Effects of Multi-Walled Carbon Nanotubes on Mechanical Properties and Microstructure of Ordinary Portland Cement–Sulfoaluminate Cement Repair Mortar

Abstract

1. Introduction

2. Experimental Schemes

2.1. Materials

2.2. Sample Preparation

2.3. Dispersion of MWCNTs

2.4. Test Programs

3. Results and Discussion

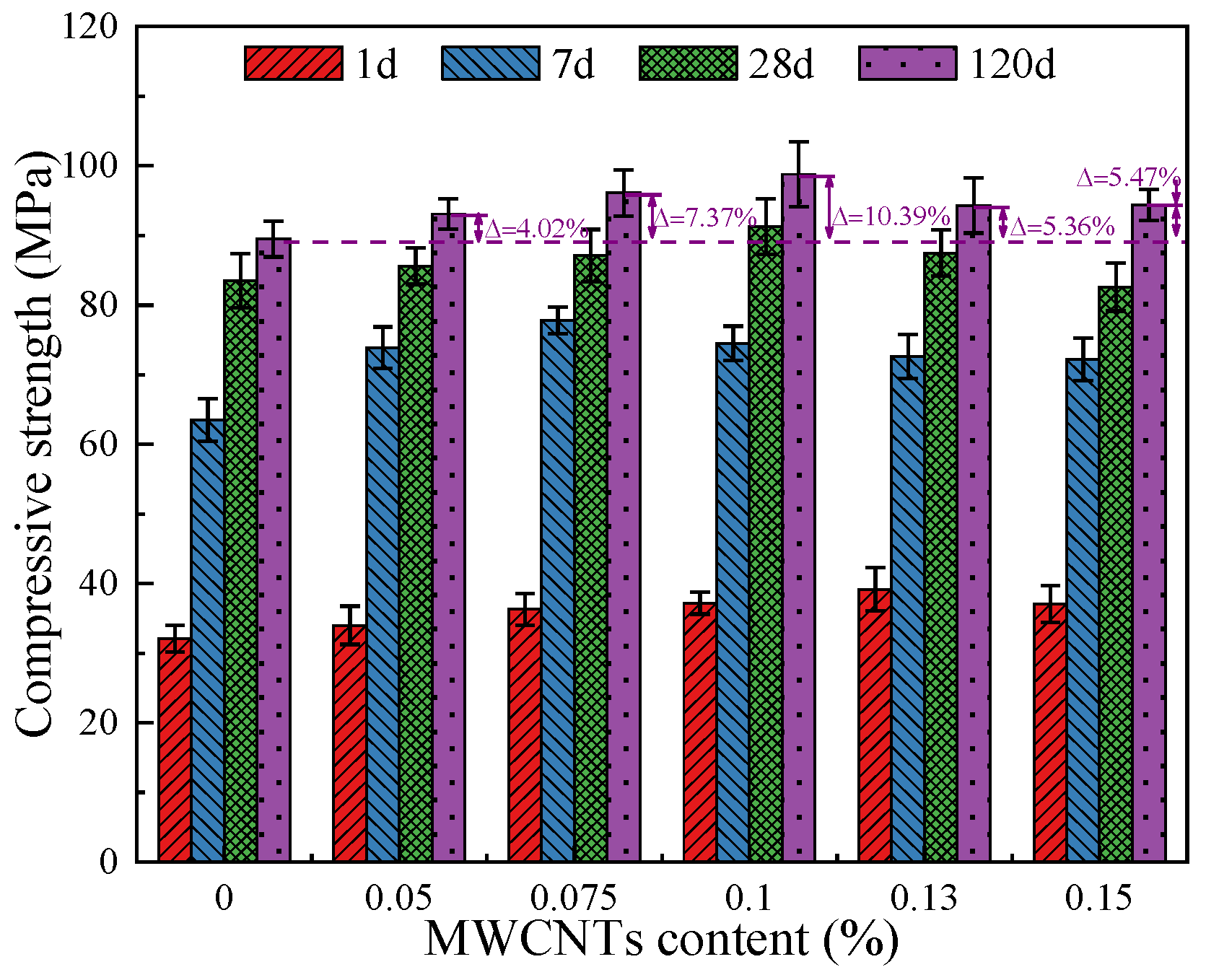

3.1. Mechanical Properties

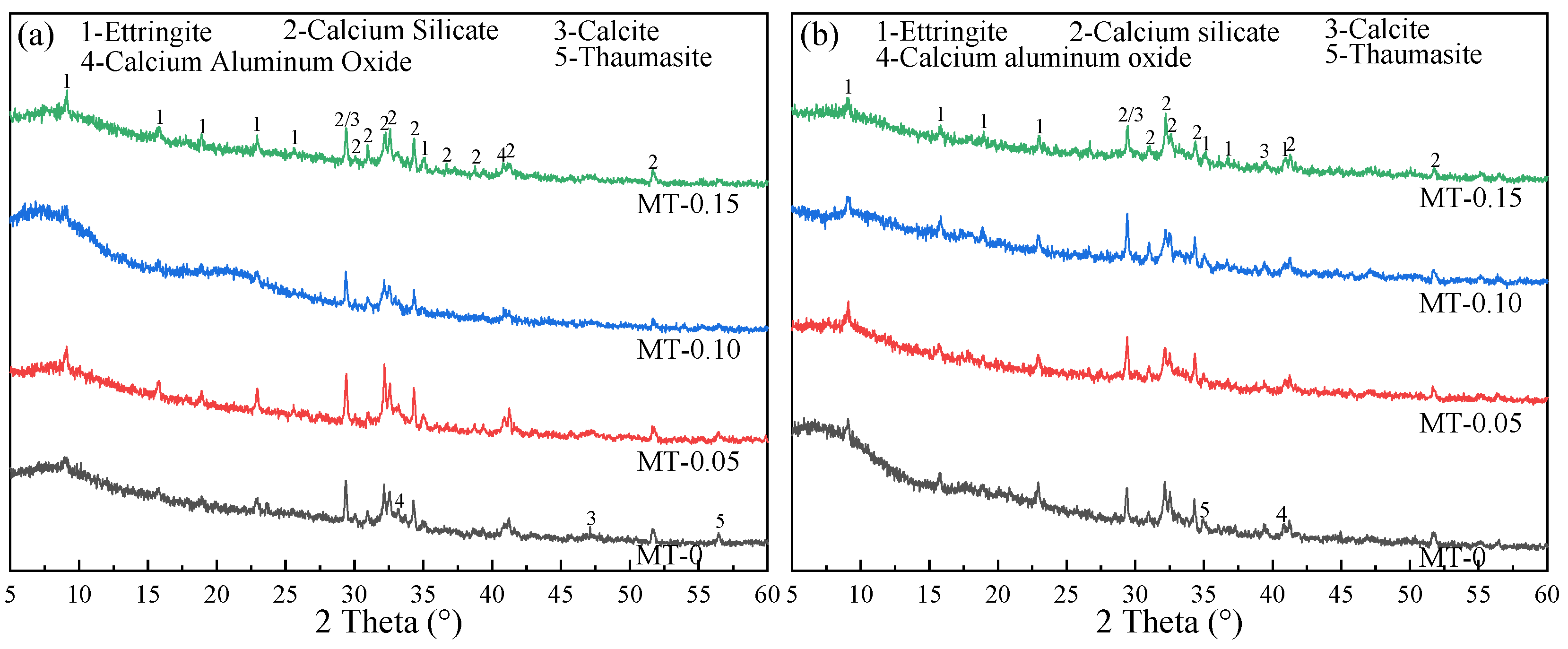

3.2. X-Ray Diffraction

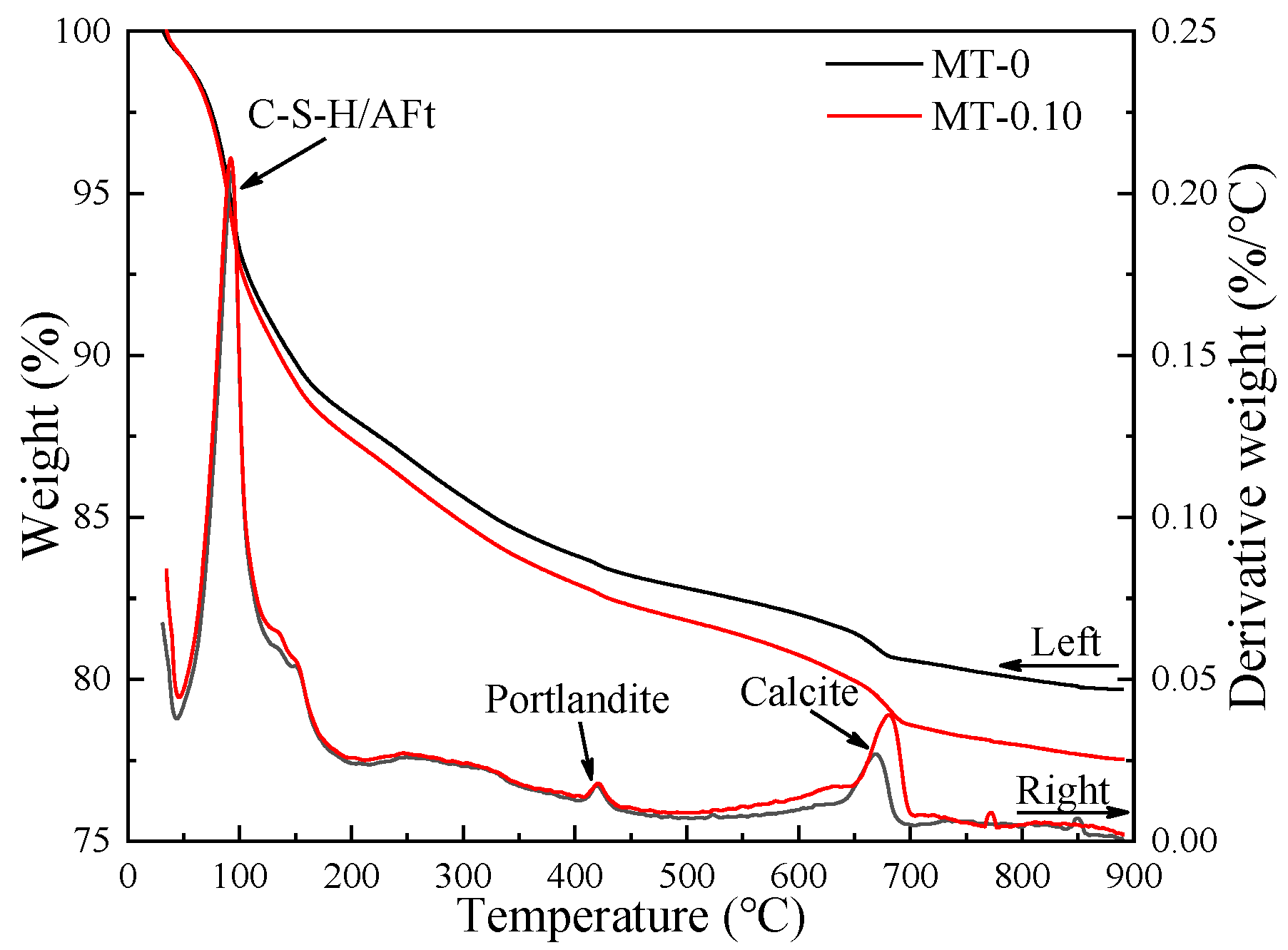

3.3. TG Analysis

