Comparative Study on the Tensile and Compression Process of the Collapsible Ultra-Thin-Walled Composite Lens Rod

Highlights

- Theoretical modeling of Composite Thin-walled Lenticular Tubes (CTLTs) compression deformation process;

- Validation of the theoretical model through finite element simulation analysis results and experimental results;

- The Composite Thin-walled Lenticular Tubes (CTLTs) pattern utilizes a minimum number of layers to more accurately reflect deformation during compression;

- Conduct multiple sets of experiments to ensure the accuracy of experimental data.

Abstract

1. Introduction

2. Theoretical Modeling

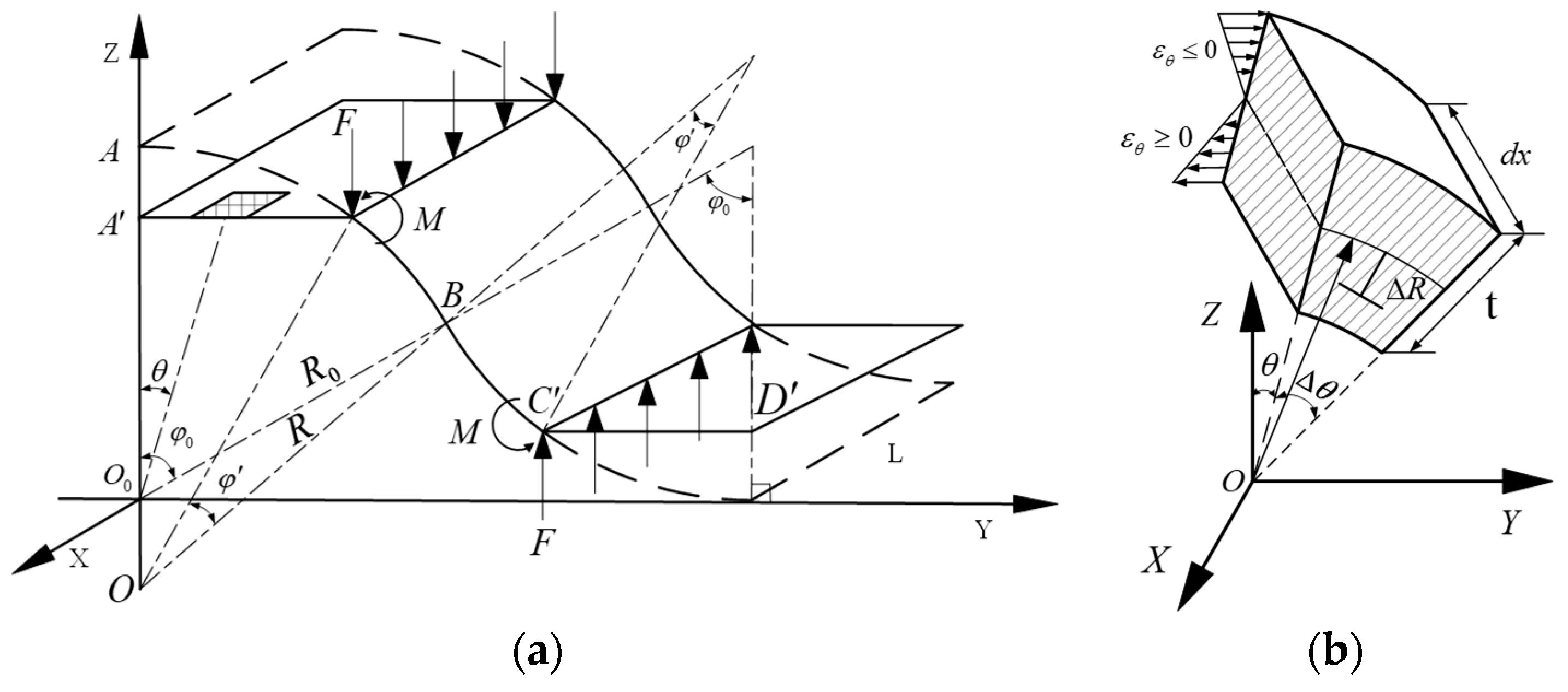

2.1. Geometric Model of Crush Deformation

2.2. Analytical Solution for the Crush Deformation of the CFRP Material Beanpole

3. Numerical Investigation

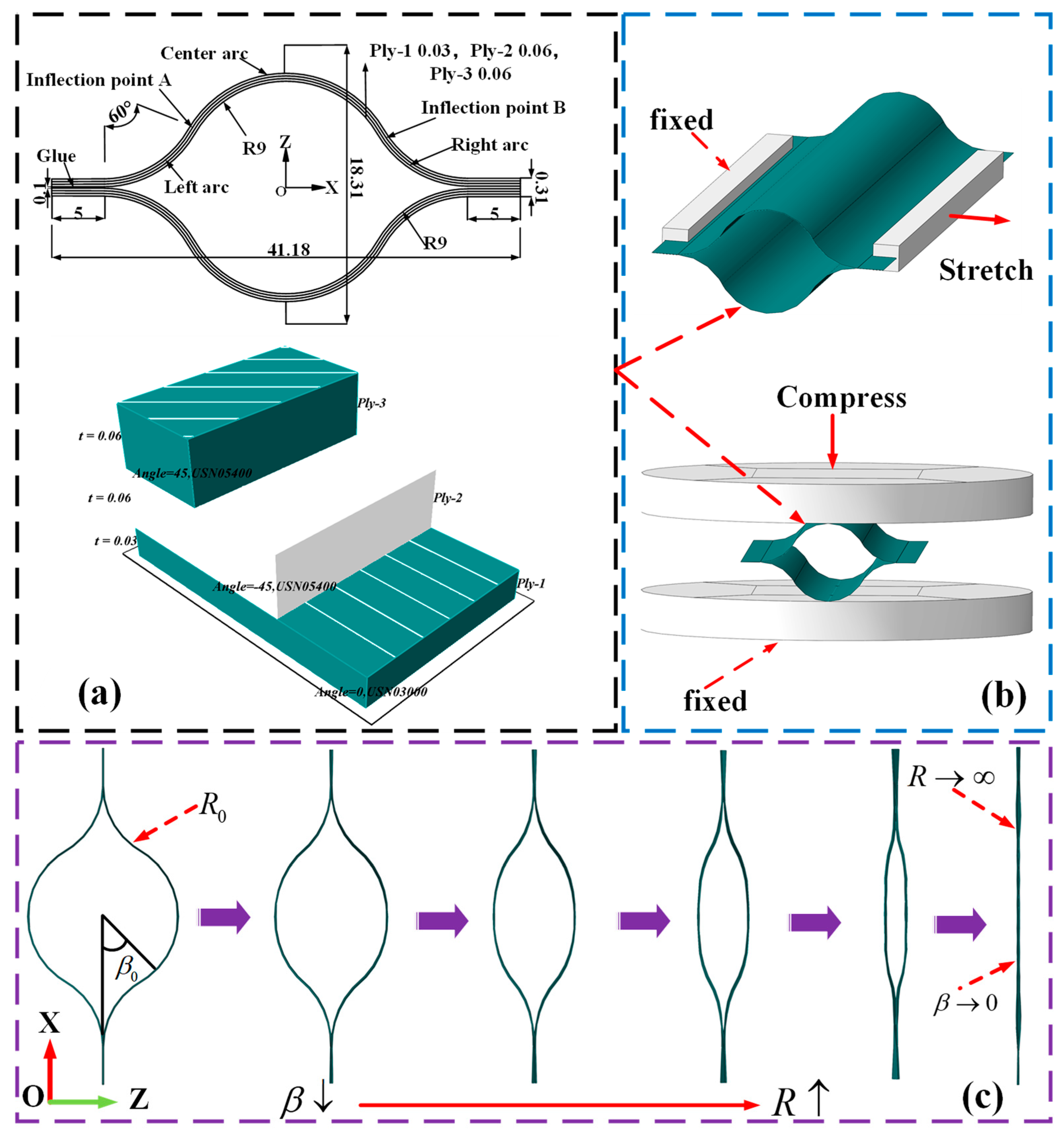

3.1. Compression Flattening Process of the CTLT

3.2. Tensile Flattening Process of CTLT

4. Experiments

4.1. Compression and Flattening Experiment

- (1)

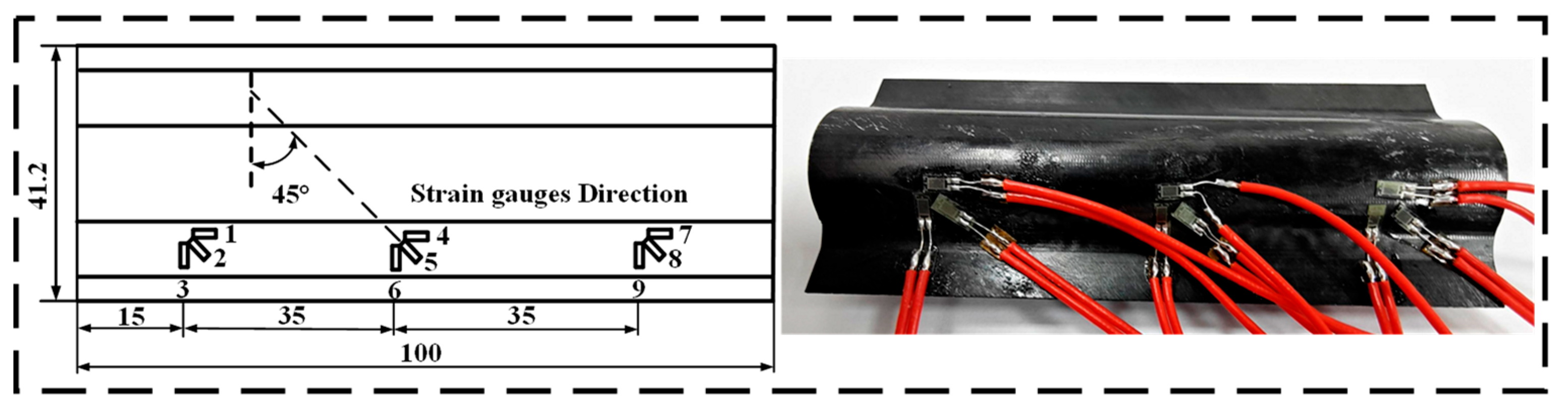

- As shown in Figure 3, due to the symmetry of the CTLT specimen, nine unidirectional strain gauges were pasted at the inflection points of one side of the arc.

- (2)

- To keep the specimen in a stable flattened state, the specimen should be horizontally placed.

- (3)

- The downward displacement of the compression plate is 0.5 mm/s. When the contact reaction force is 0.5 N, the test system starts to record the load and downward displacement. The total downward displacement is 17 mm. The entire flattening process is divided into 18 steps. Then, the experimental strain magnitude is obtained from various strain gauges. Figure 4a shows the compression and flattening process of the CTLT specimen.

4.2. Compression and Tensile Test

- (1)

- As shown in Figure 3, due to the symmetry of the CTLT specimen, nine unidirectional strain gauges were pasted at the inflection points of one side of the arc.

- (2)

- To avoid relative sliding between fixture and section, the strain gauges can be tightly fixed by applying a transverse pressure to the screw fixture.

