Microstructural and Mechanical Property Variations in 316L Stainless Steel Fabricated by Laser Powder Bed Fusion Under High-Density Processing Conditions

Abstract

1. Introduction

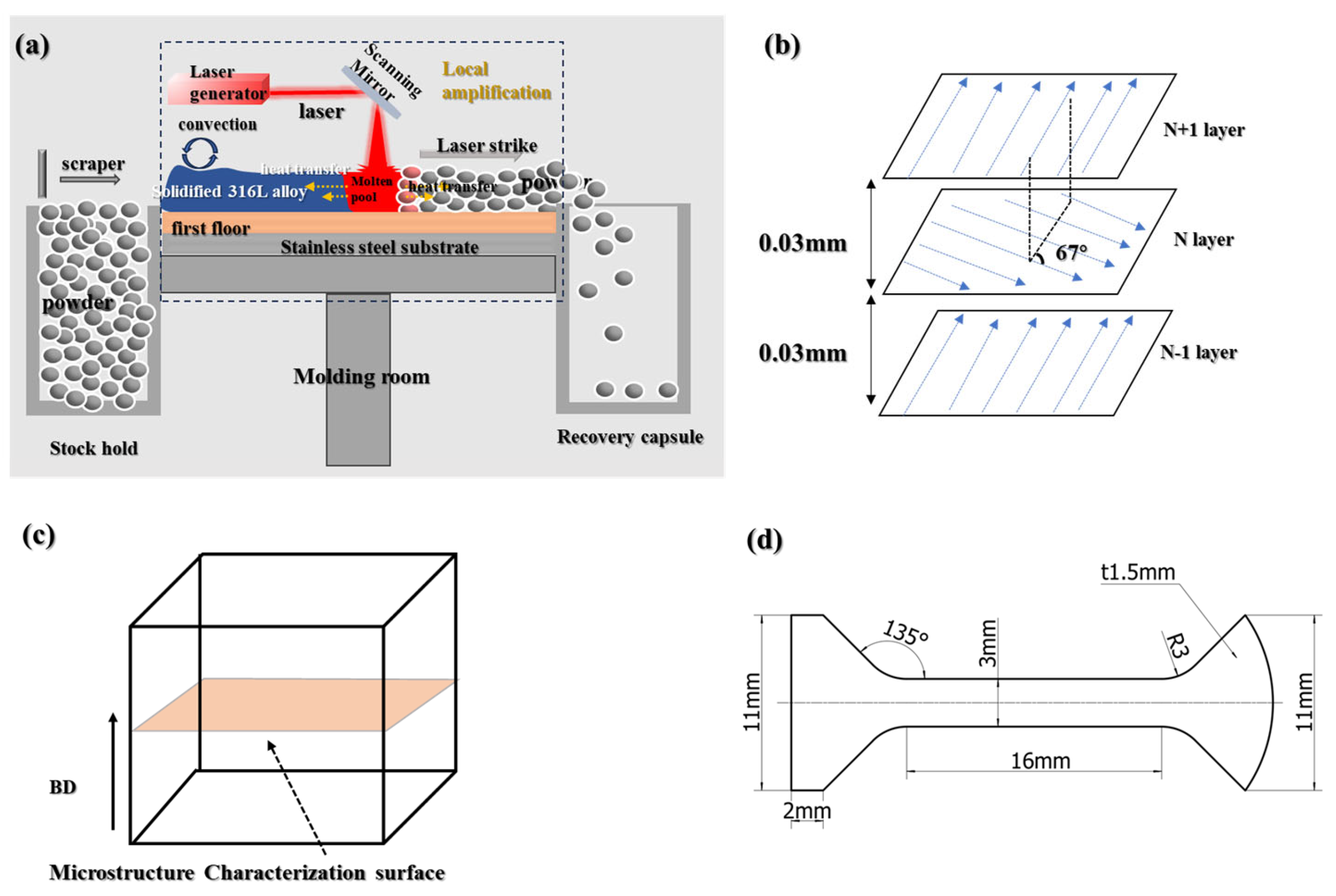

2. Materials and Experimental Methods

2.1. LPBF Equipment and Raw Materials

2.2. Mechanical Property Testing

2.3. Material Characterization

3. Results

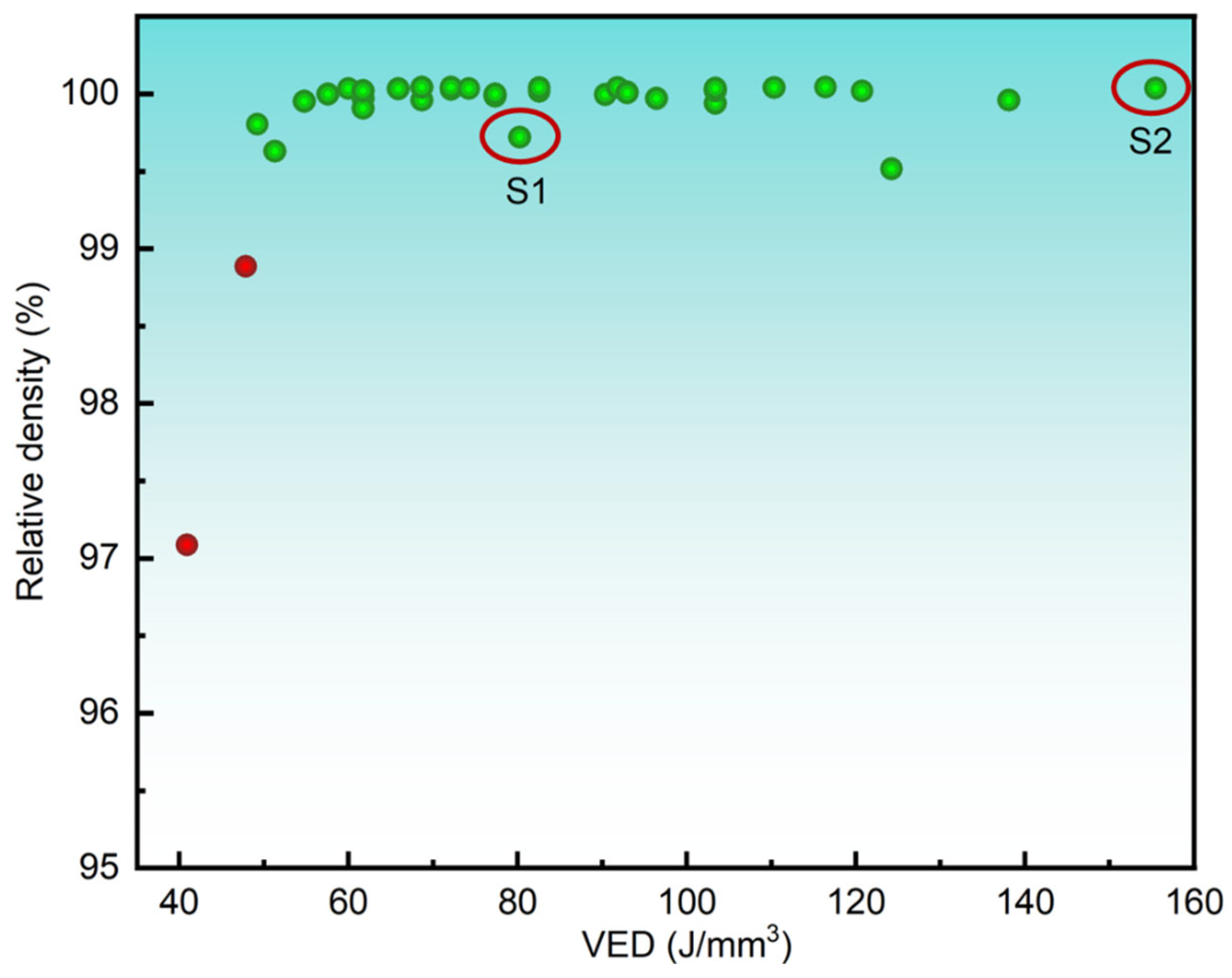

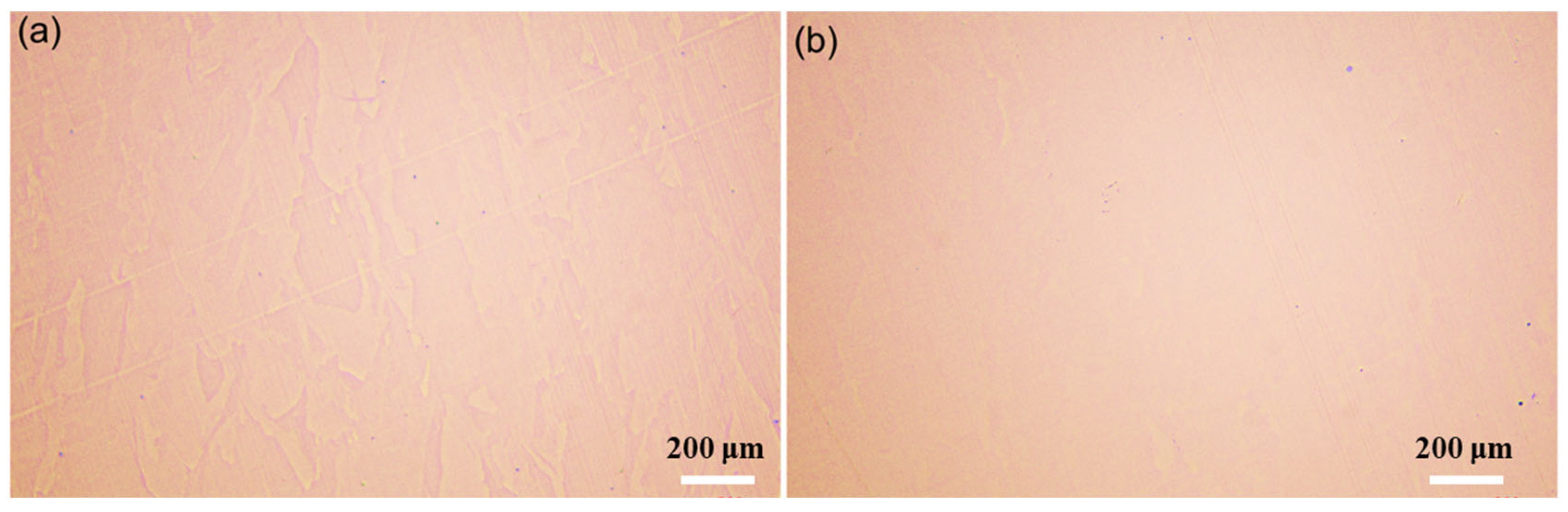

3.1. Relative Density and Metallurgical Examination

3.2. XRD Diffraction

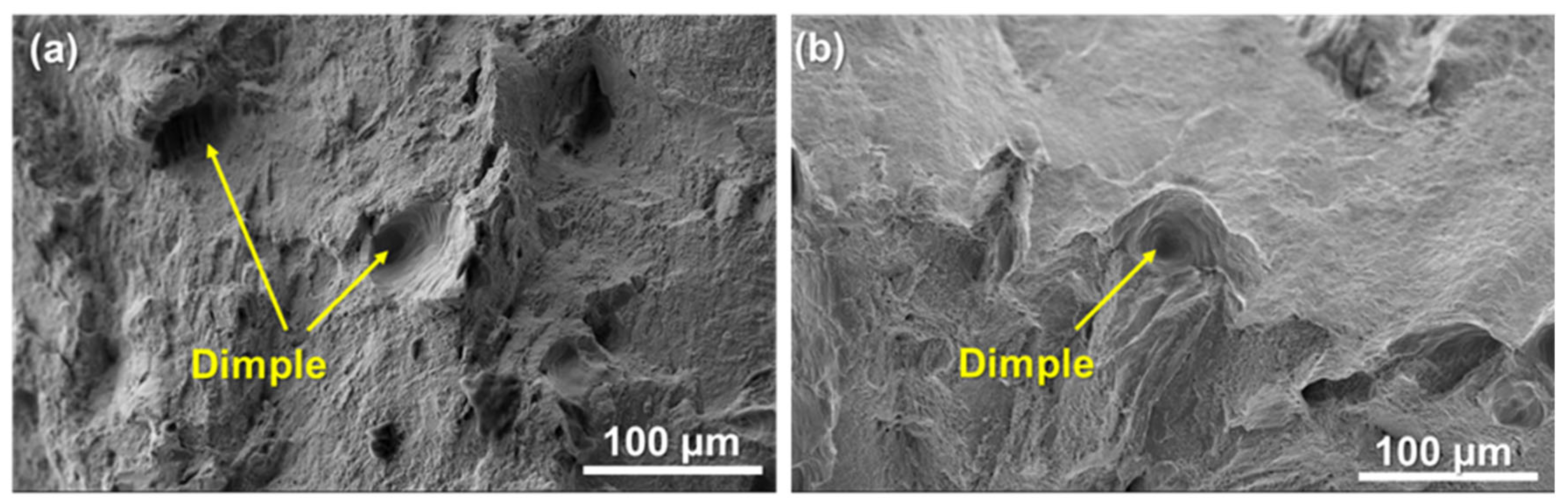

3.3. Mechanical Properties and Fracture Morphology

3.4. Microstructure

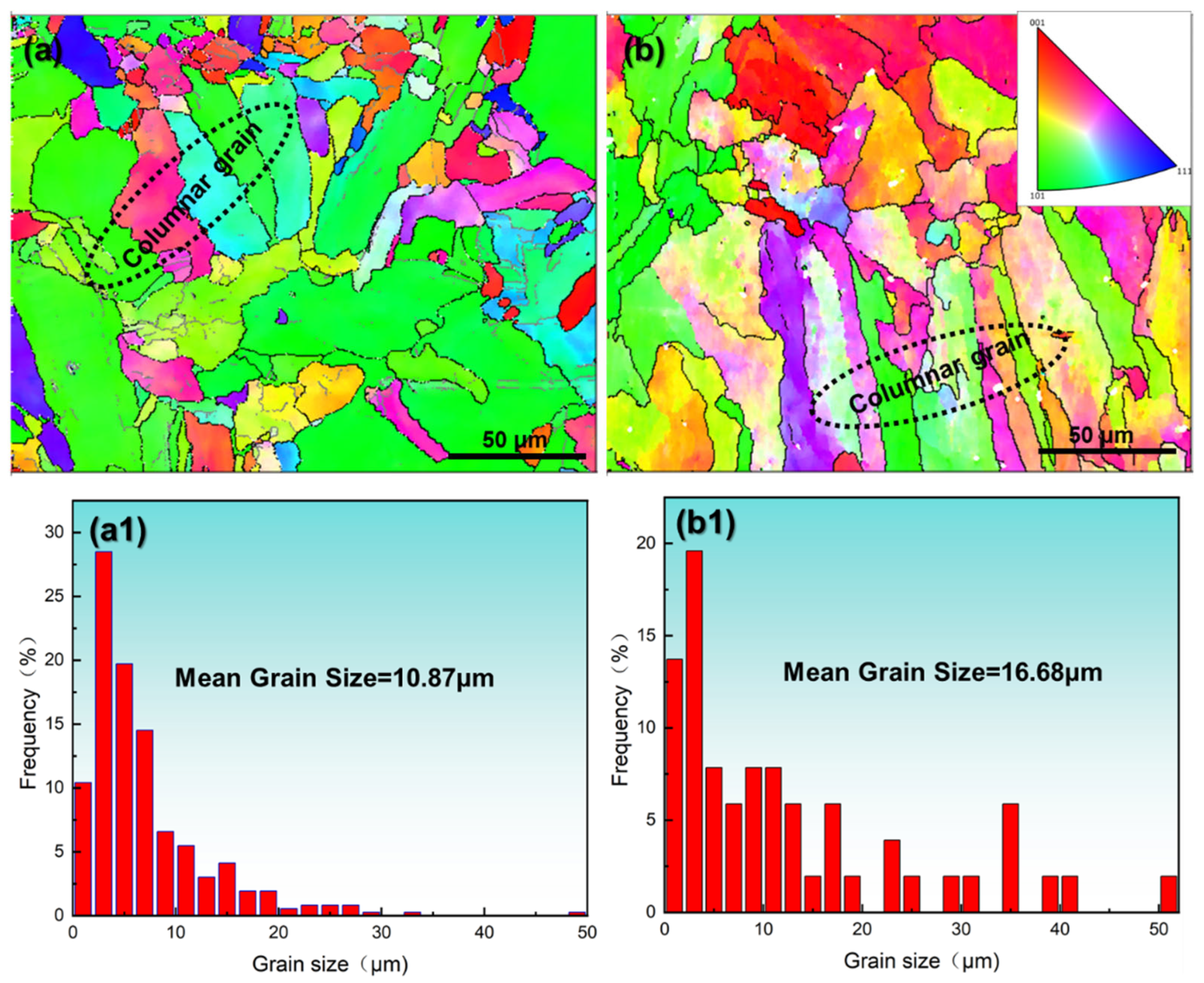

3.4.1. Grain Size and Morphology

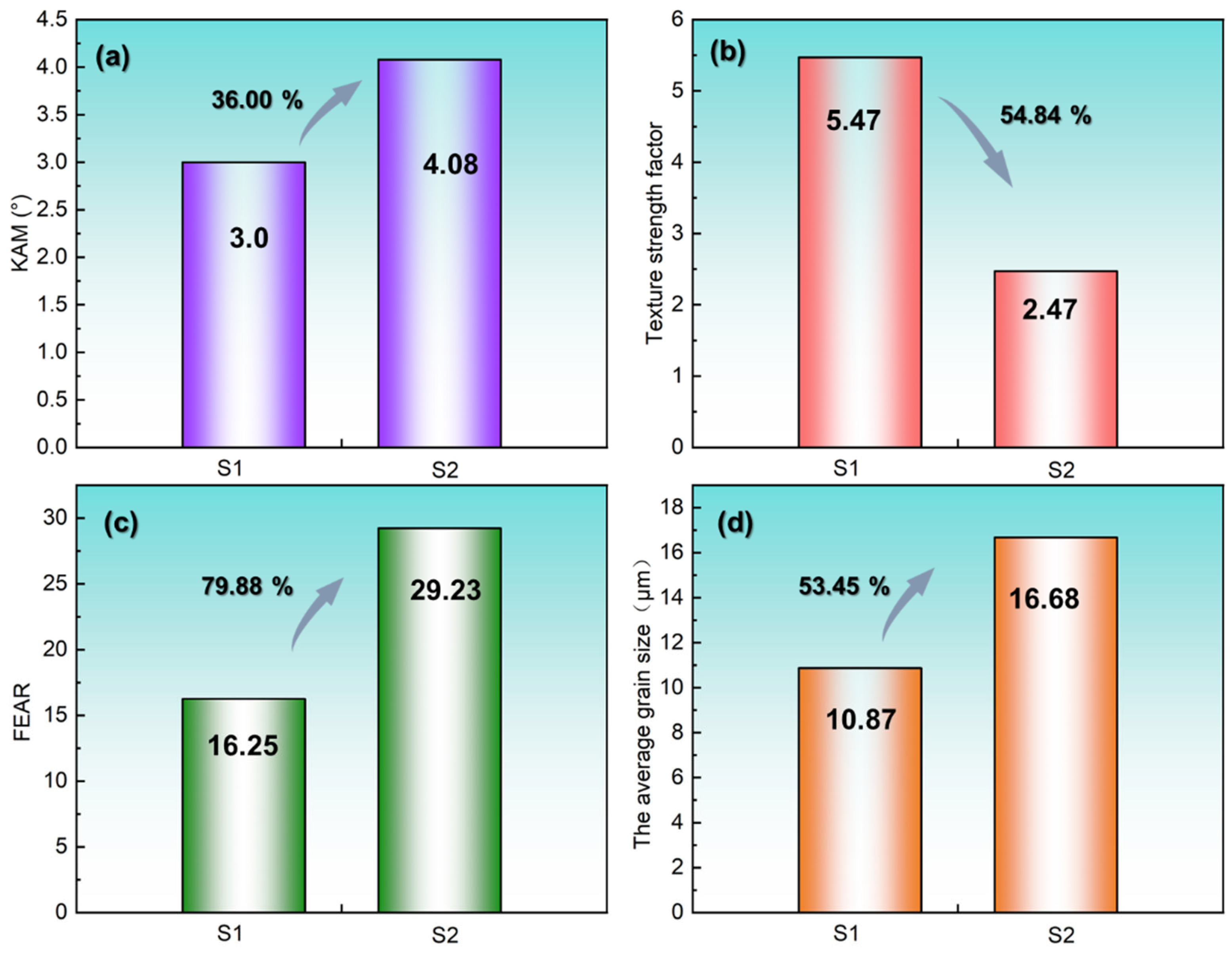

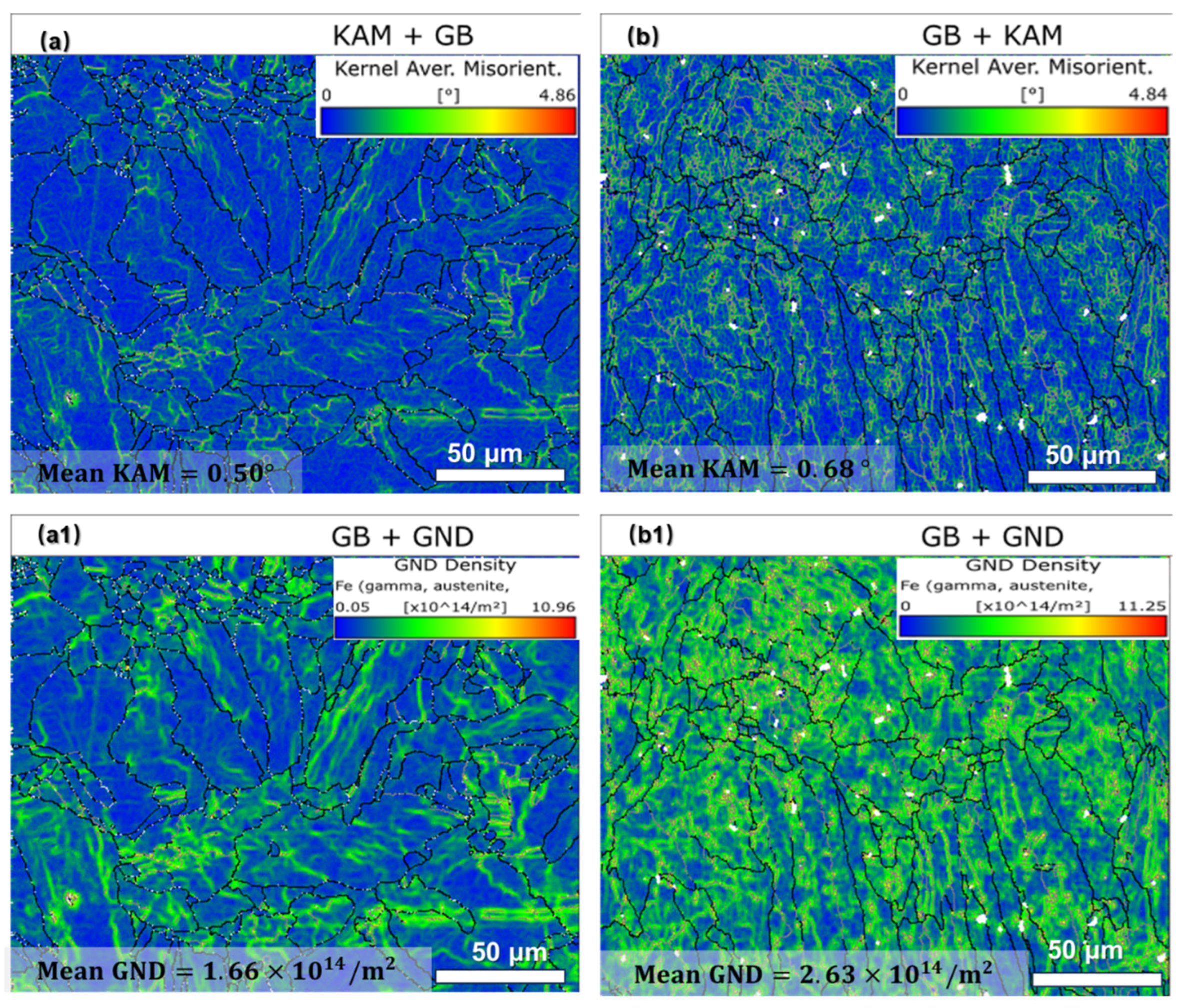

3.4.2. Texture and Dislocation Density

4. Discussion

4.1. The Differences Between the Microstructures

4.2. The Differences Between Mechanical Properties