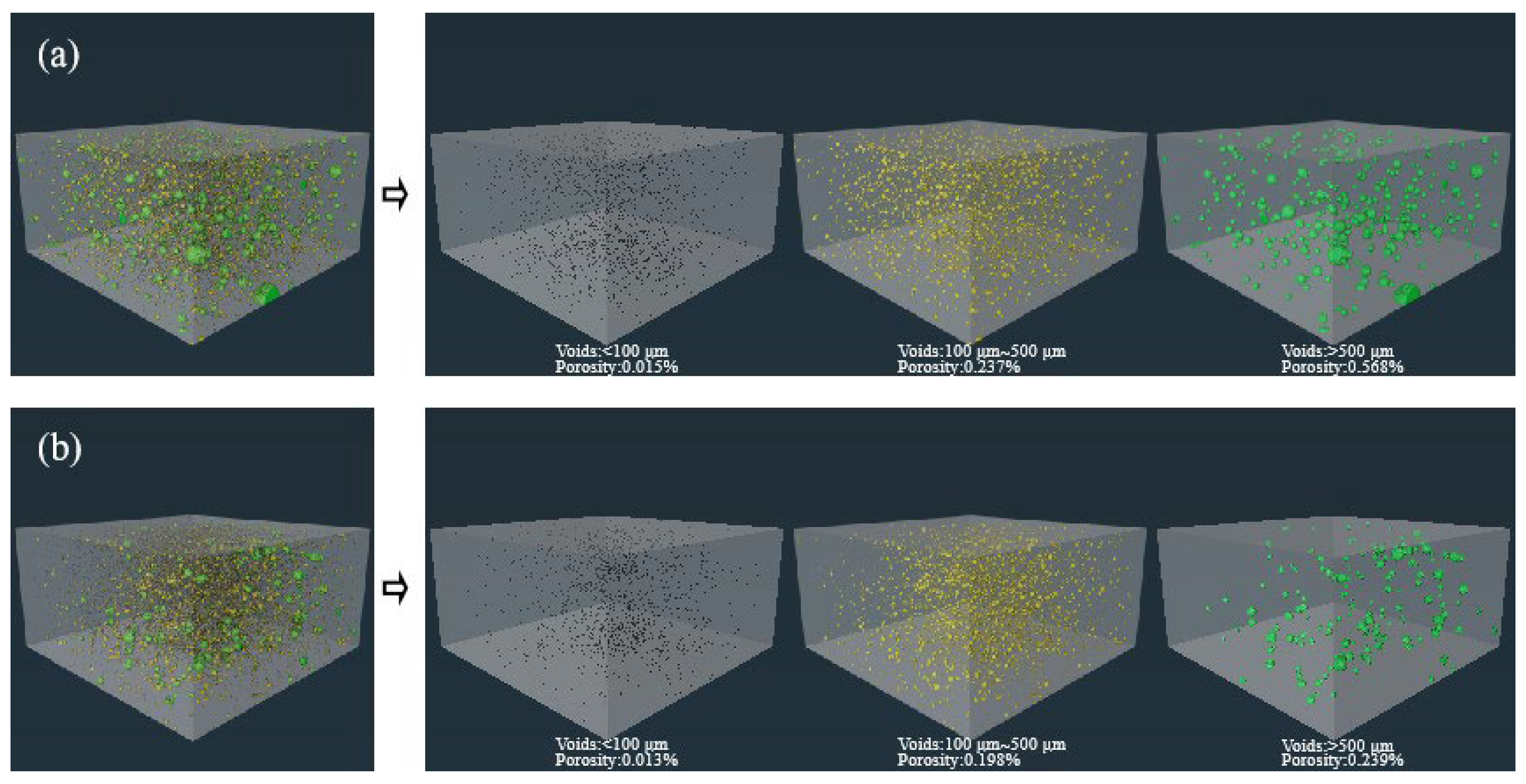

3.4. X-CT Analysis

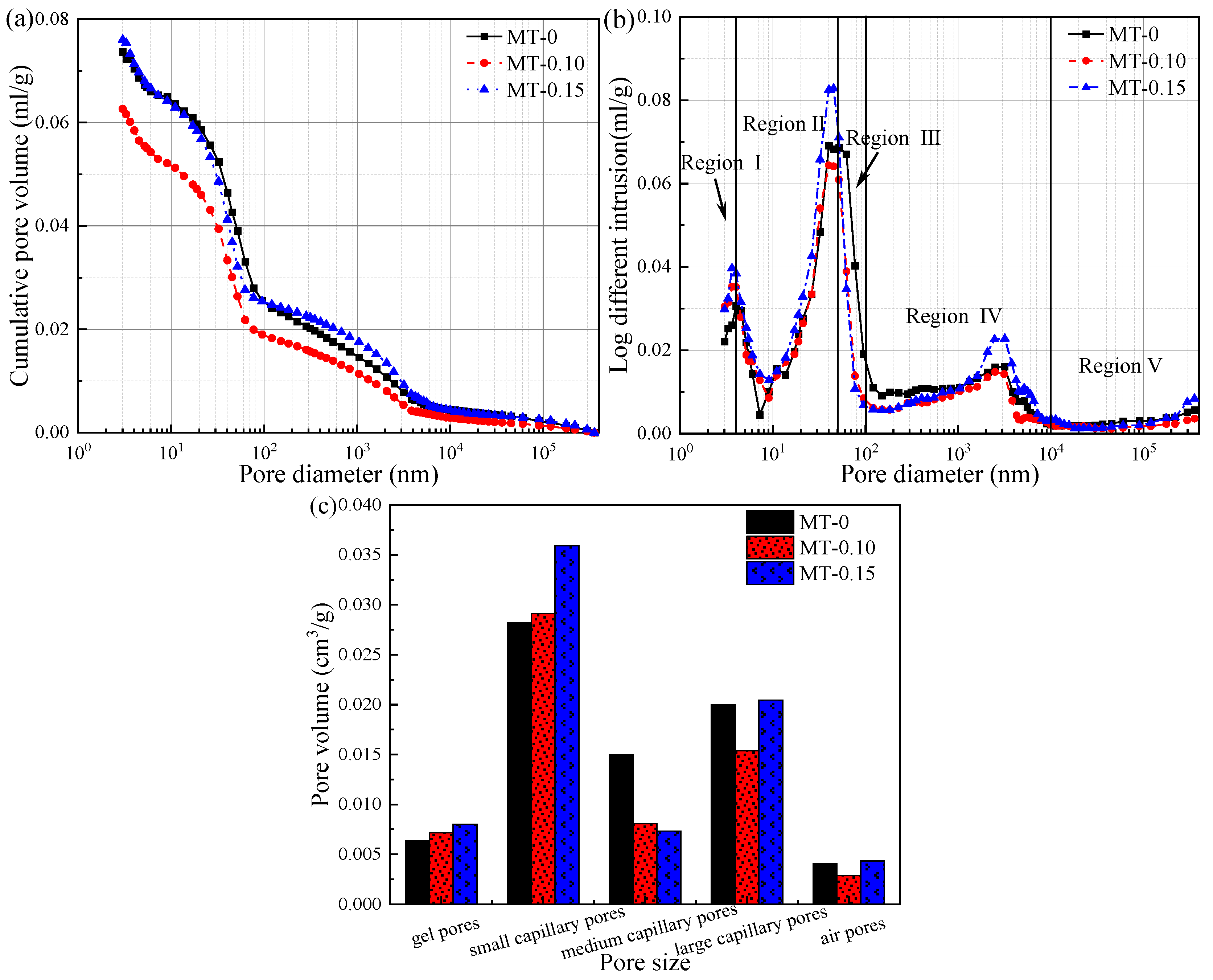

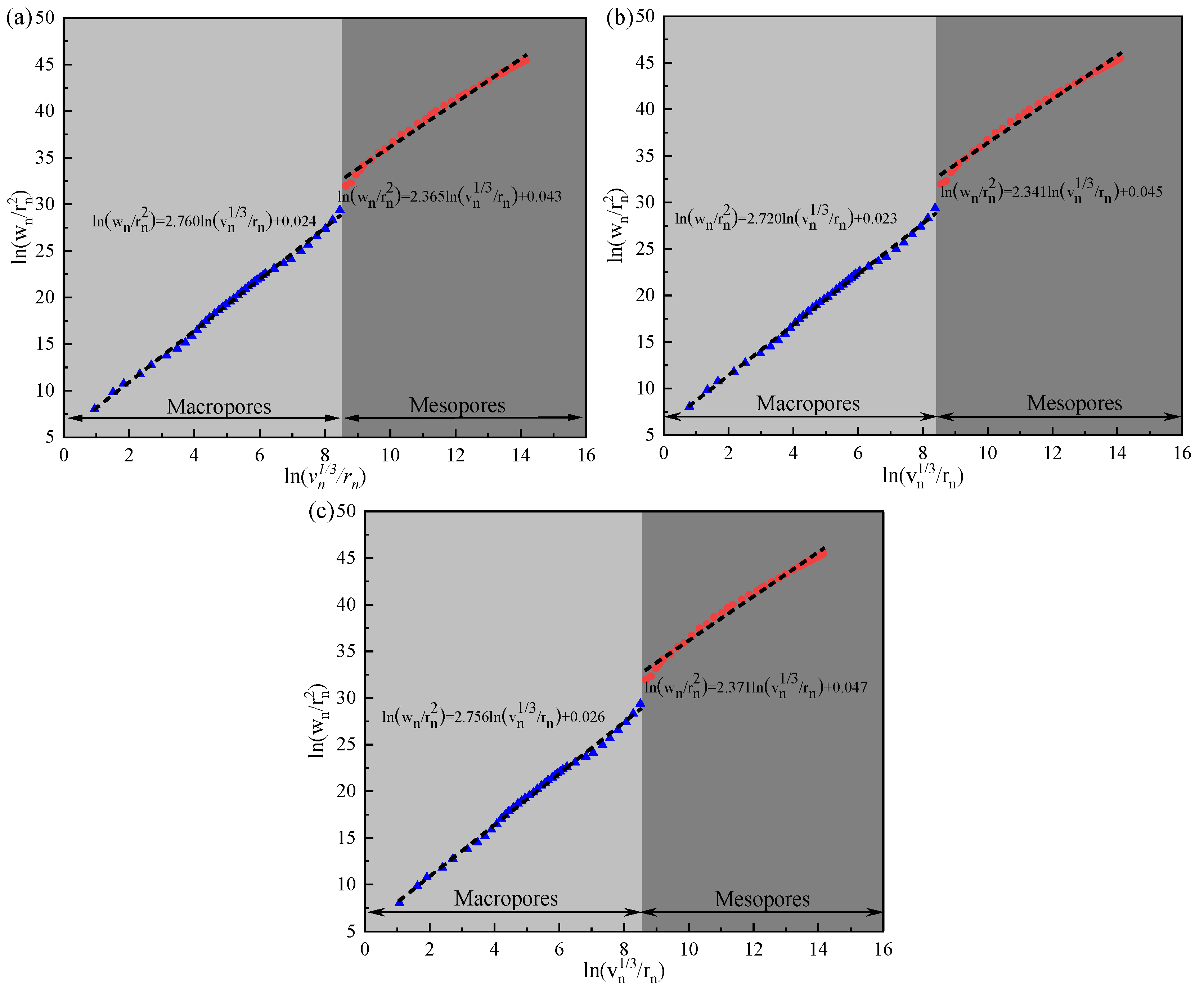

3.5. MIP Analysis

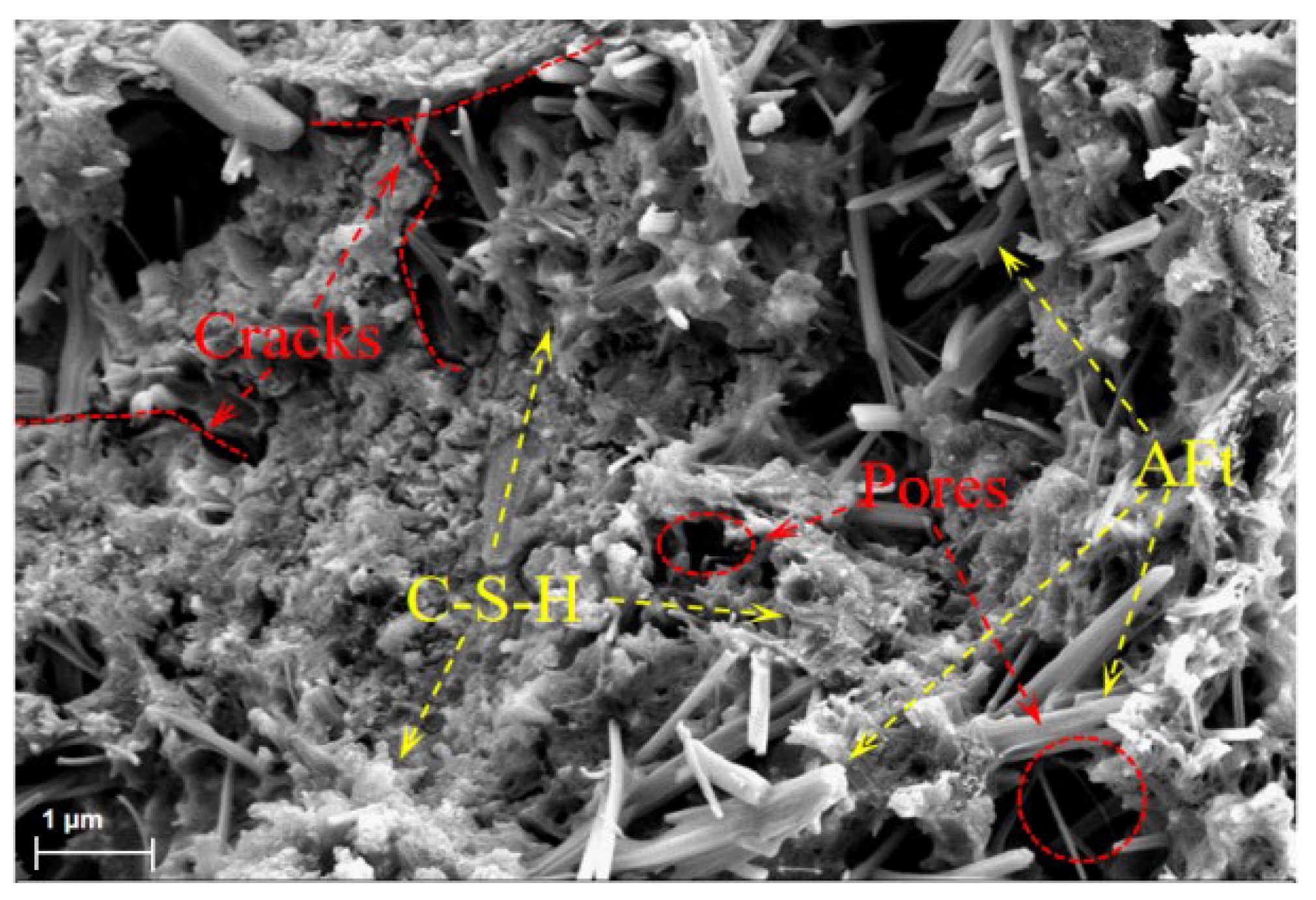

3.6. SEM Analysis

4. Conclusions

- Incorporation of MWCNTs improves the mechanical strength of OPC-SAC mortar. Contrary to that of OPC-SAC mortar without MWCNTs, the compressive strength of OPC-SAC mortar with 0.10 wt.% MWCNTs increased by 10.39%/9.3 MPa at most. Meanwhile, the flexural strength can be increased by 15.70%/1.9 MPa by adding 0.075 wt.% MWCNTs.

- Dispersed MWCNTs promote hydration of OPC-SAC composites (especially in the early stages) through functional group and nucleation effects, but did not promote the formation of new substances.

