Carbon-Negative Construction Material Based on Rice Production Residues

Abstract

1. Introduction

1.1. Environmental Footprint of Construction Sector

1.2. The National Housing Policy of Kenya

1.3. Construction Materials with Organic Filler

1.4. Natural Sources of Silica and Lime

2. Materials and Methods

2.1. Materials

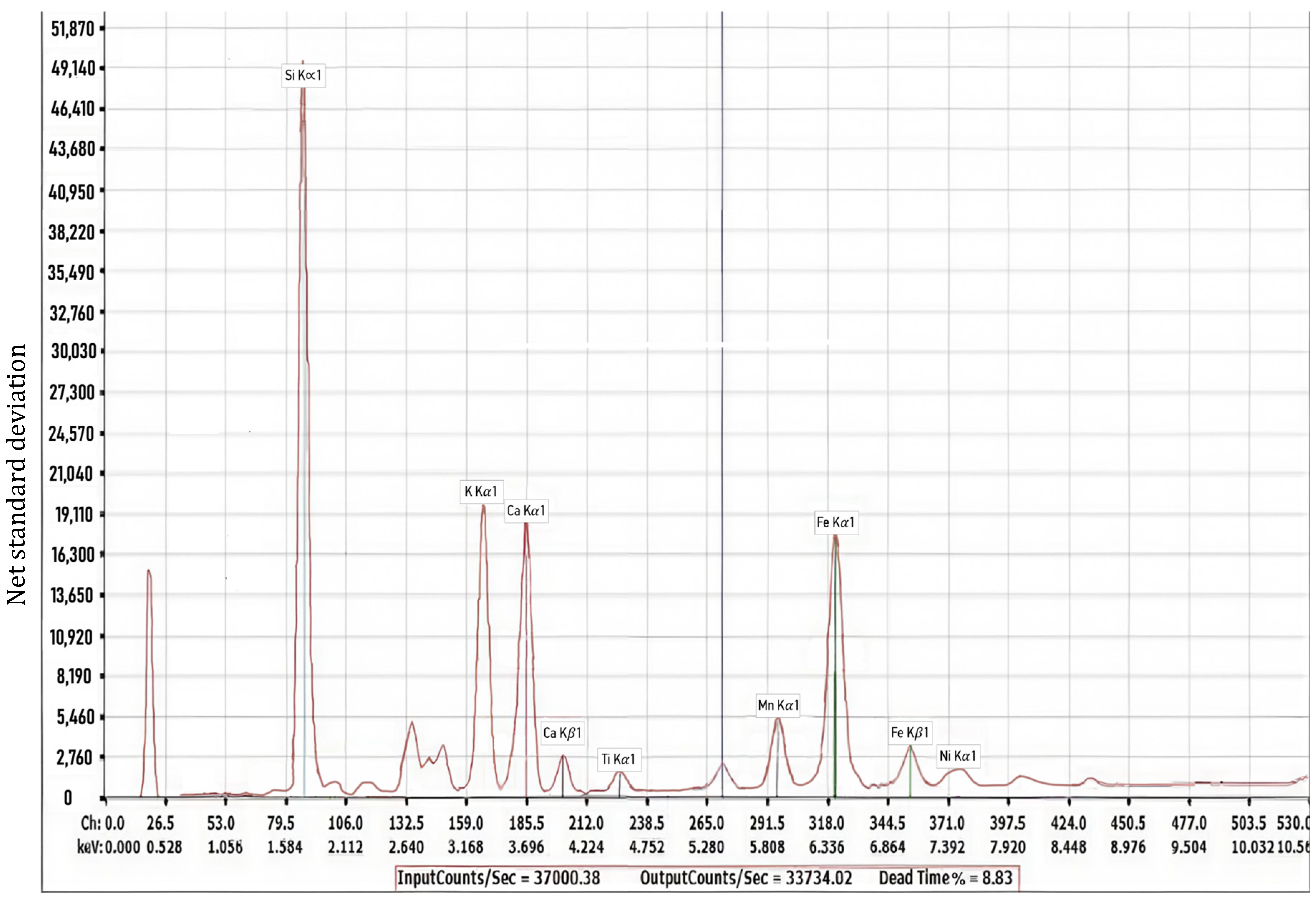

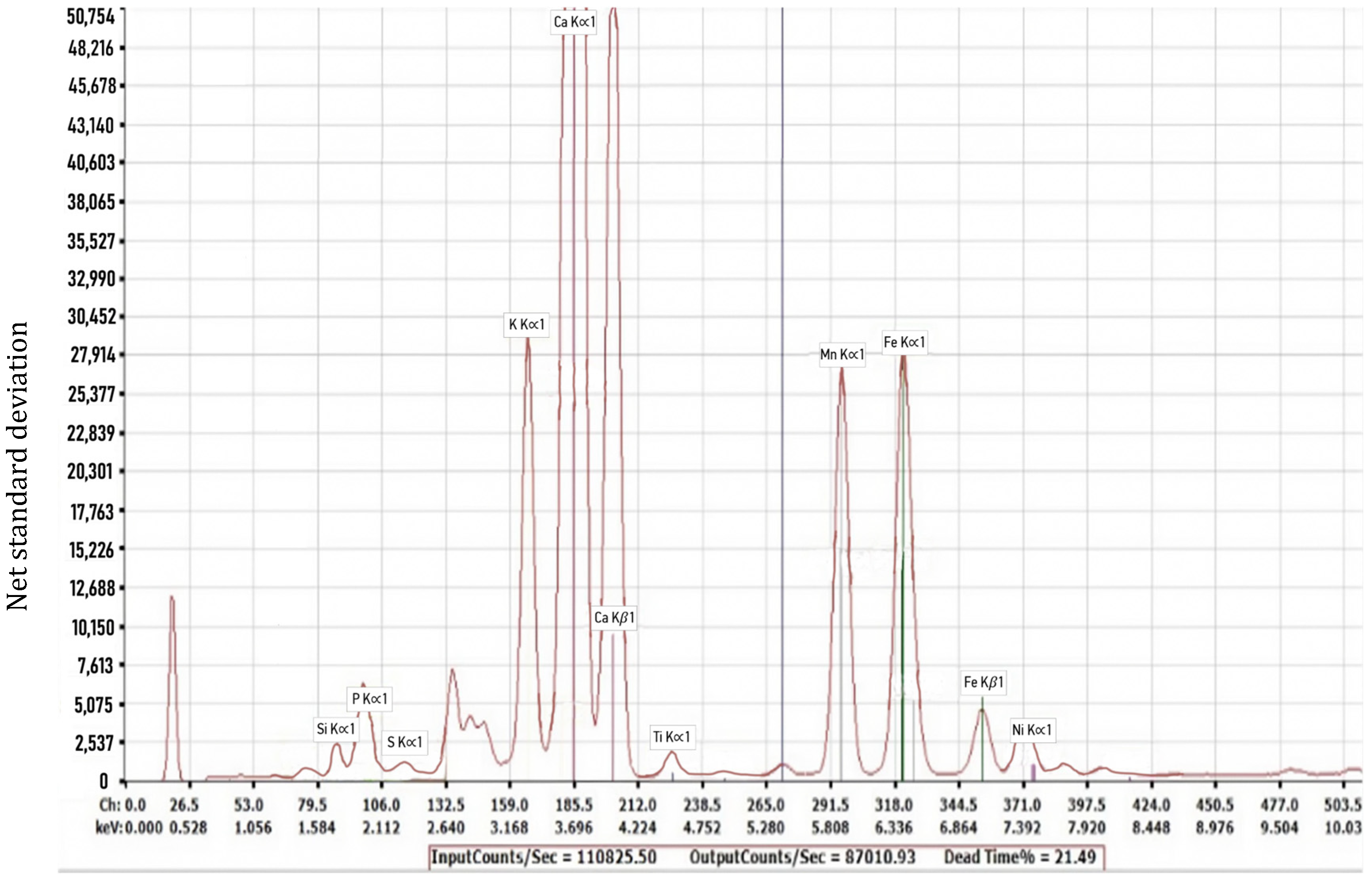

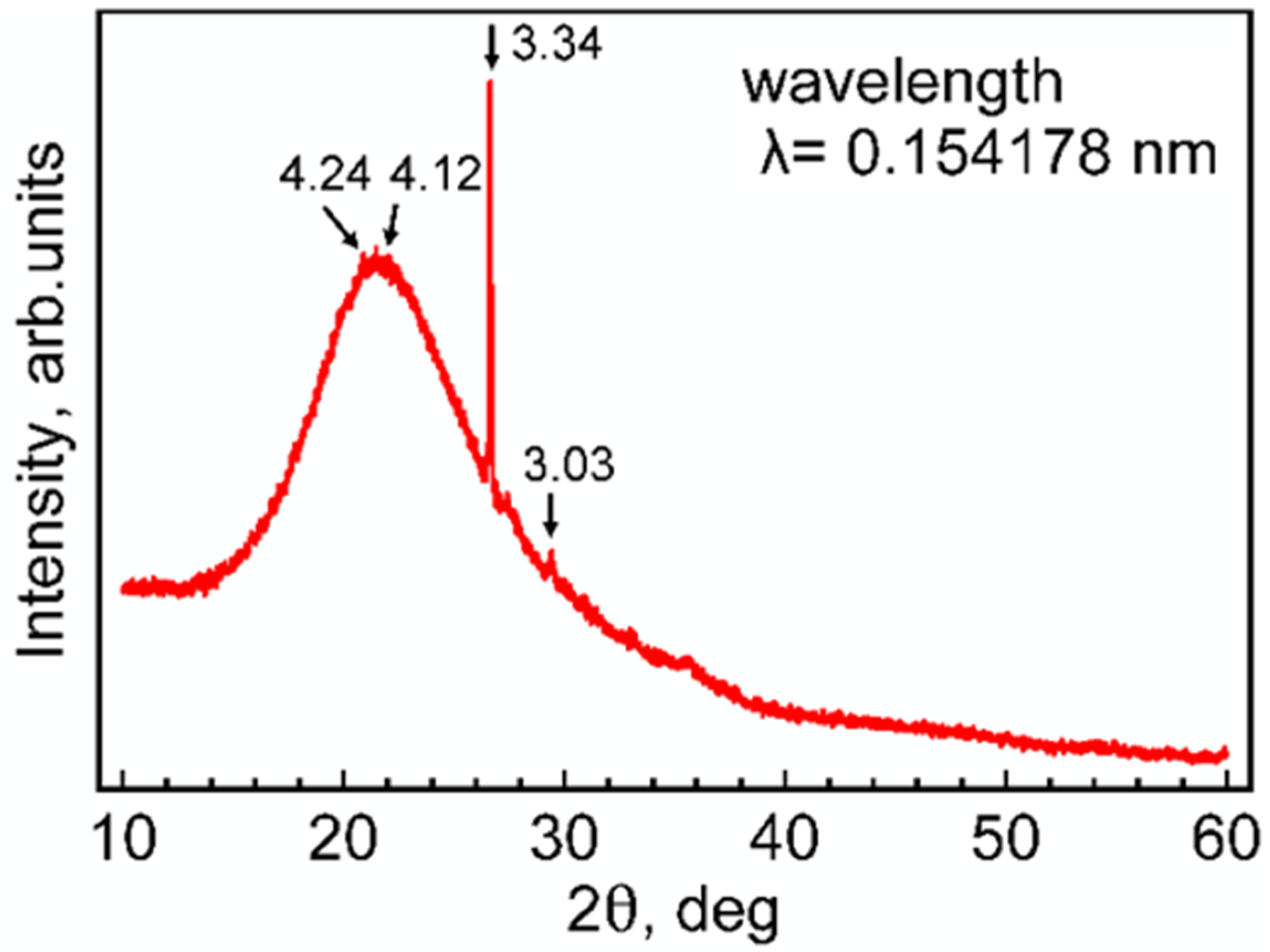