- (3)

- Apply the displacement load at 0.5 mm/s and start recording the tensile displacement and the corresponding displacement load when the reaction force is 0.5 N. The tensile displacement and the corresponding displacement load are recorded when the reaction force is 0.5 N. The tensile displacement and the corresponding displacement load are recorded when the reaction force is 0.5 N. The first step was processed with a tensile displacement of 0.5 mm, then the tensile displacement was increased by 0.5 mm and loaded continuously for 12 s until the total tensile displacement reached 65 mm.

5. Results and Discussion

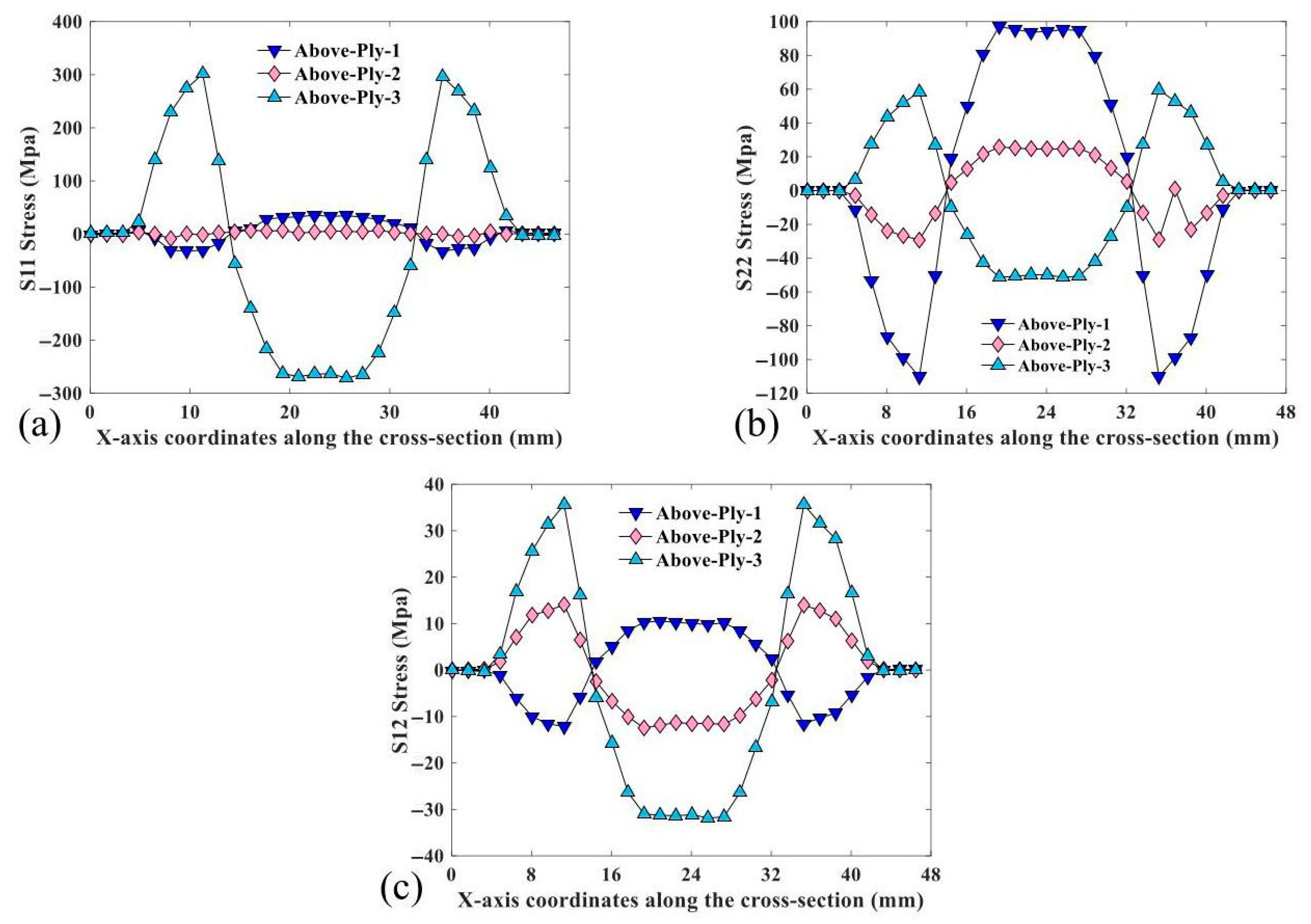

5.1. Finite Element Simulation Results and Analysis

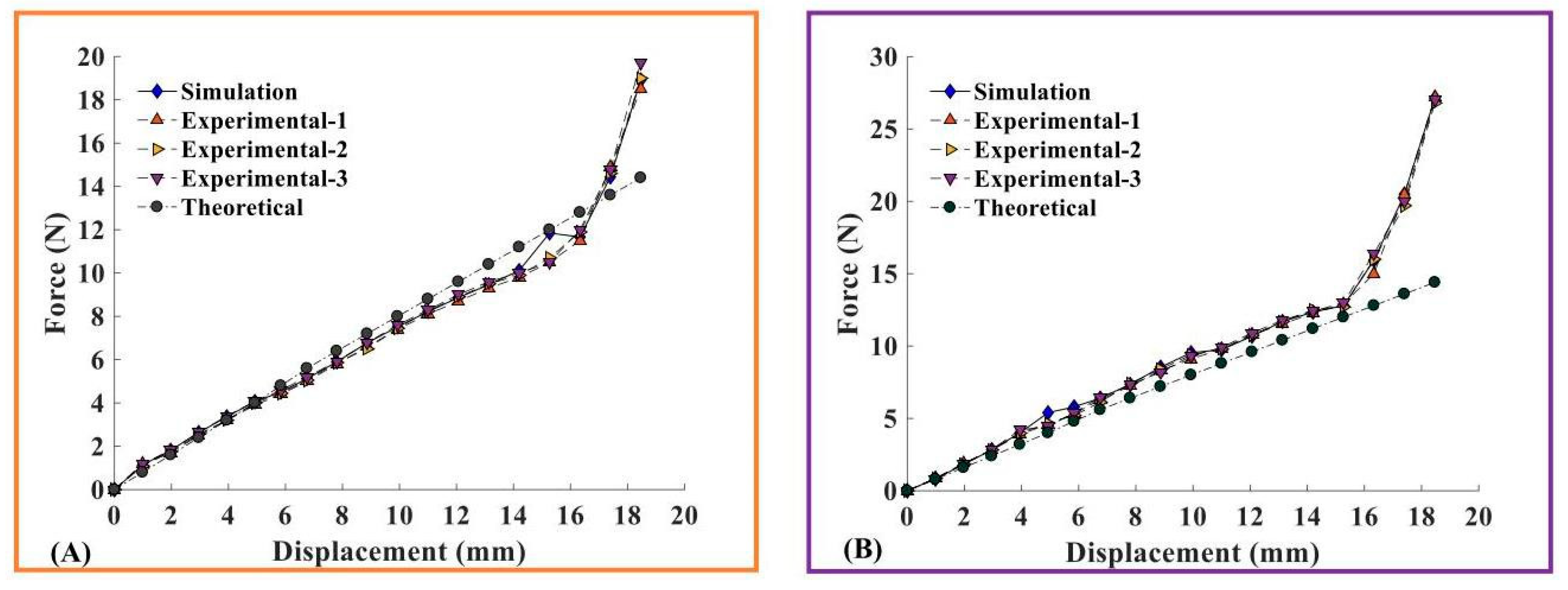

5.2. Comparative Analysis of Compression Experiment and Simulation Results

