Influence of Acidic Storage and Simulated Toothbrushing on the Translucency and Color Stability of 3D-Printed Resins for Prosthodontic Applications

Abstract

1. Introduction

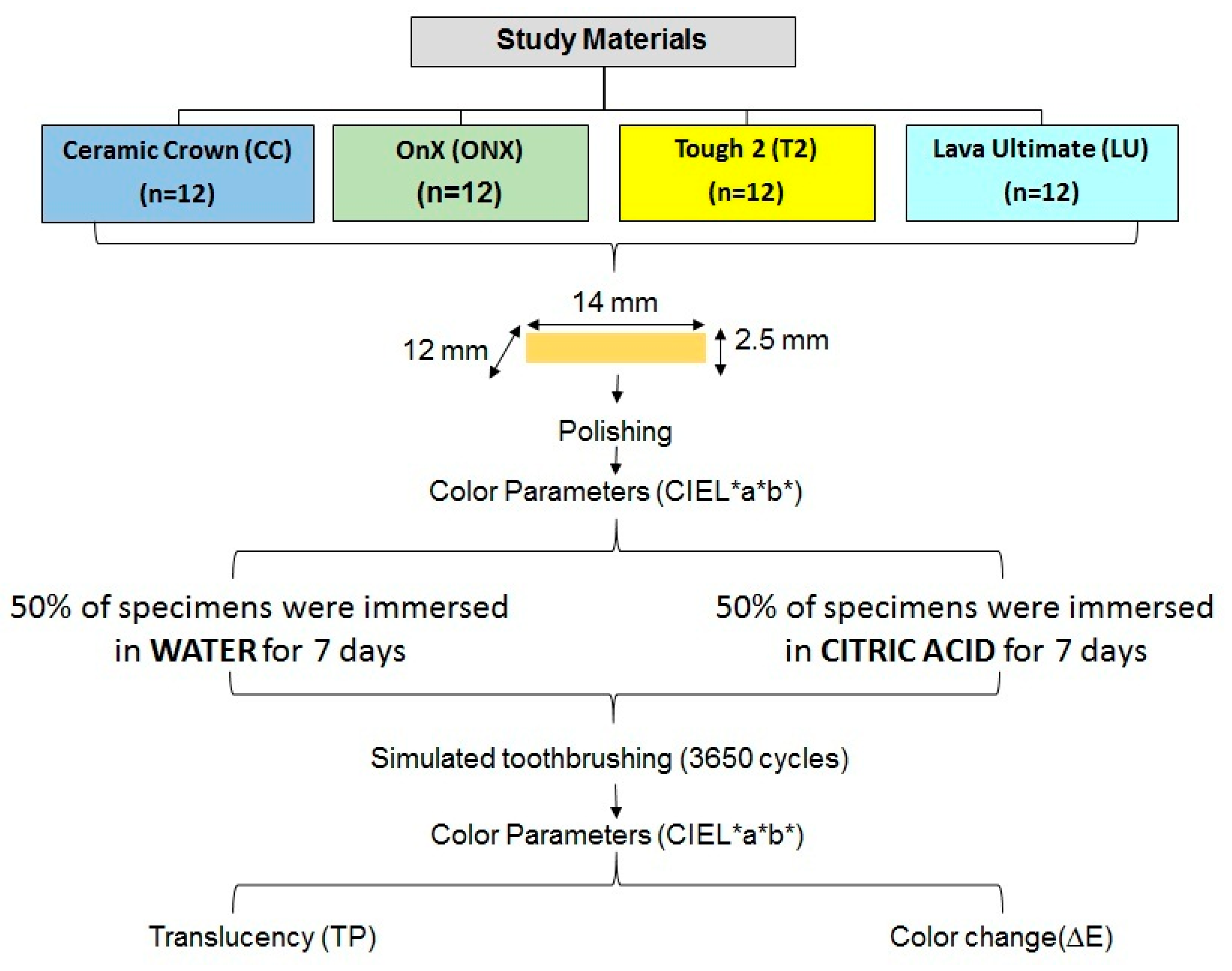

2. Materials and Methods

2.1. Materials

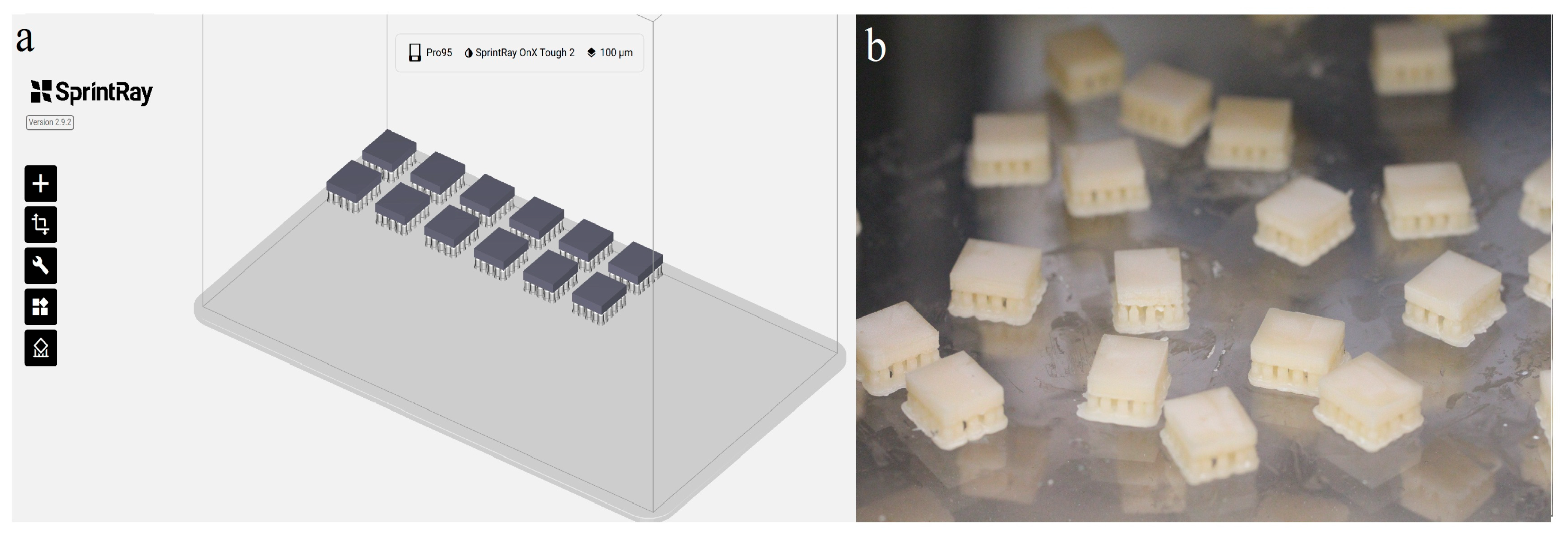

2.2. Specimen Preparation

2.3. Specimen Polishing

2.4. Specimen Allocation and Treatment

2.5. Measurement of Color and Translucency

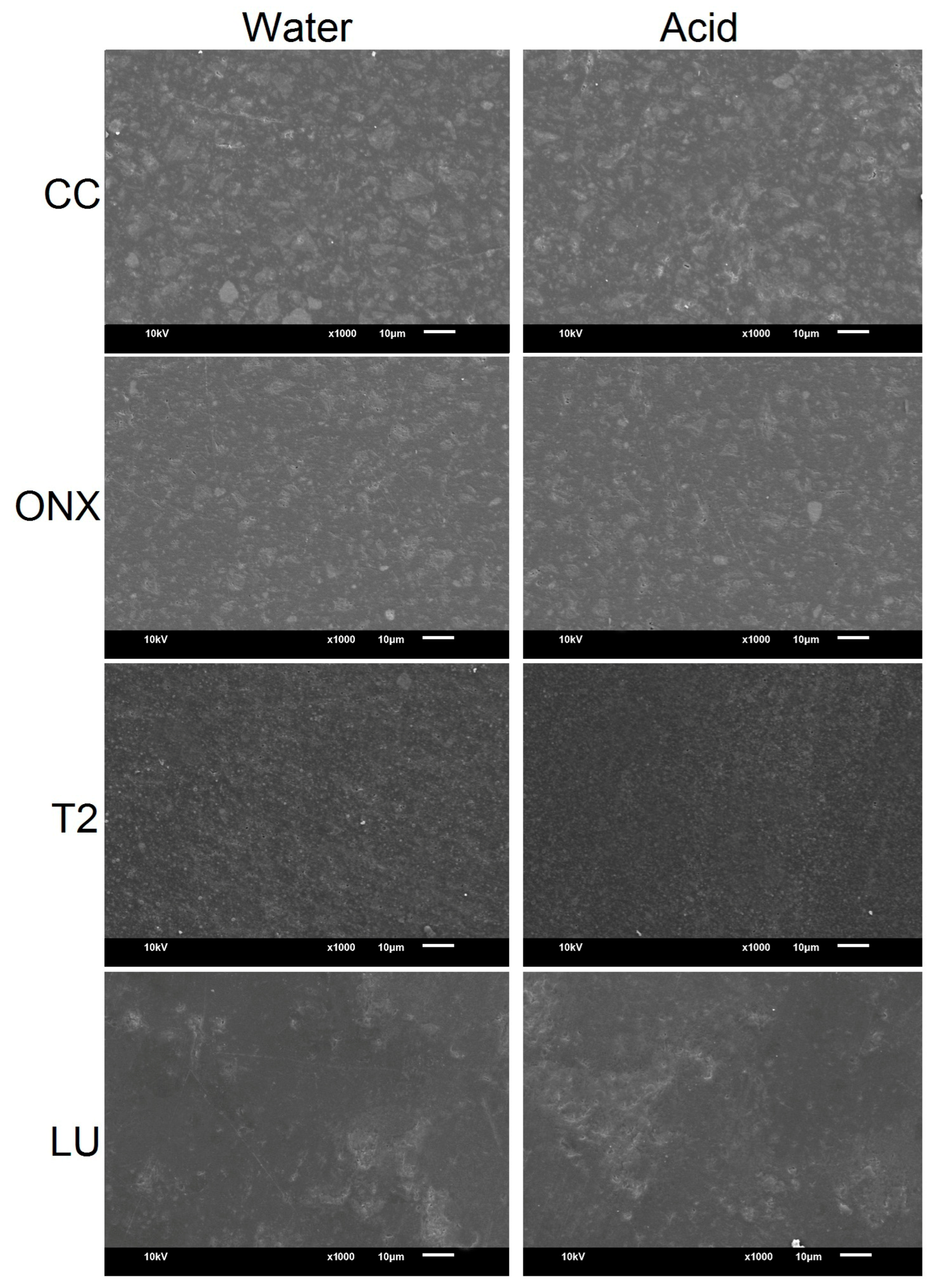

2.6. Scanning Electron Microscopy (SEM) Evaluation of the Specimens

2.7. Data Analysis

3. Results

3.1. Translucency Parameter (TP)

3.2. Color Stability (ΔE)

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| 3D | Three dimensional |

| ΔE | Color change |