2.2. Analyses of the Raw Materials

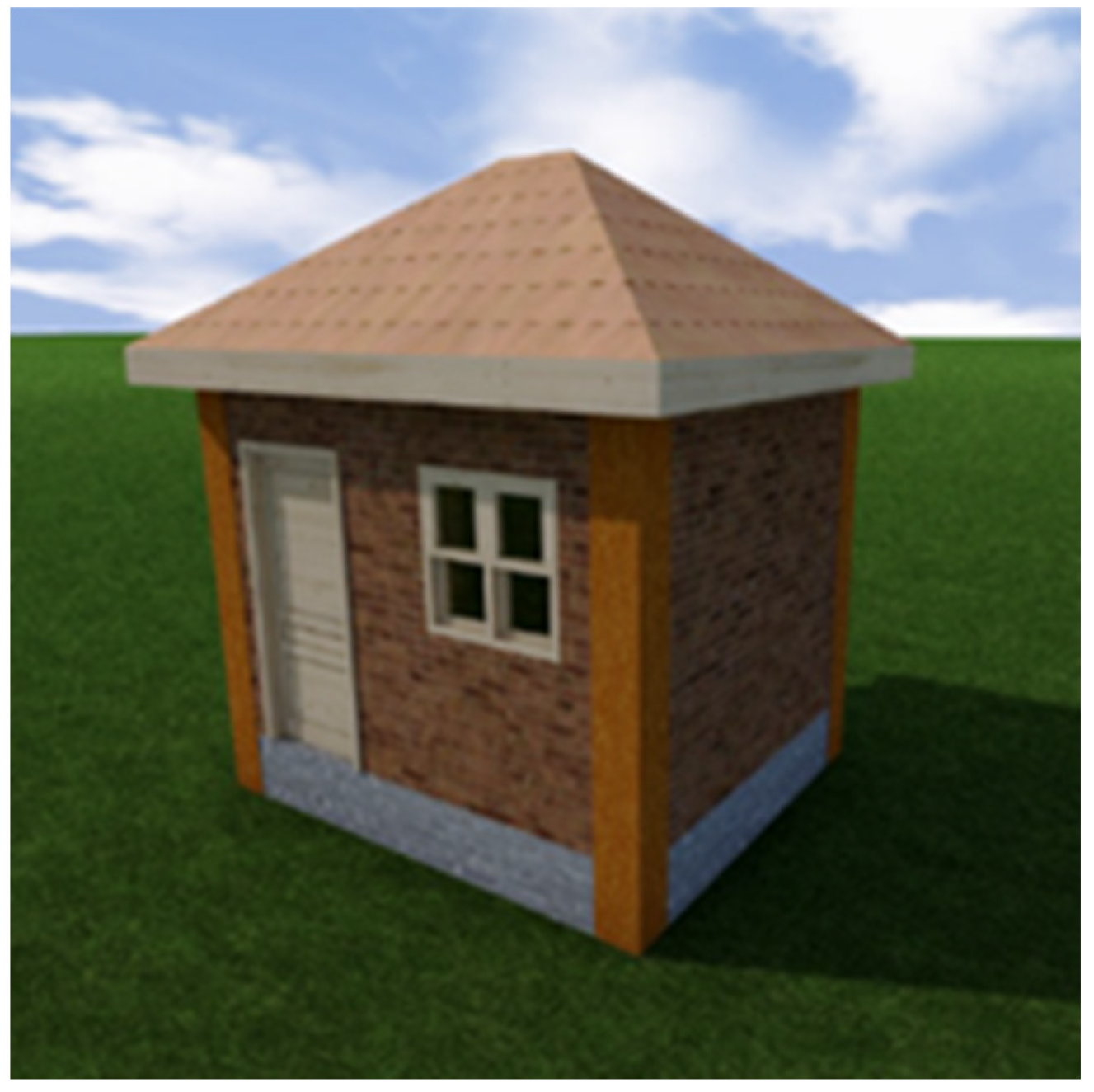

2.3. Construction of the Test House

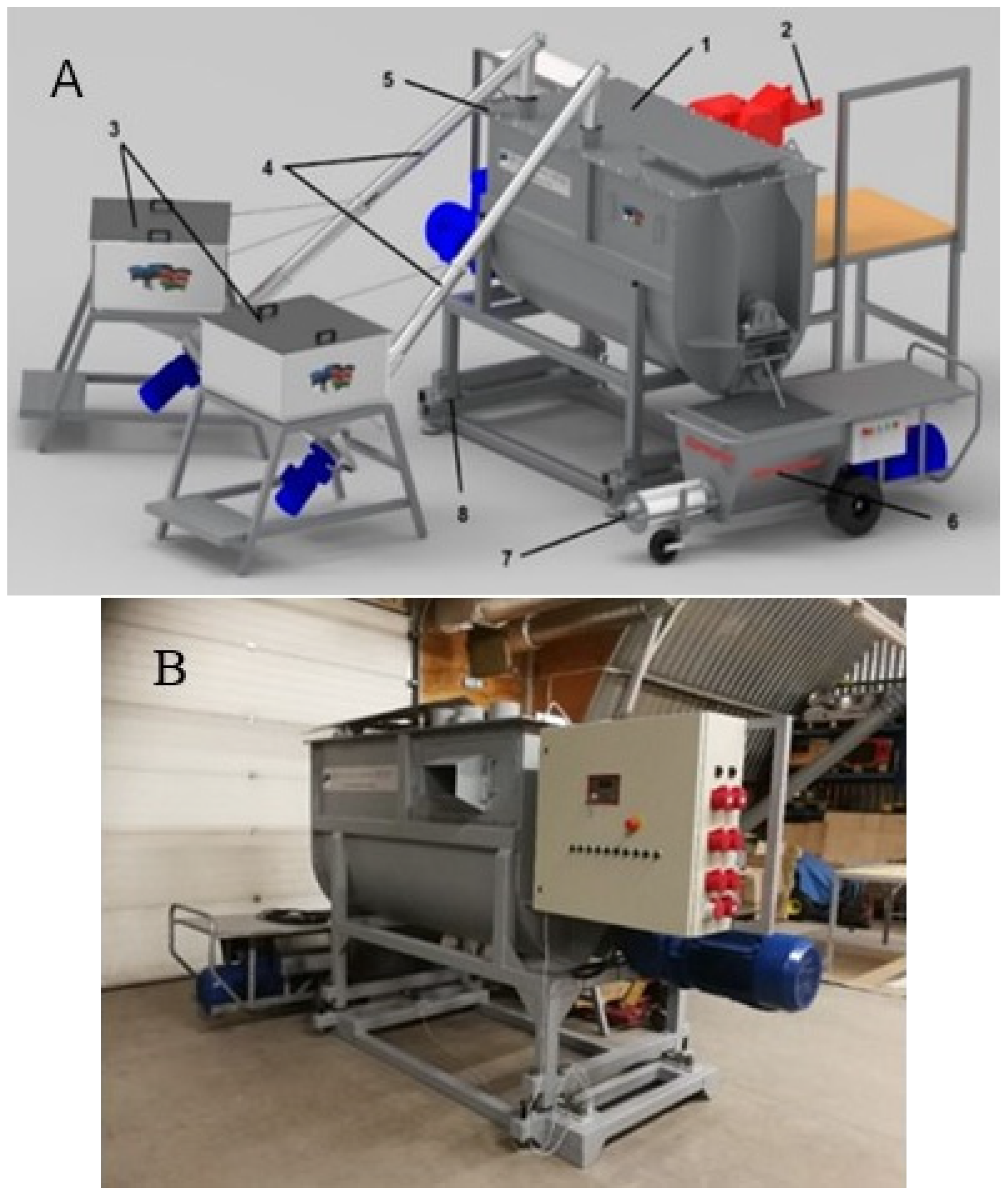

2.4. Equipment for the Mixing and Distribution of Composite Material

- screw conveyors for loading different components into the mixer

- pump for pumping the mixture

- rack for the mixer with weight sensors.

- Horizontal shaft mixer:

- power 15 kW, 3 phase 400 V

- mixer shaft speed 16 rpm

- full volume of the mixer container 1.5 m3, amount of mixture 0.7–1.0 m3.

- Screw conveyor:

- power 1.5 kW, 3 phase 400 V

- auger speed 107 rpm

- conveyor container capacity 300 L

- productivity 24 L/min.

