Mechanical Properties of CuZr Amorphous Metallic Nanofoam at Various Temperatures Investigated by Molecular Dynamics Simulation

Abstract

1. Introduction

2. Models and Methods

3. Results and Discussion

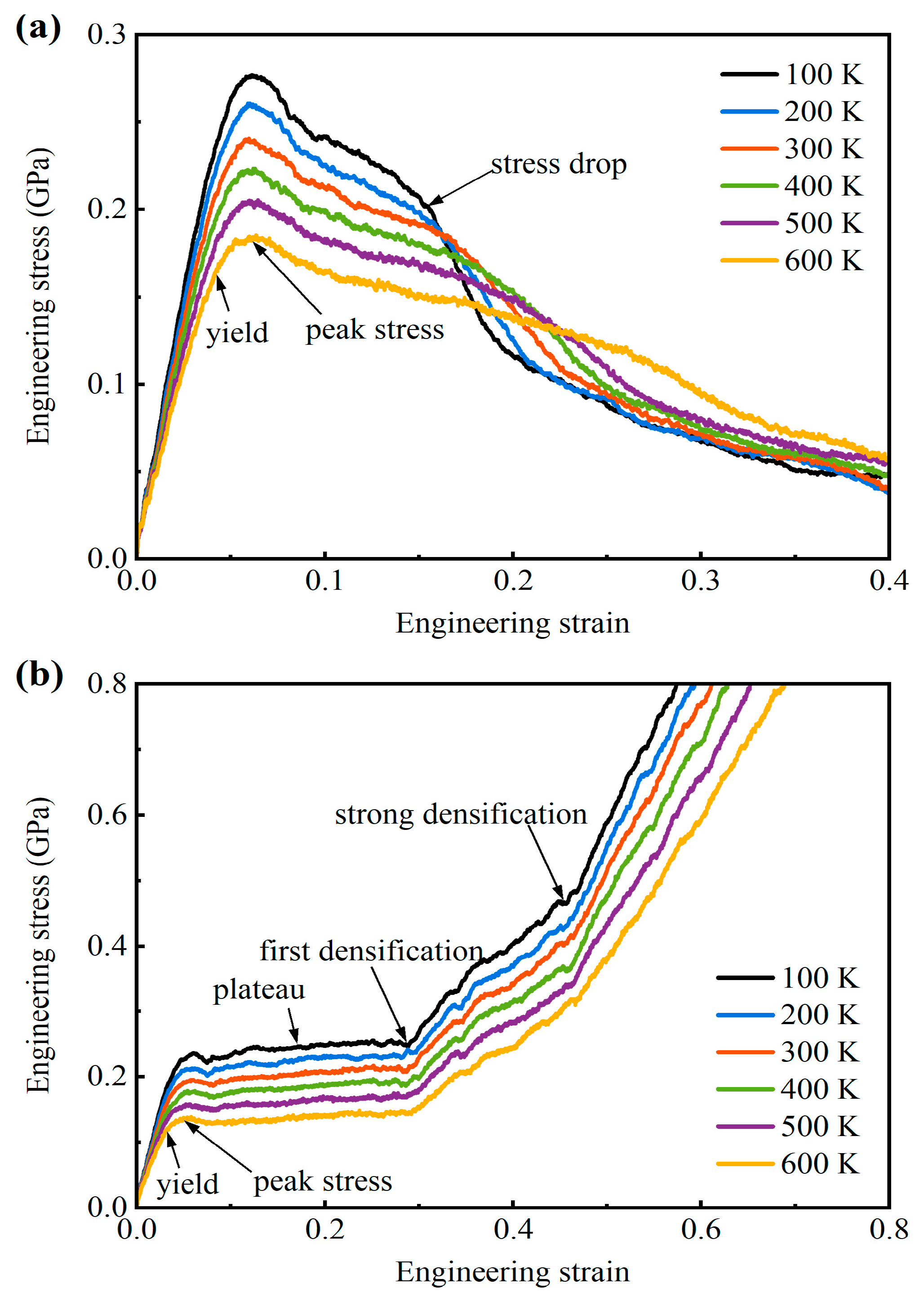