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Higashi, M.; Ozaki, T. Selective laser melting of pure molybdenum: Evolution of defect and crystallographic texture with process parameters. Mater. Des. 2020, 191, 108588. [Google Scholar] [CrossRef]

- Mark, A.; Hamid, M.; Nida, N. An overview of modern metal additive manufacturing technology. J. Manuf. Process. 2022, 84, 1001–1029. [Google Scholar] [CrossRef]

- Praveena, B.A.; Lokesh, N.; Abdulrajak, B.; Santhosh, N.; Praveena, B.L.; Vignesh, R. A comprehensive review of emerging additive manufacturing (3D printing technology): Methods, materials, applications, challenges, trends and future potential. Mater. Today Proc. 2022, 52, 1309–1313. [Google Scholar]

- Hitzler, L.; Merkel, M.; Hall, W.; Öchsner, A. A Review of Metal Fabricated with Laser- and Powder-Bed Based Additive Manufacturing Techniques: Process, Nomenclature, Materials, Achievable Properties, and its Utilization in the Medical Sector. Adv. Eng. Mater. 2018, 20, 1700658. [Google Scholar] [CrossRef]

- Narasimharaju, S.R.; Zeng, W.; See, T.L.; Zhu, Z.; Scott, P.; Jiang, X.; Lou, S. A comprehensive review on laser powder bed fusion of steels: Processing, microstructure, defects and control methods, mechanical properties, current challenges and future trends. J. Manuf. Process. 2022, 75, 375–414. [Google Scholar] [CrossRef]

- Wu, D.-S.; Xu, Y.; Li, W.; Yang, Y.; Liu, K.; Wan, W.; Qi, Z. Process optimisation of cold spray additive manufacturing of FeCoNiCrMn high-entropy alloy. Sci. Technol. Weld. Join. 2023, 28, 540–547. [Google Scholar] [CrossRef]

- Zhang, J.; Yan, Y.; Li, B. Selective Laser Melting (SLM) Additively Manufactured CoCrFeNiMn High-Entropy Alloy: Process Optimization, Microscale Mechanical Mechanism, and High-Cycle Fatigue Behavior. Materials 2022, 15, 8560. [Google Scholar] [CrossRef]

- Shen, T.; Zhang, W.; Li, B. Machine learning-enabled predictions of as-built relative density and high-cycle fatigue life of Ti6Al4V alloy additively manufactured by laser powder bed fusion. Mater. Today Commun. 2023, 37, 107286. [Google Scholar] [CrossRef]