5.3. Comparative Analysis of Tensile Experiment and Simulation Results

6. Conclusions

- (1)

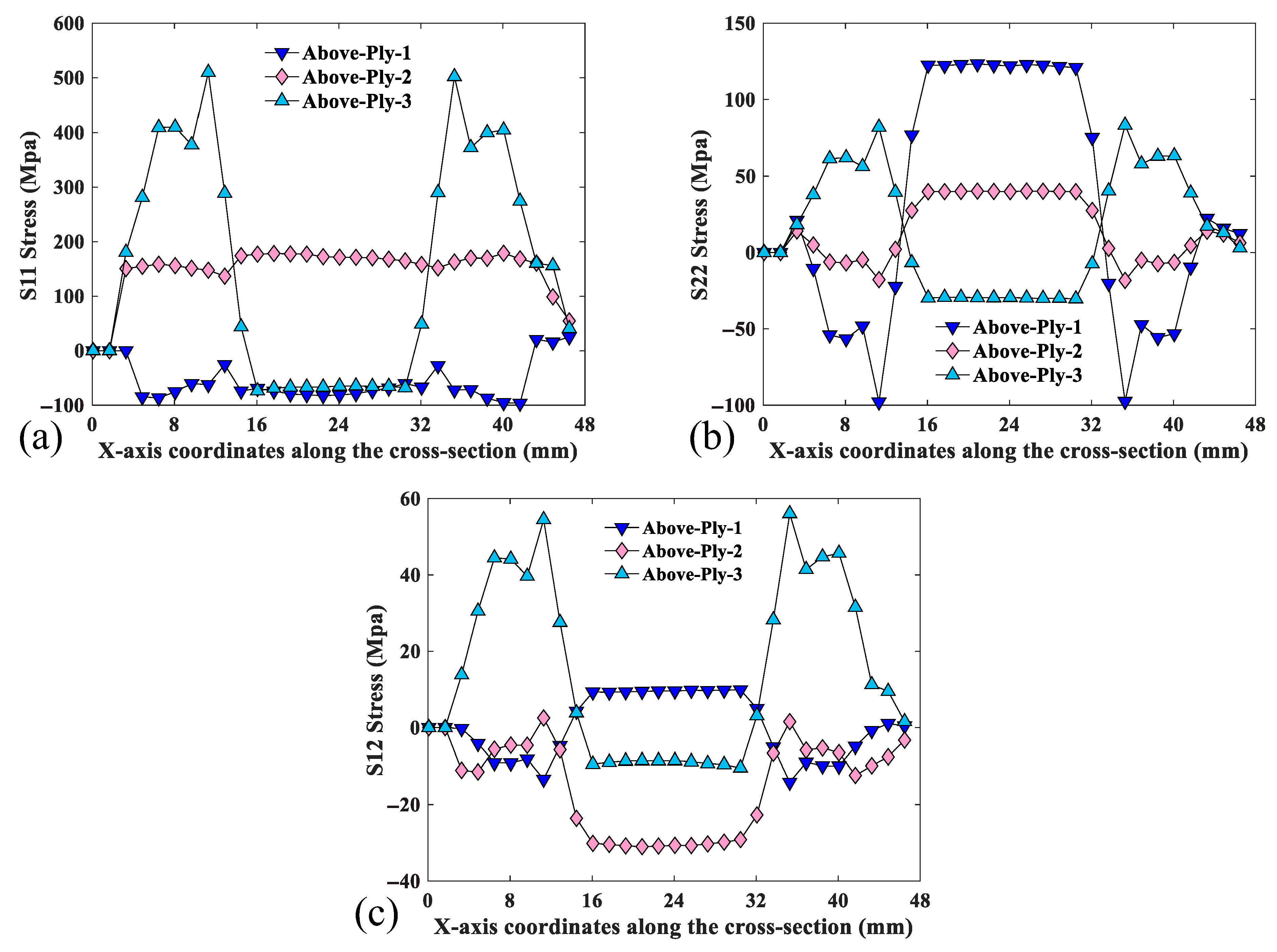

- The force characteristics of each layer of the CTLT finite element model are analyzed, including the stress, strain, and pressure characteristics of each layer. The shear stress at the two side arcs is larger than other regions, the stress distribution is very uniform, and the shear stress at inflection point B is the smallest. At the beginning of the flattening process, the load grows slowly and the displacement grows rapidly, so the CTLT is easier to flatten. However, at the end stage of the flattening process, the load grows rapidly and the displacement changes slowly. In the numerical simulation of the flattening process, the shear stress on the arc is higher and the shear stress at inflection point B is the smallest.

