Optimization of Hot-Press Sintering for Cu2+-Sn4+ Co-Doped YIG Ferrites: Microstructure, Dielectric Properties, and Magnetic Properties

Abstract

1. Introduction

2. Experiments

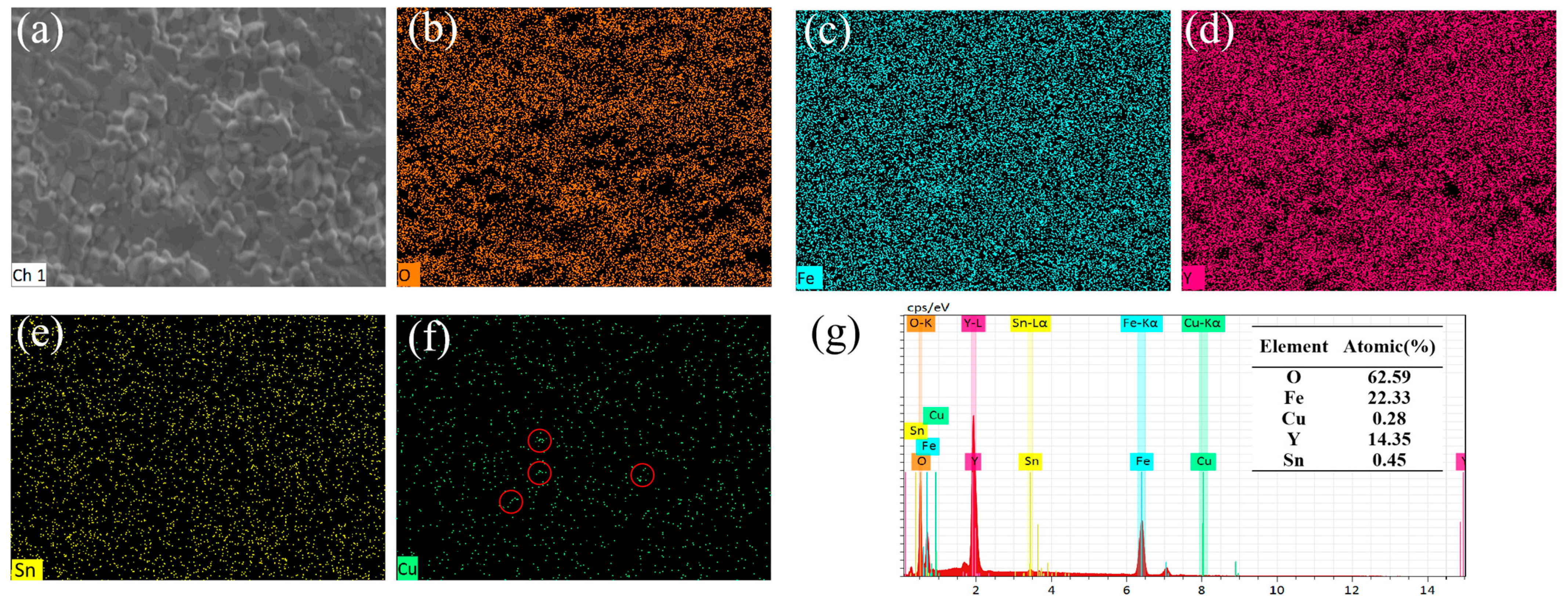

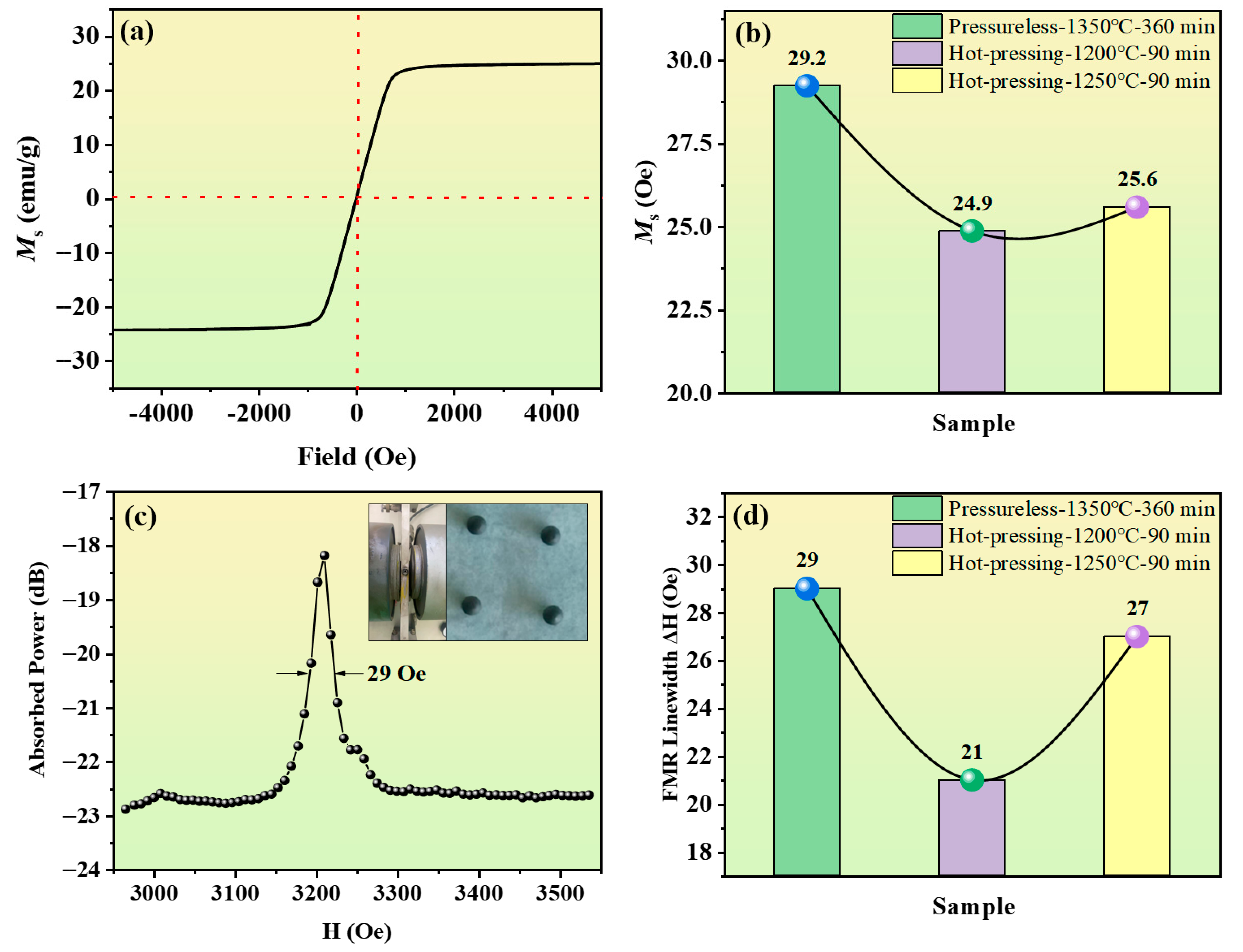

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yang, Q.; Zhang, H.; Liu, Y.; Wen, Q.; Jia, L. The magnetic and dielectric properties of microwave sintered yttrium iron garnet (YIG). Mater. Lett. 2008, 62, 2647–2650. [Google Scholar] [CrossRef]

- Zhao, W.; Wang, F.; Liu, J.; Cao, L.; Huang, X.; Yang, F.; Xian, C.; Yuan, H. Microstructure, shear strength and dielectric properties of a co-fired YIG-MCT composite substrate for circulators. Ceram. Int. 2022, 48, 11729–11735. [Google Scholar] [CrossRef]

- Aung, Y.L.; Ikesue, A.; Watanabe, T.; Makikawa, S.; Iwamoto, Y. Bi substituted YIG ceramics isolator for optical communication. J. Alloys Compd. 2019, 811, 152059. [Google Scholar] [CrossRef]