| CAD/CAM | Computer-aided design (CAD) and computer-aided manufacturing (CAM) |

| CIELAB | Commission Internationale de l’Éclairage Lab color space |

| CC | Ceramic Crown |

| LU | Lava Ultimate |

| OnX | SprintRay OnX |

| T2 | Tough 2 |

| SPSS | Statistical Package for the Social Sciences |

| TP | Translucency |

References

- Alfouzan, A.F.; Alnafaiy, S.M.; Alsaleh, L.S.; Bawazir, N.H.; Al-Otaibi, H.N.; Taweel, S.M.A.; Alshehri, H.A.; Labban, N. Effects of background color and thickness on the optical properties of CAD-CAM resin-matrix ceramics. J. Prosthet. Dent. 2022, 128, 497.e1–497.e9. [Google Scholar] [CrossRef]

- Nagai, T.; Alfaraj, A.; Chu, T.G.; Yang, C.C.; Lin, W.S. Color stability of CAD-CAM hybrid ceramic materials following immersion in artificial saliva and wine. J. Prosthodont. 2024, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Alzahrani, S.J.; Hajjaj, M.S.; Azhari, A.A.; Ahmed, W.M.; Yeslam, H.E.; Carvalho, R.M. Mechanical Properties of Three-Dimensional Printed Provisional Resin Materials for Crown and Fixed Dental Prosthesis: A Systematic Review. Bioengineering 2023, 10, 663. [Google Scholar] [CrossRef] [PubMed]

- Marchesi, G.; Camurri Piloni, A.; Nicolin, V.; Turco, G.; Di Lenarda, R. Chairside CAD/CAM Materials: Current Trends of Clinical Uses. Biology 2021, 10, 1170. [Google Scholar] [CrossRef] [PubMed]

- Watanabe, H.; Fellows, C.; An, H. Digital Technologies for Restorative Dentistry. Dent. Clin. N. Am. 2022, 66, 567–590. [Google Scholar] [CrossRef]

