Dry Machining of Inconel 713LC: Surface Integrity and Force Response to Cutting Conditions

Abstract

1. Introduction

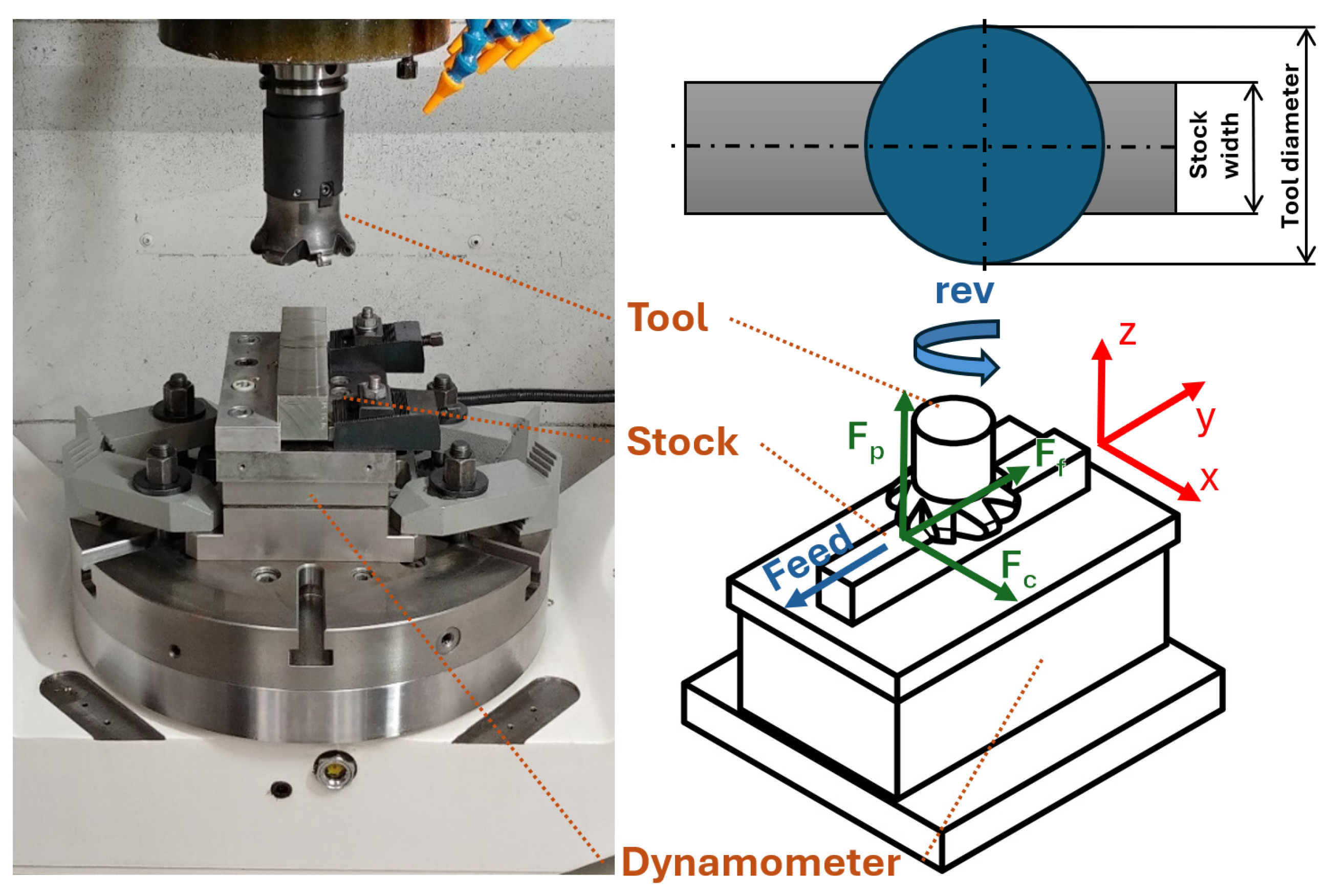

2. Materials and Methods

- Dynamometer: Kistler 9265B