- (2)

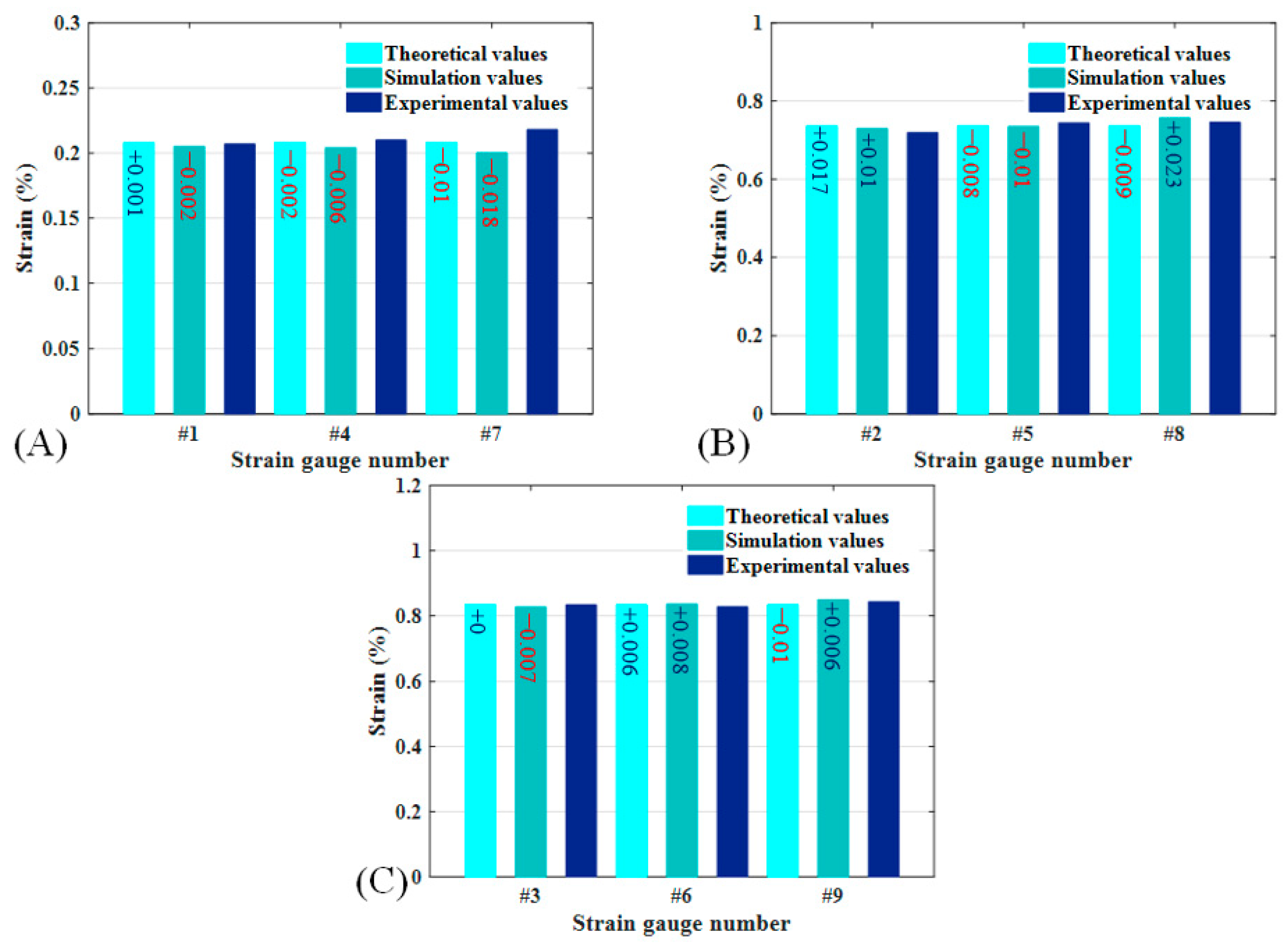

- In the process of flattening and pulling, by the theoretical results and finite element analysis results, the linear relationship between strain and displacement is more obvious, and the growth rate of strain is very fast. According to the experimental collection of multiple sets of data, excluding the possibility of experimental errors, the strain experimental value does not have a relatively obvious nonlinear change, indicating that in the pod rod in the actual storage application, a larger load can be applied to completely flatten the pod rod to save storage space.

- (3)

- In the experiments and simulations, the CTLT specimens are fabricated according to the geometry of their corresponding finite element models. The experimental and numerical simulations have good correlation in terms of load displacement and stress–strain variation with loading state, both of which reflect the validity of the theoretical model well. Both squashing processes are nonlinear deformation and small strain processes. The compression squash is smaller and more uniformly distributed than the tensile squash stress, and the squash method should be preferred in the design of the mechanism.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Radius of curvature of the neutral axis of the cross-section of the pod bar during the flattening process. | |

| Central angle of the neutral axis of the cross-section of the pod bar during the flattening process. | |

| Polar angle at any position of the cross-section of the bean pod rod in the polar coordinate system. | |

| External compression load in the vertical direction of the center of the top arc of the pod rod. | |

| Radius of curvature of the neutral axis of the cross-section of the pod rod in the initial state. | |

| Central angle of the neutral axis of the cross-section of the pod rod in the initial state. | |

| Strain in the direction of theta tangent during the flattening deformation of the pod rod. | |

| Change in radius of curvature of the neutral axis of the pod rod cross-section. | |

| x-direction of the restrained reaction moment. | |

| Off-axis modulus of elasticity of the composite monolayer along the direction. | |

| Restraint reaction force. |

References

- Block, J.; Straubel, M.; Wiedemann, M. Ultralight deployable booms for solar sails and other large gossamer structures in space. Acta Astronaut. 2011, 68, 984–992. [Google Scholar] [CrossRef]