- Xiao, Y.; Li, J.; Peng, Z.; Zhou, T.; Yang, Y.; Lei, Y.; Ma, Y.; Liu, Y. High-dielectric-constant, low-loss YIG ferrites for miniaturized microwave devices through multi-ion substitution composite regulation. J. Eur. Ceram. Soc. 2025, 45, 117105. [Google Scholar] [CrossRef]

- Wen, D.; Zhang, J.; Kulikov, A.; Cui, J.; Chen, Z.; Wang, Z.; Zhang, Q.; Guo, J.; Li, R. The effect of Al3+ ion substitution on microwave dielectric and magnetic properties of YIG ferrites. Ceram. Int. 2025, 51, 6272–6280. [Google Scholar] [CrossRef]

- Kajiwara, Y.; Harii, K.; Takahashi, S.; Ohe, J.; Uchida, K.; Mizuguchi, M.; Umezawa, H.; Kawai, H.; Ando, K.; Takanashi, K.; et al. Transmission of electrical signals by spin-wave interconversion in a magnetic insulator. Nature 2010, 464, 262. [Google Scholar] [CrossRef]

- Geller, S.; Gilleo, M.A. The crystal structure and ferrimagnetism of yttrium-iron garnet, Y3Fe2(FeO4)3. J. Phys. Chem. Solids 1957, 3, 30–36. [Google Scholar] [CrossRef]

- Serga, A.A.; Chumak, A.V.; Hillebrands, B. YIG magnonics. J. Phys. D Appl. Phys. 2010, 43, 264002. [Google Scholar] [CrossRef]