3.1. Stress–Strain Responses

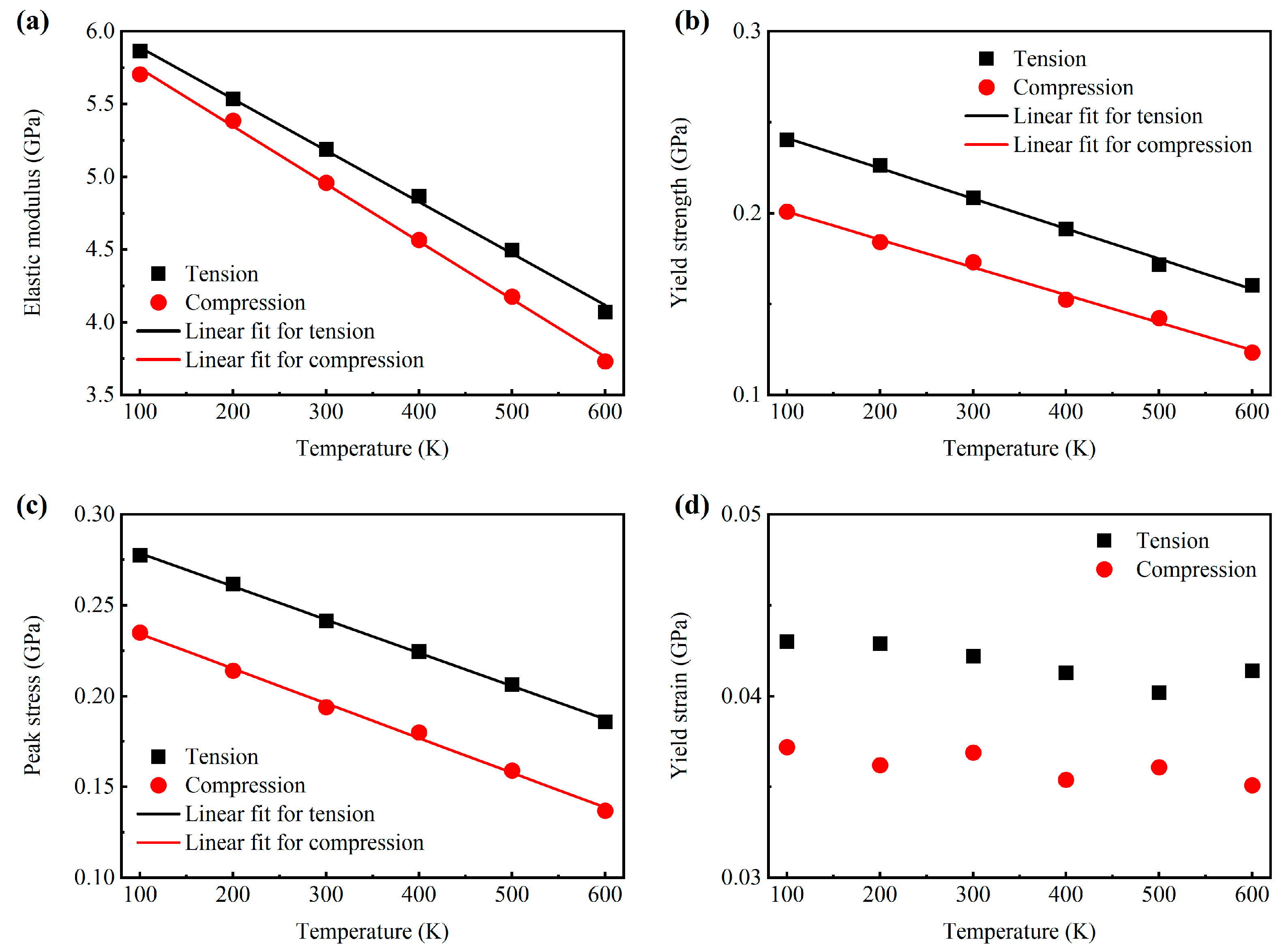

3.2. Mechanical Parameters at Different Temperatures

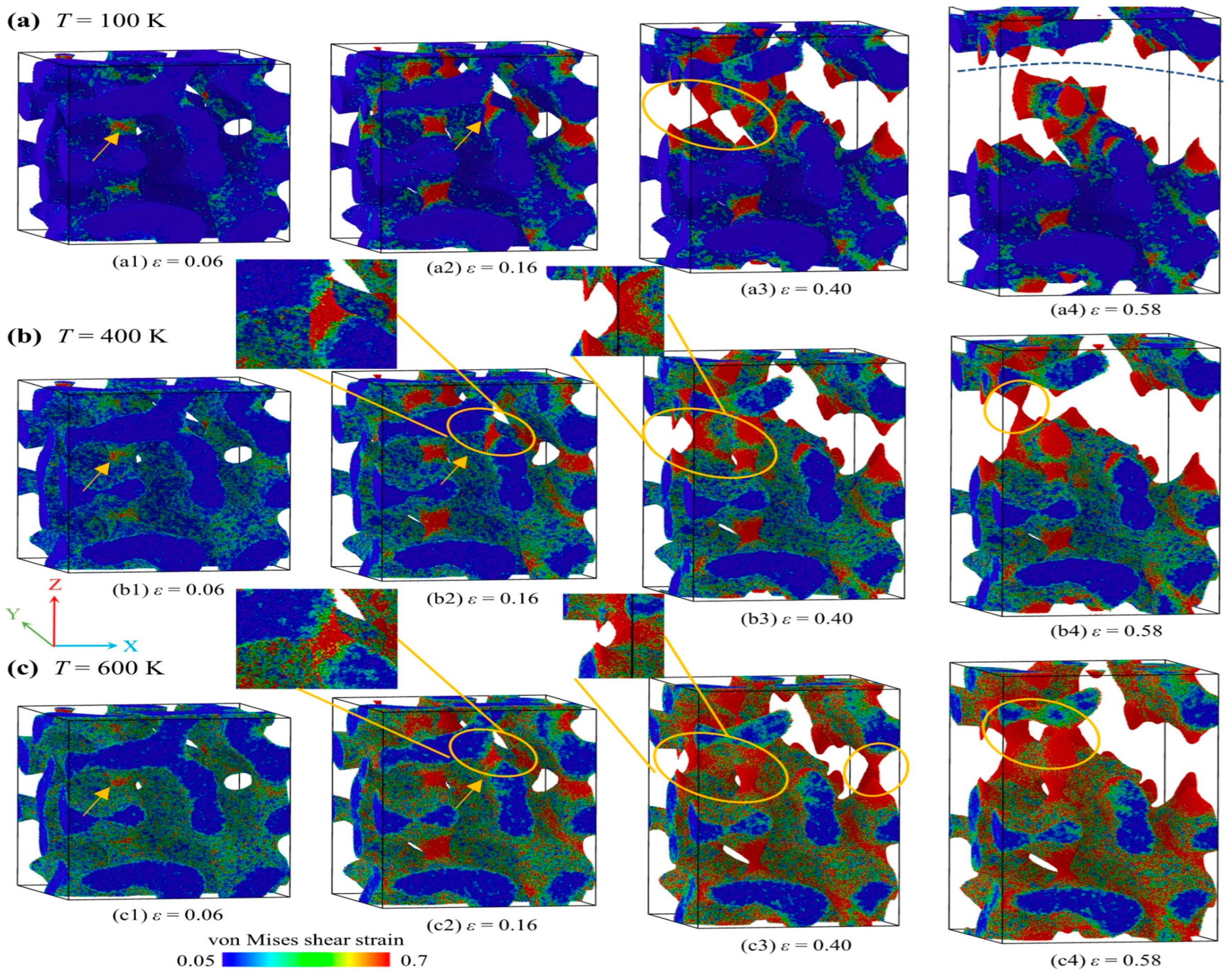

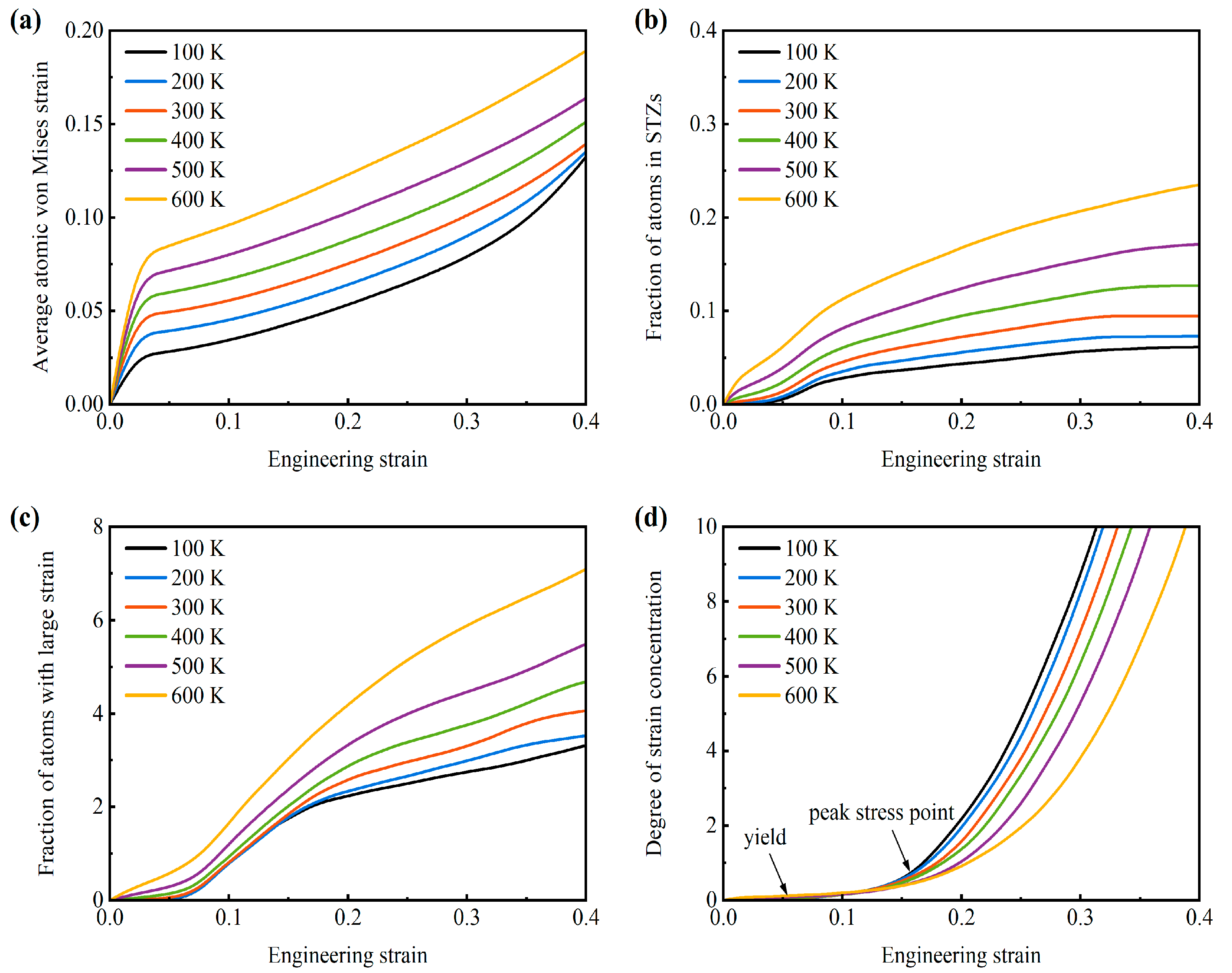

