Concrete Obtained with the Viterbo O’Reilly Method for Aggregate Gradation: A Potential Model for Sustainable Design and Reducing Development Costs

Abstract

1. Introduction

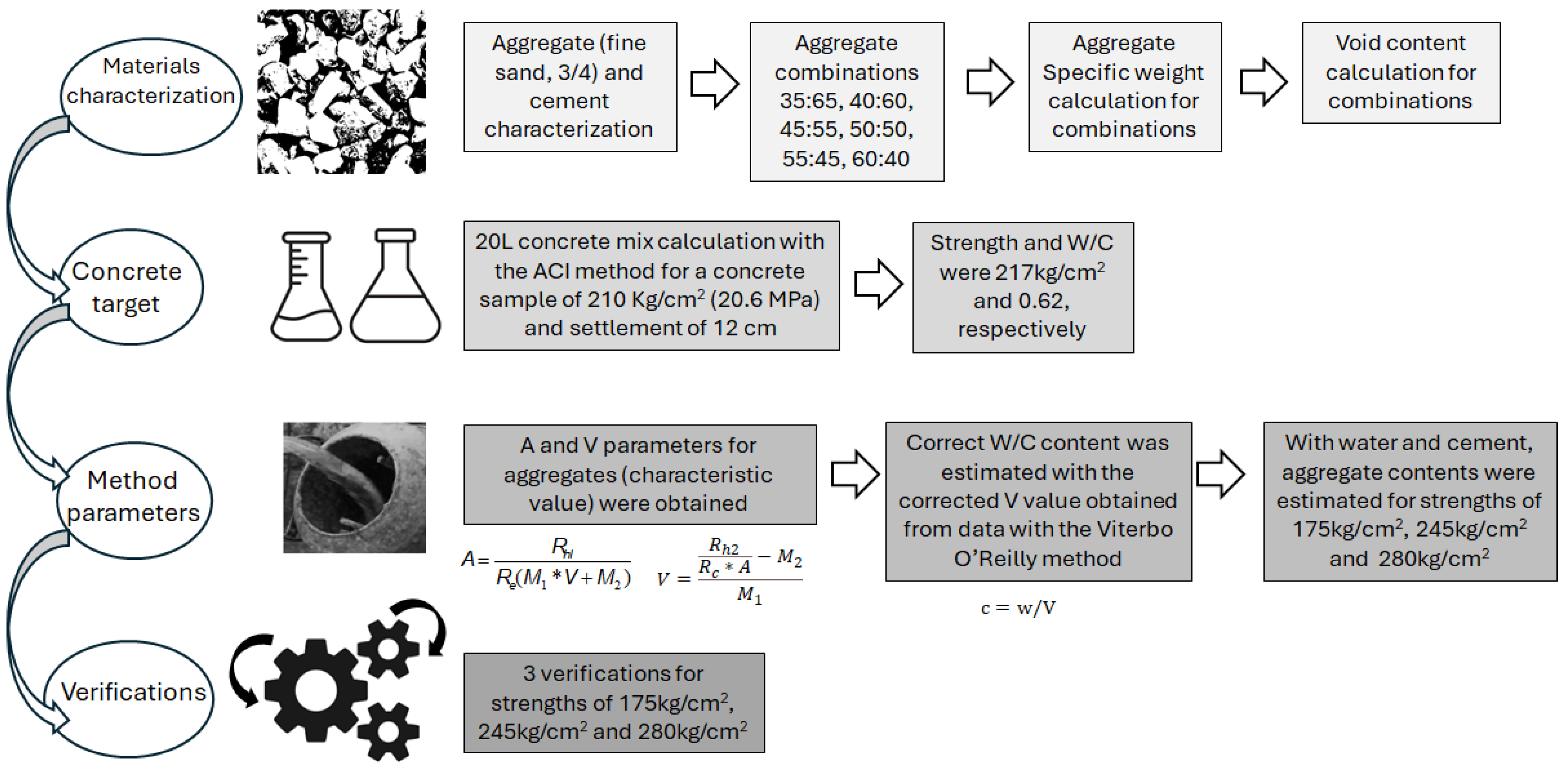

2. Materials and Methods

2.1. Materials

2.2. Used Mix Design Method

2.3. Materials Characterization

3. Results

3.1. Granulometric Analysis

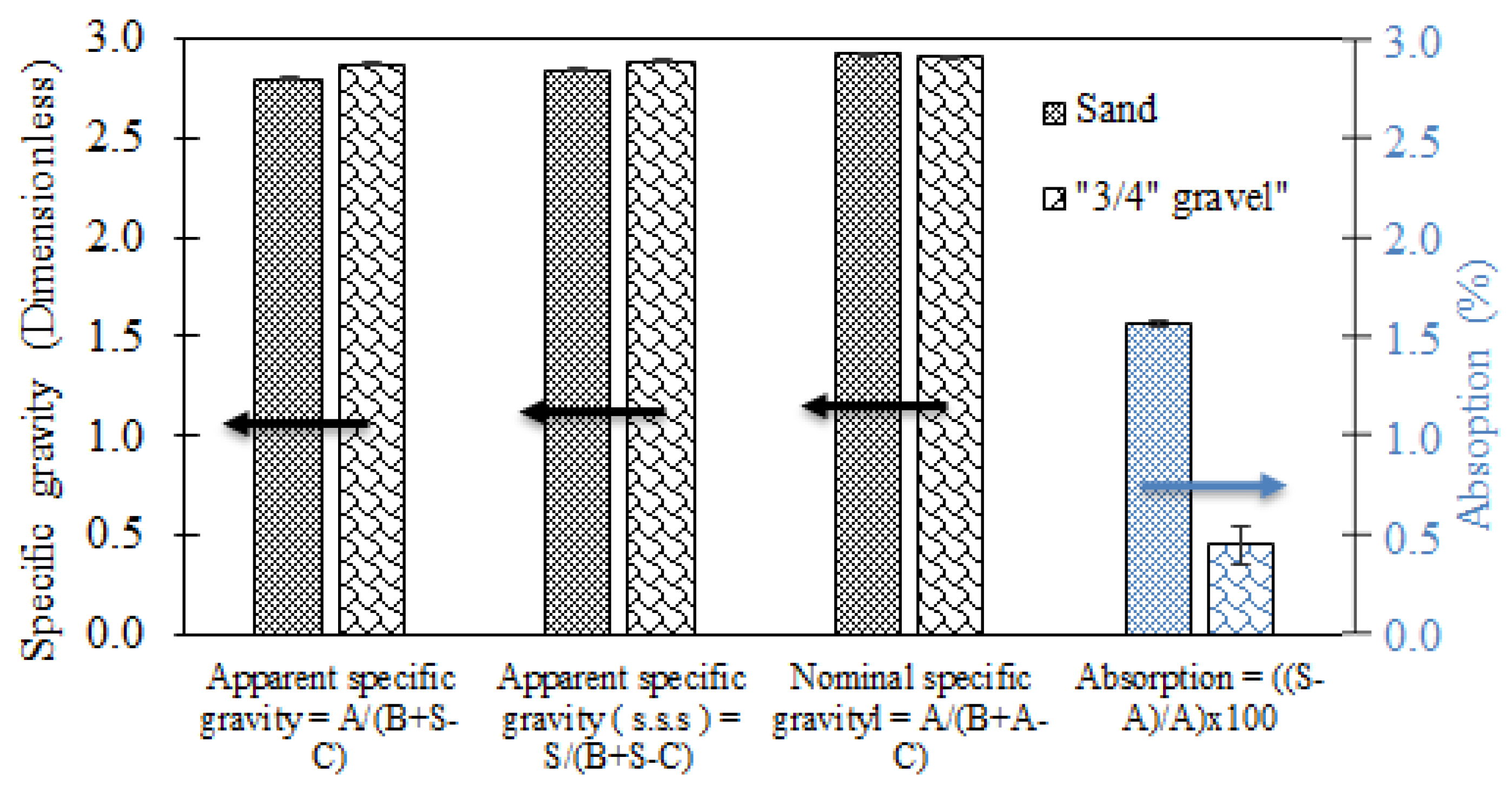

3.2. Specific Weight and Water Absorption