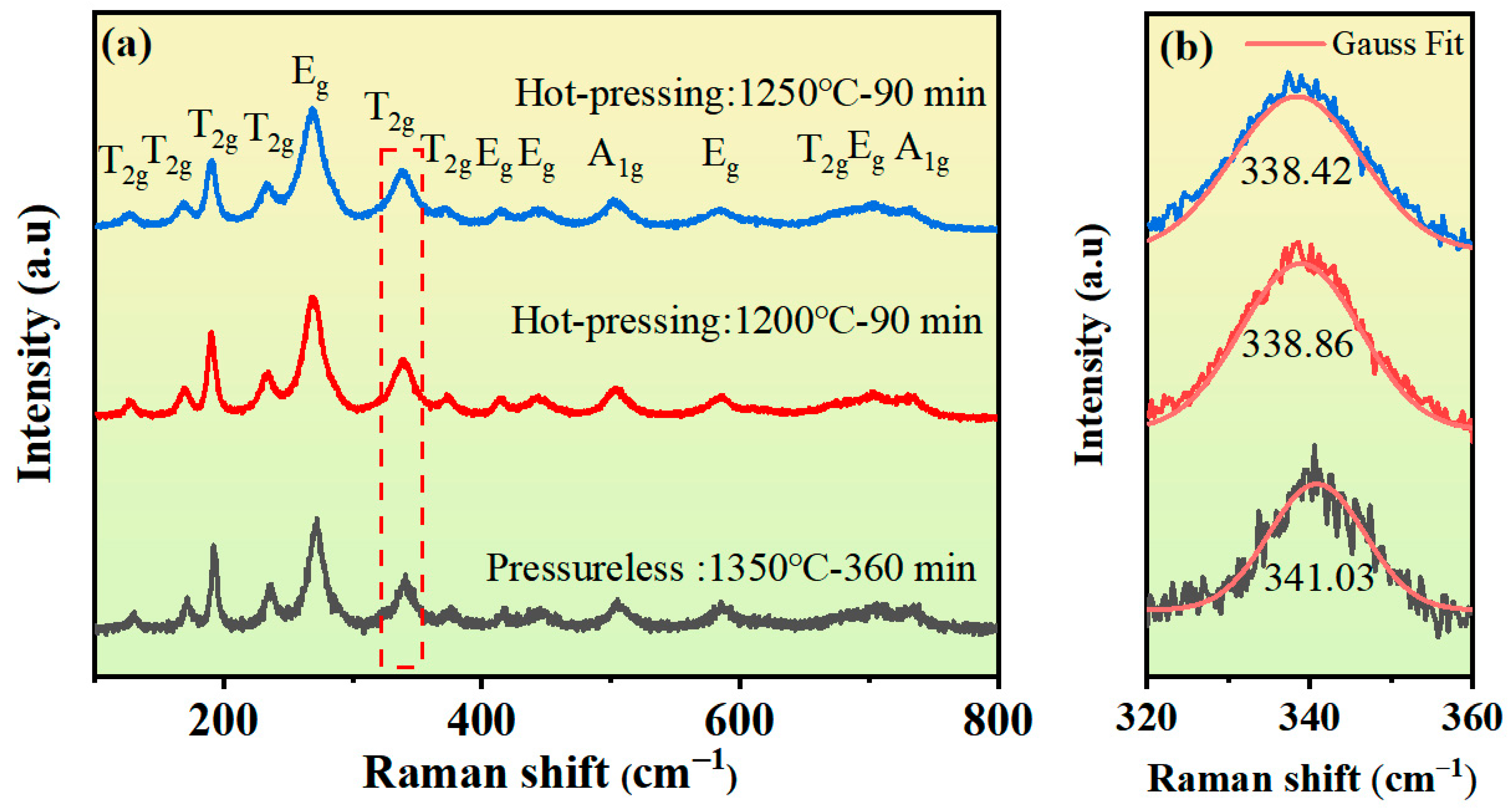

- Susneha, T.; Someshwar, P.; Prasad, N.V. Electrical, magnetic, and Raman spectroscopic studies on Bi-modified YIG ceramics. J. Mater. Sci. Mater. Electron. 2024, 35, 968. [Google Scholar] [CrossRef]

- Zhong, W.; Chen, K.; Nan, Y.; Zhang, J.; Guo, X.; Zhou, X.; Ge, X.; Wu, Q.; Zheng, H. Regulation of Fe2+ contents in yttrium iron garnet by doping with different valence states of Mn and its dielectric and magnetic properties. J. Mater. Sci. Mater. Electron. 2024, 35, 984. [Google Scholar] [CrossRef]

- Lin, Y.; Chen, F.; Chen, K.; Zhang, J.; Ge, X.; Qian, Y.; Wang, Q.; Wu, Q.; Zheng, H. In–Sn–Cu co-doped yttrium iron garnet ferrite: Magnetic and dielectric properties. Ceram. Int. 2024, 50, 34133–34142. [Google Scholar] [CrossRef]

