An Insight into Compositionally Complex Carbide Ceramic Coatings

Abstract

1. Introduction

1.1. The Role of Coatings in Surface Protection and Enhancement

1.2. A Brief Explanation of the Concept of High Entropy in Ceramics

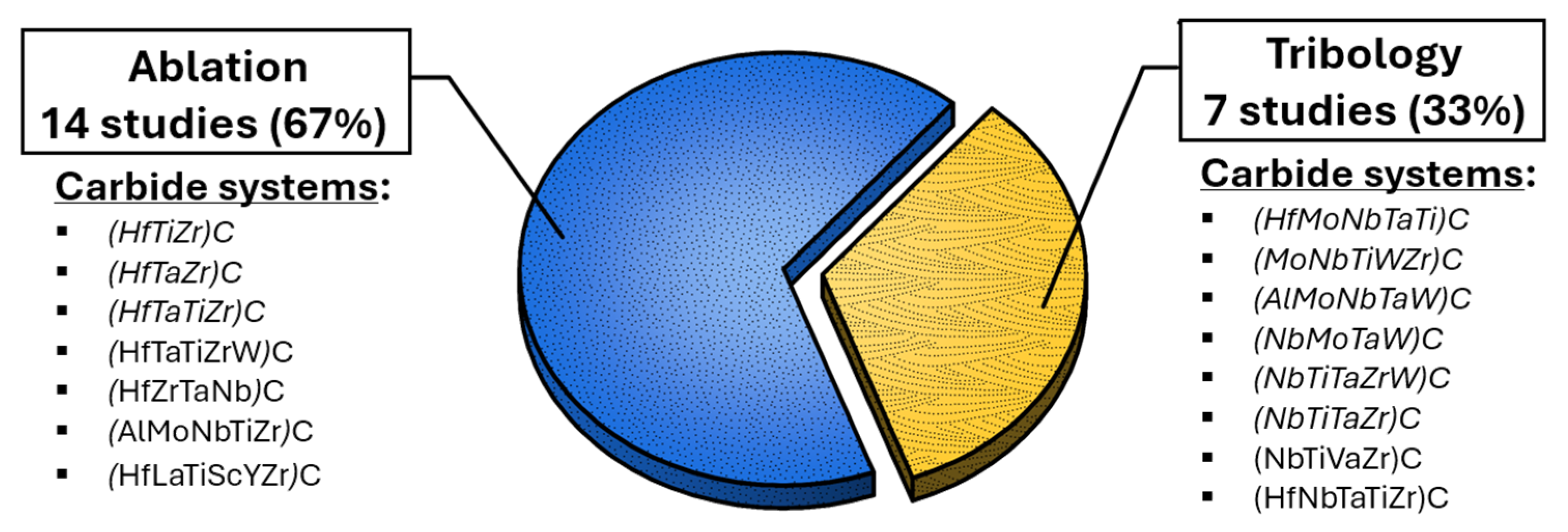

2. The Current State of the Literature on Compositionally Complex Carbide Coatings

2.1. Ablation-Resistant Compositionally Complex Carbide Coatings

2.2. Tribology-Focused Coatings Composed of Compositionally Complex Carbides

3. Discussion and Future Perspective

4. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wu, Q.; Long, W.; Zhang, L.; Zhao, H. A Review on Ceramic Coatings Prepared by Laser Cladding Technology. Opt. Laser Technol. 2024, 176, 110993. [Google Scholar] [CrossRef]

- Akrami, S.; Edalati, P.; Fuji, M.; Edalati, K. High-Entropy Ceramics: Review of Principles, Production and Applications. Mater. Sci. Eng. R Rep. 2021, 146, 100644. [Google Scholar] [CrossRef]

- Dong, M.; Wang, Z.; Li, H.; Guo, H.; Li, X.; Shih, K.; Wang, J. Metallurgy Inspired Formation of Homogeneous Al2O3 Coating Layer to Improve the Electrochemical Properties of LiNi0.8Co0.1Mn0.1O2 Cathode Material. ACS Sustain. Chem. Eng. 2017, 5, 10199–10205. [Google Scholar] [CrossRef]

- Singh, K.; Ul Haq, M.I.; Mohan, S. Tribological Behavior of Novel Al2O3-La2O3 HVOF Composite Coatings. Tribol. Int. 2024, 193, 109427. [Google Scholar] [CrossRef]

- Wang, R.; He, X.; Gao, Y.; Zhang, X.; Yao, X.; Tang, B. Antimicrobial Property, Cytocompatibility and Corrosion Resistance of Zn-Doped ZrO2/TiO2 Coatings on Ti6Al4V Implants. Mater. Sci. Eng. C 2017, 75, 7–15. [Google Scholar] [CrossRef] [PubMed]