- Grzebieluch, W.; Kowalewski, P.; Grygier, D.; Rutkowska-Gorczyca, M.; Kozakiewicz, M.; Jurczyszyn, K. Printable and Machinable Dental Restorative Composites for CAD/CAM Application-Comparison of Mechanical Properties, Fractographic, Texture and Fractal Dimension Analysis. Materials 2021, 14, 4919. [Google Scholar] [CrossRef]

- Alghauli, M.A.; Alqutaibi, A.Y.; Wille, S.; Kern, M. The physical-mechanical properties of 3D-printed versus conventional milled zirconia for dental clinical applications: A systematic review with meta-analysis. J. Mech. Behav. Biomed. Mater. 2024, 156, 106601. [Google Scholar] [CrossRef]

- Majeed, H.F.; Hamad, T.I.; Bairam, L.R. Enhancing 3D-printed denture base resins: A review of material innovations. Sci. Prog. 2024, 107, 368504241263484. [Google Scholar] [CrossRef]

- Balestra, D.; Lowther, M.; Goracci, C.; Mandurino, M.; Cortili, S.; Paolone, G.; Louca, C.; Vichi, A. 3D Printed Materials for Permanent Restorations in Indirect Restorative and Prosthetic Dentistry: A Critical Review of the Literature. Materials 2024, 17, 1380. [Google Scholar] [CrossRef]

- Alshamrani, A.; Alhotan, A.; Kelly, E.; Ellakwa, A. Mechanical and Biocompatibility Properties of 3D-Printed Dental Resin Reinforced with Glass Silica and Zirconia Nanoparticles: In Vitro Study. Polymers 2023, 15, 2523. [Google Scholar] [CrossRef]

- Chistyakov, E.M.; Kolpinskaya, N.; Posokhova, V.; Chuev, V. Dental Composition Modified with Aryloxyphosphazene Containing Carboxyl Groups. Polymers 2020, 12, 1176. [Google Scholar] [CrossRef] [PubMed]

- Srivastava, R.; Liu, J.; He, C.; Sun, Y. BisGMA analogues as monomers and diluents for dental restorative composite materials. Mater. Sci. Eng. C 2018, 88, 25–31. [Google Scholar] [CrossRef]

- Pereira, S.G.; Osorio, R.; Toledano, M.; Nunes, T.G. Evaluation of two Bis-GMA analogues as potential monomer diluents to improve the mechanical properties of light-cured composite resins. Dent. Mater. 2005, 21, 823–830. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.W.; Kim, L.U.; Kim, C.K.; Cho, B.H.; Kim, O.Y. Characteristics of Novel Dental Composites Containing 2,2-Bis [4-(2-methoxy-3-methacryloyloxy propoxy) phenyl] propane as a Base Resin. Biomacromolecules 2006, 7, 154–160. [Google Scholar] [CrossRef] [PubMed]

- He, J.; Garoushi, S.; Säilynoja, E.; Vallittu, P.K.; Lassila, L. The effect of adding a new monomer “Phene” on the polymerization shrinkage reduction of a dental resin composite. Dent. Mater. 2019, 35, 627–635. [Google Scholar] [CrossRef]

- Al Amri, M.D.; Labban, N.; Alhijji, S.; Alamri, H.; Iskandar, M.; Platt, J.A. In Vitro Evaluation of Translucency and Color Stability of CAD/CAM Polymer-Infiltrated Ceramic Materials after Accelerated Aging. J. Prosthodont. 2020, 30, 318–328. [Google Scholar] [CrossRef]

- Alnafaiy, S.; Labban, N.; Maawadh, A.; Alshehri, H.; Aljamhan, A.; Alghamdi, W. Biaxial flexural strength and hardness of resin-matrix ceramic CAD/CAM materials. Ceram.-Silikáty 2021, 65, 285–294. [Google Scholar] [CrossRef]

- Krajangta, N.; Klaisiri, A.; Leelaponglit, S.; Intralawan, N.; Tiansuwan, P.; Pisethsalasai, N. Color alteration of CAD/CAM 3D-printed, milled resin-ceramic hybrid material compared to enamel. Dent. Mater. J. 2024, 43, 386–393. [Google Scholar] [CrossRef]

- Duarte, S., Jr.; Phark, J.-H. Advances in Dental Restorations: A Comprehensive Review of Machinable and 3D-Printed Ceramic-Reinforced Composites. J. Esthet. Restor. Dent. 2024, 37, 257–276. [Google Scholar] [CrossRef]

- Egilmez, F.; Ergun, G.; Cekic-Nagas, I.; Bozkaya, S. Implant-supported hybrid prosthesis: Conventional treatment method for borderline cases. Eur. J. Dent. 2015, 9, 442–448. [Google Scholar] [CrossRef]