- Matilla-Arias, J.; Guerra, Y.; Mariño-Castellanos, P.A.; Peña-Garcia, R. Theoretical investigation of cation distribution and their effect on the physical properties of Ni-doped YIG system. Appl. Phys. A 2022, 128, 1087. [Google Scholar] [CrossRef]

- Harmer, M.P. Hort Pressing: Technology and Theory, Concise Encyclopedia of Advanced Ceramic Materials; Pergamon: South Croydon, UK, 1991; pp. 222–225. [Google Scholar]

- Xu, L.; Wang, Y.; Li, C.; Ji, G.; Mi, G. MPFEM simulation on hot-pressing densification process of SiC particle/6061Al composite powders. J. Phys. Chem. Solids 2021, 159, 110259. [Google Scholar] [CrossRef]

- Manikandan, R.; Kothari, A.A.; Deshpande, Y.A.; Annamalai, R.A. Grain boundary evolution and micro texture development in hot press sintered GRCop alloys. Results Eng. 2025, 25, 104471. [Google Scholar] [CrossRef]

- Sayagués, M.J.; Otero, A.; Santiago-Andrades, L.; Poyato, R.; Monzón, M.; Paz, R.; Gotor, F.J.; Moriche, R. Fine-grained BCZT piezoelectric ceramics by combining high-energy mechanochemical synthesis and hot-press sintering. J. Alloys Compd. 2024, 1007, 176453. [Google Scholar] [CrossRef]

- Naziripour, G.A.; Tooke, A.O.; Standley, K.J.; Storey, B.E. Hot-pressed polycrystalline yttrium iron garnet. J. Mater. Sci. 1985, 20, 375–380. [Google Scholar] [CrossRef]

- Yang, W.; Qian, Y.; Zheng, H. Hot press sintering of Bi-Zn-In-Sn doped yttrium iron garnet ferrite: Magnetism, ferromagnetic resonance linewidth and dielectric properties. Ceram. Int. 2025, 51, 23779–23787. [Google Scholar] [CrossRef]

- Xiao, Y.; Li, J.; Lei, Y.; Sun, K.; Chen, Y.; Wang, S.; Zhang, P. Ca-Sn co-substituted BiIn-YIG ferrite with narrow FMR linewidth for microwave device application. Ceram. Int. 2024, 50, 1031–1037. [Google Scholar] [CrossRef]

- Zhou, X.; Wu, Y.; Zheng, H. Effect of Sn4+-Cu2+ co-doping on the microstructure and magnetic properties of YIG ceramics. J. Magn. Mater. Devices 2023, 54, 56–60. [Google Scholar]

- Bisht, P.; Meenakshi; Gaur, A.; Mahato, R.N. Structural and magnetocaloric properties (0.75)La0.7Ca0.3MnO3/(0.25)La0.84Sr0.16MnO3 nanocomposite. Phys. B Condens. Matter 2021, 619, 413215. [Google Scholar] [CrossRef]

- Han, X.; Li, J.; Wu, H.; Sun, K.; Chen, Y.; Jia, L.; Zhang, H.; Zhang, P.; Wu, C. High dielectric constant and magnetic properties of Bi-In Co-substituted YIG ferrites. J. Magn. Magn. Mater. 2023, 570, 170512. [Google Scholar] [CrossRef]

- Naik, S.R.; Salker, A.V. Variation in the magnetic moment of Indium doped Ce0.1Y2.9Fe5O12 garnet relative to the site inversion. J. Alloys Compd. 2014, 600, 137–145. [Google Scholar] [CrossRef]

- Alves, C.; Matilla-Arias, J.; Guerrero, F.; Castro-Lopes, S.; Guerra, Y.; Viana, B.C.; Padrón-Hernández, E.; Soares, J.M.; da Silva, R.B.; Ghislandi, M.G.; et al. Influence of Fe3+ by La3+ cations substitution on the crystallography and magnetic properties of yttrium iron garnet compound. Ceram. Int. 2023, 49, 27567–27576. [Google Scholar] [CrossRef]

- Tan, P.; Huang, X.; Liu, J.; Cao, L.; Yang, F.; Xian, C.; Yuan, H. Study on Bi3+-Al3+ co-doped YIG for co-firing YIG-Al0.2/NZF ferrite composite substrates. J. Eur. Ceram. Soc. 2023, 43, 993–999. [Google Scholar] [CrossRef]

- Chen, Y.F.; Wu, K.T.; Yao, Y.D.; Peng, C.H.; You, K.L.; Tse, W.S. The influence of Fe concentration on Y3Al5−xFexO12 garnets. Microelectron. Eng. 2005, 81, 329–335. [Google Scholar] [CrossRef]

