Advances in Wire EDM Technology for Cutting Silicon Carbide Ceramics: A Review

Abstract

1. Introduction

1.1. Machining Characteristics of Silicon Carbide Ceramics

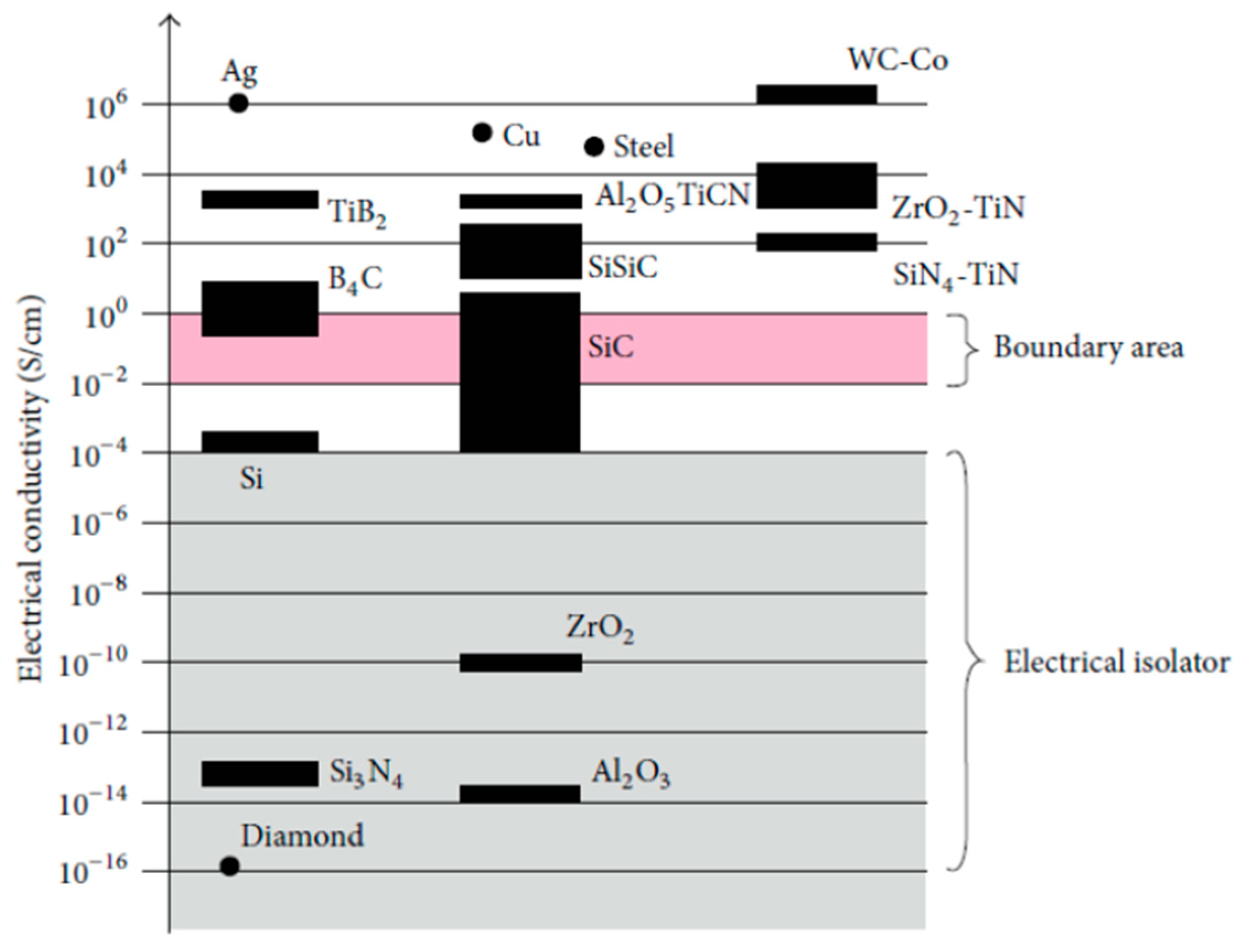

1.2. SiC Ceramic Types: Implications for WEDM Performance

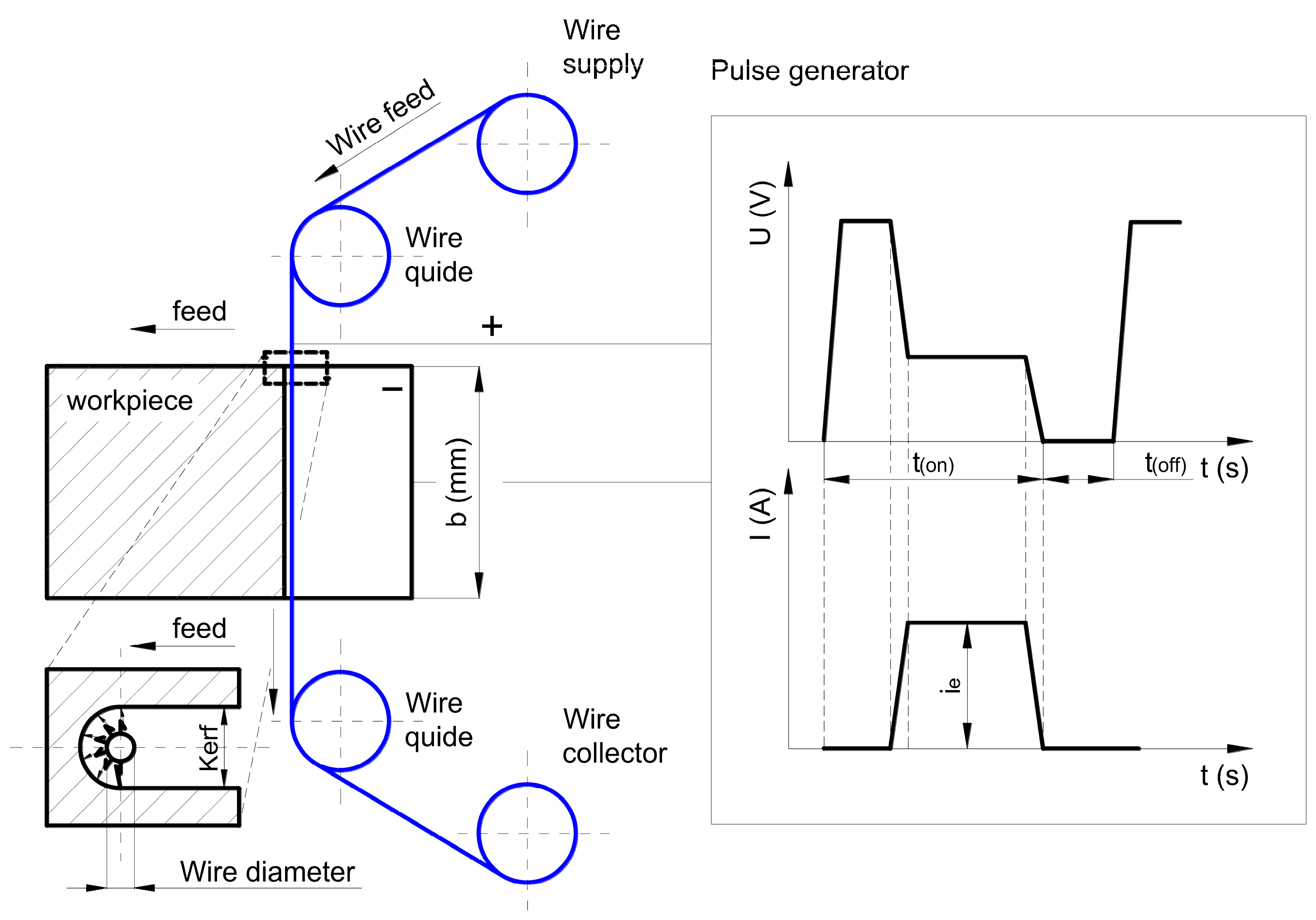

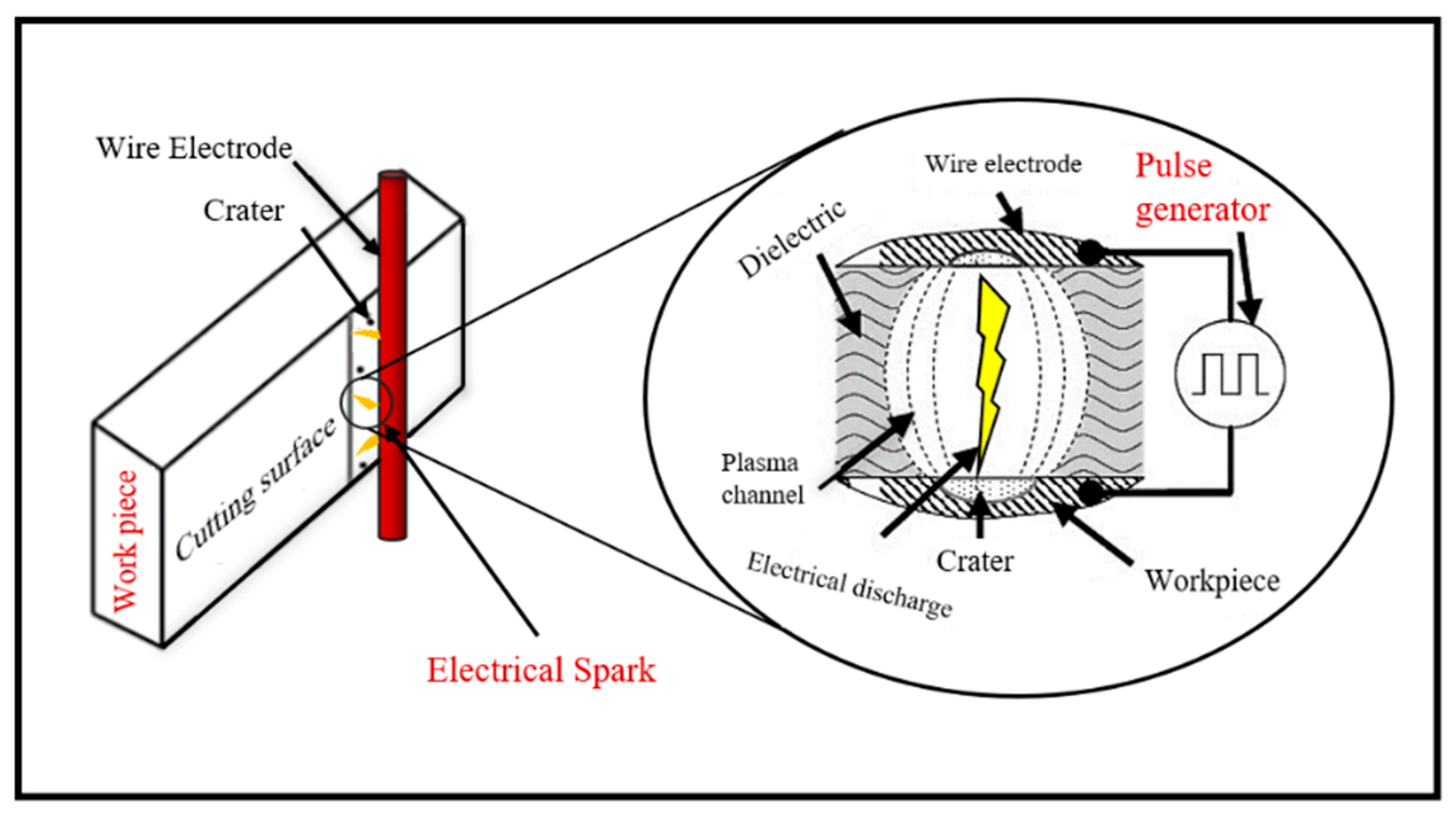

1.3. Fundamentals of Wire Electrical Discharge Machining

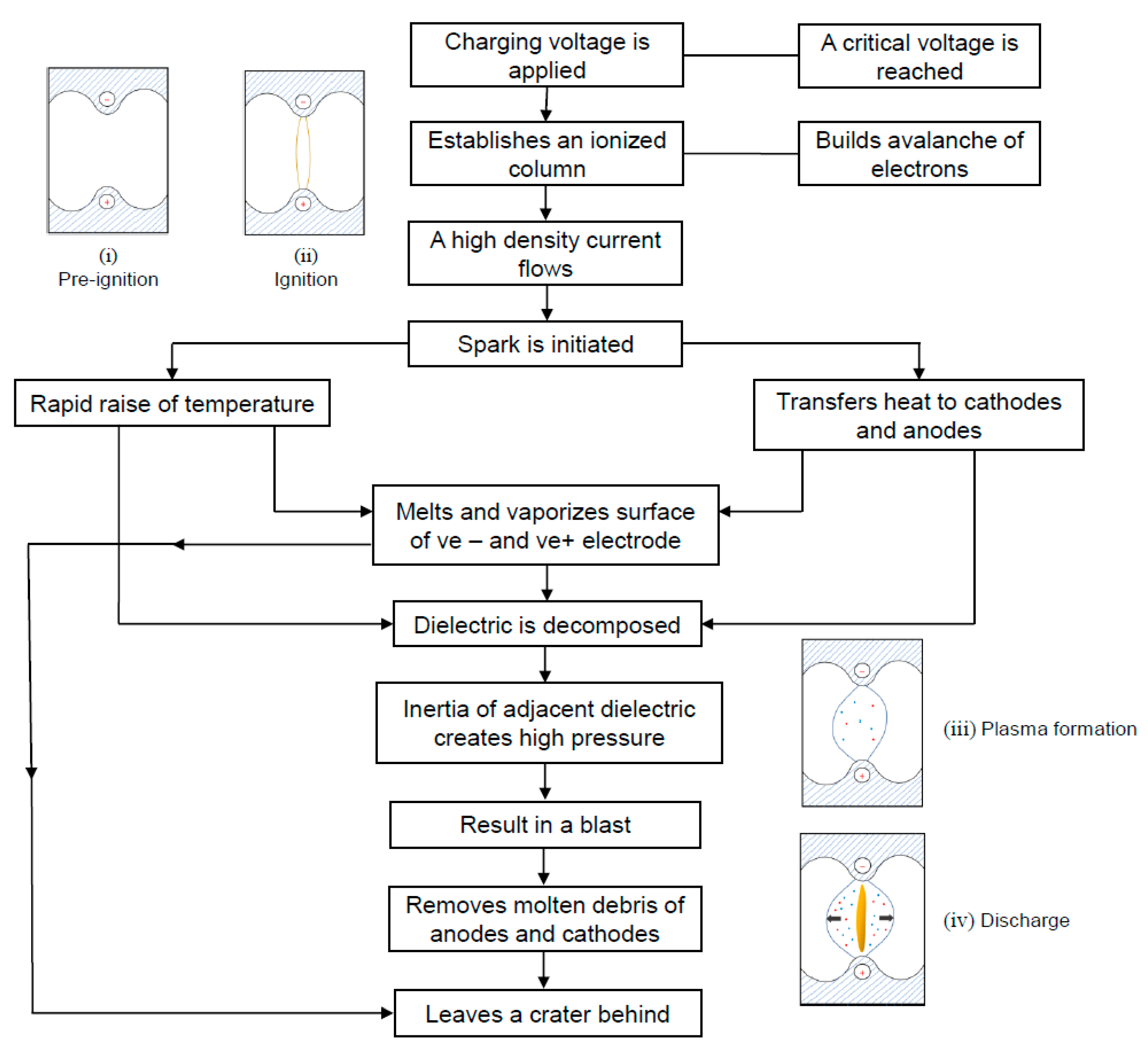

2. Material Removal Mechanisms in WEDM

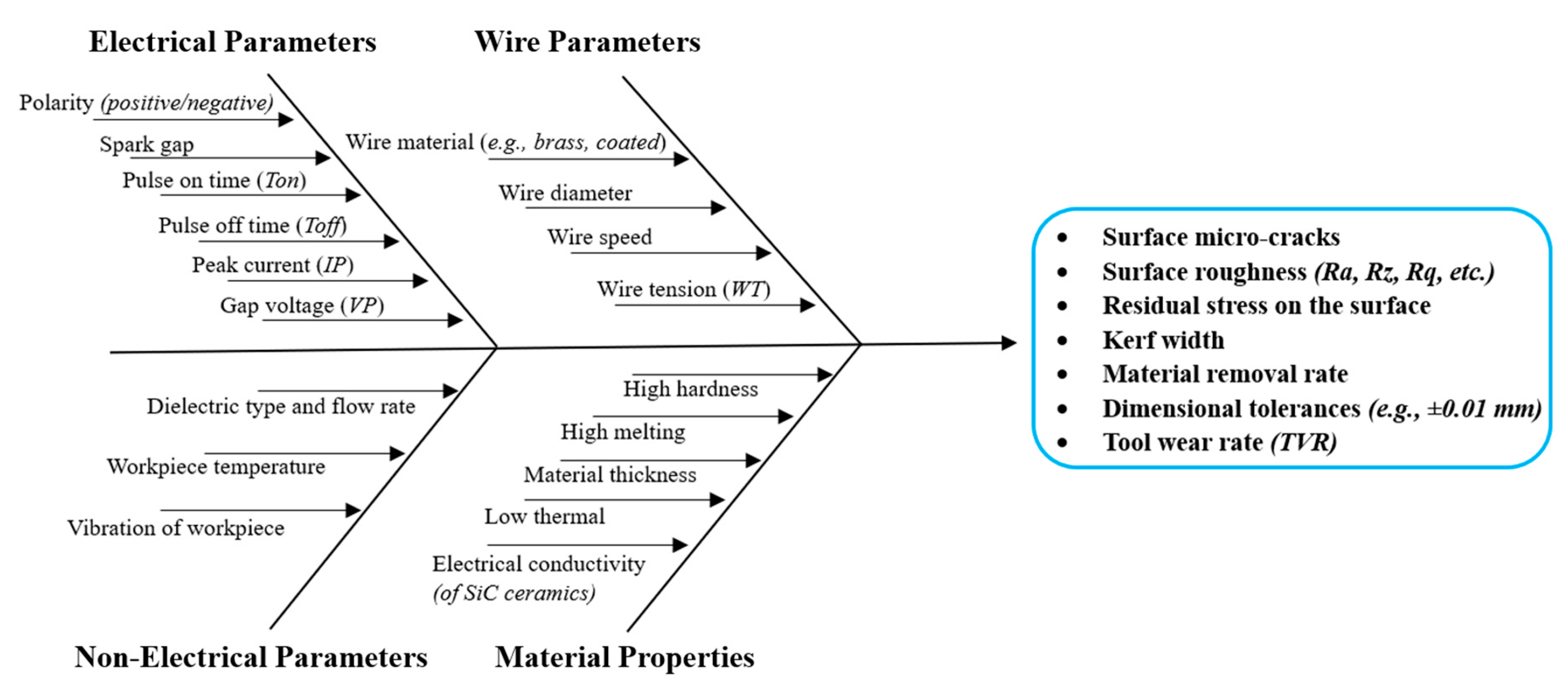

3. Process Parameters Influencing WEDM for SiC

4. Electrode Selection in WEDM Technology

5. Advances in WEDM Technology for SiC

5.1. Cryogenic Wire EDM: Enhancing Efficiency and Practicality

5.2. Eco-Friendly Approaches and Challenges in WEDM

6. Conclusions

- Using assisting electrodes can enhance the electrical conductivity of SiC during the WEDM process by introducing a conductive layer or material that is in contact with the SiC workpiece.

- Adjusting the pulse duration, discharge energy, and frequency can improve the efficiency of WEDM for SiC, with shorter pulse durations and lower discharge energies reducing thermal damage and improving surface quality.

- Utilizing advanced wire materials, such as coated or composite wires, can reduce wire wear and breakage, while specialized dielectric fluids with enhanced cooling and flushing capabilities can help dissipate heat more effectively and remove debris from the cutting zone.

- Implementing multi-wire EDM techniques can increase cutting efficiency and reduce kerf loss, as multiple wires are used simultaneously to slice through the SiC material.