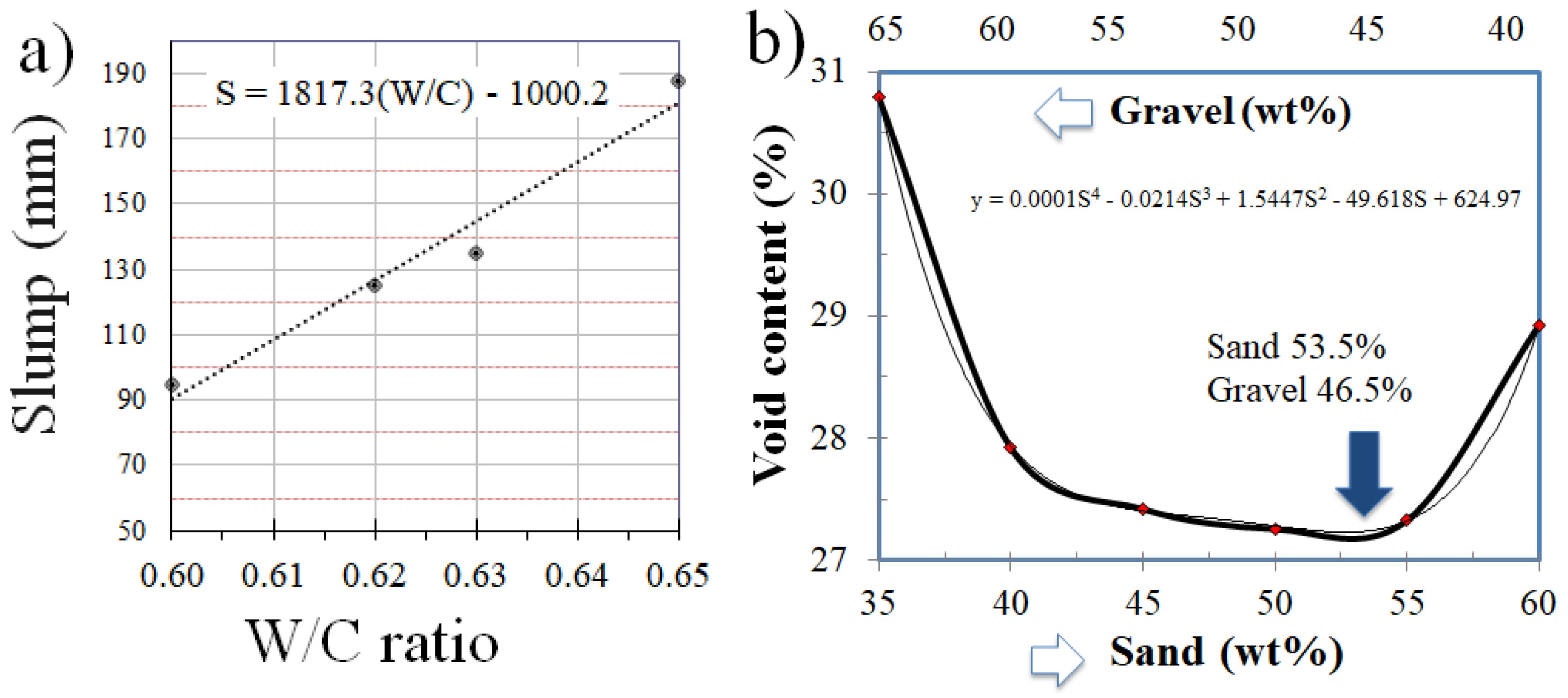

3.3. Slump

3.4. Dosage of Mixtures

3.5. Sample Manufacturing

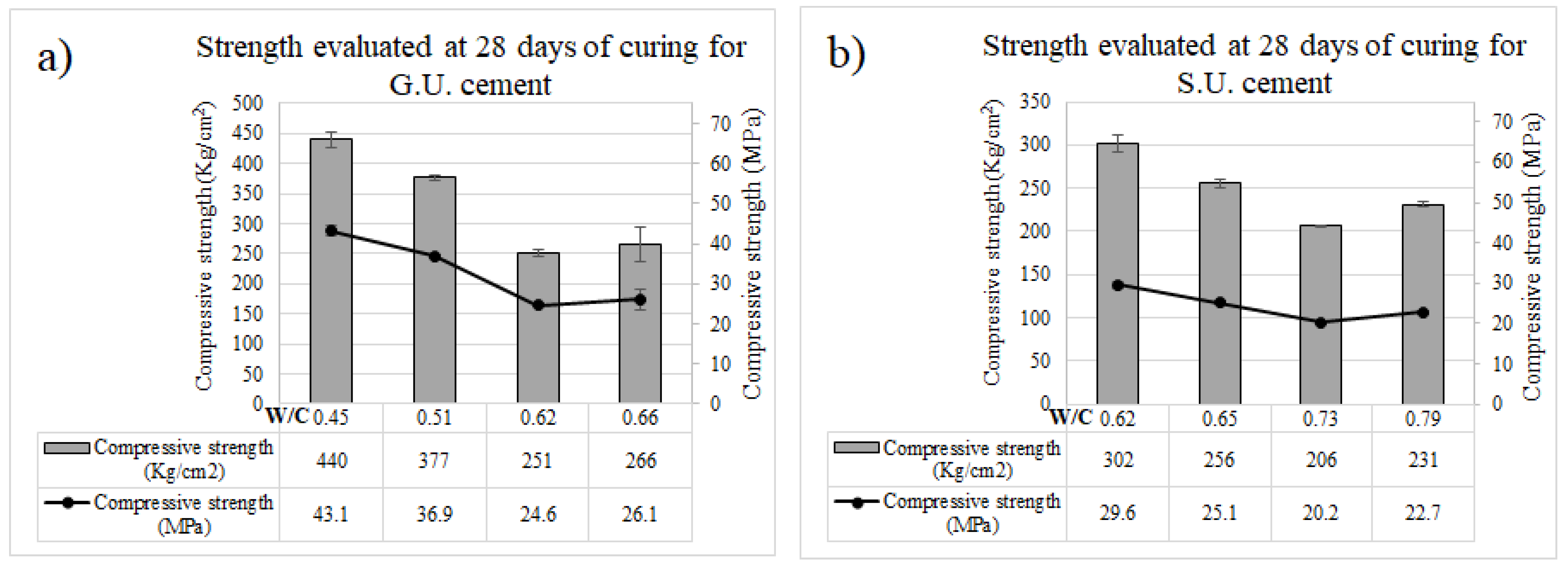

3.6. Compressive Strength

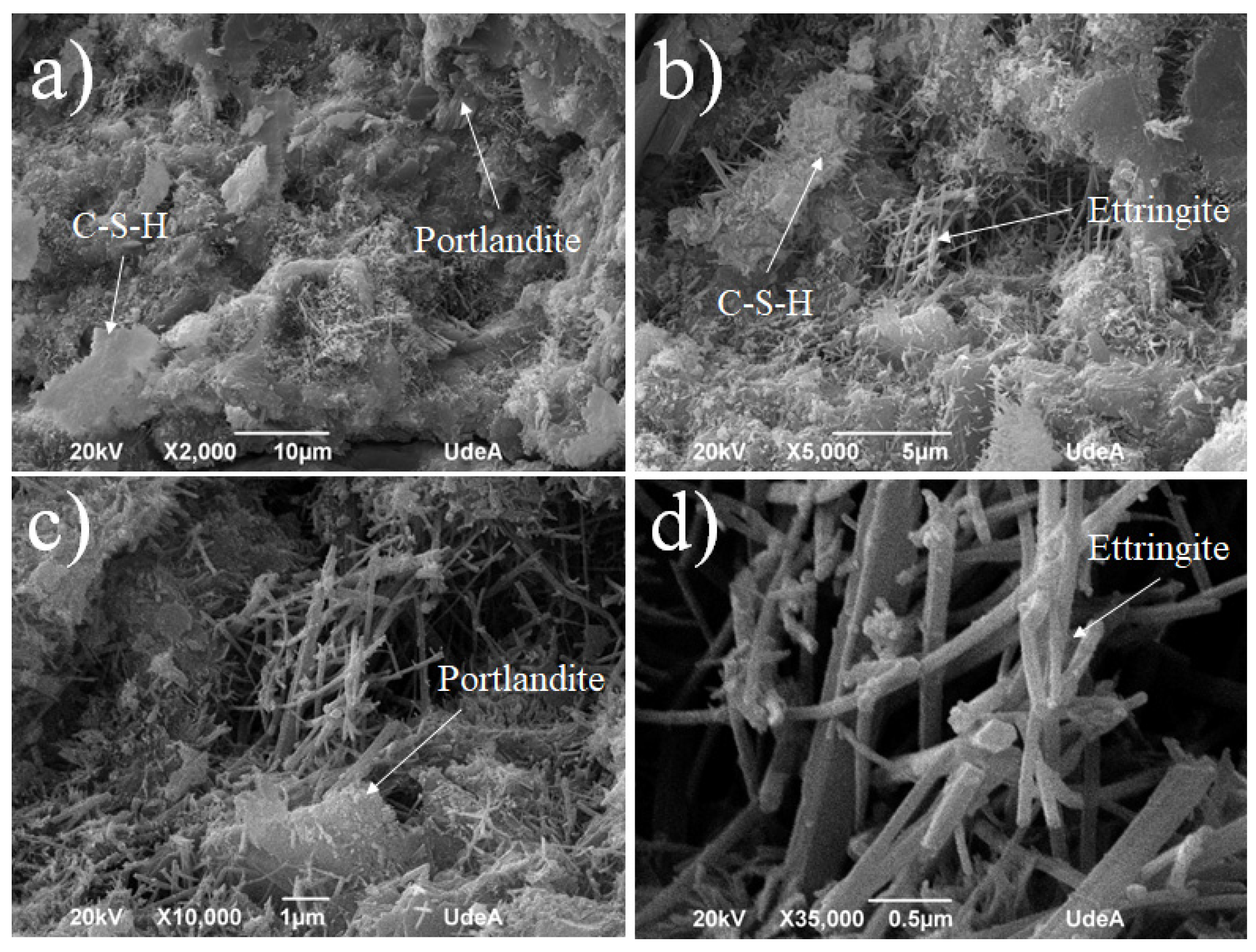

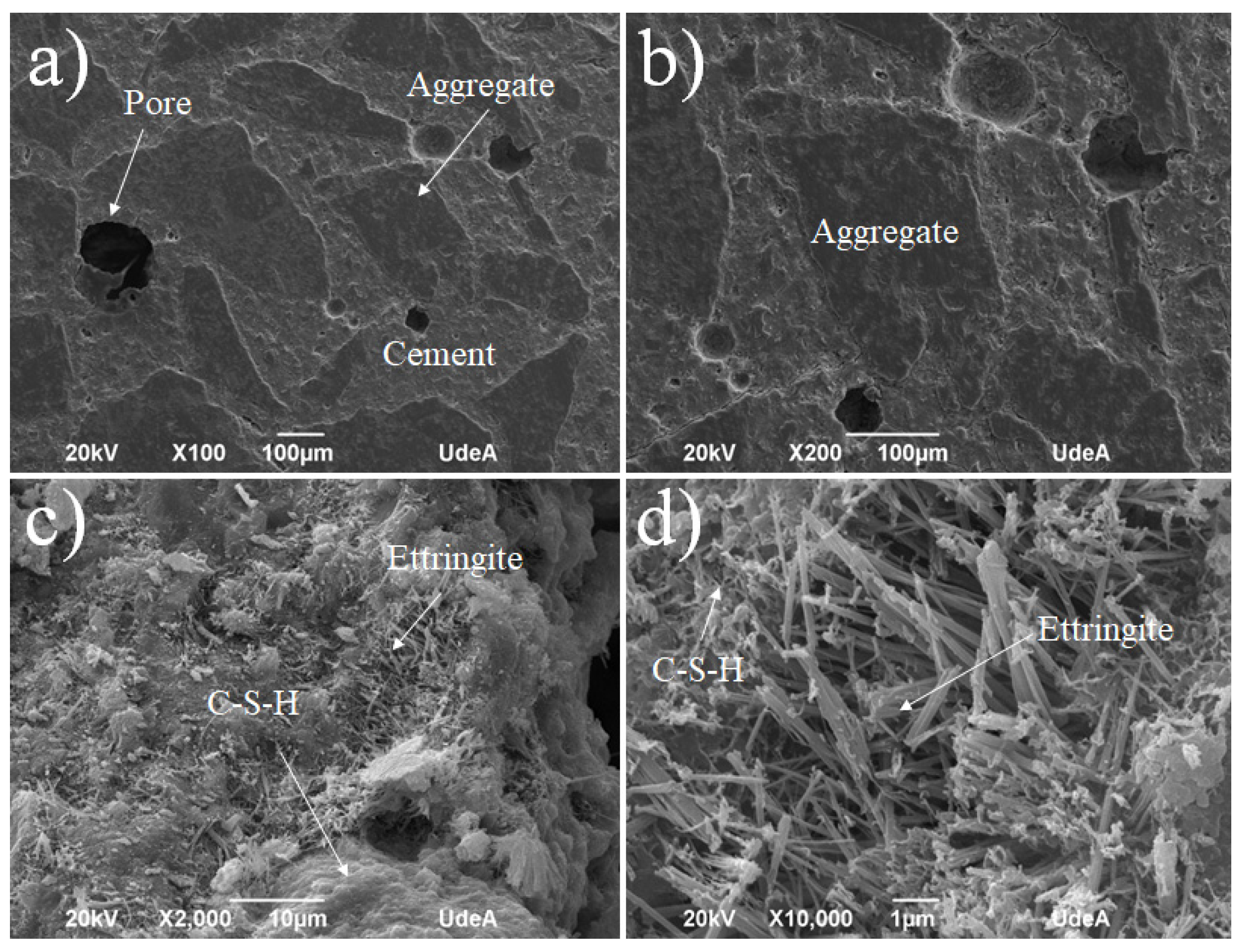

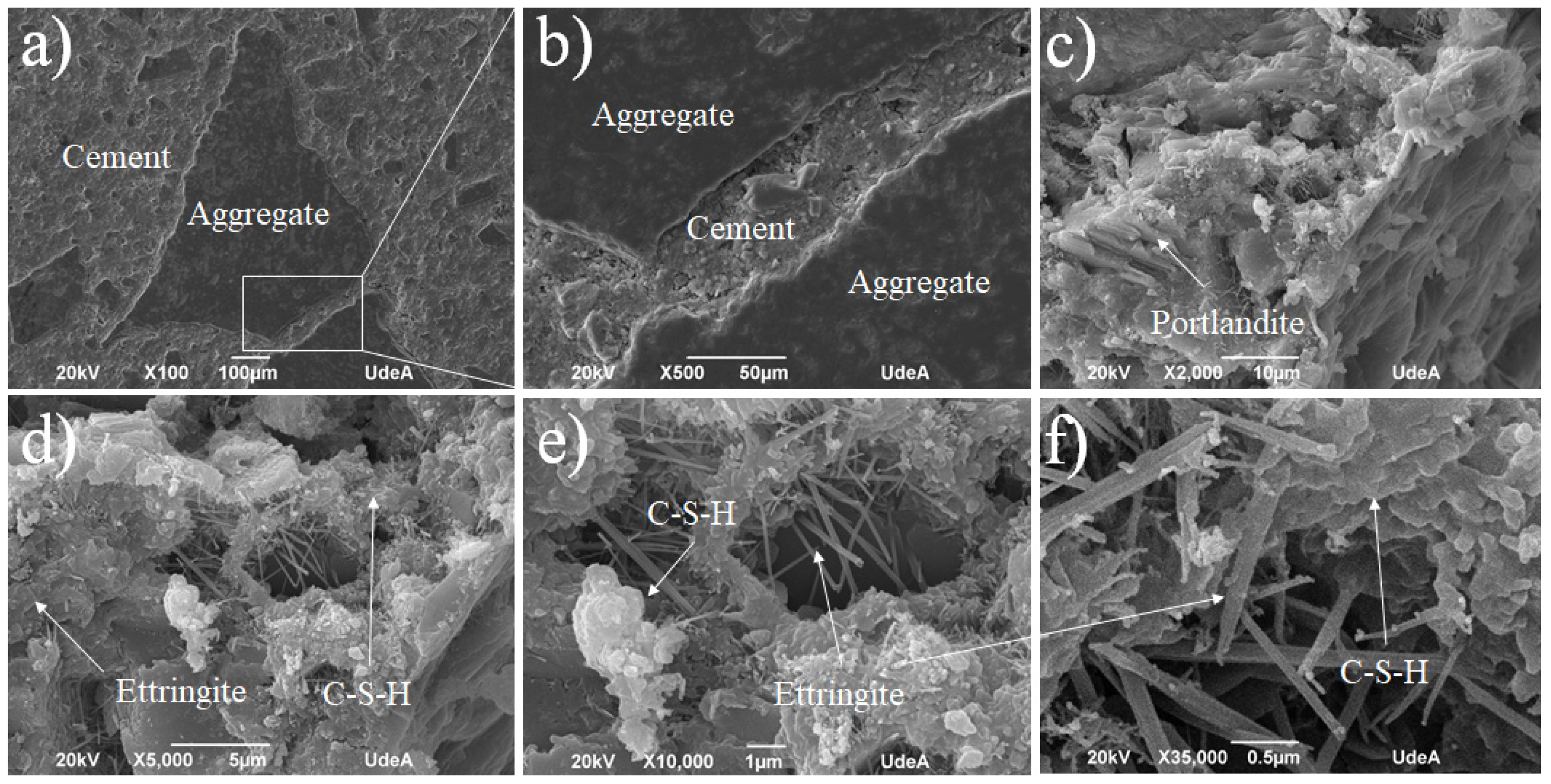

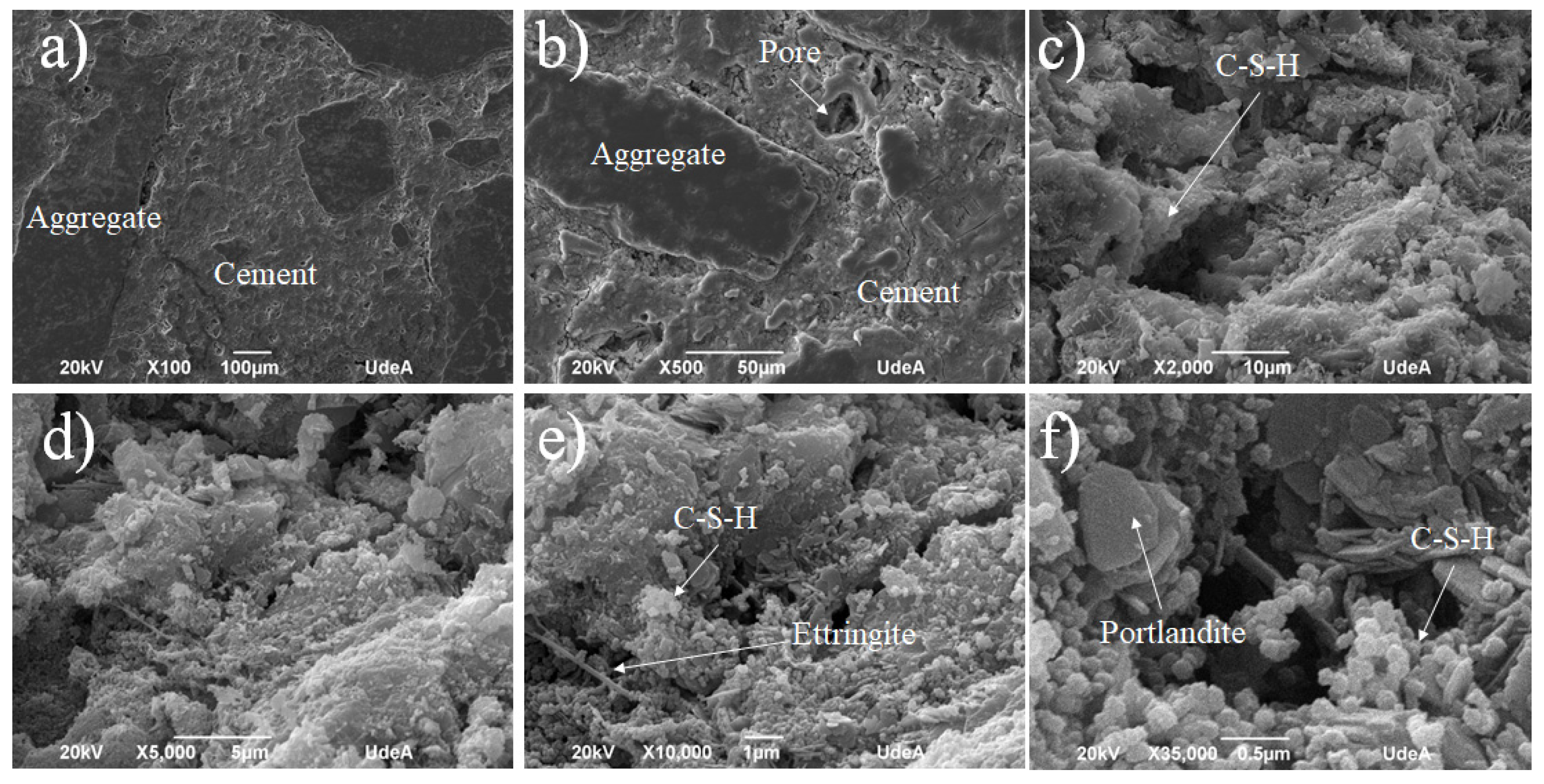

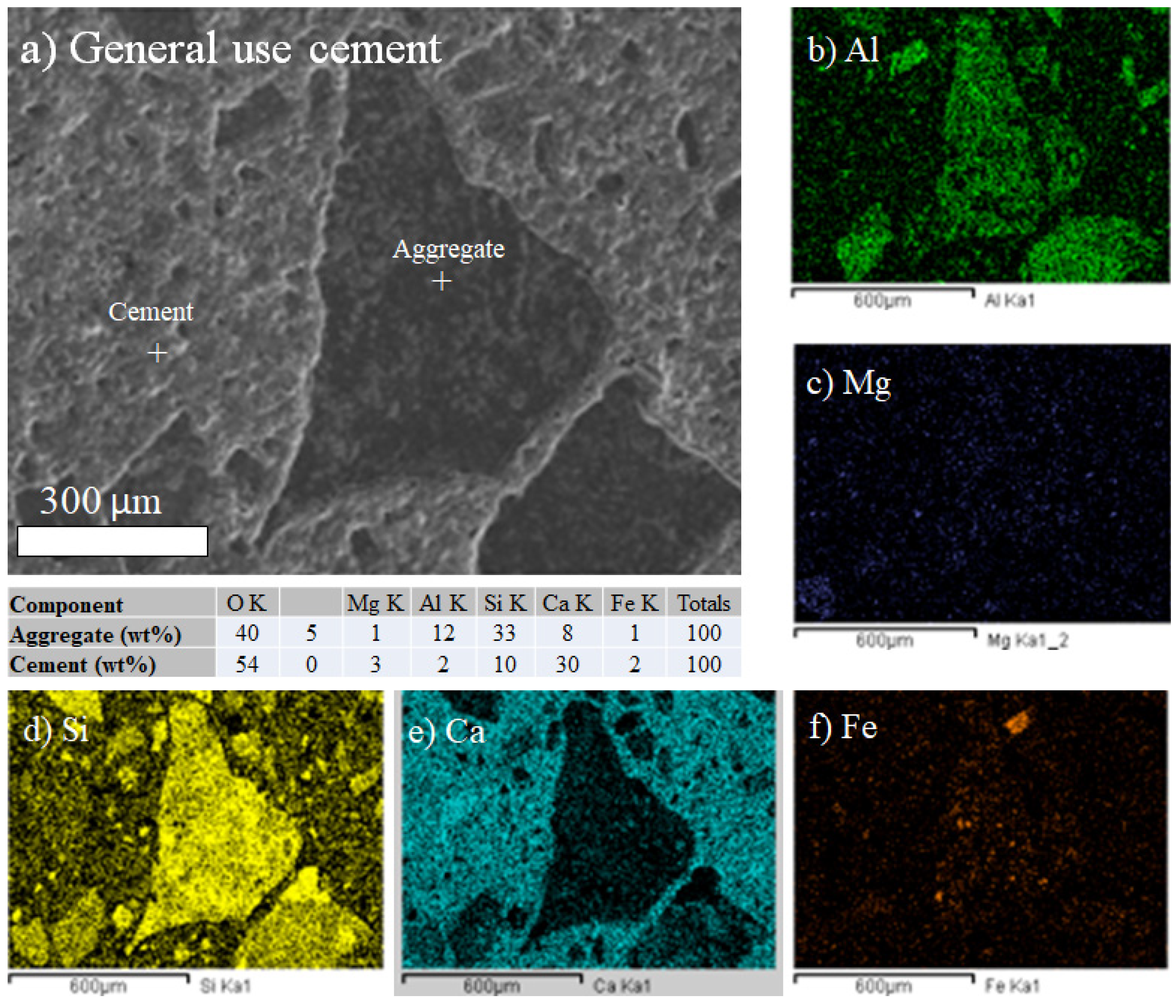

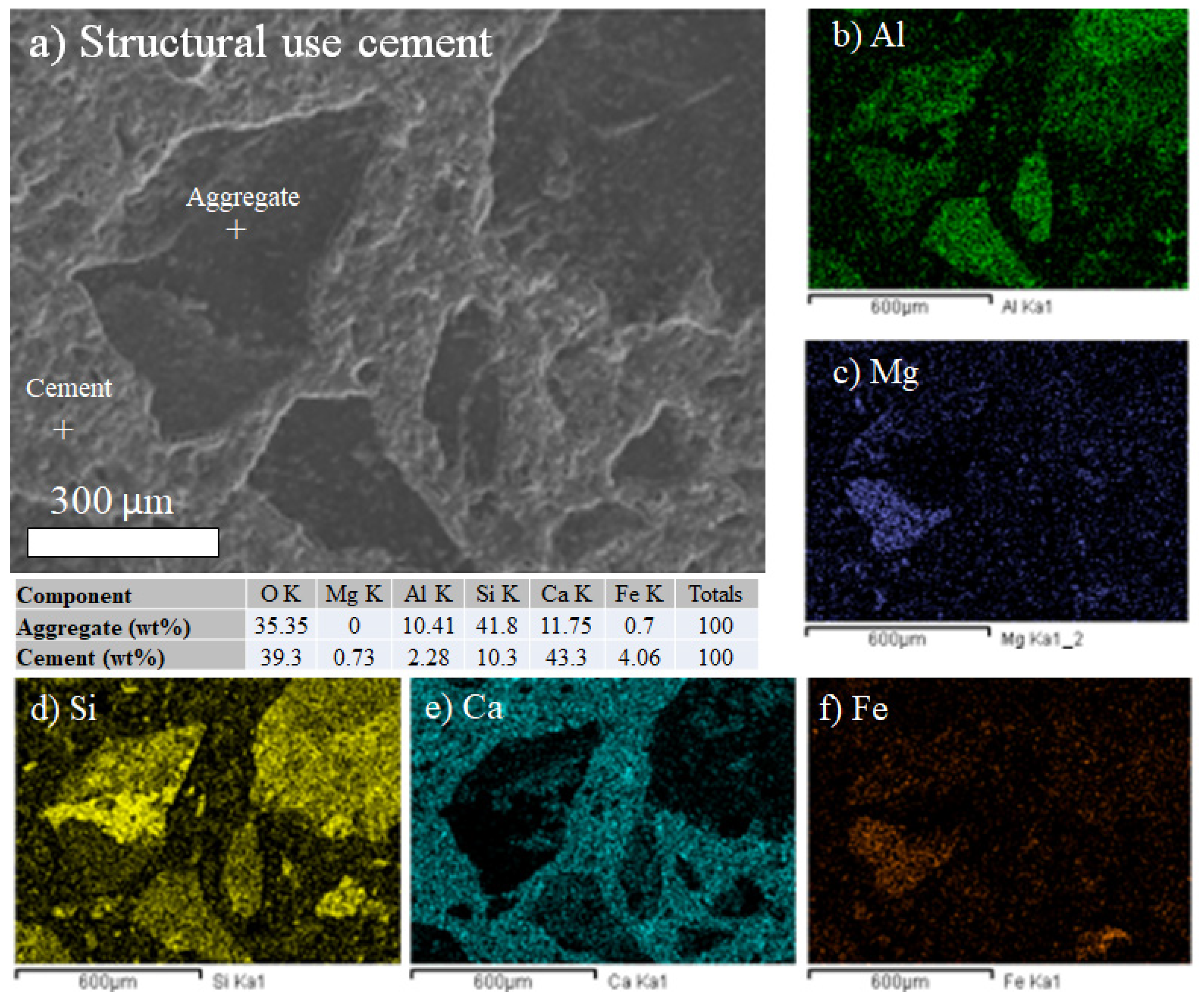

3.7. Scanning Electron Microscopy Characterization

4. Discussion

5. Conclusions

- There is little data available on the Viterbo O’Reilly method, possibly because of the poor reports and lack of research on it. However, this research shows that it is a valid method, feasible for use with good results.

- The Viterbo O’Reilly method showed very different results for each of the cements. For the G.U. cement, the G.U.1 test showed 374 kg for 210 kg/cm2 (20.6 MPa). This means that for this specific cement type, the amount of cement increased by 7% with the method followed in this research, when compared with the 350 kg cement estimated by the ACI method. The verification tests (G.U.2, G.U.3, and G.U.4) gave acceptable strengths. For the S.U. cement, the S.U.1 test showed 275 kg for 210 kg/cm2 (20.6 MPa). This means that for this specific cement type, the amount of cement decreased by 21.4% with the method used in this research, when compared with the 350 kg cement estimated by the ACI method. The verification tests (S.U.2, S.U.3, and S.U.4) gave acceptable strengths.

- The compressive strength behavior of concretes manufactured for structural use is lower than that manufactured with cement for structural use, but even so, it falls within the permissible range for the target resistance of 210 kg/cm2.