- Fernández, A.; Araujo, F.P.; Guerra, Y.; Castro-Lopes, S.; Matilla-Arias, J.; de Lima, I.S.; Silva-Filho, E.C.; Osajima, J.A.; Guerrero, F.; Peña-Garcia, R. Synthesis of coral-like structures of Pr–Yb co-doped YIG: Structural, optical, magnetic and antimicrobial properties. J. Rare Earths 2024, 42, 543–554. [Google Scholar] [CrossRef]

- Sahu, V.; Dubey, K.; Dubey, S.; Soni, P.; Modi, A.; Pandey, D.K.; Rathore, D.; Gaur, N.K. Sr2+ doping-induced changes in structural, magnetic, and dielectric properties of ferrimagnetic yttrium iron garnet. Ceram. Int. 2025, 51, 11844–11856. [Google Scholar] [CrossRef]

- Wang, X.; Xu, K.; Ma, N.; Feng, X.; Zhou, G.; Chen, G.; Zhao, L. Investigations for the effects of Ce-substitution on microstructure and magnetic properties of multi-doped YIG ferrites. Ceram. Int. 2025, 51, 31565–31574. [Google Scholar] [CrossRef]

- Koops, C.G. On the Dispersion of Resistivity and Dielectric Constant of Some Semiconductors at Audiofrequencies. Phys. Rev. 1951, 83, 121–124. [Google Scholar] [CrossRef]

- O′Dell, T.H. An induced magneto-electric effect in yttrium iron garnet. Philos. Mag. 1967, 16, 487–494. [Google Scholar] [CrossRef]

- Ramesh, B.; Ravinder, D. Electrical properties of Li-Mn ferrites. Mater. Lett. 2008, 62, 2043–2046. [Google Scholar] [CrossRef]

- Sun, K.; Li, J.; Chen, Y.; Xiao, Y.; Yang, Y.; Liu, L.; Liu, Y. Microwave magnetic and high dielectric properties of Ca2+-Sn4+ co-substituted BiIn-YIG ferrites for device application. Appl. Phys. A 2024, 130, 760. [Google Scholar] [CrossRef]

- Fu, R.; Li, Y.; Peng, R.; Lu, Y.; Wen, Q. High Dielectric Constant YIG Ferrites with Low Sintering Temperature. J. Mater. Sci. Mater. Electron. 2022, 33, 4914–4923. [Google Scholar] [CrossRef]

- Luo, H.; Zhou, D.; Wei, T.; Chen, W.; Zhao, Y.; Wang, L. Synthesis and analysis of the magnetic properties of YIG by means of sol–gel and spark plasma sintering. J. Magn. Magn. Mater. 2024, 589, 171595. [Google Scholar] [CrossRef]

- Baños-López, E.; Cortés-Escobedo, C.A.; Jesús, F.S.-D.; Barba-Pingarrón, A.; Bolarín-Miró, A.M. Crystal structure and magnetic properties of cerium-doped YIG: Effect of doping concentration and annealing temperature. J. Alloys Compd. 2018, 730, 127–134. [Google Scholar] [CrossRef]

- Wu, H.; Li, J.; Han, X.; Li, W.; Sun, K.; Chen, Y.; Yan, Y.; Chen, D. Microstructure and gyromagnet properties of In-substituted YIG ferrite prepared by sol–gel method. J. Mater. Sci. Mater. Electron. 2023, 34, 823. [Google Scholar] [CrossRef]