- Amplifier: Kistler 5019

- A/D Converter: Kistler 5697

- Sampling rate: 5000 Hz

- Force limits: Fx, Fy = 2000 N, Fz = 2500 N

3. Results and Discussion

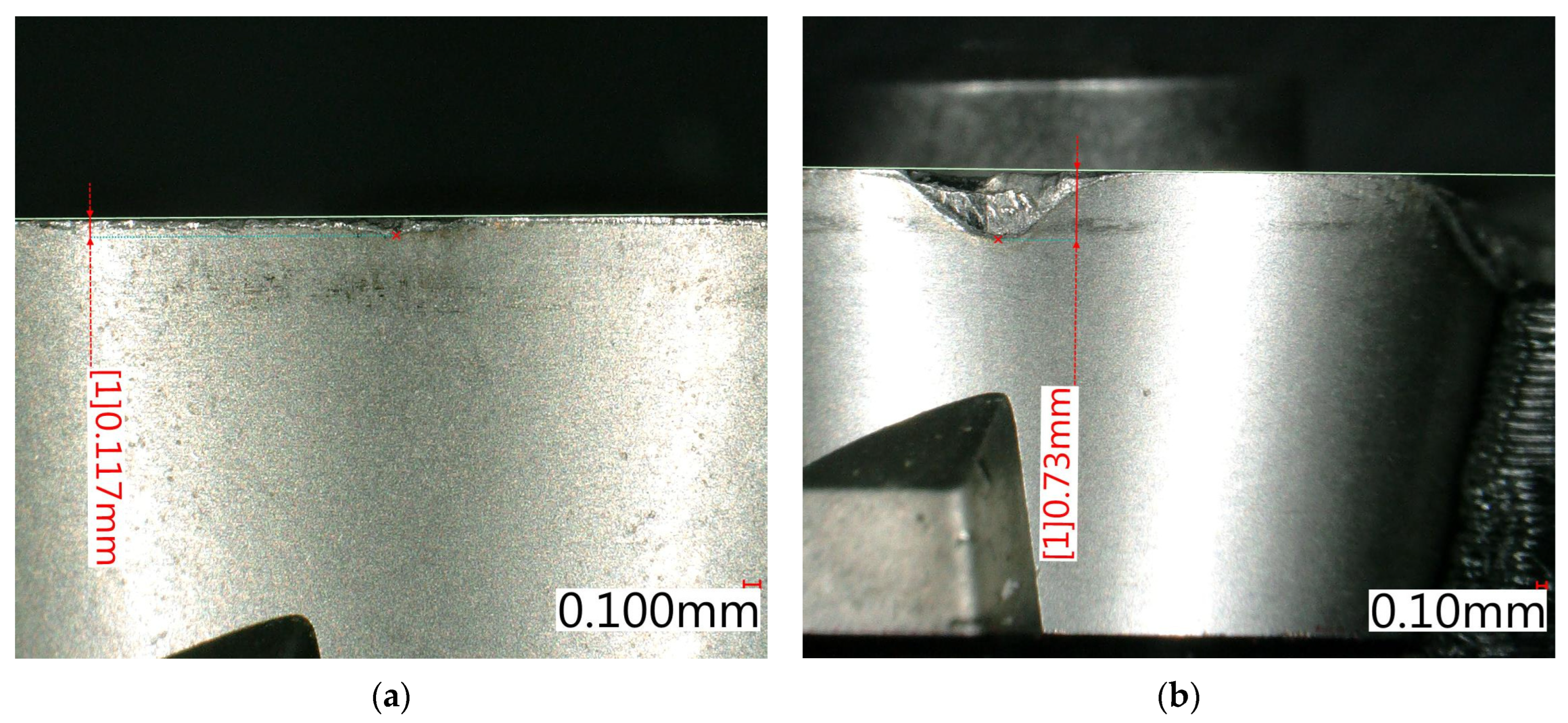

3.1. Tool Wear