- Nikoomanzari, E.; Fattah-alhosseini, A.; Pajohi Alamoti, M.R.; Keshavarz, M.K. Effect of ZrO2 Nanoparticles Addition to PEO Coatings on Ti–6Al–4V Substrate: Microstructural Analysis, Corrosion Behavior and Antibacterial Effect of Coatings in Hank’s Physiological Solution. Ceram. Int. 2020, 46, 13114–13124. [Google Scholar] [CrossRef]

- Xu, T.; Liu, J.; Guo, L.; Zhang, Z.; Sun, J. Superior Ablation Resistance of Plasma Sprayed SiC Based Coating by Structural Optimized Powders. J. Mater. Res. Technol. 2024, 32, 2705–2717. [Google Scholar] [CrossRef]

- Zhu, X.; Zhang, Y.; Su, Y.; Fu, Y.; Zhang, P. SiC-Si Coating with Micro-Pores to Protect Carbon/Carbon Composites against Oxidation. J. Eur. Ceram. Soc. 2021, 41, 114–120. [Google Scholar] [CrossRef]

- Eyvazi, Z.; Abdollah-zadeh, A.; Seraj, R.A.; Azarniya, A. Effect of SiC Content on the Microstructure and Wear Behavior of Cold-Sprayed Al-SiC Coatings Deposited on AZ31 Alloy Substrate. Surf. Coat. Technol. 2024, 489, 131170. [Google Scholar] [CrossRef]

- Bello, Z.A.; Kang, M.; Ndumia, J.N.; Geng, C.; Jibril, A.N.; Liu, Z. Microstructure and Wear Behavior of WC-Reinforced AlCoCrFeNiSi High Entropy Alloy Coatings Prepared by High-Velocity Arc Spraying. Surf. Coat. Technol. 2024, 494, 131421. [Google Scholar] [CrossRef]

- Cao, Q.; Fan, L.; Chen, H.; Hou, Y.; Dong, L.; Ni, Z. Wear Behavior of Laser Cladded WC-Reinforced Ni-Based Coatings under Low Temperature. Tribol. Int. 2022, 176, 107939. [Google Scholar] [CrossRef]

- Xian, G.; Xiong, J.; Fan, H.; Jiang, F.; Guo, Z.; Zhao, H.; Xian, L.; Jing, Z.; Liao, J.; Liu, Y. Investigations on Microstructure, Mechanical and Tribological Properties of TiN Coatings Deposited on Three Different Tool Materials. Int. J. Refract. Met. Hard Mater. 2022, 102, 105700. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, Y.; Qin, Y.; Lu, J.; Liu, W. Improvement of TiN Coating on Comprehensive Performance of NiTi Alloy Braided Vascular Stent. Ceram. Int. 2023, 49, 13405–13413. [Google Scholar] [CrossRef]

- Zhang, J.; Chu, S.; Jin, W.; Cai, F.; Zhu, H.; Xiao, S. Fabrication of TiB2 Coatings by Electrophoretic Deposition of Synthesized TiB2 Nanoparticles in Molten Salts. J. Mater. Res. Technol. 2022, 18, 2451–2457. [Google Scholar] [CrossRef]

- Wang, X.Y.; Hu, Y.; Yang, Y.; Wang, Y.W.; Li, W.; Shao, Y.X.; Sun, W.W.; Zhao, H.J.; Ma, Y.D. Microstructure Evolution and Hardening Mechanism of Plasma-Sprayed TiB2 Nanocomposite Coating. J. Alloys Compd. 2024, 1007, 176389. [Google Scholar] [CrossRef]

- Geng, J.; Yang, X.; Wang, G.; Yin, M.; Li, J.; Li, Y. Effect of TiB2 Content on the Microstructure, Corrosion Behavior, and Wear Resistance of (Fe50Mn30Co10Cr10)0.8-x (TiB2)x Mo0.2 High-Entropy Alloy Coatings by Laser Cladding. Surf. Coat. Technol. 2025, 496, 131662. [Google Scholar] [CrossRef]

- Fan, Z.; Tan, Q.; Kang, C.; Huang, H. Advances and Challenges in Direct Additive Manufacturing of Dense Ceramic Oxides. Int. J. Extrem. Manuf. 2024, 6, 052004. [Google Scholar] [CrossRef]

- Sun, H.; Zou, B.; Wang, X.; Chen, W.; Zhang, G.; Quan, T.; Huang, C. Advancements in Multi-Material Additive Manufacturing of Advanced Ceramics: A Review of Strategies, Techniques and Equipment. Mater. Chem. Phys. 2024, 319, 129337. [Google Scholar] [CrossRef]

- Zhang, W.T.; Wang, X.Q.; Zhang, F.Q.; Cui, X.Y.; Fan, B.B.; Guo, J.M.; Guo, Z.M.; Huang, R.; Huang, W.; Li, X.B.; et al. Frontiers in High Entropy Alloys and High Entropy Functional Materials. Rare Metals 2024, 43, 4639–4776. [Google Scholar] [CrossRef]