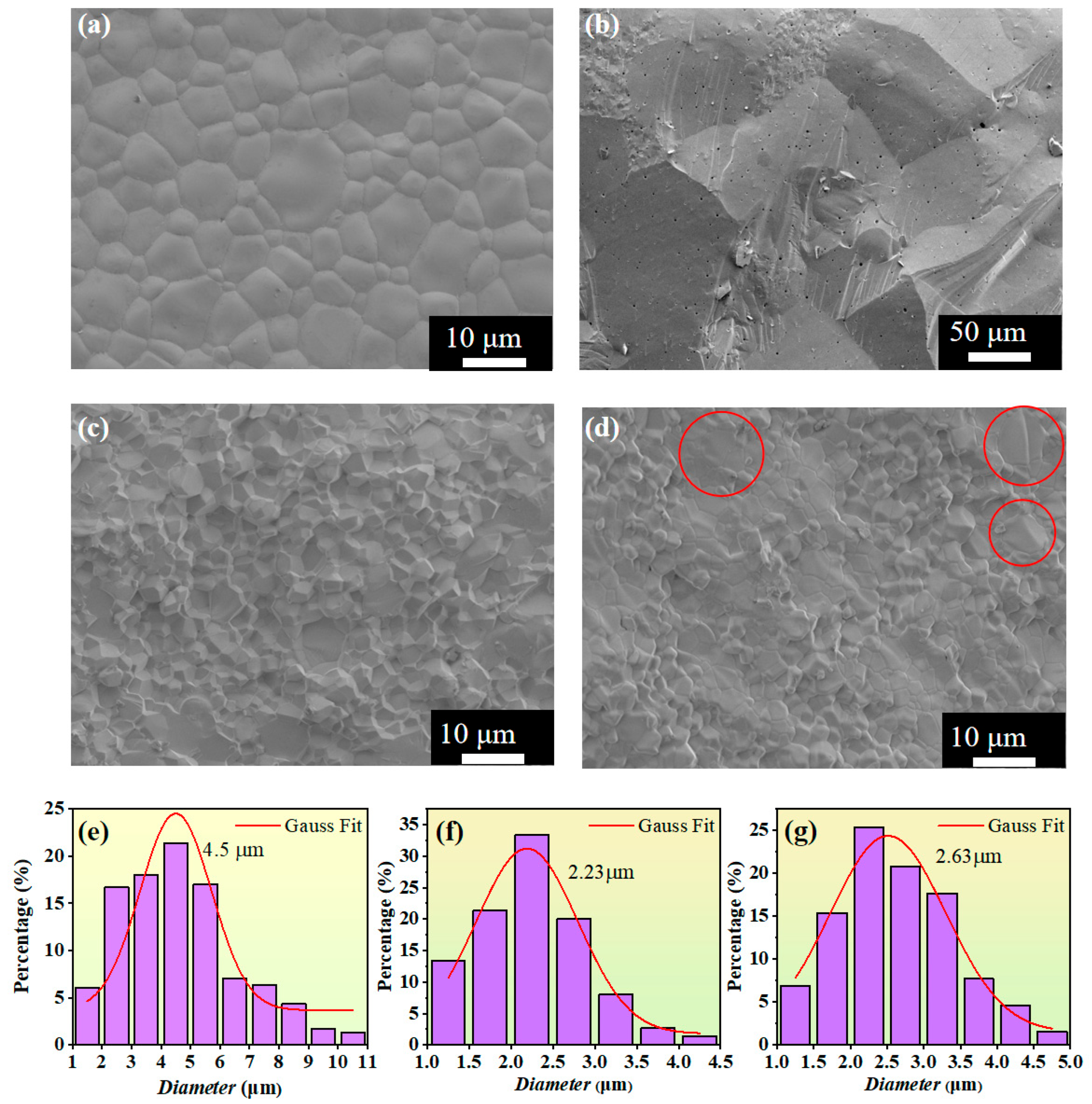

- Wu, H.; Huang, F.; Lu, X.; Xu, T.; Lu, X.; Ti, R.; Jin, Y.; Zhu, J. Grain size and Fe2+ concentration-dependent magnetic, dielectric, and magnetodielectric properties of Y3Fe5O12 ceramics. Phys. Status Solidi 2016, 213, 146–153. [Google Scholar] [CrossRef]

- Hapishah, A.N.; Hamidon, M.N.; Syazwan, M.M.; Shafiee, F.N. Effect of grain size on microstructural and magnetic properties of holmium substituted yttrium iron garnets (Y1.5Ho1.5Fe5O12). Results Phys. 2019, 14, 102391. [Google Scholar] [CrossRef]

- Smetanina, K.E.; Andreev, P.V.; Nokhrin, A.V.; Lantsev, E.A.; Chuvildeev, V.N. Carbon contamination during spark plasma sintering of powder materials: A brief overview. J. Alloys Compd. 2024, 973, 172823. [Google Scholar] [CrossRef]

- Yang, W.; Wang, L.; Ding, Y.; Zhang, Q. Narrowing of ferromagnetic resonance linewidth in calcium substituted YIG powders by Zr4+/Sn4+ substitution. J. Mater. Sci. Mater. Electron. 2014, 25, 4517–4523. [Google Scholar] [CrossRef]

- Hu, Y.; Liu, X.; Feng, S.; Zen, L. Ferromagnetic resonance linewidth mechanism of Sr-Sn substituting YIG ferrite. J. Mater. Sci. Mater. Electron. 2022, 33, 14663–14671. [Google Scholar] [CrossRef]

- Xiao, Y.; Li, J.; Yang, Y.; Lei, Y.; Ma, Y.; Liu, Y. Reducing the FMR Linewidth of high-dielectric-constant BiZr-YIG ferrites by adjusting the pre-sintering temperature. Ceram. Int. 2025, 51, 25042–25051. [Google Scholar] [CrossRef]

- Xiao, Y.; Li, J.; Zhou, T.; Yang, Y.; Sun, K.; Liu, Y. Mechanism of the impact of Ca–Ge co-substitution on the FMR linewidth in BiV-YIG ferrites. Ceram. Int. 2024, 50, 20144–20150. [Google Scholar] [CrossRef]

