Lap Welding of Nickel-Plated Steel and Copper Sheets Using Coaxial Laser Beams

Abstract

1. Introduction

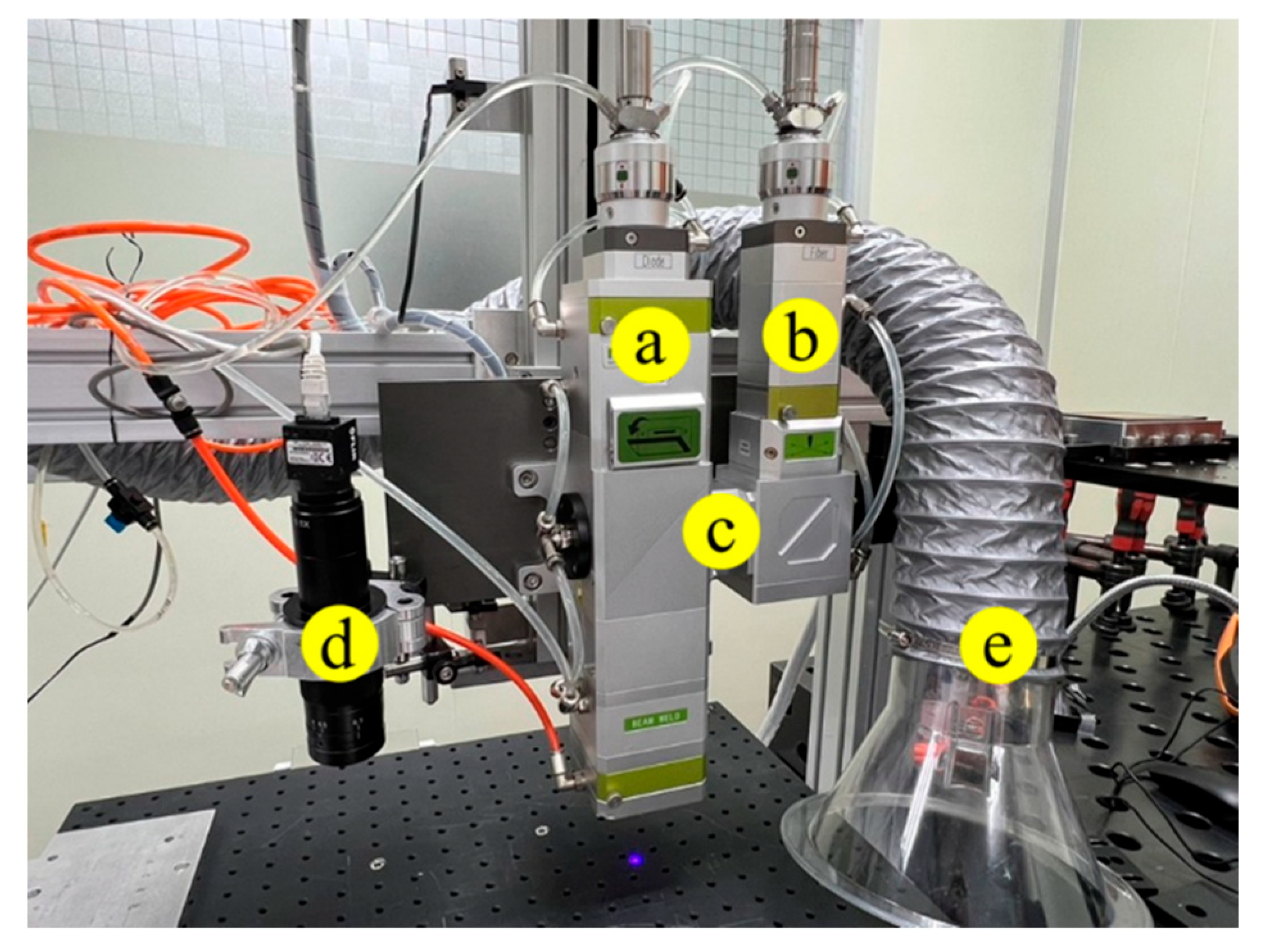

2. Materials and Experimental

3. Results and Discussion

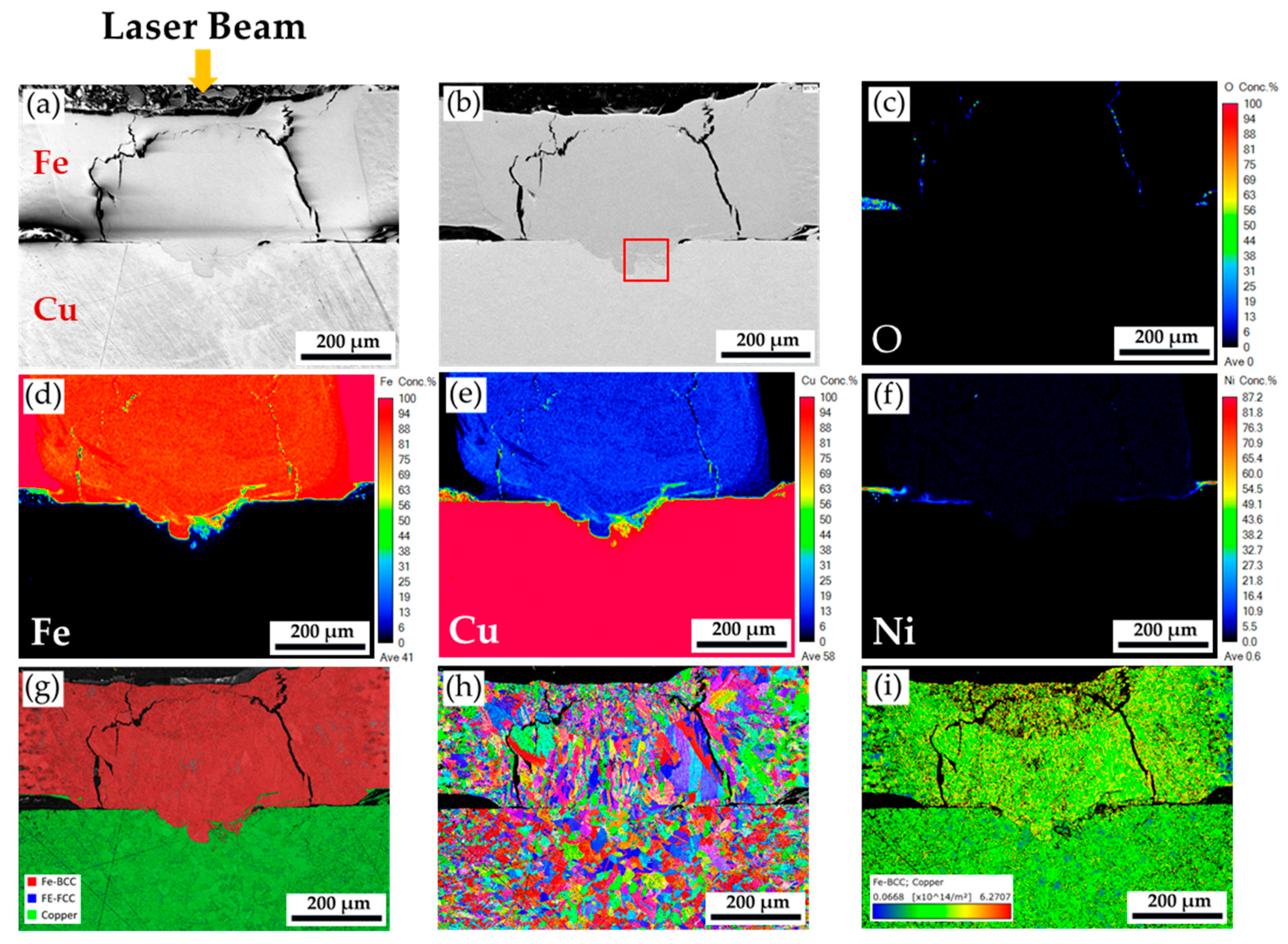

3.1. Microstructural Analyses of the YAG Laser Spot Welding Specimen

