A Study on Three-Dimensional Flexible Mesh Influence on the Stability of Reserved Tunnels in Cemented Backfill

Abstract

1. Introduction

2. Experimental Materials and Methods

2.1. Experimental Materials

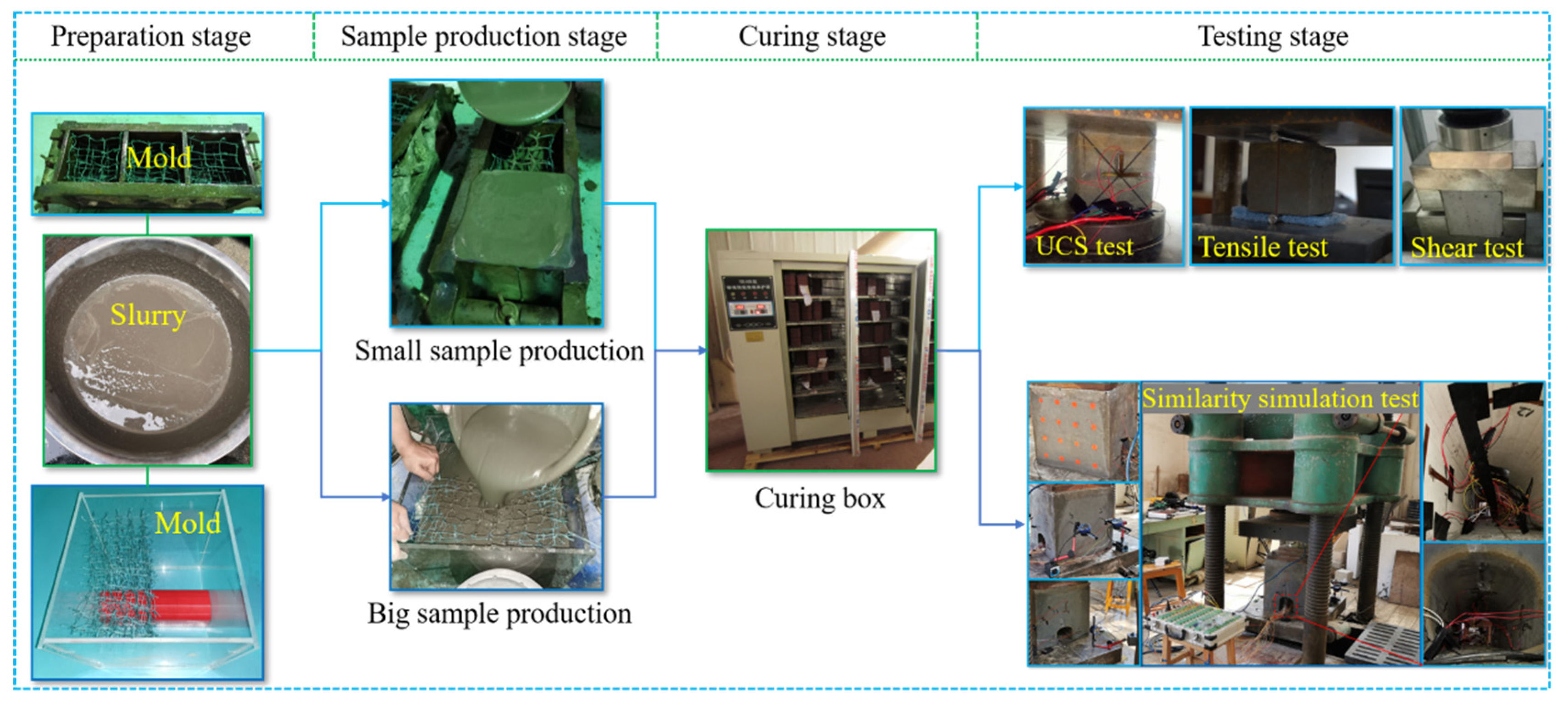

2.2. Experimental Methods

3. Experimental Result

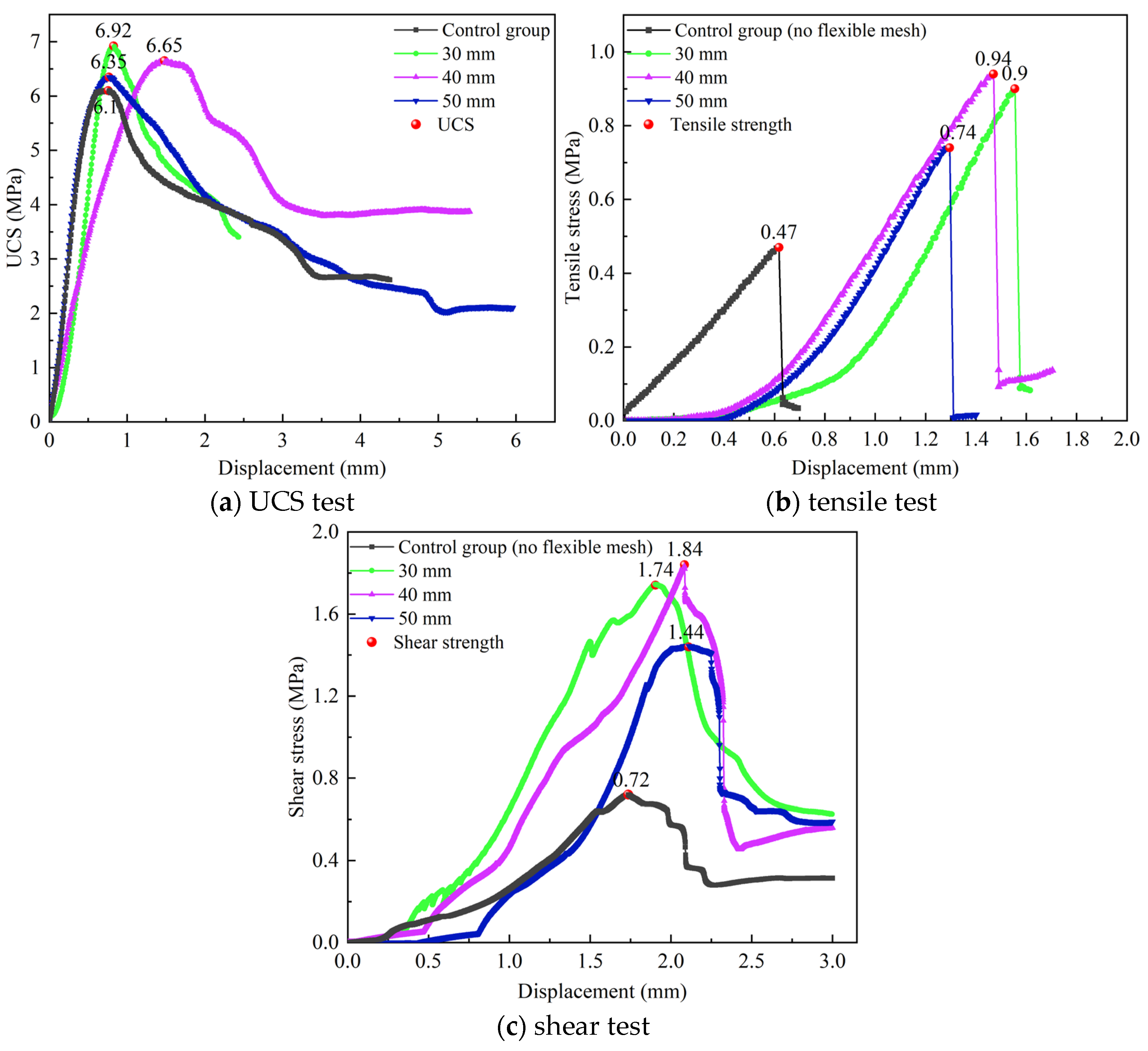

3.1. Mechanical Characteristics

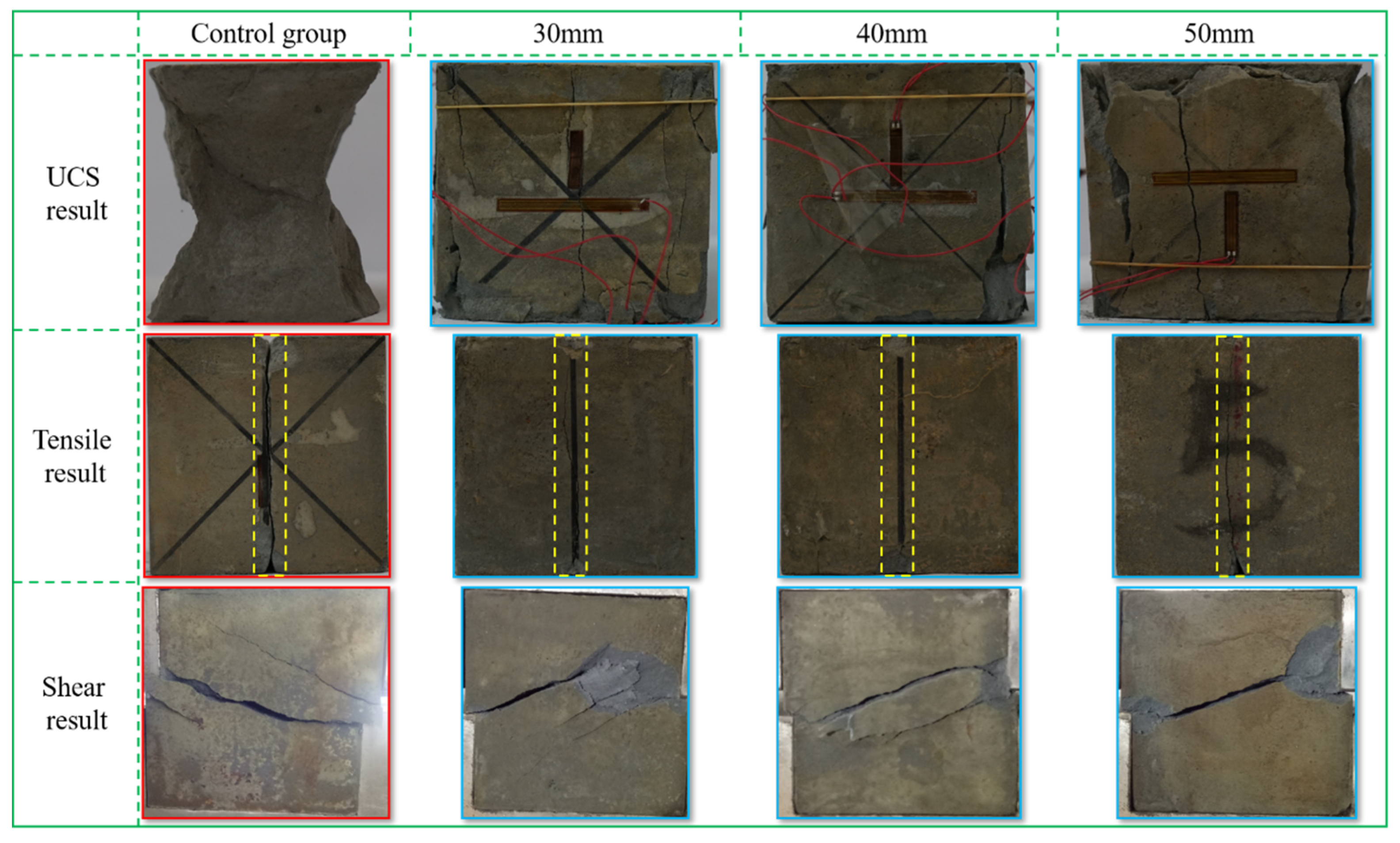

3.2. Failure Mode Analysis