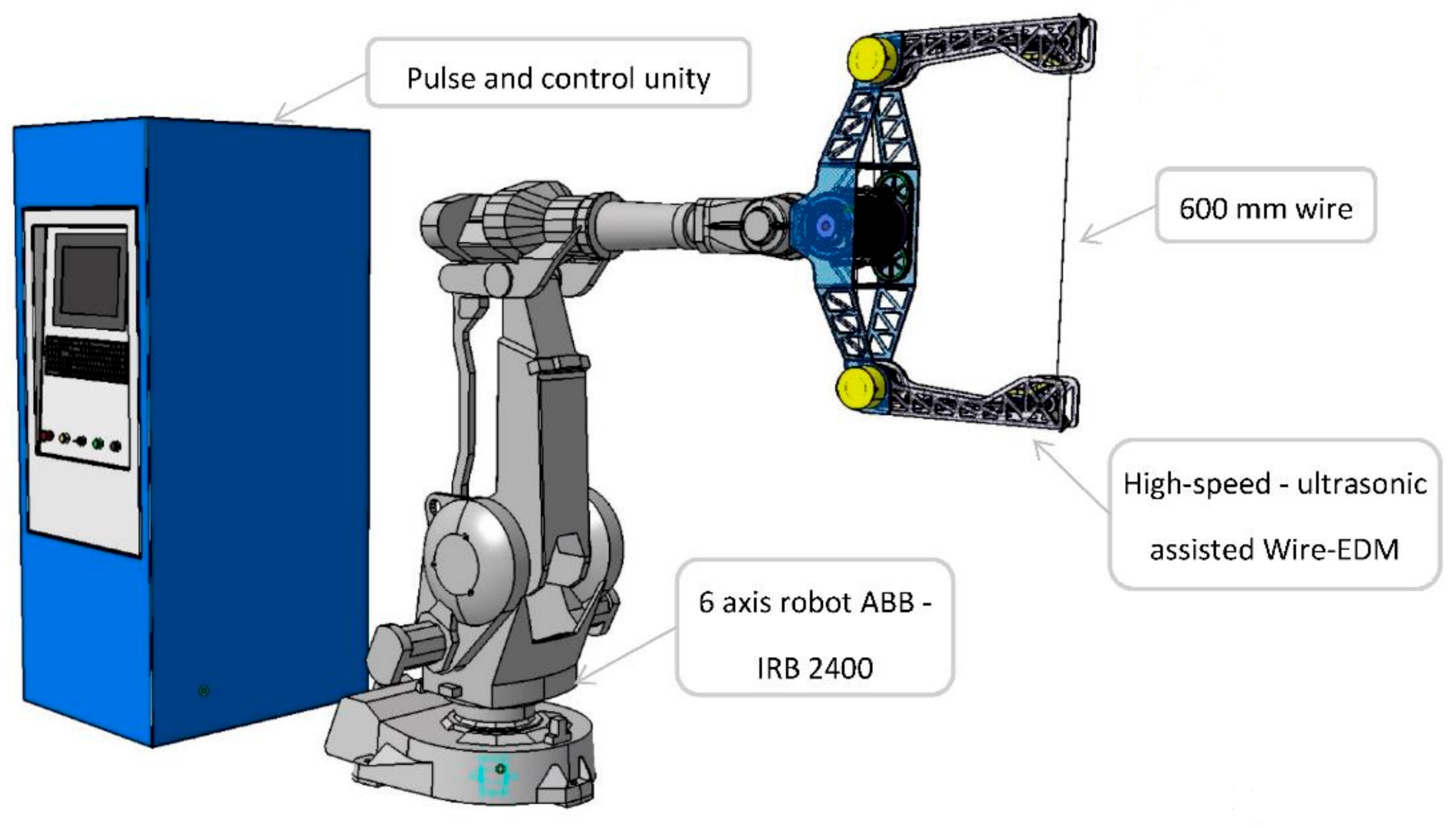

- Combining WEDM with other machining processes, such as laser or ultrasonic machining, can enhance overall cutting performance. For instance, laser-assisted WEDM can be used to pre-treat the SiC surface, creating controlled microcracks that facilitate increased material erosion via subsequent electrical discharges. Similarly, ultrasonic-assisted WEDM, where high-frequency vibrations are applied to the wire or workpiece, can improve debris evacuation and dielectric circulation in the cutting zone, leading to a more stable process and improved surface finish. These hybrid approaches synergistically combine the strengths of different processes to overcome the inherent challenges of machining SiC. Finally, advanced temperature-control systems can help manage the heat generated during the WEDM process, ensuring consistent and high-quality cuts.

- To bridge the gap between academic research and industrial application, collaborative efforts are needed to establish standardized WEDM process parameters and testing protocols for different variants of SiC ceramics. This would enhance process reliability and consistency, a crucial step for wider adoption.

- Recent advancements in manufacturing are increasingly leveraging Artificial Intelligence (AI) and Machine Learning (ML) to optimize complex processes, and WEDM is no exception. For SiC machining, where the process window for achieving high quality and efficiency is narrow, AI offers significant potential. As noted in the literature, models such as Artificial Neural Networks (ANNs) and Machine Learning algorithms are already being used to predict outcomes for other materials. Applying these techniques to SiC could involve developing models to predict surface roughness, material removal rate, and the likelihood of microcrack formation based on real-time sensor data (e.g., discharge voltage, acoustic emissions). Such intelligent systems could enable real-time parameter adjustments to maintain process stability, prevent wire breakage, and ensure consistent part quality, moving beyond static optimization tables toward adaptive, intelligent manufacturing.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lee, S.; Lee, Y.; Kim, Y.; Xie, R.; Mitomo, M.; Zhan, G. Mechanical properties of hot-forged silicon carbide ceramics. Scr. Mater. 2004, 52, 153–156. [Google Scholar] [CrossRef]

- Salvado, O.A.; Cheng, C.; Buttay, C.; Morel, H.; Labrousse, D.; Lefebvre, S.; Ali, M. SiC MOSFETs robustness for diode-less applications. EPE J. 2018, 28, 128–135. [Google Scholar] [CrossRef]

- Liu, L.; Wang, L.; Jin, P.; Liu, J.; Zhang, X.; Chen, L.; Zhang, J.; Ouyang, X.; Liu, A.; Huang, R.; et al. The Fabrication and Characterization of Ni/4H-SiC Schottky Diode Radiation Detectors with a Sensitive Area of up to 4 cm2. Sensors 2017, 17, 2334. [Google Scholar] [CrossRef] [PubMed]

- Bao, J.; Wang, Y.; Cheng, X.; Wang, F.; Cheng, H. Ballistic properties of silicon carbide ceramic under weak support conditions. J. Mater. Res. Technol. 2023, 28, 1764–1773. [Google Scholar] [CrossRef]

- Luo, T.; Chao, Z.; Du, S.; Jiang, L.; Chen, S.; Zhang, R.; Han, H.; Han, B.; Wang, Z.; Chen, G.; et al. A novel multi-scale ceramic-based array (SICB + B4CP)/7075AL as promising materials for armor structure. Materials 2023, 16, 5796. [Google Scholar] [CrossRef]

- Subha, S.; Benny, N.; Singh, D. Thermo-mechanical behavior of SiC-based composites for gas turbine engines. Mater. Today Proc. 2022, 68, 2301–2309. [Google Scholar] [CrossRef]

- Liu, X.; Guo, X.; Xu, Y.; Li, L.; Zhu, W.; Zeng, Y.; Li, J.; Luo, X.; Hu, X. Cyclic thermal shock damage behavior in CVI SIC/SIC High-Pressure Turbine twin guide vanes. Materials 2021, 14, 6104. [Google Scholar] [CrossRef]

- Ding, X.; Cheng, J.; Chen, F. Impact of silicon carbide devices on the powertrain systems in electric vehicles. Energies 2017, 10, 533. [Google Scholar] [CrossRef]

- Li, X.; Wang, X.; Bondokov, R.; Morris, J.; An, Y.H.; Sudarshan, T.S. Micro/nanoscale mechanical and tribological characterization of SiC for orthopedic applications. J. Biomed. Mater. Res. Part B Appl. Biomater. 2004, 72B, 353–361. [Google Scholar] [CrossRef]

- Shen, K.; Maharbiz, M.M. Ceramic packaging in neural implants. Ceramic packaging in neural implants. J. Neural Eng. 2021, 18, 025002. [Google Scholar] [CrossRef]

- Mohammadi, H.; Beddu, S.; Petrů, M.; Sepantafar, M.; Ebadi, M.; Yap, B.K.; Bang, L.T.; Yong, T.C.; Ramesh, S.; Koloor, S.S.R. Advances in silicon nitride ceramic biomaterials for dental applications—A review. J. Mater. Res. Technol. 2023, 28, 2778–2791. [Google Scholar] [CrossRef]

- Heimann, R.B. Silicon nitride, a close to ideal ceramic material for medical application. Ceramics 2021, 4, 208–223. [Google Scholar] [CrossRef]

- Tian, J.; Wu, Y.; Sun, J.; Xia, Z.; Ren, K.; Wang, H.; Li, S.; Yao, J. Thermal Dynamic Exploration of Full-Ceramic Ball Bearings under the Self-Lubrication Condition. Lubricants 2022, 10, 213. [Google Scholar] [CrossRef]

- Du, Y.; Xie, F.; Wang, J.; Xu, B.; Chen, H.; Yan, B.; Wu, Y.; Huang, W.; Li, H. Dry friction properties of Diamond-Coated silicon carbide. Materials 2023, 16, 3640. [Google Scholar] [CrossRef] [PubMed]

- Mefexport. Ceramic Cutting Tools. MEFexport.com. Available online: https://mefexport.com/ceramic-cutting-tools/ (accessed on 22 May 2020).

