Sustainable PLA Composites Filled with Poaceae Fibers: Thermal, Structural, and Mechanical Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Fiber Processing

2.2.1. Alkaline Maceration with Potassium Hydroxide

2.2.2. Boiling

2.3. Preparation of Granulate

2.4. Injection Moulding Process

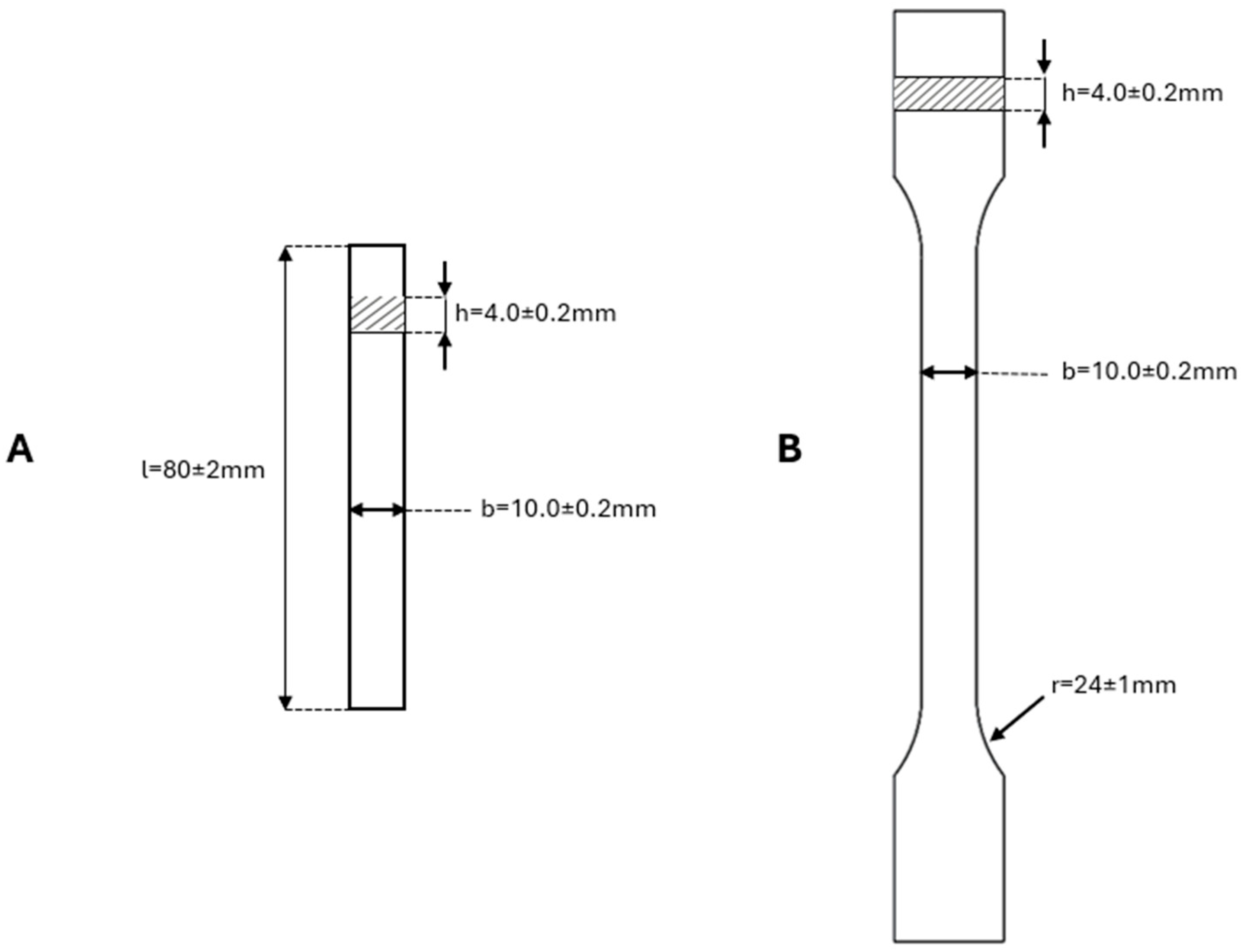

2.5. Analysis

3. Results

3.1. Filler Analysis

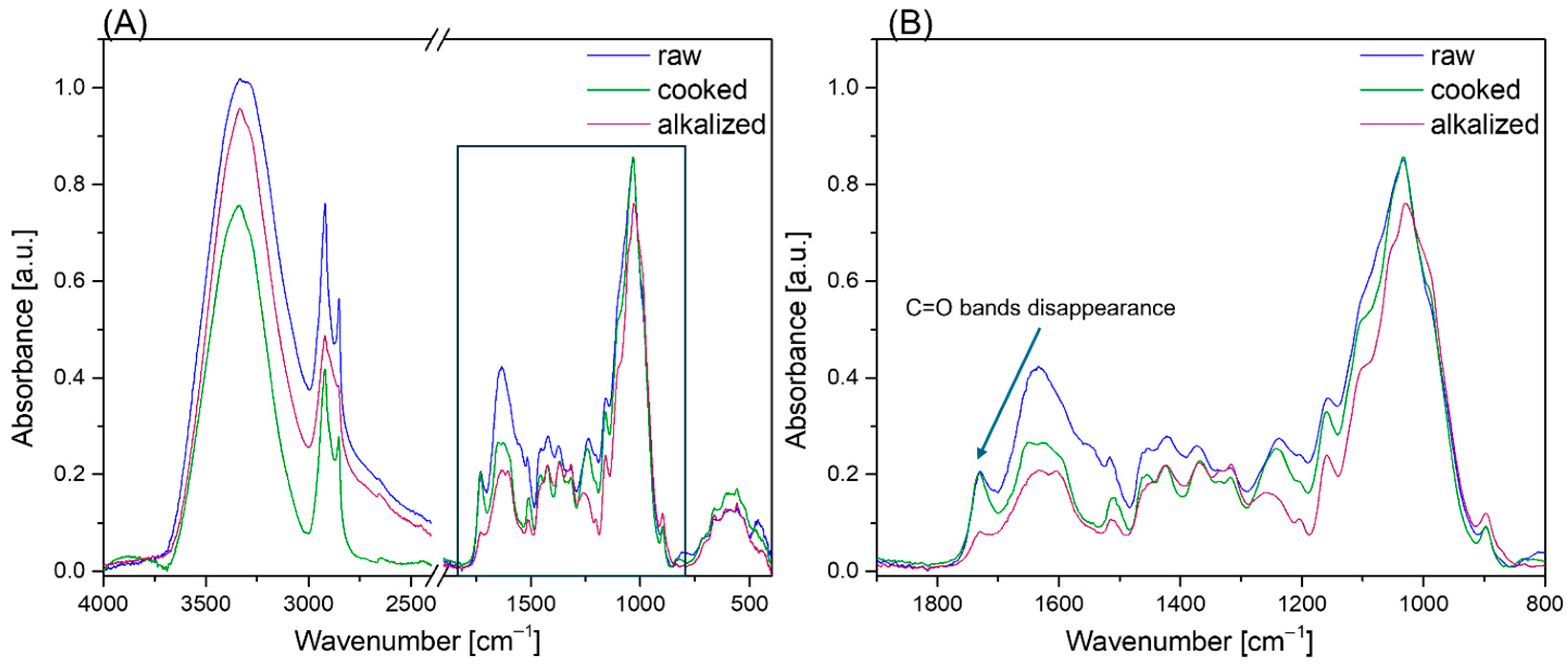