3.2. Estimated Taylor Model of Tool Life

3.3. Forces

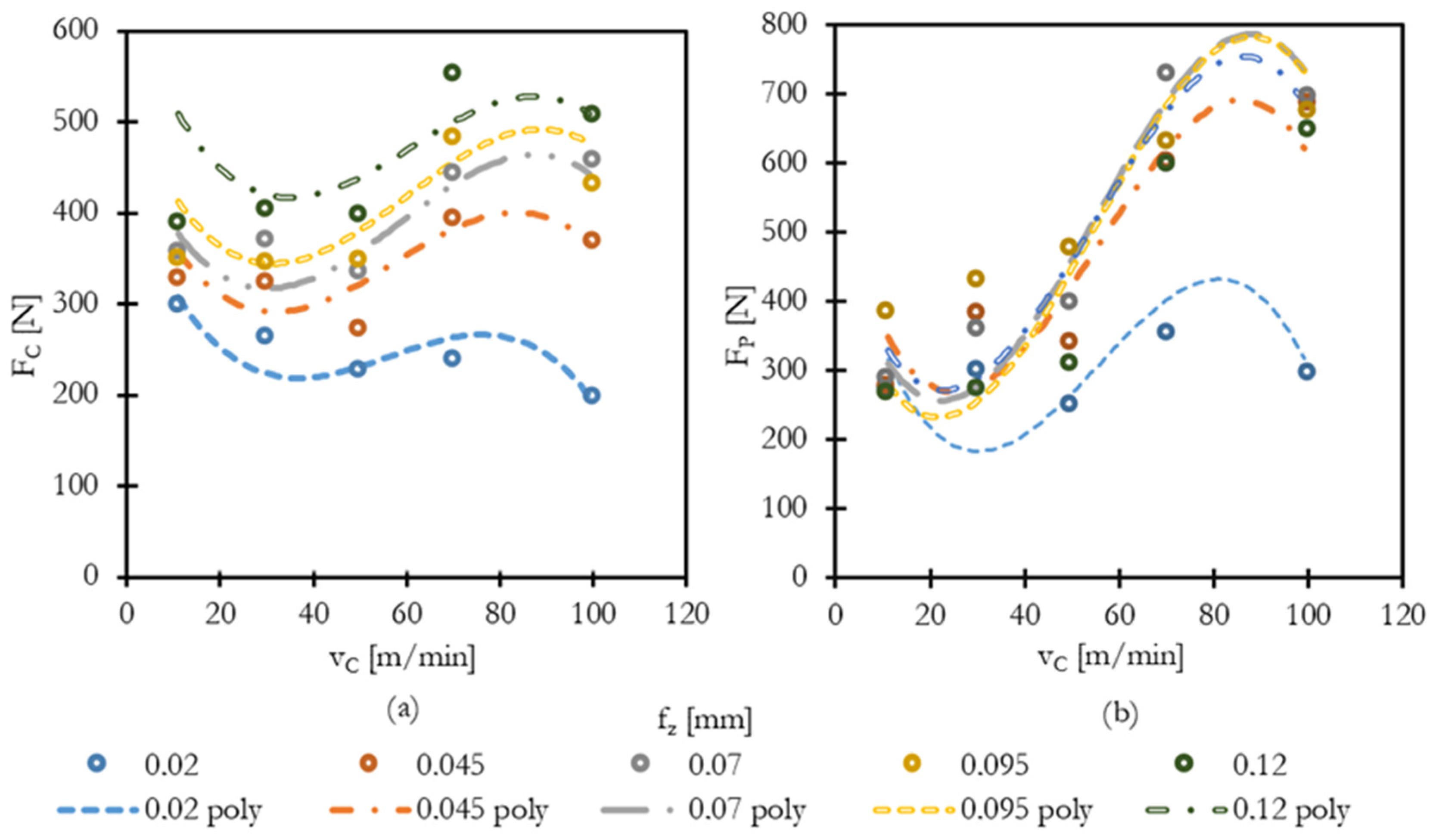

3.4. Surface Roughness

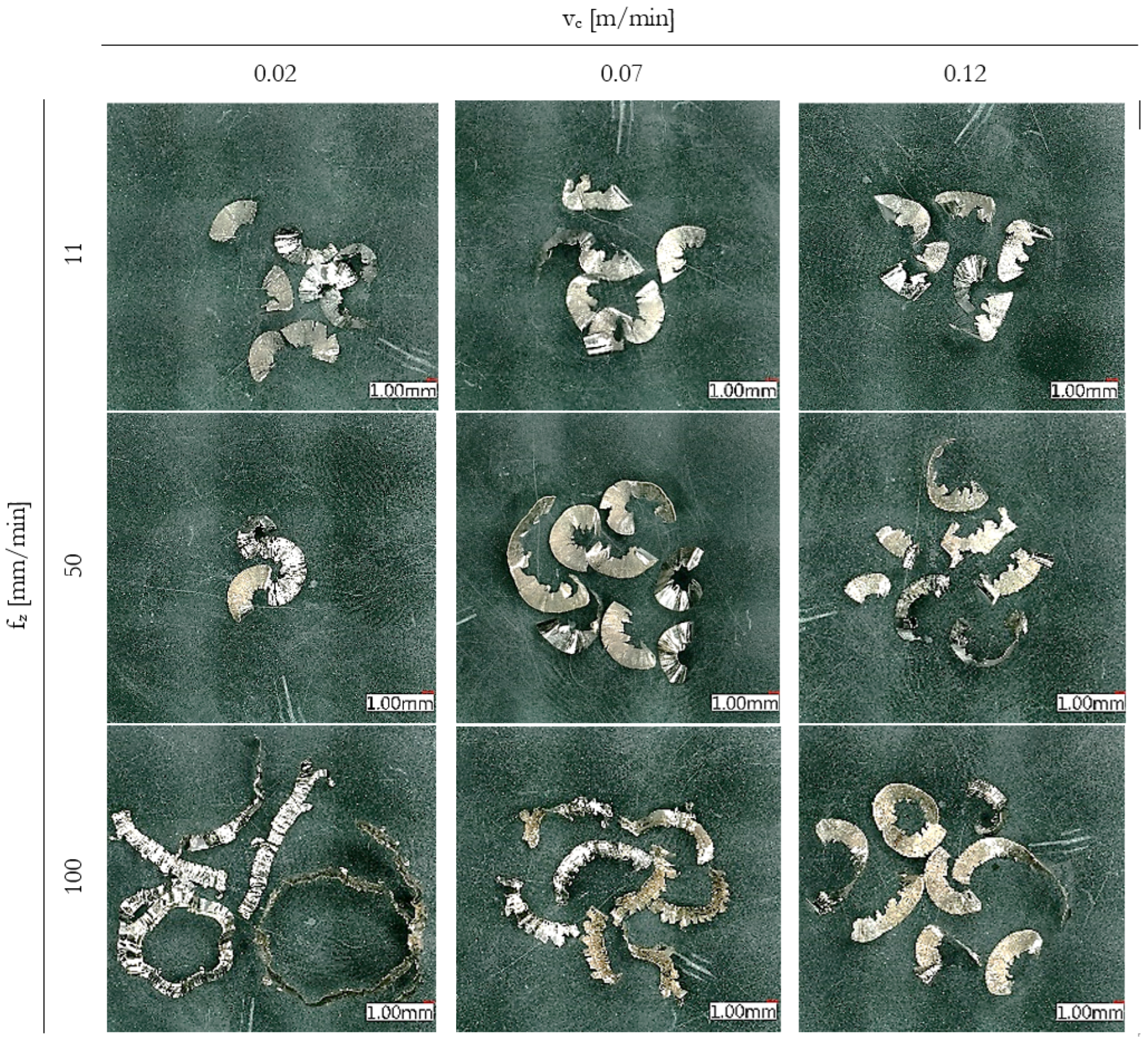

3.5. Chip Formation

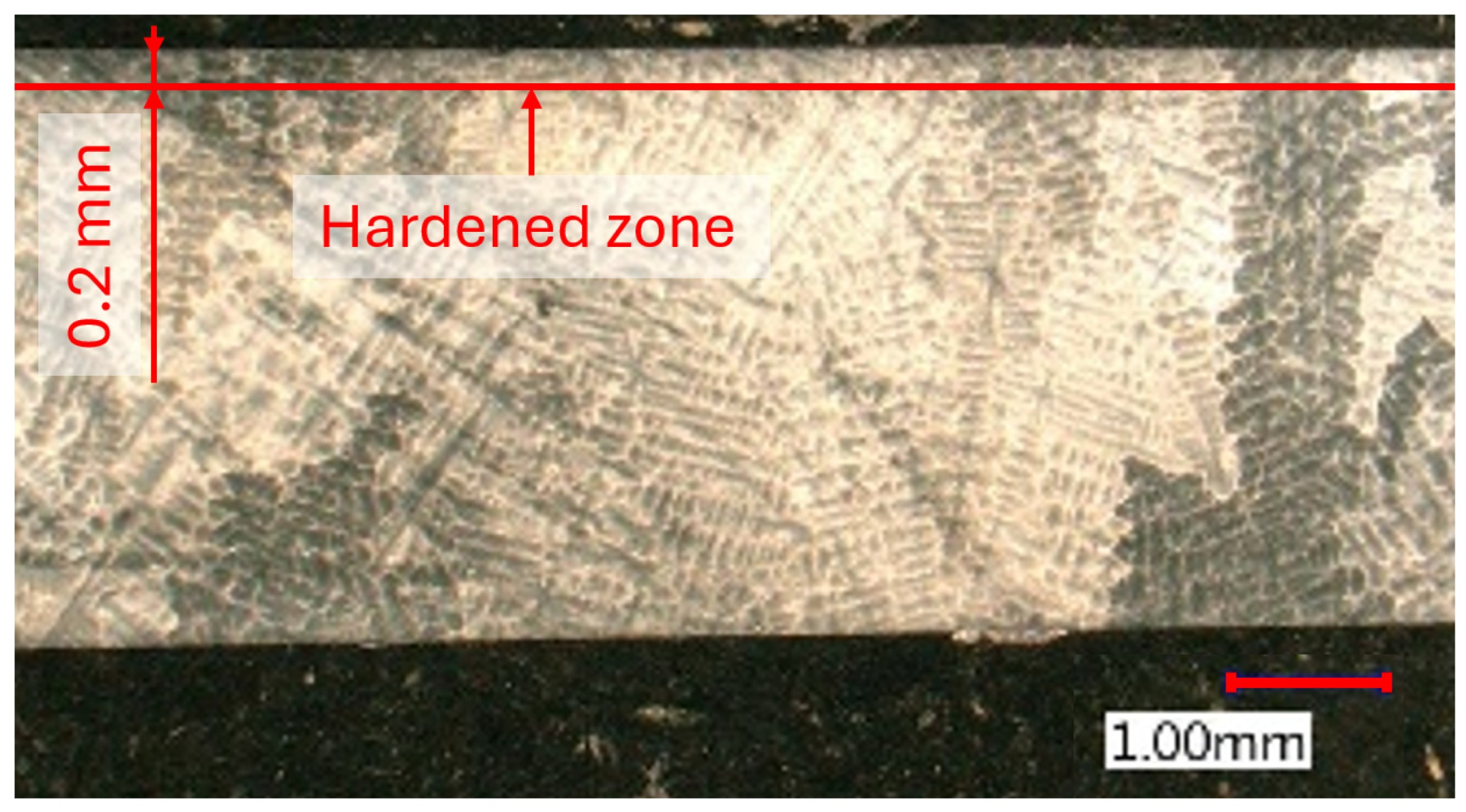

3.6. Surface Hardening

4. Conclusions

- Tool wear accelerates at high speeds (vc ≥ 70 m/min) and feed rates (fz ≥ 0.12 mm/tooth), often leading to catastrophic flank failure; lower parameters greatly extend tool life.