- Roccaforte, F.; Fiorenza, P.; Greco, G.; Vivona, M.; Lo Nigro, R.; Giannazzo, F.; Patti, A.; Saggio, M. Recent advances on dielectrics technology for SiC and GaN power devices. Appl. Surf. Sci. 2014, 301, 9–18. [Google Scholar] [CrossRef]

- ROHM Semiconductor. SiC Power Devices and Modules Application Note Rev.003. ROHM Co., Ltd. 2020. Available online: https://fscdn.rohm.com/en/products/databook/applinote/discrete/sic/common/sic_appli-e.pdf (accessed on 11 April 2025).

- Patrick, L.; Choyke, W.J.; Hamilton, D.R. Luminescence of4HSIC, and location of Conduction-Band minima in SIC polytypes. Phys. Rev. 1965, 137, A1515–A1520. [Google Scholar] [CrossRef]

- Choyke, W.J.; Patrick, L. Exciton recombination radiation and phonon spectrum of6HSIC. Phys. Rev. 1962, 127, 1868–1877. [Google Scholar] [CrossRef]

- Agarwal, S.; Rao, P.V. Experimental investigation of surface/subsurface damage formation and material removal mechanisms in SiC grinding. Int. J. Mach. Tools Manuf. 2007, 48, 698–710. [Google Scholar] [CrossRef]

- Katahira, K.; Ohmori, H.; Takesue, S.; Komotori, J.; Yamazaki, K. Effect of atmospheric-pressure plasma jet on polycrystalline diamond micro-milling of silicon carbide. CIRP Ann. 2015, 64, 129–132. [Google Scholar] [CrossRef]

- Xie, J.; Li, Q.; Sun, J.; Li, Y. Study on ductile-mode mirror grinding of SiC ceramic freeform surface using an elliptical torus-shaped diamond wheel. J. Mater. Process. Technol. 2015, 222, 422–433. [Google Scholar] [CrossRef]

- Yoo, H.; Ko, J.; Lim, K.; Kwon, W.T.; Kim, Y. Micro-electrical discharge machining characteristics of newly developed conductive SiC ceramic. Ceram. Int. 2014, 41, 3490–3496. [Google Scholar] [CrossRef]

- Okamoto, Y.; Kimura, Y.; Okada, A.; Uno, Y.; Ohya, J.; Yamauchi, T. Challenge to Development of Functional Multi-Wire EDM Slicing Method Using Wire Electrode with Track-Shaped Section. Key Eng. Mater. 2012, 523–524, 287–292. [Google Scholar] [CrossRef]

- Bilal, A.; Jahan, M.P.; Talamona, D.; Perveen, A. Electro-Discharge Machining of Ceramics: A review. Micromachines 2018, 10, 10. [Google Scholar] [CrossRef] [PubMed]

- Pandey1, A.; Singh, S. Current research Trends in Variants of Electrical Discharge Machining: A review. Int. J. Eng. Sci. Technol. 2010, 2, 2172–2191. [Google Scholar]

- Schubert, A.; Zeidler, H.; Kühn, R.; Hackert-Oschätzchen, M. Microelectrical discharge machining: A suitable process for machining ceramics. J. Ceram. 2015, 2015, 470801. [Google Scholar] [CrossRef]

- La Via, F.; Roccaforte, F.; La Magna, A.; Nipoti, R.; Mancarella, F.; Wellmann, P.J.; Crippa, D.; Mauceri, M.; Ward, P.; Miglio, L.; et al. 3C-SIC Hetero-Epitaxially grown on silicon compliance substrates and new 3C-SIC substrates for sustainable Wide-Band-Gap power devices (CHALLENGE). Mater. Sci. Forum 2018, 924, 913–918. [Google Scholar] [CrossRef]

- Beygi, M.; Bentley, J.T.; Frewin, C.L.; Kuliasha, C.A.; Takshi, A.; Bernardin, E.K.; La Via, F.; Saddow, S.E. Fabrication of a Monolithic Implantable Neural Interface from Cubic Silicon Carbide. Micromachines 2019, 10, 430. [Google Scholar] [CrossRef]

- Han, T.; Privitera, S.; Milazzo, R.; Bongiorno, C.; Di Franco, S.; La Via, F.; Song, X.; Shi, Y.; Lanza, M.; Lombardo, S. Photo-electrochemical water splitting in silicon based photocathodes enhanced by plasmonic/catalytic nanostructures. Mater. Sci. Eng. B 2017, 225, 128–133. [Google Scholar] [CrossRef]

- Praveen, D.V.; Raju, D.R.; Raju, M.J. Optimization of machining parameters of wire-cut EDM on ceramic particles reinforced Al-metal matrix composites—A review. Mater. Today Proc. 2019, 23, 495–498. [Google Scholar] [CrossRef]

- Müller, F.; Monaghan, J. Non-conventional machining of particle reinforced metal matrix composite. Int. J. Mach. Tools Manuf. 2000, 40, 1351–1366. [Google Scholar] [CrossRef]

- Surya, V.R.; Kumar, K.V.; Keshavamurthy, R.; Ugrasen, G.; Ravindra, H. Prediction of Machining Characteristics using Artificial Neural Network in Wire EDM of Al7075 based In-situ Composite. Mater. Today Proc. 2017, 4, 203–212. [Google Scholar] [CrossRef]

- Saini, V.K.; Zahid, A. Khan and Arshad Noor Siddiquee. Optimization of wire electric discharge machining of composite material (Al6061/SICP) using Taguchi Method. Int. J. Mech. Prod. Eng. 2013, 2, 61–64. [Google Scholar]

- Zhang, C. Effect of wire electrical discharge machining (WEDM) parameters on surface integrity of nanocomposite ceramics. Ceram. Int. 2014, 40, 9657–9662. [Google Scholar] [CrossRef]

- Smirnov, A.; Seleznev, A.; Pinargote, N.W.S.; Pristinskiy, Y.; Peretyagin, P.; Bartolomé, J.F. The influence of wire electrical discharge machining cutting parameters on the surface roughness and flexural strength of ZRO2/TIN ceramic nanocomposites obtained by spark plasma sintering. Nanomaterials 2019, 9, 1391. [Google Scholar] [CrossRef] [PubMed]

- Rubi, C.S.; Prakash, J.U.; Juliyana, S.J.; Čep, R.; Salunkhe, S.; Kouril, K.; Gawade, S.R. Comprehensive review on wire electrical discharge machining: A non-traditional material removal process. Front. Mech. Eng. 2024, 10, 1322605. [Google Scholar] [CrossRef]

- Kamenskikh, A.A.; Muratov, K.R.; Shlykov, E.S.; Sidhu, S.S.; Mahajan, A.; Kuznetsova, Y.S.; Ablyaz, T.R. Recent Trends and Developments in the electrical discharge machining industry: A review. J. Manuf. Mater. Process. 2023, 7, 204. [Google Scholar] [CrossRef]

- Ho, K.; Newman, S.; Rahimifard, S.; Allen, R. State of the art in wire electrical discharge machining (WEDM). Int. J. Mach. Tools Manuf. 2004, 44, 1247–1259. [Google Scholar] [CrossRef]

- Qudeiri, J.E.A.; Zaiout, A.; Mourad, A.I.; Abidi, M.H.; Elkaseer, A. Principles and characteristics of different EDM processes in machining tool and die steels. Appl. Sci. 2020, 10, 2082. [Google Scholar] [CrossRef]

- Yan, M.; Lai, Y. Surface quality improvement of wire-EDM using a fine-finish power supply. Int. J. Mach. Tools Manuf. 2007, 47, 1686–1694. [Google Scholar] [CrossRef]

- Dhanik, S.; Joshi, S.S. Modeling of a single resistance capacitance pulse discharge in Micro-Electro Discharge machining. J. Manuf. Sci. Eng. 2005, 127, 759–767. [Google Scholar] [CrossRef]

- Bamberg, E.; Rakwal, D. Experimental investigation of wire electrical discharge machining of gallium-doped germanium. J. Mater. Process. Technol. 2007, 197, 419–427. [Google Scholar] [CrossRef]

- Tsai, T.; Horng, J.; Liu, N.; Chou, C.; Chiang, K. The effect of heterogeneous second phase on the machinability evaluation of spheroidal graphite cast irons in the WEDM process. Mater. Des. 2008, 29, 1762–1767. [Google Scholar] [CrossRef]

- Antar, M.; Soo, S.; Aspinwall, D.; Sage, C.; Cuttell, M.; Perez, R.; Winn, A. Fatigue response of Udimet 720 following minimum damage wire electrical discharge machining. Mater. Des. 2012, 42, 295–300. [Google Scholar] [CrossRef]

- Liu, J.; Guo, Y.; Butler, T.; Weaver, M. Crystallography, compositions, and properties of white layer by wire electrical discharge machining of nitinol shape memory alloy. Mater. Des. 2016, 109, 1–9. [Google Scholar] [CrossRef]

- Shehata, M.; El-Hadad, S.; Attia, H. Wire Electrical Discharge Machining Process: Challenges and Future Prospects. Int. J. Mater. Technol. Innov. 2022, 2, 31–37. [Google Scholar] [CrossRef]

- Zhao, Y.; Kunieda, M.; Abe, K. Study of EDM cutting of single crystal silicon carbide. Precis. Eng. 2013, 38, 92–99. [Google Scholar] [CrossRef]

- Pramanik, A. Developments in the non-traditional machining of particle reinforced metal matrix composites. Int. J. Mach. Tools Manuf. 2014, 86, 44–61. [Google Scholar] [CrossRef]

- Pramanik, A.; Basak, A. Sustainability in wire electrical discharge machining of titanium alloy: Understanding wire rupture. J. Clean. Prod. 2018, 198, 472–479. [Google Scholar] [CrossRef]

- Singh, M.A.; Joshi, K.; Hanzel, O.; Singh, R.K.; Šajgalík, P.; Marla, D. Identification of wire electrical discharge machinability of SiC sintered using rapid hot-pressing technique. Ceram. Int. 2020, 46, 17261–17271. [Google Scholar] [CrossRef]

- Joshi, K.; Ananya, A.; Bhandarkar, U.; Joshi, S.S. Ultra-thin silicon wafer slicing using wire-EDM for solar cell application. Mater. Des. 2017, 124, 158–170. [Google Scholar] [CrossRef]