- Sun, X.; Zhang, J.; Pan, W.; Wang, W.; Tang, C. Research Progress in Surface Strengthening Technology of Carbide-Based Coating. J. Alloys Compd. 2022, 905, 164062. [Google Scholar] [CrossRef]

- Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.B. Microstructural Development in Equiatomic Multicomponent Alloys. Mater. Sci. Eng. A 2004, 375–377, 213–218. [Google Scholar] [CrossRef]

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Miracle, D.B.; Senkov, O.N. A Critical Review of High Entropy Alloys and Related Concepts. Acta Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef]

- Wright, A.J.; Luo, J. A Step Forward from High-Entropy Ceramics to Compositionally Complex Ceramics: A New Perspective. J. Mater. Sci. 2020, 55, 9812–9827. [Google Scholar] [CrossRef]

- Rost, C.M.; Sachet, E.; Borman, T.; Moballegh, A.; Dickey, E.C.; Hou, D.; Jones, J.L.; Curtarolo, S.; Maria, J.P. Entropy-Stabilized Oxides. Nat. Commun. 2015, 6, 8485. [Google Scholar] [CrossRef]

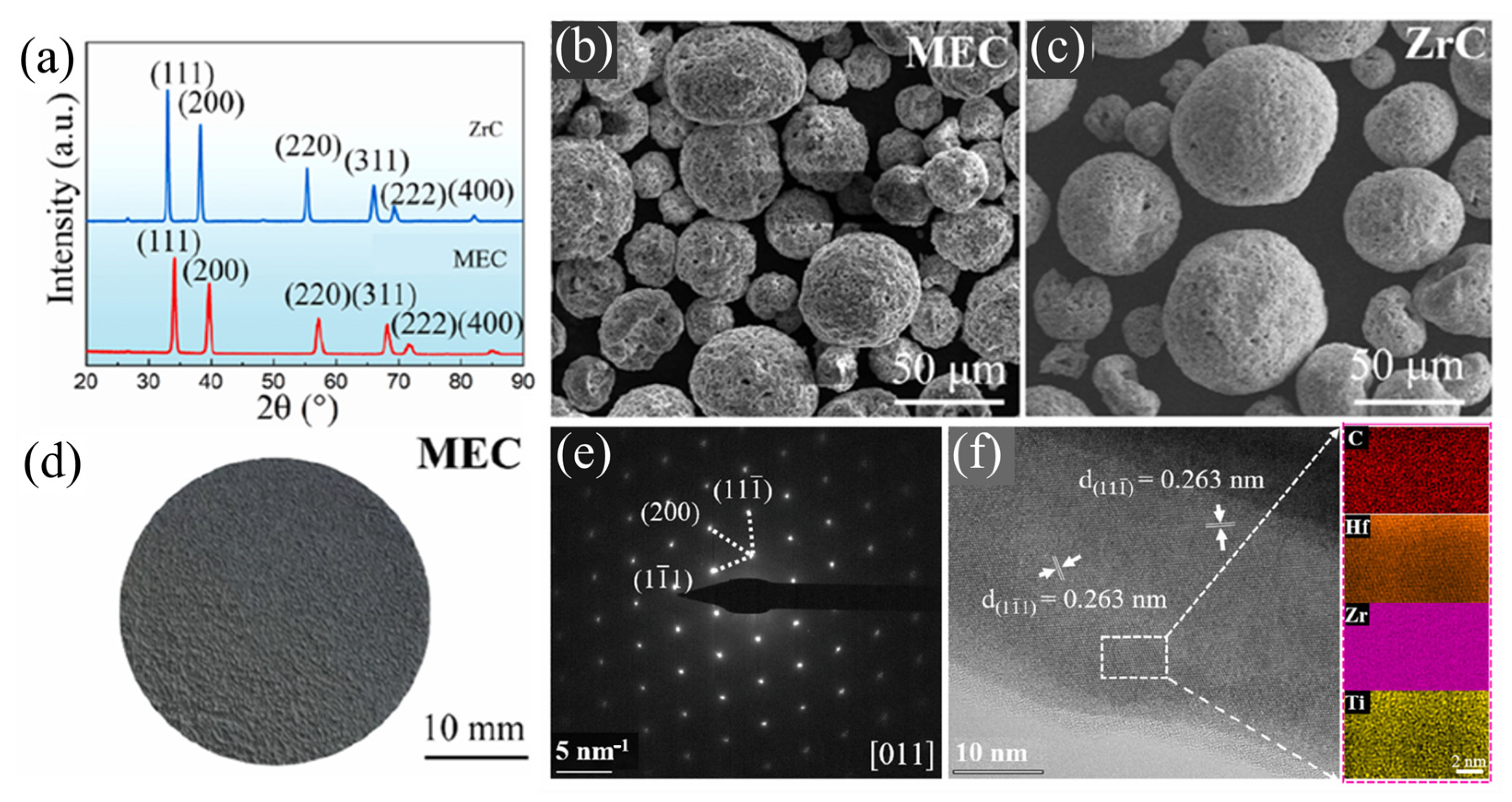

- Li, J.; Zhang, Y.; Zhao, Y.; Zou, Y.; Lv, J.; Li, J. A Novel (Hf1/3Zr1/3Ti1/3)C Medium-Entropy Carbide Coating with Excellent Long-Life Ablation Resistance Applied above 2100 °C. Compos. B Eng. 2023, 251, 110467. [Google Scholar] [CrossRef]

