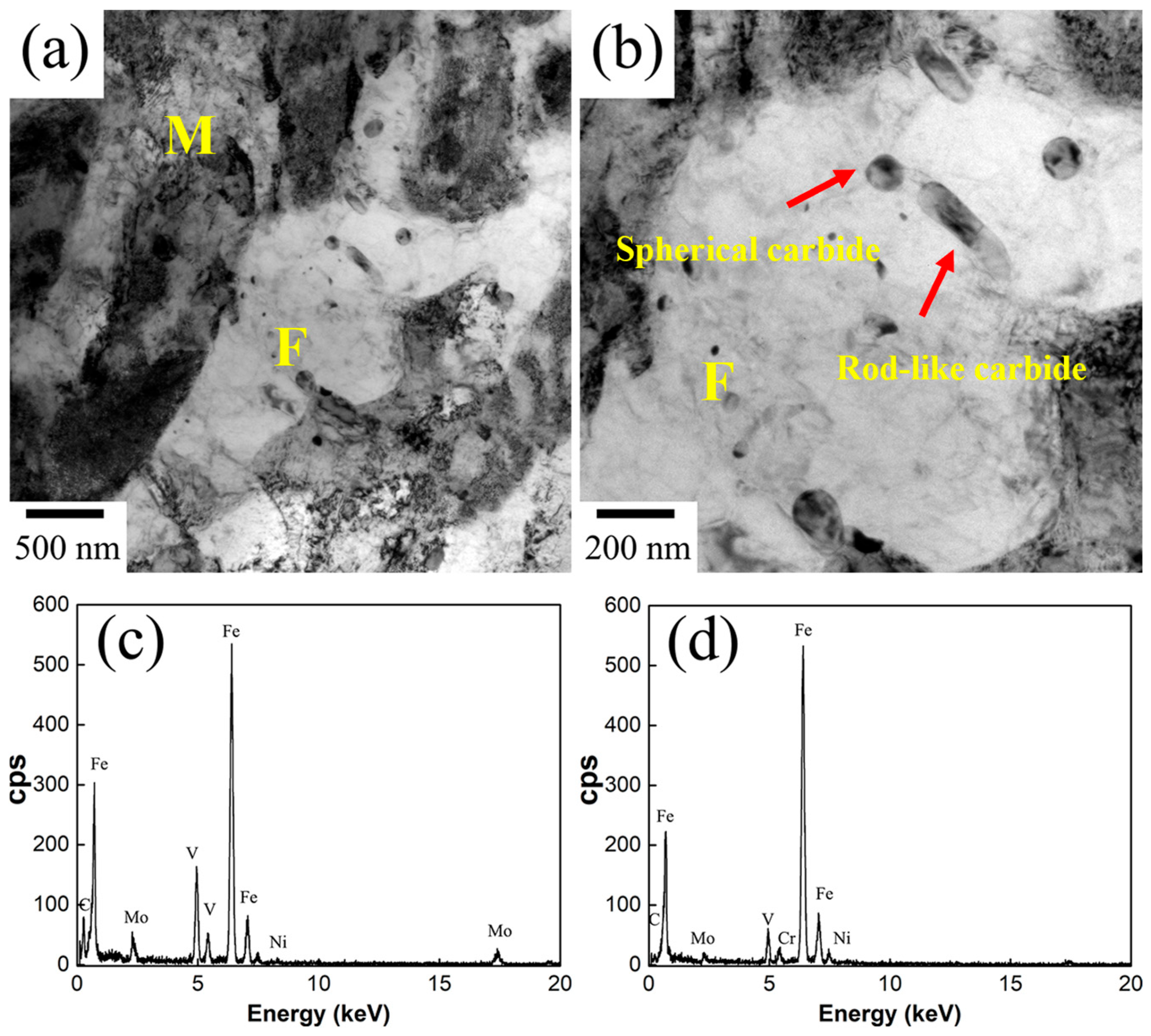

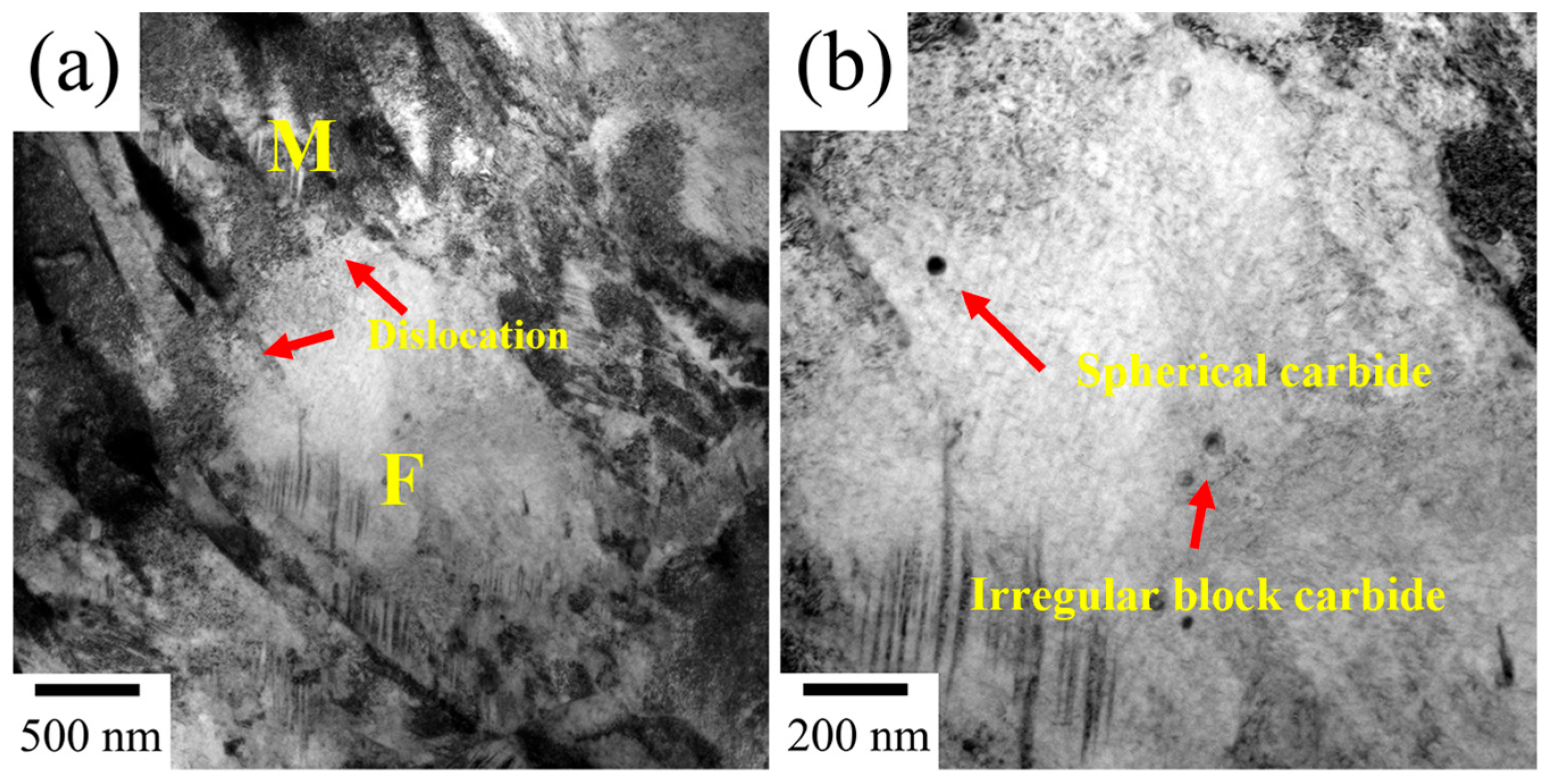