- Banerjee, S.; Thapliyal, S.; Agilan, M.; Dineshraj, S.; Bajargan, G.; Sigatapu, S. A Machine Learning-Based Model for Multiple Material Density Prediction Developed by Powder Bed Fusion Additive Manufacturing. J. Mater. Eng. Perform. 2024, 34, 8768–8772. [Google Scholar] [CrossRef]

- Hodroj, A.; Bouglia, R.; Ding, Y.; Zghal, M. Machine learning for density prediction and process optimization of 316L stainless steel fabricated by selective laser melting. J. Intell. Manuf. 2025, 1, 1–15. [Google Scholar] [CrossRef]

- Ahmed, N.; Barsoum, I.; Haidemenopoulos, G.; Al-Rub, R.K.A. Process parameter selection and optimization of laser powder bed fusion for 316L stainless steel: A review. J. Manuf. Process. 2022, 75, 415–434. [Google Scholar] [CrossRef]

- Meng, L.X.; Yang, H.J.; Ben, D.D.; Ji, H.B.; Lian, D.L.; Ren, D.C.; Li, Y.; Bai, T.S.; Cai, Y.S.; Chen, J.; et al. Effects of defects and microstructures on tensile properties of selective laser melted Ti6Al4V alloys fabricated in the optimal process zone. Mater. Sci. Eng. A 2022, 830, 142294. [Google Scholar] [CrossRef]

- Bian, J.X.; Lian, X.; Jing, Z.C.; Jing, Q. Research on Numerical Simulation and Process Optimization of Invar Alloy Micro-electrolytic Machining Process. BASIC Clin. Pharmacol. Toxicol. 2020, 126, 153. [Google Scholar]

- Lu, X.; Tian, Y.; Wang, Z.; Wang, X.; Liang, S.Y. Numerical Simulation and Parameters Optimization of Invar 36 Alloy Multi-Pulse Femtosecond Laser Processing. Int. J. Precis. Eng. Manuf. 2025, 26, 1075–1089. [Google Scholar] [CrossRef]

- Jai, T.; Ersilia, C.; Sivasrinivasu, D.; Antonello, A.; Hariharan, K. Determination of process parameters for selective laser melting of inconel 718 alloy through evolutionary multi-objective optimization. Mater. Manuf. Process. 2024, 39, 1019–1028. [Google Scholar] [CrossRef]

- Zhang, Z.; Mativenga, P.; Zhang, W.; Huang, S.-q. Deep Learning-Driven Prediction of Mechanical Properties of 316L Stainless Steel Metallographic by Laser Powder Bed Fusion. Micromachines 2024, 15, 1167. [Google Scholar] [CrossRef] [PubMed]