- Mixture pump:

- power 11 kW, 3 phase 400 V

- container volume 175 L

- pump capacity 120 L/min (measured with water)

- hose ID 65 mm, length 15 m.

- Straw crusher:

- power 4 kW, 3 phase 400 V

- rotation speed 2870 rpm.

3. Results

3.1. Elemental Analysis of the Raw Materials

3.2. Compressive Strength Tests

3.3. Construction of Test House

4. Discussion

4.1. Efficiency of Apparatus

4.2. Effect of Ash Content on Compressive Strength

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gagg, C.R. Cement and concrete as an engineering material: An historic appraisal and case study analysis. Eng. Fail. Anal. 2014, 40, 114–140. [Google Scholar] [CrossRef]

- Ismail, M.A.; Mueller, C.T. Minimizing embodied energy of reinforced concrete floor systems in developing countries through shape optimization. Eng. Struct. 2021, 246, 112955. [Google Scholar] [CrossRef]

- Sinha, R.; Lennartsson, M.; Frostell, B. Environmental footprint assessment of building structures: A comparative study. Build. Environ. 2016, 104, 162–171. [Google Scholar] [CrossRef]

- Research in Estonia 2022 Homes Made of Rice Ash Under Construction in Kenya Thanks to Estonian Scientists. Available online: https://researchinestonia.eu/2022/09/16/homes-made-of-rice-ash-under-construction-in-kenya-thanks-to-estonian-scientists/ (accessed on 10 April 2023).

- Kenyatta University Pursuing the BIG 4 Agenda—Converting rice husks into eco-friendly building material—KU and Tartu University team up. Kenyatta Univ. News 2022, 9, 35–36. Available online: http://www.ku.ac.ke/images/2022/rio_newsletter_july_2022.pdf (accessed on 15 June 2023).

- Universitas Tartuensis|Ajakiri.ut.ee. 2022 Tartlaste Tehnoloogia viib Keeniasse Ülisoodsad Ökomajad (In Estonian). Available online: https://chem.ut.ee/et/sisu/tartlaste-tehnoloogia-viib-keeniasse-ulisoodsad-okomajad (accessed on 27 December 2022).

- Castro, J.C.L.; Zaborova, D.D.; Musorina, T.A.; Arkhipov, I.E. Indoor environment of a building under the conditions of tropical climate. Mag. Civ. Eng. 2017, 76, 50–57. [Google Scholar] [CrossRef]

- Joshima, V.M.; Naseer, M.A.; Lakshmi-Prabha, E. Assessing the real-time thermal performance of reinforced cement concrete roof during summer: A study in the warm humid climate of Kerala. J. Build. Eng. 2021, 41, 102735. [Google Scholar] [CrossRef]

- Republic of Kenya 2010, The Constitution of Kenya. Available online: https://www.parliament.go.ke/sites/default/files/2023-03/The_Constitution_of_Kenya_2010.pdf (accessed on 15 June 2023).

- Government of Kenya 2016, Sessional Paper No. 3 on National Housing Policy for Kenya. Available online: https://www.housingandurban.go.ke/wp-content/uploads/2019/10/Updated-Sessional-Paper-No.3-of-2016-National-Housing-Policy.pdf (accessed on 15 June 2023).

- Concha-Riedel, J.; Antico, F.; López-Querol, S. Mechanical strength, mass loss and volumetric changes of drying adobe matrices combined with kaolin and fine soil particles. Constr. Build. Mater. 2021, 312, 125246. [Google Scholar] [CrossRef]

- Larbi, S.; Khaldi, A.; Maherzi, W.; Abriak, N.E. Formulation of compressed earth blocks stabilized by glass waste activated with NaOH solution. Sustainability 2022, 14, 102. [Google Scholar] [CrossRef]

- Akinyemi, B.A.; Elijah, A.; Oluwasegun, A.; Akpenpuun, D.T.; Glory, O. The use of red earth, lateritic soils and quarry dust as an alternative building material in sandcrete block. Sci. Afr. 2020, 7, e00263. [Google Scholar] [CrossRef]