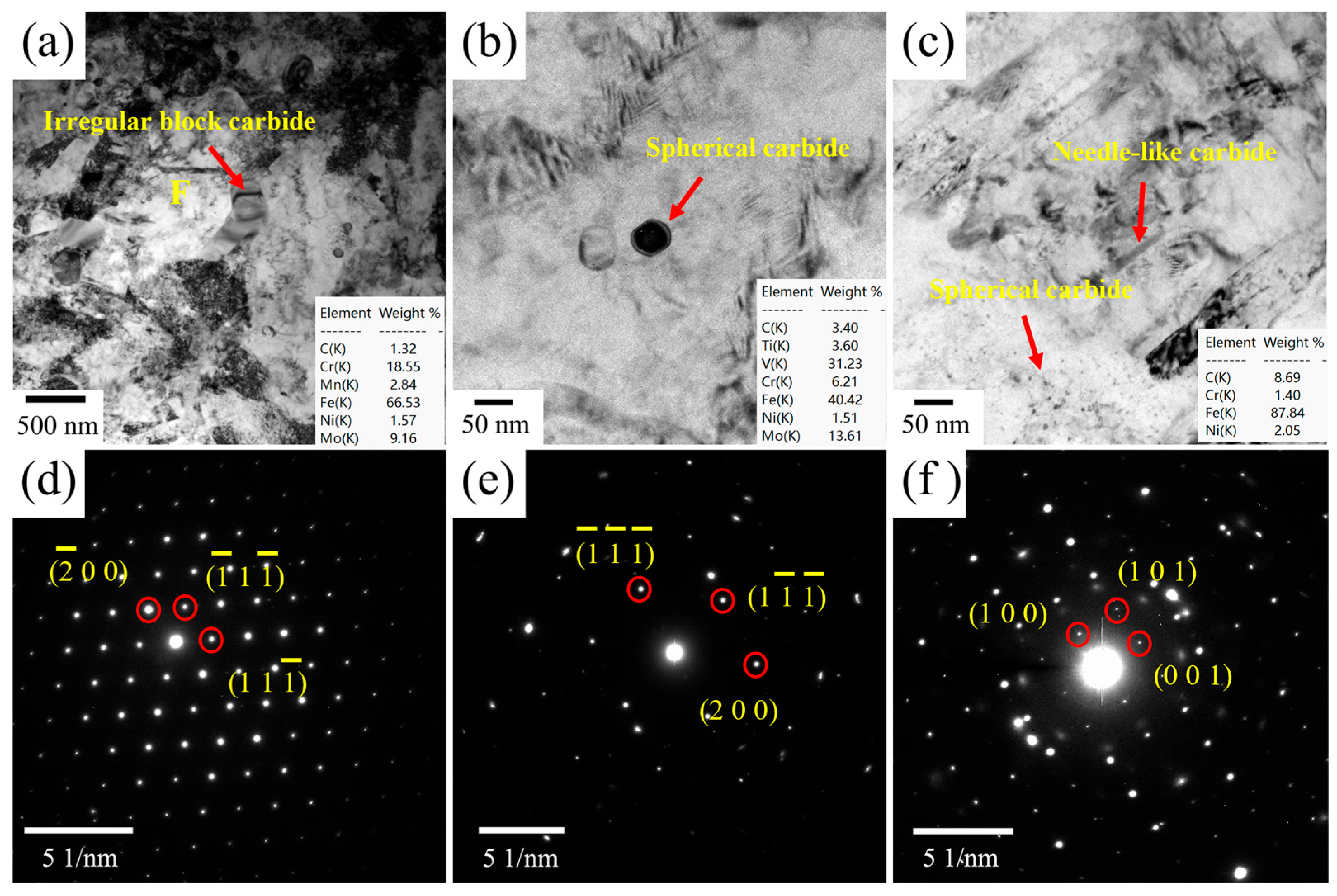

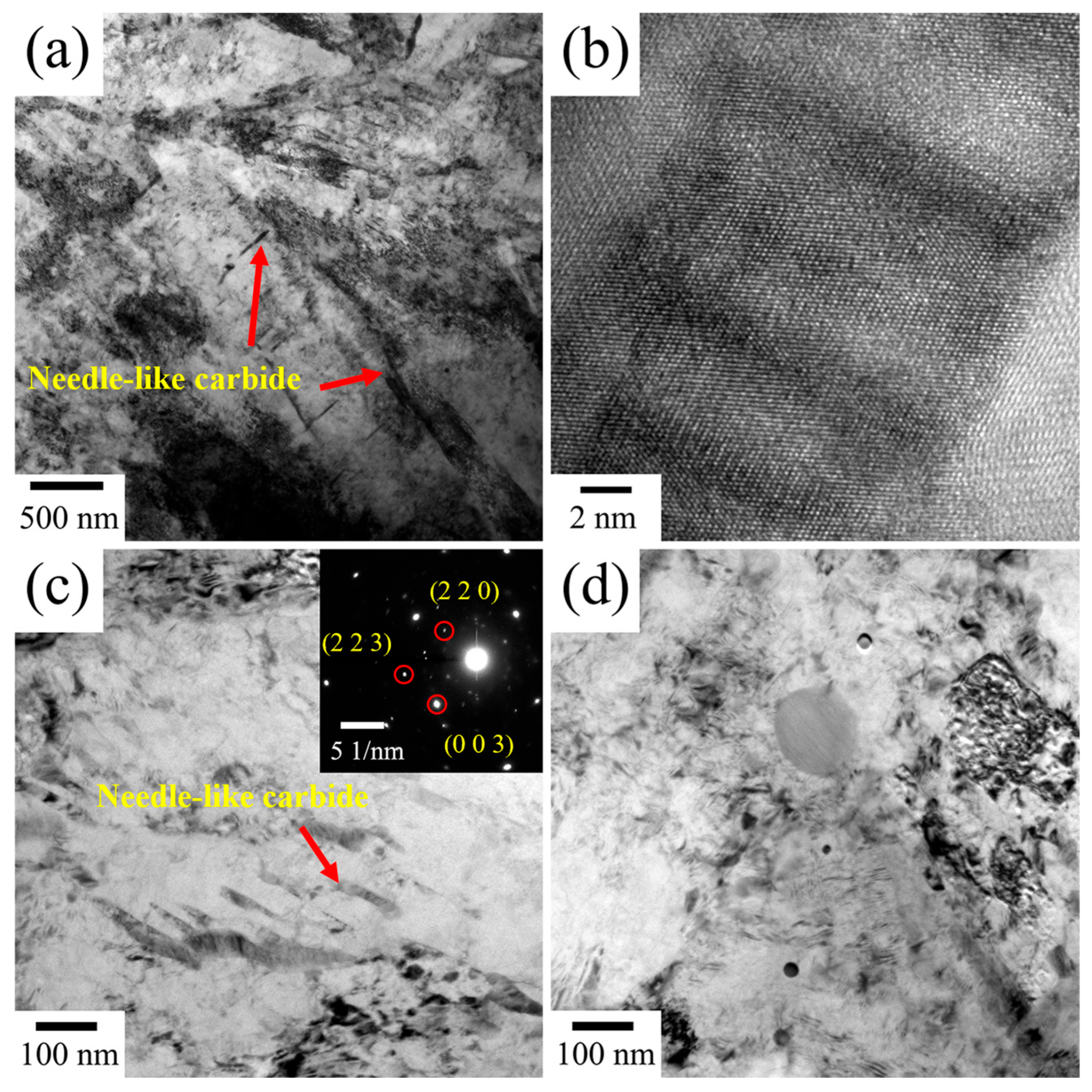