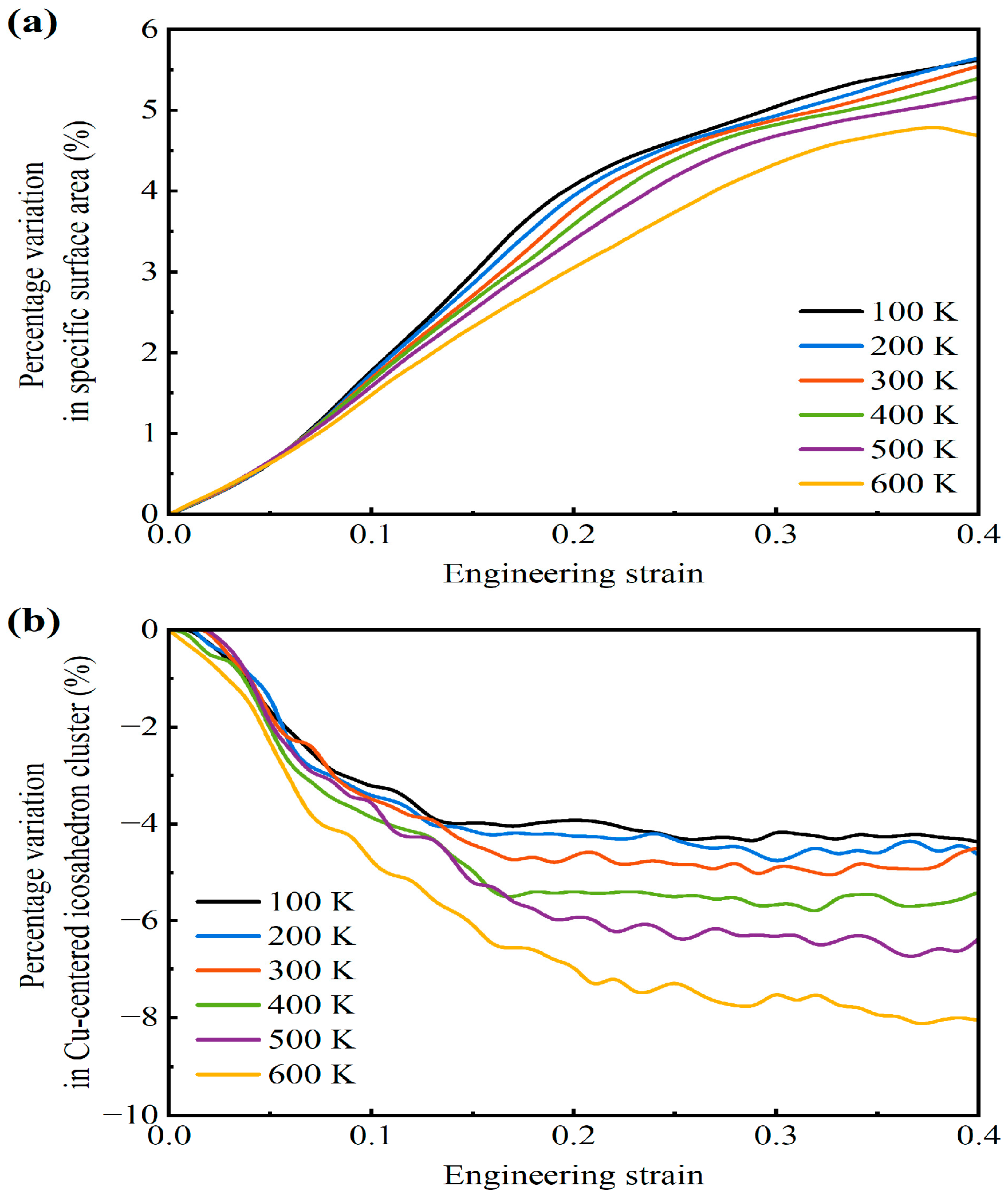

3.3. Deformation Modes Under Tension

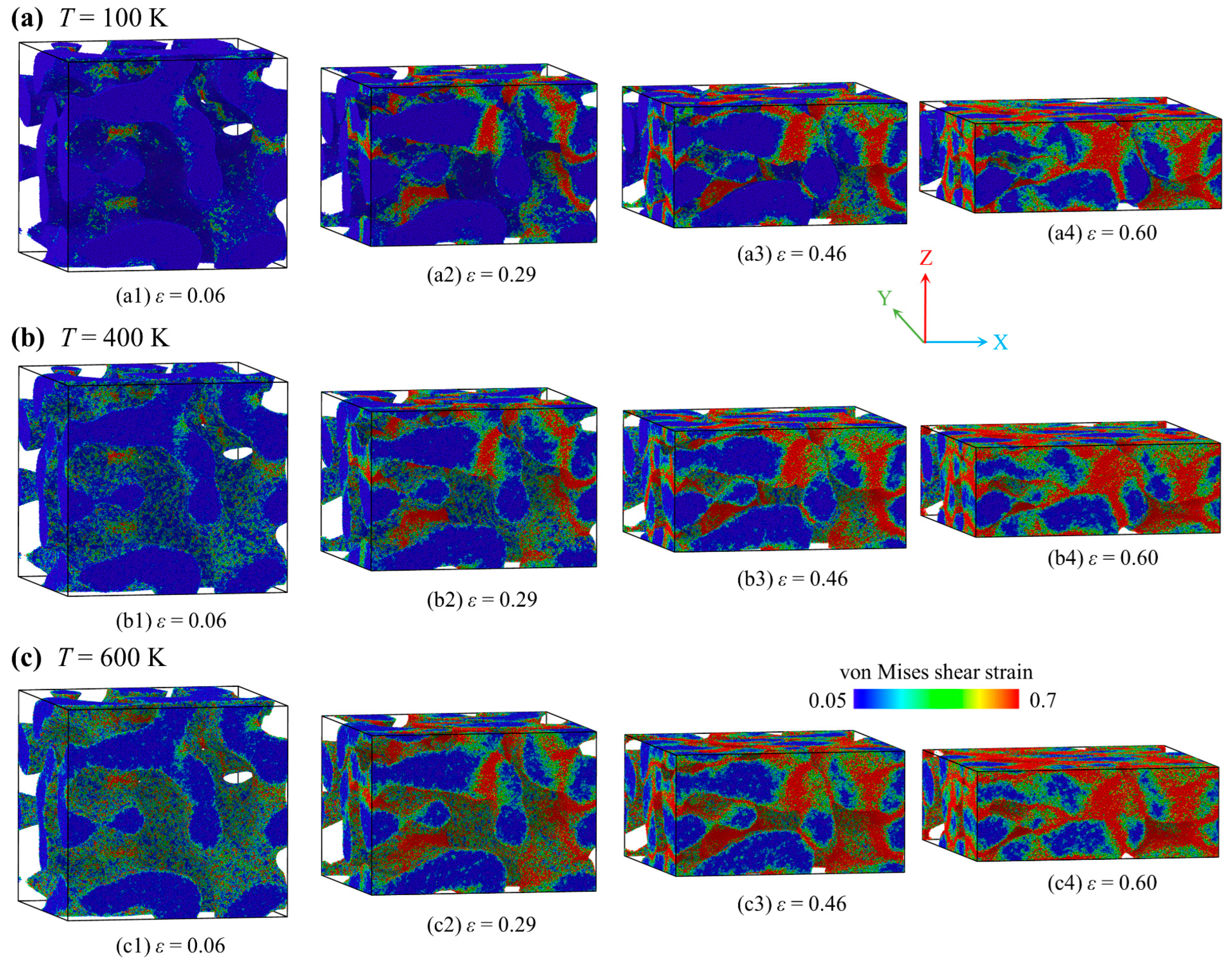

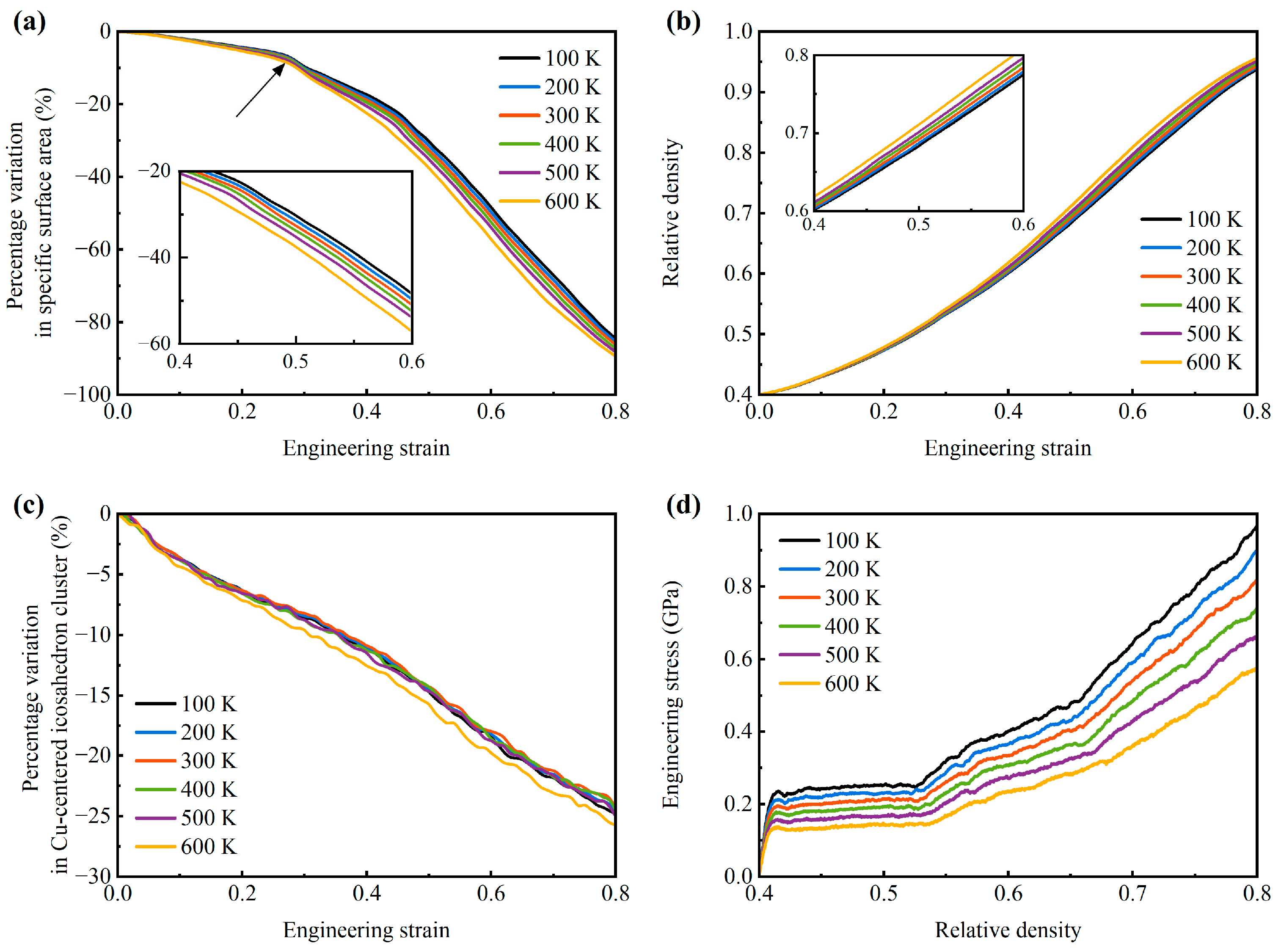

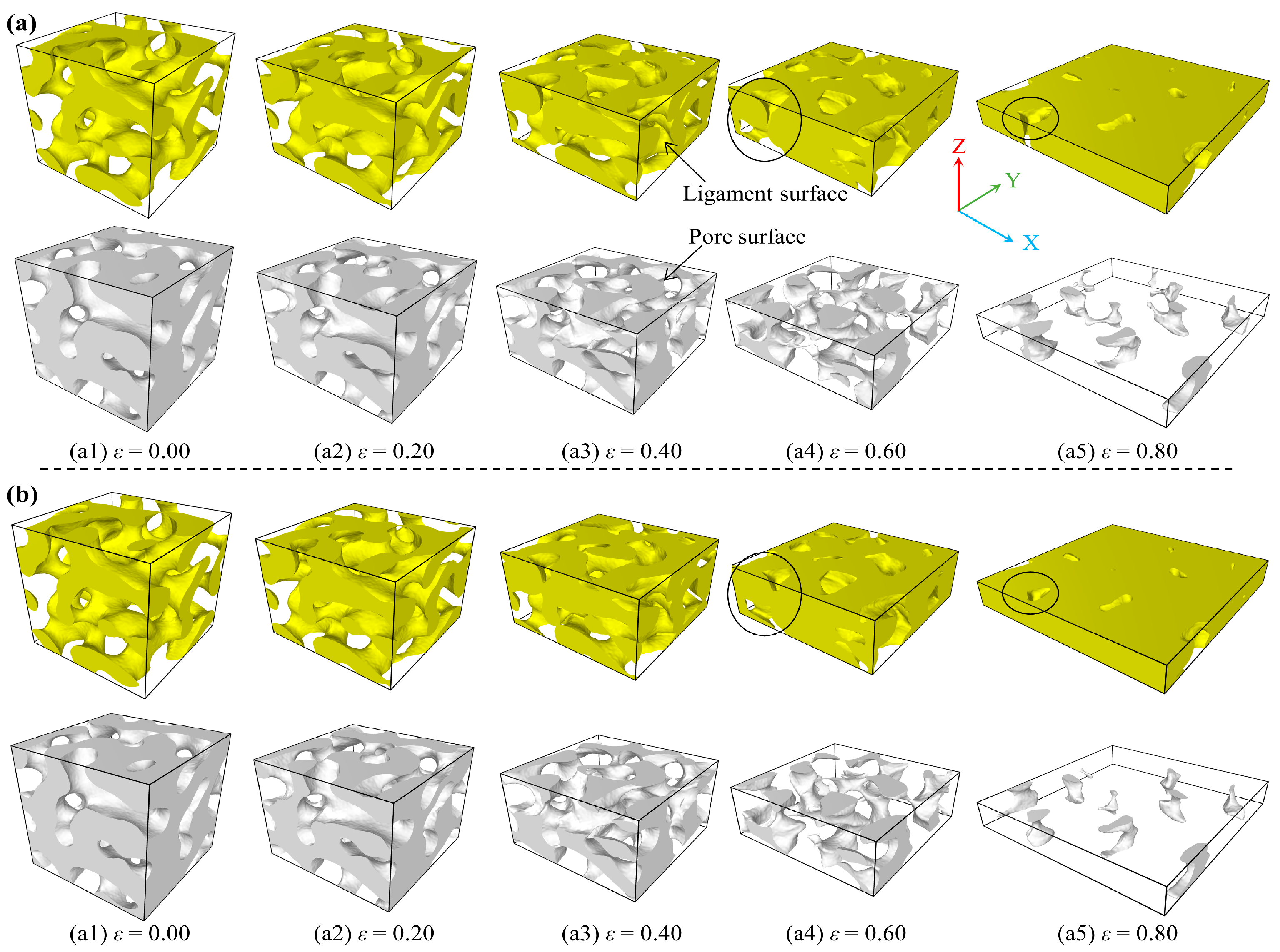

3.4. Deformation Modes Under Compression