- Von Seidlein, L.; Ikonomidis, K.; Mshamu, S.; Nkya, T.E.; Mukaka, M.; Pell, C.; Lindsay, S.W.; Deen, J.L.; Kisinza, W.N.; Knudsen, J.B. Affordable house designs to improve health in rural Africa: A field study from northeastern Tanzania. Lancet Planet. Health 2017, 1, e188–e199. [Google Scholar] [CrossRef] [PubMed]

- Van Der Veen, M. The economic value of chaff and straw in arid and temperate zones. Veg. Hist. Archaeobot. 1999, 8, 211–224. [Google Scholar] [CrossRef]

- Toguyeni, D.Y.K.; Coulibaly, O.; Ouedraogo, A.; Koulidiati, J.; Dutil, Y.; Rousse, D. Study of the influence of roof insulation involving local materials on cooling loads of houses built of clay and straw. Energy Build. 2012, 50, 74–80. [Google Scholar] [CrossRef]

- Vincevica-Gaile, Z.; Teppand, T.; Kriipsalu, M.; Krievans, M.; Jani, Y.; Klavins, M.; Setyobudi, R.H.; Grinfelde, I.; Rudovica, V.; Tamm, T.; et al. Towards sustainable soil stabilization in peatlands: Secondary raw materials as an alternative. Sustainability 2021, 13, 6726. [Google Scholar] [CrossRef]

- Hung, V.N.; Maguyon-Detras, M.C.; Migo, M.V.; Quilloy, R.; Balingbing, C.; Chivenge, P.; Gummert, M. Rice straw overview: Availability, properties, and management practices. In Sustainable Rice Straw Management; Gummert, M., Hung, V.N., Chivenge, P., Douthwaite, B., Eds.; Springer: Cham, Switzerland, 2020; pp. 1–13. [Google Scholar] [CrossRef]

- Singh, S.; Maiti, S.; Bisht, R.S.; Balam, N.B.; Solanki, R.; Chourasia, A.; Panigrahi, S.K. Performance behaviour of agro-waste based gypsum hollow blocks for partition walls. Sci. Rep. 2022, 12, 3204. [Google Scholar] [CrossRef]

- De Melo, R.R.; Stangerlin, D.M.; Santana, R.R.C.; Pedrosa, T.D. Decay and termite resistance of particleboard manufactured from wood, bamboo and rice husk. Maderas Cienc. Tecnol. 2015, 17, 55–62. [Google Scholar] [CrossRef]

- Jongpradist, P.; Homtragoon, W.; Sukkarak, R.; Kongkitkul, W.; Jamsawang, P. Efficiency of rice husk ash as cementitious material in high-strength cement-admixed clay. Adv. Civ. Eng. 2018, 2018, 8346319. [Google Scholar] [CrossRef]

- Van Ryssen, J.B.J.; Ndlovu, H. Ash from fireplaces at homesteads in rural regions of South Africa as potential source of minerals to goats. S. Afr. J. Anim. Sci. 2004, 34 (Suppl. S1), 111–113. [Google Scholar]

- Neina, D.; Faust, S.; Joergensen, R.G. Characterization of charcoal and firewood ash for use in African peri-urban agriculture. Chem. Biol. Technol. Agric. 2020, 7, 5. [Google Scholar] [CrossRef]

- Xu, Q.; Ji, T.; Gao, S.J.; Yang, Z.; Wu, N. Characteristics and applications of sugar cane bagasse ash waste in cementitious materials. Materials 2018, 12, 39. [Google Scholar] [CrossRef] [PubMed]

- Liiv, J.; Teppand, T.; Rikmann, E.; Tenno, T. Novel ecosustainable peat and oil shale ash-based 3D-printable composite material. Sustain. Mater. Technol. 2018, 17, e00067. [Google Scholar] [CrossRef]

- Rikmann, E.; Zekker, I.; Teppand, T.; Pallav, V.; Shanskiy, M.; Mäeorg, U.; Tenno, T.; Burlakovs, J.; Liiv, J. Relationship between phase composition and mechanical properties of peat soils stabilized using oil shale ash and pozzolanic additive. Water 2021, 13, 942. [Google Scholar] [CrossRef]