- Liu, Z.; Li, Q.; Lan, X.; Bian, W.; Liu, L.; Hao, S.; Liu, Y.; Leng, J. Structural and dynamic analysis of a flexible solar array based on shape memory polymer composites. Compos. Struct. 2022, 280, 114918. [Google Scholar] [CrossRef]

- Meng, M.; Le, H.R.; Rizvi, M.J.; Grove, S.M. 3D FEA modelling of laminated composites in bending and their failure mechanisms. Compos. Struct. 2015, 119, 693–708. [Google Scholar] [CrossRef]

- Liu, T.W.; Bai, J.B.; Lin, Q.H.; Cong, Q. An analytical model for predicting compressive behaviour of composite helical Structures: Considering geometric nonlinearity effect. Compos. Struct. 2021, 255, 112908. [Google Scholar] [CrossRef]

- Sakovsky, M.; Pellegrino, S. Closed cross-section dual-matrix composite hinge for deployable structures. Compos. Struct. 2019, 208, 784–795. [Google Scholar] [CrossRef]

- Xu, J.; Ma, Y.; Zhang, Q.; Sugahara, T.; Yang, Y.; Hamada, H. Crashworthiness of carbon fiber hybrid composite tubes molded by filament winding. Compos. Struct. 2016, 139, 130–140. [Google Scholar] [CrossRef]

- Bai, J.B.; Liu, T.W.; Wang, Z.Z.; Lin, Q.H.; Cong, Q.; Wang, Y.F.; Ran, J.N.; Li, D.; Bu, G.Y. Determining the best practice—Optimal designs of composite helical structures using Genetic Algorithms. Compos. Struct. 2021, 268, 113982. [Google Scholar] [CrossRef]

- Sun, G.; Tian, X.; Fang, J.; Xu, F.; Li, G.; Huang, X. Dynamical bending analysis and optimization design for functionally graded thickness (FGT) tube. Int. J. Impact Eng. 2015, 78, 128–137. [Google Scholar] [CrossRef]

- Tavassolimanesh, A.; Niknejad, A.; Assaee, H. Effects of polyethylene and polyurethane Teflon-fillers on the energy absorption behavior of composite tubes during the flattening tests. J. Compos. Mater. 2015, 49, 2057–2072. [Google Scholar] [CrossRef]

- Sun, G.; Yu, H.; Wang, Z.; Xiao, Z.; Li, Q. Energy absorption mechanics and design optimization of CFRP/aluminium hybrid structures for transverse loading. Int. J. Mech. Sci. 2019, 150, 767–783. [Google Scholar] [CrossRef]

- Huang, Z.; Zhang, X.; Yang, C. Experimental and numerical studies on the bending collapse of multi-cell Aluminum/CFRP hybrid tubes. Compos. B Eng. 2020, 181, 107527. [Google Scholar] [CrossRef]

- Liu, X.; Belkassem, B.; Jonet, A.; Lecompte, D.; Van Hemelrijck, D.; Pintelon, R.; Pyl, L. Experimental investigation of energy absorption behaviour of circular carbon/epoxy composite tubes under quasi-static and dynamic crush loading. Compos. Struct. 2019, 227, 111266. [Google Scholar] [CrossRef]

- Swolfs, Y.; Gorbatikh, L.; Verpoest, I. Fibre hybridisation in polymer composites: A review. Compos. Part A Appl. Sci. Manuf. 2014, 67, 181–200. [Google Scholar] [CrossRef]

- Morioka, K.; Ohtake, Y.; Suzuki, H.; Nagai, Y.; Hishida, H.; Inagaki, K.; Nakamura, T.; Watanabe, F. Flattening simulations of 3D thick sheets made of fiber composite materials. J. Comput. Des. Eng. 2015, 2, 88–95. [Google Scholar] [CrossRef][Green Version]

- Guo, Y.; Zhai, C.; Li, F.; Zhu, X.; Xu, F.; Wu, X. Formability, defects and strengthening effect of steel/CFRP structures fabricated by using the differential temperature forming process. Compos. Struct. 2019, 216, 32–38. [Google Scholar] [CrossRef]

- Lopatin, A.V.; Morozov, E.V. Fundamental frequency of a cantilever composite cylindrical shell. Compos. Struct. 2015, 119, 638–647. [Google Scholar] [CrossRef]

- Supian, A.B.M.; Sapuan, S.M.; Zuhri, M.Y.M.; Zainudin, E.S.; Ya, H.H. Hybrid reinforced thermoset polymer composite in energy absorption tube application: A review. Def. Technol. 2018, 14, 291–305. [Google Scholar] [CrossRef]

- Yadav, K.K.; Gerasimidis, S. Instability of thin steel cylindrical shells under bending. Thin-Walled Struct. 2019, 137, 151–166. [Google Scholar] [CrossRef]

- Yan, L.; Chouw, N.; Jayaraman, K. Lateral crushing of empty and polyurethane-foam filled natural flax fabric reinforced epoxy composite tubes. Compos. B Eng. 2014, 63, 15–26. [Google Scholar] [CrossRef]

- Leclerc, C.; Pellegrino, S. Nonlinear elastic buckling of ultra-thin coilable booms. Int. J. Solids Struct. 2020, 203, 46–56. [Google Scholar] [CrossRef]