- Li, J.; Lu, F.; Li, T.; Lv, J.; Zhu, F.; Zhang, Y. The Interface Interaction within Multi-Phase Oxides on the Ablation Behavior of the (Hf0.25Zr0.25Ti0.5)C-Coated C/C Composites. Surf. Coat. Technol. 2024, 493, 131293. [Google Scholar] [CrossRef]

- Li, J.; Zhang, Y.; Fu, Y.; Li, T.; Zhang, J.; Yang, D.; Cao, L.; Lu, F.; Zhao, J.; Lv, J.; et al. Twin Toughening-Driven Martensitic Transformation Strategy Synergistic Improvement for Plasticity-Thermal Shock Resistance of (Hf–Zr–Ti)C Ceramic Coating in Severe Thermal Environments. Adv. Sci. 2025, 12, 2503226. [Google Scholar] [CrossRef] [PubMed]

- Song, X.; Yan, H.; Cui, T.; Ye, L.; Han, W.; Yan, S.; Zhang, Z. Ablation Behavior of Medium Entropy Carbide Ceramics with Different Molar Ratios of (Hf, Zr, Ti)C in Oxyacetylene Flame. Ceram. Int. 2025, 51, 5987–5997. [Google Scholar] [CrossRef]

- Gao, S.; Wang, Y.; Hu, J.; Zeng, Y.; Xiong, X. Ablation Behaviour of Multi-Component (Hf, Zr, Ti)C Ceramics Modified Carbon/Carbon Composites. J. Eur. Ceram. Soc. 2025, 45, 117141. [Google Scholar] [CrossRef]

- Haibo, O.; Zihao, C.; Cuiyan, L.; Tianzhan, S.; Jintao, W.; Qianqian, C.; Ruinan, G. C/C-(HfZrTi)C Composites Prepared by a Novel Precursor Infiltration and Pyrolysis Method: A Silicon-Free Strategy to Improve the Ablation Resistance at Ultra-High Temperatures. J. Alloys Compd. 2025, 1036, 181690. [Google Scholar] [CrossRef]