3.1.1. FTIR Analysis

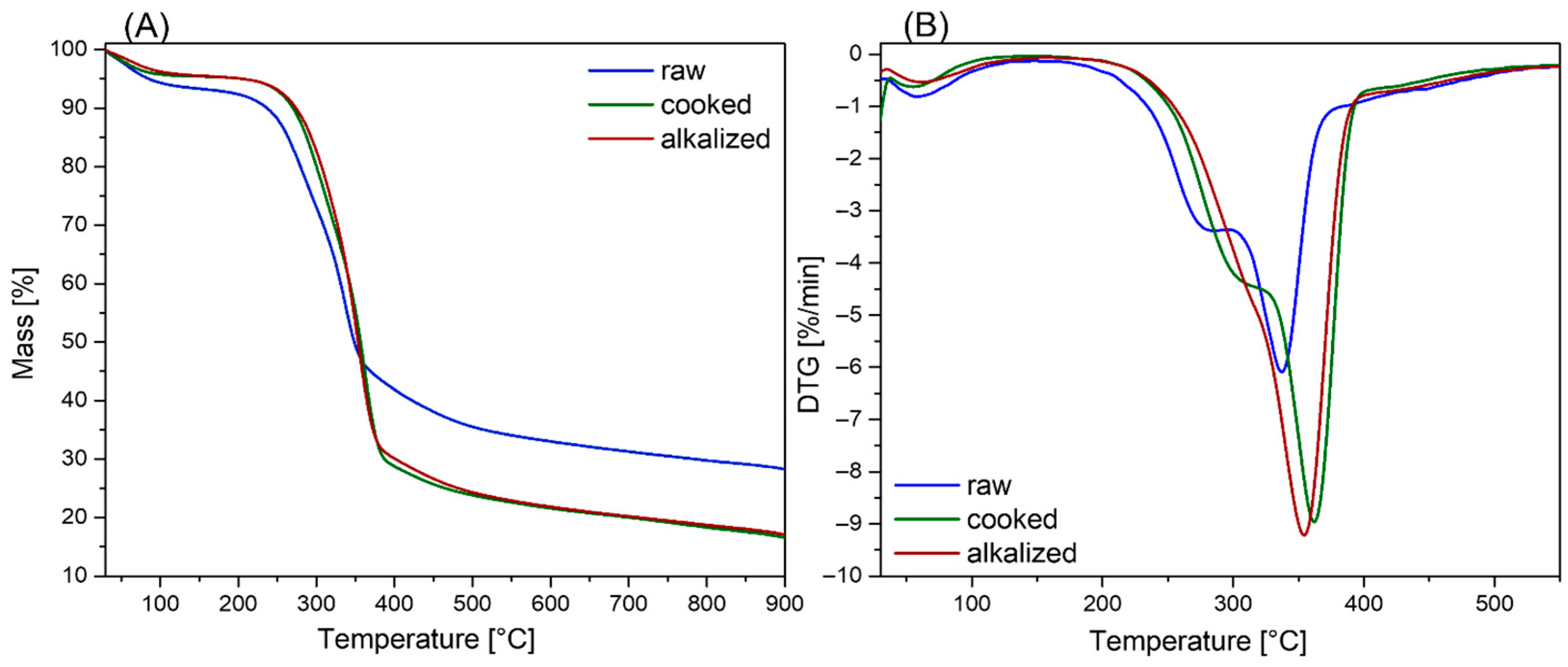

3.1.2. TGA Analysis

3.1.3. Microscopy

3.2. Analysis of PLA/Fiber Composites

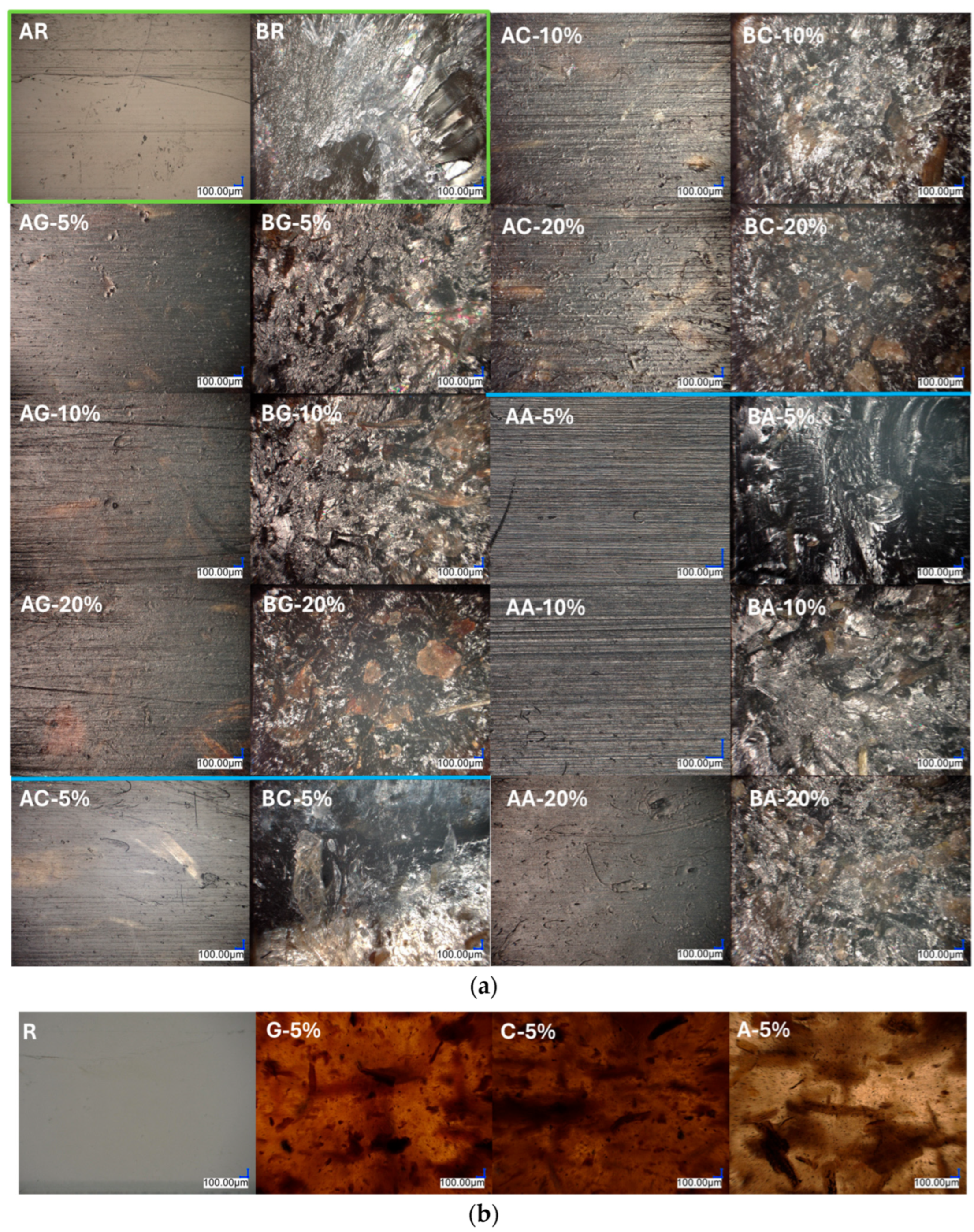

3.2.1. Optical Microscopy

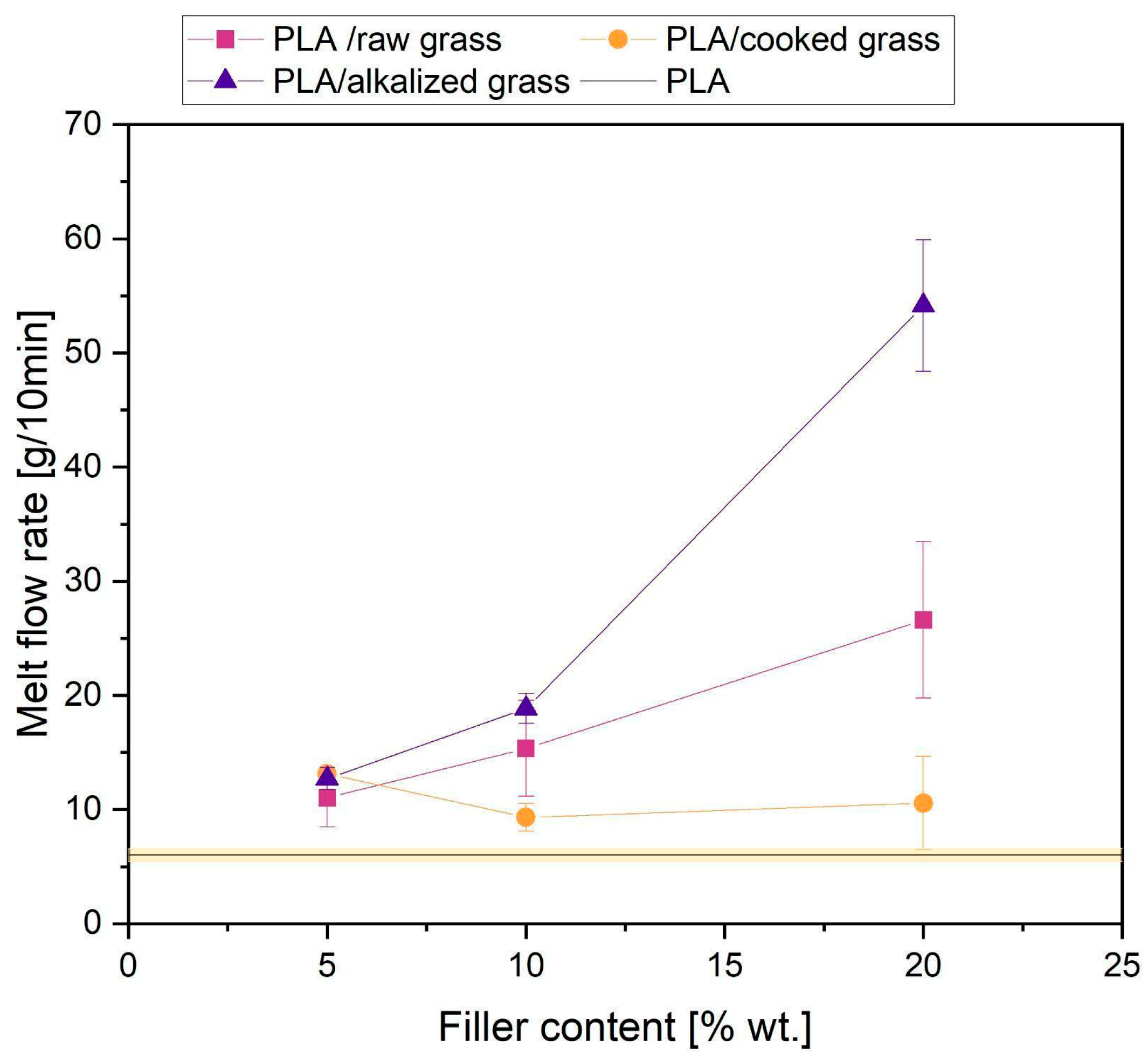

3.2.2. Melt Flow Index (MFI)

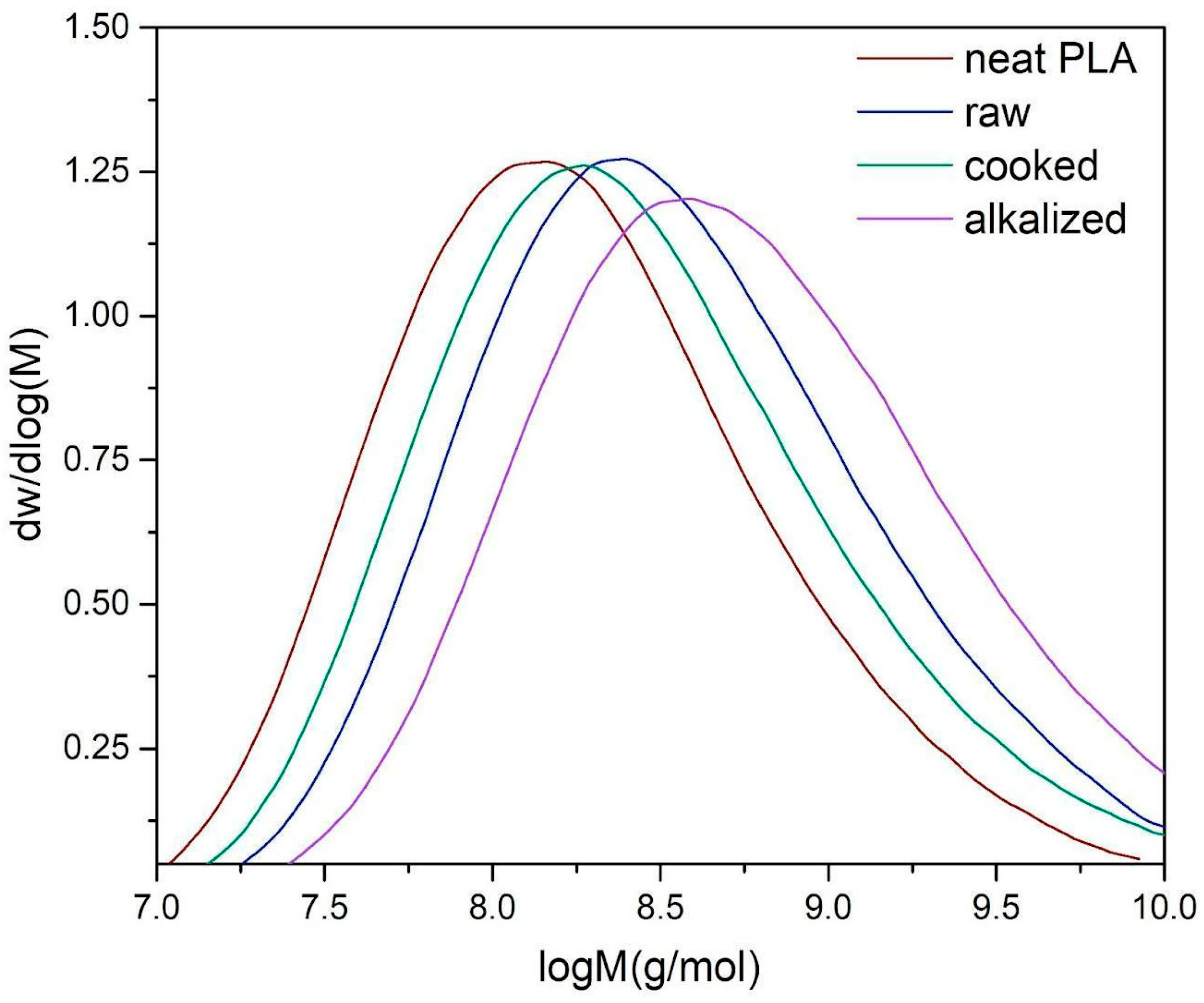

3.2.3. Gel Permeation Chromatography (GPC)

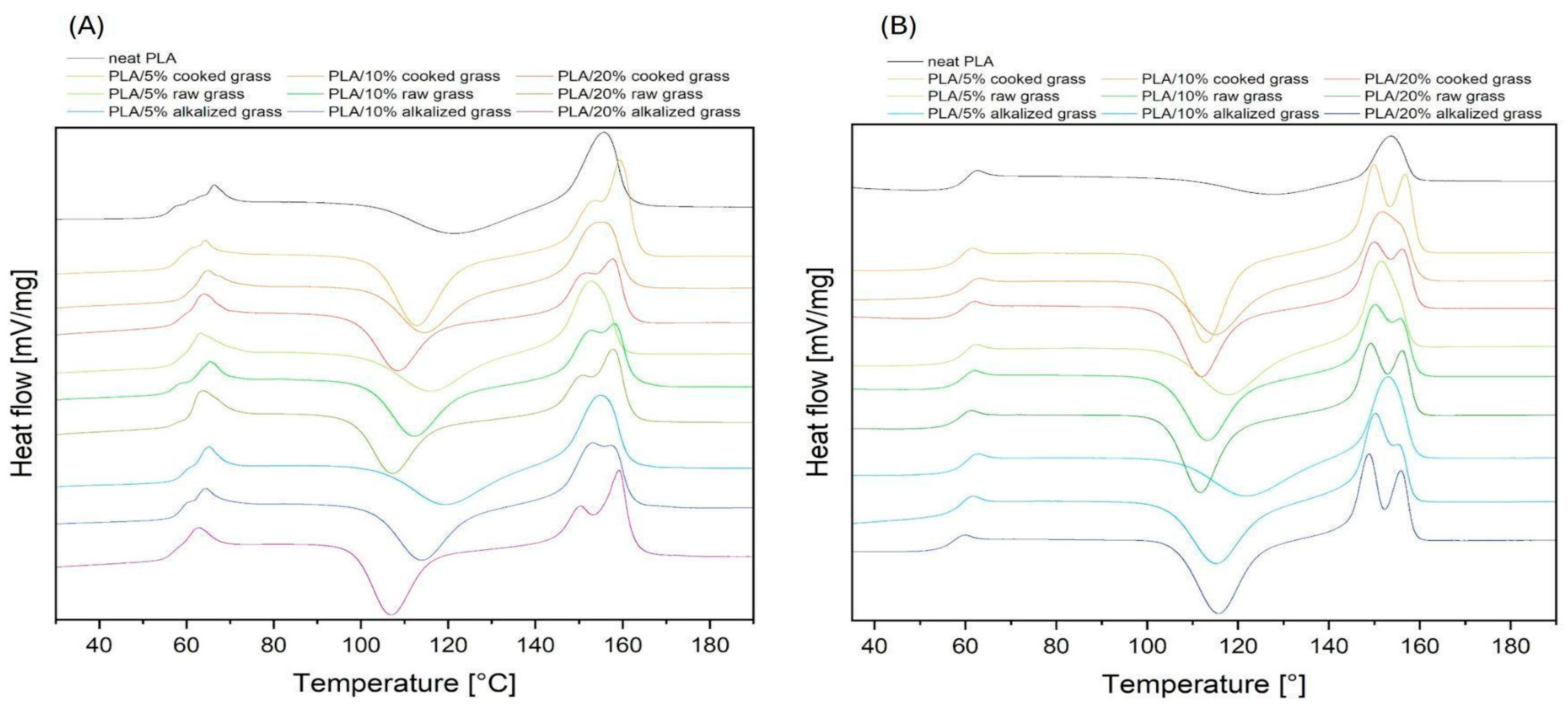