3.2. Tempered State

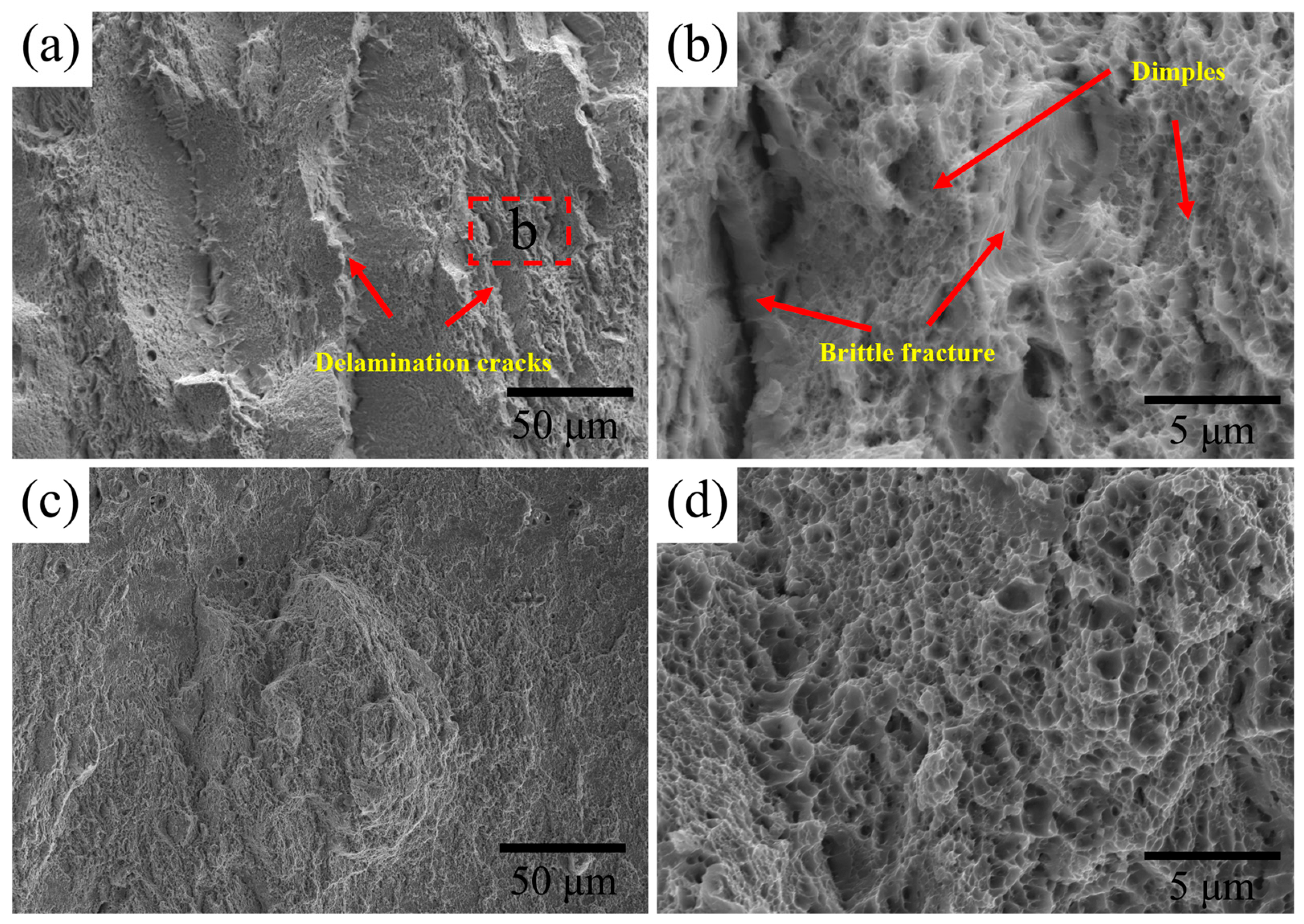