- The tests were carried out with a reliability level of 95% for all the cases studied, and the standard deviation values confirm that there is no notable dispersion between the resistance results obtained for each tested specimen. With the application of the experimental method for dosing materials with the Viterbo O’Reilly method, it is possible to obtain concrete with the lowest use of the necessary aggregates.

- SEM images show very low porosity and, in general, a good aggregate–cement relation. The amount of C-S-H formed at the age of 28 days is similar in the two designs studied, indicating similar hydration levels in the two samples. Likewise, at this age, the pastes show microstructures characterized by extensive growth of C-S-H, whose main differences lie in the morphology, composition, and size of the different crystalline phases, which, in principle, do not contribute significantly to the development of resistance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cement and Concrete Association. December 2023. Available online: https://gccassociation.org/concretefuture/cement-concrete-around-the-world/ (accessed on 1 February 2025).

- Flower, D.J.; Sanjayan, J.G. Greenhouse gas emissions due to concrete manufacture. Int. J. Life Cycle Assess. 2007, 12, 282–288. [Google Scholar] [CrossRef]

- Miller, S.A.; Horvath, A.; Monteiro, P.J. Impacts of booming concrete production on water resources worldwide. Nat. Sustain. 2018, 1, 69–76. [Google Scholar] [CrossRef]

- Benhelal, E.; Zahedi, G.; Shamsaei, E.; Bahadori, A. Global strategies and potentials to curb CO2 emissions in cement industry. J. Clean. Prod. 2013, 51, 142–161. [Google Scholar] [CrossRef]

- Dixit, A.; Du, H.; Dai Pang, S. Carbon capture in ultra-high performance concrete using pressurized CO2 curing. Constr. Build. Mater. 2021, 288, 123076. [Google Scholar] [CrossRef]

- Papadakis, V.G.; Tsimas, S. Supplementary cementing materials in concrete: Part I: Efficiency and design. Cem. Concr. Res. 2002, 32, 1525–1532. [Google Scholar] [CrossRef]

- Norhasri, M.M.; Hamidah, M.S.; Fadzil, A.M. Applications of using nano material in concrete: A review. Constr. Build. Mater. 2017, 133, 91–97. [Google Scholar] [CrossRef]

- Rashid, K.; Rehman, M.U.; de Brito, J.; Ghafoor, H. Multi-criteria optimization of recycled aggregate concrete mixes. J. Clean. Prod. 2020, 276, 124316. [Google Scholar] [CrossRef]

- Colorado, H.A.; Muñoz, A.; Neves Monteiro, S. Circular economy of construction and demolition waste: A case study of Colombia. Sustainability 2022, 14, 7225. [Google Scholar] [CrossRef]

- Colorado, H.A.; García, E.; Buchely, M.F. White Ordinary Portland Cement blended with superfine steel dust with high zinc oxide contents. Constr. Build. Mater. 2016, 112, 816–824. [Google Scholar] [CrossRef]

- Vishwakarma, V.; Ramachandran, D. Green Concrete mix using solid waste and nanoparticles as alternatives–A review. Constr. Build. Mater. 2018, 162, 96–103. [Google Scholar] [CrossRef]

- Zapata, A.; Bosch, P. Low temperature preparation of belitic cement clinker. J. Eur. Ceram. Soc. 2009, 29, 1879–1885. [Google Scholar] [CrossRef]

- Duxson, P.; Mallicoat, S.W.; Lukey, G.C.; Kriven, W.M.; Van Deventer, J.S. The effect of alkali and Si/Al ratio on the development of mechanical properties of metakaolin-based geopolymers. Colloids Surf. A Physicochem. Eng. Asp. 2007, 292, 8–20. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymer Cement. A Review; Technical papers; Geopolymer Institute: Saint-Quentin, France, 2013; Volume 21, pp. 1–11. [Google Scholar]

- Shi, C.; Roy, D.; Krivenko, P. Alkali-Activated Cements and Concretes; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Colorado, H.A.; Hiel, C.; Hahn, H.T. Chemically bonded phosphate ceramics composites reinforced with graphite nanoplatelets. Compos. Part A Appl. Sci. Manuf. 2011, 42, 376–384. [Google Scholar] [CrossRef]

- Colorado, H.A.; Singh, D. High-sodium waste streams stabilized with inorganic acid–base phosphate ceramics fabricated at room temperature. Ceram. Int. 2014, 40, 10621–10631. [Google Scholar] [CrossRef]

- Colorado, H.A.; Pleitt, J.; Hiel, C.; Yang, J.M.; Hahn, H.T.; Castano, C.H. Wollastonite based-Chemically Bonded Phosphate Ceramics with lead oxide contents under gamma irradiation. J. Nucl. Mater. 2012, 425, 197–204. [Google Scholar] [CrossRef]

- Ren, J.; Xu, Y.; Huang, J.; Wang, Y.; Jia, Z. Gradation optimization and strength mechanism of aggregate structure considering macroscopic and mesoscopic aggregate mechanical behaviour in porous asphalt mixture. Constr. Build. Mater. 2021, 300, 124262. [Google Scholar] [CrossRef]

- Fernández, E.; Collet, M.; Alarcón, P.; Bauduin, S.; Duysinx, P. An aggregation strategy of maximum size constraints in density-based topology optimization. Struct. Multidiscip. Optim. 2019, 60, 2113–2130. [Google Scholar] [CrossRef]

- Bian, J.; Zhang, W.; Shen, Z.; Li, S.; Chen, Z. Analysis and optimization of mechanical properties of recycled concrete based on aggregate characteristics. Sci. Eng. Compos. Mater. 2021, 28, 516–527. [Google Scholar] [CrossRef]

- Wang, L.J.; Liu, H.; Zhao, S.Y. Aggregate gradation design of asphalt mixture with stone-to-stone contact based on fuller’s model. J. Shanghai Univ. 2010, 14, 387–390. [Google Scholar] [CrossRef]

- Cramer, S.M.; Hall, M.; Parry, J. Effect of optimized total aggregate gradation on Portland cement concrete for Wisconsin pavements. Transp. Res. Rec. 1995, 100–106. [Google Scholar]

- O’Reiily, D.; Viterbo, A. Methods of Concrete Mix Proportioning; Cuaderno 20; INTERMAC: Madrid, Spain, 1995. [Google Scholar]

- Wadud, Z.; Ahmad, S. ACI method of concrete mix design: A parametric study. In Proceedings of the Eighth East Asia-Pacific Conference on Structural Engineering and Construction, Singapore, 5–7 December 2001; Nanyang Technological University: Singapore, 2001. [Google Scholar]

- Olard, F.; Pouget, S. A new approach for aggregate grading optimization for mixtures. In Advances in Asphalt Materials; Woodhead Publishing: Cambridge, UK, 2015; pp. 427–457. [Google Scholar]

- Moini, M.; Flores-Vivian, I.; Amirjanov, A.; Sobolev, K. The optimization of aggregate blends for sustainable low cement concrete. Constr. Build. Mater. 2015, 93, 627–634. [Google Scholar] [CrossRef]

- ASTM C1157; Standard Performance Specification for Hydraulic Cement. ASTM International: West Conshohocken, PA, USA, 2010.

- ASTM C150/C150M-24; Standard Specification for Portland Cement. ASTM International: West Conshohocken, PA, 2024.

- ASTM C702/C702M-18; Standard Practice for Reducing Samples of Aggregate to Testing Size. ASTM International: West Conshohocken, PA, USA, 2025.

- ASTM C136/C136M-19; Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM C-29-78; Test method for unit weight and voids in aggregates. ASTM International: West Conshohocken, PA, USA, 2023.

- ASTM C39-20/C39M-20; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM C78-18/C78M-18; Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading). ASTM International: West Conshohocken, PA, USA, 2021.