- Yin, Q.; Liu, Y.; Wu, J.; Li, J.; Chen, J.; Lu, S.; Liu, K. Mechanistic study of the effect of Ca–Sn co-doping on the microwave dielectric properties and magnetic properties of YIG. Ceram. Int. 2022, 48, 32827–32836. [Google Scholar] [CrossRef]

- Kittel, C. Interpretation of Anomalous Larmor Frequencies in Ferromagnetic Resonance Experiment. Phys. Rev. 1947, 71, 270. [Google Scholar] [CrossRef]

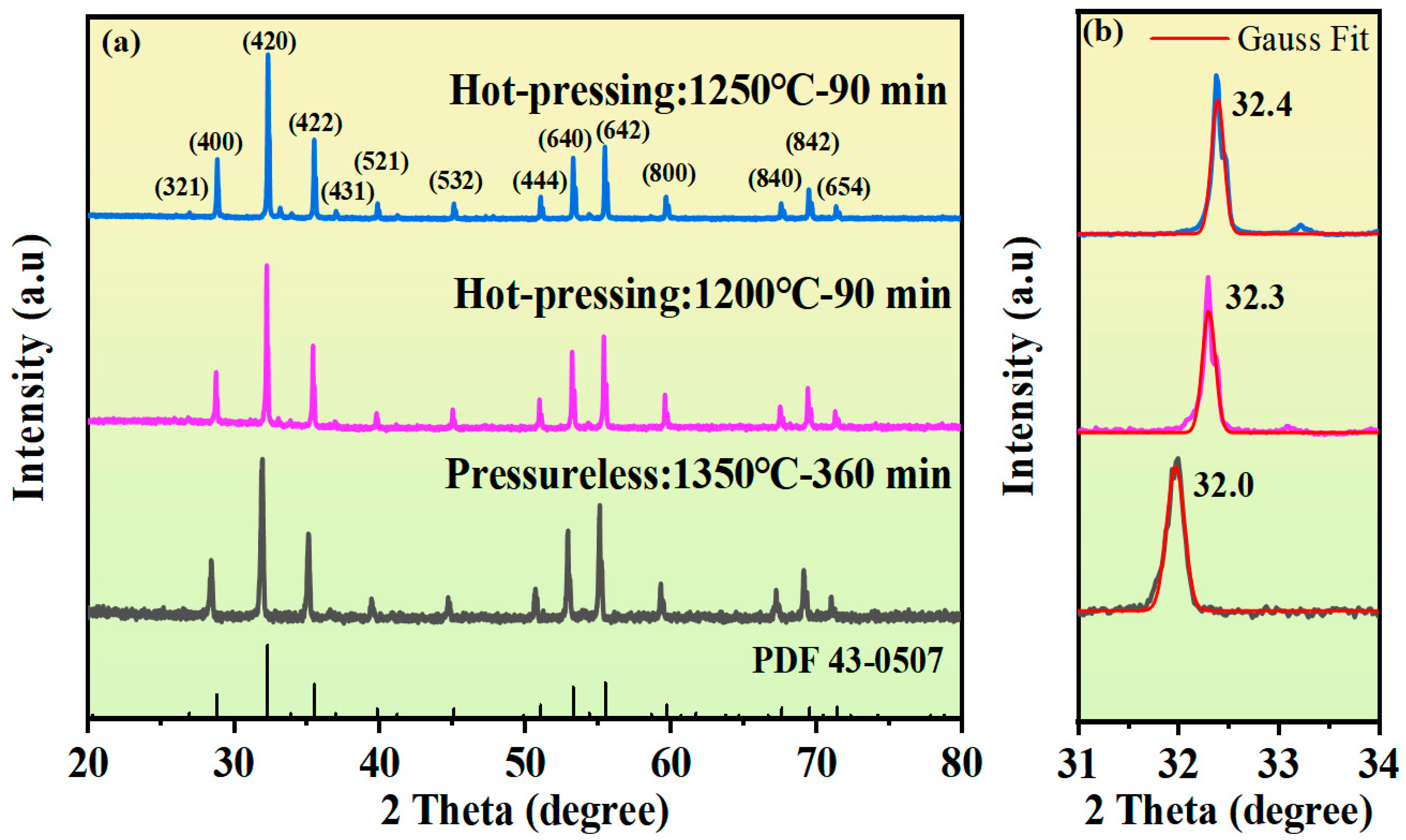

| Sintering Method | Pressureless Sintering | Hot-Press Sintering | Hot-Press Sintering |