3.2.4. DSC Results—Tg, Tcc, and Tm of PLA Composites

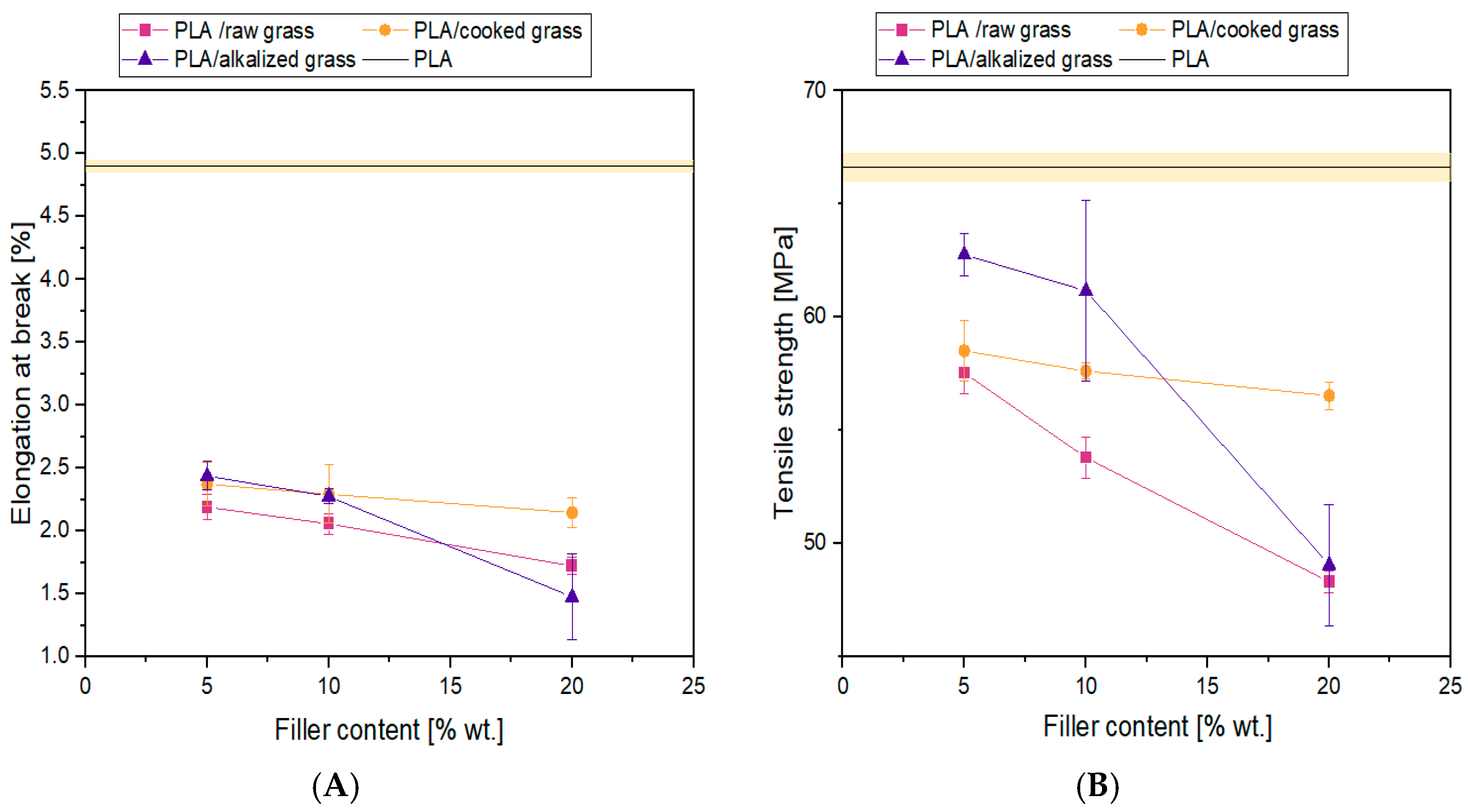

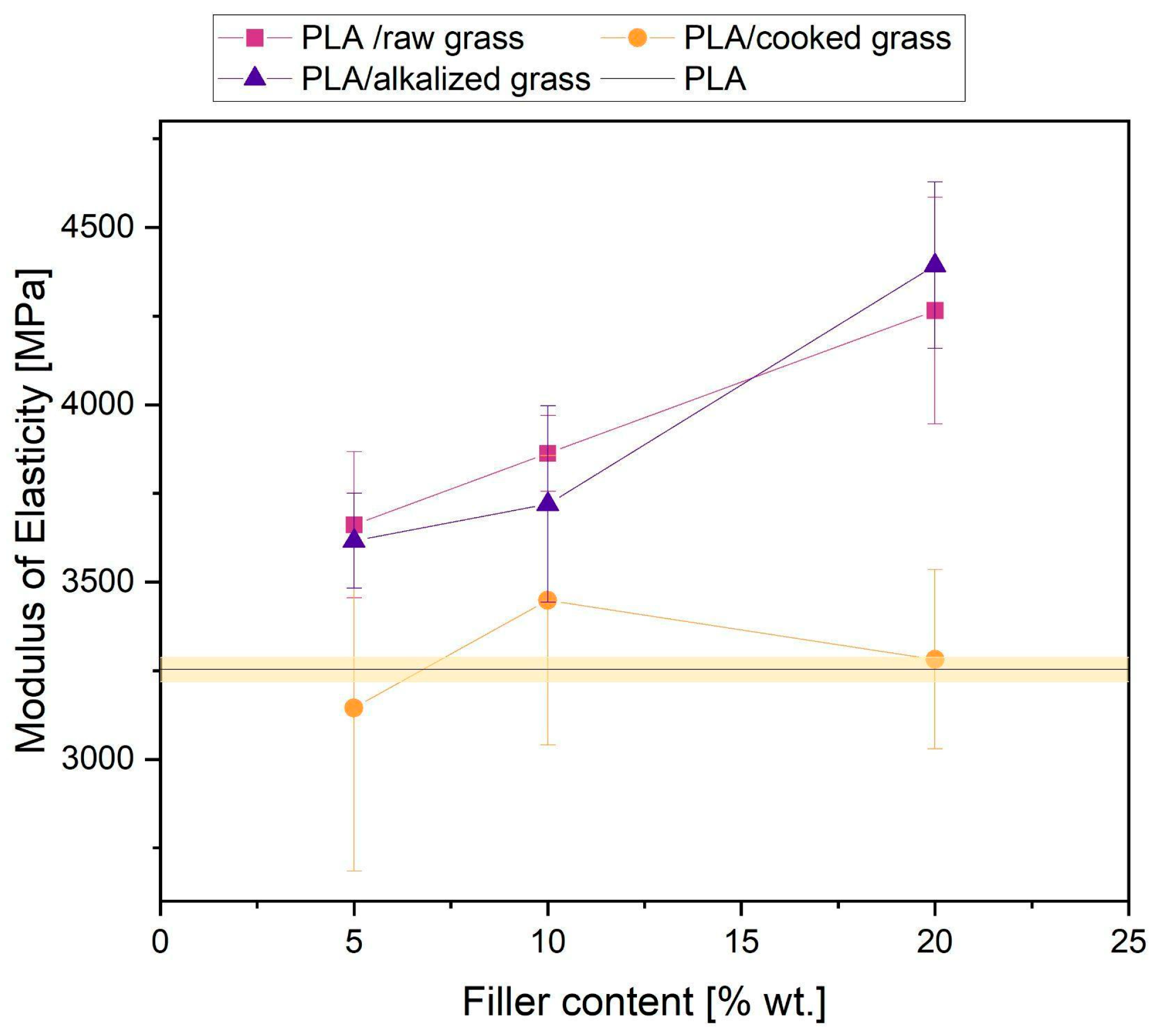

3.2.5. Tensile Strength of PLA Composites with Poaceae-Based Fillers: Influence of Filler Content and Fiber Treatment

3.2.6. Impact Strength of PLA Composites with Poaceae Fillers

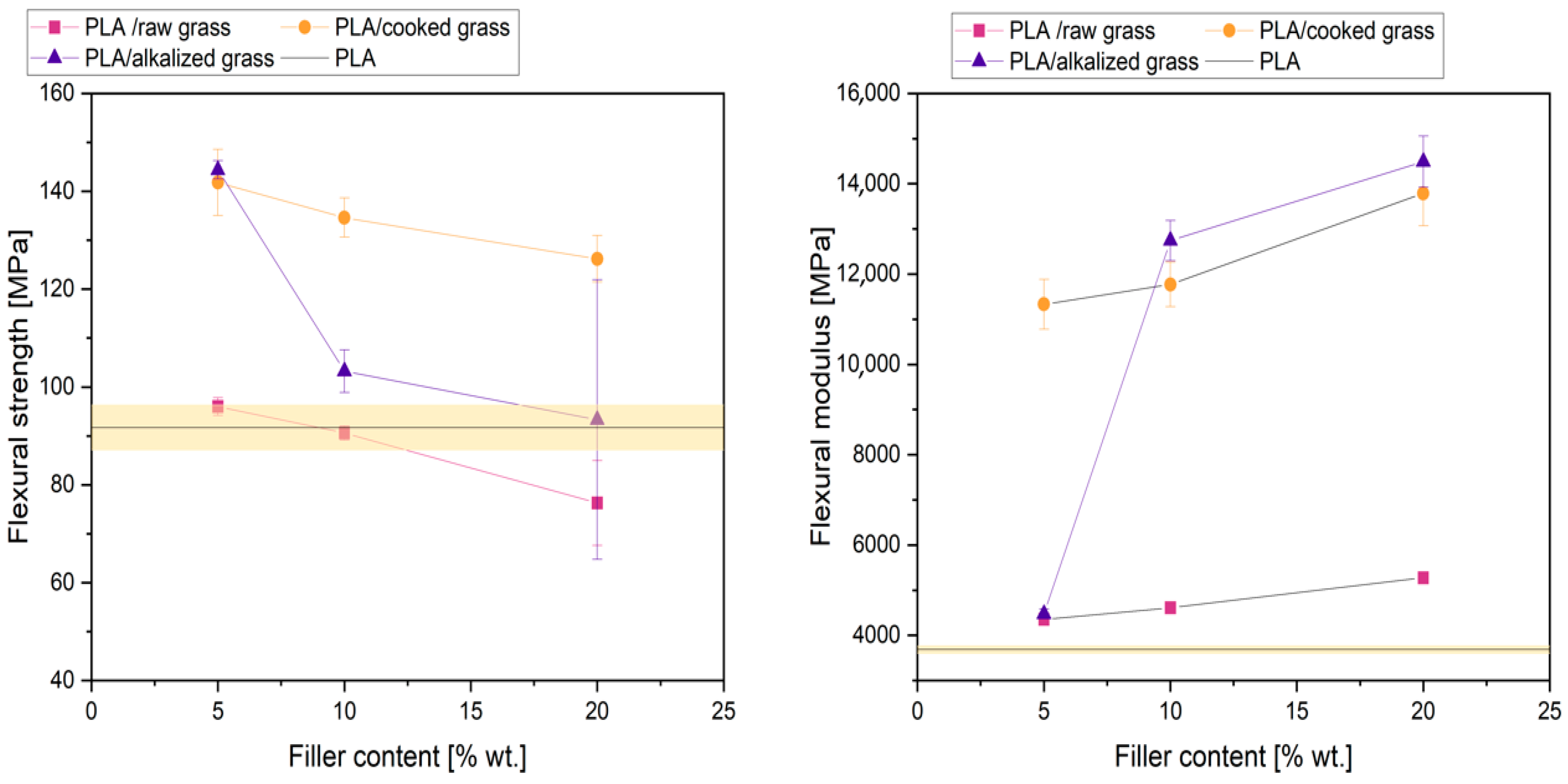

3.2.7. Flexural Strength and Flexural Modulus Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef] [PubMed]

- Barnes, D.K.A.; Galgani, F.; Thompson, R.C.; Barlaz, M. Accumulation and fragmentation of plastic debris in global environments. Philos. Trans. R. Soc. Lond. B Biol. Sci. 2009, 364, 1985–1998. [Google Scholar] [CrossRef]

- Peelman, N.; Ragaert, P.; De Meulenaer, B.; Adons, D.; Peeters, R.; Cardon, L.; Van Impe, F.; Devlieghere, F. Application of bioplastics for food packaging. Trends Food Sci. Technol. 2013, 32, 128–141. [Google Scholar] [CrossRef]

- Gołębiewski, J.; Gibas, E.; Malinowski, R. Wybrane Polimery Biodegradowalne—Otrzymywanie, Właściwości, Zastosowanie. Available online: https://yadda.icm.edu.pl/baztech/element/bwmeta1.element.baztech-article-BAT7-0013-0002 (accessed on 10 June 2025).

- EUBIO_Admin Market. Available online: https://www.european-bioplastics.org/market/ (accessed on 10 June 2025).