- Shin, D.K.; Kim, H.C.; Lee, J.J. Numerical analysis of the damage behavior of an aluminum/CFRP hybrid beam under three point bending. Compos. B Eng. 2014, 56, 397–407. [Google Scholar] [CrossRef]

- Jalalvand, M.; Czél, G.; Wisnom, M.R. Numerical modelling of the damage modes in UD thin carbon/glass hybrid laminates. Compos. Sci. Technol. 2014, 94, 39–47. [Google Scholar] [CrossRef]

- Wang, Z.; Jin, X.; Li, Q.; Sun, G. On crashworthiness design of hybrid metal-composite structures. Int. J. Mech. Sci. 2020, 171, 105380. [Google Scholar] [CrossRef]

- Li, S.; Guo, X.; Li, Q.; Ruan, D.; Sun, G. On lateral compression of circular aluminum, CFRP and GFRP tubes. Compos. Struct. 2020, 232, 111534. [Google Scholar] [CrossRef]

- Chen, D.; Sun, G.; Jin, X.; Li, Q. Quasi-static bending and transverse crushing behaviors for hat-shaped composite tubes made of CFRP, GFRP and their hybrid structures. Compos. Struct. 2020, 239, 111842. [Google Scholar] [CrossRef]

- Liu, Y.P.; Wang, C.G.; Tan, H.F.; Wadee, M.K. The interactive bending wrinkling behaviour of inflated beams. Proc. Math. Phys. Eng. Sci. 2016, 472, 20160504. [Google Scholar] [CrossRef]

- Zhang, H.; Bilotti, E.; Peijs, T. The use of carbon nanotubes for damage sensing and structural health monitoring in laminated composites: A review. Nanocomposites 2015, 1, 167–184. [Google Scholar] [CrossRef]

- Eratbeni, M.G.; Rostamiyan, Y. Vibration behavior of a carbon fiber-reinforced polymer composite sandwich panel: Rhombus core versus elliptical core. Polym. Compos. 2022, 44, 1741–1751. [Google Scholar] [CrossRef]

- Tao, Q.; Wang, C.; Xue, Z.; Xie, Z.; Tan, H. Wrinkling and collapse of mesh reinforced membrane inflated beam under bending. Acta Astronaut. 2016, 128, 551–559. [Google Scholar] [CrossRef]

- Jia, Q.; An, N.; Ma, X.; Zhou, J. A dynamic finite element procedure for bending collapse of composite thin-walled lenticular tubes. Compos. Struct. 2022, 287, 115364. [Google Scholar] [CrossRef]

- Jia, Q.; An, N.; Ma, X.; Zhou, J. Exploring the design space for nonlinear buckling of composite thin-walled lenticular tubes under pure bending. Int. J. Mech. Sci. 2021, 207, 106661. [Google Scholar] [CrossRef]

- Hu, Y.; Chen, W.; Gao, J.; Hu, J.; Fang, G.; Peng, F. A study of flattening process of deployable composite thin-walled lenticular tubes under compression and tension. Compos. Struct. 2017, 168, 164–177. [Google Scholar] [CrossRef]

- Hu, Y.; Chen, W.; Li, R.; Fang, G. Mechanical characteristics of deployable composite thin-walled lenticular tubes. Compos. Struct. 2016, 153, 601–613. [Google Scholar] [CrossRef]

- Chen, W.; Fang, G.; Hu, Y. An experimental and numerical study of flattening and wrapping process of deployable composite thin-walled lenticular tubes. Thin-Walled Struct. 2017, 111, 38–47. [Google Scholar] [CrossRef]

- Firth, J.A.; Pankow, M.R. Advanced Dual-Pull Mechanism for Deployable Spacecraft Booms. J. Spacecr. Rocket. 2019, 56, 569–576. [Google Scholar] [CrossRef]

- Bai, J.B.; Xiong, J.J.; Gao, J.P.; Yi, X.S. Analytical solutions for predicting in-plane strain and interlaminar shear stress of ultra-thin-walled lenticular collapsible composite tube in fold deformation. Compos. Struct. 2013, 97, 64–75. [Google Scholar] [CrossRef]

- Liu, T.W.; Bai, J.B.; Fantuzzi, N.; Xi, H.T.; Xu, H.; Li, S.L.; Cao, P.C. Folding behavior of thin-walled tubular deployable composite boom for space applications: Experiments and numerical simulation. Acta Astronaut. 2023, 209, 159–171. [Google Scholar] [CrossRef]

- Wang, L.W.; Bai, J.B.; Shi, Y. Simplified Analytical Model for Predicting Neutral Cross-Section Position of Lenticular Deployable Composite Boom in Tensile Deformation. Materials 2021, 14, 7809. [Google Scholar] [CrossRef]

- Bai, J.B.; Shenoi, R.A.; Xiong, J.J. Thermal analysis of thin-walled deployable composite boom in simulated space environment. Compos. Struct. 2017, 173, 210–218. [Google Scholar] [CrossRef]

- Lee, A.J.; Fernandez, J.M. Inducing bistability in Collapsible Tubular Mast booms with thin-ply composite shells. Compos. Struct. 2019, 225, 111166. [Google Scholar] [CrossRef]

- Sickinger, C.; Herbeck, L.; Breitbach, E. Structural engineering on deployable CFRP booms for a solar propelled sailcraft. Acta Astronaut. 2006, 58, 185–196. [Google Scholar] [CrossRef]

- Zhang, Z.; Guo, X.; Pan, B.; Sun, M.; Zhang, G.; Chai, H.; Wu, H.; Jiang, S. Experimental study and numerical simulation of load-bearing/coiling characteristics of thin-walled lenticular composite booms. Compos. Struct. 2023, 324, 117515. [Google Scholar] [CrossRef]