- Grover, R.K.; Jain, S.; Sharma, R.; Borse, P.; Singh, A. Restoring Function and Esthetics in Complete Edentulism: A Case Report of Implant-Supported Hybrid Denture. Cureus 2024, 16, e71399. [Google Scholar] [CrossRef]

- Schweiger, J.; Edelhoff, D.; Güth, J.F. 3D Printing in Digital Prosthetic Dentistry: An Overview of Recent Developments in Additive Manufacturing. J. Clin. Med. 2021, 10, 2010. [Google Scholar] [CrossRef]

- SprintRay. OnX—A 3D Printing Resin to Revolutionize Dentistry. Available online: https://sprintray.com/sprintray-onx-3dprinting-resin/ (accessed on 22 November 2024).

- SprintRay. Tough 2: FDA Cleared 3D Resin for Fixed Hybrid Dentures. Available online: https://sprintray.com/introducing-onx-tough-2-the-first-3d-printing-resin-fda-cleared-for-fixed-hybrid-dentures/ (accessed on 22 November 2024).

- SprintRay. Ceramic Crown Resin. Available online: https://sprintray.com/digital-dentistry/ceramic-crown/ (accessed on 22 November 2024).

- Jones, C.S.; Billington, R.W.; Pearson, G.J. The in vivo perception of roughness of restorations. Br. Dent. J. 2004, 196, 42–45; discussion 31. [Google Scholar] [CrossRef] [PubMed]

- Kawai, K.; Urano, M.; Ebisu, S. Effect of surface roughness of porcelain on adhesion of bacteria and their synthesizing glucans. J. Prosthet. Dent. 2000, 83, 664–667. [Google Scholar] [CrossRef] [PubMed]

- Pop-Ciutrila, I.S.; Dudea, D.; Eugenia Badea, M.; Moldovan, M.; Cimpean, S.I.; Ghinea, R. Shade Correspondence, Color, and Translucency Differences between Human Dentine and a CAD/CAM Hybrid Ceramic System. J. Esthet. Restor. Dent. 2016, 28, 29. [Google Scholar] [CrossRef] [PubMed]

- Gigilashvili, D.; Thomas, J.-B.; Hardeberg, J.Y.; Pedersen, M. Translucency perception: A review. J. Vis. 2021, 21, 4. [Google Scholar] [CrossRef]

- Labban, N.; Al Amri, M.; Alhijji, S.; Alnafaiy, S.; Alfouzan, A.; Iskandar, M.; Feitosa, S. Influence of toothbrush abrasion and surface treatments on the color and translucency of resin infiltrated hybrid ceramics. J. Adv. Prosthodont. 2021, 13, 1–11. [Google Scholar] [CrossRef]

- Taşın, S.; Ismatullaev, A. Effect of coffee thermocycling on the color and translucency of milled and 3D printed definitive restoration materials. J. Prosthet. Dent. 2024, 131, 969.e1–969.e7. [Google Scholar] [CrossRef]

- Kurklu, Z.G.B.; Sonkaya, E. Comparison of discoloration of ceramic containing 3D printable material and CAD/CAM blocks. Dent. Mater. J. 2024, 43, 28–35. [Google Scholar] [CrossRef]

- Çakmak, G.; Donmez, M.B.; de Paula, M.S.; Akay, C.; Fonseca, M.; Kahveci, Ç.; Abou-Ayash, S.; Yilmaz, B. Surface roughness, optical properties, and microhardness of additively and subtractively manufactured CAD-CAM materials after brushing and coffee thermal cycling. J. Prosthodont. Off. J. Am. Coll. Prosthodont. 2025, 34, 68–77. [Google Scholar] [CrossRef]

- Sharma, G.; Wu, W.; Dalal, E.N. The CIEDE2000 color-difference formula: Implementation notes, supplementary test data, and mathematical observations. Color Res. Appl. 2005, 30, 21–30. [Google Scholar] [CrossRef]

- Barutçugil, Ç.; Bilgili, D.; Barutcigil, K.; Dündar, A.; Büyükkaplan, U.; Yilmaz, B. Discoloration and translucency changes of CAD-CAM materials after exposure to beverages. J. Prosthet. Dent. 2019, 122, 325–331. [Google Scholar] [CrossRef]

- Bangalore, D.; Alshehri, A.M.; Alsadon, O.; Alaqeel, S.M.; Alageel, O.; Alsarani, M.M.; Almansour, H.; AlShahrani, O. Coffee Staining and Simulated Brushing Induced Color Changes and Surface Roughness of 3D-Printed Orthodontic Retainer Material. Polymers 2023, 15, 2164. [Google Scholar] [CrossRef]

- ISO/TR-28642:2016(E); Technical Report: Dentistry-Guidance on Colour Measurements. International Organization for Standardization: Geneva, Switzerland, 2016.