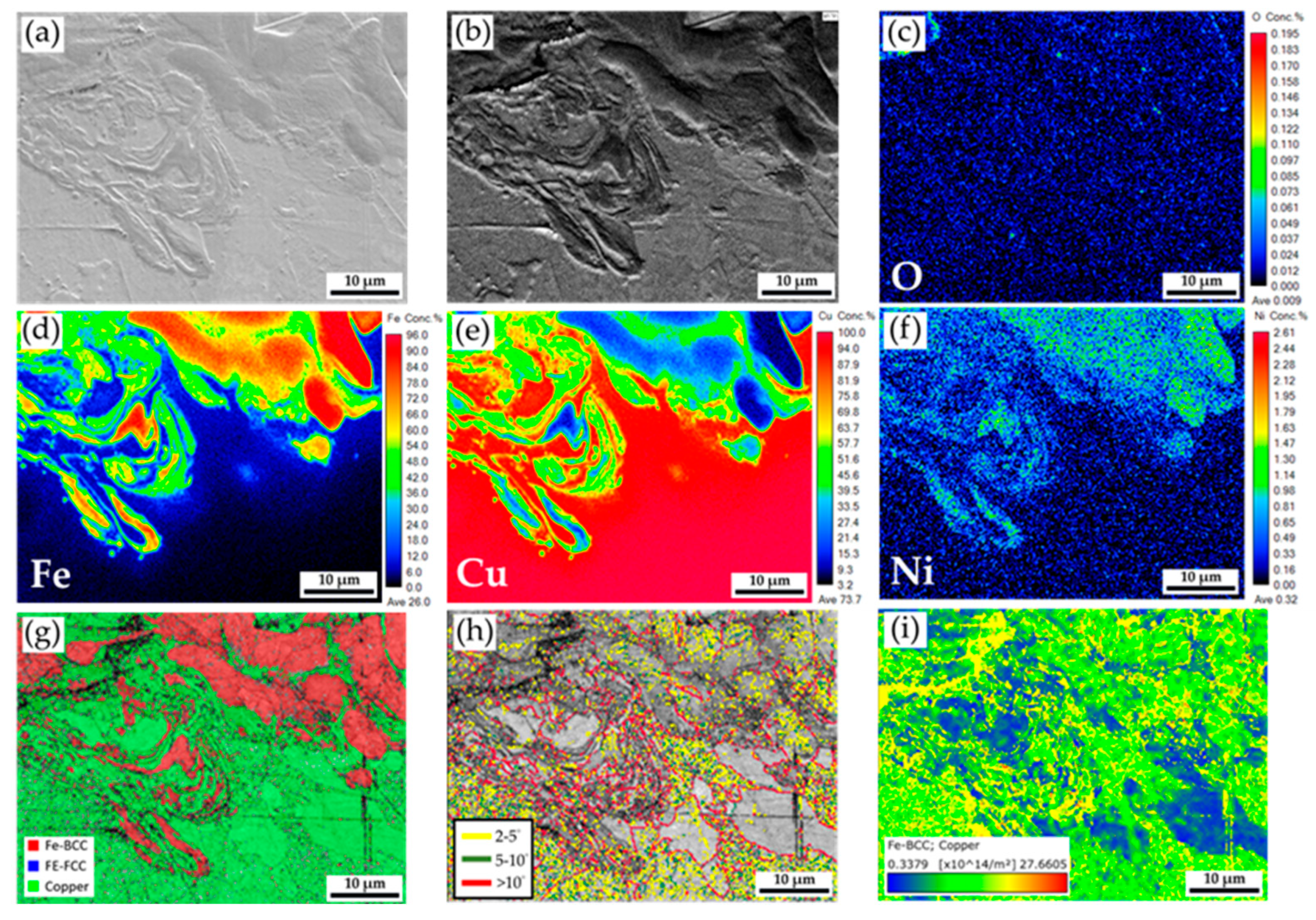

3.2. Microstructural Analyses of the Fiber/Blue-Light Coaxial Laser Spot Welding Specimen

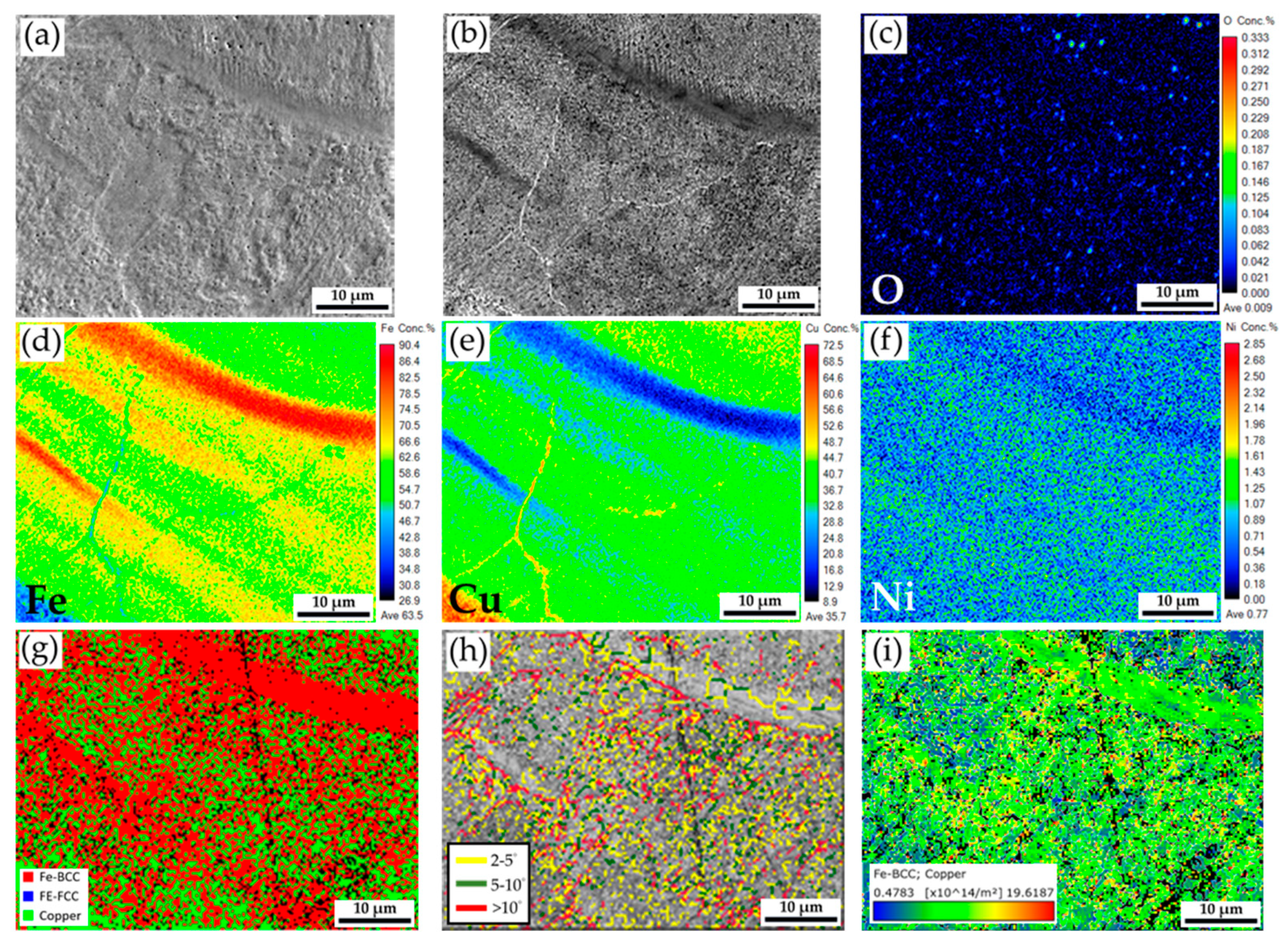

3.3. Microstructural Analyses of the Fiber/Blue-Light Coaxial Laser Continuous Welding Specimen

3.4. The Advantages of the Coaxial Laser Beam in Lap Welding the Nickel-Plated Steel and Copper Sheets