- Huang, G.; Chen, H.; Ma, Z.; Zhang, R.; Pei, J.; Lie, Z.; Du, P.; Peng, X.; Liu, Y.; Huang, K. Microstructure and mechanical properties of stainless steel addictively manufactured via laser powder bed fusion in high-dense process parameter window. Mater. Sci. Eng. A 2025, 928, 148033. [Google Scholar] [CrossRef]

- Eom, Y.S.; Park, J.M.; Choi, J.-W.; Seong, D.-J.; Joo, H.; Jo, Y.C.; Kim, T.K.; Yu, J.H.; Son, I. Fine-tuning of mechanical properties of additively manufactured AlSi10Mg alloys by controlling the microstructural heterogeneity. J. Alloys Compd. 2023, 956, 170348. [Google Scholar] [CrossRef]

- Yu, Y.; Zhao, Y.; Feng, K.; Chen, R.; Han, B.; Ji, K.; Qin, M.; Li, Z.; Ramamurty, U. Tuning of the mechanical properties of a laser powder bed fused eutectic high entropy alloy Ni30Co30Cr10Fe10Al18W2 through heat treatment. Mater. Sci. Eng. A 2024, 918, 147469. [Google Scholar] [CrossRef]

- Zhan, J.; Wu, J.; Ma, R.; Li, K.; Lin, J.; Murr, L.E. Tuning the functional properties by laser powder bed fusion with partitioned repetitive laser scanning: Toward editable 4D printing of NiTi alloys. J. Manuf. Process. 2023, 101, 1468–1481. [Google Scholar] [CrossRef]

- Zhang, D.; Qiu, D.; Gibson, M.A.; Zheng, Y.; Fraser, H.L.; StJohn, D.H.; Easton, M.A. Additive manufacturing of ultrafine-grained high-strength titanium alloys. Nature 2019, 576, 91–95. [Google Scholar] [CrossRef] [PubMed]

- Fang, Y.; Kim, M.-K.; Zhang, Y.; Jin, H.; Duan, Z.; Yuan, Q.; Suhr, J. Enhanced strength-ductility synergy in super duplex stainless steel matrix composites with bimodal austenite grains via laser powder bed fusion. Mater. Sci. Eng. A 2025, 928, 148079. [Google Scholar] [CrossRef]

- Evlashin, S.A.; Kuzminova, Y.O.; Simonov, A.P.; Firsov, D.G.; Dubinin, O.N.; Rogozin, O.A.; Perevozchikov, M.V.; Akhatov, I.S. Boron as an alloying element for improving mechanical properties of austenitic stainless steels in laser powder bed fusion. Materialia 2023, 32, 101908. [Google Scholar] [CrossRef]

- Gao, S.; Li, Z.; Van Petegem, S.; Ge, J.; Goel, S.; Vas, J.V.; Luzin, V.; Hu, Z.; Seet, H.L.; Sanchez, D.F.; et al. Additive manufacturing of alloys with programmable microstructure and properties. Nat. Commun. 2023, 14, 6752. [Google Scholar] [CrossRef]

- ASTM A240; Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip for Pressure Vessels and for General Applications. ASTM International: West Conshohocken, PA, USA, 2025.

- UNS S31603 (SS316L); Standard Specification for Austenitic Stainless Steel Sheet/Plate (Grade 316L). ASTM International: West Conshohocken, PA, USA, 2025.

- ASTM E8; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2024.

- Gonzalez, J.A.; Mireles, J.; Stafford, S.W.; Perez, M.A.; Terrazas, C.A.; Wicker, R.B. Characterization of Inconel 625 fabricated using powder-bed-based additive manufacturing technologies. J. Mater. Process. Technol. 2017, 264, 200–210. [Google Scholar] [CrossRef]

- Huang, G.; He, G.; Peng, X.; He, Y.; Chen, H.; Huang, K.; Liu, Y. Effect of processing parameters on the microstructure, mechanical properties and thermal expansion behavior of Invar 36 alloy manufactured by laser powder bed fusion. Mater. Sci. Eng. A 2024, 897, 146329. [Google Scholar] [CrossRef]

- Xie, Q.; Cao, Y.; Huang, J.; Li, N.; Liu, Y. Effect of laser energy density on microstructural evolution of selective laser melted Ti-15Zr alloy. J. Alloys Compd. 2023, 934, 167778. [Google Scholar] [CrossRef]

- Xiong, Y.; Zhang, F.; Dai, T.; Shang, C.; Wan, Q. Crystal growth mechanism and mechanical properties of Ti-6Al-4 V alloy during selective laser melting. Mater. Charact. 2022, 194, 112455. [Google Scholar] [CrossRef]

- Wang, F.Z.; Zhang, C.H.; Cui, X.; Zhou, F.Q.; Zhang, S.; Chen, H.T.; Chen, J. Effect of Energy Density on the Defects, Microstructure, and Mechanical Properties of Selective-Laser-Melted 24CrNiMo Low-Alloy Steel. J. Mater. Eng. Perform. 2022, 31, 3520–3534. [Google Scholar] [CrossRef]

- Li, R.; Wang, M.; Yuan, T.; Song, B.; Chen, C.; Zhou, K.; Cao, P. Selective laser melting of a novel Sc and Zr modified Al-6.2Mg alloy: Processing, microstructure, and properties. Powder Technol. 2017, 319, 117–128. [Google Scholar] [CrossRef]

- Gu, D.; Hagedorn, Y.-C.; Meiners, W.; Meng, G.; Batista, R.J.S.; Wissenbach, K.; Poprawe, R. Densification behavior, microstructure evolution, and wear performance of selective laser melting processed commercially pure titanium. Acta Mater. 2012, 60, 3849–3860. [Google Scholar] [CrossRef]

- Kurz, W.; Bezencon, C.; Gaumann, M. Columnar to equiaxed transition in solidification processing. Sci. Technol. Adv. Mater. 2001, 2, 185–191. [Google Scholar] [CrossRef]