- Wang, P.; Wu, N.; Luo, H.T.; Sun, Z. Study on Vibration Response of a Non-uniform Beam with Nonlinear Boundary Condition. Facta Univ.-Ser. Mech. Eng. 2021, 19, 781–804. [Google Scholar] [CrossRef]

- Vasiliev, V.V.; Morozov, E.V. Advanced Mechanics of Composite Materials; Elsevier: Oxford, UK, 2007; pp. 38–40. [Google Scholar]

- Luo, H.T.; Li, Y.X.; Yu, C.S.; Liu, G.; Mao, X. Numerical and experimental analysis of nonlinear static and dynamic stiffness of angular contact ball bearing. Nonlinear Dyn. 2023, 111, 2281–2309. [Google Scholar] [CrossRef]

- Zhang, H.; Sun, W.; Luo, H.T.; Shen, J.; Zhang, R. A method of layout optimization for MFC actuators in active vibration control of composite laminates. Appl. Acoust. 2024, 220, 109961. [Google Scholar] [CrossRef]

| Property | USN05400 | USN03000 |

|---|---|---|

| Longitudinal modulus of elasticity /GPa | 116.62 | 141.98 |

| Transverse modulus of elasticity /GPa | 8.9834 | 10.171 |

| Cut the variable /MPa | 4377 | 3645 |

| Cut the variable /MPa | 4377 | 3645 |

| Cut the variable /MPa | 4000 | 3500 |

| Poisson’s ratio | 0.29992 | 0.2923 |

| Density ρ/(kg/) | 1600 | 1600 |

| Strain Gauge Number (%) | #1 | #2 | #3 | #4 | #5 | #6 | #7 | #8 | #9 |

|---|---|---|---|---|---|---|---|---|---|

| Theoretical value | 0.208 | 0.736 | 0.833 | 0.208 | 0.736 | 0.833 | 0.208 | 0.736 | 0.833 |

| Simulation value | 0.205 | 0.729 | 0.826 | 0.204 | 0.734 | 0.835 | 0.200 | 0.768 | 0.849 |

| Experimental value 1 | 0.206 | 0.724 | 0.838 | 0.218 | 0.744 | 0.827 | 0.224 | 0.754 | 0.847 |

| Experimental value 2 | 0.198 | 0.721 | 0.840 | 0.212 | 0.751 | 0.824 | 0.217 | 0.756 | 0.835 |

| Experimental value 3 | 0.218 | 0.712 | 0.821 | 0.199 | 0.737 | 0.830 | 0.213 | 0.724 | 0.846 |

| Experimental mean value | 0.207 | 0.719 | 0.833 | 0.210 | 0.744 | 0.827 | 0.218 | 0.745 | 0.843 |

| Difference between simulation and experiment | 0.001 | 0.017 | 0 | −0.002 | −0.008 | 0.006 | −0.01 | −0.009 | −0.01 |

| Difference between theory and experiment | −0.002 | 0.01 | −0.007 | −0.006 | −0.01 | 0.008 | −0.018 | 0.023 | 0.006 |

| Strain Gauge number | #1 | #2 | #3 | #4 | #5 | #6 | #7 | #8 | #9 |

|---|---|---|---|---|---|---|---|---|---|

| Theoretical value | 0.208 | 0.736 | 0.833 | 0.208 | 0.736 | 0.833 | 0.208 | 0.736 | 0.833 |

| Simulation value | 0.221 | 0.758 | 0.867 | 0.224 | 0.757 | 0.859 | 0.223 | 0.771 | 0.869 |

| Experimental value 1 | 0.234 | 0.762 | 0.872 | 0.227 | 0.765 | 0.865 | 0.227 | 0.768 | 0.875 |

| Experimental value 2 | 0.245 | 0.768 | 0.871 | 0.231 | 0.763 | 0.867 | 0.230 | 0.765 | 0.873 |

| Experimental value 3 | 0.247 | 0.767 | 0.869 | 0.225 | 0.768 | 0.864 | 0.228 | 0.763 | 0.876 |

| Experimental mean value | 0.242 | 0.766 | 0.871 | 0.228 | 0.765 | 0.865 | 0.228 | 0.765 | 0.875 |

| Difference between simulation and experiment | −0.021 | −0.008 | −0.004 | −0.004 | −0.008 | −0.006 | −0.005 | 0.006 | −0.006 |

| Difference between theory and experiment | −0.034 | −0.03 | −0.038 | −0.02 | −0.029 | −0.032 | −0.02 | −0.029 | −0.042 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, H.; Fu, J.; Li, Y.; Ni, C.; Tong, H.; Wang, P. Comparative Study on the Tensile and Compression Process of the Collapsible Ultra-Thin-Walled Composite Lens Rod. Materials 2025, 18, 3993. https://doi.org/10.3390/ma18173993

Luo H, Fu J, Li Y, Ni C, Tong H, Wang P. Comparative Study on the Tensile and Compression Process of the Collapsible Ultra-Thin-Walled Composite Lens Rod. Materials. 2025; 18(17):3993. https://doi.org/10.3390/ma18173993

Chicago/Turabian StyleLuo, Haitao, Jia Fu, Yuxin Li, Chengzhi Ni, Haowen Tong, and Peng Wang. 2025. "Comparative Study on the Tensile and Compression Process of the Collapsible Ultra-Thin-Walled Composite Lens Rod" Materials 18, no. 17: 3993. https://doi.org/10.3390/ma18173993

APA StyleLuo, H., Fu, J., Li, Y., Ni, C., Tong, H., & Wang, P. (2025). Comparative Study on the Tensile and Compression Process of the Collapsible Ultra-Thin-Walled Composite Lens Rod. Materials, 18(17), 3993. https://doi.org/10.3390/ma18173993