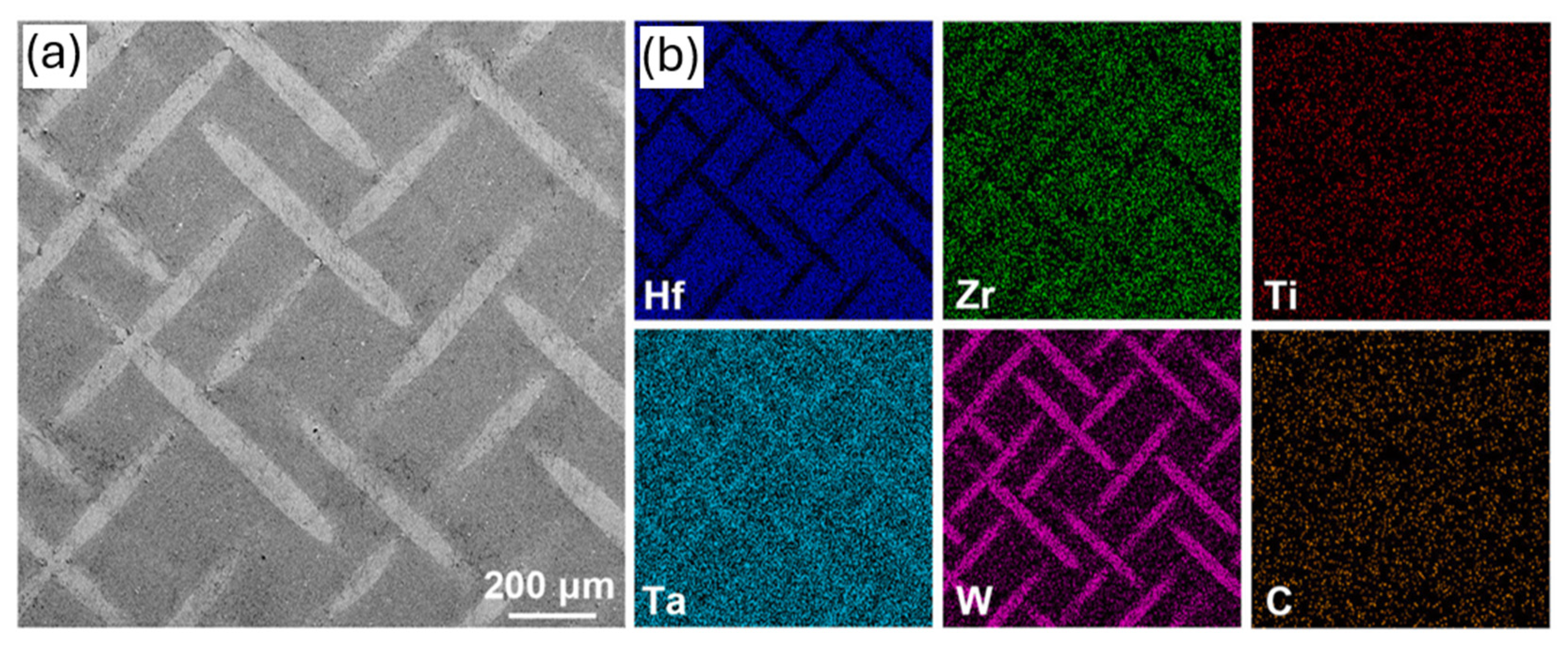

- Xu, J.; Sun, W.; Xiong, X.; Zhang, H. C/C-(Hf0.5Zr0.3Ti0.2)C–W–Cu Composites: Long-Term Ablation Resistance Based on Active-Passive Protection at 2600 °C. Compos. B Eng. 2025, 289, 111889. [Google Scholar] [CrossRef]

- Zhang, X.; Luo, X.; Liu, Z.; Zuo, Y.; Yang, X.; Huang, Q. Effect of (Ti, Zr, Hf)C Medium-Entropy and (Ti, Zr, Hf, Ta)C High-Entropy Modification on Microstructure and Ablative Properties of C/C-SiC Composites. Mater. Charact. 2025, 223, 114952. [Google Scholar] [CrossRef]