- Tekoglu, E.; Bae, J.-S.; Kim, H.-A.; Lim, K.-H.; Liu, J.; Doležal, T.D.; Kim, S.Y.; Alrizqi, M.A.; Penn, A.; Chen, W.; et al. Superior high-temperature mechanical properties and microstructural features of LPBF-printed In625-based metal matrix composites. Mater. Today 2024, 80, 297–307. [Google Scholar] [CrossRef]

- Yan, J.; Ran, M.; Chen, Y.; Wen, Z.; Wang, W. Deformation behavior and mechanical properties of Invar 36 alloy TPMS and its gradient lattice structure prepared by LPBF. Mater. Today Commun. 2025, 43, 111654. [Google Scholar] [CrossRef]

- Huang, G.; He, G.; Liu, Y.; Huang, K. Anisotropy of microstructure, mechanical properties and thermal expansion in Invar 36 alloy fabricated via laser powder bed fusion. Addit. Manuf. 2024, 82, 104025. [Google Scholar] [CrossRef]

- Schreiber, M.; Speer, J.G.; Klemm-Toole, J.; Gockel, J.; Brice, C.; Findley, K.O. Influence of annealing on microstructures and mechanical properties of laser powder bed fusion and wire arc directed energy deposition additively manufactured 316L. Mater. Sci. Eng. A 2024, 917, 147390. [Google Scholar] [CrossRef]

- Surya Prakash, N.; Mandal, S.; Chakrabarti, D.; Roy, M. Unraveling the effects of nano-grained microstructure on mechanical behavior, corrosion, and in vitro biocompatibility of 316L austenitic stainless steel. Mater. Chem. Phys. 2024, 318, 129292. [Google Scholar] [CrossRef]

- Tan, C.; Zhou, K.; Ma, W.; Zhang, P.; Liu, M.; Kuang, T. Microstructural evolution, nanoprecipitation behavior and mechanical properties of selective laser melted high-performance grade 300 maraging steel. Mater. Des. 2017, 134, 23–34. [Google Scholar] [CrossRef]

- Bian, P.; Shi, J.; Liu, Y.; Xie, Y. Influence of laser power and scanning strategy on residual stress distribution in additively manufactured 316L steel. Opt. Laser Technol. 2020, 132, 106477. [Google Scholar] [CrossRef]

- Mugwagwa, L.; Dimitrov, D.; Matope, S.; Yadroitsev, I. Influence of process parameters on residual stress related distortions in selective laser melting. Procedia Manuf. 2018, 21, 92–99. [Google Scholar] [CrossRef]

- Shi, Q.; Gu, D.; Xia, M.; Cao, S.; Rong, T. Effects of laser processing parameters on thermal behavior and melting/solidification mechanism during selective laser melting of TiC/Inconel 718 composites. Opt. Laser Technol. 2016, 84, 9–22. [Google Scholar] [CrossRef]

- Bi, J.; Wang, K.; Wu, C.; Liu, B.; Chi, J.; Qin, X.; Chen, W.; Starostenkov, M.D.; Dong, G.; Chen, X.; et al. Microstructure, mechanical properties and multiphase synergistic strengthening mechanisms of LPBF fabricated AlZnMgZr alloy with high Zn content. Addit. Manuf. 2024, 89, 104305. [Google Scholar] [CrossRef]

- Garibaldi, M.; Ashcroft, I.; Simonelli, M.; Hague, R. Metallurgy of high-silicon steel parts produced using Selective Laser Melting. Acta Mater. 2016, 110, 207–216. [Google Scholar] [CrossRef]

- Alnajjar, M.; Christien, F.; Wolski, K.; Bosch, C. Evidence of austenite by-passing in a stainless steel obtained from laser melting additive manufacturing. Addit. Manuf. 2019, 25, 187–195. [Google Scholar] [CrossRef]

- Sun, S.-H.; Hagihara, K.; Nakano, T. Effect of scanning strategy on texture formation in Ni-25at.%Mo alloys fabricated by selective laser melting. Mater. Des. 2018, 140, 307–316. [Google Scholar] [CrossRef]

- Kurzynowski, T.; Gruber, K.; Stopyra, W.; Kuźnicka, B.; Chlebus, E. Correlation between process parameters, microstructure and properties of 316 L stainless steel processed by selective laser melting. Mater. Sci. Eng. A 2018, 718, 64–73. [Google Scholar] [CrossRef]

- Yin, Y.J.; Sun, J.Q.; Guo, J.; Kan, X.F.; Yang, D.C. Mechanism of high yield strength and yield ratio of 316 L stainless steel by additive manufacturing. Mater. Sci. Eng. A 2019, 744, 773–777. [Google Scholar] [CrossRef]

- Gao, S.; Hu, Z.; Duchamp, M.; Krishnan, P.S.S.R.; Tekumalla, S.; Song, X.; Seita, M. Recrystallization-based grain boundary engineering of 316L stainless steel produced via selective laser melting. Acta Mater. 2020, 200, 366–377. [Google Scholar] [CrossRef]

- Andreau, O.; Koutiri, I.; Peyre, P.; Penot, J.-D.; Saintier, N.; Pessard, E.; De Terris, T.; Dupuy, C.; Baudin, T. Texture control of 316L parts by modulation of the melt pool morphology in selective laser melting. J. Mater. Process. Technol. 2019, 264, 21–31. [Google Scholar] [CrossRef]

- Pham, M.-S.; Dovgyy, B.; Hooper, P.A.; Gourlay, C.M.; Piglione, A. The role of side-branching in microstructure development in laser powder-bed fusion. Nat. Commun. 2020, 11, 749. [Google Scholar] [CrossRef]

- Suryawanshi, J.; Prashanth, K.G.; Ramamurty, U. Mechanical behavior of selective laser melted 316L stainless steel. Mater. Sci. Eng. A 2017, 696, 113–121. [Google Scholar] [CrossRef]

- Wang, Y.M.; Voisin, T.; McKeown, J.T.; Ye, J.; Calta, N.P.; Li, Z.; Zeng, Z.; Zhang, Y.; Chen, W.; Roehling, T.T.; et al. Additively manufactured hierarchical stainless steels with high strength and ductility. Nat. Mater. 2018, 17, 63–71. [Google Scholar] [CrossRef] [PubMed]