3.3. Strengthening Effect of Flexible Mesh

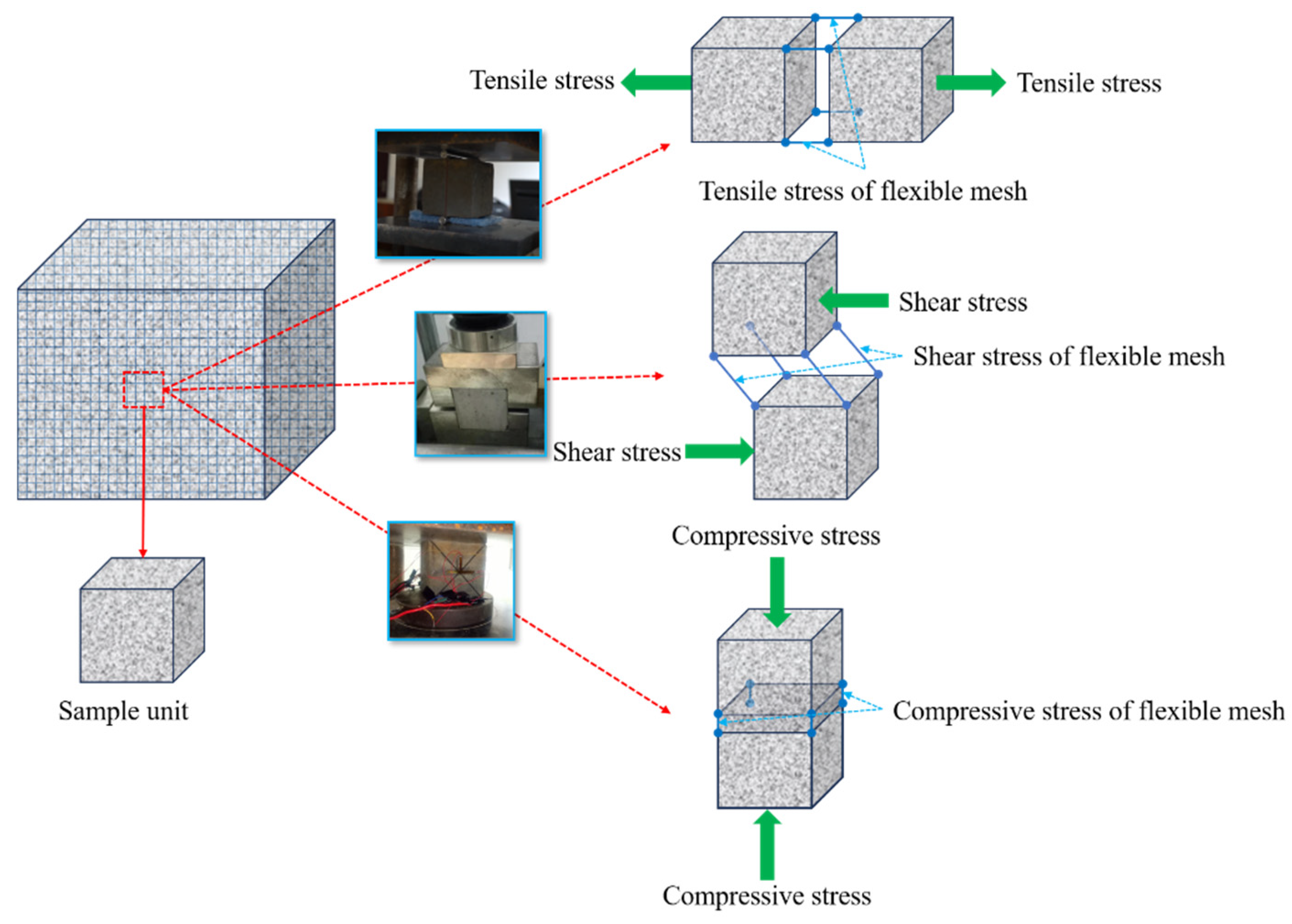

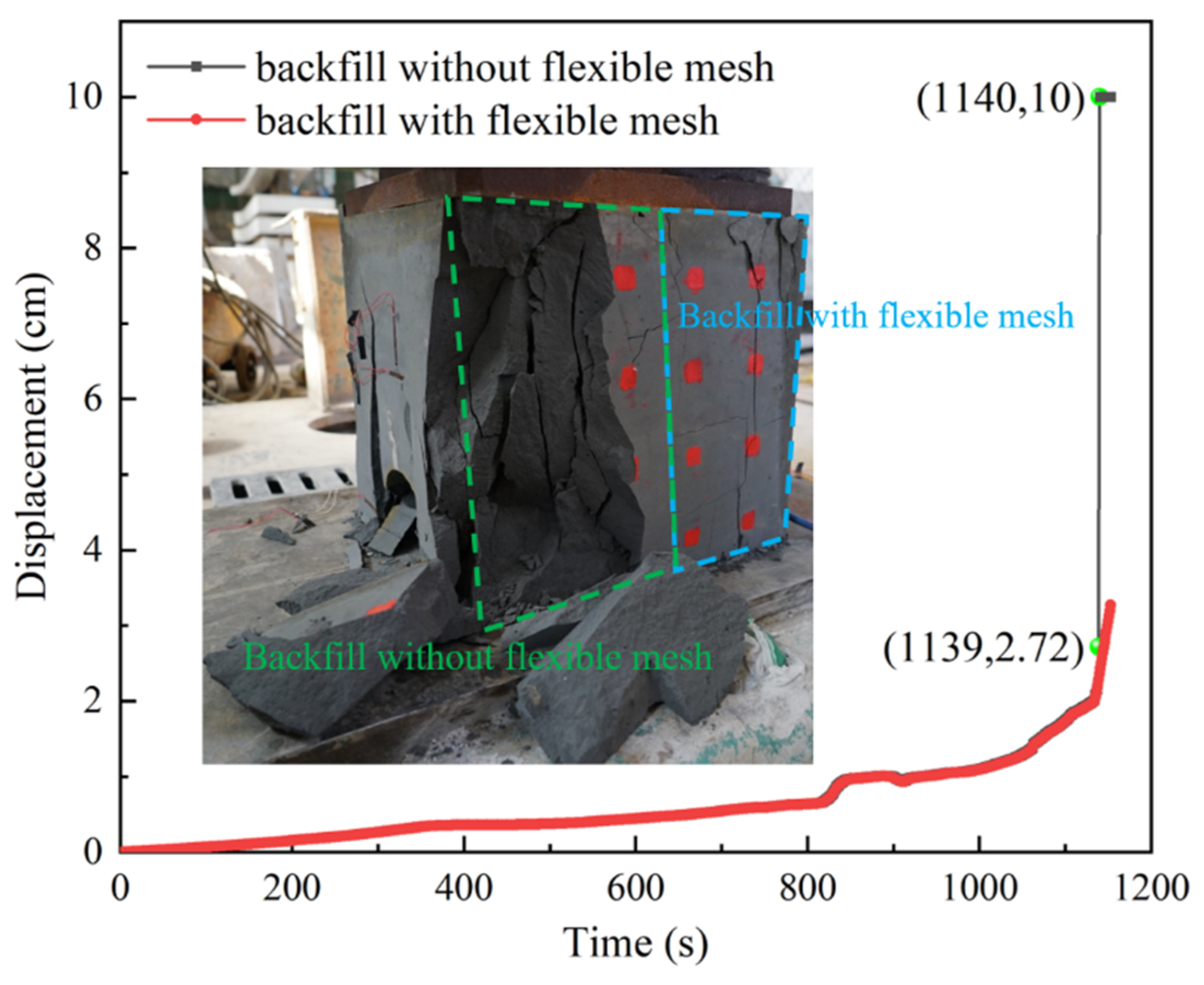

3.4. Deformation and Failure of Backfill

3.5. Deformation and Failure of Surrounding Rock of Reserved Roadway in the Backfill

4. Numerical Simulation

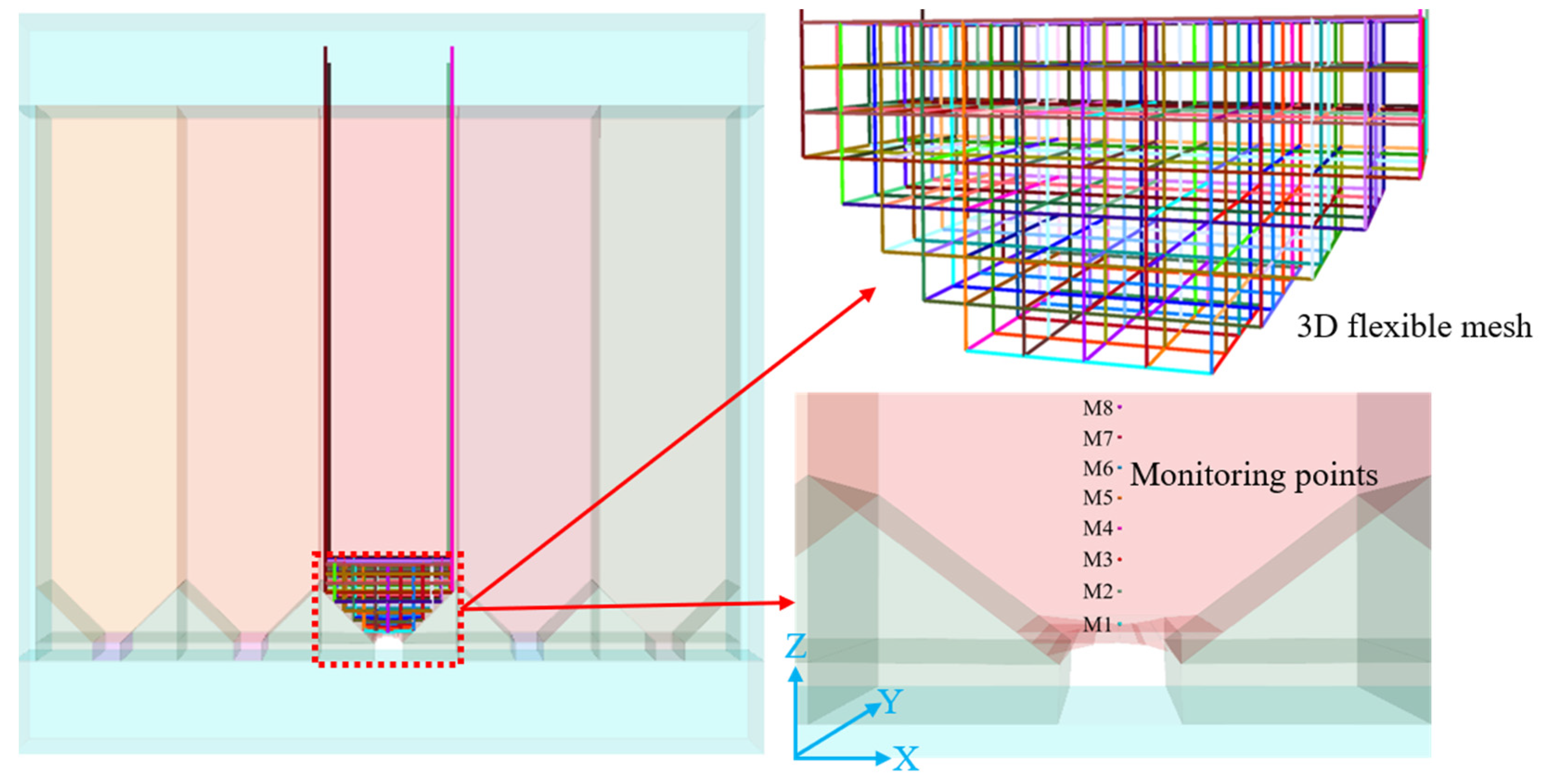

4.1. Model Building

4.2. Simulation Result Analysis

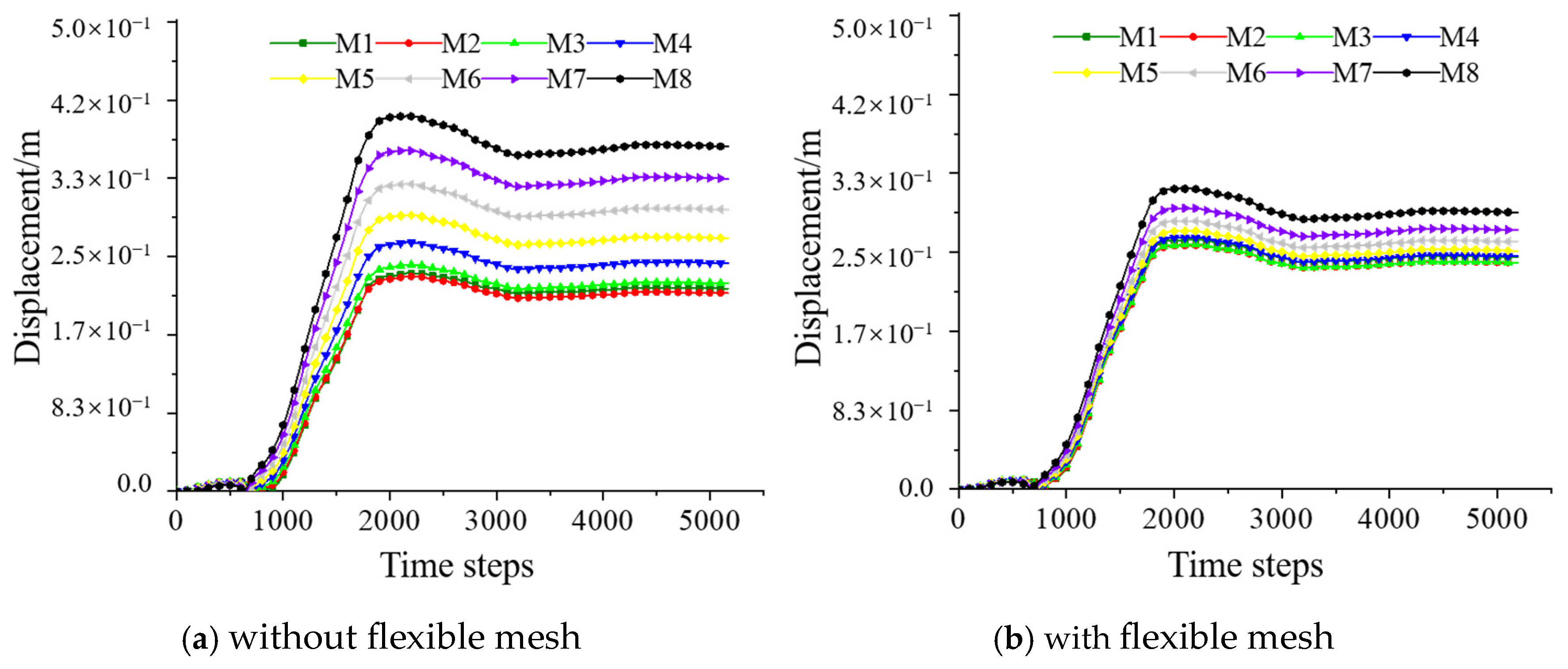

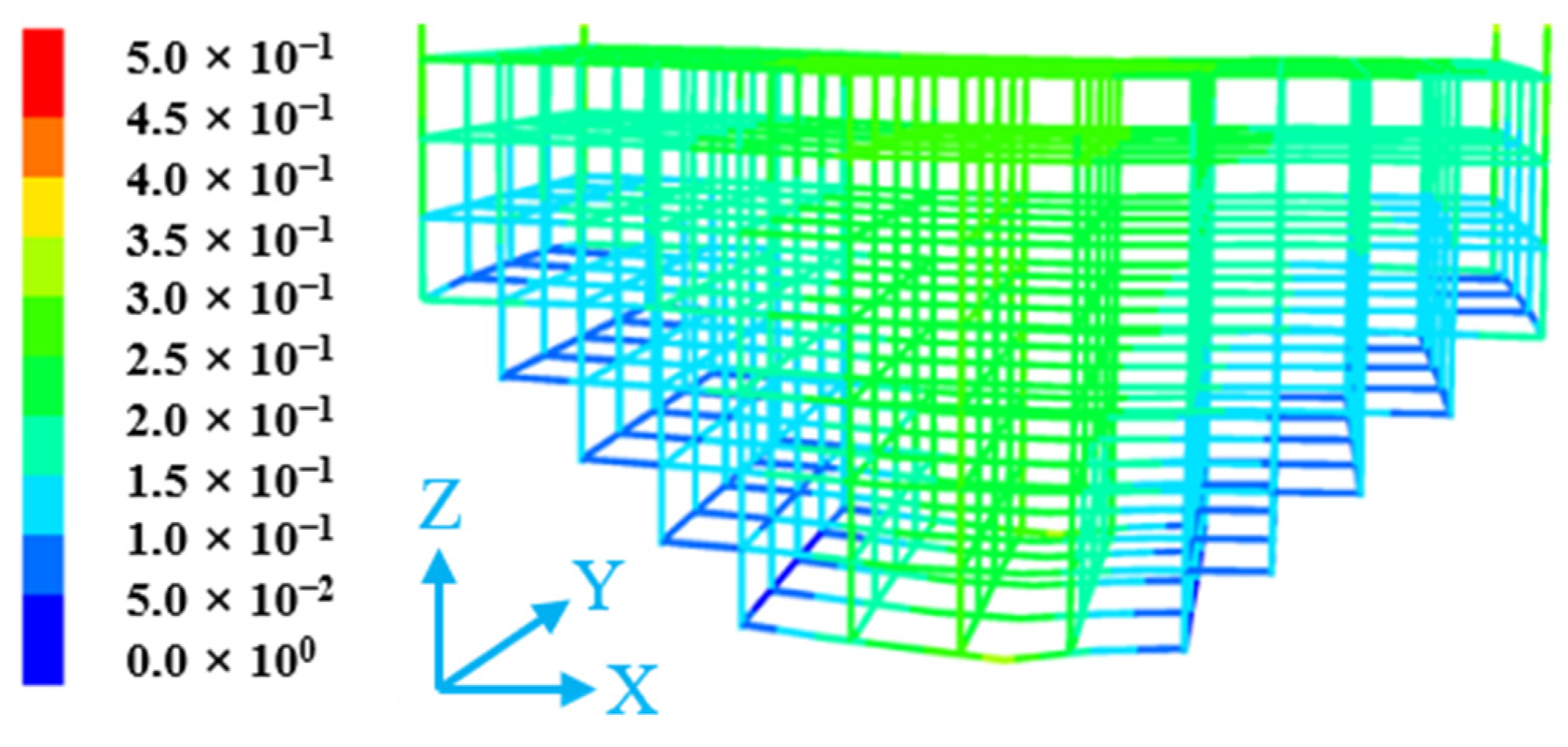