- Jamshidian, M.; Tehrany, E.A.; Imran, M.; Jacquot, M.; Desobry, S. Poly—Lactic Acid: Production, Applications, Nanocomposites, and Release Studies. Compr. Rev. Food Sci. Food Saf. 2010, 9, 552–571. [Google Scholar] [CrossRef] [PubMed]

- Kale, G.; Kijchavengkul, T.; Auras, R.; Rubino, M.; Selke, S.E.; Singh, S.P. Compostability of Bioplastic Packaging Materials: An Overview. Macromol. Biosci. 2007, 7, 255–277. [Google Scholar] [CrossRef] [PubMed]

- Garlotta, D. A Literature Review of Poly(Lactic Acid). J. Polym. Environ. 2001, 9, 63–84. [Google Scholar] [CrossRef]

- Zuza, E.; Meaurio, E.; Sarasua, J.-R. Biodegradable Polylactide-Based Composites. In Composites from Renewable and Sustainable Materials; InTech: London, UK, 2016. [Google Scholar]

- Ramanjaneyulu, B.; Venkatachalapathi, N.; Prasanthi, G. Thermal and Mechanical Properties of PLA/ABS/TCS Polymer Blend Composites. J. Inst. Eng. (India) Ser. C 2021, 102, 799–806. [Google Scholar] [CrossRef]

- El-Taweel, S.H.; Abboudi, M. Nonisothermal crystallization kinetics of PLA/nanosized YVO4 composites as a novel nucleating agent. J. Appl. Polym. Sci. 2019, 137, 48340. [Google Scholar] [CrossRef]

- Brząkalski, D.; Sztorch, B.; Frydrych, M.; Pakuła, D.; Dydek, K.; Kozera, R.; Boczkowska, A.; Marciniec, B.; Przekop, R.E. Limonene Derivative of Spherosilicate as a Polylactide Modifier for Applications in 3D Printing Technology. Molecules 2020, 25, 5882. [Google Scholar] [CrossRef]

- Kulinski, Z.; Piorkowska, E.; Gadzinowska, K.; Stasiak, M. Plasticization of Poly(l–lactide) with Poly(propylene glycol). Biomacromolecules 2006, 7, 2128–2135. [Google Scholar] [CrossRef]

- Marin, N.M. Green Chemistry Applications Using Complexing Materials for Water Treatment. Polymers 2025, 17, 1467. [Google Scholar] [CrossRef]

- Abraha, K.G.; Debeli, D.K.; Ghani, M.U.; Zhou, B.; Tesfahunegn, A.A.; Guo, J. Enhancing enset fiber-reinforced polylactic acid composites through different surface treatments for emerging applications. Polym. Compos. 2024, 46, 5140–5155. [Google Scholar] [CrossRef]

- Sholokhova, A.; Varžinskas, V.; Rutkaitė, R. Valorization of Agro-waste in Bio-based and Biodegradable Polymer Composites: A Comprehensive Review with Emphasis on Europe Perspective. Waste Biomass Valorization 2024, 16, 1537–1571. [Google Scholar] [CrossRef]

- Vinod, B.; Murthy, B.V.; Ramesh, V.; Venkataramana, P. Extraction and Performance of Novel Lignocellulose from Agro-Wastes: Synergistic Integration of Waste into Ecofriendly Polymer Composites. Key Eng. Mater. 2025, 1013, 41–56. [Google Scholar] [CrossRef]

- Członka, S.; Strąkowska, A.; Kairytė, A. Effect of walnut shells and silanized walnut shells on the mechanical and thermal properties of rigid polyurethane foams. Polym. Test. 2020, 87, 106534. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Zuhri, M.Y.M.; Aisyah, H.A.; Asyraf, M.R.M.; Hassan, S.A.; Zainudin, E.S.; Sapuan, S.M.; Sharma, S.; Bangar, S.P.; Jumaidin, R.; et al. Natural Fiber-Reinforced Polylactic Acid, Polylactic Acid Blends and Their Composites for Advanced Applications. Polymers 2022, 14, 202. [Google Scholar] [CrossRef]

- Guo, R.; Azaiez, J.; Bellehumeur, C. Rheology of fiber filled polymer melts: Role of fiber-fiber interactions and polymer-fiber coupling. Polym. Eng. Sci. 2005, 45, 385–399. [Google Scholar] [CrossRef]

- Liang, J.; Li, R.; Tjong, S. Effects of pressure and temperature on the melt density and the melt flow rate of LDEP and glass bead-filled LDPE composite. J. Mech. Work. Technol. 1999, 91, 167–171. [Google Scholar] [CrossRef]

- Lafranche, E.; Martins, C.I.; Oliveira, V.M.; Krawczak, P. Prediction of Tensile Properties of Injection Moulding Flax Fibre Reinforced Polypropylene from Morphology Analysis. Key Eng. Mater. 2013, 554–557, 1573–1582. [Google Scholar] [CrossRef]

- Lee, C.H.; Sapuan, S.M.; Lee, J.H.; Hassan, M.R. Melt volume flow rate and melt flow rate of kenaf fibre reinforced Floreon/magnesium hydroxide biocomposites. SpringerPlus 2016, 5, 1680. [Google Scholar] [CrossRef]

- Li, X.; Tabil, L.G.; Panigrahi, S. Chemical Treatments of Natural Fiber for Use in Natural Fiber-Reinforced Composites: A Review. J. Polym. Environ. 2007, 15, 25–33. [Google Scholar] [CrossRef]

- Pickering, K.L.; Aruan Efendy, M.G.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef]

- Kumar, G.; Ohkubo, T.; Hono, K. Effect of melt temperature on the mechanical properties of bulk metallic glasses. J. Mater. Res. 2009, 24, 2353–2360. [Google Scholar] [CrossRef]

- Gunti, R.; Prasad, A.R.; Gupta, A. Mechanical and degradation properties of natural fiber-reinforced PLA composites: Jute, sisal, and elephant grass. Polym. Compos. 2016, 39, 1125–1136. [Google Scholar] [CrossRef]

- George, J.; Sreekala, M.S.; Thomas, S. A review on interface modification and characterization of natural fiber reinforced plastic composites. Polym. Eng. Sci. 2001, 41, 1471–1485. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Battegazzore, D.; Noori, A.; Frache, A. Natural wastes as particle filler for poly(lactic acid)-based composites. J. Compos. Mater. 2018, 53, 783–797. [Google Scholar] [CrossRef]

- Salasinska, K.; Polka, M.; Gloc, M.; Ryszkowska, J. Natural fiber composites: The effect of the kind and content of filler on the dimensional and fire stability of polyolefin-based composites. Polimery 2016, 61, 255–265. [Google Scholar] [CrossRef]

- Song, X.; Song, P.; Qin, H.; Meng, H. Fused Deposition Modeling of Montmorillonite Modified Poly (Lactic Acid)/Sunflower Seed Husk Composites. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020. [Google Scholar]

- Salasinska, K.; Barczewski, M.; Borucka, M.; Górny, R.L.; Kozikowski, P.; Celiński, M.; Gajek, A. Thermal Stability, Fire and Smoke Behaviour of Epoxy Composites Modified with Plant Waste Fillers. Polymers 2019, 11, 1234. [Google Scholar] [CrossRef]

- Fayzullin, I.; Gorbachev, A.; Volfson, S.; Serikbayev, Y.; Nakyp, A.; Akylbekov, N. Composite Material Based on Polypropylene and Modified Natural Fillers. Polymers 2024, 16, 1703. [Google Scholar] [CrossRef]

- Kuram, E. UV and thermal weathering of green composites: Comparing the effect of different agricultural waste as fillers. J. Compos. Mater. 2020, 54, 3683–3697. [Google Scholar] [CrossRef]

- Zakrzewska, P.; Zygmunt-Kowalska, B.; Pielichowska, K.; Nowicka-Dunal, K.; Telejko, T.; Kuźnia, M. Effect of the silanization process on the fire resistance and thermal properties of closed-cell foams with sunflower husk ash. Ind. Crop. Prod. 2024, 218. [Google Scholar] [CrossRef]

- Keller, A. Compounding and mechanical properties of biodegradable hemp fibre composites. Compos. Sci. Technol. 2003, 63, 1307–1316. [Google Scholar] [CrossRef]

- Kausar, A.; Ahmad, I. Hemp Fibres: Essentials, Composites or Nanocomposites and Technical Applications. Nano-Horizons J. Nanosci. Nanotechnol. 2023, 2, 28. [Google Scholar] [CrossRef] [PubMed]

- Ari, A.; Karahan, M.; Kopar, M.; Ahrari, M.; Khan, R.M.W.U.; Hussain, M. Comparative analysis of natural fibres characteristics as composite reinforcement. Ind. Textila 2023, 74, 403–411. [Google Scholar] [CrossRef]