- Paravina, R.D.; Ghinea, R.; Herrera, L.J.; Bona, A.D.; Igiel, C.; Linninger, M.; Sakai, M.; Takahashi, H.; Tashkandi, E.; Perez Mdel, M. Color difference thresholds in dentistry. J. Esthet. Restor. Dent. 2015, 27, 17. [Google Scholar] [CrossRef]

- Bozoğulları, H.N.; Temizci, T. Evaluation of the Color Stability, Stainability, and Surface Roughness of Permanent Composite-Based Milled and 3D Printed CAD/CAM Restorative Materials after Thermocycling. Appl. Sci. 2023, 13, 1895. [Google Scholar] [CrossRef]

- Vichi, A.; Balestra, D.; Scotti, N.; Louca, C.; Paolone, G. Translucency of CAD/CAM and 3D Printable Composite Materials for Permanent Dental Restorations. Polymers 2023, 15, 1443. [Google Scholar] [CrossRef] [PubMed]

- Espinar, C.; Bona, A.D.; Pérez, M.M.; Tejada-Casado, M.; Pulgar, R. The influence of printing angle on color and translucency of 3D printed resins for dental restorations. Dent. Mater. 2023, 39, 410–417. [Google Scholar] [CrossRef] [PubMed]

- Arikawa, H.; Kanie, T.; Fujii, K.; Takahashi, H.; Ban, S. Effect of Filler Properties in Composite Resins on Light Transmittance Characteristics and Color. Dent. Mater. J. 2007, 26, 38–44. [Google Scholar] [CrossRef] [PubMed]

- Lee, Y.-K. Criteria for clinical translucency evaluation of direct esthetic restorative materials. Restor. Dent. Endod. 2016, 41, 159–166. [Google Scholar] [CrossRef]

- Gunal, B.; Ulusoy, M.M. Optical properties of contemporary monolithic CAD-CAM restorative materials at different thicknesses. J. Esthet. Restor. Dent. 2018, 30, 434–441. [Google Scholar] [CrossRef]

- Kim, J.-E.; Choi, W.-H.; Lee, D.; Shin, Y.; Park, S.-H.; Roh, B.-D.; Kim, D. Color and Translucency Stability of Three-Dimensional Printable Dental Materials for Crown and Bridge Restorations. Materials 2021, 14, 650. [Google Scholar] [CrossRef]

- El Shazely, A.A.; Kamel, M.S.M.; Hasnain, F.A. Influence of thickness difference on color change of contemporary Computer Aided Designing/Computer Aided Manufacturing glass-ceramic materials. Tanta Dent. J. 2023, 20, 6–11. [Google Scholar] [CrossRef]

- Kim, H.K.; Kim, S.H.; Lee, J.B.; Han, J.S.; Yeo, I.S.; Ha, S.R. Effect of the amount of thickness reduction on color and translucency of dental monolithic zirconia ceramics. J. Adv. Prosthodont. 2016, 8, 37–42. [Google Scholar] [CrossRef] [PubMed]

- Tad, K.N.; Gürbüz, A.; Oyar, P. Influence of acidic solutions on surface roughness of polished and glazed CAD-CAM restorative materials. Head. Face Med. 2025, 21, 16. [Google Scholar] [CrossRef] [PubMed]

- Paravina, R.D.; Pérez, M.M.; Ghinea, R. Acceptability and perceptibility thresholds in dentistry: A comprehensive review of clinical and research applications. J. Esthet. Restor. Dent. 2019, 31, 103–112. [Google Scholar] [CrossRef]

- Mohammadipour, H.S.; Yazdi, S.S.; Mashhad, M.J.M.; Babazadeh, S.; Shahri, A. Color matching and translucency of single-shade resin composites: Effects of restoration thickness, background shade, and aging. BMC Oral Health 2025, 25, 616. [Google Scholar] [CrossRef]

- Aromaa, M.K.; Vallittu, P.K. Delayed post-curing stage and oxygen inhibition of free-radical polymerization of dimethacrylate resin. Dent. Mater. 2018, 34, 1247–1252. [Google Scholar] [CrossRef]