4.2.1. Displacement

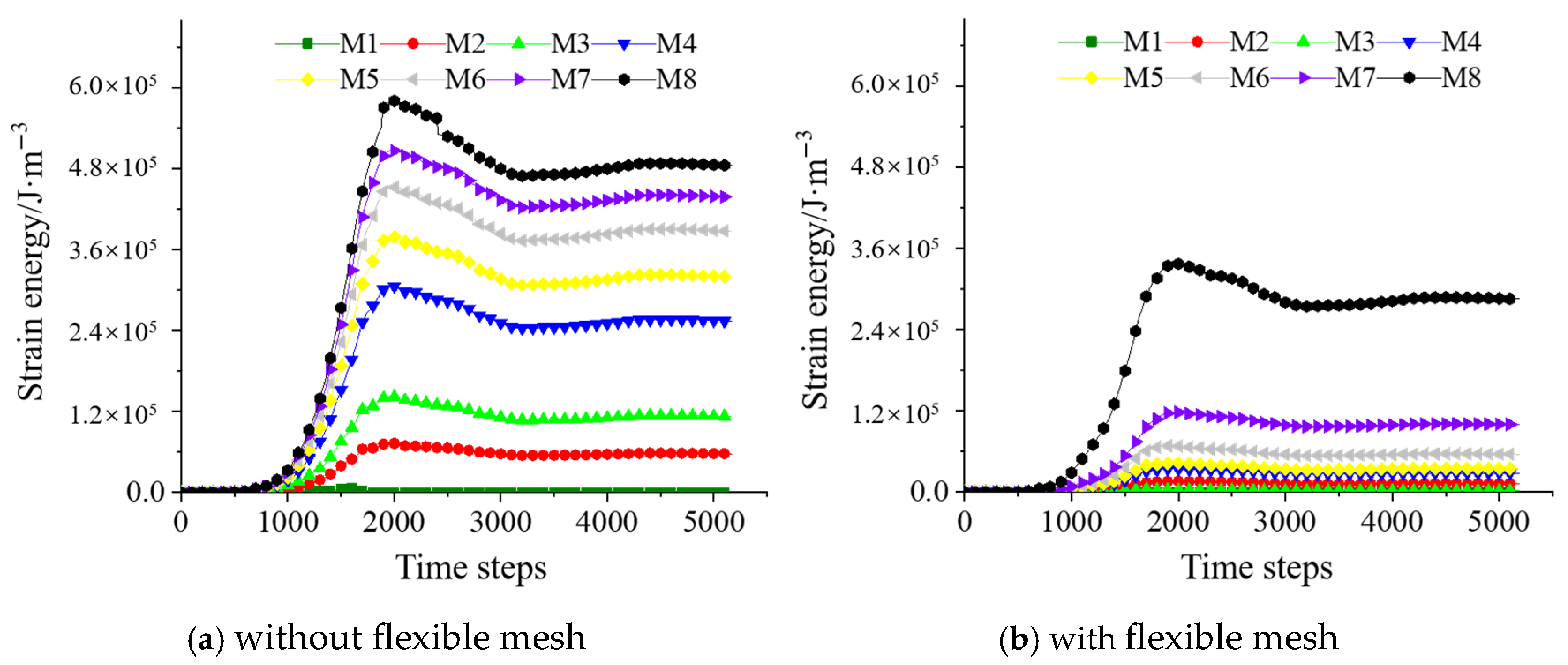

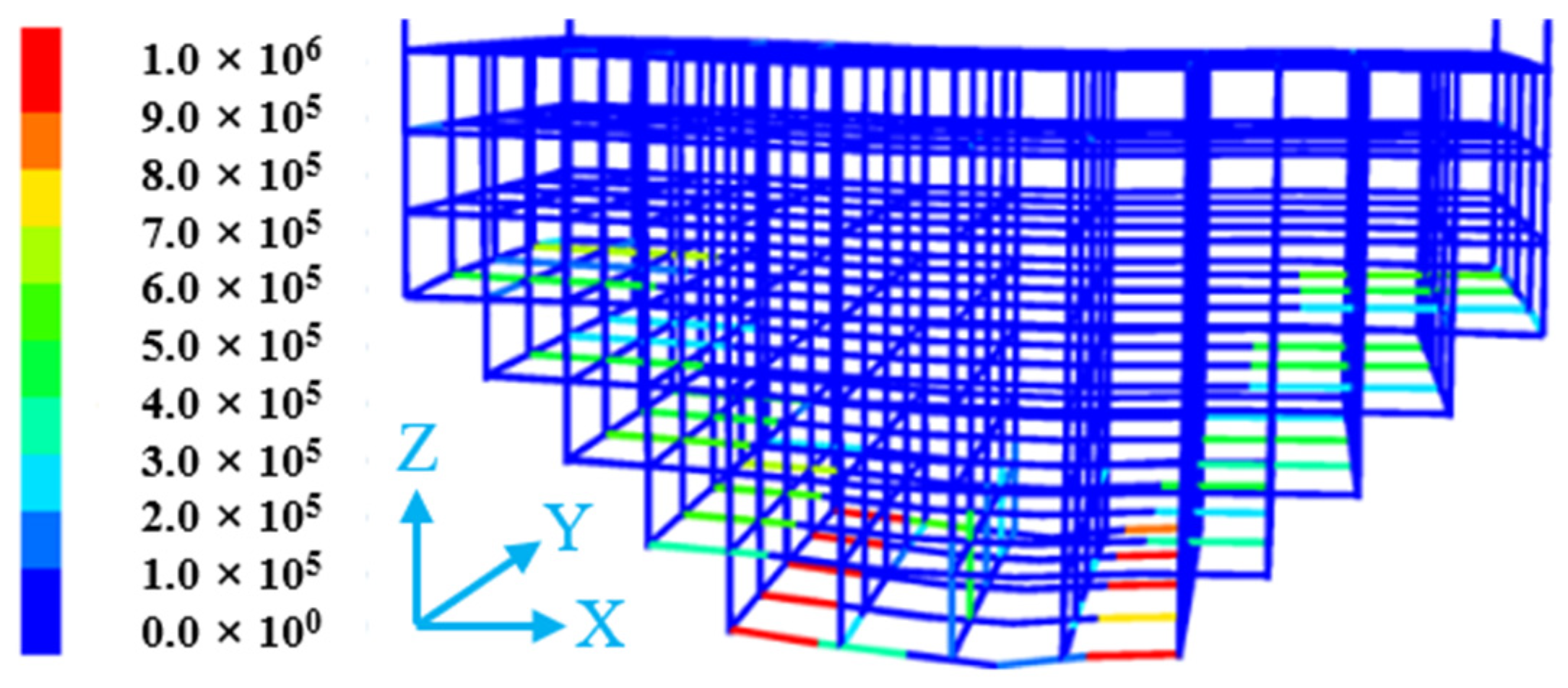

4.2.2. Strain Energy

4.2.3. Flexible Mesh State Analysis

5. Conclusions

- (1)

- The three-dimensional flexible mesh has a strengthening effect on the backfill. After adding the three-dimensional flexible mesh, the various strengths (UCS, tensile strength, and shear strength) of the backfill were improved, the tensile strength and shear