- Hou, P.; Guo, Y.; Sun, L.; Deng, G. Simulation of Temperature and Thermal Stress Filed during Reciprocating Traveling WEDM of Insulating Ceramics. Procedia CIRP 2013, 6, 410–415. [Google Scholar] [CrossRef]

- Luis, C.; Puertas, I.; Villa, G. Material removal rate and electrode wear study on the EDM of silicon carbide. J. Mater. Process. Technol. 2005, 164–165, 889–896. [Google Scholar] [CrossRef]

- Yamada, H.; Yamaguchi, S.; Yamamoto, N.; Kato, T. Cutting speed of electric discharge machining for SIC ingot. Mater. Sci. Forum 2012, 717–720, 861–864. [Google Scholar] [CrossRef]

- Pinargote, N.W.S.; Malakhinsky, A.; Soe, T.N.; Pristinskiy, Y.; Smirnov, A.; Meleshkin, Y.; Apelfeld, A.; Peretyagin, N.; Peretyagin, P.; Grigoriev, S.N. Investigation of the WEDM parameters’ influence on the recast layer thickness of spark plasma sintered SIC-TIB2-TIC ceramic. Coatings 2023, 13, 1728. [Google Scholar] [CrossRef]

- Gotoh, H.; Tani, T.; Mohri, N. EDM of insulating ceramics by electrical conductive surface layer control. Procedia CIRP 2016, 42, 201–205. [Google Scholar] [CrossRef]

- Sánchez, J.A.; Cabanes, I.; De Lacalle, L.N.L.; Lamikiz, A. Development of optimum electrodischarge machining technology for advanced ceramics. Int. J. Adv. Manuf. Technol. 2001, 18, 897–905. [Google Scholar] [CrossRef]

- Tani, T.; Fukuzawa, Y.; Mohri, N.; Saito, N.; Okada, M. Machining phenomena in WEDM of insulating ceramics. J. Mater. Process. Technol. 2004, 149, 124–128. [Google Scholar] [CrossRef]

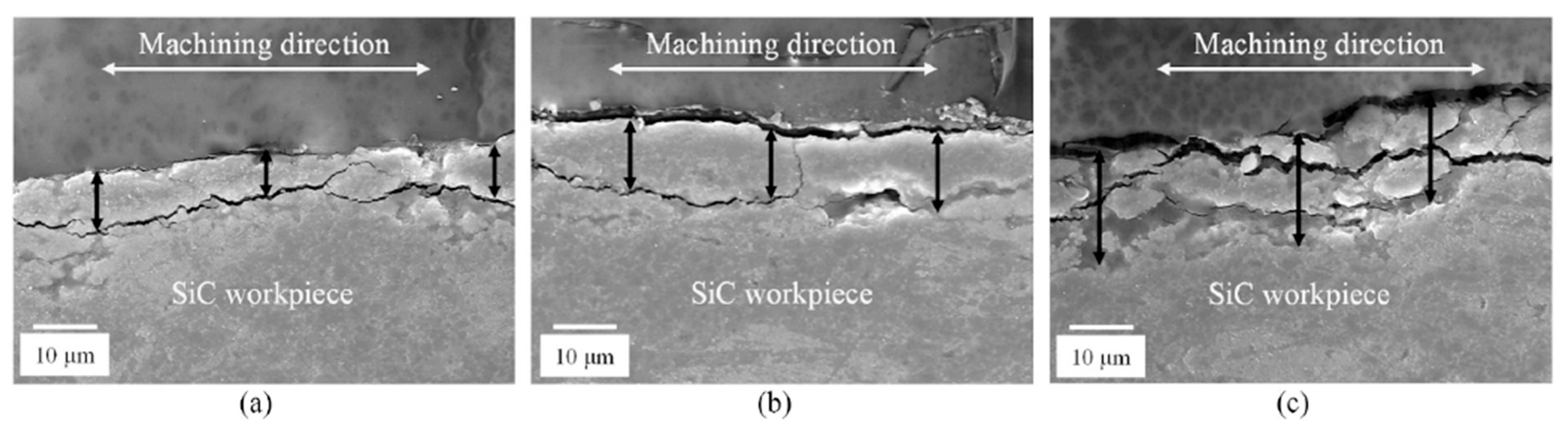

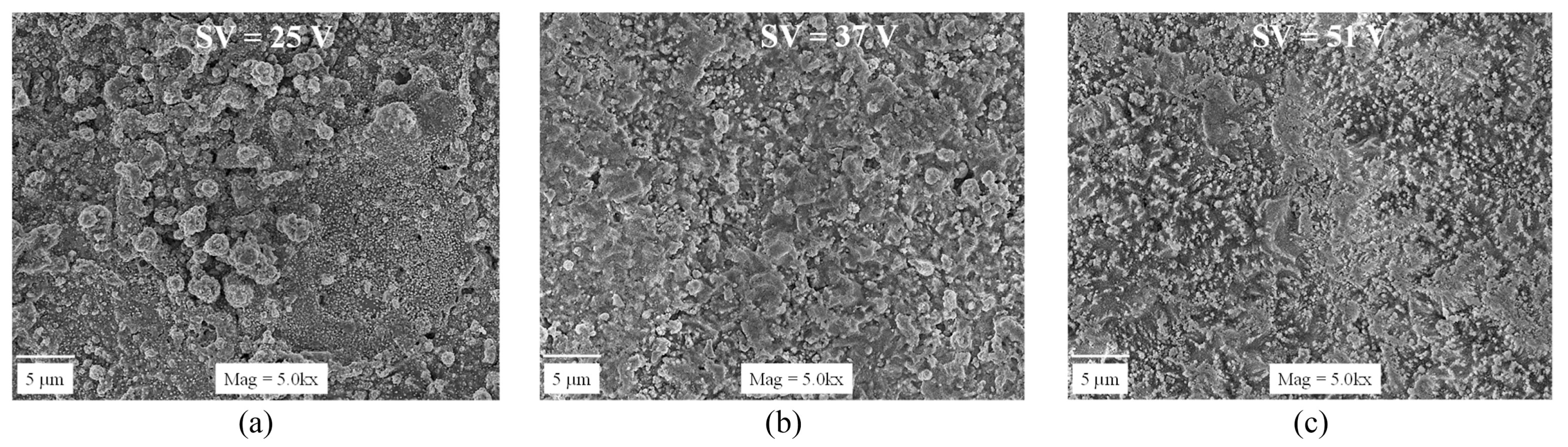

- Singh, M.A.; Joshi, K.; Hanzel, O.; Singh, R.; Sajgalik, P.; Marla, D. Influence of open voltage and servo voltage during Wire-EDM of silicon carbides. Procedia CIRP 2020, 95, 285–289. [Google Scholar] [CrossRef]

- Masahiro, Y.; Ryuichiro, H.; Kazuma, A.; Soichiro, M.; Tomohiko, K. Study on Slicing of Conductive SiC Ingot by Oil and Water type WEDM. Procedia CIRP 2022, 113, 155–159. [Google Scholar] [CrossRef]

- Rahim, M.Z.; Yusof, M.S.; Rahim, E.A.; Ibrahim, R.; Mohid, Z. Wire-cut EDM of SiSiC-preliminary investigation in machining parameter. AIP Conf. Proc. 2017, 1831, 020052. [Google Scholar] [CrossRef]

- Clijsters, S.; Liu, K.; Reynaerts, D.; Lauwers, B. EDM technology and strategy development for the manufacturing of complex parts in SiSiC. J. Mater. Process. Technol. 2009, 210, 631–641. [Google Scholar] [CrossRef]

- Ge, M.; Liu, Z.; Chen, H.; Shen, L.; Qiu, M.; Tian, Z. Machining damage of monocrystalline silicon by specific crystallographic plane cutting of wire electrical discharge machining. J. Mater. Sci. Mater. Electron. 2017, 28, 8437–8445. [Google Scholar] [CrossRef]

- Saleem, M.Q.; Naqvi, M.; Khan, S.A.; Mufti, N.A.; Ishfaq, K. Performance Evaluation of SiC Powder Mixed Electrical Discharge Machining: A Case of Wire Cut Mode with Re-Circulating Molybdenum Wire, PREPRINT (Version 1). 28 June 2021. Research Square. Available online: https://www.researchsquare.com/article/rs-159588/v1 (accessed on 24 January 2023).

- Flaño, O.; Zhao, Y.; Kunieda, M.; Abe, K. Approaches for improvement of EDM cutting performance of SiC with foil electrode. Precis. Eng. 2017, 49, 33–40. [Google Scholar] [CrossRef]

- Dongre, G.; Zaware, S.; Dabade, U.; Joshi, S.S. Multi-objective optimization for silicon wafer slicing using wire-EDM process. Mater. Sci. Semicond. Process. 2015, 39, 793–806. [Google Scholar] [CrossRef]

- Reynaerts, D.; Heeren, P.; Van Brussel, H. Microstructuring of silicon by electro-discharge machining (EDM)—Part I: Theory. Sens. Actuators A Phys. 1997, 60, 212–218. [Google Scholar] [CrossRef]

- Dongre, G.; Singh, R.; Joshi, S.S. Response surface analysis of slicing of silicon ingots with focus on photovoltaic application. Mach. Sci. Technol. 2012, 16, 624–652. [Google Scholar] [CrossRef]

- Sheth, M.; Sheth, N.; Radadia, N.; Parsana, S.; Savsani, V.; Mishra, R.K.; Arivarasu, M.; Prabhu, T.R. Optimization of WEDM parameters for Mg-Zn-RE-Zr alloy using Passing Vehicle Search algorithm. Mater. Res. Express 2019, 6, 1265k6. [Google Scholar] [CrossRef]

- Ali, M.A.; Mufti, N.A.; Sana, M.; Tlija, M.; Khan, A.M. An intrinsic investigation on high-speed wire-EDM for surface integrity, kerf width, and cutting performance of hybrid composite. Mater. Today Commun. 2025, 42, 111548. [Google Scholar] [CrossRef]

- Das, S.; Joshi, S.N. Prediction of crater induced failure of coated wires during wire EDM of Ti-6Al-4V alloy. Procedia CIRP 2025, 133, 519–524. [Google Scholar] [CrossRef]