|---|---|---|---|

| Temperature (°C) | 1350 | 1200 | 1250 |

| Holding Time (min) | 360 | 90 | 90 |

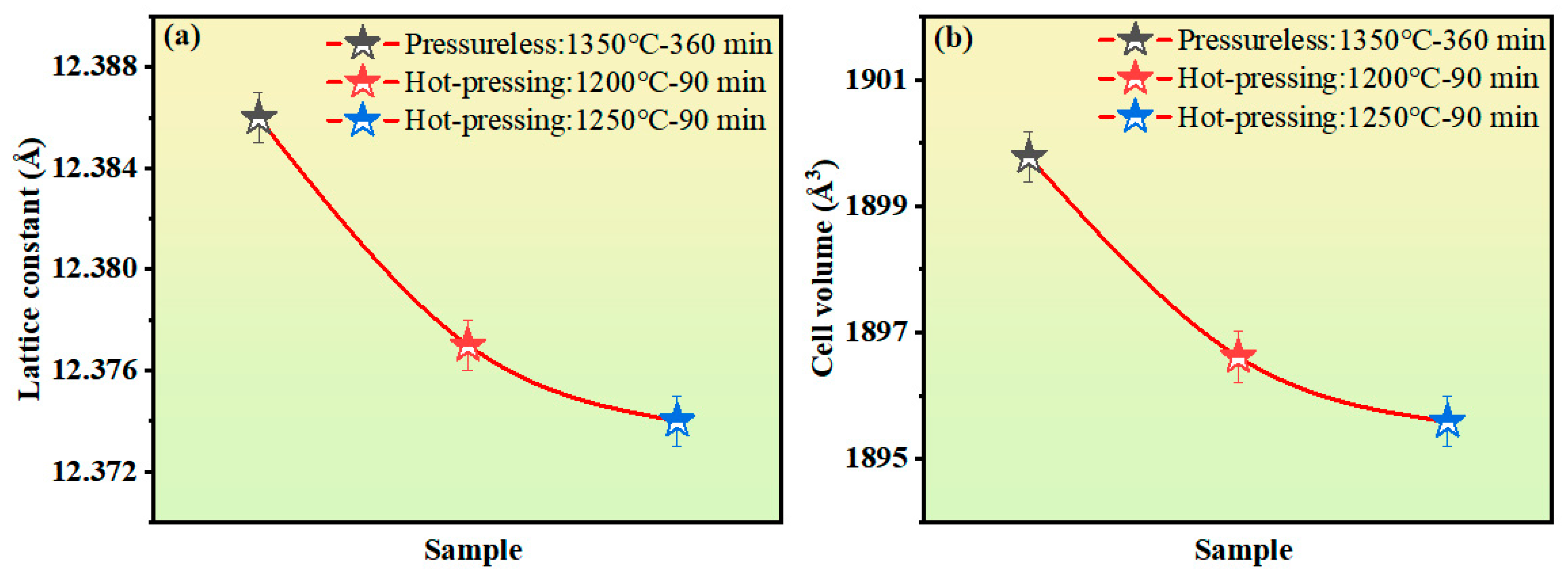

| Lattice Constant (a = b = c, Å) | 12.387 | 12.377 | 12.375 |

| Rp (%) | 9.79 | 9.38 | 8.88 |

| Rwp (%) | 12.47 | 12.56 | 12.62 |

| χ2 | 2.568 | 2.303 | 2.716 |

| Lattice constant | 12.385 | 12.377 | 12.374 |

| Cell Volume (Å3) | 1899.78 | 1896.61 | 1895.59 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Y.; Meng, X.; Wu, J.; Li, R.; Ren, X.; Gu, J.; Zhou, X.; Wu, Y.; Zheng, H. Optimization of Hot-Press Sintering for Cu2+-Sn4+ Co-Doped YIG Ferrites: Microstructure, Dielectric Properties, and Magnetic Properties. Materials 2025, 18, 3749. https://doi.org/10.3390/ma18163749

Sun Y, Meng X, Wu J, Li R, Ren X, Gu J, Zhou X, Wu Y, Zheng H. Optimization of Hot-Press Sintering for Cu2+-Sn4+ Co-Doped YIG Ferrites: Microstructure, Dielectric Properties, and Magnetic Properties. Materials. 2025; 18(16):3749. https://doi.org/10.3390/ma18163749

Chicago/Turabian StyleSun, Yuhao, Xin Meng, Jiawen Wu, Renhao Li, Xinrong Ren, Jia Gu, Xiaoyuan Zhou, Yanhui Wu, and Hui Zheng. 2025. "Optimization of Hot-Press Sintering for Cu2+-Sn4+ Co-Doped YIG Ferrites: Microstructure, Dielectric Properties, and Magnetic Properties" Materials 18, no. 16: 3749. https://doi.org/10.3390/ma18163749

APA StyleSun, Y., Meng, X., Wu, J., Li, R., Ren, X., Gu, J., Zhou, X., Wu, Y., & Zheng, H. (2025). Optimization of Hot-Press Sintering for Cu2+-Sn4+ Co-Doped YIG Ferrites: Microstructure, Dielectric Properties, and Magnetic Properties. Materials, 18(16), 3749. https://doi.org/10.3390/ma18163749