4. Conclusions

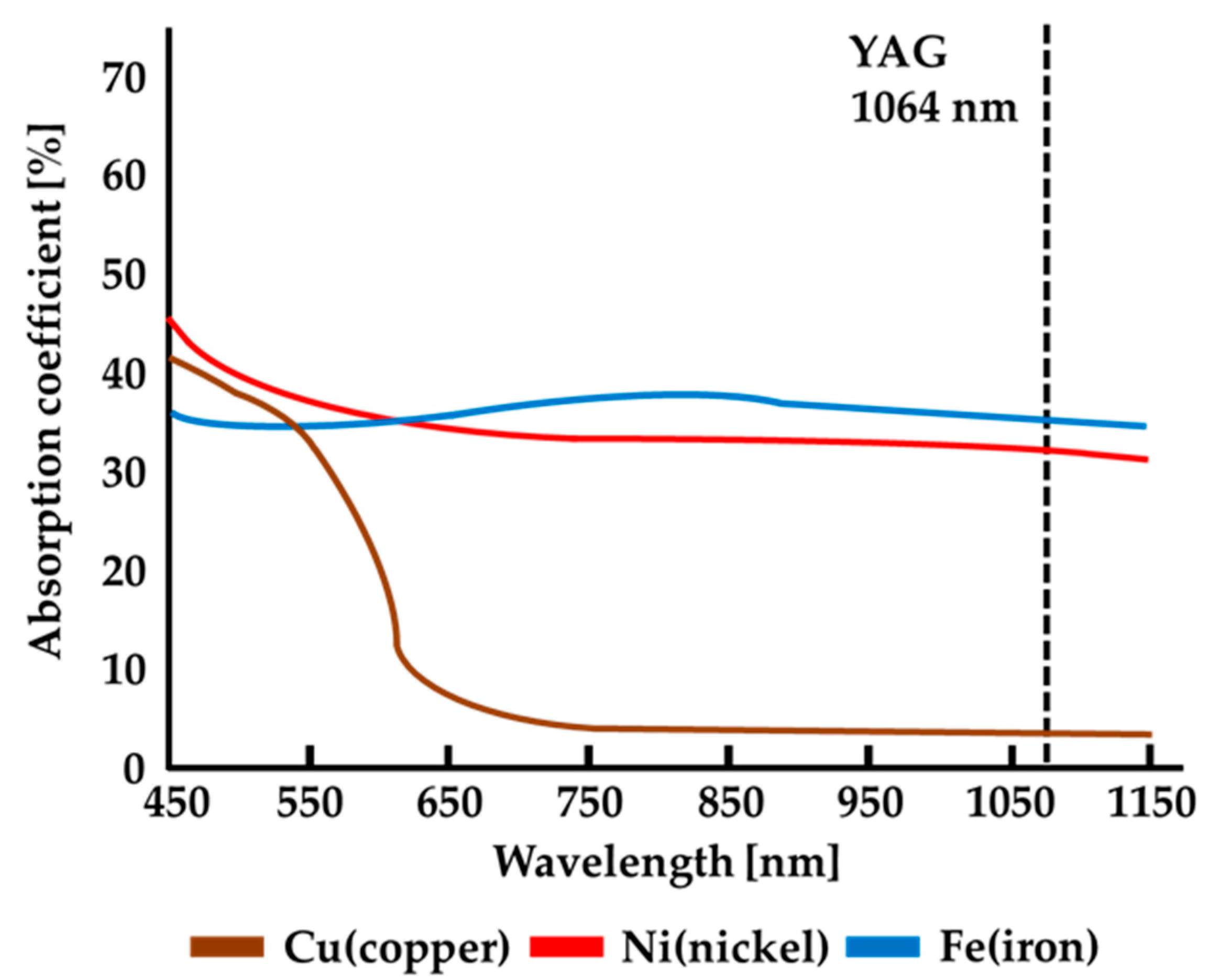

- The YAG laser beam only penetrates the upper Ni-plated steel sheet and cannot weld the bottom Cu sheet due to the extremely low absorption coefficient of the YAG laser beam. The laser beam has little effect on melting Cu, and only stratification occurs at the interfacial gap between the upper Ni-plated steel and the bottom Cu plate. The YAG laser is inappropriate for welding Ni-plated steel and Cu sheets.

- Introducing the blue-light laser into the coaxial laser beam significantly improves the spot welding specimen’s quality due to the blue-light laser’s high absorption coefficient by the bottom copper sheet. The fiber laser beam can penetrate the nickel-plated steel sheet, and the blue-light laser beam can melt the bottom copper sheet. The plated nickel layer on the steel sheet is completely dissolved into the weld fusion zone, and a mixture of Fe and Cu is achieved in the weld.