- The X-CT, MIP, and SEM results indicate that the MWCNTs optimizes the microstructure and microstructure of the composites. One role is to cause partial cross-linking occurs between hydration products, which enhances the complexity (higher Ds) and integrity of the binder (more cross-linking sites). The other one is to reduce the generation and propagation of microcracks through nanofiber bridging. The third is to optimize the pore structure and reduce the porosity, especially the volume of medium capillary pores.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Song, X.; Shang, S.; Chen, D.; Gu, X. Multi-walled carbon nanotube reinforced mortar-aggregate interfacial properties. Constr. Build. Mater. 2020, 133, 57–64. [Google Scholar] [CrossRef]

- Guan, X.; Bai, S.; Li, H.; Ou, J. Mechanical properties and microstructure of multi-walled carbon nanotube-reinforced cementitious composites under the early-age freezing conditions. Constr. Build. Mater. 2017, 233, 117317. [Google Scholar] [CrossRef]

- Chen, J.; Akono, A. Influence of multi-walled carbon nanotubes on the hydration products of ordinary Portland cement paste. Cem. Concr. Res. 2020, 137, 106197. [Google Scholar] [CrossRef]

- Konsta-Gdoutos, M.S.; Metaxa, Z.S.; Shah, S.P. Multi-scale mechanical and fracture characteristics and early-age strain capacity of high performance carbon nanotube/cement nanocomposites. Cem. Concr. Compos. 2010, 32, 110–115. [Google Scholar] [CrossRef]

- Tyson, B.M.; Abu Al-Rub, R.K.; Yazdanbakhsh, A.; Grasley, Z. Carbon nanotubes and carbon nanofibers for enhancing the mechanical properties of nanocomposite cementitious materials. J. Mater. Civ. Eng. 2011, 23, 1028–1035. [Google Scholar] [CrossRef]

- Aslani, F.; Gunawardena, Y.; Dehghani, A. Behaviour of concrete filled glass fibrereinforced polymer tubes under static and flexural fatigue loading. Constr. Build. Mater. 2019, 212, 57–76. [Google Scholar] [CrossRef]

- Gao, F.F.; Tian, W.; Wang, Z.; Wang, F. Effect of diameter of multi-walled carbon nanotubes on mechanical properties and microstructure of the cement-based materials. Constr. Build. Mater. 2020, 260, 120452. [Google Scholar] [CrossRef]

- Lee, S.-C.; Oh, J.-H.; Cho, J.-Y. Compressive behavior of fiber-reinforced concrete with end-hooked steel fibers. Materials 2015, 8, 1442–1458. [Google Scholar] [CrossRef]

- Mendoza Reales, O.A.; Toledo Filho, R.D. A review on the chemical, mechanical and microstructural characterization of carbon nanotubes-cement based composites. Constr. Build. Mater. 2017, 154, 697–710. [Google Scholar] [CrossRef]

- Ramezani, M.; Dehghani, A.; Sherif, M.M. Carbon nanotube reinforced cementitious composites: A comprehensive review. Constr. Build. Mater. 2022, 315, 125100. [Google Scholar] [CrossRef]

- Zheng, L.X.; O’Connell, M.J.; Doorn, S.K.; Liao, X.Z.; Zhao, Y.H.; Akhadov, E.A.; Hoffbauer, M.A.; Roop, B.J.; Jia, Q.X.; Dye, R.C.; et al. Ultralong single-wall carbon nanotubes. Nat. Mater. 2004, 3, 673–676. [Google Scholar] [CrossRef] [PubMed]

- Nuaklong, P.; Boonchoo, N.; Jongvivatsakul, P.; Charinpanitkul, T.; Sukontasukkul, P. Hybrid effect of carbon nanotubes and polypropylene fibers on mechanical properties and fire resistance of cement mortar. Constr. Build. Mater. 2021, 275, 122189. [Google Scholar] [CrossRef]

- Li, G.Y.; Wang, P.M.; Zhao, X. Mechanical behavior and microstructure of cement composites incorporating surface-treated multi-walled carbon nanotubes. Carbon 2005, 43, 1239–1245. [Google Scholar] [CrossRef]

- Mohsen, M.O.; Taha, R.; Taqa, A.A.; Shaat, A. Optimum carbon nanotubes’ content for improving flexural and compressive strength of cement paste. Constr. Build. Mater. 2017, 150, 395–403. [Google Scholar] [CrossRef]

- Jung, M.; Lee, Y.; Hong, S. Effect of incident area size on estimation of EMI shielding effectiveness for ultra-high performance concrete with carbon nanotubes. IEEE Access 2019, 7, 183105–183117. [Google Scholar] [CrossRef]

- Yoo, D.Y.; You, I.; Lee, S.J. Electrical and piezoresistive sensing capacities of cement paste with multi-walled carbon nanotubes. Arch. Civ. Mech. Eng. 2018, 18, 371–384. [Google Scholar] [CrossRef]

- Kim, G.M.; Park, S.M.; Ryu, G.U.; Lee, H. Electrical characteristics of hierarchical conductive pathways in cementitious composites incorporating CNT and carbon fiber. Cem. Concr. Compos. 2017, 82, 165–175. [Google Scholar] [CrossRef]

- Jung, M.; Park, J.; Hong, S.; Moon, J. Micro- and meso-structural changes on electrically cured ultra-high performance fiber-reinforced concrete with dispersed carbon nanotubes. Cem. Concr. Res. 2020, 137, 106214. [Google Scholar] [CrossRef]

- Xu, S.; Liu, J.; Li, Q. Mechanical properties and microstructure of multi-walled carbon nanotube-reinforced cement paste. Constr. Build. Mater. 2015, 76, 16–23. [Google Scholar] [CrossRef]

- Sobolkina, A.; Mechtcherine, V.; Khavrus, V.; Maier, D.; Mende, M.; Ritschel, M.; Leonhardt, A. Dispersion of carbon nanotubes and its influence on the mechanical properties of the cement matrix. Cem. Concr. Compos. 2012, 34, 1104–1113. [Google Scholar] [CrossRef]

