1. Introduction

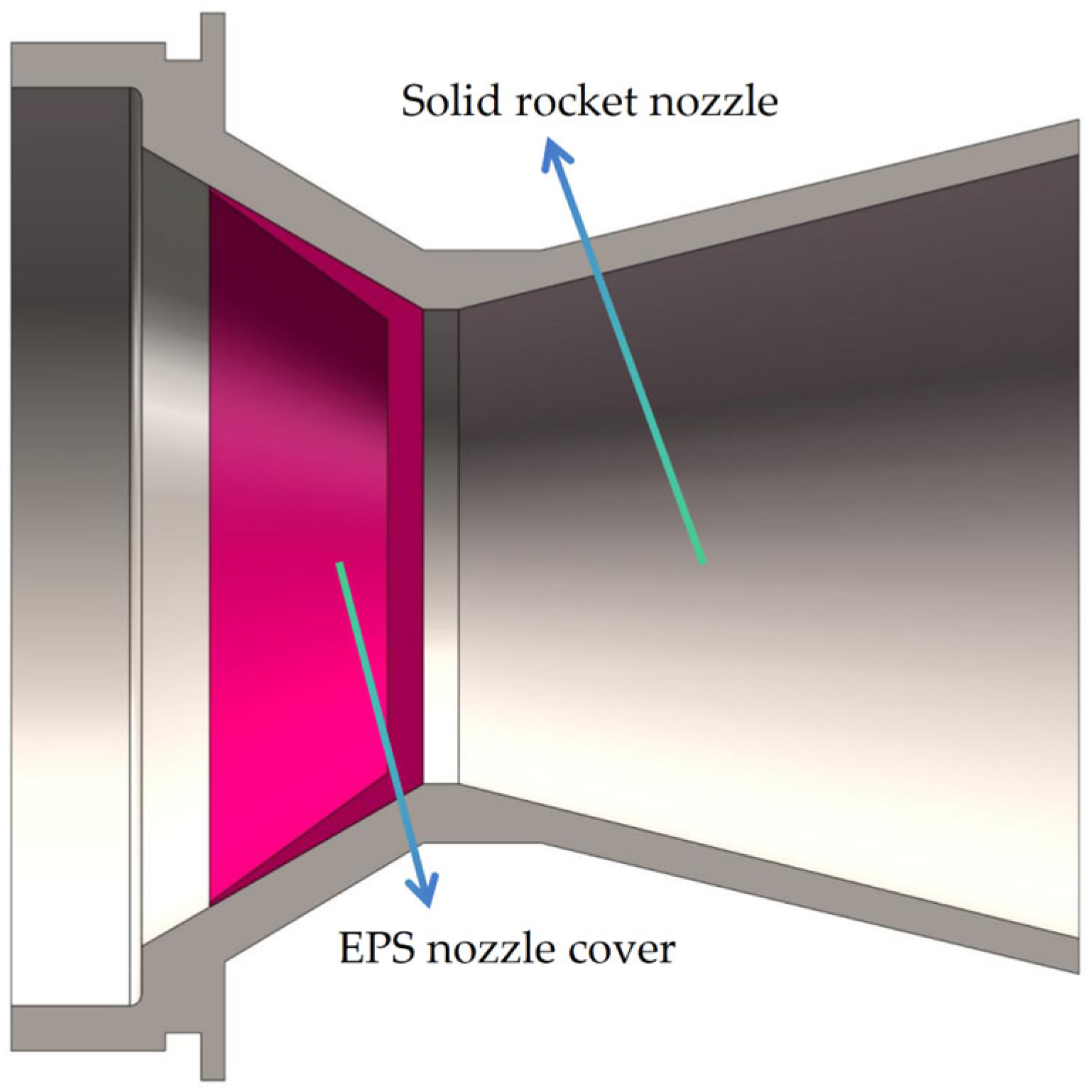

As an important part of the solid rocket motor, the main functions of the nozzle cover are as follows: before ignition, it plays an important role in sealing moisture proof and maintaining internal pressure balance, avoiding the moisture of the internal grain and grain box of the motor, and ensuring the normal operation of the propellant and ignition powder; during ignition, the ignition pressure of the engine is established, the ignition delay period is shortened, and the ignition reliability is improved. In the design, the material selection, thickness, placement position and failure pressure should be studied in depth [

1].

The nozzle cover can be divided into a metal-based nozzle cover and a non-metal nozzle cover according to its substrate properties. The research on metal-based nozzle cover mainly includes: Chen Changjiang et al. used 1Cr18Ni9Ti stainless steel. The single-layer and double-layer structures were compared by experiment and simulation. It was found that the double-layer design significantly improved the pressure bearing capacity [

2]; fan Ding et al. used aluminum alloy material to optimize the structural design by combining test and simulation, which effectively improved the opening reliability of the nozzle cover [

3]. In addition, Liu Daokun et al. developed a metal-based composite nozzle cover, which uses aluminum alloy as the substrate to composite WL-640 insulation layer, and verified its excellent thermal insulation performance under cold flow conditions through experiments and simulations [

4]. The study of non-metallic nozzle cover includes: Tu Xiaochang et al. prepared a single material polyurethane rigid foam nozzle cover, and the test confirmed its feasibility [

5]; zhang Meng et al. developed a composite non-metallic nozzle cover, using rubber and sandwich composite materials, and innovatively applied a simplified finite element model for simulation analysis (error as low as 5.3%), which provides a reliable simulation method support for the design of nozzle cover of this kind of material [

6].

In summary, most of the existing studies on nozzle cover are based on conventional materials with known material parameters. Although some literature [

6] explored new materials, their research only focuses on the specific material itself, failing to cover the performance changes under different densities, and it is difficult to provide a basis for subsequent scholars to design such material products similar to the parameterized design of metal materials.

Conventional solid rocket motors mostly use metal-based nozzle covers, because the metal material is difficult to ablate or can not be completely ablated, high-speed flying out of the nozzle cover debris may pose a serious threat to the rear personnel and the launch platform. Therefore, there is an urgent need to develop a new type of nozzle cover material—not only to maintain the mechanical properties of metal materials, but also to be able to quickly and completely ablate after engine ignition, thus fundamentally eliminating this safety risk.

With the development of materials science and engineering, many non-metallic materials now possess mechanical properties comparable to those of metallic materials, while also exhibiting numerous characteristics that metallic materials lack.

Polymer foam, as a typical non-metallic material, mainly contains three kinds of foamed plastics, such as polystyrene (EPS), polypropylene (EPP) and polyethylene (EPE). The EPS material is characterized by light weight, high flexural modulus, high multiplicity, and an easy-to-produce closed-cell structure [

7]. As a material with excellent performance, EPS can not only be used alone, but also can be further optimized by compounding with other materials. According to its combination, it can be divided into stacked combination type optimization and matrix material hybrid optimization. In the study of stacked combination type optimization, Zexiong Zhang et al. investigated the mechanical properties and cushioning properties of flexible polyurethane foam (FPUF) and EPS combination materials with different structural scale parameters through theoretical analysis and finite element simulation, revealing the complementary advantages of parallel and tandem structures [

8]. Itsara Rojana et al. tested aluminum honeycomb structures partially filled with EPS foams by axial quasi-static compression tests. Tests on an aluminum honeycomb structure partially filled with EPS foam found that a specific amount of partial filling can significantly enhance its energy absorption capacity and mean crush force [

9]. Of the matrix material mix optimization, Quan You et al. investigated the fatigue and durability behavior of structural EPS concrete, and the results showed that, compared with ordinary concrete of the same strength, the material has superior energy absorption capacity and toughness, and exhibits excellent fatigue stability, and also in the wet-dry (W-D) cyclic test, the structural EPS concrete also demonstrated good sulfate corrosion resistance [

10].

EPS material not only has excellent performance, but also has excellent processing adaptability. The material can be processed into different shapes and sizes by cutting, molding [

11] and other molding processes, which can flexibly meet the customization needs of various application scenarios.

It can be seen that the use of EPS material to make a nozzle cover has the following advantages: lightweight; impact resistance; heat insulation; corrosion resistance; easy to mold; low cost; no residue of burnt fusion.

With the development of finite element analysis technology, the use of finite element software to analyze the nozzle cover has become an indispensable key link in the design and analysis of the nozzle cover. Numerical simulation replaces some of the expensive tests and significantly reduces R&D costs. In Reference [

12], ABAQUS finite element simulation software was used to analyze the influence of the opening pressure of the cover, the pressure building rate of the combustion chamber and the density of the cover material on the opening process of the cover.