- Cutting forces increase significantly with feed rate; cutting speed has a nonlinear effect, remaining stable up to ~50 m/min, but increasing sharply above 70 m/min, particularly in the passive force component.

- Surface roughness (Ra ≈ 0.4–0.6 µm) deteriorates at 30–50 m/min due to unstable chip formation and likely BUE effects.

- Chip Compression Ratio (CCR) decreases from >9 to ~2 as speed increases, strongly correlating with surface hardening and tool wear rates.

- Surface microhardness is highest at low cutting speeds, indicating significant plastic deformation and work hardening, in line with CCR observations.

- Empirical models (Taylor tool life and polynomial force models) fit well (R2 ≈ 0.8–0.9), offering predictive insight for process optimization within the tested parameters.

- For best results, maintain cutting speeds between 30 and 50 m/min and feed per tooth between 0.045 and 0.07 mm to ensure balanced performance.

- Avoid fz > 0.095 mm/tooth under dry conditions, unless the productivity demand justifies increased tool consumption.

- Tests were conducted exclusively under dry conditions; results may differ with MQL or flood cooling.

- Only uncoated tools were tested; alternative tool materials or coatings may exhibit different wear and thermal behaviors.

- In situ thermal monitoring was not included, limiting direct insight into heat-related degradation mechanisms.

- Machining lengths were limited (~20 mm), so long-term wear progression and surface evolution remain to be explored.

- Residual stress and fatigue performance were not evaluated, though observed surface hardening implies potential mechanical implications.

- The regression models are valid only within the tested range; extrapolation beyond it may introduce artifacts and requires further validation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| MQL | Minimum quantity lubrication |

| CCR | Chip compression ratio |

| BUE | Built-up edge |

References

- Reed, R.C. The Superalloys: Fundamentals and Applications; Cambridge University Press: Cambridge, UK, 2008; ISBN 978-1-139-45863-4. [Google Scholar]

- Davis, J.R. Nickel, Cobalt, and Their Alloys; ASM International, Ed.; ASM Specialty Handbook; ASM International: Novelty, OH, USA, 2000; ISBN 978-0-87170-685-0. [Google Scholar]

- Ezugwu, E.O. Key Improvements in the Machining of Difficult-to-Cut Aerospace Superalloys. Int. J. Mach. Tools Manuf. 2005, 45, 1353–1367. [Google Scholar] [CrossRef]

- Kurniawan, R.; Park, G.C.; Park, K.M.; Zhen, Y.; Kwak, Y.I.; Kim, M.C.; Lee, J.M.; Ko, T.J.; Park, C.-S. Machinability of Modified Inconel 713C Using a WC TiAlN-Coated Tool. J. Manuf. Process. 2020, 57, 409–430. [Google Scholar] [CrossRef]

- Klocke, F.; Veselovac, D.; Gierlings, S.; Tamayo, L. Development of Process Monitoring Strategies in Broaching of Nickel-Based Alloys. Mech. Ind. 2012, 13, 3–9. [Google Scholar] [CrossRef]

- Liao, Y.S.; Lin, H.M.; Wang, J.H. Behaviors of End Milling Inconel 718 Superalloy by Cemented Carbide Tools. J. Mater. Process. Technol. 2008, 201, 460–465. [Google Scholar] [CrossRef]

- Maiyar, L.M.; Ramanujam, R.; Venkatesan, K.; Jerald, J. Optimization of Machining Parameters for End Milling of Inconel 718 Super Alloy Using Taguchi Based Grey Relational Analysis. Procedia Eng. 2013, 64, 1276–1282. [Google Scholar] [CrossRef]

- De Bartolomeis, A. State-of-The-Art Cooling and Lubrication for Machining Inconel 718. J. Manuf. Sci. Eng. 2020, 143, 1–73. [Google Scholar] [CrossRef]

- Outeiro, J.C.; Pina, J.C.; M’Saoubi, R.; Pusavec, F.; Jawahir, I.S. Analysis of Residual Stresses Induced by Dry Turning of Difficult-to-Machine Materials. CIRP Ann. 2008, 57, 77–80. [Google Scholar] [CrossRef]

- Attia, H.; Tavakoli, S.; Vargas, R.; Thomson, V. Laser-Assisted High-Speed Finish Turning of Superalloy Inconel 718 under Dry Conditions. CIRP Ann. 2010, 59, 83–88. [Google Scholar] [CrossRef]

- Jovicic, G.; Milosevic, A.; Kanovic, Z.; Sokac, M.; Simunovic, G.; Savkovic, B.; Vukelic, D. Optimization of Dry Turning of Inconel 601 Alloy Based on Surface Roughness, Tool Wear, and Material Removal Rate. Metals 2023, 13, 1068. [Google Scholar] [CrossRef]

- Umbrello, D. Investigation of Surface Integrity in Dry Machining of Inconel 718. Int. J. Adv. Manuf. Technol. 2013, 69, 2183–2190. [Google Scholar] [CrossRef]

- Zhou, B.; Zhang, W.; Gao, Z.; Luo, G. Machining-Induced Work Hardening Behavior of Inconel 718 Considering Edge Geometries. Materials 2022, 15, 397. [Google Scholar] [CrossRef]