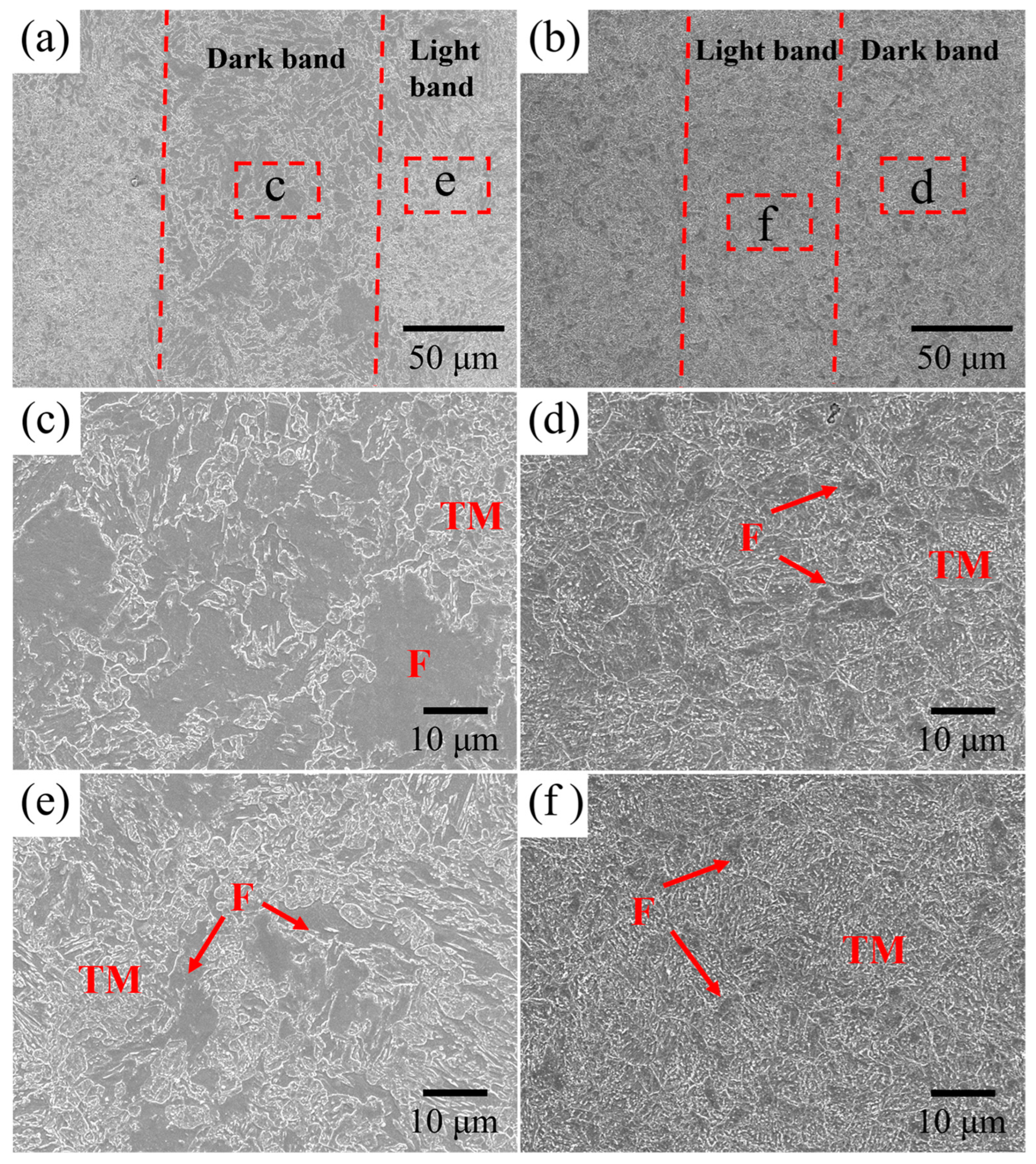

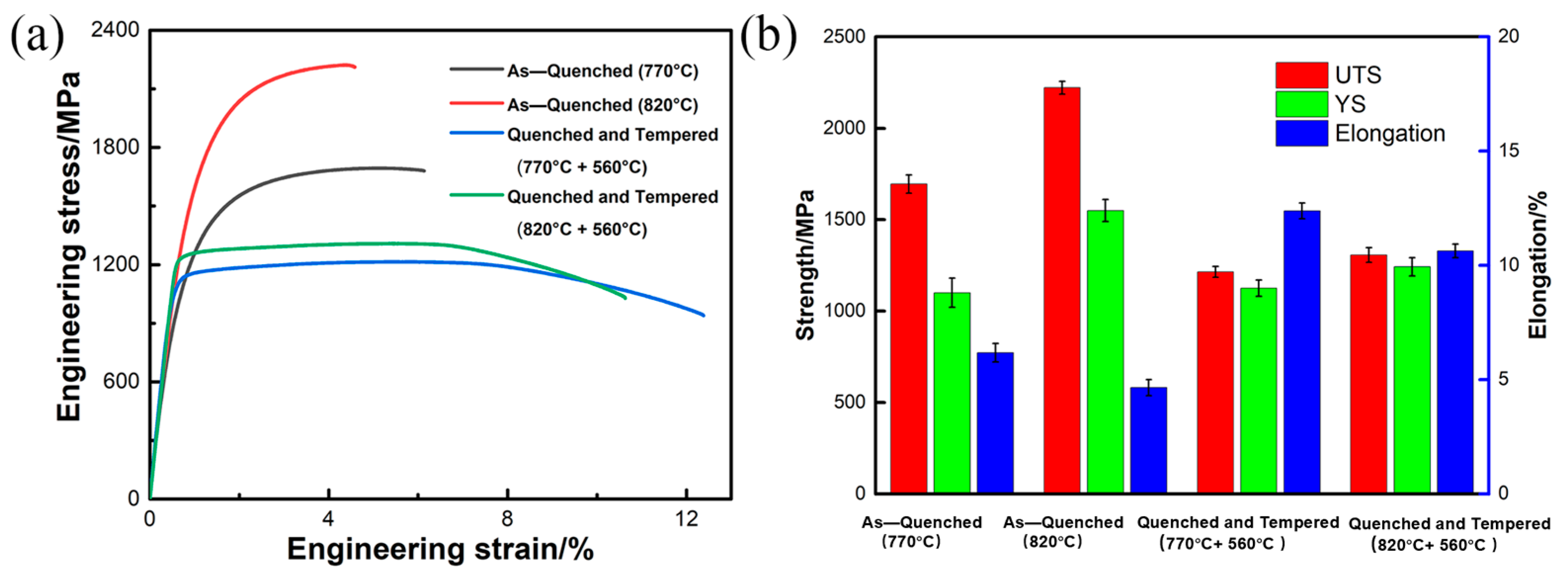

3.3. Mechanical Properties and Deformation Behavior

4. Conclusions

- (1)