- Muñoz-Zapata, A.; Cifuentes-Mosquera, S.; Colorado-Lopera, H.A. Portland Cement Mortars Tested with Two Superplasticizers: A Case Study to Reduce Cement and Water in Concrete. Tecnura 2022, 26, 114–146. [Google Scholar] [CrossRef]

- Sahu, S.; Badger, S.; Thaulow, N.; Lee, R.J. Determination of water–cement ratio of hardened concrete by scanning electron microscopy. Cem. Concr. Compos. 2004, 26, 987–992. [Google Scholar] [CrossRef]

- Bangaru, S.S.; Wang, C.; Zhou, X.; Hassan, M. Scanning electron microscopy (SEM) image segmentation for microstructure analysis of concrete using U-net convolutional neural network. Autom. Constr. 2022, 144, 104602. [Google Scholar] [CrossRef]

- Zhang, J. Recent advance of MgO expansive agent in cement and concrete. J. Build. Eng. 2022, 45, 103633. [Google Scholar] [CrossRef]

- Guo, J.; Zhang, S.; Qi, C.; Cheng, L.; Yang, L. Effect of calcium sulfoaluminate and MgO expansive agent on the mechanical strength and crack resistance of concrete. Constr. Build. Mater. 2021, 299, 123833. [Google Scholar] [CrossRef]

- González, M.D.; Plaza Caballero, P.; Fernández, D.B.; Jordán Vidal, M.M.; Del Bosque, I.F.S.; Medina Martínez, C. The design and development of recycled concretes in a circular economy using mixed construction and demolition waste. Materials 2021, 14, 4762. [Google Scholar] [CrossRef] [PubMed]

- Çimen, Ö. Construction and built environment in circular economy: A comprehensive literature review. J. Clean. Prod. 2021, 305, 127180. [Google Scholar] [CrossRef]

- Sammalisto, K.; Sundström, A.; Von Haartman, R.; Holm, T.; Yao, Z. Learning about sustainability—What influences students’ self-perceived sustainability actions after undergraduate education? Sustainability 2016, 8, 510. [Google Scholar] [CrossRef]

- Cardoza, A.; Colorado, H.A. Alkaline activation of brick waste with partial addition of ordinary Portland cement (OPC) for reducing brick industry pollution and developing a feasible and competitive construction material. Open Ceram. 2024, 18, 100569. [Google Scholar] [CrossRef]

- Wang, B.; Yan, L.; Fu, Q.; Kasal, B. A comprehensive review on recycled aggregate and recycled aggregate concrete. Resour. Conserv. Recycl. 2021, 171, 105565. [Google Scholar] [CrossRef]

- Rocha, J.H.A.; Toledo Filho, R.D.; Cayo-Chileno, N.G. Sustainable alternatives to CO2 reduction in the cement industry: A short review. Mater. Today Proc. 2022, 57, 436–439. [Google Scholar] [CrossRef]

- Rajalo, S.; Vadi, M. University-industry innovation collaboration: Reconceptualization. Technovation 2017, 62, 42–54. [Google Scholar] [CrossRef]

- O’Dwyer, M.; Filieri, R.; O’Malley, L. Establishing successful university–industry collaborations: Barriers and enablers deconstructed. J. Technol. Transf. 2023, 48, 900–931. [Google Scholar] [CrossRef]

- Cramer, S.M.; Carpenter, A.J. Influence of total aggregate gradation on freeze-thaw durability and other performance measures of paving concrete. Transp. Res. Rec. 1999, 1668, 1–8. [Google Scholar] [CrossRef]

- Akobo, I.Z.S.; Ode, T.; Gokana, J.P.B. Optimization of All-In Aggregate Gradation Combination to Improve Concrete Sustainability. Int. J. Civ. Eng. 2019, 6, 46–50. [Google Scholar] [CrossRef]

- Madani, H.; Rostami, J.; Norouzifar, M.N.; Maleh, H.K.; Maleh, H.K. An investigation on the effect of aggregates packing density on the properties of high-performance concrete mixtures. AUT J. Civ. Eng. 2017, 1, 205–214. [Google Scholar]

- Gong, C.; Zhang, J.; Wang, S.; Lu, L. Effect of aggregate gradation with fuller distribution on properties of sulphoaluminate cement concrete. J. Wuhan Univ. Technol.-Mater. Sci. 2015, 30, 1029–1035. [Google Scholar] [CrossRef]

- Rached, M.; Fowler, D.; Koehler, E. Use of Aggregates to Reduce Cement Content in Concrete. In Second International Conference Sustainable Construction Materials and Technology; Universita Politecnia delle Marche: Ancona, Italy, 2010. [Google Scholar]

- ASTM C270-19ae1; Standard Specification for Mortar for Unit Masonry. ASTM International: West Conshohocken, PA, USA, 2024.

- Fattouh, M.S.; Abouelnour, M.A.; Mahmoud, A.A.; Fathy, I.N.; El Sayed, A.F.; Elhameed, S.A.; Nabil, I.M. Impact of modified aggregate gradation on the workability, mechanical, microstructural and radiation shielding properties of recycled aggregate concrete. Sci. Rep. 2015, 15, 18428. [Google Scholar] [CrossRef] [PubMed]

- Albogami, A.; Fayed, S.; Ghalla, M.; Nawar, M.E.; El-Din, A.B. Effects of type and gradation of coarse aggregates on tensile strength of concrete with different grades: An experimental investigation. Innov. Infrastruct. Solut. 2025, 10, 236. [Google Scholar] [CrossRef]

- Kong, J.; Chen, Z.; Liu, Q.; Li, J.; Liu, J.; Chi, L.; Jiao, Z. The screening effect of coarse aggregate on the air void structure and durability of air-entrained concrete. Constr. Build. Mater. 2024, 451, 138786. [Google Scholar] [CrossRef]

- Wang, Y.; Liang, T.; Jin, F. Void effect study on the compressive behavior of RFC based on the 3D four-phase mesoscopic finite element model. Constr. Build. Mater. 2024, 417, 135145. [Google Scholar] [CrossRef]

- Shemirani, A.B. Prediction of fracture toughness of concrete using the machine learning approach. Theor. Appl. Fract. Mech. 2024, 134, 104749. [Google Scholar] [CrossRef]

- Long, Z.; Long, G.; Tang, Z.; Shangguan, M.; Gao, C.; Yi, M.; He, Z.; Zhang, Y. Effects of aggregates and fibers on the strength and permeability of concrete exposed to low vacuum environment. J. Build. Eng. 2024, 97, 110902. [Google Scholar] [CrossRef]

- Lei, M.; Liu, Z.; Wang, F. Review of lightweight cellular concrete: Towards low-carbon, high-performance and sustainable development. Constr. Build. Mater. 2024, 429, 136324. [Google Scholar] [CrossRef]

- Zhou, Z.; Xiao, J.; Ye, T.; Wang, J.; Choi, D. Influence of recycled concrete powder and CO2 curing on the properties of thermal insulation mortars. Constr. Build. Mater. 2024, 414, 134907. [Google Scholar] [CrossRef]

- Kapicová, A.; Bílý, P.; Fládr, J.; Šeps, K.; Chylík, R.; Trtík, T. Development of sound-absorbing pervious concrete for interior applications. J. Build. Eng. 2024, 85, 108697. [Google Scholar] [CrossRef]

- Nodehi, M.; Gencel, O.; Erdogmus, E.; Karagöz, M.E.; Shi, J.; Mo, K.H.; Gholampour, A.; Ozbakkaloglu, T. Effect of cement type and water-to-cement (w/c) ratio on characteristics of lightweight mortars produced with pumice: A comparative study on calcium aluminate (rapid hardening) and ordinary Portland cements. Innov. Infrastruct. Solut. 2024, 9, 48. [Google Scholar] [CrossRef]