- Goulmy, J.P.; Toualbi, L.; Boyer, V.; Kanoute, P.; Retraint, D.; Rouhaud, E. A Model for the Influence of Work Hardening and Microstructure on the Evolution of Residual Stresses under Thermal Loading—Application to Inconel 718. Eur. J. Mech. A/Solids 2024, 107, 105361. [Google Scholar] [CrossRef]

- Ramanujam, R.; Venkatesan, K.; Saxena, V.; Joseph, P. Modeling and Optimization of Cutting Parameters in Dry Turning of Inconel 718 Using Coated Carbide Inserts. Procedia Mater. Sci. 2014, 5, 2550–2559. [Google Scholar] [CrossRef]

- Shokrani, A.; Dhokia, V.; Newman, S.T. Hybrid Cooling and Lubricating Technology for CNC Milling of Inconel 718 Nickel Alloy. Procedia Manuf. 2017, 11, 625–632. [Google Scholar] [CrossRef]

- Velmurgan, K.V.; Venkatesan, K. An Investigation of the Parametric Effects of Cutting Parameters on Quality Characteristics during the Dry Turning of Inconel 718 Alloy. Indian J. Sci. Technol. 2016, 9, 1–7. [Google Scholar] [CrossRef]

- Liu, Z.R.; Chen, L.; Du, Y.; Zhang, S. Influence of Ru-Addition on Thermal Decomposition and Oxidation Resistance of TiAlN Coatings. Surf. Coat. Technol. 2020, 401, 126234. [Google Scholar] [CrossRef]

- Yang, K.; Xian, G.; Zhao, H.; Fan, H.; Wang, J.; Wang, H.; Du, H. Effect of Mo Content on the Structure and Mechanical Properties of TiAlMoN Films Deposited on WC–Co Cemented Carbide Substrate by Magnetron Sputtering. Int. J. Refract. Met. Hard Mater. 2015, 52, 29–35. [Google Scholar] [CrossRef]

- Aninat, R.; Valle, N.; Chemin, J.-B.; Duday, D.; Michotte, C.; Penoy, M.; Bourgeois, L.; Choquet, P. Addition of Ta and Y in a Hard Ti-Al-N PVD Coating: Individual and Conjugated Effect on the Oxidation and Wear Properties. Corros. Sci. 2019, 156, 171–180. [Google Scholar] [CrossRef]

- Silva, F.J.G.; Sebbe, N.P.V.; Costa, R.D.F.S.; Pedroso, A.F.V.; Sales-Contini, R.C.M.; Barbosa, M.L.S.; Martinho, R.P. Investigations on the Surface Integrity and Wear Mechanisms of TiAlYN-Coated Tools in Inconel 718 Milling Operations. Materials 2024, 17, 443. [Google Scholar] [CrossRef]

- Moser, M.; Kiener, D.; Scheu, C.; Mayrhofer, P.H. Influence of Yttrium on the Thermal Stability of Ti-Al-N Thin Films. Materials 2010, 3, 1573–1592. [Google Scholar] [CrossRef]

- Tomaszewski, Ł.; Gulbiński, W.; Urbanowicz, A.; Suszko, T.; Lewandowski, A.; Gulbiński, W. TiAlN Based Wear Resistant Coatings Modified by Molybdenum Addition. Vacuum 2015, 121, 223–229. [Google Scholar] [CrossRef]

- Yi, J.; Chen, S.; Chen, K.; Xu, Y.; Chen, Q.; Zhu, C.; Liu, L. Effects of Ni Content on Microstructure, Mechanical Properties and Inconel 718 Cutting Performance of AlTiN-Ni Nanocomposite Coatings. Ceram. Int. 2019, 45, 474–480. [Google Scholar] [CrossRef]

- Azhar, M.; Haron, C.; Ghani, J.; Abdul Halim, N.H. Surface Integrity of Inconel 718 under Cryogenic and Dry Cutting Conditions. J. Kejuruter. 2024, 36, 1135–1145. [Google Scholar] [CrossRef]

- Qiu, W.; Pan, D.; Li, J.; Guo, P.; Qiao, Y.; Wang, X. Chip Formation Mechanism in Cryogenic Machining of High Temperature Alloy-Inconel 718 and Ti-47.5Al-2.5V-1.0Cr. J. Manuf. Process. 2023, 97, 35–47. [Google Scholar] [CrossRef]

- Musfirah, A.H.; Ghani, J.; Haron, C. Tool Wear and Surface Integrity of Inconel 718 in Dry and Cryogenic Coolant at High Cutting Speed. Wear 2017, 376–377, 125–133. [Google Scholar] [CrossRef]

- Virdi, R.L.; Chatha, S.; Sidhu, H. Performance Evaluation of Inconel 718 under Vegetable Oils Based Nanofluids Using Minimum Quantity Lubrication Grinding. Mater. Today Proc. 2020, 33, 1538–1545. [Google Scholar] [CrossRef]