- Sikora, P.; Elrahman, M.A.; Chung, S.Y.; Cendrowski, K.; Mijowska, E.; Stephan, D. Mechanical and microstructural properties of cement pastes containing carbon nanotubes and carbon nanotube-silica core-shell structures, exposed to elevated temperature. Cem. Concr. Compos. 2019, 95, 193–204. [Google Scholar] [CrossRef]

- Wang, J.L.; Dong, S.F.; Dai, S.P.; Zhou, C.; Han, B. Pore structure characteristics of reactive powder concrete composites with surface-modified carbon nanotubes. Cem. Concr. Compos. 2022, 128, 104453. [Google Scholar] [CrossRef]

- Trauchessec, R.; Mechling, J.M.; Lecomte, A.; Roux, A.; Le Rolland, B. Hydration of ordinary Portland cement and calcium sulfoaluminate cement blends. Cem. Concr. Compos. 2015, 56, 106–114. [Google Scholar] [CrossRef]

- Mehdipour, I.; Khayat, K.H. Effect of shrinkage reducing admixture on early expansion and strength evolution of calcium sulfoaluminate blended cement. Cem. Concr. Compos. 2018, 92, 82–91. [Google Scholar] [CrossRef]

- Chaunsali, P.; Mondal, P. Physico-chemical interaction between mineral admixtures and OPC-calcium sulfoaluminate (CSA) cements and its influence on early-age expansion. Cem. Concr. Res. 2016, 80, 10–20. [Google Scholar] [CrossRef]

- Saoût, G.L.; Lothenbach, B.; Hori, A.; Higuchi, T.; Winnefeld, F. Hydration of Portland cement with additions of calcium sulfoaluminates. Cem. Concr. Res. 2013, 43, 81–94. [Google Scholar] [CrossRef]

- Li, Z.; Corr, D.J.; Han, B.G.; Shah, S.P. Investigating the effect of carbon nanotube on early age hydration of cementitious composites with isothermal calorimetry and Fourier transform infrared spectroscopy. Cem. Concr. Compos. 2020, 107, 103513. [Google Scholar] [CrossRef]

- Materazzi, A.L.; Ubertini, F.; Alessandro, A.D. Carbon nanotube cement-based transducers for dynamic sensing of strain. Cem. Concr. Compos. 2013, 37, 2–11. [Google Scholar] [CrossRef]

- GB/T 17671-2021; Test Method of Cement Mortar Strength (ISO Method). Standardization Administration of the People’s Republic of China: Beijing, China, 2021.

- Wang, X.F.; Chen, C.; Wang, Y.B. Fractal analysis of porous alumina and its relationships with the pore structure and mechanical properties. Fractal Fract. 2022, 6, 460. [Google Scholar] [CrossRef]

- Cwirzen, A.; Habermehl-Cwirzen, K.; Penttala, V. Surface decoration of carbon nanotubes and mechanical properties of cement/carbon nanotube composites. Adv. Cem. Res. 2008, 20, 65–73. [Google Scholar] [CrossRef]

- Collins, F.; Lambert, J.; Duan, W.H. The influences of admixtures on the dispersion, workability, and strength of carbon nanotube-OPC paste mixtures. Cem. Concr. Compos. 2012, 34, 201–207. [Google Scholar] [CrossRef]

- Zou, B.; Chen, S.J.; Korayem, A.H.; Collins, F.; Wang, C.; Duan, W.H. Effect of ultrasonication energy on engineering properties of carbon nanotube reinforced cement pastes. Carbon 2015, 85, 212–220. [Google Scholar] [CrossRef]

- Liu, Q.; Sun, W.; Jiang, H.; Wang, C. Effects of carbon nanotubes on mechanical and 2D-3D microstructure properties of cement mortar. J. Wuhan Univ. Technol. 2014, 29, 513–517. [Google Scholar] [CrossRef]

- Dong, S.F.; Wang, D.N.; Ashour, A.; Han, B.; Ou, J. Nickel plated carbon nanotubes reinforcing concrete composites: From nano/micro structures to macro mechanical properties. Compos. Part A 2021, 141, 106228. [Google Scholar] [CrossRef]

- Zhang, J.; Ye, C.; Tan, H.; Liu, X. Potential application of Portland cementsulfoaluminate cement system in precast concrete cured under ambient temperature. Constr. Build. Mater. 2020, 251, 118869. [Google Scholar] [CrossRef]

- Liu, G.F.; Kan, D.Y.; Cao, S.C.; Chen, Z.; Lyu, Q. Effect of multi-walled carbon nanotube on reactive powder concrete (RPC) performance in sulfate dry-wet cycling environment. Constr. Build. Mater. 2022, 342, 128075. [Google Scholar] [CrossRef]

- Ren, J.; Zhang, L.; Walkley, B.; Black, J.R.; Nicolas, R.S. Degradation resistance of different cementitious materials to phosphoric acid attack at early stage. Cem. Concr. Res. 2022, 151, 106606. [Google Scholar] [CrossRef]

- Aiken, T.A.; Kwasny, J.; Sha, W.; Soutsos, M.N. Effect of slag content and activator dosage on the resistance of fly ash geopolymer binders to sulfuric acid attack. Cem. Concr. Res. 2018, 111, 23–40. [Google Scholar] [CrossRef]

- Zajac, M.; Hoock, S.; Stabler, C.; Ben Haha, M. Effect of hydration kinetics on properties of compositionally similar binders. Cem. Concr. Res. 2017, 101, 13–24. [Google Scholar] [CrossRef]

- Stynoski, P.; Mondal, P.; Marsh, C. Effects of silica additives on fracture properties of carbon nanotube and carbon fiber reinforced portland cement mortar. Cem. Concr. Compos. 2015, 55, 232–240. [Google Scholar] [CrossRef]