- Introducing the blue-light laser to the coaxial laser beams overcame the reflectivity of the bottom copper sheet. The fiber/blue-light coaxial laser continuous welding can achieve the best integrity and defect-free welding. It shows potential in the mass production of the next generation of lithium batteries.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gomez, W.G.; Wang, F.K.; Chou, J.H. Li-ion battery capacity prediction using improved temporal fusion transformer model. Energy 2024, 296, 131114. [Google Scholar] [CrossRef]

- Zhang, J.; Huang, H.; Zhang, G.; Dai, Z.; Wen, Y.; Jiang, L. Cycle life studies of lithium-ion power batteries for electric vehicles: A review. J. Energy Storage 2024, 93, 112231. [Google Scholar] [CrossRef]

- Zubi, G.; Dufo-López, R.; Carvalho, M.; Pasaoglu, G. The lithium-ion battery: State of the art and future perspectives. Renew. Sustain. Energy Rev. 2018, 89, 292–308. [Google Scholar] [CrossRef]

- Zhu, P.; Gastol, D.; Marshall, J.; Sommerville, R.; Goodship, V.; Kendrick, E. A review of current collectors for lithium-ion batteries. J. Power Source 2021, 485, 229321. [Google Scholar] [CrossRef]

- Reddy, M.V.; Mauger, A.; Julien, C.M.; Paolella, A.; Zaghib, K. Brief history of early lithium-battery development. Materials 2020, 13, 1884. [Google Scholar] [CrossRef] [PubMed]

- Kim, T.; Song, W.; Son, D.Y.; Ono, L.K.; Qi, Y. Lithium-ion batteries: Outlook on present, future, and hybridized technologies. J. Mater. Chem. A 2019, 7, 2942–2964. [Google Scholar] [CrossRef]

- He, J.; Meng, J.; Huang, Y. Challenges and recent progress in fast-charging lithium-ion battery materials. J. Power Source 2023, 570, 232965. [Google Scholar] [CrossRef]

- Schmalstieg, J.; Käbitz, S.; Ecker, M.; Sauer, D.U. A holistic aging model for Li(NiMnCo)O2 based 18650 lithium-ion batteries. J. Power Source 2014, 257, 325–334. [Google Scholar] [CrossRef]

- Armand, M.; Axmann, P.; Bresser, D.; Copley, M.; Edström, K.; Ekberg, C.; Guyomard, D.; Lestriez, B.; Novák, P.; Petranikova, M.; et al. Lithium-ion batteries—Current state of the art and anticipated developments. J. Power Source 2020, 479, 228708. [Google Scholar] [CrossRef]

- Pegel, H.; Wycisk, D.; Sauer, D.W. Influence of cell dimensions and housing material on the energy density and fast-charging performance of tabless cylindrical lithium-ion cells. Energy Storage Mater. 2023, 60, 102796. [Google Scholar] [CrossRef]

- Rikka, V.R.; Sahu, S.R.; Roy, A.; Jana, S.N.; Sivaprahasam, D.; Prakash, R.; Gopalan, R.; Sundararajan, G. Tailoring micro resistance spot welding parameters for joining nickel tab to inner aluminium casing in a cylindrical lithium ion cell and its influence on the electrochemical performance. J. Manuf. Process 2020, 49, 463–471. [Google Scholar] [CrossRef]

- Bieliszczuk, K.; Zręda, J.; Chmielewski, T. Selected properties of aluminum ultrasonic wire bonded joints with nickel-plated steel substrate for 18650 cylindrical cells. J. Adv. Joining Process 2024, 9, 100197. [Google Scholar] [CrossRef]

- Kumar, N.; Ramakrishnan, S.M.; Panchapakesan, K.; Subramaniam, D.; Dowson, M.; Das, A. Utilizing a novel multi-electrode approach for improving micro-resistance spot welding productivity for electric-mobility battery interconnects. Sci. Technol. Weld. Join. 2023, 28, 643–652. [Google Scholar] [CrossRef]

- Mo, J.; Zhang, G.; Zhang, J.; Mo, C.; Wang, B.; Guo, S.; Jiang, R.; Liu, J.; Peng, K. Effect of cold welding on the inconsistencies and thermal safety of battery modules based on a constructed discharge model. Appl. Energy 2025, 377, 124570. [Google Scholar] [CrossRef]

- Schmitz, P.; Habedank, J.B.; Zaeh, M.F. Spike laser welding for the electrical connection of cylindrical lithium-ion batteries. J. Laser Appl. 2018, 30, 012004. [Google Scholar] [CrossRef]