- Soundararajan, R.; Ramesh, A.; Ponappa, K.; Sivasankaran, S.; Arvind, D. Optimization of WEDM process parameters by RSM in machining of stir cum squeeze cast A413–B4C composites. SN Appl. Sci. 2020, 2, 1768. [Google Scholar] [CrossRef]

- Kumar, P.; Gupta, M.; Kumar, V. Microstructural analysis and multi response optimization of WEDM of Inconel 825 using RSM based desirability approach. J. Mech. Behav. Mater. 2019, 28, 39–61. [Google Scholar] [CrossRef]

- Alduroobi, A.A.A.; Ubaid, A.M.; Tawfiq, M.A.; Elias, R.R. Wire EDM process optimization for machining AISI 1045 steel by use of Taguchi method, artificial neural network and analysis of variances. Int. J. Syst. Assur. Eng. Manag. 2020, 11, 1314–1338. [Google Scholar] [CrossRef]

- Abbas, A.T.; Sharma, N.; Alsuhaibani, Z.A.; Sharma, V.S.; Soliman, M.S.; Sharma, R.C. Processing of AL/SIC/GR hybrid composite on EDM by different electrode materials using RSM-COPRAS approach. Metals 2023, 13, 1125. [Google Scholar] [CrossRef]

- Sharma, N.; Khanna, R.; Gupta, R. Multi Quality Characteristics of WEDM Process Parameters with RSM. Procedia Eng. 2013, 64, 710–719. [Google Scholar] [CrossRef]

- Khanna, R.; Sharma, N.; Kumar, N.; Gupta, R.D.; Sharma, A. WEDM of Al/SiC/Ti composite: A hybrid approach of RSM-ARAS-TLBO algorithm. Int. J. Lightweight Mater. Manuf. 2022, 5, 315–325. [Google Scholar] [CrossRef]

- Srinivasan, V.; Palani, P. Surface integrity, fatigue performance and dry sliding wear behaviour of Si3N4–TiN after wire-electro discharge machining. Ceram. Int. 2020, 46, 10734–10739. [Google Scholar] [CrossRef]

- Tamari, N.; Kondo, I.; Ueno, K.; Toibana, Y. Electrical discharge machining of SI3N4-SIC whisker composite ceramics. J. Ceram. Assoc. Jpn. 1986, 94, 1231–1235. [Google Scholar] [CrossRef]

- Landfried, R.; Kern, F.; Burger, W.; Leonhardt, W.; Gadow, R. Development of Electrical Discharge Machinable ZTA Ceramics with 24 vol% of TiC, TiN, TiCN, TiB2 and WC as Electrically Conductive Phase. Int. J. Appl. Ceram. Technol. 2012, 10, 509–518. [Google Scholar] [CrossRef]

- Lauwers, B.; Kruth, J.; Liu, W.; Eeraerts, W.; Schacht, B.; Bleys, P. Investigation of material removal mechanisms in EDM of composite ceramic materials. J. Mater. Process. Technol. 2004, 149, 347–352. [Google Scholar] [CrossRef]

- Mazzocchi, M.; Bellosi, A. On the possibility of silicon nitride as a ceramic for structural orthopaedic implants. Part I: Processing, microstructure, mechanical properties, cytotoxicity. J. Mater. Sci. Mater. Med. 2008, 19, 2881–2887. [Google Scholar] [CrossRef]

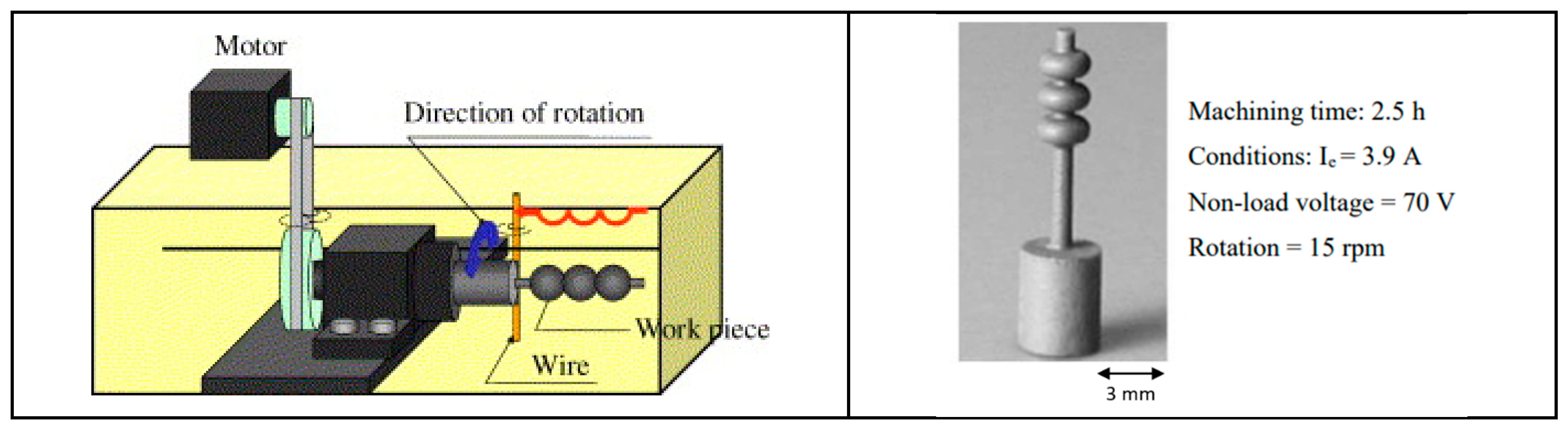

- Kimura, A.; Okamoto, Y.; Okada, A.; Ohya, J.; Yamauchi, T. Fundamental Study on Multi-wire EDM Slicing of SiC by Wire Electrode with Track-shaped Section. Procedia CIRP 2013, 6, 232–237. [Google Scholar] [CrossRef]

- Ogawa, M.; Mine, K.; Fuchiyama, S.; Tawa, Y.; Kato, T. Development of Multi-Wire electric discharge machining for SIC wafer processing. Mater. Sci. Forum 2014, 778–780, 776–779. [Google Scholar] [CrossRef]

- Srivastava, V.; Pandey, P.M. Performance evaluation of electrical discharge machining (EDM) process using cryogenically cooled electrode. Mater. Manuf. Process. 2012, 27, 683–688. [Google Scholar] [CrossRef]

- Deng, J.; Lee, T. Techniques for improved surface integrity of electrodischarge machined ceramic composites. Surf. Eng. 2000, 16, 411–414. [Google Scholar] [CrossRef]

- Almeida, S.T.; Mo, J.; Bil, C.; Ding, S.; Wang, X. Conceptual design of a High-Speed Wire EDM Robotic End-Effector based on a systematic review followed by TRIZ. Machines 2021, 9, 132. [Google Scholar] [CrossRef]

- Tahir, W.; Jahanzaib, M.; Raza, A. Effect of process parameters on cutting speed of wire EDM process in machining HSLA steel with cryogenic treated brass wire. Adv. Prod. Eng. Manag. 2019, 14, 143–152. [Google Scholar] [CrossRef]

- Goyal, A. Investigation of material removal rate and surface roughness during wire electrical discharge machining (WEDM) of Inconel 625 super alloy by cryogenic treated tool electrode. J. King Saud Univ.-Sci. 2017, 29, 528–535. [Google Scholar] [CrossRef]

- Özbek, N.A.; Çiçek, A.; Gülesin, M.; Özbek, O. Investigation of the effects of cryogenic treatment applied at different holding times to cemented carbide inserts on tool wear. Int. J. Mach. Tools Manuf. 2014, 86, 34–43. [Google Scholar] [CrossRef]

- Yao, Y.; Zhou, Y. Effects of deep cryogenic treatment on wear resistance and structure of GB 35CRMOV steel. Metals 2018, 8, 502. [Google Scholar] [CrossRef]

- Senthilkumar, D.; Rajendran, I. Optimization of deep cryogenic treatment to reduce wear loss of 4140 steel. Mater. Manuf. Process. 2011, 27, 567–572. [Google Scholar] [CrossRef]

- Gebler, M.; Uiterkamp, A.J.S.; Visser, C. A global sustainability perspective on 3D printing technologies. Energy Policy 2014, 74, 158–167. [Google Scholar] [CrossRef]

- Seah, K.H.W.; Rahman, M.; Yong, K.H. Performance evaluation of cryogenically treated tungsten carbide cutting tool inserts. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2003, 217, 29–43. [Google Scholar] [CrossRef]

- Kosaraju, S.; Bobba, P.B.; Salkuti, S.R. Optimization and microstructural studies on the machining of Inconel 600 in WEDM using untreated and cryogenically treated zinc electrodes. Materials 2023, 16, 3181. [Google Scholar] [CrossRef]

- Viswanth, V.S.; Ramanujam, R.; Rajyalakshmi, G. A Review of research scope on Sustainable and Eco-Friendly Electrical Discharge Machining (E-EDM). Mater. Today Proc. 2018, 5, 12525–12533. [Google Scholar] [CrossRef]

- Garg, A.; Lam, J.S.L. Modeling multiple-response environmental and manufacturing characteristics of EDM process. J. Clean. Prod. 2016, 137, 1588–1601. [Google Scholar] [CrossRef]

- Zhang, Z.; Yu, H.; Zhang, Y.; Yang, K.; Li, W.; Chen, Z.; Zhang, G. Analysis and optimization of process energy consumption and environmental impact in electrical discharge machining of titanium superalloys. J. Clean. Prod. 2018, 198, 833–846. [Google Scholar] [CrossRef]

- Salahi, N.; Jafari, M.A. Energy-Performance as a driver for optimal production planning. Appl. Energy 2016, 174, 88–100. [Google Scholar] [CrossRef]

- USA Energy Information Administration. Annual Energy Review 2011; Energy Information Administration: Washington, DC, USA, 2011.