- Intercritical quenching temperature has a significant effect on the morphology, distribution, and relative amount of ferrite/martensite of Cr-Ni-Mo-V steel. At the intercritical temperature of 770 °C, 30 ± 3.2 vol.% ferrite with a blocky morphology is obtained; as the quenching temperature increases to 820 °C, the amount of ferrite in the Cr-Ni-Mo-V steel decreases to 18 ± 2.8 vol.%.

- (2)

- Tempering treatment has no significant effect on the distribution characteristics of ferrite, but it promotes the recovery of martensite laths and the precipitation of carbides. Specifically, under a quenching temperature of 770 °C, carbides precipitated upon tempering, including MC, M23C6, and M3C. Under a quenching temperature of 820 °C, the precipitation of carbides is mainly M3C, and the distribution density of MC is reduced.

- (3)

- The mechanical properties of Cr-Ni-Mo-V steel are determined by both the variation in ferrite content induced by intercritical quenching and the evolution of carbide types during tempering. Delamination cracks observed on the fracture surface improve the ductility of Cr-Ni-Mo-V steel through stress dispersion and a multi-stage energy absorption mechanism.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhao, X.; Li, H. Experimental study on the dynamic behavior of a Cr-Ni-Mo-V steel under different shock stresses. Metals 2023, 13, 663. [Google Scholar] [CrossRef]

- Maropoulos, S.; Ridley, N.; Karagiannis, S. Structural variations in heat treated low alloy steel forgings. Mater. Sci. Eng. A 2004, 380, 79–92. [Google Scholar] [CrossRef]

- Yang, Y.; Fan, L.; Xu, C.; Dong, X. Experimental Study of Mechanical Properties of 30SiMn2MoVA Steel Gun Barrel Processed by Cold Radial Forging. J. Press. Vessel Technol. 2020, 143, 22–29. [Google Scholar] [CrossRef]

- Ren, Q.; Kou, Z.; Wu, J.; Hou, T.; Xu, P. Effect of Tempering Temperature on Microstructure and Mechanical Properties of 35CrMo Steel. Metals 2023, 13, 771. [Google Scholar] [CrossRef]

- Wei, A.; Feng, Y.; Wu, L.; Li, Y.; Xie, Z. Corrosion Wear Behavior of 30CrNi2MoVA Steel in Simulated Seawater. Mater. Lett. 2023, 349, 134750. [Google Scholar] [CrossRef]

- Huang, X.D.; Zhou, M.H.; Zhang, T.Y.; Chen, P.; Fu, H.; Huang, X.M.; Chen, S.D.; Wu, H.; Shan, Q. Effect of Banded Structure on the Cr–Ni–Mo–V Steel High-Temperature Frictional and Wear Performance. Tribol. Lett. 2023, 71, 58. [Google Scholar] [CrossRef]

- Zhao, C.; Jia, X.; Zhao, C.; Bai, S.; Huang, Y.; Zhang, Q.; Zhang, J.; Hu, Y.; Huang, J. Study on Low-Cycle Fatigue Behavior and Life Prediction of Cr–Ni–Mo–V Gun Steel at Room Temperature and 600 °C. Fatigue Fract. Eng. Mater. Struct. 2025, 48, 118–131. [Google Scholar] [CrossRef]

- Polášek, M.; Krbata, M.; Eckert, M.; Mikuš, P.; Cíger, R. Contact Fatigue Resistance of Gun Barrel Steels. Procedia Struct. Integr. 2023, 43, 306–311. [Google Scholar] [CrossRef]

- Wang, Z.; Hui, W.; Chen, Z.; Zhang, Y.; Zhao, X. Effect of vanadium on microstructure and mechanical properties of bainitic forging steel. Mater. Sci. Eng. A 2020, 771, 138653. [Google Scholar] [CrossRef]

- Ze, T.Y.; Zhang, S.Z.; Shi, X.B.; Wang, W.; Yan, W.; Yang, K. Effect of NbC and VC carbides on microstructure and strength of high-strength low-alloyed steels for oil country tubular goods. Mater. Sci. Eng. A 2021, 824, 141845. [Google Scholar]

- Bai, R.; Du, Y.F.; He, X.L.; Zhang, Y.Q. The Influence of Cr Addition on the Microstructure and Mechanical Properties of Fe-25Mn-10Al-1.2 C Lightweight Steel. Metals 2024, 14, 687. [Google Scholar] [CrossRef]

- Hu, Z.; Fu, H. Effect of Si Content on Microstructure and Properties of Low-Carbon Medium-Manganese Steel after Intercritical Heat Treatment. Metals 2024, 14, 675. [Google Scholar] [CrossRef]