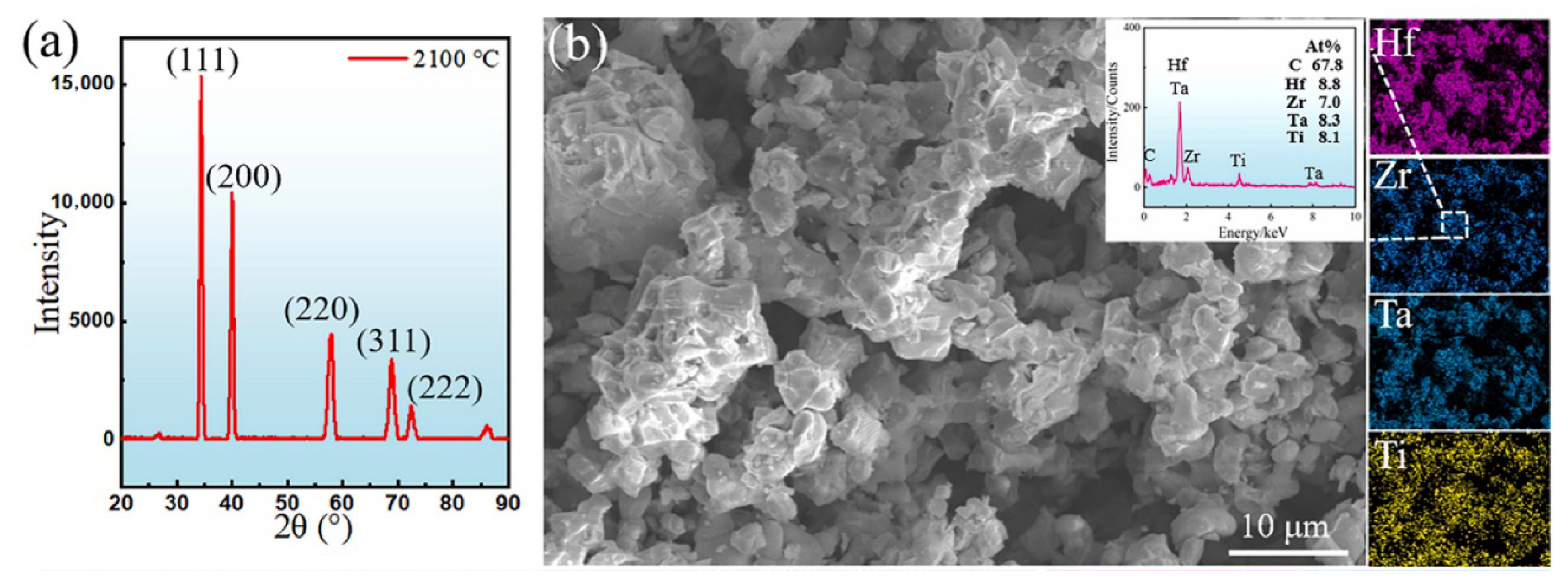

- Zhang, J.; Li, T.; Fu, Y.; Lv, J.; Chen, H.; Zhang, Y.; Bao, Y.; Wang, X. Ablation Resistance of (Hf⅓Zr⅓Ta⅓)C Solid Solution Ceramic Coating for Carbon/Carbon Composites at 2100 °C. Ceram. Int. 2024, 50, 45232–45241. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, Z.; Zhu, L.; Ye, Y.; Li, F.; Gong, J.; Bai, S. In-Situ Preparation and Ablative Resistance of Multicomponent Refractory Carbide Ceramic Gradient Coatings. Ceram. Int. 2024, 50, 38070–38078. [Google Scholar] [CrossRef]

- Li, J.; Zhao, J.; Li, T.; Li, J.; Yang, D.; Fu, Y.; Lv, J.; Guo, L.; Zhang, Y. Microstructure Evolution and Phase Interface Characterization in Anti-Ablation (Hf1/4Zr1/4Ta1/4Ti1/4)C-Coated C/C Composites. Compos. B Eng. 2024, 281, 111569. [Google Scholar] [CrossRef]

- Li, Y.; Qin, F.; Li, R.; Wang, X.; Qin, Y.; Hu, L.; Ma, E.; Sun, J.; Ding, X. Decent Ablative Resistance, Enhanced Thermal Conductivity and High Mechanical Properties of High-Entropy (Hf, Zr, Ti, Ta)C-W Composites. Ceram. Int. 2025, 51, 14608–14618. [Google Scholar] [CrossRef]

- Li, X.; Zhang, M.; Hu, D.; Chen, S.; Yan, Z.; Fu, Q. Long-Term Performance Optimization on (Hf-Zr-Ta-Nb)C Coatings above 2000 °C: Element, Composition and Ablation Property. J. Eur. Ceram. Soc. 2025, 45, 117403. [Google Scholar] [CrossRef]

- Guo, L.; Huang, S.; Li, W.; Lv, J.; Sun, J. Theoretical Design and Experimental Verification of High-Entropy Carbide Ablative Resistant Coating. Adv. Powder Mater. 2024, 3, 100213. [Google Scholar] [CrossRef]

- Tang, L.; Pan, Q.; Yan, K.; Wang, J.; Gao, Z.; Wang, L.; Huang, W. Competition between Strong and Weak Carbide-Forming Elements in Monolayer Mixed Oxide Formation on (TiZrNbMoAl)C: Experimental and First-Principles Study. Ceram. Int. 2025, 51, 26948–26959. [Google Scholar] [CrossRef]

- Ciulli, E. Tribology and Industry: From the Origins to 4.0. Front. Mech. Eng. 2019, 5, 469821. [Google Scholar] [CrossRef]

- Braic, V.; Vladescu, A.; Balaceanu, M.; Luculescu, C.R.; Braic, M. Nanostructured Multi-Element (TiZrNbHfTa)N and (TiZrNbHfTa)C Hard Coatings. Surf. Coat. Technol. 2012, 211, 117–121. [Google Scholar] [CrossRef]

- Sun, Q.; Geng, Y.; Bian, Z.; Zhu, Z.; Zhu, S.; Cheng, J.; Yang, J.; Liu, W. The Self-Lubrication Property of Single-Phase High-Entropy Carbide Ceramic under Tribo-Induced Effect. J. Eur. Ceram. Soc. 2024, 44, 116704. [Google Scholar] [CrossRef]