- Engler, M.L.P.D.; Güth, J.-F.; Keul, C.; Erdelt, K.; Edelhoff, D.; Liebermann, A. Residual monomer elution from different conventional and CAD/CAM dental polymers during artificial aging. Clin. Oral Investig. 2020, 24, 277–284. [Google Scholar] [CrossRef]

- Berli, C.; Thieringer, F.M.; Sharma, N.; Müller, J.A.; Dedem, P.; Fischer, J.; Rohr, N. Comparing the mechanical properties of pressed, milled, and 3D-printed resins for occlusal devices. J. Prosthet. Dent. 2020, 124, 780–786. [Google Scholar] [CrossRef]

- Heffernan, M.J.; Aquilino, S.A.; Diaz-Arnold, A.M.; Haselton, D.R.; Stanford, C.M.; Vargas, M.A. Relative translucency of six all-ceramic systems. Part II: Core and veneer materials. J. Prosthet. Dent. 2002, 88, 10–15. [Google Scholar] [CrossRef]

- Hirata, R.; de Abreu, J.L.; Benalcázar-Jalkh, E.B.; Atria, P.; Cascales, Á.F.; Cantero, J.S.; Sampaio, C.S. Analysis of translucency parameter and fluorescence intensity of 5 resin composite systems. J. Clin. Exp. Dent. 2024, 16, e71–e77. [Google Scholar] [CrossRef]

- Bora, P.V.; Sayed Ahmed, A.; Alford, A.; Pitttman, K.; Thomas, V.; Lawson, N.C. Characterization of materials used for 3D printing dental crowns and hybrid prostheses. J. Esthet. Restor. Dent. 2024, 36, 220–230. [Google Scholar] [CrossRef]

- Zattera, A.C.A.; Morganti, F.A.; de Souza Balbinot, G.; Della Bona, A.; Collares, F.M. The influence of filler load in 3D printing resin-based composites. Dent. Mater. 2024, 40, 1041–1046. [Google Scholar] [CrossRef]

| Resin/Material | Shade/Abbreviation | Manufacturer | Composition | Batch Number |

|---|---|---|---|---|

| Ceramic Crown | A1/CC | SprintRay Inc., Los Angeles, CA, USA | Mixture of methacrylic acid esters, photoinitiators *, pigment * Inorganic composition includes irregular and some rounded silica (SiO2) and ytterbium oxide (Yb2O3) (1.0–5.0 nm) up to 50% [19] | SRI 0202057 |

| OnX | A1/ONX | SprintRay Inc., Los Angeles, CA, USA | Methacrylate monomers and oligomers, acrylic monomers, inorganic ceramic fillers, photoinitiators * | SRI 0202057 |

| Tough 2 | A1/T2 | SprintRay Inc., Los Angeles, CA, USA | Mixture of methacrylic acid esters, photoinitiators *, pigment * | SRI 0202164 |

| Lava Ultimate | A1/(LT)/LU | 3M ESPE, St. Paul, MN, USA | Nano ceramic fillers (zirconia filler (4–11 nm), silica filler (20 nm), and aggregated zirconia/silica cluster filler) 80 wt%; cross-linked polymer matrix (TEGDMA) 20 wt% | 5074A1-LT |

| Source | Type III SS | df | Mean Square | F | p-Value |

|---|---|---|---|---|---|

| Corrected Model | 215.16 | 7 | 30.74 | 210.99 | <0.001 * |

| Intercept | 723.08 | 1 | 723.08 | 4963.49 | <0.001 * |

| Storage media | 0.38 | 1 | 0.38 | 2.57 | 0.12 |

| Materials | 213.42 | 3 | 71.14 | 488.33 | <0.001 * |

| Storage media × Materials | 1.37 | 3 | 0.46 | 3.13 | 0.04 * |

| Error | 5.83 | 40 | 0.15 | ||

| Total | 944.07 | 48 | |||

| Corrected Total | 220.99 | 47 |

| Storage | Materials | Baseline | Simulated Brushing |

|---|---|---|---|

| Water | Ceramic Crown | 2.79 ± 0.28 | 1.96 ± 0.12 |

| OnX | 2.55 ± 0.28 | 2.18 ± 0.18 | |

| Tough 2 | 4.93 ± 0.47 | 4.21 ± 0.41 | |

| Lava Ultimate | 7.49 ± 0.74 | 7.51 ± 0.64 | |

| Acid | Ceramic Crown | 3.20 ± 1.11 | 2.34 ± 0.12 |

| OnX | 2.64 ± 0.38 | 1.97 ± 0.22 | |

| Tough 2 | 4.91 ± 0.60 | 3.80 ± 0.35 | |

| Lava Ultimate | 7.23 ± 0.87 | 7.04 ± 0.59 |

| Time | Storage | Ceramic Crown | OnX | Tough 2 | Lava Ultimate | p |

|---|---|---|---|---|---|---|

| Baseline | Water | 2.79 ± 0.28 | 2.55 ± 0.28 | 4.93 ± 0.4 | 7.49 ± 0.74 | <0.001 * |