- Cui, H.; Yang, S.; Memon, S. Development of carbon nanotube modified cement paste with microencapsulated phase-change material for structural- functional integrated application. Int. J. Mol. Sci. 2015, 16, 8027–8039. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Guo, X.Y.; Liu, Y.Y.; Zhao, Y.; Chen, Z.; Zhang, Y.; Guo, L.; Shu, X.; Liu, J. Hydration kinetics, pore structure, 3D network calcium silicate hydrate, and mechanical behavior of graphene oxide reinforced cement composites. Constr. Build. Mater. 2018, 190, 150–163. [Google Scholar] [CrossRef]

- Zeng, Q.; Luo, M.; Pang, X.; Li, L.; Li, K. Surface fractal dimension: An indicator to characterize the microstructure of cement-based porous materials. Appl. Surf. Sci. 2013, 282, 302–307. [Google Scholar] [CrossRef]

- Yang, J.; Su, Y.; He, X.; Tan, H.; Jiang, Y.; Zeng, L.; Strnadel, B. Pore structure evaluation of cementing composites blended with coal by-products: Calcined coal gangue and coal fly ash. Fuel Process. Technol. 2018, 181, 75–90. [Google Scholar] [CrossRef]

- Zeng, Q.; Li, K.F.; Fen-Chong, T.; Dangla, P. Surface fractal analysis of pore structure of high-volume fly-ash cement pastes. Appl. Surf. Sci. 2010, 257, 762–768. [Google Scholar] [CrossRef]

- Zhang, B.; Li, S. Determination of the surface fractal dimension for porous media by mercury porosimetry. Ind. Eng. Chem. Res. 1995, 34, 1383–1386. [Google Scholar] [CrossRef]

| Mass Fraction (w/%) | CaO | Al2O3 | SiO2 | Fe2O3 | MgO | SO3 | K2O | Na2O | LOI |

|---|---|---|---|---|---|---|---|---|---|

| OPC | 68.62 | 3.42 | 17.52 | 4.61 | 1.79 | 1.23 | 1.10 | 0.66 | 1.05 |

| SAC | 42.70 | 36.27 | 6.56 | 2.48 | 1.55 | 8.75 | 0.17 | 0.22 | 0.70 |

| Out Diameter (nm) | Inner Diameter (nm) | Length (um) | Specific Surface Area (m2/g) | Purity (%) |

|---|---|---|---|---|

| 10–20 | 5–10 | 20–30 | ˃250 | ˃95 |

| Sample Code | MWCNTs | OPC | SAC | Sand | Water | Superplasticizer |

|---|---|---|---|---|---|---|

| MT-0 | 0 | 800.0 | 200.0 | 800 | 250 | 6 |

| MT-0.05 | 0.50 | 799.6 | 199.9 | 800 | 250 | 8 |

| MT-0.075 | 0.75 | 799.4 | 199.9 | 800 | 250 | 8 |

| MT-0.10 | 1.00 | 799.2 | 199.8 | 800 | 250 | 10 |

| MT-0.125 | 1.25 | 799.0 | 199.8 | 800 | 250 | 10 |

| MT-0.15 | 1.50 | 798.8 | 199.7 | 800 | 250 | 12 |

| Simple Code | Porosity (%) | Equivalent Diameter (μm) | Pore Quantity |

|---|---|---|---|

| MT-0 | 0.82 | 86.1 | 27,042 |

| MT-0.10 | 0.45 | 70.3 | 22,874 |

| Sample Code | Most Probable Aperture/nm | Average Pore Diameter/nm | Medium Pore Diameter/nm | Porosity/% |

|---|---|---|---|---|

| MT-0 | 40.3 | 22.5 | 55.6 | 15.17 |

| MT-0.10 | 40.3 | 17.8 | 43.4 | 13.34 |

| MT-0.15 | 45.3 | 19.0 | 43.9 | 15.86 |

| Simple Code | Mesopores | Macropores | ||

|---|---|---|---|---|

| Fractal Dimension | Correlation | Fractal Dimension | Correlation | |

| MT-0 | 2.365 | 0.990 | 2.760 | 0.997 |

| MT-0.10 | 2.341 | 0.989 | 2.720 | 0.997 |

| MT-0.15 | 2.371 | 0.988 | 2.756 | 0.997 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Q.; Cao, R.; Ma, X. Effects of Multi-Walled Carbon Nanotubes on Mechanical Properties and Microstructure of Ordinary Portland Cement–Sulfoaluminate Cement Repair Mortar. Materials 2025, 18, 3748. https://doi.org/10.3390/ma18163748

Zhou Q, Cao R, Ma X. Effects of Multi-Walled Carbon Nanotubes on Mechanical Properties and Microstructure of Ordinary Portland Cement–Sulfoaluminate Cement Repair Mortar. Materials. 2025; 18(16):3748. https://doi.org/10.3390/ma18163748

Chicago/Turabian StyleZhou, Qun, Runzhuo Cao, and Xiaodong Ma. 2025. "Effects of Multi-Walled Carbon Nanotubes on Mechanical Properties and Microstructure of Ordinary Portland Cement–Sulfoaluminate Cement Repair Mortar" Materials 18, no. 16: 3748. https://doi.org/10.3390/ma18163748

APA StyleZhou, Q., Cao, R., & Ma, X. (2025). Effects of Multi-Walled Carbon Nanotubes on Mechanical Properties and Microstructure of Ordinary Portland Cement–Sulfoaluminate Cement Repair Mortar. Materials, 18(16), 3748. https://doi.org/10.3390/ma18163748