- Thakur, A.; Gangopadhyay, S. Dry Machining of Nickel-Based Super Alloy as a Sustainable Alternative Using TiN/TiAlN Coated Tool. J. Clean. Prod. 2016, 129, 256–268. [Google Scholar] [CrossRef]

- Sousa, V.F.C.; Silva, F.J.G.; Lopes, H.; Casais, R.C.B.; Baptista, A.; Pinto, G.; Alexandre, R. Wear Behavior and Machining Performance of TiAlSiN-Coated Tools Obtained by Dc MS and HiPIMS: A Comparative Study. Materials 2021, 14, 5122. [Google Scholar] [CrossRef]

- Mitsuo, A.; Uchida, S.; Nihira, N.; Iwaki, M. Improvement of High-Temperature Oxidation Resistance of Titanium Nitride and Titanium Carbide Films by Aluminum Ion Implantation. Surf. Coat. Technol. 1998, 103–104, 98–103. [Google Scholar] [CrossRef]

- Liew, W.Y.H.; Lim, H.P.; Melvin, G.J.H.; Dayou, J.; Jiang, Z.-T. Thermal Stability, Mechanical Properties, and Tribological Performance of TiAlXN Coatings: Understanding the Effects of Alloying Additions. J. Mater. Res. Technol. 2022, 17, 961–1012. [Google Scholar] [CrossRef]

- Choi, W.S.; Hwang, S.K.; Lee, C.M. Microstructure and Chemical State of Ti1−xYxN Film Deposited by Reactive Magnetron Sputtering. J. Vac. Sci. Technol. A 2000, 18, 2914–2921. [Google Scholar] [CrossRef]

- Čapek, J.; Kyncl, J.; Kolařík, K.; Beránek, L.; Pitrmuc, Z.; Medřický, J.; Pala, Z. Grinding of Inconel 713 Superalloy for Gas Turbines. Manuf. Technol. 2016, 16, 38–45. [Google Scholar] [CrossRef]

- Alauddin, M.; El Baradie, M.A.; Hashmi, M.S.J. End-Milling Machinability of Inconel 718. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 1996, 210, 11–23. [Google Scholar] [CrossRef]

- Sebbe, N.P.V.; Fernandes, F.; Sousa, V.F.C.; Silva, F.J.G. Hybrid Manufacturing Processes Used in the Production of Complex Parts: A Comprehensive Review. Metals 2022, 12, 1874. [Google Scholar] [CrossRef]

- Nogueira, F.; Pedroso, A.; Sousa, V.; Sebbe, N.; Sales-Contini, R.D.C.; Barbosa, M. A Brief Review of Injection-Mould Materials Hybrid Manufacturing Processes. In Flexible Automation and Intelligent Manufacturing: Establishing Bridges for More Sustainable Manufacturing Systems; Springer: Berlin/Heidelberg, Germany, 2023; pp. 796–806. ISBN 978-3-031-38240-6. [Google Scholar]

- ISO 3685:1993; Tool-Life Testing with Single-Point Turning Tools. International Organization for Standardization: Geneva, Switzerland, 1993.

- ISO 6507-1:2023; Metallic Materials—Vickers Hardness Test. International Organization for Standardization: Geneva, Switzerland, 2023.

- Mrkvica, I.; Špalek, F.; Szotkowski, T. Influence of Cutting Tool Wear When Milling Inconel 718 on Resulting Roughness. Manuf. Technol. 2018, 18, 457–461. [Google Scholar] [CrossRef]

- Pérez-Salinas, C.; de Lacalle, L.N.L.; del Olmo, A.; Kumar, C.S. The Relationship between the Cutting-Edge, Tool Wear, and Chip Formation during Inconel 718 Dry Cutting. Int. J. Adv. Manuf. Technol. 2024, 132, 6001–6017. [Google Scholar] [CrossRef]

- Rowe, R.A.; Allison, P.G.; Palazotto, A.N.; Davami, K. Adiabatic Shear Banding in Nickel and Nickel-Based Superalloys: A Review. Metals 2022, 12, 1879. [Google Scholar] [CrossRef]

- Karantza, K.D.; Manolakos, D.E. A Review on the Adiabatic Shear Banding Mechanism in Metals and Alloys Considering Microstructural Characteristics, Morphology and Fracture. Metals 2023, 13, 1988. [Google Scholar] [CrossRef]