- Zhong, Y.; Liu, L.; Wikman, S.; Cui, D.; Shen, Z. Intragranular cellular segregation network structure strengthening 316L stainless steel prepared by selective laser melting. J. Nucl. Mater. 2016, 470, 170–178. [Google Scholar] [CrossRef]

- Cui, L.; Jiang, S.; Xu, J.; Peng, R.L.; Mousavian, R.T.; Moverare, J. Revealing relationships between microstructure and hardening nature of additively manufactured 316L stainless steel. Mater. Des. 2021, 198, 109385. [Google Scholar] [CrossRef]

- Bahl, S.; Mishra, S.; Yazar, K.U.; Kola, I.R.; Chatterjee, K.; Suwas, S. Non-equilibrium microstructure, crystallographic texture and morphological texture synergistically result in unusual mechanical properties of 3D printed 316L stainless steel. Addit. Manuf. 2019, 28, 65–77. [Google Scholar] [CrossRef]

- Liu, L.; Ding, Q.; Zhong, Y.; Zou, J.; Wu, J.; Chiu, Y.-L.; Li, J.; Zhang, Z.; Yu, Q.; Shen, Z. Dislocation network in additive manufactured steel breaks strength–ductility trade-off. Mater. Today 2018, 21, 354–361. [Google Scholar] [CrossRef]

- Gokcekaya, O.; Ishimoto, T.; Hibino, S.; Yasutomi, J.; Narushima, T.; Nakano, T. Unique crystallographic texture formation in Inconel 718 by laser powder bed fusion and its effect on mechanical anisotropy. Acta Mater. 2021, 212, 116876. [Google Scholar] [CrossRef]

- Agrawal, A.K.; Meric de Bellefon, G.; Thoma, D. High-throughput experimentation for microstructural design in additively manufactured 316L stainless steel. Mater. Sci. Eng. A 2020, 793, 139841. [Google Scholar] [CrossRef]

- Juuti, T.; Rovatti, L.; Porter, D.; Angella, G.; Kömi, J. Factors controlling ambient and high temperature yield strength of ferritic stainless steel susceptible to intermetallic phase formation. Mater. Sci. Eng. A 2018, 726, 45–55. [Google Scholar] [CrossRef]

- Chung, S.; Lee, B.; Lee, S.Y.; Do, C.; Ryu, H.J. The effects of Y pre-alloying on the in-situ dispersoids of ODS CoCrFeMnNi high-entropy alloy. J. Mater. Sci. Technol. 2021, 85, 62–75. [Google Scholar] [CrossRef]

- Dong, Z.; Ouyang, P.; Zhang, S.; Liu, L.; Li, H.; Wu, Y. Effect of building direction on anisotropy of mechanical properties of GH4169 alloy fabricated by laser powder bed fusion. Mater. Sci. Eng. A 2023, 862, 144430. [Google Scholar] [CrossRef]

| Elements | Fe | Cr | Ni | Mo | Si | Mn | P | S | C | N |

|---|---|---|---|---|---|---|---|---|---|---|

| ASTM A240 [25] | Bal. | 16–18 | 10–14 | 2–3 | 0.50 | 2 | 0.045 | 0.03 | 0.03 | 0.1 |

| SS316L [26] | Bal. | 17.12 | 11.01 | 2.54 | 0.31 | 0.66 | 0.005 | 0.006 | 0.021 | 0.002 |

| No. | P (W) | V (mm/s) | h (μm) | t (mm) | VED (J/mm3) |

|---|---|---|---|---|---|

| S1 | 175 | 600 | 120 | 0.03 | 81.0 |

| S2 | 225 | 600 | 80 | 0.03 | 156.3 |

| No. | YS (MPa) | UTS (MPa) | EL (%) |

|---|---|---|---|

| S1 | 566.34 ± 6.21 | 665.49 ± 7.63 | 46.17 ± 1.95 |

| S2 | 525.13 ± 17.03 | 623.31 ± 26.73 | 37.33 ± 10.15 |

| Yield Strength (YS, MPa) | Reinforced Contribution | Calculated Value | Measured Value | Difference Radio (%) | ||

|---|---|---|---|---|---|---|

| S1 | 183.30 | 160.79 | 230.81 | 574.90 | 566.34 ± 6.21 | 1.51 |

| S2 | 183.30 | 202.39 | 186.33 | 572.02 | 525.13 ± 17.03 | 8.93 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; Wu, X.; Wang, Z.; Jiang, M.; Huang, G.; Peng, X.; Yang, C.; Zhu, J.; Huang, K. Microstructural and Mechanical Property Variations in 316L Stainless Steel Fabricated by Laser Powder Bed Fusion Under High-Density Processing Conditions. Materials 2025, 18, 3899. https://doi.org/10.3390/ma18163899

Zhang S, Wu X, Wang Z, Jiang M, Huang G, Peng X, Yang C, Zhu J, Huang K. Microstructural and Mechanical Property Variations in 316L Stainless Steel Fabricated by Laser Powder Bed Fusion Under High-Density Processing Conditions. Materials. 2025; 18(16):3899. https://doi.org/10.3390/ma18163899

Chicago/Turabian StyleZhang, Shun, Xudong Wu, Zhong Wang, Meiling Jiang, Guoliang Huang, Xiaoqiang Peng, Chen Yang, Junyan Zhu, and Ke Huang. 2025. "Microstructural and Mechanical Property Variations in 316L Stainless Steel Fabricated by Laser Powder Bed Fusion Under High-Density Processing Conditions" Materials 18, no. 16: 3899. https://doi.org/10.3390/ma18163899

APA StyleZhang, S., Wu, X., Wang, Z., Jiang, M., Huang, G., Peng, X., Yang, C., Zhu, J., & Huang, K. (2025). Microstructural and Mechanical Property Variations in 316L Stainless Steel Fabricated by Laser Powder Bed Fusion Under High-Density Processing Conditions. Materials, 18(16), 3899. https://doi.org/10.3390/ma18163899