- Ding, D.H.; Pan, Z.X.; Cuiuri, D.; Li, H.J. Wire-feed additive manufacturing of metal components: Technologies, developments and future interests. Int. J. Adv. Manuf. Technol. 2015, 81, 465–481. [Google Scholar] [CrossRef]

- Verma, J.; Taiwade, R.V. Effect of welding processes and conditions on the microstructure, mechanical properties and corrosion resistance of duplex stainless steel weldments—A review. J. Manuf. Process 2017, 25, 134–152. [Google Scholar] [CrossRef]

- Çam, G.; Ipekoglu, G. Recent developments in joining of aluminum alloys. Int. J. Adv. Manuf. Technol. 2017, 91, 1851–1866. [Google Scholar] [CrossRef]

- Klimpel, A. Review and analysis of modern laser beam welding processes. Materials 2024, 17, 4657. [Google Scholar] [CrossRef] [PubMed]

- Pfleging, W. Recent progress in laser texturing of battery materials: A review of tuning electrochemical performances, relatedmaterial development, and prospects for large-scale manufacturing. Int. J. Extrem. Manuf. 2021, 3, 012002. [Google Scholar] [CrossRef]

- Kou, S. Welding Metallurgy, 2nd ed.; John Wiley & Sons: New York, NY, USA, 2003. [Google Scholar]

- Lippold, J.C. Welding Metallurgy and Weldability; John Wiley & Sons: New York, NY, USA, 2015. [Google Scholar]

- Helm, J.; Schulz, A.; Olowinsky, A.; Dohrn, A.; Poprawe, R. Laser welding of laser-structured copper connectors for battery applications and power electronics. Weld. World 2020, 64, 611–622. [Google Scholar] [CrossRef]

- Maina, M.R.; Okamoto, Y.; Inoue, R.; Nakashiba, S.I.; Okada, A.; Sakagawa, T. Influence of surface state in micro-welding of copper by Nd: YAG Laser. Appl. Sci. 2018, 8, 2364. [Google Scholar] [CrossRef]

- Gao, X. Laser welding technology. Metals 2025, 15, 86. [Google Scholar] [CrossRef]

- Ready, J.F. Industrial Applications of Lasers, 2nd ed.; Academic Press: San Diego, CA, USA, 1997. [Google Scholar]

- Mattern, M.; Kukreja, L.M.; Ostendorf, A. Temperature-dependent reflectance of copper with different surface conditions measured at 1064 nm. J. Mater. Eng. Perform. 2024, 33, 2897–2909. [Google Scholar] [CrossRef]

- Mitelea, I.; Groza, C.; Craciunescu, C. Copper interlayer contribution on Nd: YAG laser welding of dissimilar Ti-6Al-4V alloy with X5CrNi18-10 steel. J. Mater. Eng. Perform. 2013, 22, 2219–2223. [Google Scholar] [CrossRef]

- Lerra, F.; Ascari, A.; Fortunato, A. The influence of laser pulse shape and separation distance on dissimilar welding of Al and Cu films. J. Manuf. Process 2019, 45, 331–339. [Google Scholar] [CrossRef]

- Fujio, S.; Sato, Y.; Sudo, M.; Takenaka, K.; Tojo, K.; Pasang, T.; Tsukamoto, M. Spatter reduction in deep penetration welding of pure copper using blue-IR hybrid laser. Weld. World 2024, 68, 1515–1524. [Google Scholar] [CrossRef]

- Takenaka, K.; Sato, Y.; Fujio, S.; Nishida, K.; Ito, R.; Hori, E.; Kato, S.; Suwa, M.; Uno, S.; Tojo, K. Bead-on-plate welding of pure copper with a 1.5 kW high-power blue diode laser. Weld. World 2023, 67, 99–107. [Google Scholar] [CrossRef]

- Takenaka, K.; Sato, Y.; Fujio, S.; Tsukamoto, M. Comparison of melting efficiency between blue, green, and IR lasers in pure copper welding. J. Laser Appl. 2023, 35, 042012. [Google Scholar] [CrossRef]