- Camposeco-Negrete, C. Analysis and optimization of sustainable machining of AISI O1 tool steel by the wire-EDM process. Adv. Manuf. 2021, 9, 304–317. [Google Scholar] [CrossRef]

- Sampath, B. Sustainable eco-friendly wire-cut electrical Discharge Machining: Gas Emission Analysis, PREPRINT (Version 1). Research Square. 2 June 2021. Available online: https://www.researchsquare.com/article/rs-502937/v1 (accessed on 24 January 2023).

- Boopathi, S.; Myilsamy, S. Material removal rate and surface roughness study on Near-dry wire electrical discharge Machining process. Mater. Today Proc. 2021, 45, 8149–8156. [Google Scholar] [CrossRef]

- Das, P.P.; Chakraborty, S. Parametric analysis of a green electrical discharge machining process using DEMATEL and SIR methods. OPSEARCH 2019, 57, 513–540. [Google Scholar] [CrossRef]

- Ng, P.S.; Kong, S.A.; Yeo, S.H. Investigation of biodiesel dielectric in sustainable electrical discharge machining. Int. J. Adv. Manuf. Technol. 2016, 90, 2549–2556. [Google Scholar] [CrossRef]

- Venkatarao, K.; Reddy, M.C.; Kumar, Y.P.; Raju, L.S.; Rao, B.R.; Azad, D. Multi-response optimization in WEDM process of Al–Si alloy using TLBO-graph theory algorithm towards sustainability. Int. J. Adv. Manuf. Technol. 2023, 126, 3679–3694. [Google Scholar] [CrossRef]

- Ming, W.; Zhang, Z.; Wang, S.; Zhang, Y.; Shen, F.; Zhang, G. Comparative study of energy efficiency and environmental impact in magnetic field assisted and conventional electrical discharge machining. J. Clean. Prod. 2018, 214, 12–28. [Google Scholar] [CrossRef]

- He, Y.; Wu, P.; Li, Y.; Wang, Y.; Tao, F.; Wang, Y. A generic energy prediction model of machine tools using deep learning algorithms. Appl. Energy 2020, 275, 115402. [Google Scholar] [CrossRef]

| Industry | Part | Description | |

|---|---|---|---|

| Power | Used in power devices such as MOSFETs and diodes [2] |  [3] | These components are usually small, measuring in the millimeter range, which allows for compact and efficient power conversion systems. |

| Defense | Armor [4] |  [5] | Large silicon carbide (SiC) components, measuring from centimeters to meters, are utilized for their exceptional strength and ability to withstand extreme conditions. |

| Aerospace | Gas turbine engines |  Reprinted with permission from Ref. [6]. Copyright 2022 Elsevier. | These components experience extremely high temperatures and harsh conditions within the engine. SiC’s exceptional thermal stability, high strength, and resistance to oxidation and thermal shock make it an ideal material for these applications. |

| Nozzle vanes |  [7] | These components must possess thermal stability and oxidation resistance under extreme temperature conditions. | |

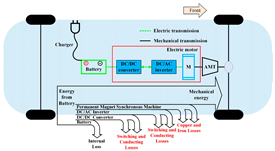

| Automotive | (EV) powertrains |  [8] | The size of these components can vary, but they are generally designed to fit within the compact spaces of automotive systems. |

| Biomedical devices | Biosensors [9], neural implants [10], dental implants [11] |  [12] | Small components, ranging from millimeters to centimeters, are utilized for their biocompatibility and durability in advanced medical applications. |

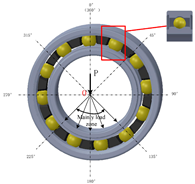

| Industry | Bearings |  [13] | SiC is used in the production of high-performance brake disks. These discs offer superior thermal conductivity and wear resistance, improving braking performance and durability. |

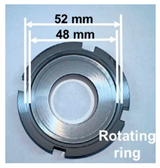

| Mechanical seals |  [14] | SiC is used in mechanical seals for pumps and compressors, providing excellent wear resistance and extending the lifespan of these components. | |

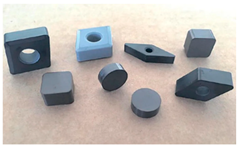

| Cutting tools |  [15] | These are ideal for machining hard materials due to their exceptional wear resistance and hardness, making them suitable for cutting and grinding applications. |

| Property | Value | Description |

|---|---|---|

| Density | ~3.15–3.21 g/cm3 | Low density contributes to lightweight components in high-performance applications. |

| Hardness | ~25–28 GPa (Vickers) | Extremely high hardness, making it one of the hardest ceramics available. |

| Thermal Conductivity | ~120–180 W/m·K | Excellent thermal conductivity, ideal for high-temperature environments. |

| Thermal Expansion | ~4.0 × 10−6/K (20–1000 °C) | Low thermal expansion ensures dimensional stability under temperature variations. |

| Flexural Strength | ~350–500 MPa | High strength across a wide range of temperatures. |

| Compressive Strength | ~3900 MPa | Exceptional resistance to compression, ideal for structural applications. |

| Elastic Modulus | ~410 GPa | High stiffness is suitable for precision engineering applications. |

| Electrical Conductivity | Semi-conductive | Conductivity varies depending on doping; used in electronic devices. |

| Chemical Resistance | High | Resistant to oxidation, acids, and bases, enhancing longevity in harsh environments. |

| Property | SSiC | SiSiC | Doped SiC |

|---|---|---|---|

| Electrical Conductivity | Very low | Moderate (due to Si) | Moderate to high |

| Hardness (Vickers, GPa) | ~25–28 | ~22–26 | ~20–27 |

| Thermal Conductivity (W/m·K) | ~120–180 | ~130–160 | ~140–180 |

| Brittleness | High | Moderate | Moderate |

| WEDM Suitability | Requires enhancement | Suitable | Suitable |

| Reference | Electrode | Assisting Electrode | Polarity | Peak Current | Pulse Duration | Pulse-off Time | Interval Time | Open Voltage | Servo Voltage | Wire Tension | Wire Feed Rate | Dielectric Flushing Pressure | Outcomes |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [59] | Brass (Ø 0.2 mm) | TiN (t = 3 μm) | Negative | 3.9 –4.9 A | 4 μs | 16 μs | 2.45 N | They reported that the most important considerations for slicing ultra-thin wafers are balancing the wafer thickness, kerf loss, and slicing rate. A wafer thickness of 150 μm with a slicing rate of 1.05 mm/min and kerf loss of 121 μm is optimal for minimizing material waste while maintaining efficiency. The use of response methodology and composite desirability optimization reduced kerf loss by 40–50%. Surface analysis revealed crack-free wafers with minor defects such as dents and holes, highlighting complex material removal phenomena during machining. | |||||

| [60] | 0.3 μs | 20 μs | 4 N | 62 | 10 (bar/kg) | By increasing servo voltage, the kerf loss and the inter-electrode gap also increased, leading to significant debris accumulation on the machined surface. | |||||||

| [25] | Brass (Ø 0.2 mm) | Negative | 80 V | 58 V | 8 | 8 | When the tool electrode has a negative polarity, a higher machining speed and a lower tool wear ratio will be reached during foil EDM of SiC with short pulse durations. Due to the larger kerf width and slower machining speed, long pulse durations are not acceptable for SiC EDM. | ||||||

| [61] | Brass (Ø 0.2 mm) | 50.85 mm/14.3 mm | 1 | 4 μs | 3.5 μs | 100 V | 75 V | 20 N | 80 m/min | 2 l/min | They investigated the efficiency and quality of slicing under oil- and water-based Wire Electrical Discharge Machining (WEDM) conditions. Water machining is faster at a discharge current of 1 A, but only by about 1.1-fold compared to that of oil machining. Additionally, the average width of the machined groove during water machining at 1 A is smaller than that of oil machining. The groove width remains wider even at a discharge current of 0.7 A for water machining compared to a discharge current of 1 A for oil machining. | ||

| [62] | Zinc-coated (Ø 0.25 mm) | Negative | 11.2 A | 12.82 (μs) | 42 V | 600 g | 10 m/min | Because of its high electrical resistivity and thermal conductivity, SiSiC requires a high sparking power during EDM machining. To initiate the spark and for it to remain stable, in this study, a high peak current was necessary. The high thermal conductivity of the material triggered heat loss owing to the conductivity that decreased the energy output of the operation. The connection between machining parameters and several responses was established experimentally. Statistical analysis provided a clear understanding on the influence of the machining parameter, elucidated by validated mathematical models. | |||||