| Acid | 3.20 ± 1.11 | 2.64 ± 0.38 | 4.91 ± 0.60 | 7.23 ± 0.87 | <0.001 * | |

| Simulated brushing | Water | 1.96 ± 0.12 | 2.18 ± 0.18 | 4.21 ± 0.41 | 7.51 ± 0.64 | <0.001 * |

| Acid | 2.34 ± 0.12 | 1.97 ± 0.22 | 3.80 ± 0.35 | 7.04 ± 0.59 | <0.001 * | |

| p † | p > 0.05 | p > 0.05 | p > 0.05 | p > 0.05 |

| Source | Type III SS | df | Mean Square | F | p-Value |

|---|---|---|---|---|---|

| Corrected Model | 2.27 | 7 | 0.33 | 1.26 | 0.30 |

| Intercept | 57.01 | 1 | 57.01 | 220.92 | <0.001 * |

| Storage media | 0.09 | 1 | 0.09 | 0.34 | 0.56 |

| Materials | 1.90 | 3 | 0.64 | 2.46 | 0.08 |

| Storage media × Materials | 0.28 | 3 | 0.09 | 0.37 | 0.78 |

| Error | 10.32 | 40 | 0.26 | ||

| Total | 69.60 | 48 | |||

| Corrected Total | 12.60 | 47 |

| Parameter | Storage Media | Materials | p * | |||

|---|---|---|---|---|---|---|

| Ceramic Crown | OnX | Tough 2 | Lava Ultimate | |||

| ΔE | Water | 0.97 ± 0.85 | 1.00 ± 0.24 | 1.28 ± 0.24 | 1.26 ± 0.62 | 0.67 |

| Acid | 0.66 ± 0.42 | 0.98 ± 0.23 | 1.40 ± 0.34 | 1.13 ± 0.68 | 0.07 | |

| p † | 0.45 | 0.88 | 0.53 | 0.74 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alnafaiy, S.M.; Labban, N.; Aldegheishem, A.S.; Alhijji, S.; Albaijan, R.S.; AlResayes, S.S.; Alsultan, R.A.; Alrossais, A.M.; Alanazi, R.F. Influence of Acidic Storage and Simulated Toothbrushing on the Translucency and Color Stability of 3D-Printed Resins for Prosthodontic Applications. Materials 2025, 18, 3942. https://doi.org/10.3390/ma18173942

Alnafaiy SM, Labban N, Aldegheishem AS, Alhijji S, Albaijan RS, AlResayes SS, Alsultan RA, Alrossais AM, Alanazi RF. Influence of Acidic Storage and Simulated Toothbrushing on the Translucency and Color Stability of 3D-Printed Resins for Prosthodontic Applications. Materials. 2025; 18(17):3942. https://doi.org/10.3390/ma18173942

Chicago/Turabian StyleAlnafaiy, Sarah M., Nawaf Labban, Alhanoof Saleh Aldegheishem, Saleh Alhijji, Refal Saad Albaijan, Saad Saleh AlResayes, Rafa Abdulrahman Alsultan, Abeer Mohammed Alrossais, and Rahaf Farhan Alanazi. 2025. "Influence of Acidic Storage and Simulated Toothbrushing on the Translucency and Color Stability of 3D-Printed Resins for Prosthodontic Applications" Materials 18, no. 17: 3942. https://doi.org/10.3390/ma18173942

APA StyleAlnafaiy, S. M., Labban, N., Aldegheishem, A. S., Alhijji, S., Albaijan, R. S., AlResayes, S. S., Alsultan, R. A., Alrossais, A. M., & Alanazi, R. F. (2025). Influence of Acidic Storage and Simulated Toothbrushing on the Translucency and Color Stability of 3D-Printed Resins for Prosthodontic Applications. Materials, 18(17), 3942. https://doi.org/10.3390/ma18173942