- Alao, P.F.; Press, R.; Ruponen, J.; Mikli, V.; Kers, J. Influence of Protic Ionic Liquid-Based Flame Retardant on the Flammability and Water Sorption of Alkalized Hemp Fiber-Reinforced PLA Composites. Polymers 2023, 15, 3661. [Google Scholar] [CrossRef]

- Aguado, R.J.; Bastida, G.A.; Espinach, F.X.; Llorens, J.; Tarrés, Q.; Delgado-Aguilar, M.; Mutjé, P. Comparative Study on the Stiffness of Poly(lactic acid) Reinforced with Untreated and Bleached Hemp Fibers. Polymers 2023, 15, 2960. [Google Scholar] [CrossRef]

- Benhadou, B.; Haddout, A.; Benhadou, M.; Ourchid, H. Study of Thermorheological Behavior of Polypropylene Composites Reinforced with Short Hemp Fibers During Industrial Injection Molding Process. Int. J. Mech. Eng. Technol. (IJMET) 2016, 7, 29–37. [Google Scholar]

- Rajesh, G.; Revuri, A.; Arekapudi, M.S.; Dbm, G.R. Evaluating Tensile Properties of Phragmites Karka Fibre Reinforced Polyester Composites. Mater. Today Proc. 2019, 18, 8–14. [Google Scholar] [CrossRef]

- Ortega, Z.; Suárez, L.; Kelly-Walley, J.; Hanna, P.R.; McCourt, M.; Millar, B. Use of Pressure in Rotational Molding to Reduce Cycle Times: Comparison of the Thermomechanical Behavior of Rotomolded Reed/Polyethylene Composites. J. Compos. Sci. 2024, 8, 17. [Google Scholar] [CrossRef]

- Honoré, M.; Pimbert, S.; Lecompte, T. Characterisation of plant flours for biocomposite applications focussing on Phragmites australis properties. Biosyst. Eng. 2020, 197, 367–377. [Google Scholar] [CrossRef]

- Suárez, L.; Barczewski, M.; Kosmela, P.; Marrero, M.D.; Ortega, Z. Giant Reed (Arundo donax L.) Fiber Extraction and Characterization for Its Use in Polymer Composites. J. Nat. Fibers 2022, 20, 2131687. [Google Scholar] [CrossRef]

- Ganesan, K.; Kailasanathan, C.; Rajini, N.; Ismail, S.O.; Ayrilmis, N.; Mohammad, F.; Al-Lohedan, H.A.; Tawfeek, A.M.; Issa, Z.A.; Aldhayan, D.M. Assessment on hybrid jute/coir fibers reinforced polyester composite with hybrid fillers under different environmental conditions. Constr. Build. Mater. 2021, 301, 124117. [Google Scholar] [CrossRef]

- Kim, B.S.; Nguyen, M.H.; Hwang, B.S.; Lee, S. Effect of plasma treatment on the mechanical properties of natural fiber/PP composites. WIT Trans. Built Environ. 2008, 97, 159–166. [Google Scholar] [CrossRef]

- Hasan, K.M.F.; Horváth, P.G.; Bak, M.; Alpár, T. A state-of-the-art review on coir fiber-reinforced biocomposites. RSC Adv. 2021, 11, 10548–10571. [Google Scholar] [CrossRef]

- Adeniyi, A.G.; Onifade, D.V.; Ighalo, J.O.; Adeoye, A.S. A review of coir fiber reinforced polymer composites. Compos. Part B Eng. 2019, 176, 107305. [Google Scholar] [CrossRef]

- Kakou, C.A.; Essabir, H.; Bensalah, M.-O.; Bouhfid, R.; Rodrigue, D.; Qaiss, A. Hybrid composites based on polyethylene and coir/oil palm fibers. J. Reinf. Plast. Compos. 2015, 34, 1684–1697. [Google Scholar] [CrossRef]

- Reddy, N. Sustainable Applications of Coir and Other Coconut By-products; Springer Nature: Dordrecht, GX, The Netherlands, 2019. [Google Scholar]

- Ramirez, C.; Agaliotis, E.; Pettarin, V. Fracture toughness and overall characterization of PLA based biocomposites with natural fibers: A comparative study. Polymer 2024, 307, 127309. [Google Scholar] [CrossRef]

- Gregorova, A.; Hrabalova, M.; Kovalcik, R.; Wimmer, R. Surface modification of spruce wood flour and effects on the dynamic fragility of PLA/wood composites. Polym. Eng. Sci. 2010, 51, 143–150. [Google Scholar] [CrossRef]

- Jubinville, D.; Tzoganakis, C.; Mekonnen, T.H. Recycled PLA—Wood flour based biocomposites: Effect of wood flour surface modification, PLA recycling, and maleation. Constr. Build. Mater. 2022, 352, 129026. [Google Scholar] [CrossRef]

- Bhayana, M.; Singh, J.; Sharma, A.; Gupta, M. A review on optimized FDM 3D printed Wood/PLA bio composite material characteristics. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- PN-EN ISO 20753:2019-01; Plastics—Test Specimens. Polski Komitet Normalizacyjny (PKN): Warsaw, Poland, 2019.

- PN-EN ISO 527-1:2020-01; Plastics—Determination of tensile properties—Part 1: General principles. Polski Komitet Normalizacyjny (PKN): Warsaw, Poland, 2020.

- PN-EN ISO 178:2019-06; Plastics—Determination of flexural properties. Polski Komitet Normalizacyjny (PKN): Warsaw, Poland, 2019.

- PN-EN ISO 1133:2006; Plastics - Determination of the melt mass-flow rate (MFR) and the melt volume-flow rate (MVR) of thermoplastics (ISO 1133:2005). Polski Komitet Normalizacyjny (PKN): Warsaw, Poland, 2006.

- Tiwari, Y.M.; Sarangi, S.K. Characterization of raw and alkali treated cellulosic Grewia Flavescens natural fiber. Int. J. Biol. Macromol. 2022, 209, 1933–1942. [Google Scholar] [CrossRef]

- Zhou, X.-L.; Liu, Z.-M.; Kiss, J.; Sloan, D.W.; White, J.M. Surface Chemistry of Chloroiodomethane, Coadsorbed with H and O, on Pt(111). J. Am. Chem. Soc. 1995, 117, 3565–3592. [Google Scholar] [CrossRef]

- Reddy, K.O.; Maheswari, C.U.; Shukla, M.; Rajulu, A. Chemical composition and structural characterization of Napier grass fibers. Mater. Lett. 2012, 67, 35–38. [Google Scholar] [CrossRef]

- Reza, S.; Islam, S.N.; Afroze, S.; Abu Bakar, M.S.; Taweekun, J.; Azad, A.K. Data on FTIR, TGA – DTG, DSC of invasive pennisetum purpureum grass. Data Brief 2020, 30, 105536. [Google Scholar] [CrossRef] [PubMed]

- Pozo, M.B.-D.; Gallardo-Guerrero, L.; Gandul-Rojas, B. Influence of Alkaline Treatment on Structural Modifications of Chlorophyll Pigments in NaOH—Treated Table Olives Preserved without Fermentation. Foods 2020, 9, 701. [Google Scholar] [CrossRef]

- Helander, M.; Theliander, H.; Lawoko, M.; Henriksson, G.; Zhang, L.; Lindström, M.E. Fractionation of Technical Lignin: Molecular Mass and pH Effects. BioResources 2013, 8, 2270–2282. [Google Scholar] [CrossRef]

- Arias, A.; Sojoudiasli, H.; Heuzey, M.-C.; Huneault, M.A.; Wood-Adams, P. Rheological study of crystallization behavior of polylactide and its flax fiber composites. J. Polym. Res. 2017, 24, 46. [Google Scholar] [CrossRef]

- Běhálek, L.; Maršálková, M. Study of Crystallization of Polylactic Acid Composites and Nanocomposites with Natural Fibres by DSC Method. 2018. Available online: https://www.researchgate.net/publication/288205389_Study_of_crystallization_of_polylactic_acid_composites_and_nanocomposites_with_natural_fibres_by_DSC_method (accessed on 10 June 2025).