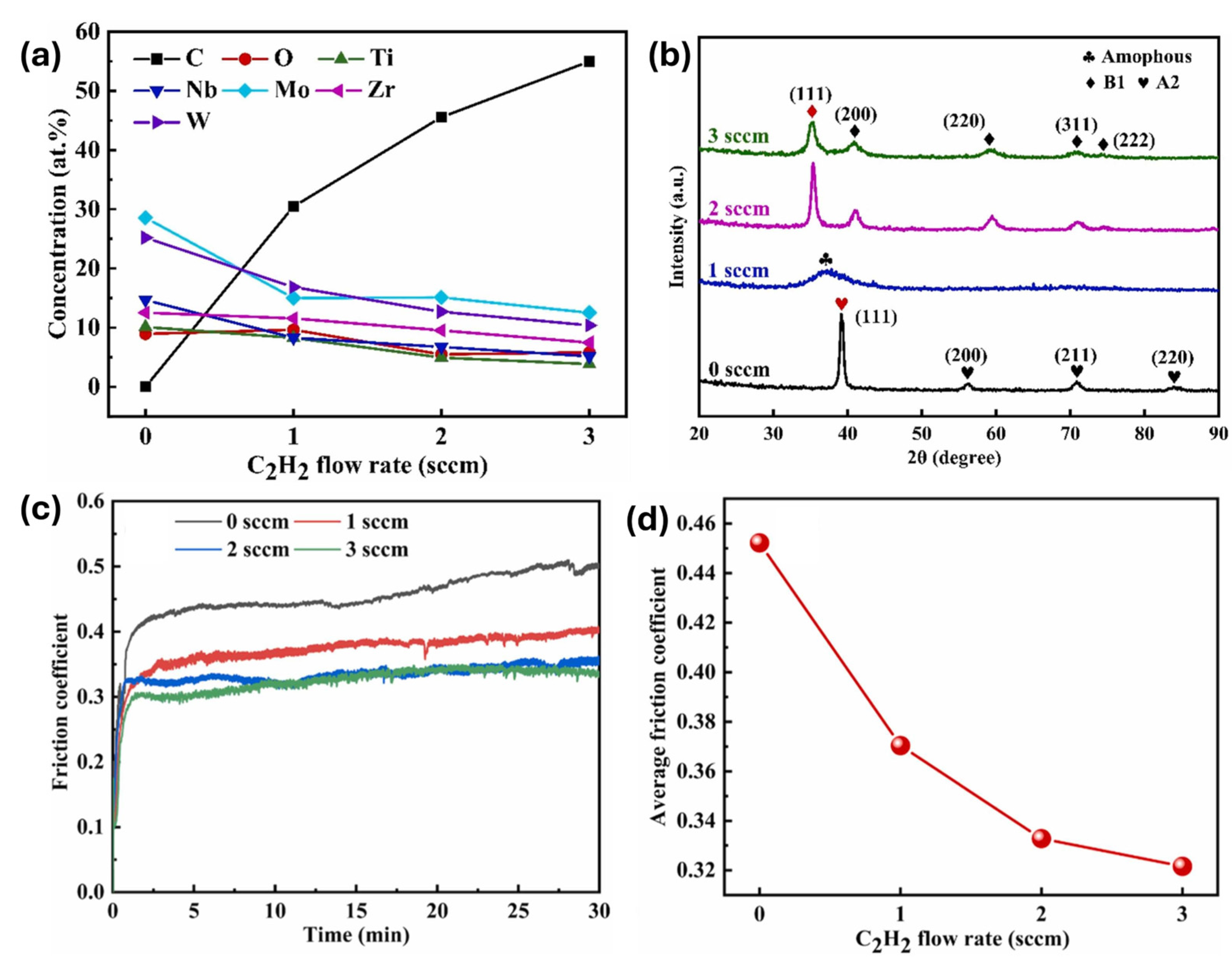

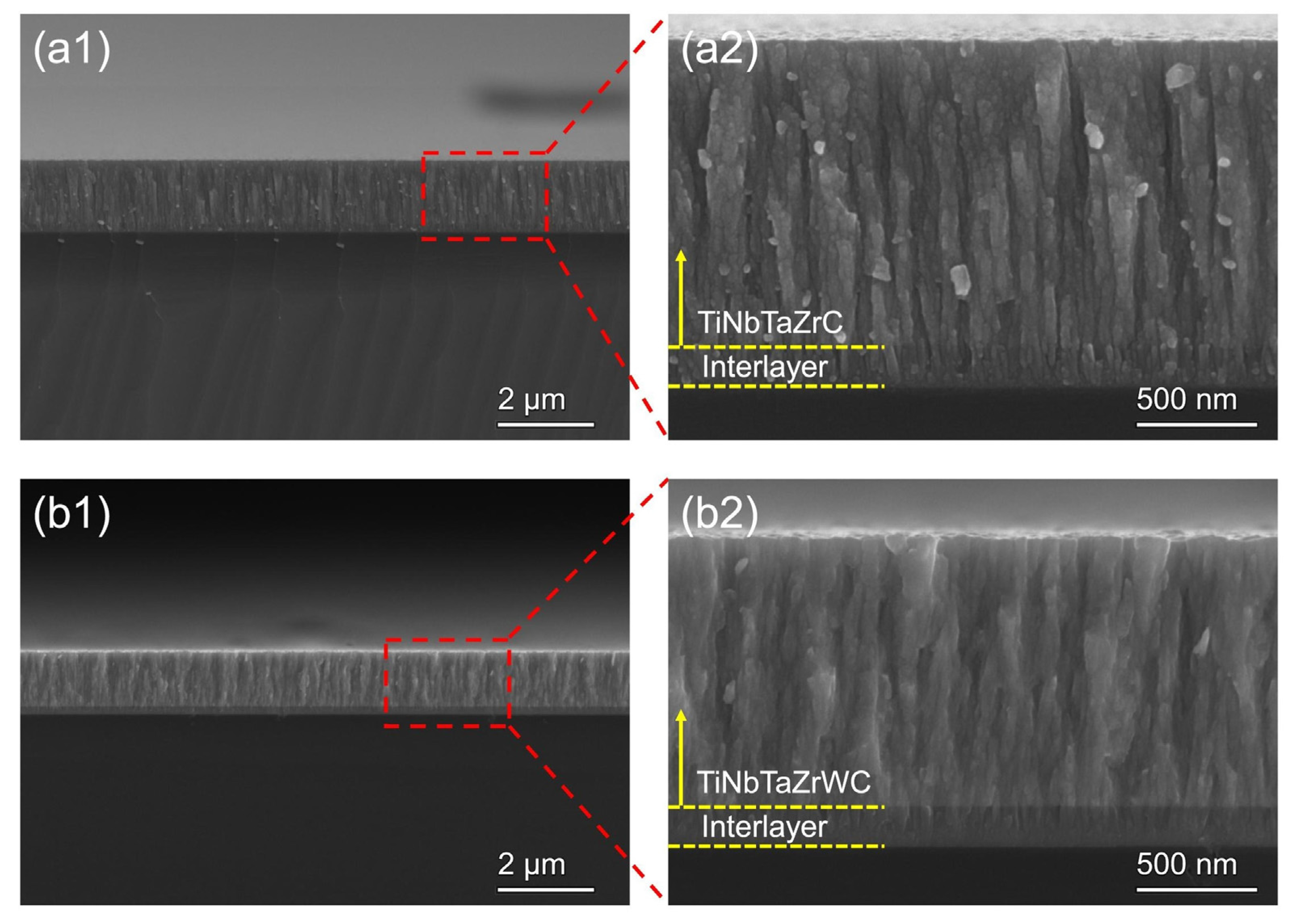

- Wang, L.; Yang, J.; Tian, Z.; Wu, L.; Wang, J. Microstructure, Mechanical and Tribological Behavior of High-Entropy (TiNbMoZrW)Cx Coatings Prepared by Reactive Magnetron Sputtering. Mater. Today Commun. 2025, 46, 112750. [Google Scholar] [CrossRef]

- Shi, X.; Xu, F.; Gao, C.; Zhou, Q.; Zhang, H.; Zhao, W.; Ge, Y.; Zuo, D. Microstructure, Mechanical and Wear Mechanisms of NbTaMoWAlC High Entropy Ceramics Coating Designed Based on Chemical Descriptors. Mater. Today Commun. 2025, 46, 112831. [Google Scholar] [CrossRef]

- Gao, C.; Xu, F.; Shi, X.; Zhao, W.; Zhou, Q.; Liu, Y.; Zhan, Q.; Zuo, D. Enhanced Tribo-Corrosion Resistance of Biocompatible TiNbTaZrWC Coating through Intelligent Design Strategy. Chem. Eng. J. 2025, 504, 158740. [Google Scholar] [CrossRef]

- Li, Y.; Du, Y.; Pei, X.; Li, T.; Wu, H.; Zhou, W.; Wang, H.; Liu, W. High-Temperature Tribological Behavior and Mechanisms of a High Entropy Carbide Ceramic. J. Eur. Ceram. Soc. 2025, 45, 117170. [Google Scholar] [CrossRef]

- Sun, W.W.; Hu, Y.; Yang, Y.; Zhao, H.J.; Wang, Y.W.; Li, W.; Shao, Y.X.; Ru, P.W.; Ma, Y.D.; Gao, S.Y.; et al. The Influence of Metal Element Types on the Formation Mechanism and Properties of High-Entropy Ceramic Powders and Coatings. J. Alloys Compd. 2025, 1010, 177680. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lopes, J.G.; Oliveira, J.P. An Insight into Compositionally Complex Carbide Ceramic Coatings. Materials 2025, 18, 3953. https://doi.org/10.3390/ma18173953

Lopes JG, Oliveira JP. An Insight into Compositionally Complex Carbide Ceramic Coatings. Materials. 2025; 18(17):3953. https://doi.org/10.3390/ma18173953

Chicago/Turabian StyleLopes, J. G., and J. P. Oliveira. 2025. "An Insight into Compositionally Complex Carbide Ceramic Coatings" Materials 18, no. 17: 3953. https://doi.org/10.3390/ma18173953

APA StyleLopes, J. G., & Oliveira, J. P. (2025). An Insight into Compositionally Complex Carbide Ceramic Coatings. Materials, 18(17), 3953. https://doi.org/10.3390/ma18173953