- Zhang, S.; Zhou, W.; Hu, F.; Yershov, S.; Wu, K. The role of Si in enhancing the stability of residual austenite and mechanical properties of a medium carbon bainitic steel. J. Mater. Res. Technol. 2024, 30, 1939–1949. [Google Scholar] [CrossRef]

- Wang, Y.L.; Chen, Y.L.; Yu, W. Effect of Cr/Mn segregation on pearlite—Martensite banded structure of high carbon bearing steel. Int. J. Miner. Metall. Mater. 2021, 28, 665–675. [Google Scholar] [CrossRef]

- Du, Y.F.; Lu, H.H.; Sheng, X.Q. Coupled effects of banded structure and carbide precipitation on mechanical performance of Cr-Ni-Mo-V steel. Mater. Sci. Eng. A 2022, 832, 142478. [Google Scholar] [CrossRef]

- Lu, Y.F.; Wang, G.L.; Zhang, M.B.; Li, R.S.; Zhang, H.O. Microstructures, heat treatments and mechanical properties of AerMet100 steel fabricated by hybrid directed energy deposition. Addit. Manuf. 2022, 56, 102885. [Google Scholar] [CrossRef]

- McClelland, Z.; Petersen, H.; Dunsford, K. Dynamic Tensile Behavior of Laser-Directed Energy Deposition and Additive Friction Stir-Deposited AerMet 100. Metals 2023, 13, 1736. [Google Scholar] [CrossRef]

- Zhao, C.; Zhang, X.; Liang, X.; Song, G.; Wang, B.; Guo, L.; Zhang, P.; Zhang, S. Effect of Tempering Temperature on Microstructure and Mechanical Properties of Cr-Ni-Mo-V Rotor Steel. Materials 2025, 18, 555. [Google Scholar] [CrossRef] [PubMed]

- Wu, W.; Zhu, M.L.; Liu, X.; Xuan, F.Z. Effect of temperature on high-cycle fatigue and very high cycle fatigue behaviours of a low-strength Cr–Ni–Mo–V steel welded joint. Fatigue Fract. Eng. Mater. Struct. 2017, 40, 45–54. [Google Scholar] [CrossRef]

- Xia, B.; Zhang, P.; Wang, B.; Li, X.W.; Zhang, Z.F. Effects of quenching temperature on the microstructure and impact toughness of 50CrMnSiVNb spring steel. Mater. Sci. Eng. A 2023, 870, 144856. [Google Scholar] [CrossRef]

- Xie, Y.; Cheng, X.; Wei, J.; Luo, R. Characterization of Carbide Precipitation during Tempering for Quenched Dievar Steel. Materials 2022, 15, 6448. [Google Scholar] [CrossRef]

- DelRio, F.W.; Martin, M.L.; Santoyo, R.L.; Lucon, E. Effect of Tempering on the Ductile-to-Brittle Transitional Behavior of Ni-Cr-Mo Low-Alloy Steel. Exp. Mech. 2020, 60, 1167–1172. [Google Scholar] [CrossRef]

- Lv, Z.W.; Fan, J.; Wang, R.; Yu, Z.Q.; Kang, Y.; Hu, Y.; Tuo, L.F.; Eckert, J.; Yan, Z.J. Microstructural evolution during tempering process and mechanical properties of Cr–Ni–Mo–V/Nb high strength steel. J. Iron Steel Res. Int. 2025, 32, 270–281. [Google Scholar] [CrossRef]

- Zhang, J.; Zhao, M.C.; Tian, Y.; Zhang, J.; Wang, Z.; Zhao, Y.C.; Peng, L. Simultaneous Enhancement of Strength and Sulfide Stress Cracking Resistance of Hot-Rolled Pressure Vessel Steel Q345 via a Quenching and Tempering Treatment. Materials 2024, 17, 1636. [Google Scholar] [CrossRef]

- Deng, Y.G.; Yang, Y.P. Fine-grained dual-phase steels fabricated via cold-rolling ferrite-martensite structure and subsequent intercritical annealing. J. Mater. Res. Technol. 2023, 27, 3881–3886. [Google Scholar] [CrossRef]

- Wu, H.; Deng, X.; Li, X.; Fu, T.; Wang, Z. Heterolamellar structure design simultaneously enhances strength and plasticity in ultrahigh strength steel. Mater. Sci. Eng. A 2024, 906, 146719. [Google Scholar] [CrossRef]

- Sang, Y.; Sun, G.S.; Liu, J.Z. A 4340 steel with superior strength and toughness achieved by heterostructure via intercritical quenching and tempering. Metals 2023, 13, 675. [Google Scholar] [CrossRef]

- Gao, B.; Hu, R.; Pan, Z.Y.; Chen, X.F.; Liu, Y.; Xiao, L.R.; Cao, Y.; Li, Y.S.; Lai, Q.Q.; Zhou, H. Strengthening and ductilization of laminate dual-phase steels with high martensite content. J. Mater. Sci. Technol. 2021, 65, 29–37. [Google Scholar] [CrossRef]

- Du, Y.F.; Gu, Z.Z.; Zhang, Y.Q.; Bai, R. Microstructural evolution and mechanical properties of Cr–Ni–Mo–V steel with banded structure during tempering. J. Alloys Metall. Syst. 2024, 8, 100131. [Google Scholar] [CrossRef]

- ASTM E8M-24; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2024.