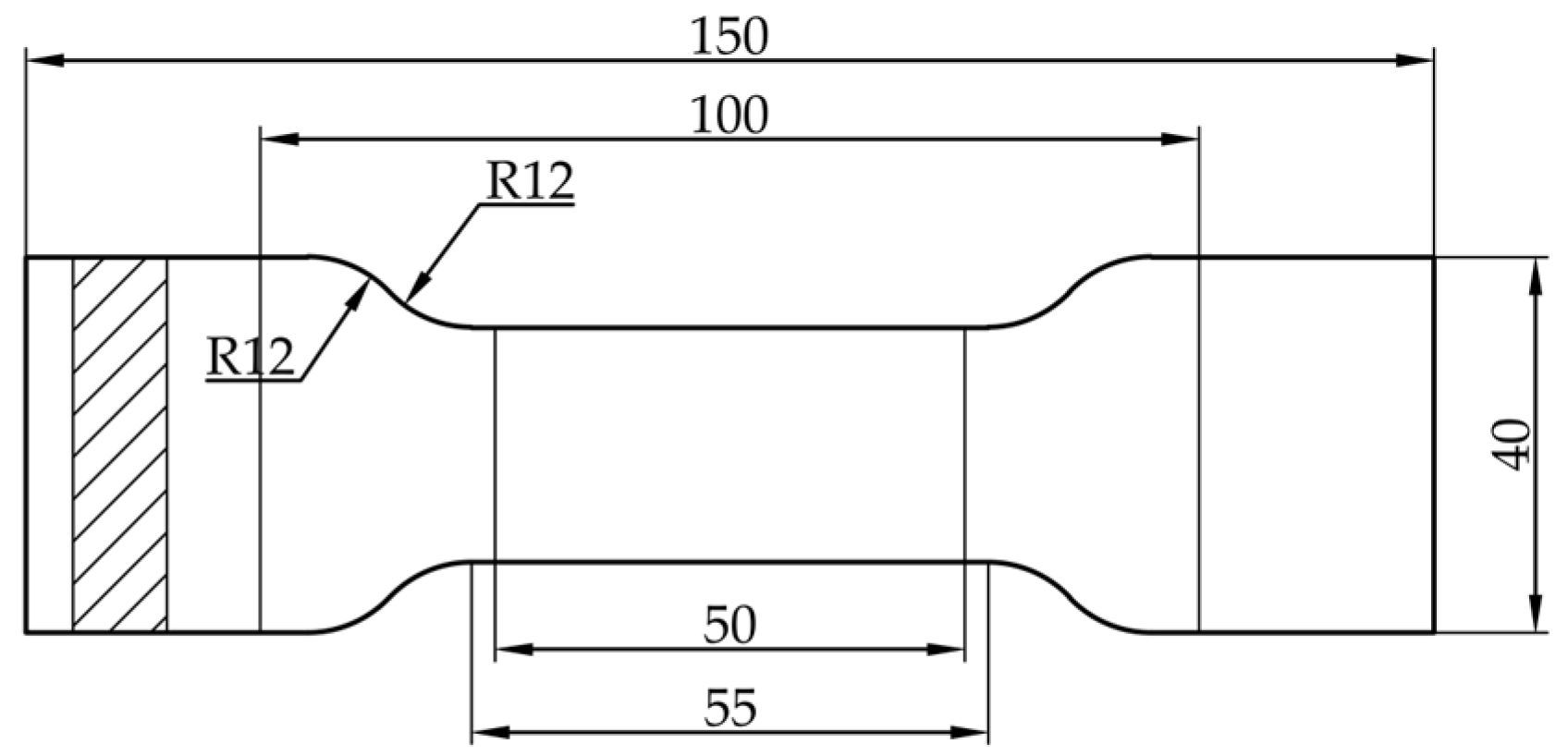

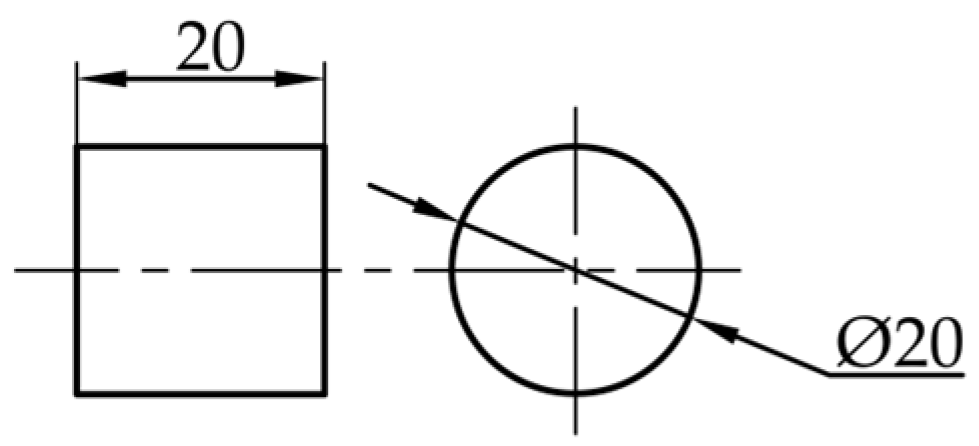

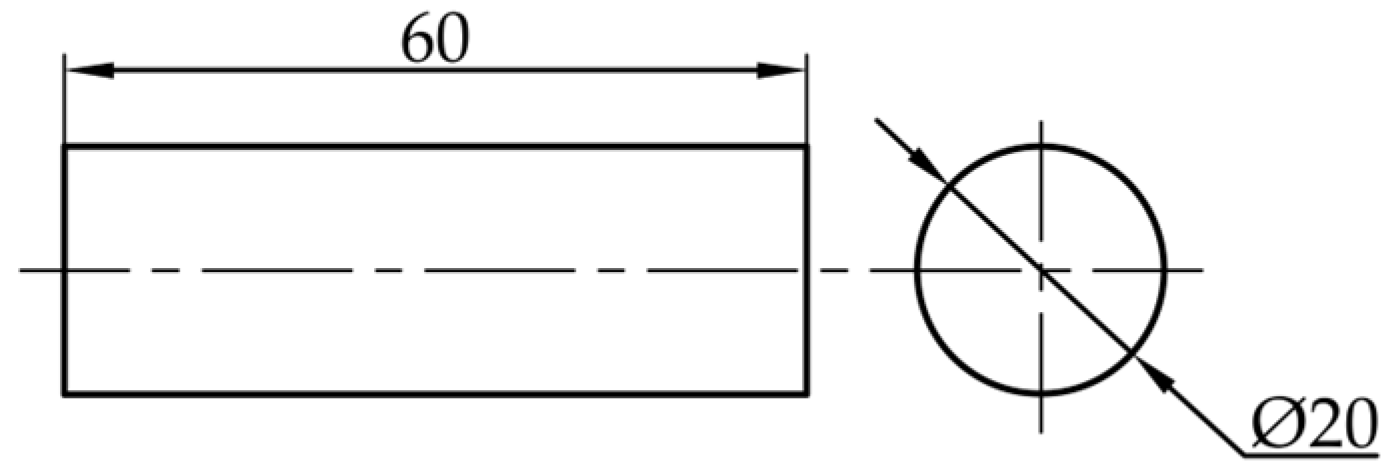

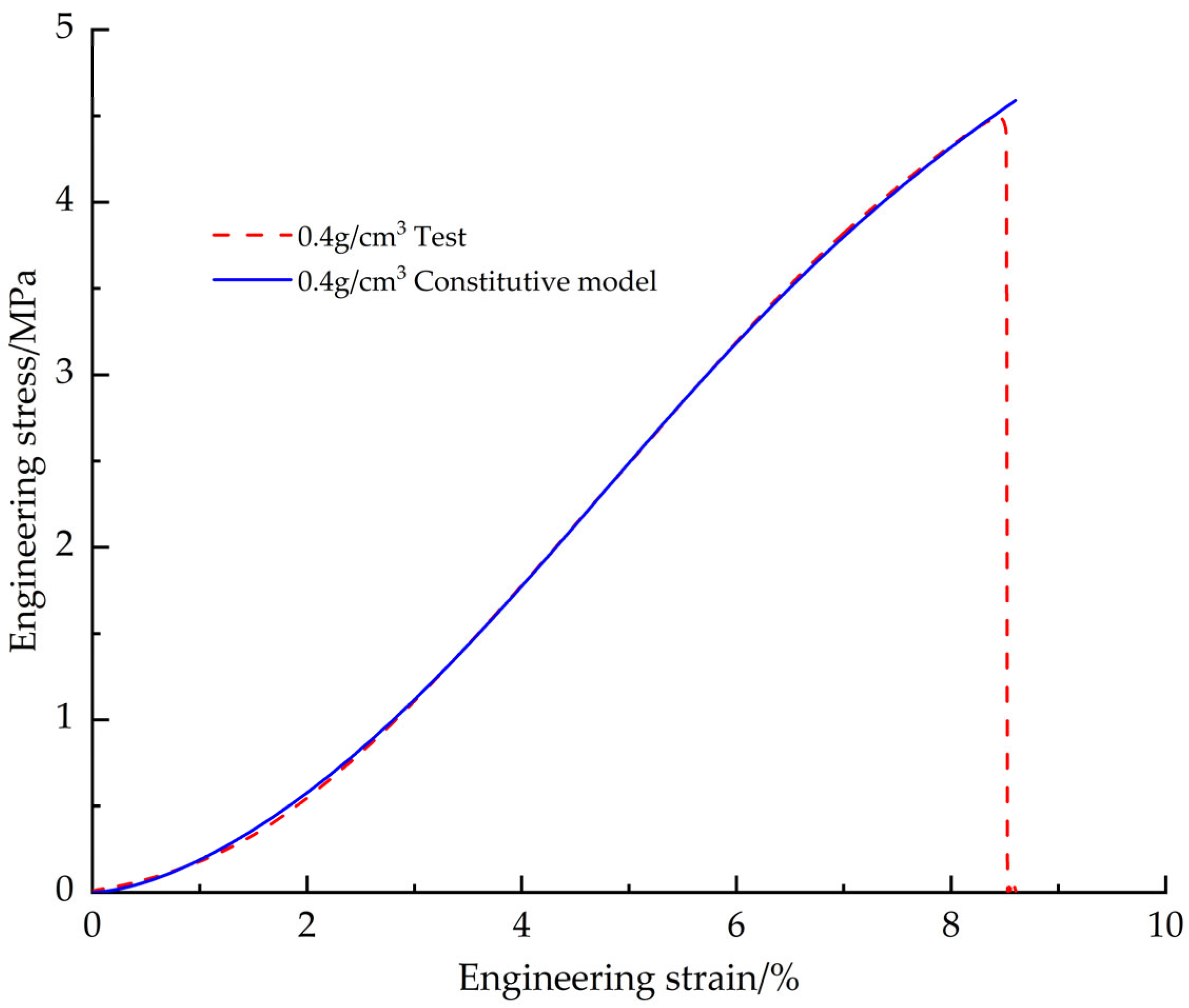

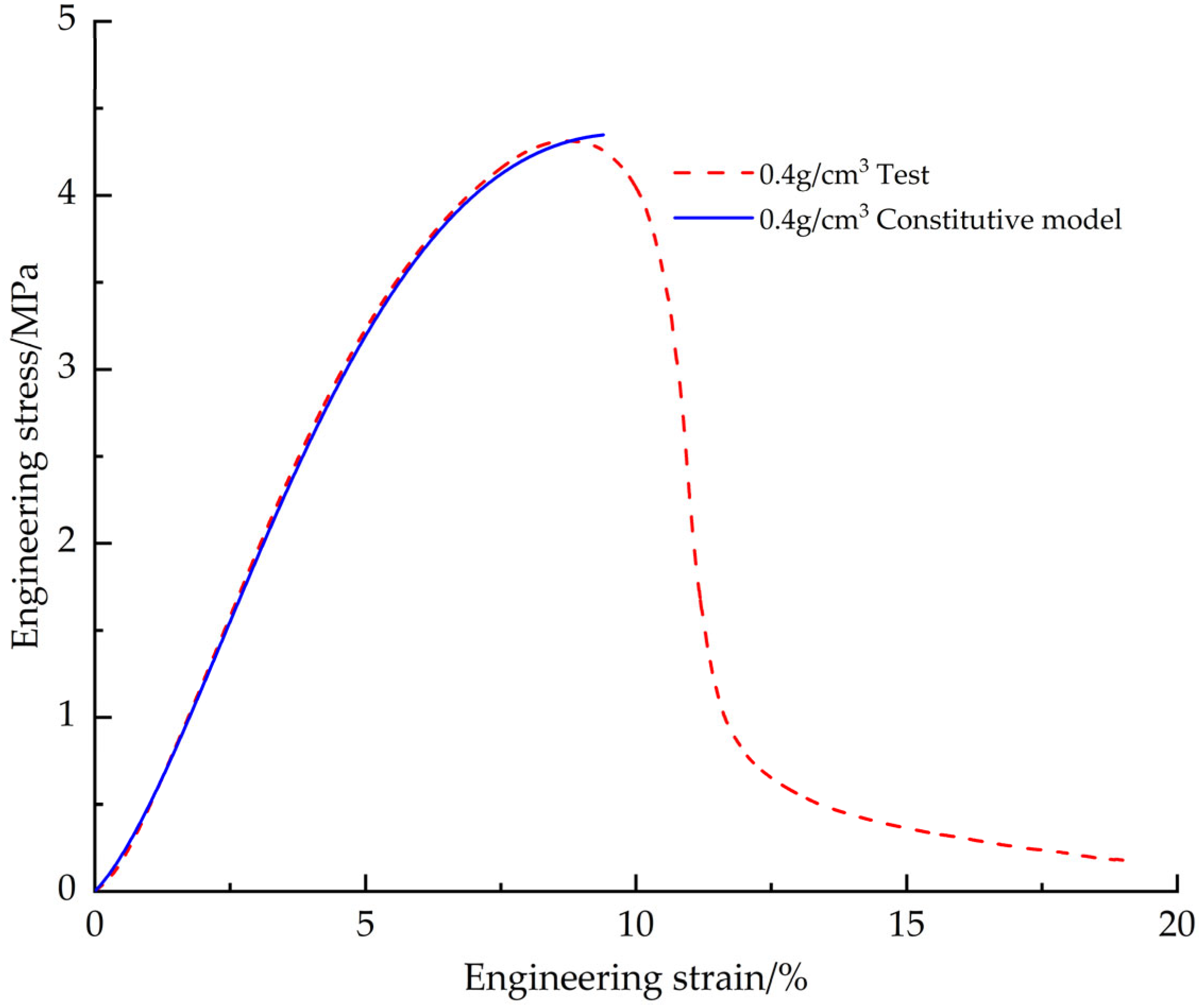

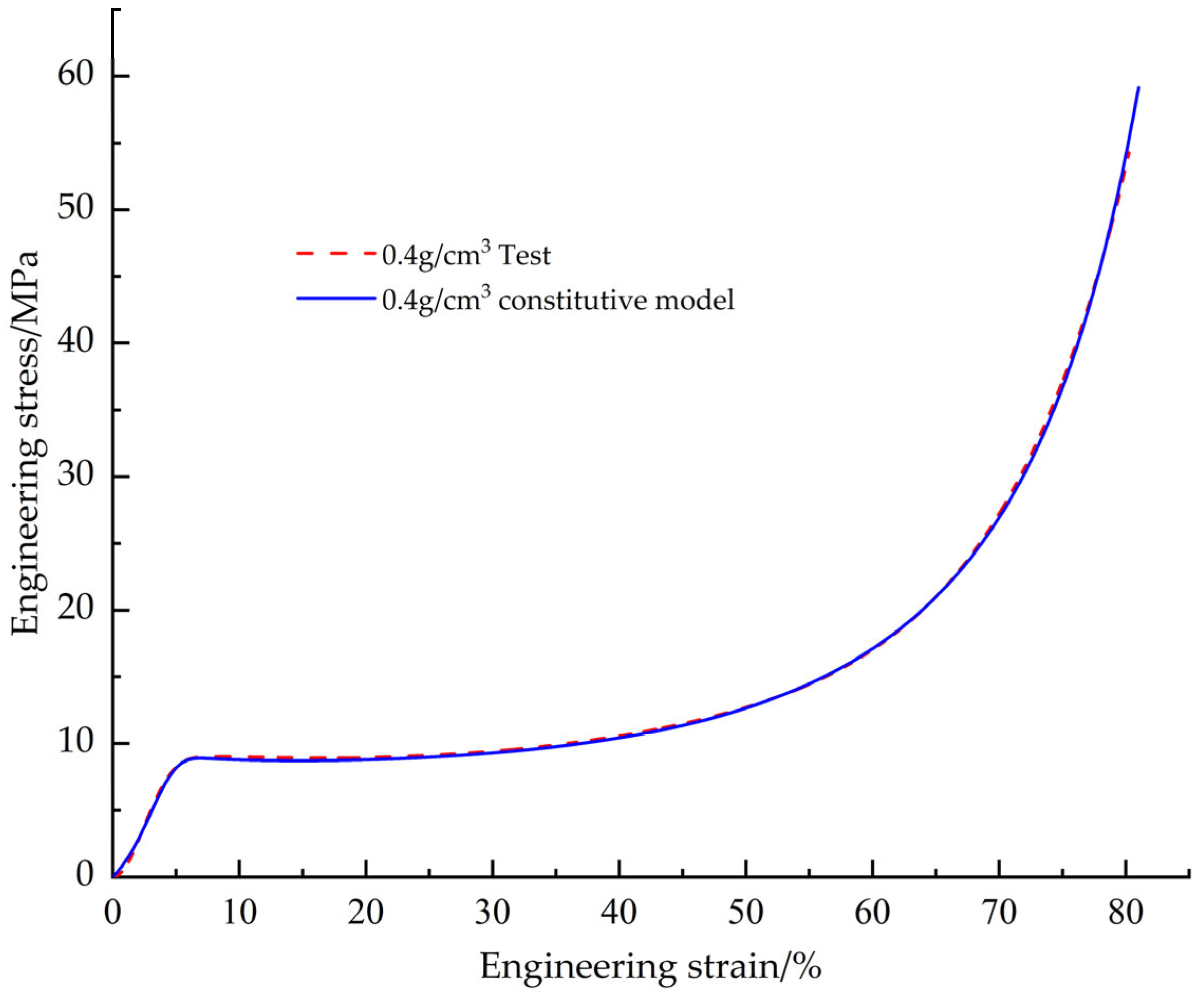

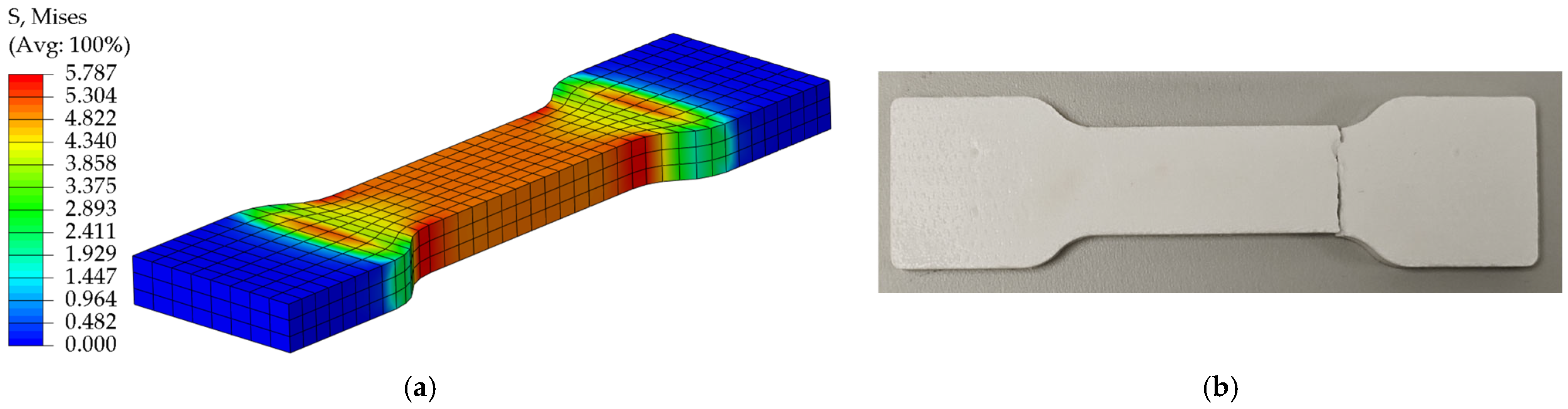

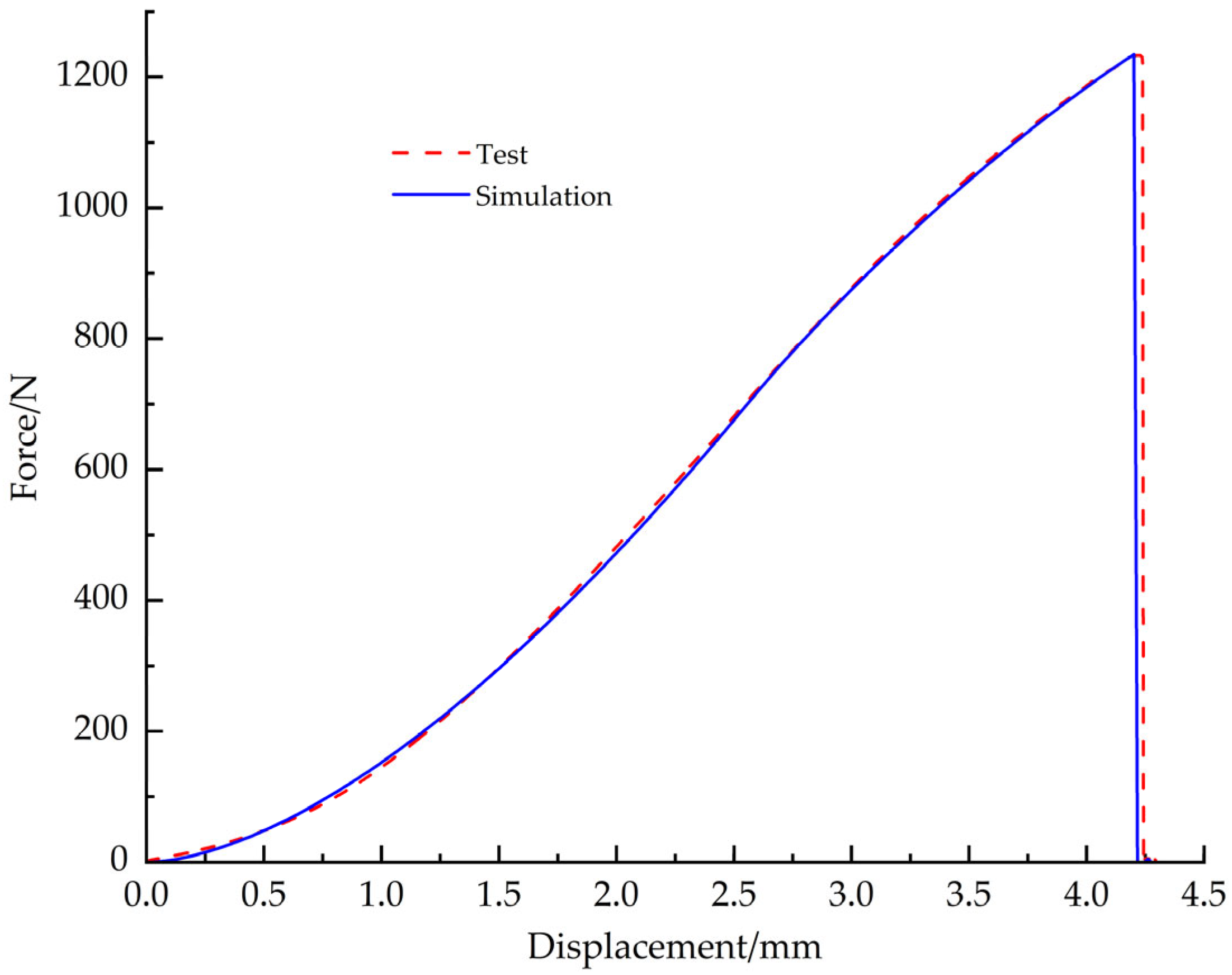

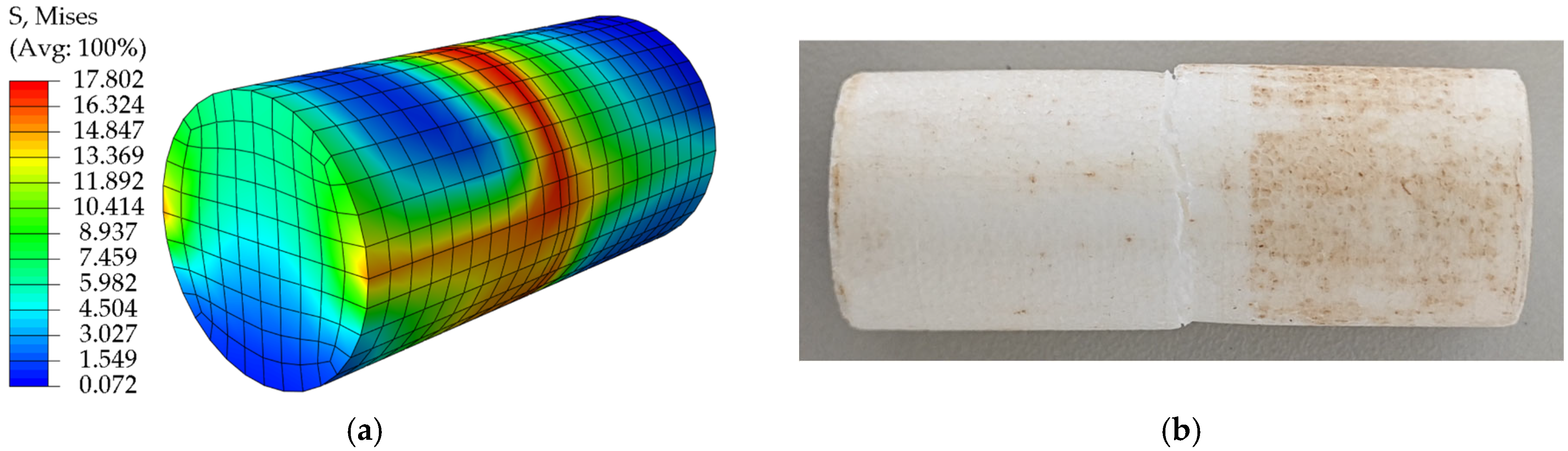

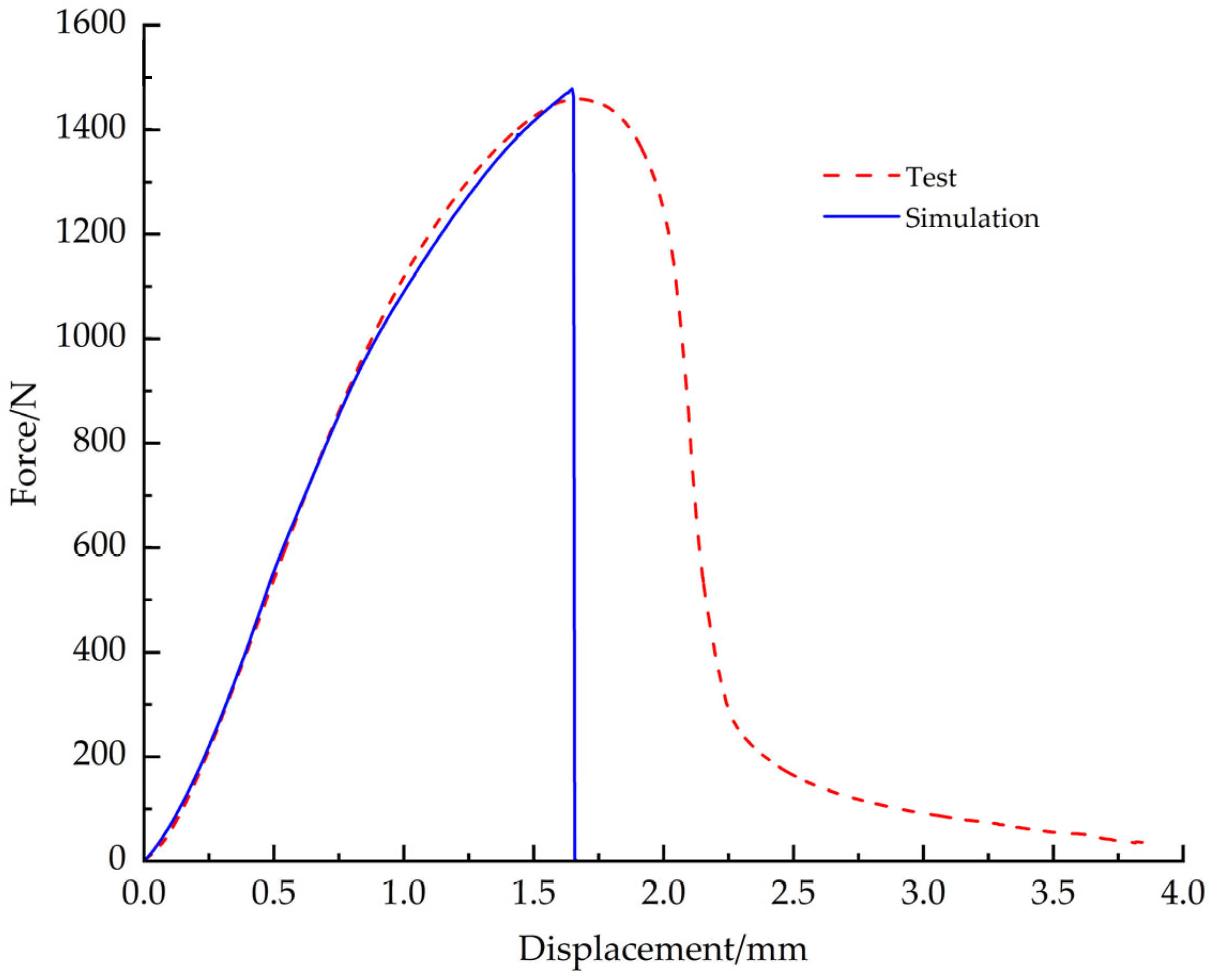

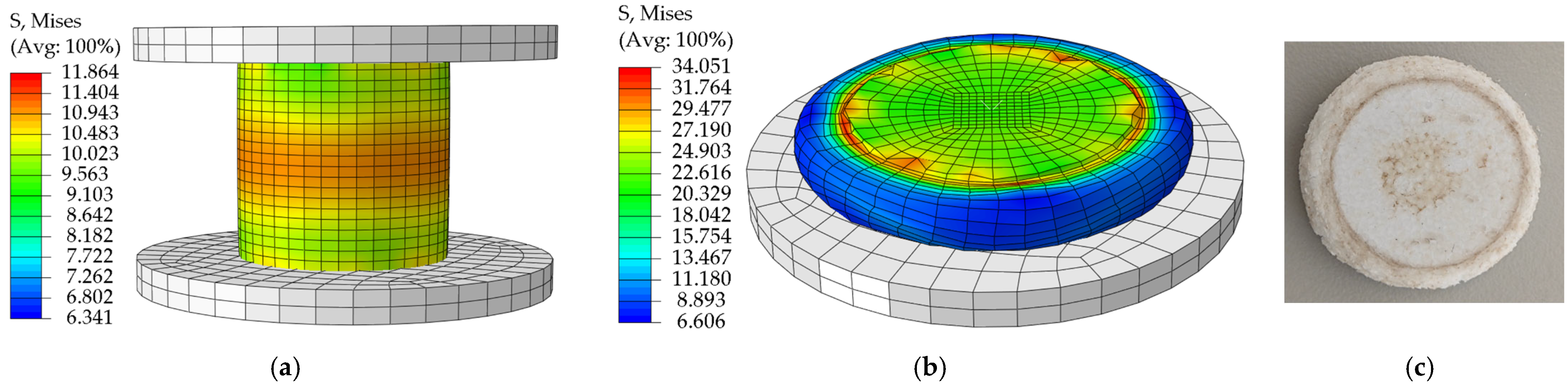

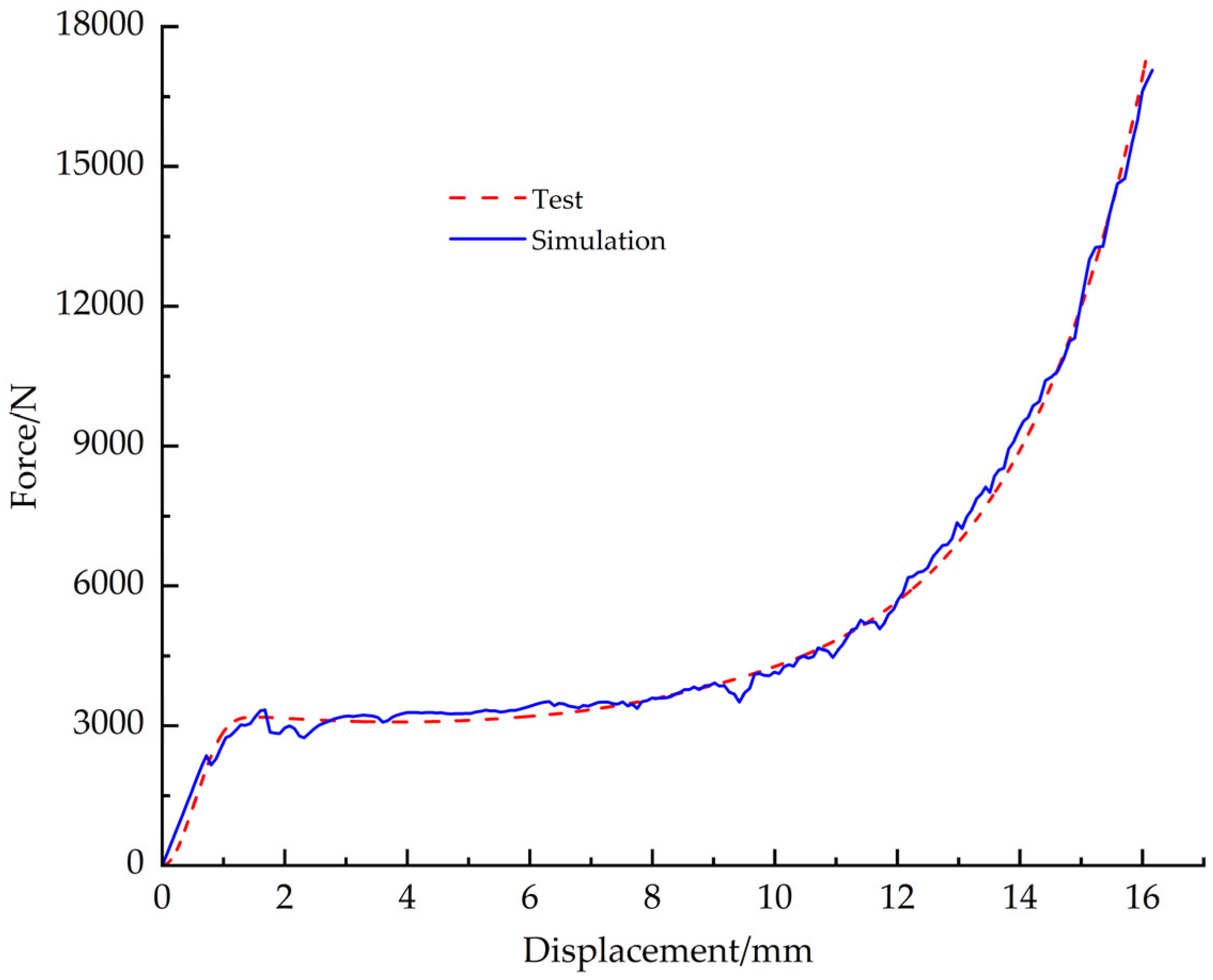

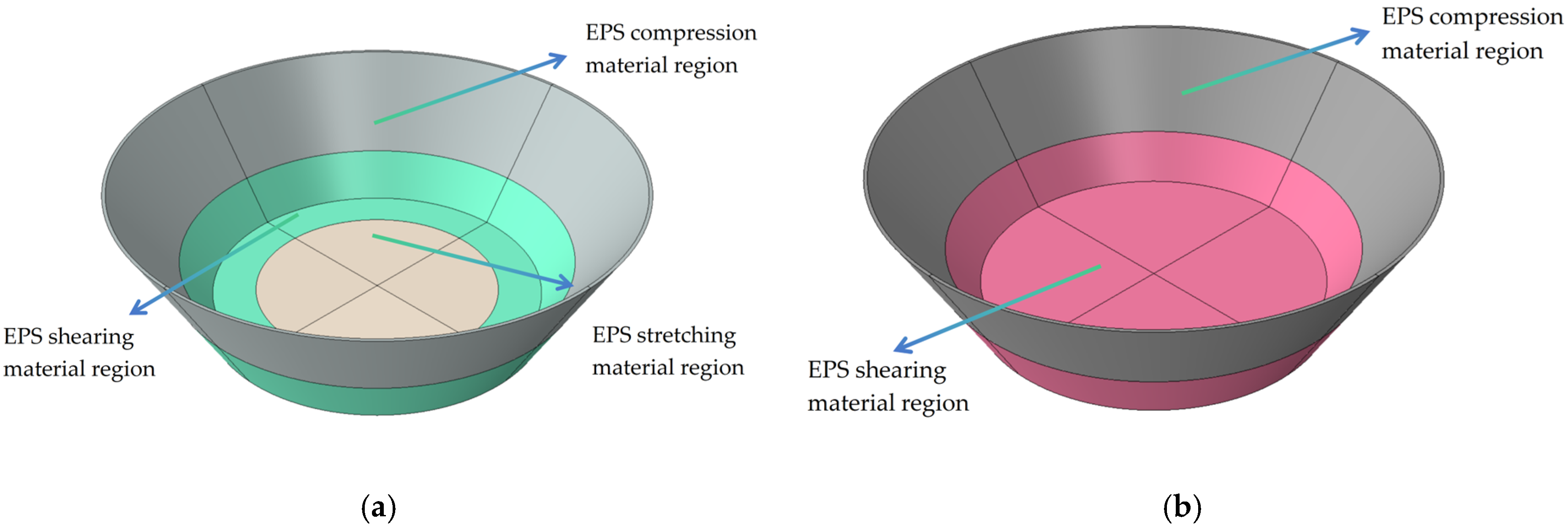

This paper employs a combined experimental, theoretical, and numerical simulation approach to systematically investigate the pressure-bearing capacity of EPS nozzle covers. First, tensile, compressive, and shear mechanical property tests were conducted to obtain stress-strain data for EPS samples with densities ranging from 0.13 to 0.58 g/cm3 (10 uniformly spaced density groups), and the influence of density on mechanical properties was analyzed. Based on the test data, a constitutive model was established to characterize the mechanical behavior of EPS material as a function of density. The model was modified to significantly improve its fitting accuracy to the stress-strain test data. Subsequently, based on the modified and optimized constitutive model, a VUMAT user subroutine for EPS material was developed, and the model was validated using ABAQUS 2023 finite element analysis software and its user subroutine interface. Based on the primary stress characteristics of the nozzle cover under actual operating conditions, it was divided into several characteristic regions, and each region was assigned verified material properties. Through preliminary simulation verification, the three-dimensional finite element model was determined. Finally, using this model, a systematic study was conducted on the stress distribution patterns and changes in pressure-bearing capacity of nozzle cover structures with different thicknesses under the action of internal and external pressure loads.

This study provides theoretical support for the structure optimization and performance design of the solid rocket motor EPS nozzle cover and other EPS products.