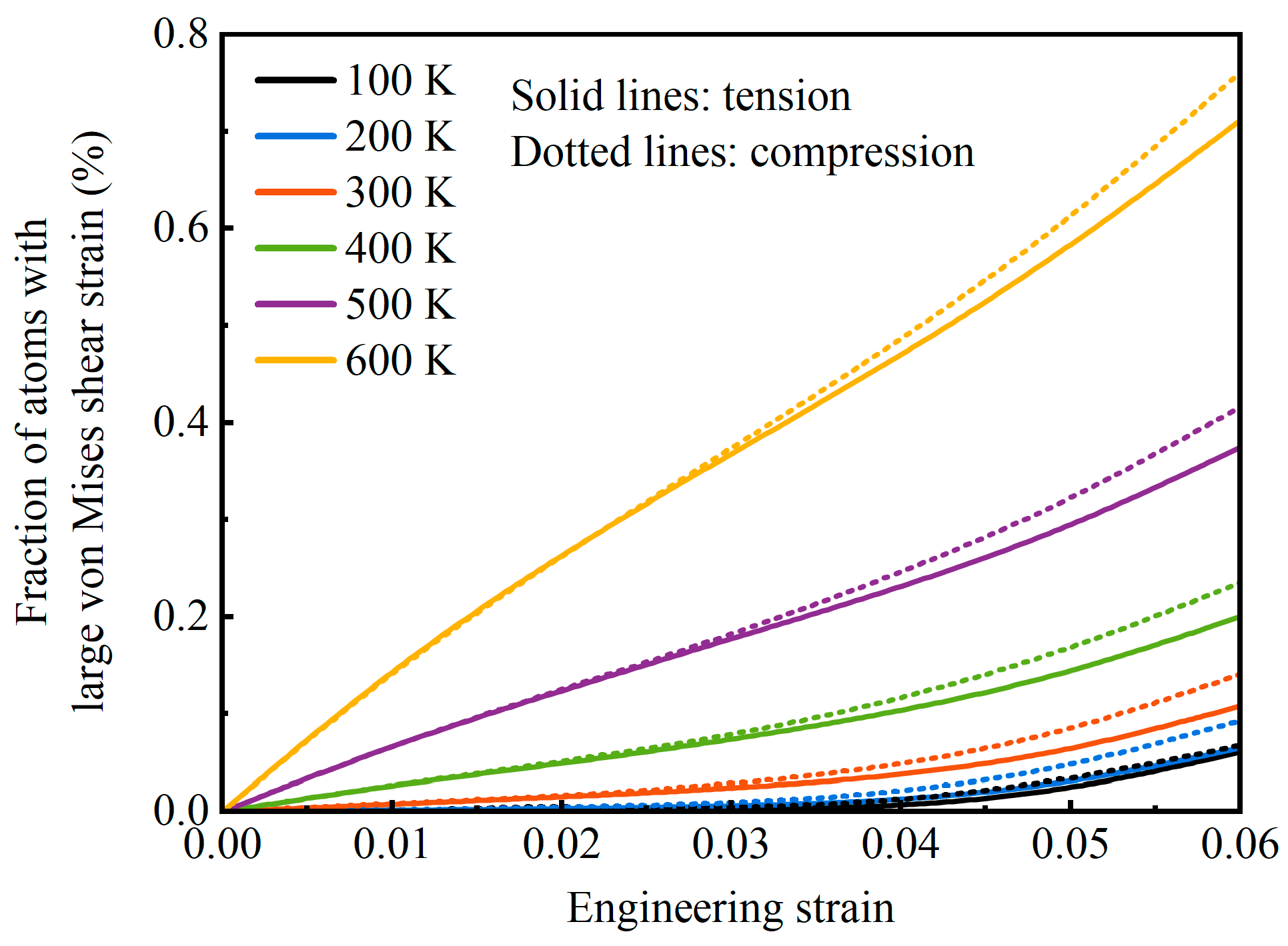

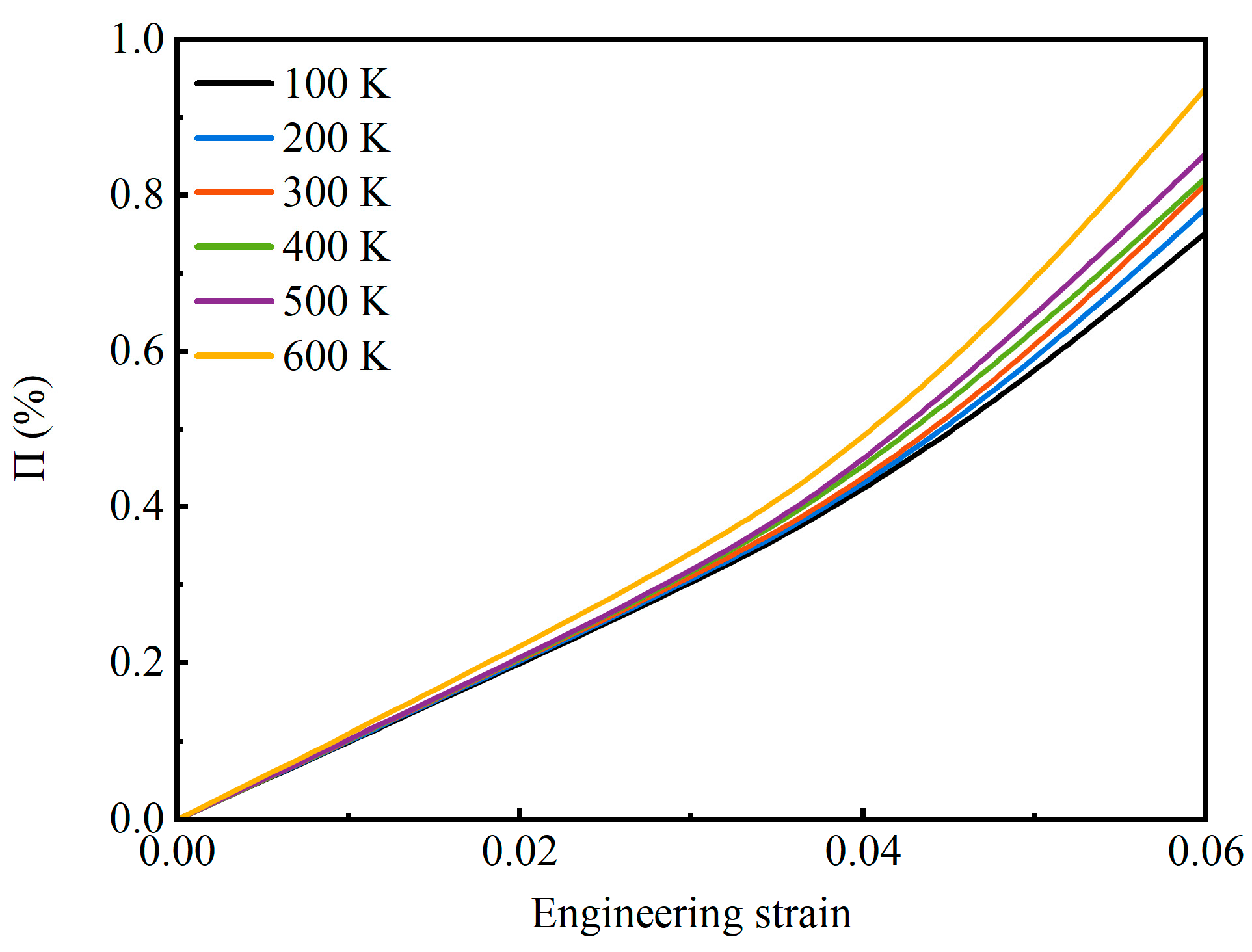

3.5. Tension–Compression Asymmetry

4. Conclusions

- (1)

- The key mechanical properties of the AMNF, including tensile/compressive elastic modulus, yield strength, and maximum tensile stress, show tension–compression asymmetry and strong sensitivity to temperature variations. These mechanical properties intensify with a reduction in temperature and are stronger in tension than in compression.

- (2)