- Wen, T.; Hu, X.F.; Song, Y.Y.; Yan, D.S.; Rong, L.J. Carbides and mechanical properties in a Fe-Cr-Ni-Mo high-strength steel with different V contents. Mater. Sci. Eng. A 2013, 588, 201–207. [Google Scholar] [CrossRef]

- Ridley, N.; Maropoulos, S.; Paul, J.D.H. Effects of heat treatment on microstructure and mechanical properties of Cr–Mo–3·5Ni–V steel. Mater. Sci. Technol. 1994, 10, 239–249. [Google Scholar] [CrossRef]

- Hosseinifar, F.; Ekrami, A. The effect of cold-rolling prior to the inter-critical heat treatment on microstructure and mechanical properties of 4340 steel with ferrite–martensite microstructure. Mater. Sci. Eng. A 2022, 830, 142314. [Google Scholar] [CrossRef]

- Yang, G.; Xia, S.L.; Zhang, F.C.; Branco, R.; Long, X.Y.; Li, Y.G.; Li, J.H. Effect of tempering temperature on monotonic and low-cycle fatigue properties of a new low-carbon martensitic steel. Mater. Sci. Eng. A 2021, 826, 141939. [Google Scholar] [CrossRef]

- Chen, H.; Zeng, T.Y.; Shi, Q.Q.; Wang, N.M.; Zhang, S.Z.; Yang, K.; Yna, W.; Wang, W. Microstructure evolution and mechanical properties during long-term tempering of a low carbon martensitic stainless bearing steel. J. Mater. Res. Technol. 2023, 25, 297–309. [Google Scholar] [CrossRef]

- Zhang, Y.P.; Zhan, D.P.; Qi, Z.W.; Jiang, Z.H. Effect of tempering temperature on the microstructure and properties of ultrahigh-strength stainless steel. J. Mater. Sci. Technol. 2019, 35, 1240–1349. [Google Scholar] [CrossRef]

- Pathak, N.; Adrien, J.; Butcher, C.; Maire, E.; Worswick, M. Experimental stress state-dependent void nucleation behavior for advanced high strength steels. Int. J. Mech. Sci. 2022, 179, 105661. [Google Scholar] [CrossRef]

- Gao, B.; Xiang, Q.; Guo, T.F.; Guo, X.; Tang, S.; Huang, X.X. In situ TEM investigation on void coalescence in metallic materials. Mater. Sci. Eng. A 2018, 734, 260–268. [Google Scholar] [CrossRef]

- Ning, J.L.; Zhang, Y.T.; Huang, L.; Feng, Y.L. Stabilized uniform deformation in a high-strength ferrite-cementite steel with multiscale lamellar structure. Mater. Des. 2017, 120, 280–290. [Google Scholar] [CrossRef]

- Shen, X.J.; Li, D.Z.; Tang, S.; Chen, J.; Fang, H.; Wang, G.D. Delamination toughening in a low carbon microalloyed steel plate rolled in the dual-phase region. Mater. Sci. Eng. A 2019, 766, 138342. [Google Scholar] [CrossRef]

- Inoue, T.; Kimura, Y. Effect of Delamination and Grain Refinement on Fracture Energy of Ultrafine-Grained Steel Determined Using an Instrumented Charpy Impact Test. Materials 2022, 15, 867. [Google Scholar] [CrossRef] [PubMed]

| C | Si | Mn | Cr | Ni | Mo | Cu | V | P | S | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.36 | 0.27 | 0.32 | 1.3 | 3.19 | 0.4 | 0.12 | 0.2 | 0.005 | 0.001 | Bal. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, Y.; Zhou, X.; Bai, R.; Zhang, Y. Effect of Intercritical Quenching Temperature on Microstructure and Mechanical Performance of Cr-Ni-Mo-V Steel with Banded Structure. Materials 2025, 18, 4017. https://doi.org/10.3390/ma18174017

Du Y, Zhou X, Bai R, Zhang Y. Effect of Intercritical Quenching Temperature on Microstructure and Mechanical Performance of Cr-Ni-Mo-V Steel with Banded Structure. Materials. 2025; 18(17):4017. https://doi.org/10.3390/ma18174017

Chicago/Turabian StyleDu, Yunfei, Xiaosheng Zhou, Rui Bai, and Yaqin Zhang. 2025. "Effect of Intercritical Quenching Temperature on Microstructure and Mechanical Performance of Cr-Ni-Mo-V Steel with Banded Structure" Materials 18, no. 17: 4017. https://doi.org/10.3390/ma18174017

APA StyleDu, Y., Zhou, X., Bai, R., & Zhang, Y. (2025). Effect of Intercritical Quenching Temperature on Microstructure and Mechanical Performance of Cr-Ni-Mo-V Steel with Banded Structure. Materials, 18(17), 4017. https://doi.org/10.3390/ma18174017