- Sánchez-Mendieta, C.; Galán-Díaz, J.J.; Martinez-Lage, I. Relationships between density, porosity, compressive strength and permeability in porous concretes: Optimization of properties through control of the water-cement ratio and aggregate type. J. Build. Eng. 2024, 97, 110858. [Google Scholar] [CrossRef]

- Bekturganova, N.Y.; Kolesnikova, I.V. Effect of Polymer Additives on Improvement of Concrete Properties. Adv. Polym. Technol. 2025, 2025, 6235216. [Google Scholar] [CrossRef]

- Han, X.; Xu, F.; He, Y.; Qian, W.; Lu, J.; Ge, J.; Li, H.; Meng, X. Research on the Improvement of Underwater Workability of Cement Paste by Composite Polymers. Case Stud. Constr. Mater. 2025, 22, e04386. [Google Scholar] [CrossRef]

- Alghrairi, N.N.; Aznieta, F.; MIbrahim, A.; Wan Hu, J.; Mohammed Najm, H.; Anas, S.M. Improvement of Concrete Characterization Using Nanomaterials: State-of-the-Art. J. Eng. 2025, 2025, 8027667. [Google Scholar] [CrossRef]

- Fan, R.; Tian, A.; Li, Y.; Gu, Y.; Wei, Z. Research Progress on Machine Learning Prediction of Compressive Strength of Nano-Modified Concrete. Appl. Sci. 2025, 15, 4733. [Google Scholar] [CrossRef]

- Shinde, K.K.; Mane, B.V. A Review of the Durability and Performance Assessment of Pavement Quality Concrete (PQC) Using Mineral Admixtures. IJSAT-Int. J. Sci. Technol. 2025, 16, 1–10. [Google Scholar] [CrossRef]

- Malaiškienė, J.; Jakubovskis, R. Influence of Pozzolanic Additives on the Structure and Properties of Ultra-High-Performance Concrete. Materials 2025, 18, 1304. [Google Scholar] [CrossRef] [PubMed]

- Abouelnour, M.A.; Fathy, I.N.; Mahmoud, A.A.; Alturki, M.; Abdelaziz, M.M.; Mostafa, S.A.; Mahmoud, K.A.; Dahish, H.A.; Nabil, I.M.; Fattouh, M.S. Valorization of nano additives effects on the physical, mechanical and radiation shielding properties of high strength concrete. Sci. Rep. 2025, 15, 14440. [Google Scholar] [CrossRef] [PubMed]

- Nasabolhosseini, S.A.; Honarbakhsh, A.; Zhiani, R.; Movahedifar, S.M.; Nobahari, M. CNT/DFNS nanoparticles as a valuable admixture for ultrahigh-performance concrete. Results Eng. 2025, 25, 104084. [Google Scholar] [CrossRef]

- Mousavi, S.S.; Ahmadi, K.; Dehestani, M.; Yeon, J.H. Influence of Coated Steel Fibers on Mechanical Properties of UHPC Considering Graphene Oxide, Nano-Aluminum Oxide, and Nano-Calcium Carbonate. Fibers 2025, 13, 37. [Google Scholar] [CrossRef]

- Zapata, J.F.; Azevedo, A.; Fontes, C.; Monteiro, S.N.; Colorado, H.A. Environmental impact and sustainability of calcium aluminate cements. Sustainability 2022, 14, 2751. [Google Scholar] [CrossRef]

| Sand (%) | 65 | 60 | 55 | 50 | 45 | 40 |

|---|---|---|---|---|---|---|

| Gravel (%) | 35 | 40 | 45 | 50 | 55 | 60 |

| Total (%) | 100 | 100 | 100 | 100 | 100 | 100 |

| Sample Type | Sample Name | Cement (kg) | Water (kg) | W/C | Sand (kg) | Gravel 3/4” (kg) |

|---|---|---|---|---|---|---|

| General use Portland cement (G.U.) | G.U.1 | 350 | 217 | 0.62 | 955 | 896 |

| G.U.2 | 329 | 217 | 0.66 | 945 | 822 | |

| G.U.3 | 425 | 217 | 0.51 | 897 | 780 | |

| G.U.4 | 482 | 217 | 0.45 | 869 | 755 | |

| Structural use Portland cement (S.U.) | S.U.1 | 350 | 217 | 0.62 | 955 | 896 |

| S.U.2 | 275 | 217 | 0.79 | 972 | 845 | |

| S.U.3 | 297 | 217 | 0.73 | 961 | 835 | |

| S.U.4 | 334 | 217 | 0.65 | 943 | 819 |

| Parameter | General Use (G.U.) Cement | Structural Use (S.U.) Cement |

|---|---|---|

| Water (kg) | 217 | 217 |

| Cement (kg) | 374 | 275 |

| Aggregates (kg) | 1720 | 1813 |

| Gravel (kg) | 800 | 843 |

| Sand (kg) | 920 | 970 |

| Samples | W/C | Cement (kg) | Water (kg) | Sand (kg) | 3/4” Gravel (kg) | As (cm) | σ (kg/cm2) Targeted | σ (kg/cm2) Obtained |

|---|---|---|---|---|---|---|---|---|

| G.U.1 | 0.62 | 350 | 217 | 955 | 896 | 12 | 210 (20.6 MPa) | 211 (20.7 MPa) |

| G.U.2 | 0.66 | 329 | 217 | 945 | 822 | 10 | 175 (17.2 MPa) | 251 (24.6 MPa) |

| G.U.3 | 0.51 | 425 | 217 | 897 | 780 | 10 | 245 (24 MPa) | 377 (37.0 MPa) |

| G.U.4 | 0.45 | 482 | 217 | 869 | 755 | 70 | 280 (27.5 MPa) | 440 (MPa) |

| S.U.1 | 0.62 | 350 | 217 | 955 | 896 | 12.5 | 210 (20.6 MPa) | 315 (43.1 MPa) |

| S.U.2 | 0.79 | 275 | 217 | 972 | 845 | 10 | 175 (17.2 MPa) | 231 (22.7 MPa) |

| S.U.3 | 0.73 | 297 | 217 | 961 | 835 | 14 | 245 (24 MPa) | 206 (20.2 MPa) |

| S.U.4 | 0.65 | 334 | 217 | 943 | 819 | 17.5 | 280 (27.5 MPa) | 256 (25.1 MPa) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Murillo Mosquera, E.; Cifuentes, S.; Obando, J.C.; Monteiro, S.N.; Colorado, H.A. Concrete Obtained with the Viterbo O’Reilly Method for Aggregate Gradation: A Potential Model for Sustainable Design and Reducing Development Costs. Materials 2025, 18, 3558. https://doi.org/10.3390/ma18153558

Murillo Mosquera E, Cifuentes S, Obando JC, Monteiro SN, Colorado HA. Concrete Obtained with the Viterbo O’Reilly Method for Aggregate Gradation: A Potential Model for Sustainable Design and Reducing Development Costs. Materials. 2025; 18(15):3558. https://doi.org/10.3390/ma18153558

Chicago/Turabian StyleMurillo Mosquera, Edinson, Sergio Cifuentes, Juan Carlos Obando, Sergio Neves Monteiro, and Henry A. Colorado. 2025. "Concrete Obtained with the Viterbo O’Reilly Method for Aggregate Gradation: A Potential Model for Sustainable Design and Reducing Development Costs" Materials 18, no. 15: 3558. https://doi.org/10.3390/ma18153558

APA StyleMurillo Mosquera, E., Cifuentes, S., Obando, J. C., Monteiro, S. N., & Colorado, H. A. (2025). Concrete Obtained with the Viterbo O’Reilly Method for Aggregate Gradation: A Potential Model for Sustainable Design and Reducing Development Costs. Materials, 18(15), 3558. https://doi.org/10.3390/ma18153558