3. Test Results and Analysis

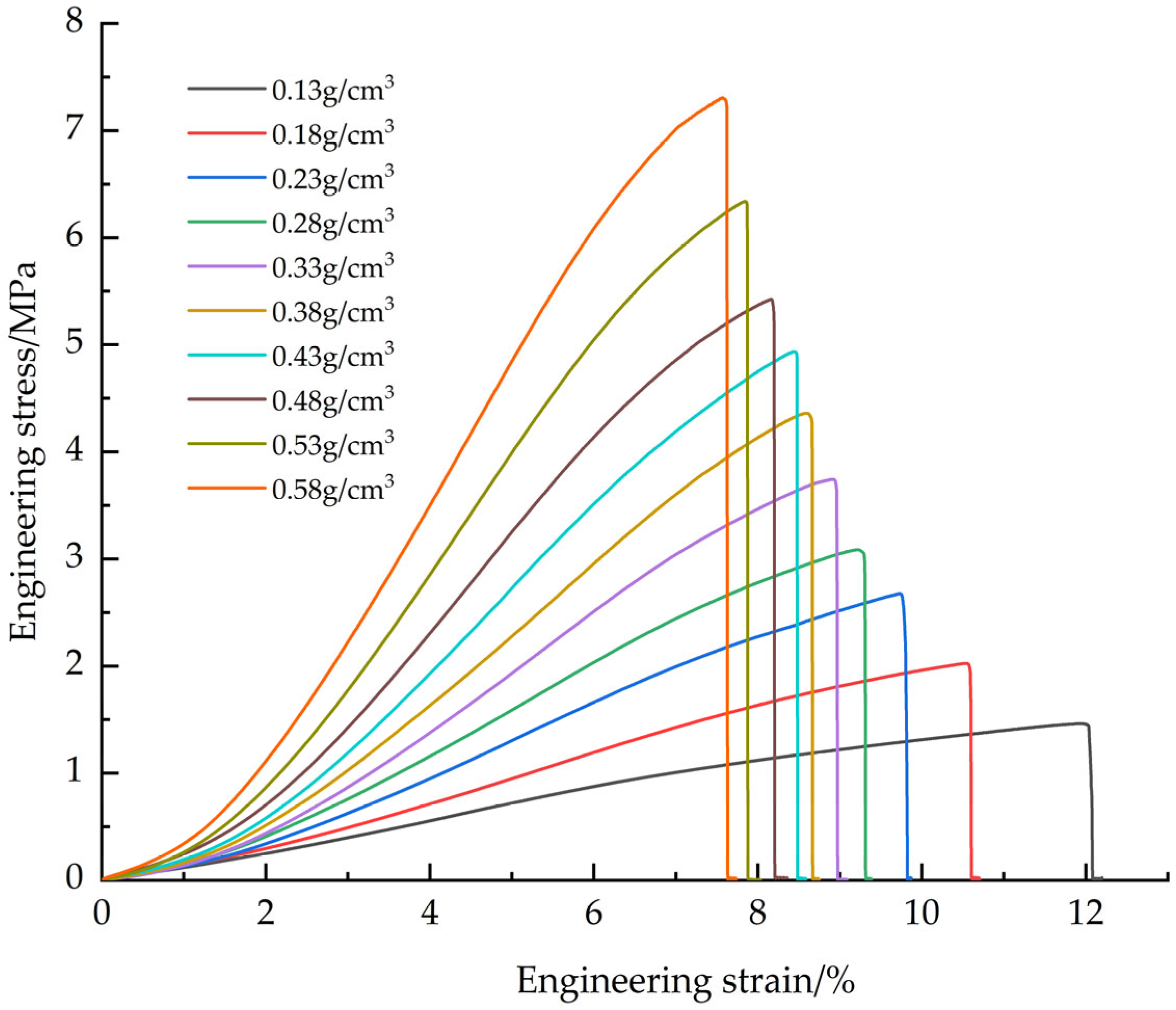

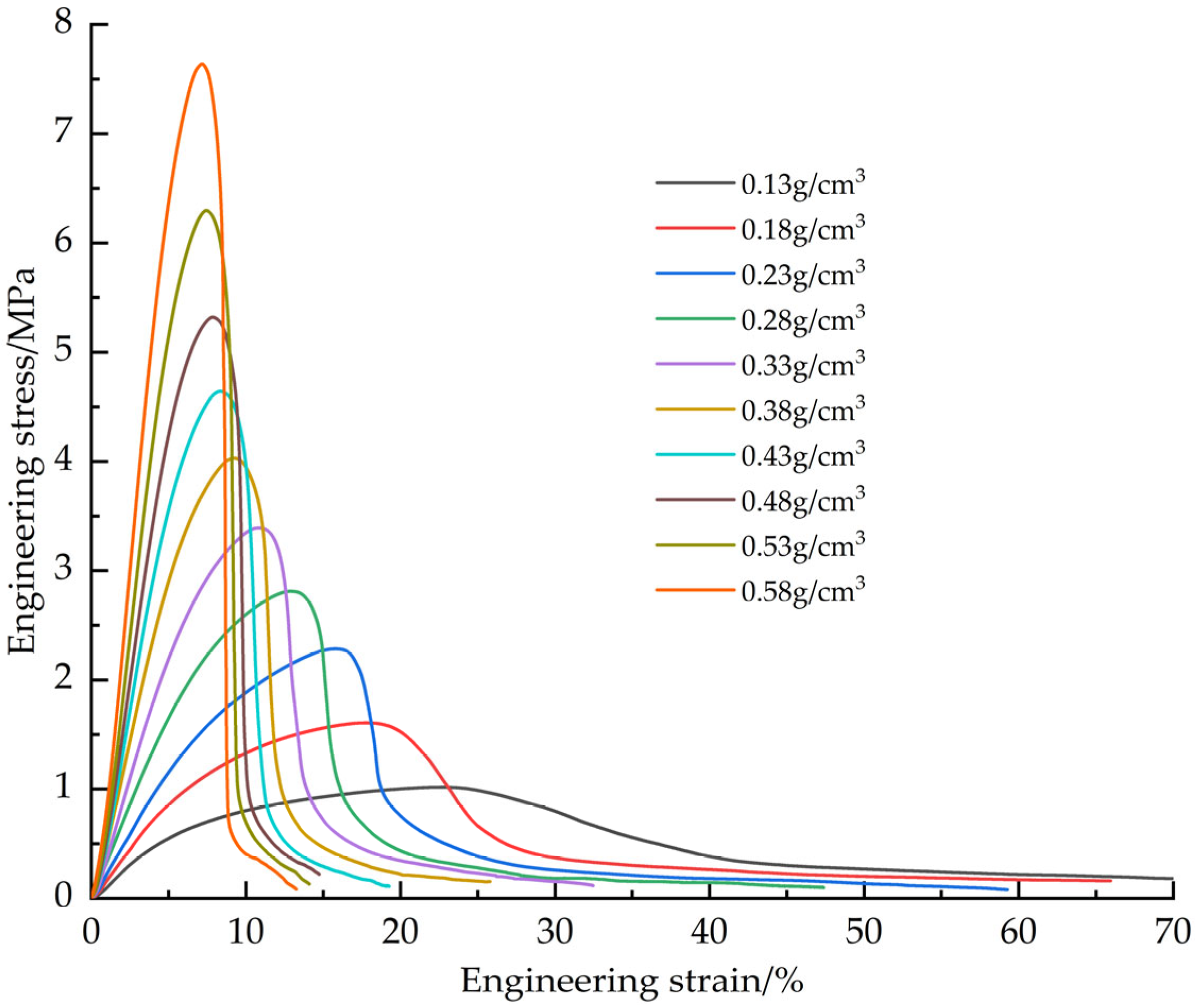

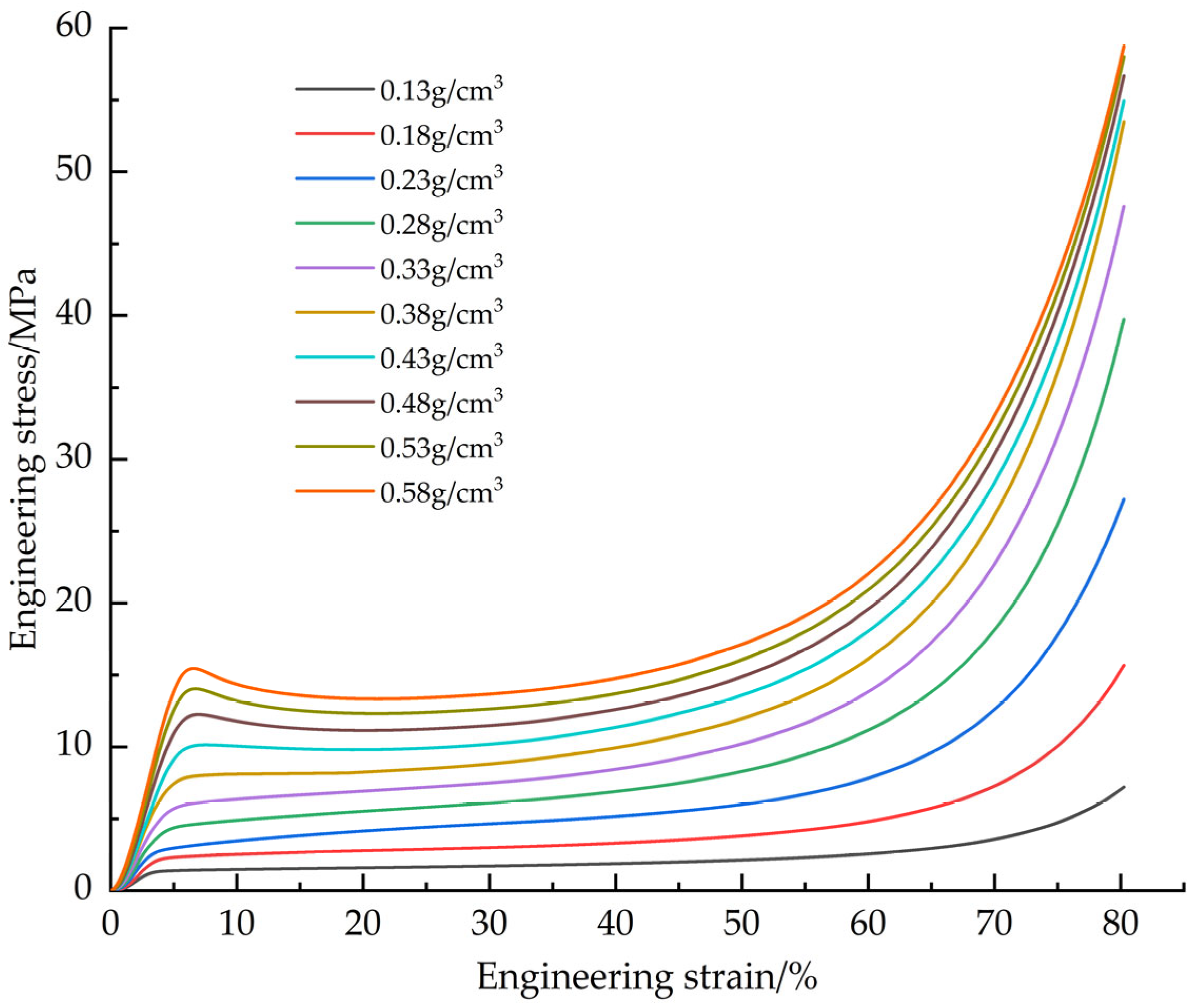

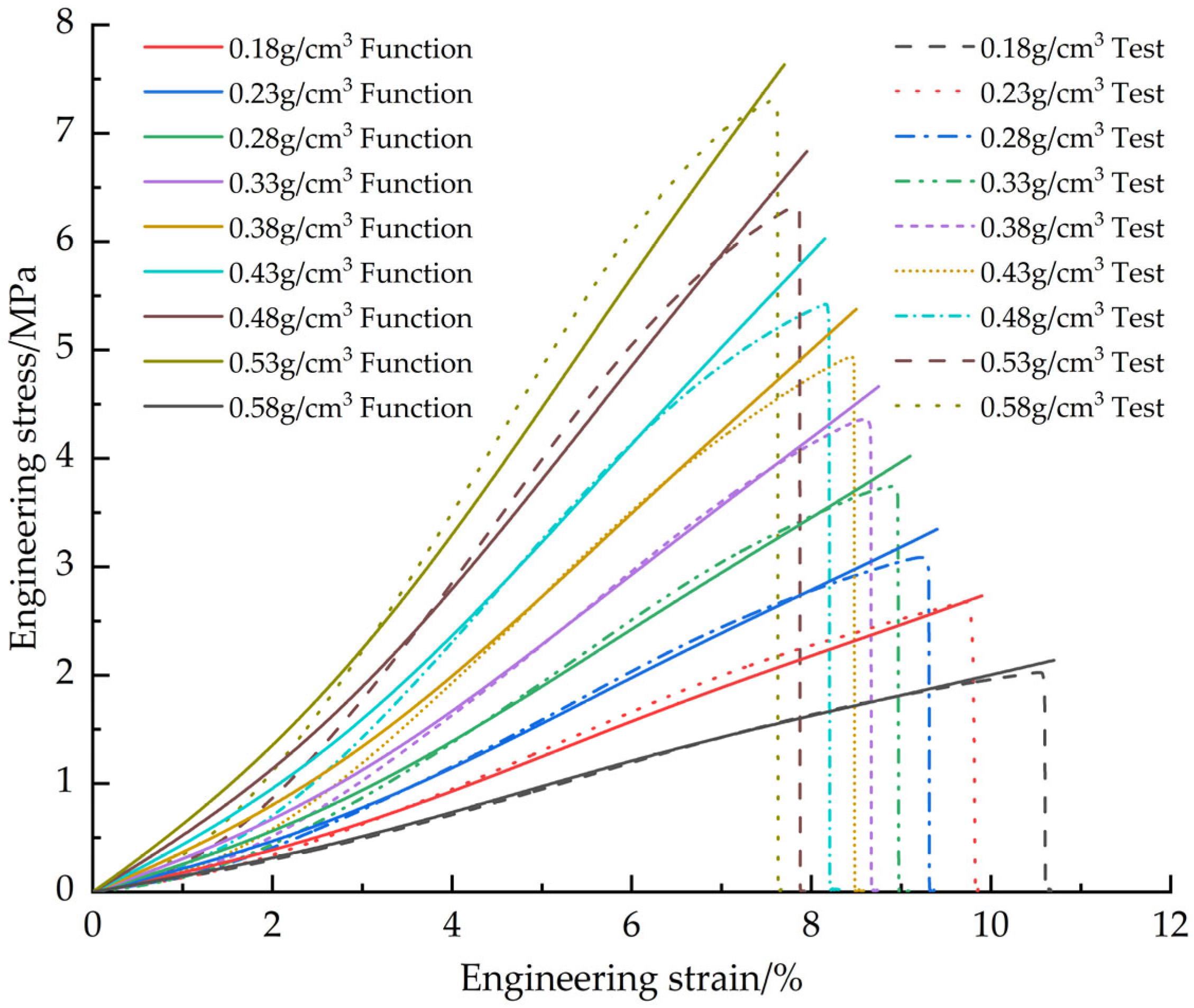

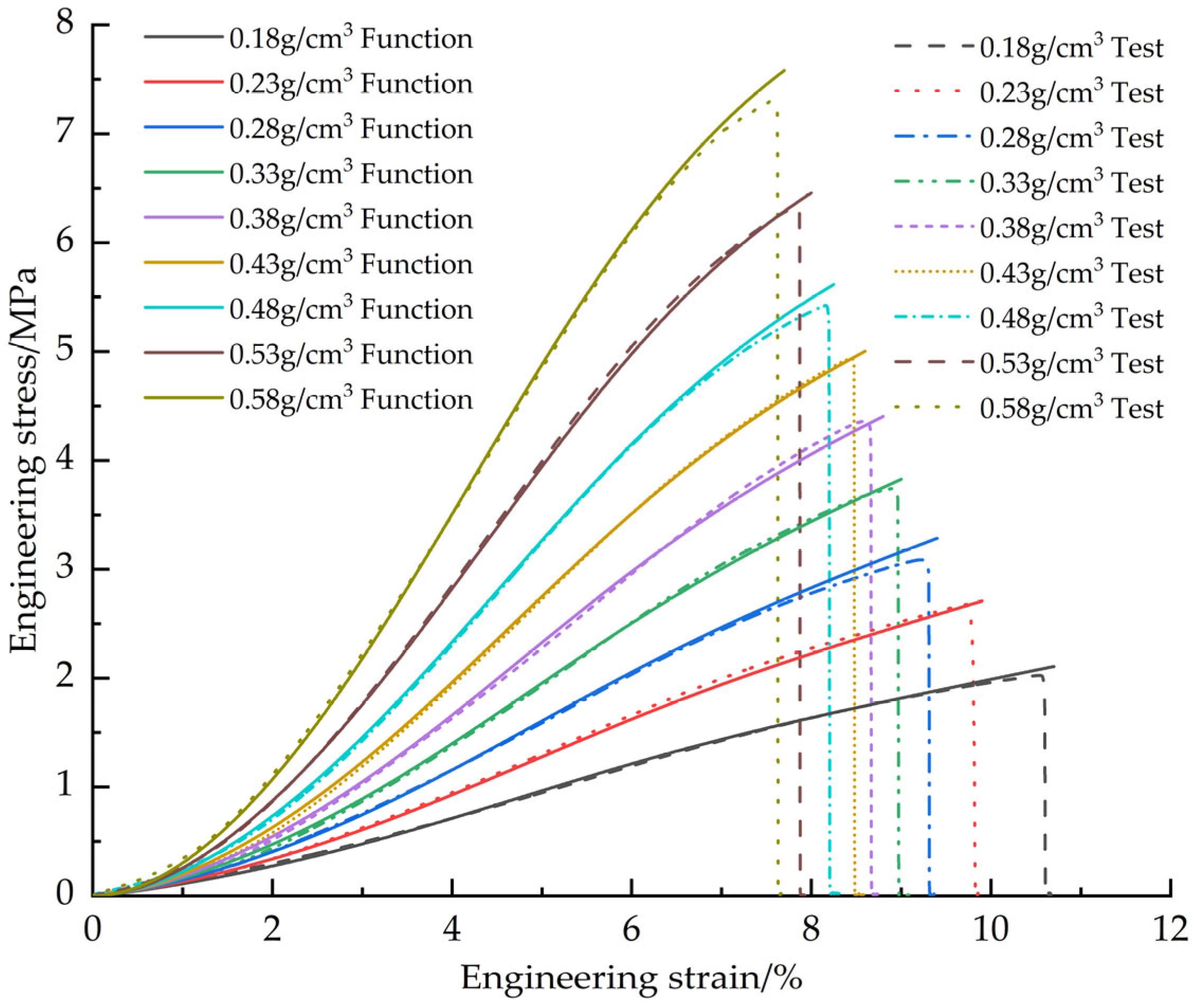

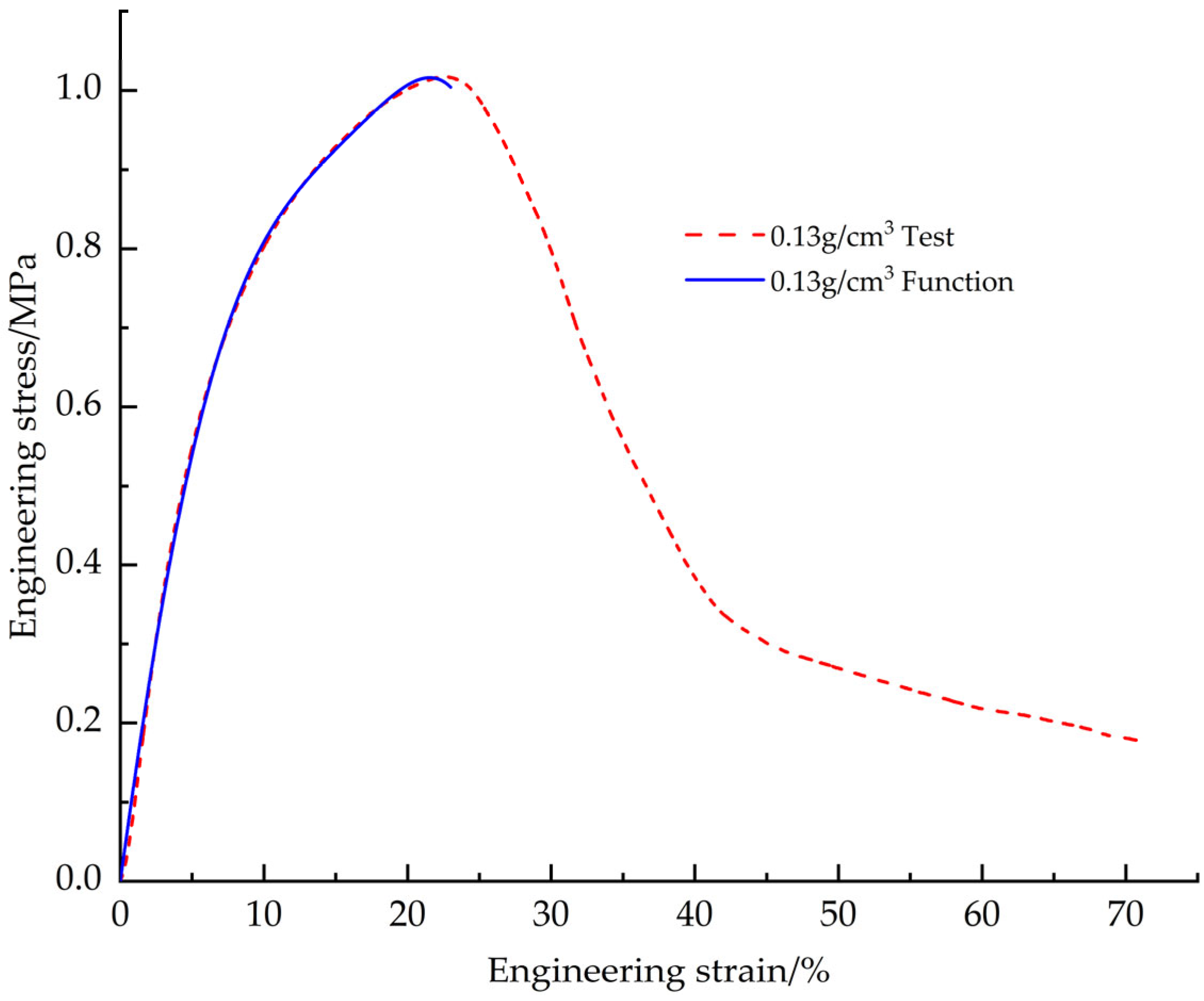

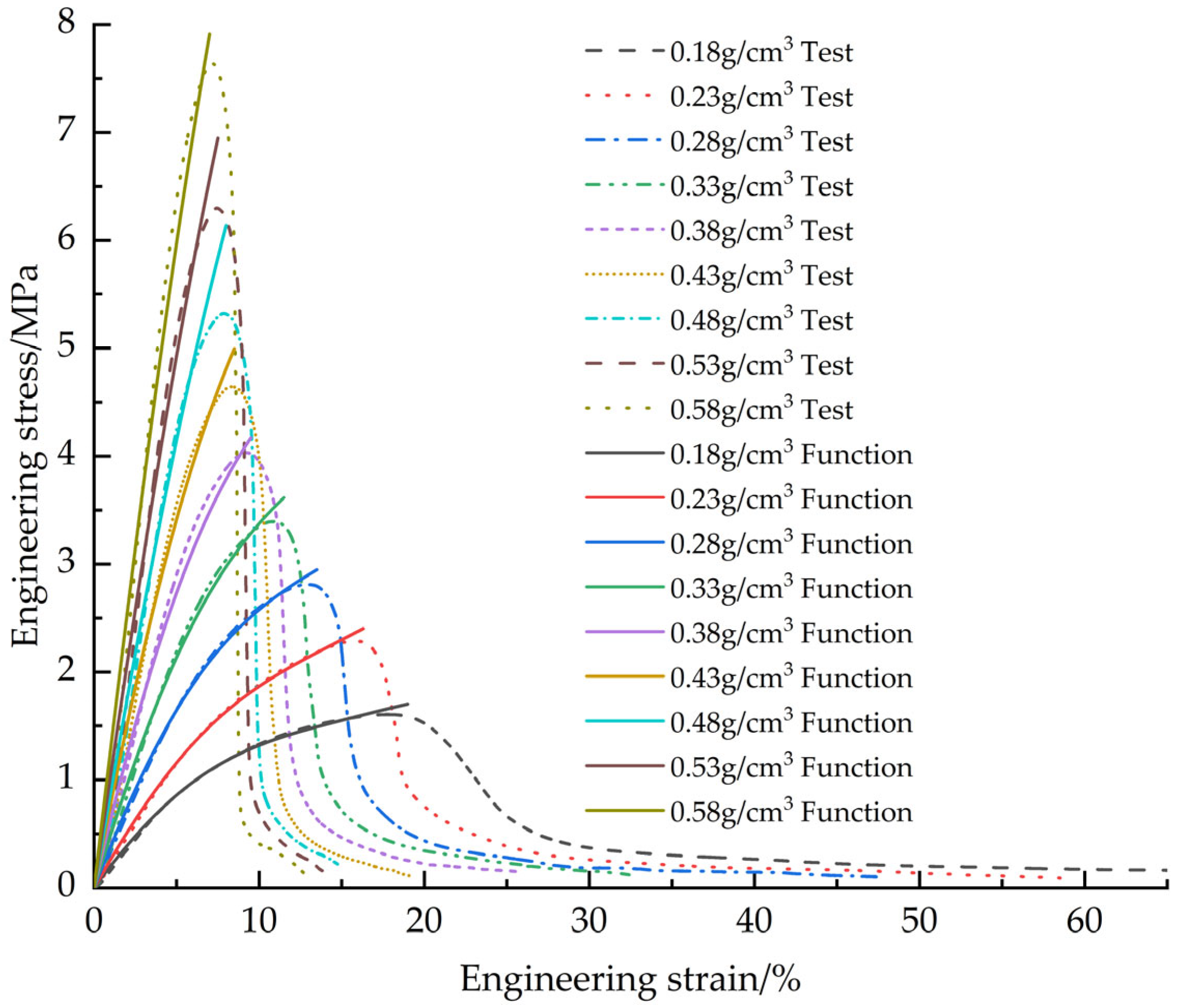

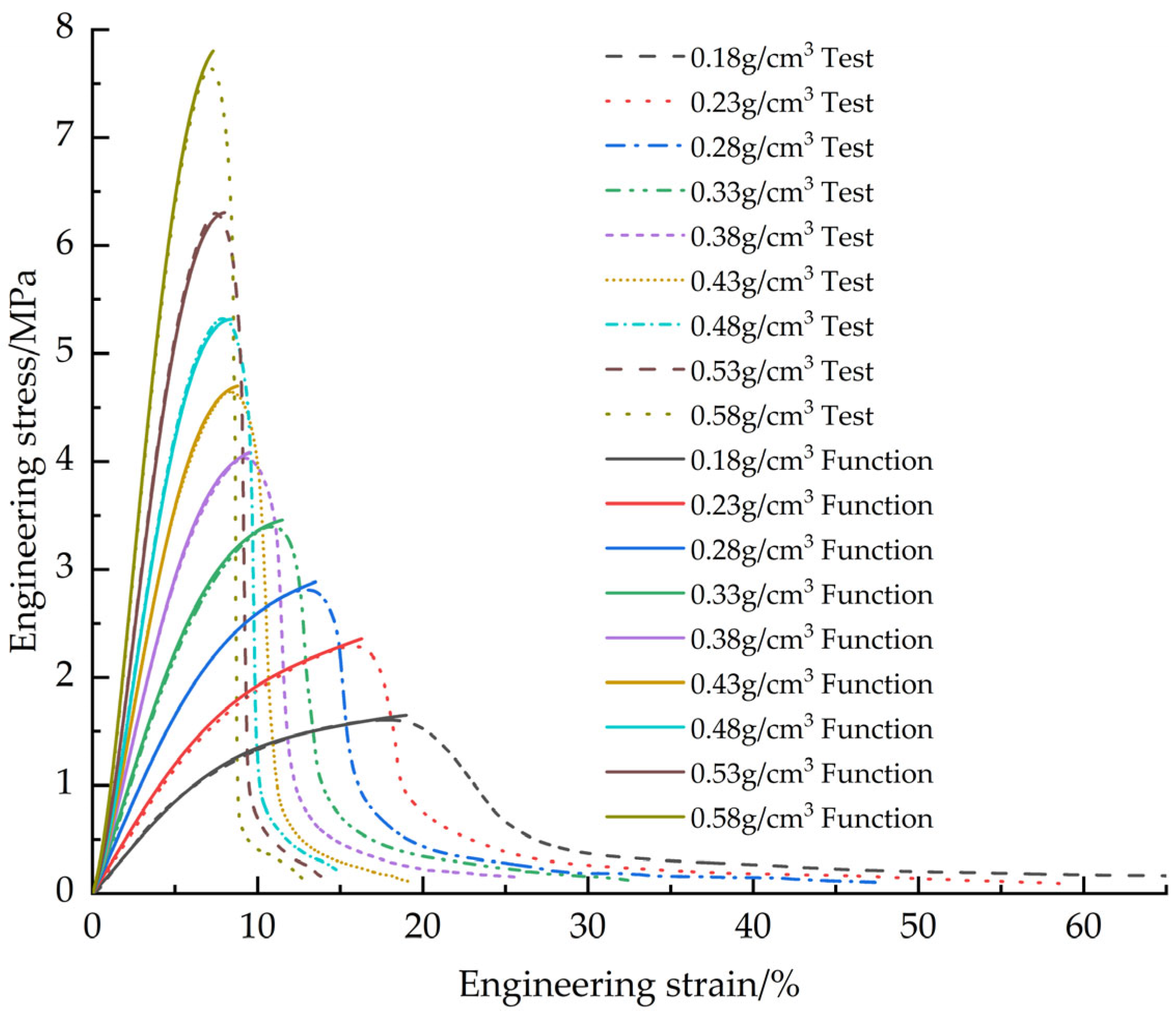

The EPS samples with densities of 0.13, 0.18, 0.23, 0.28, 0.33, 0.38, 0.43, 0.48, 0.53 and 0.58 g/cm

3 were tested. The tensile average engineering stress-strain curves of EPS with different densities (

Figure 6), EPS shear average engineering stress-strain curves (

Figure 7) and compression average engineering stress-strain curves (

Figure 8) were obtained.

Young’s modulus is determined by the slope of the initial linear segment of the engineering stress-strain curve. Analysis of the stress-strain curves for tensile and shear tests showed that the point of maximum stress corresponded to the failure