- Zemnukhova, L.A.; Panasenko, A.E.; Artem’yanov, A.P.E.; Tsoy, A. Dependence of porosity of amorphous silicon dioxide prepared from rice straw on plant variety. BioResources 2015, 10, 3713–3723. [Google Scholar] [CrossRef]

- Liesegang, M.; Milke, R.; Berthold, C. Amorphous silica maturation in chemically weathered clastic sediments. Sediment. Geol. 2018, 365, 54–61. [Google Scholar] [CrossRef]

- Behak, L. Soil stabilization with rice husk ash. In Rice—Technology and Production; Matovic, M.D., Ed.; IntechOpen: London, UK, 2017; ISBN 978-953-51-3123-4. [Google Scholar] [CrossRef]

| No. | Element | Line | Energy/keV | Net Standard Deviation |

|---|---|---|---|---|

| 1 | Na | K12 | 1.04 | 94 |

| 2 | Mg | K12 | 1.254 | 780 |

| 3 | Al | K12 | 1.486 | 3098 |

| 4 | Si | K12 | 1.74 | 12,590 |

| 5 | P | K12 | 2.01 | 16,718 |

| 6 | S | K12 | 2.309 | 3889 |

| 7 | K | K12 | 3.314 | 170,049 |

| 8 | Ca | K12 | 3.692 | 2,585,050 |

| 9 | Ti | K12 | 4.512 | 13,445 |

| 10 | V | K12 | 4.953 | 3035 |

| 11 | Mn | K12 | 5.9 | 194,477 |

| 12 | Fe | K12 | 6.405 | 210,743 |

| 13 | Ni | K12 | 7.48 | 31,591 |

| 14 | Cu | K12 | 8.046 | 4080 |

| 15 | Zn | K12 | 8.637 | 771 |

| Element | wt% | Equivalent Oxide | wt% |

|---|---|---|---|

| O | 50.6 | ─ | ─ |

| Si | 43.5 | SiO2 | 86.8 |

| C | 2.5 | CO2 | 8.5 |

| K | 0.8 | K2O | 0.9 |

| Al | 0.6 | Al2O3 | 1.1 |

| Fe | 0.5 | Fe2O3 | 0.6 |

| Ca | 0.4 | CaO | 0.6 |

| P | 0.3 | P2O5 | 0.6 |

| Mg | 0.2 | MgO | 0.3 |

| Mn | 0.1 | MnO2 | 0.1 |

| Ti | 0.1 | TiO2 | 0.2 |

| S | 0.07 | SO3 | 0.2 |

| Batch Number | Wood Ash to Rice Husk Ash Ratio | Load at Failure (kN) | Maximum Compressive Strength (MPa) |

|---|---|---|---|

| 1 | 1:1 | 233.811 | 5.759 |

| 2 | 2:1 | 189.985 | 4.679 |

| 3 | 3:1 | 143.863 | 3.543 |

| 4 | 4:1 | 98.782 | 2.433 |

| 5 | 5:1 | 80.651 | 1.986 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liiv, J.; Githuku, C.R.; Mwai, M.; Mändar, H.; Ritslaid, P.; Shanskiy, M.; Rikmann, E. Carbon-Negative Construction Material Based on Rice Production Residues. Materials 2025, 18, 3534. https://doi.org/10.3390/ma18153534

Liiv J, Githuku CR, Mwai M, Mändar H, Ritslaid P, Shanskiy M, Rikmann E. Carbon-Negative Construction Material Based on Rice Production Residues. Materials. 2025; 18(15):3534. https://doi.org/10.3390/ma18153534

Chicago/Turabian StyleLiiv, Jüri, Catherine Rwamba Githuku, Marclus Mwai, Hugo Mändar, Peeter Ritslaid, Merrit Shanskiy, and Ergo Rikmann. 2025. "Carbon-Negative Construction Material Based on Rice Production Residues" Materials 18, no. 15: 3534. https://doi.org/10.3390/ma18153534

APA StyleLiiv, J., Githuku, C. R., Mwai, M., Mändar, H., Ritslaid, P., Shanskiy, M., & Rikmann, E. (2025). Carbon-Negative Construction Material Based on Rice Production Residues. Materials, 18(15), 3534. https://doi.org/10.3390/ma18153534