- Fujio, S.; Sato, Y.; Takenaka, K.; Ito, R.; Ito, M.; Harada, M.; Nishikawa, T.; Suga, T.; Tsukamoto, M. Welding of pure copper wires using a hybrid laser system with a blue diode laser and a single-mode fiber laser. J. Laser Appl. 2021, 33, 042056. [Google Scholar] [CrossRef]

- Zediker, M.S.; Fritz, R.D.; Finuf, M.J.; Pelaprat, J.M. Stable keyhole welding of 1 mm thick copper with a 600 W blue laser system. J. Laser Appl. 2019, 31, 022404. [Google Scholar] [CrossRef]

- Chen, C.; Jia, J.; Xu, Q.; Zhang, J.; Long, Y. Study on laser welding of Cu/Ti dissimilar materials using a hybrid light. J. Manuf. Process 2024, 115, 94–107. [Google Scholar] [CrossRef]

- Alter, L.; Heider, A.; Bergmann, J.P. Influence of hydrogen, oxygen, nitrogen, and water vapor on the formation of pores at welding of copper using laser light at 515 nm wavelength. J. Laser Appl. 2020, 32, 022020. [Google Scholar] [CrossRef]

- Massalski, T.B. Binary Alloy Phase Diagrams, 2nd ed.; ASM International: Materials Park, USA, 1992. [Google Scholar]

- Chen, Y.Z.; Liu, F.; Yang, G.C.; Xu, X.Q.; Zhou, Y.H. Rapid solidification of bulk undercooled hypoperitectic Fe–Cu alloy. J. Alloy. Comp. 2007, 427, L1–L5. [Google Scholar] [CrossRef]

- Hishida, M.; Kobata, N.; Miyano, K.; Nobuoka, M.; Okada, T.; Noguchi, T. Highly productive laser annealing manufacturing method using continuous blue WBC (wavelength beam combining) technique. Materials 2024, 17, 5399. [Google Scholar] [CrossRef] [PubMed]

- Fakhrutdinova, E.; Reutova, O.; Maliy, L.; Kharlamova, T.; Vodyankina, O.; Svetlichnyi, V. Laser-based synthesis of TiO2-Pt photocatalysts for hydrogen generation. Materials 2022, 15, 7413. [Google Scholar] [CrossRef] [PubMed]

- Jurczyszyn, K.; Trzeciakowski, W.; Woźniak, Z.; Ziółkowski, P.; Trafalski, M. Assessment of effects of laser light combining three wavelengths (450, 520 and 640 nm) on temperature increase and depth of tissue lesions in an ex vivo study. Materials 2020, 13, 5340. [Google Scholar] [CrossRef] [PubMed]

| Type of Laser Welding | Power (W) | Pulse Width (ms) | Spot Size (μm) | Travel Speed (mm/s) |

|---|---|---|---|---|

| YAG laser spot welding | 500 | 12 | 150 | --- |

| Fiber/blue-light coaxial laser spot welding | 1010 (fiber laser) 320 (blue-light laser) | 20 20 | 50 300 | --- |

| Fiber/blue-light coaxial laser continuous welding | 740 (fiber laser) 320 (blue-light laser) | 20 20 | 50 300 | 50 50 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, K.-W.; Chen, Y.-H.; Chu, H.-Y.; Shiue, R.-K. Lap Welding of Nickel-Plated Steel and Copper Sheets Using Coaxial Laser Beams. Materials 2025, 18, 3407. https://doi.org/10.3390/ma18143407

Su K-W, Chen Y-H, Chu H-Y, Shiue R-K. Lap Welding of Nickel-Plated Steel and Copper Sheets Using Coaxial Laser Beams. Materials. 2025; 18(14):3407. https://doi.org/10.3390/ma18143407

Chicago/Turabian StyleSu, Kuan-Wei, Yi-Hsuan Chen, Hung-Yang Chu, and Ren-Kae Shiue. 2025. "Lap Welding of Nickel-Plated Steel and Copper Sheets Using Coaxial Laser Beams" Materials 18, no. 14: 3407. https://doi.org/10.3390/ma18143407

APA StyleSu, K.-W., Chen, Y.-H., Chu, H.-Y., & Shiue, R.-K. (2025). Lap Welding of Nickel-Plated Steel and Copper Sheets Using Coaxial Laser Beams. Materials, 18(14), 3407. https://doi.org/10.3390/ma18143407