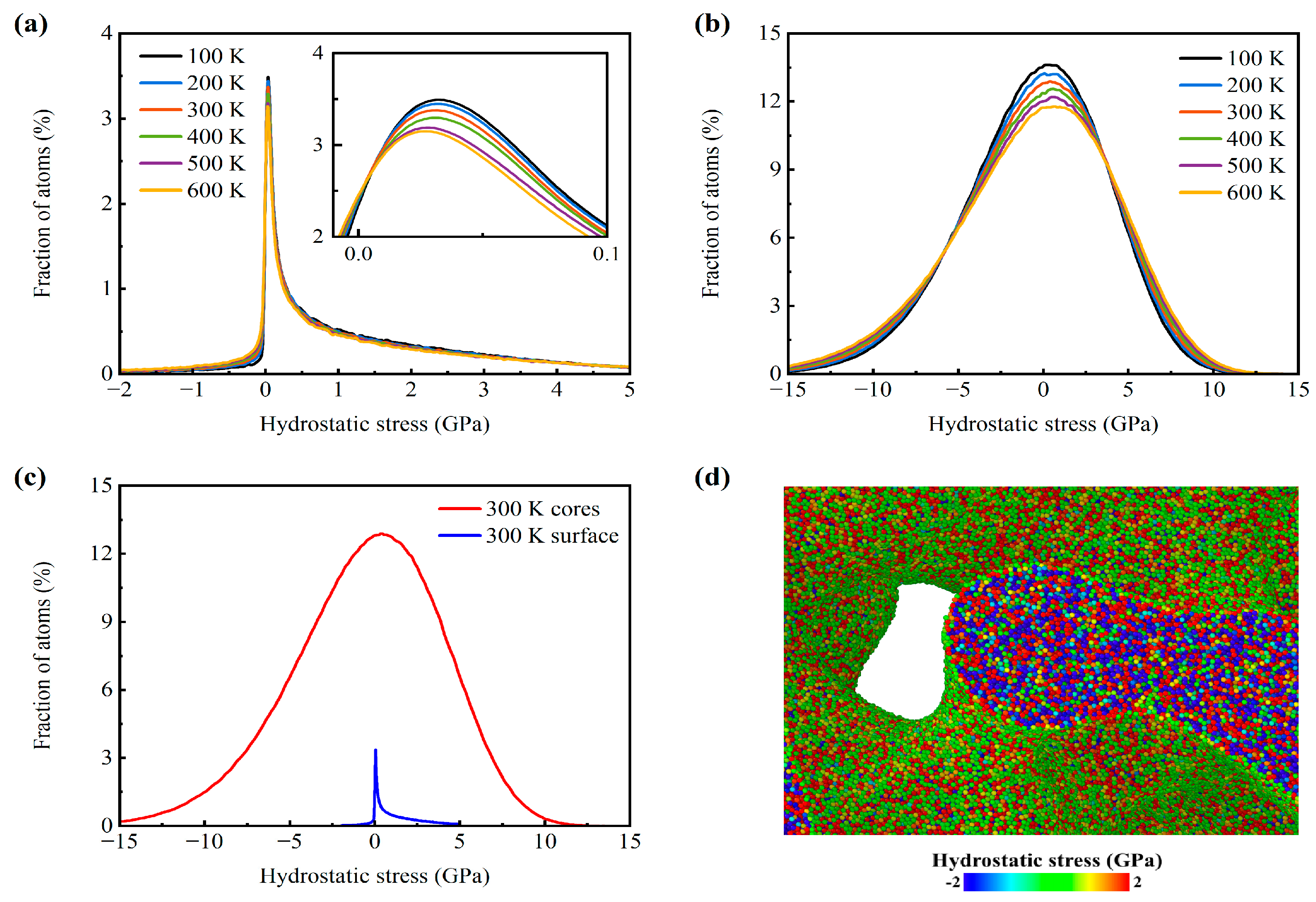

- The tension–compression asymmetry of yield strength originates from the initial surface stress state. The yield behavior is especially sensitive to localized extreme conditions in the weakest ligaments and localized regions with high stress concentrations. Additionally, the methods used to determine yield stress/strain strongly influence the calculated values. As a result, the tension–compression asymmetry in yield stress/strain is insensitive to temperature variation.

- (3)

- The difference between tensile elastic modulus and compressive elastic modulus increases with rising temperature. This phenomenon is explained by the surface energy effect. At the same global strain, the variation in the percentage of specific surface area between tension and compression is greater at higher temperatures. Therefore, as temperatures increase, the effect of surface energy becomes increasingly prominent, leading to a greater tension–compression asymmetry of elastic modulus.

- (4)

- Temperature variation quantitatively affects the deformation behaviors of AMNF. Although increased temperature softens the material, it also delays ligament decay and enhances the structural resistance of the porous structure under large plastic strain conditions by facilitating global homogeneous deformation. On the other hand, a higher temperature increases atomic distances and potential energy, facilitating the contact and merging of ligament surfaces into an integrated solid. This process accelerates the densification of AMNF at higher temperatures.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, Y.Y.; Xie, H.; Liu, L.Z.; Jin, H.J. Surface Triple Junctions Govern the Strength of a Nanoscale Solid. Phys. Rev. Lett. 2021, 126, 235501. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.W.; Weissmueller, J. Phase decomposition in nanoporous Au-Pt. Acta Mater. 2022, 241, 118419. [Google Scholar] [CrossRef]

- Loaiza, A.; Tsai, J.T.; Bahr, D.F. Strengthening mechanisms in nanoporous alloy foams with a hierarchical structure. J. Mater. Sci. 2022, 57, 13660–13670. [Google Scholar] [CrossRef]

- Zhang, Y.Y.; Zou, L.J.; Liu, L.Z.; Xie, H.; Li, C.H.; Jin, H.J. Mechanical properties of unidirectional nanoporous gold under compression. Acta Mater. 2022, 235, 118078. [Google Scholar] [CrossRef]

- Benetti, G.; Banfi, F.; Cavaliere, E.; Gavioli, L. Mechanical Properties of Nanoporous Metallic Ultrathin Films: A Paradigmatic Case. Nanomaterials 2021, 11, 3116. [Google Scholar] [CrossRef] [PubMed]

- Xia, R.; Wu, R.N.; Liu, Y.L.; Sun, X.Y. The Role of Computer Simulation in Nanoporous Metals-A Review. Materials 2015, 8, 5060–5083. [Google Scholar] [CrossRef] [PubMed]

- Jin, H.J.; Weissmüller, J.; Farkas, D. Mechanical response of nanoporous metals: A story of size, surface stress, and severed struts. Mrs Bull. 2018, 43, 35–42. [Google Scholar] [CrossRef]

- Liu, L.Z.; Zhang, Y.Y.; Xie, H.; Jin, H.J. Transition from Homogeneous to Localized Deformation in Nanoporous Gold. Phys. Rev. Lett. 2021, 127, 095501. [Google Scholar] [CrossRef] [PubMed]

- Tsai, W.H.; Tang, C.H.; Cheng, I.C. The mechanical and catalytic behavior of nanoporous copper film on octet-truss lattice via magnetron sputtering. Thin Solid Film. 2021, 724, 138628. [Google Scholar] [CrossRef]

- Sarac, B.; Karazehir, T.; Yüce, E.; Mühlbacher, M.; Sarac, A.S.; Eckert, J. Nanoporous Pd-Cu-Si Amorphous Thin Films for Electrochemical Hydrogen Storage and Sensing. Acs Appl. Energy Mater. 2021, 4, 2672–2680. [Google Scholar] [CrossRef]

- Jin, Y.; Xi, G.G.; Li, R.; Li, Z.A.; Chen, X.B.; Zhang, T. Nanoporous metallic-glass electrocatalysts for highly efficient oxygen evolution reaction. J. Alloys Compd. 2021, 852, 156876. [Google Scholar] [CrossRef]

- Sohn, S.; Shi, S.; Markmann, J.; Berger, S.A.; Weissmüller, J. Compressive behavior and connecting topology of monolithic nanoporous niobium. Mater. Res. Lett. 2025, 13, 76–85. [Google Scholar] [CrossRef]

- Zhang, Y.; Bai, Q.G.; Yang, W.F.; Zhang, Z.H. Liquid metal assisted regulation of macro-/micro-structures and mechanical properties of nanoporous copper. Sci. China-Technol. Sci. 2021, 64, 2229–2236. [Google Scholar] [CrossRef]

- Melis, C.; Pia, G.; Sogne, E.; Falqui, A.; Giordano, S.; Delogu, F.; Colombo, L. Stiffening of nanoporous gold: Experiment, simulation and theory. Eur. Phys. J. Plus 2022, 137, 858. [Google Scholar] [CrossRef]

- Peng, X.J.; Han, J.H.; Wang, Y.T.; Bo, Z.X.; Nie, A.M.; Li, P.H.; Li, Y.Y.; Wu, H.F.; Liu, P.; Lu, Z.; et al. Unexpected enhanced catalytic performance via highly dense interfaces in ultra-fine amorphous-nanocrystalline biphasic structure. Appl. Mater. Today 2022, 29, 101689. [Google Scholar] [CrossRef]

- Fu, J.N.; Li, Z.; Liu, Z.H.; Li, X.; Wen, W.X.; Sun, F.; Li, L.Y.; Huang, J.B.; Ruan, W.Q.; Ren, S.; et al. Manufacture of porous metallic glass using dissolvable templates. Sci. China-Mater. 2022, 65, 2833–2841. [Google Scholar] [CrossRef]

- Fu, J.A.; Ma, J. Nanoengineering of Metallic Glasses. Adv. Eng. Mater. 2023, 25, 2200659. [Google Scholar] [CrossRef]

- Zhang, C.; Ouyang, D.; Pauly, S.; Liu, L. 3D printing of bulk metallic glasses. Mater. Sci. Eng. R Rep. 2021, 145, 100625. [Google Scholar] [CrossRef]

- Yang, Y.C.; Xia, Z.H.; Mukherjee, S. Unraveling the structural statistics and its relationship with mechanical properties in metallic glasses. Nano Letters 2021, 21, 9108–9114. [Google Scholar] [CrossRef] [PubMed]