- Thakur, D.G.; Ramamoorthy, B.; Vijayaraghavan, L. Machinability Investigation of Inconel 718 in High-Speed Turning. Int. J. Adv. Manuf. Technol. 2009, 45, 421–429. [Google Scholar] [CrossRef]

| Element | Ni | Al | Ti | Cr | Zr | Fe | Nb | Mo |

|---|---|---|---|---|---|---|---|---|

| wt. % | 73.87 ± 0.22 | 5.65 ± 0.22 | 0.75 ± 0.04 | 12.63 ± 0.08 | 0.091 ± 0.004 | 0.18 ± 0.01 | 2.16 ± 0.02 | 4.29 ± 0.02 |

| Flank Wear [mm] | Cutting Speed vc [m/min] | |||||

|---|---|---|---|---|---|---|

| 11 | 30 | 50 | 70 | 100 | ||

| Feed per tooth fz [mm] | 0.02 | 0.04 | 0.08 | 0.12 | 0.19 | 0.46 |

| 0.045 | 0.05 | 0.07 | 0.14 | 0.22 | 0.59 | |

| 0.07 | 0.05 | 0.10 | 0.16 | 0.38 | 0.65 | |

| 0.095 | 0.06 | 0.11 | 0.18 | 0.42 | 0.83 | |

| 0.12 | 0.08 | 0.17 | 0.36 | 0.73 | 1.56 | |

| Tool Life Estimation [min] | Cutting Speed vc [m/min] | |||||

|---|---|---|---|---|---|---|

| 11 | 30 | 50 | 70 | 100 | ||

| Feed per tooth fz [mm] | 0.02 | 247.3 | 45.3 | 18.1 | 8.2 | 2.4 |

| 0.045 | 87.9 | 23.0 | 6.9 | 3.1 | 0.8 | |

| 0.07 | 56.5 | 10.4 | 3.9 | 1.2 | 0.5 | |

| 0.095 | 34.7 | 6.9 | 2.5 | 0.8 | 0.3 | |

| 0.12 | 20.6 | 3.6 | 1.0 | 0.4 | 0.1 | |

| Fc [N] | Cutting Speed vc [m/min] | |||||

|---|---|---|---|---|---|---|

| 11 | 30 | 50 | 70 | 100 | ||

| Feed per tooth fz [mm/tooth] | 0.02 | 298 | 262 | 227 | 237 | 197 |

| 0.045 | 328 | 322 | 272 | 393 | 368 | |

| 0.07 | 357 | 370 | 335 | 443 | 458 | |

| 0.095 | 430 | 345 | 348 | 483 | 430 | |

| 0.12 | 520 | 403 | 397 | 552 | 507 | |

| Fp [N] | Cutting Speed vc [m/min] | |||||

|---|---|---|---|---|---|---|

| 11 | 30 | 50 | 70 | 100 | ||

| Feed per tooth fz [mm/tooth] | 0.02 | 273 | 300 | 250 | 353 | 298 |

| 0.045 | 277 | 382 | 340 | 600 | 687 | |

| 0.07 | 288 | 360 | 338 | 778 | 695 | |

| 0.095 | 303 | 327 | 337 | 755 | 675 | |

| 0.12 | 347 | 273 | 308 | 857 | 648 | |

| vc [m/min] | 11 | 30 | 50 | 70 | 100 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| fz [mm] | h0 [mm] | hc [mm] | CCR [-] | hc [mm] | CCR [-] | hc [mm] | CCR [-] | hc [mm] | CCR [-] | hc [mm] | CCR [-] |

| 0.02 | 0.008 | 0.073 | 9.2 | 0.070 | 8.7 | 0.055 | 6.8 | 0.062 | 7.8 | 0.036 | 4.5 |

| 0.045 | 0.018 | 0.092 | 5.1 | 0.067 | 3.7 | 0.053 | 2.9 | 0.061 | 3.4 | 0.070 | 3.9 |

| 0.07 | 0.028 | 0.098 | 3.5 | 0.096 | 3.4 | 0.088 | 3.1 | 0.089 | 3.2 | 0.093 | 3.3 |

| 0.095 | 0.037 | 0.127 | 3.4 | 0.124 | 3.3 | 0.124 | 3.3 | 0.132 | 3.6 | 0.107 | 2.9 |

| 0.12 | 0.047 | 0.130 | 2.8 | 0.141 | 3.0 | 0.141 | 3.0 | 0.148 | 3.1 | 0.101 | 2.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Slaný, M.; Mádl, J.; Pitrmuc, Z.; Sommer, J.; Stránský, O.; Beránek, L. Dry Machining of Inconel 713LC: Surface Integrity and Force Response to Cutting Conditions. Materials 2025, 18, 3992. https://doi.org/10.3390/ma18173992

Slaný M, Mádl J, Pitrmuc Z, Sommer J, Stránský O, Beránek L. Dry Machining of Inconel 713LC: Surface Integrity and Force Response to Cutting Conditions. Materials. 2025; 18(17):3992. https://doi.org/10.3390/ma18173992

Chicago/Turabian StyleSlaný, Michal, Jan Mádl, Zdeněk Pitrmuc, Jiří Sommer, Ondřej Stránský, and Libor Beránek. 2025. "Dry Machining of Inconel 713LC: Surface Integrity and Force Response to Cutting Conditions" Materials 18, no. 17: 3992. https://doi.org/10.3390/ma18173992

APA StyleSlaný, M., Mádl, J., Pitrmuc, Z., Sommer, J., Stránský, O., & Beránek, L. (2025). Dry Machining of Inconel 713LC: Surface Integrity and Force Response to Cutting Conditions. Materials, 18(17), 3992. https://doi.org/10.3390/ma18173992