strain of the material. For compression tests, although the stress-strain curves do not show obvious failure characteristics, the turning point at the transition from the elastic phase to the plastic plateau can be used as the yield point. The data obtained based on tensile, shear and compression tests are presented in

Table 1,

Table 2 and

Table 3: Young’s modulus (all three tables), as well as maximum stress and failure strain (

Table 1 and

Table 2), yield stress and yield strain (

Table 3).

The failure modes of EPS material in tensile and shear tests are mainly crack propagation and hole wall fracture between foam walls, and crack propagation gradually dominates with the increase of density. In the compression test, the failure mode is the crushing of foam beads. Due to the volume limitation, increasing the density of the material requires filling more EPS beads in the same volume, resulting in a decrease in the degree of foaming of a single bead and a decrease in the proportion of foam, thereby increasing the hardness of the material. The mechanical properties and density of materials show regular changes: Young‘s modulus, failure stress and yield stress increase with the increase of density. In tensile and shear tests, the failure strain decreases with increasing density. In the compression test, the yield strain increases with the increase of density and finally tends to be stable (about 6.5%). At the same time, with the increase of density, the platform stage of the engineering stress-strain curve is shortened, and the densification stage appears in advance. When the density exceeds 0.33 g/cm3, there will be a stress drop section in the critical region of the transition from the elastic stage to the platform stage, and this phenomenon becomes more significant with the increase of density. The above density-related regular changes provide a good basis for the establishment of the EPS variable density constitutive model.