- Pei, C.Q.; Chen, S.Q.; Zhou, M.J.; Chen, X.H.; Sun, B.A.; Lan, S.; Hahn, H.; Feng, T. Direct Urea/HO Fuel Cell with a Hierarchical Porous Nanoglass Anode for High-Efficiency Energy Conversion. ACS Appl. Mater. Interfaces 2023, 15, 24319–24328. [Google Scholar] [CrossRef] [PubMed]

- Fu, J.; Li, Z.; Li, X.; Sun, F.; Li, L.; Li, H.; Zhao, J.; Ma, J. Hierarchical porous metallic glass with strong broadband absorption and photothermal conversion performance for solar steam generation. Nano Energy 2023, 106, 108019. [Google Scholar] [CrossRef]

- Jiang, S.S.; Zhu, L.; Yang, Z.Z.; Wang, Y.G. Self-supported hierarchical porous FeNiCo-based amorphous alloys as high-efficiency bifunctional electrocatalysts toward overall water splitting. Int. J. Hydrogen Energy 2021, 46, 36731–36741. [Google Scholar] [CrossRef]

- Zhang, Z.F.; Wang, C.Y.; Liu, P.; Reddy, K.M.; Wang, X.D.; Chen, M.W.; Song, S.X. Deformation behavior of a nanoporous metallic glass at room temperature. Int. J. Plast. 2022, 152, 103232. [Google Scholar] [CrossRef]

- Wang, C.Y.; Li, Z.Y.; Zhu, S.L.; Liang, Y.Q.; Cui, Z.D.; Wu, S.L.; Qin, C.L.; Luo, S.Y.; Inoue, A. Dual-phase nanostructuring as a route to flexible nanoporous metals with outstanding comprehensive mechanical properties. Sci. China-Mater. 2021, 64, 2289–2304. [Google Scholar] [CrossRef]

- Jiao, W.; Liu, P.; Lin, H.J.; Zhou, W.; Wang, Z.; Fujita, T.; Hirata, A.; Li, H.W.; Chen, M.W. Tunable Nanoporous Metallic Glasses Fabricated by Selective Phase Dissolution and Passivation for Ultrafast Hydrogen Uptake. Chem. Mater. 2017, 29, 4478–4483. [Google Scholar] [CrossRef]

- Liu, C.; Yuan, S.Y.; Im, J.; De Barros, F.P.J.; Masri, S.F.; Branicio, P.S. Mechanical properties, failure mechanisms, and scaling laws of bicontinuous nanoporous metallic glasses. Acta Mater. 2022, 239, 118255. [Google Scholar] [CrossRef]

- Liu, C.; Yuan, S.Y.; Branicio, P.S. Bicontinuous nanoporous design induced homogenization of strain localization in metallic glasses. Scr. Mater. 2021, 192, 67–72. [Google Scholar] [CrossRef]

- Lin, W.H.; Teng, Y.; Sha, Z.D.; Yuan, S.Y.; Branicio, P.S. Mechanical properties of nanoporous metallic glasses: Insights from large-scale atomic simulations. Int. J. Plast. 2020, 127, 102657. [Google Scholar] [CrossRef]

- Zhang, Y.H.; Li, J.; Hu, Y.; Ding, S.; Du, F.; Xia, R. Characterization of the deformation behaviors under uniaxial stress for bicontinuous nanoporous amorphous alloys. Phys. Chem. Chem. Phys. 2022, 24, 1099–1112. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Hou, Z.; Wu, J.; Li, K.; Wang, Z.; Gao, L. Effects of pore structure characteristics on the mechanical behavior of Mg-Zn metallic glass under tensile and cyclic loading. J. Non-Cryst. Solids 2024, 625, 122766. [Google Scholar] [CrossRef]

- Song, W.; Meng, Y.; Xiao, L.; Liu, S. Tuning dynamic mechanical properties of Cu50Zr50 nanoglasses/ nanopolycrystalline Cu composites investigated by molecular dynamics simulation. J. Non-Cryst. Solids 2024, 625, 122715. [Google Scholar] [CrossRef]

- Zhao, K.; Wang, Y.J.; Cao, P.H. Fracture universality in amorphous nanowires. J. Mech. Phys. Solids 2023, 173, 105210. [Google Scholar] [CrossRef]

- Zandersons, B.; Lührs, L.; Li, Y.; Weissmüller, J. On factors defining the mechanical behavior of nanoporous gold. Acta Mater. 2021, 215, 116979. [Google Scholar] [CrossRef]

- Shi, S.; Li, Y.; Ngo-Dinh, B.N.; Markmann, J.; Weissmüller, J. Scaling behavior of stiffness and strength of hierarchical network nanomaterials. Science 2021, 371, 1026. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Ngô, B.N.D.; Markmann, J.; Weissmüller, J. Topology evolution during coarsening of nanoscale metal network structures. Phys. Rev. Mater. 2019, 3, 076001. [Google Scholar] [CrossRef]

- Thompson, A.P.; Aktulga, H.M.; Berger, R.; Bolintineanu, D.S.; Brown, W.M.; Crozier, P.S.; In’TVeld, P.J.; Kohlmeyer, A.; Moore, S.G.; Nguyen, T.D.; et al. LAMMPS–A flexible simulation tool for particle-based materials modeling at the atomic, meso, and continuum scales. Comput. Phys. Commun. 2022, 271, 108171. [Google Scholar] [CrossRef]

- Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO-the Open Visualization Tool. Model. Simul. Mater. Sci. Eng. 2010, 18, 015012. [Google Scholar] [CrossRef]

- Cheng, Y.Q.; Ma, E.; Sheng, H.W. Atomic Level Structure in Multicomponent Bulk Metallic Glass. Phys. Rev. Lett. 2009, 102, 245501. [Google Scholar] [CrossRef] [PubMed]

- Mendelev, M.I.; Sordelet, D.J.; Kramer, M.J. Using atomistic computer simulations to analyze X-ray diffraction data from metallic glasses. J. Appl. Phys. 2007, 102, 043501. [Google Scholar] [CrossRef]

- Weng, S.Y.; Fu, T.; Peng, X.H.; Chen, X. Anisotropic Phase Transformation in B2 Crystalline CuZr Alloy. Nanoscale Res. Lett. 2019, 14, 283. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.H.; Hu, Y.Q.; Xu, J.F.; Ding, S.H.; Wu, W.W.; Xia, R. Ligament rotation-dominated creep in stochastic bicontinuous nanoporous metallic glass. Mater. Des. 2023, 236, 112480. [Google Scholar] [CrossRef]

- Zhang, Y.H.; Xu, J.F.; Hu, Y.Q.; Ding, S.H.; Wu, W.W.; Xia, R. Dynamic characterization of shock wave responses of bicontinuous nanoporous amorphous alloys: Microstructure effects. Mech. Mater. 2022, 173, 104410. [Google Scholar] [CrossRef]

- Zhang, Y.H.; Xu, J.F.; Hu, Y.Q.; Ding, S.H.; Wu, W.W.; Xia, R. Nanoindentation and nanotribology behaviors of open-cell metallic glass nanofoams. Int. J. Mech. Sci. 2023, 249, 108254. [Google Scholar] [CrossRef]

- Tran, A.S.; Doan, D.Q.; Chu, V.T. Molecular simulation study on mechanical properties and elastic recovery of nanoimprinted CuAgAu metallic glasses. J. Non-Cryst. Solids 2022, 596, 121861. [Google Scholar] [CrossRef]

- Şopu, D.; Scudino, S.; Bian, X.L.; Gammer, C.; Eckert, J. Atomic-scale origin of shear band multiplication in heterogeneous metallic glasses. Scr. Mater. 2020, 178, 57–61. [Google Scholar] [CrossRef]

- Li, J.J.; Zhang, Y.H.; Tian, C.Y.; Zhou, H.J.; Hu, G.M.; Xia, R. Structurally ordered nanoporous Pt-Co alloys with enhanced mechanical behaviors in tension. Microporous Mesoporous Mater. 2020, 295, 109955. [Google Scholar] [CrossRef]