- Ma, C.; Guo, Q.; Mo, J.; Lin, F.; Chen, J.; Cao, D.; Xie, W.; He, K.; Liu, X.; Xie, G.; et al. Monitoring and kinetic study of alkaline hydrolysis of polylactic acid fibrous membrane via aggregation-induced emission (AIE) technique. Surfaces Interfaces 2023, 42, 103433. [Google Scholar] [CrossRef]

- Dittenber, D.B.; GangaRao, H.V. Critical review of recent publications on use of natural composites in infrastructure. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1419–1429. [Google Scholar] [CrossRef]

- Yang, B.-X.; Shi, J.-H.; Pramoda, K.; Goh, S.H. Enhancement of the mechanical properties of polypropylene using polypropylene-grafted multiwalled carbon nanotubes. Compos. Sci. Technol. 2008, 68, 2490–2497. [Google Scholar] [CrossRef]

- Ellis, T.S.; D’Angelo, J.S. Thermal and mechanical properties of a polypropylene nanocomposite. J. Appl. Polym. Sci. 2003, 90, 1639–1647. [Google Scholar] [CrossRef]

- Yang, B.; Pramoda, K.P.; Xu, G.Q.; Goh, S.H. Mechanical Reinforcement of Polyethylene Using Polyethylene-Grafted Multiwalled Carbon Nanotubes. Adv. Funct. Mater. 2007, 17, 2062–2069. [Google Scholar] [CrossRef]

- Cho, K.; Lee, B.H.; Hwang, K.; Lee, H.; Choe, S. Rheological and mechanical properties in polyethylene blends. Polym. Eng. Sci. 1998, 38, 1969–1975. [Google Scholar] [CrossRef]

- Qi, Z.; Wang, B.; Sun, C.; Yang, M.; Chen, X.; Zheng, D.; Yao, W.; Chen, Y.; Cheng, R.; Zhang, Y. Comparison of Properties of Poly(Lactic Acid) Composites Prepared from Different Components of Corn Straw Fiber. Int. J. Mol. Sci. 2022, 23, 6746. [Google Scholar] [CrossRef]

- Arao, Y.; Fujiura, T.; Itani, S.; Tanaka, T. Strength improvement in injection-molded jute-fiber-reinforced polylactide green-composites. Compos. Part B Eng. 2015, 68, 200–206. [Google Scholar] [CrossRef]

- Madueke, C.I.; Mbah, O.M.; Umunakwe, R. A review on the limitations of natural fibres and natural fibre composites with emphasis on tensile strength using coir as a case study. Polym. Bull. 2022, 80, 3489–3506. [Google Scholar] [CrossRef]

| T1 [°C] | Mass Change [%] | Onset [°C] | T2 [°C] | Mass Change [%] | Residual Mass [%] | |

|---|---|---|---|---|---|---|

| Raw | 58.1 | 7.16 | 249.9 | 281.5/337.3 | 60.82 | 26.36 |

| Cooked | 54.7 | 4.18 | 271.3 | 311.3/362.3 | 67.88 | 14.45 |

| Alkalized | 59.2 | 3.85 | 275.2 | 354.5 | 71.12 | 14.99 |

| Sample | PD |

|---|---|

| Neat PLA | 1.680 |

| Raw | 1.692 |

| Cooked | 1.762 |

| Alkalized | 1.818 |

| Tg [°C] | Tcc [°C] | Tm [°C] | ||||

|---|---|---|---|---|---|---|

| Cycle | 1 | 2 | 1 | 2 | 1 | 2 |

| Neat PLA | 66.4 | 62.2 | 121.3 | 127.3 | 155.7 | 153.8 |

| PLA/5% Raw Poaceae | 63.3 | 61.9 | 115.9 | 118.0 | 152.9 | 151.6 |

| PLA/10% Raw Poaceae | 58.1 | 61.7 | 112.3 | 113.3 | 152.9/158.0 | 150.2/155.6 |

| PLA/20% Raw Poaceae | 63.4 | 60.8 | 107.2 | 111.7 | 151.0/157.8 | 149.2/156.1 |

| PLA/5% Cooked Poaceae | 64.2 | 61.1 | 112.8 | 112.9 | 153.8/159.4 | 149.9/156.7 |

| PLA/10% Cooked Poaceae | 64.7 | 62.7 | 114.4 | 115.0 | 155.8 | 152.0 |

| PLA/20% Cooked Poaceae | 63.6 | 61.6 | 108.4 | 111.9 | 151.8/157.8 | 149.9/156.2 |

| PLA/5% Alkalized Poaceae | 64.9 | 62.2 | 119.5 | 121.7 | 155.2 | 153.0 |

| PLA/10% Alkalized Poaceae | 64.2 | 61.4 | 114.0 | 115.1 | 153.3/157.3 | 150.2/155.2 |

| PLA/20% Alkalized Poaceae | 62.6 | 59.5 | 106.9 | 115.7 | 150.4/159.1 | 148.8/155.9 |

| Elongation at Break [%] | st. d. [-] | Tensile Strength [MPa] | st. d. [-] | Modulus of Elasticity [MPa] | st. d. [-] | |

|---|---|---|---|---|---|---|

| Neat PLA | 4.90 | 0.05 | 66.6 | 0.6 | 3253 | 34 |

| PLA/5% Raw Poaceae | 2.19 | 0.10 | 57.5 | 0.9 | 3661 | 206 |

| PLA/10% Raw Poaceae | 2.06 | 0.08 | 53.8 | 0.9 | 3863 | 107 |

| PLA/20% Raw Poaceae | 1.72 | 0.07 | 48.3 | 0.5 | 4266 | 320 |

| Poaceae PLA/5% Cooked | 2.37 | 0.17 | 58.5 | 1.3 | 3145 | 461 |

| Poaceae PLA/10% Cooked Poaceae | 2.29 | 0.23 | 57.6 | 0.3 | 3448 | 408 |

| PLA/20% Cooked Poaceae | 2.15 | 0.12 | 56.5 | 0.6 | 3282 | 252 |

| Poaceae PLA/5% Alkalized | 2.44 | 0.11 | 62.8 | 0.9 | 3616 | 134 |

| PLA/10% Alkalized Poaceae | 2.28 | 0.06 | 61.2 | 4.0 | 3720 | 277 |

| PLA/20% Alkalized Poaceae | 1.48 | 0.34 | 49.0 | 2.7 | 4393 | 235 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kubiak, N.; Sztorch, B.; Kustosz, M.; Frydrych, M.; Pakuła, D.; Jałbrzykowski, M.; Hartmann, T.; Zopp, C.; Kroll, L.; Przekop, R.E. Sustainable PLA Composites Filled with Poaceae Fibers: Thermal, Structural, and Mechanical Properties. Materials 2025, 18, 3952. https://doi.org/10.3390/ma18173952

Kubiak N, Sztorch B, Kustosz M, Frydrych M, Pakuła D, Jałbrzykowski M, Hartmann T, Zopp C, Kroll L, Przekop RE. Sustainable PLA Composites Filled with Poaceae Fibers: Thermal, Structural, and Mechanical Properties. Materials. 2025; 18(17):3952. https://doi.org/10.3390/ma18173952

Chicago/Turabian StyleKubiak, Natalia, Bogna Sztorch, Magdalena Kustosz, Miłosz Frydrych, Daria Pakuła, Marek Jałbrzykowski, Tobias Hartmann, Camilo Zopp, Lothar Kroll, and Robert E. Przekop. 2025. "Sustainable PLA Composites Filled with Poaceae Fibers: Thermal, Structural, and Mechanical Properties" Materials 18, no. 17: 3952. https://doi.org/10.3390/ma18173952

APA StyleKubiak, N., Sztorch, B., Kustosz, M., Frydrych, M., Pakuła, D., Jałbrzykowski, M., Hartmann, T., Zopp, C., Kroll, L., & Przekop, R. E. (2025). Sustainable PLA Composites Filled with Poaceae Fibers: Thermal, Structural, and Mechanical Properties. Materials, 18(17), 3952. https://doi.org/10.3390/ma18173952