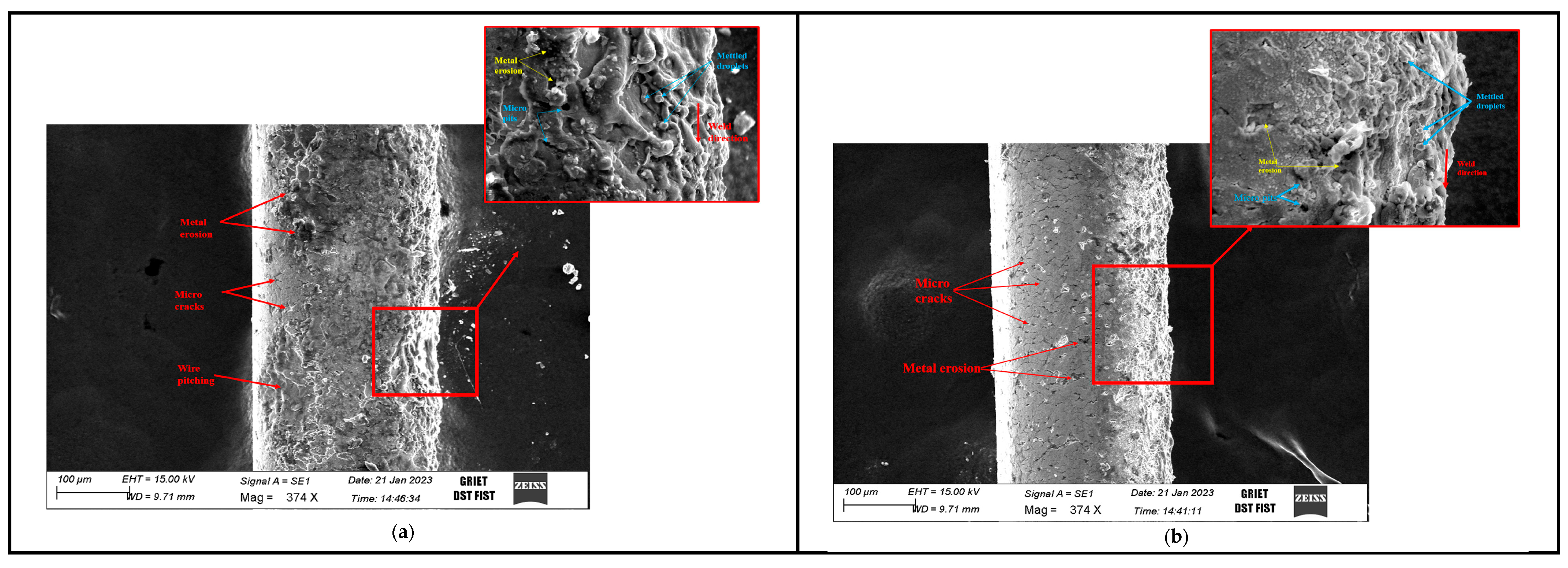

| [63] | (EDM-C3 grade) | Negative | 32 A | 3.2 µs | 100 µs | −200 V | They observed that using high-energy parameters, such as elevated peak currents and prolonged discharge durations, during the machining of conductive SiC led to instability in the process and caused significant damage to both the surface and subsurface of the material. When material melts and evaporates with high-energy discharge, there is not enough time for it to be ejected before it resolidifies. | ||||||

| [64] | Molybdenum (Ø 0.18 mm) | Workpiece (+) | 6 A | 5 µs, 10 µs, 20 µs, 40 µs, 80 µs. | 8 × Ton | Ton + Toff | 140 V | 7.2 m/s | They assessed the damage of a particular crystal face of single-crystal silicon, studying various input variables for EDM. In experiments with a variable pulse width, differences were found in material removal mechanisms. Analysis indicates that, during semiconductor processing, the melting and vaporization resulting from prolonged discharge pulses do not remove more material than the thermal stresses and explosive forces generated by brief pulses. Extended pulses often result in a concentration of the discharge, which can lead to an unpredictable process. | ||||

| [65] | Molybdenum (Ø 0.18 mm) | 2 A, 3 A, 4 A. | 100 µs, 130 µs, 150 µs. | 11 m/min | 30 kPa, 40 kPa, 50 kPa. | In the examination of material removal rate (MRR), it was discovered that the pulse-on time, along with its interplay with powder concentration and current, was an important factor. Pressure also proved to be significant. The findings demonstrated that a longer pulse-on time was associated with a lower MRR. Furthermore, the outcomes were exactly understood when these relations were taken into account. Specifically, a higher pulse-on time combined with low to average powder concentrations (2 and 4 g/l) is expected to distribute or dilute the effect of heat intensity, which in turn reduces the MRR. However, increasing the powder concentration to 6 g/l resulted in an improvement, likely due to enhanced bridging phenomena. |

| Author/Year | Wire Material | Work Material | Input Variables | Responses | Optimization Method | Key Observations |

|---|---|---|---|---|---|---|

| [70] Sheth et al. (2020) | Molybdenum (Ø 0.018 mm) | Mg-Zn-RE-Zr Alloy | Current, Ton, Toff, Wire Feed Rate | Surface Roughness | CCD + RSM + PVS | Toff is least influential; Ton and current are dominant |

| [71] Ali et al. (2025) | Molybdenum (Ø 0.18 mm) | AA2024/Al2O3/SiC/Si3N4/BN Hybrid Composite | Voltage, Current, Gap, Wire Feed, Wire Speed | Ra, CS, KW | Taguchi DOE, Desirability Index, SEM, Topography, ANOVA | Achieved smoother Ra and higher CS for complex profiles using optimal WEDM settings; reduced KW and minimized craters |

| [72] Das & Joshi (2025) | Zinc-Coated Brass (Ø 0.25 mm) | Ti-6Al-4V | Voltage, Current, Pulse-On/Off Time | Crater Volume, Wire Stress, Wire Failure Risk | 3D Thermo-Mechanical FEM, Experimental Validation | Predicted wire breakage based on crater volume; defined wire failure threshold; model improves tool longevity and sustainability |

| [73] Soundararajan et al. (2020) | Zinc-Coated Brass (Ø 0.25 mm) | A413 + 12 wt% B4C Composites | Ton, Toff, Peak Current | MRR, Surface Roughness | CCD + RSM | Ton significantly affects MRR and SR; Toff reduces SR |

| [74] Kumar et al. (2019) | Brass (Ø 0.25 mm) | Inconel 825 | Ton, Toff, Peak Current, Spark Gap, Wire Tension, Wire Feed | MRR, Surface Roughness, Wire Wear Ratio | RSM + Desirability Approach | Ton, gap voltage, and peak current positively impact MRR; Toff negatively affects SR |

| [75] Alduroobi et al. (2020) | Brass (Ø 0.25 mm) | AISI 1045 Steel | Ton, Toff, Servo Feed (SF) | MRR, SR | ANN | MRR optimal: Ton = 25 μs, Toff = 20 μs, SF = 30 mm/min; SR optimal: Ton = 10 μs, Toff = 40 μs, SF = 0 mm/min |

| [76] Abbas et al. (2023) | SS-304, Copper, Brass | Al/SiC/Gr Composite | Ton, Toff, SV, I, Tool Electrode | MRR, TWR | RSM + COPRAS + Machine Learning | Ton: 60, Toff: 60, SV: 7, I: 12; brass tool had highest TWR |

| [77] Sharma et al. (2013) | Brass | High-Strength Low-Alloy Steel (HSLA) | Ton, Toff, Peak Current, SV | MRR, Surface Roughness | RSM | Ton ↑ → SR ↑; Toff ↑ & I ↓ → better SR |

| [78] Khanna et al. (2022) | Brass (Ø 0.25 mm) | Al/SiC/Ti Hybrid Composite | Ton, Toff, SV, Wire Feed | Cutting Speed (CS), Kerf Width (Kw) | BBD + RSM + Teaching-Learning-Based Optimization (TLBO) | Ton strongly affects CS; SV influences Kw |

| Cryogenic Fluid | Temperature (°C) | Nature | Availability in Nature | Notes |

|---|---|---|---|---|

| Helium 3 | −269.96 | Inert Gas | 5 ppm | Rare isotope |

| Helium 4 | −268.94 | Inert Gas | 5 ppm | Common isotope |

| Hydrogen | −252.88 | Combustible | 0.6 ppm | Highly combustible gas |

| Neon | −246.06 | Neutral | 18 ppm | Used in lighting |

| Nitrogen | −196.06 | Neutral | 78.09% | Major component of air |

| Mixture of Air | −194.35 | Neutral | 100% | Air composition |

| Fluorine | −187.91 | Toxic | 0.6 ppb | Highly toxic |

| Argon | −185.91 | Inert Gas | 0.94% | Used in welding |

| Oxygen | −182.97 | Flammable | 20.95% | Supports combustion |

| Methane | −161.45 | Flammable | 1866 ppb | Natural gas component |

| Carbon Dioxide | −56.6 | Neutral | 0.04% | Greenhouse gas |

| Author(s), Year | Eco-Friendly Approach | Method/Principle | Environmental Benefit | Relevance to SiC Machining |

|---|---|---|---|---|

| [104] Boopathi et al., 2021 | Near-Dry WEDM | Compressed air + water mist as dielectric | Reduces toxic emissions, improves operator safety | The possibility of reducing dielectric contamination in brittle ceramics such as SiC |

| [104] Boopathi et al., 2021 | Pulse Parameter Optimization | Adjusting pulse-on/off times and discharge energy | Reduces energy usage and gas emissions | Adjusting for SiC conductivity limits may improve both efficiency and quality |

| [105] Das et al., 2020; [102] Camposeco-Negrete., 2021 | Green Dielectrics (e.g., Bio-Oils) | Use of biodegradable dielectrics like vegetable oils or nano-emulsions | Lower toxicity, safer handling, reduced disposal issues | Under investigation for ceramics such as SiC |

| [106] Ng et al., 2016 | Multi-Objective Optimization (Taguchi + TLBO) | Hybrid optimization method for energy, Ra, MRR, and kerf width | Balances multiple eco-efficiency metrics | Can be adapted for SiC if mechanical and electrical properties are considered |

| [107] Venkatarao et al., 2023 | Deionized Water as Dielectric | Substitution of hydrocarbon oils with deionized water | Lower environmental impact, cleaner machining process | Effective for SiC when combined with auxiliary electrode or conductivity coating |

| [108] Ming et al., 2019 | Magnetic-Field-Assisted WEDM | Enhancing debris evacuation using magnetic fields | Improves MRR and reduces thermal input | Underexplored for SiC, but promising for heat-sensitive materials |

| [109] He et al., 2020 | Energy Prediction Using ML | Machine learning-based prediction of energy consumption | Enables pre-optimization of energy-intensive cycles | Could guide parameter design in SiC machining for better efficiency |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fard, M.G.; Petru, J.; Hloch, S. Advances in Wire EDM Technology for Cutting Silicon Carbide Ceramics: A Review. Materials 2025, 18, 3955. https://doi.org/10.3390/ma18173955

Fard MG, Petru J, Hloch S. Advances in Wire EDM Technology for Cutting Silicon Carbide Ceramics: A Review. Materials. 2025; 18(17):3955. https://doi.org/10.3390/ma18173955

Chicago/Turabian StyleFard, Mohammad Ghasemian, Jana Petru, and Sergej Hloch. 2025. "Advances in Wire EDM Technology for Cutting Silicon Carbide Ceramics: A Review" Materials 18, no. 17: 3955. https://doi.org/10.3390/ma18173955

APA StyleFard, M. G., Petru, J., & Hloch, S. (2025). Advances in Wire EDM Technology for Cutting Silicon Carbide Ceramics: A Review. Materials, 18(17), 3955. https://doi.org/10.3390/ma18173955