- Hu, Y.Q.; Xu, J.F.; Su, L.; Zhang, Y.H.; Ding, S.H.; Xia, R. Atomistic simulations of mechanical characteristics dependency on relative density, grain size, and temperature of nanoporous tungsten. Phys. Scr. 2022, 98, 015715. [Google Scholar] [CrossRef]

- Li, J.J.; Tian, C.Y.; Lu, B.B.; Xian, Y.H.; Wu, R.N.; Hu, G.M.; Xia, R. Deformation behavior of nanoporous gold based composite in compression: A finite element analysis. Compos. Struct. 2019, 211, 229–235. [Google Scholar] [CrossRef]

- Cahn, J.W.; Hilliard, J.E. Free energy of a nonuniform system. I. Interfacial free energy. J. Chem. Phys. 1958, 28, 258–267. [Google Scholar] [CrossRef]

- Sun, X.Y.; Xu, G.K.; Li, X.Y.; Feng, X.Q.; Gao, H.J. Mechanical properties and scaling laws of nanoporous gold. J. Appl. Phys. 2013, 113, 023505. [Google Scholar] [CrossRef]

- Stuckner, J.; Frei, K.; Mccue, I.; Demkowicz, M.J.; Murayama, M. AQUAMI: An open source Python package and GUI for the automatic quantitative analysis of morphologically complex multiphase materials. Comput. Mater. Sci. 2017, 139, 320–329. [Google Scholar] [CrossRef]

- Saffarini, M.H.; Sewell, T.; Su, Y.C.; Chen, Z. Atomistic study of the impact response of bicontinuous nanoporous gold as a protection medium: Effect of porous-nonporous interface on failure evolution. Comput. Mater. Sci. 2023, 228, 112363. [Google Scholar] [CrossRef]

- Li, J.J.; Li, J.; Chen, Y.H.; Chen, J. Strengthening Modulus and Softening Strength of Nanoporous Gold in Multiaxial Tension: Insights from Molecular Dynamics. Nanomaterials 2022, 12, 4381. [Google Scholar] [CrossRef] [PubMed]

- Voyiadjis, G.Z.; Saffarini, M.H.; Ruestes, C.J. Characterization of the strain rate effect under uniaxial loading for nanoporous gold. Comput. Mater. Sci. 2021, 194, 110425. [Google Scholar] [CrossRef]

- Vu, T.N.; Pham, V.; Fang, T.H. Maintain sort order of grain boundary to investigate the deformation mechanism of CoCuFeNiPd high-entropy alloys. Curr. Appl. Phys. 2024, 59, 46–59. [Google Scholar] [CrossRef]

- Vu, T.N.; Pham, V.T.; Fang, T.H. Effects of structure and strain rate on deformation mechanism of twin lamellar Al CoCrFeNi alloys. J. Alloys Compd. 2023, 954, 170174. [Google Scholar] [CrossRef]

- Saffarini, M.H.; Voyiadjis, G.Z.; Ruestes, C.J. Temperature effect on nanoporous gold under uniaxial tension and compression. Comput. Mater. Sci. 2021, 200, 110766. [Google Scholar] [CrossRef]

- Farkas, D.; Caro, A.; Bringa, E.; Crowson, D. Mechanical response of nanoporous gold. Acta Mater. 2013, 61, 3249–3256. [Google Scholar] [CrossRef]

- Lührs, L.; Zandersons, B.; Huber, N.; Weissmüller, J. Plastic Poisson’s Ratio of Nanoporous Metals: A Macroscopic Signature of Tension–Compression Asymmetry at the Nanoscale. Nano Lett. 2017, 17, 6258–6266. [Google Scholar] [CrossRef] [PubMed]

- Zhao, L.; Chan, K.C.; Chen, S.H.; Feng, S.D.; Han, D.X.; Wang, G. Tunable tensile ductility of metallic glasses with partially rejuvenated amorphous structures. Acta Mater. 2019, 169, 122–134. [Google Scholar] [CrossRef]

- Zhou, H.F.; Zhong, C.; Cao, Q.P.; Qu, S.X.; Wang, X.D.; Yang, W.; Jiang, J.Z. Non-localized deformation in metallic alloys with amorphous structure. Acta Mater. 2014, 68, 32–41. [Google Scholar] [CrossRef]

- Zhou, X.L.; Zhou, H.F.; Li, X.Y.; Chen, C.Q. Size effects on tensile and compressive strengths in metallic glass nanowires. J. Mech. Phys. Solids 2015, 84, 130–144. [Google Scholar] [CrossRef]

| Temperature (K) | Et (GPa) | Ec (GPa) | Et − Ec (GPa) |

|---|---|---|---|

| 100 | 5.863 | 5.704 | 0.158 |

| 200 | 5.535 | 5.385 | 0.150 |

| 300 | 5.189 | 4.960 | 0.229 |

| 400 | 4.869 | 4.566 | 0.302 |

| 500 | 4.499 | 4.176 | 0.322 |

| 600 | 4.071 | 3.732 | 0.339 |

| Temperature (K) | εyt | εyc | εyt − εyc | σyt (GPa) | σyc (GPa) | σyt − σyc (GPa) |

|---|---|---|---|---|---|---|

| 100 | 0.0430 | 0.0372 | 0.0058 | 0.240 | 0.201 | 0.0396 |

| 200 | 0.0429 | 0.0362 | 0.0067 | 0.226 | 0.184 | 0.0422 |

| 300 | 0.0422 | 0.0369 | 0.0053 | 0.209 | 0.173 | 0.0355 |

| 400 | 0.0413 | 0.0354 | 0.0059 | 0.191 | 0.153 | 0.0388 |

| 500 | 0.0402 | 0.0361 | 0.0041 | 0.172 | 0.142 | 0.0295 |

| 600 | 0.0414 | 0.0351 | 0.0063 | 0.160 | 0.124 | 0.0369 |

| Temperature (K) | σpt (GPa) | σpt/σyt (GPa) | Strain at the Stress Drop Point | Stress at the Stress Drop Point (GPa) |

|---|---|---|---|---|

| 100 | 0.277 | 1.15 | 0.153 | 0.196 |

| 200 | 0.262 | 1.15 | 0.157 | 0.191 |

| 300 | 0.242 | 1.15 | 0.182 | 0.168 |

| 400 | 0.225 | 1.17 | 0.188 | 0.158 |

| 500 | 0.206 | 1.20 | 0.208 | 0.142 |

| 600 | 0.186 | 1.16 | 0.268 | 0.113 |

| Temperature (K) | Percentage of Atoms in the Initial Tensile State (%) | Percentage of Atoms in the Initial Compressive State (%) | ||

|---|---|---|---|---|

| Ligament Surface | Ligament Core | Ligament Surface | Ligament Core | |

| 100 | 92.8 | 47.6 | 7.2 | 52.4 |

| 200 | 90.8 | 47.8 | 9.2 | 52.2 |

| 300 | 89.1 | 48.1 | 10.9 | 51.9 |

| 400 | 87.4 | 48.3 | 12.6 | 51.7 |

| 500 | 85.7 | 48.4 | 14.3 | 51.6 |

| 600 | 84.2 | 48.6 | 15.8 | 51.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Zhou, H.; Liu, X. Mechanical Properties of CuZr Amorphous Metallic Nanofoam at Various Temperatures Investigated by Molecular Dynamics Simulation. Materials 2025, 18, 3423. https://doi.org/10.3390/ma18143423

Zhang Y, Zhou H, Liu X. Mechanical Properties of CuZr Amorphous Metallic Nanofoam at Various Temperatures Investigated by Molecular Dynamics Simulation. Materials. 2025; 18(14):3423. https://doi.org/10.3390/ma18143423

Chicago/Turabian StyleZhang, Yuhang, Hongjian Zhou, and Xiuming Liu. 2025. "Mechanical Properties of CuZr Amorphous Metallic Nanofoam at Various Temperatures Investigated by Molecular Dynamics Simulation" Materials 18, no. 14: 3423. https://doi.org/10.3390/ma18143423

APA StyleZhang, Y., Zhou, H., & Liu, X. (2025). Mechanical Properties of CuZr Amorphous Metallic Nanofoam at Various Temperatures Investigated by Molecular Dynamics Simulation. Materials, 18(14), 3423. https://doi.org/10.3390/ma18143423