strength, especially, being greatly increased. The UCS was 1.04–1.13 times that of the control group, the tensile strength was 1.57–2.00 times that of the control group, and the shear strength was 2.00–2.56 times that of the control group. The adhesion between the flexible mesh and the filling material was the main reason for the strength improvement.

- (2)

- The three-dimensional flexible mesh can ensure the integrity of the backfill. After adding the three-dimensional flexible mesh, there was no fragment detachment of the backfill under external force, showing that it ensures the integrity of the backfill well. The adhesion between the flexible mesh and the fragments of the backfill makes it difficult for the fragments to fall off, which is the main way in which it ensures the integrity of the backfill.

- (3)

- The three-dimensional flexible mesh can reduce the deformation of the surrounding rock in the reserved roadway. After adding the three-dimensional flexible mesh, the displacement trend of the roadway roof and two sides was similar to that without the three-dimensional flexible mesh, but the values were relatively small, and there was no sudden increase in displacement in the later stage. The maximum displacement in the later stage decreased by 50%.

- (4)

- Under static pressure, the three-dimensional flexible mesh has a good supporting effect on the roadway roof. After adding the three-dimensional flexible mesh, the displacement and overall strain energy near the roadway roof in the backfill were smaller than those of the ordinary backfill without the flexible mesh, with a maximum reduction of 21.43% in displacement and a maximum reduction of 40% in strain energy.

- (5)

- Although this study has undertaken much work and obtained many conclusions, there are still some aspects that need further research, such as the influences of dynamic and cyclic loads.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liang, B.; Dong, Q.; Jiang, L.G.; Jia, L.F. Orthogonal experiments for lead-zinc tailings cemented paste backfill material optimal matching scheme. Chin. Saf. Sci. J. 2015, 25, 81–86. [Google Scholar]

- Guo, L.J.; Liu, G.S.; Ma, Q.H.; Chen, X.Z. Research progress on mining with backfill technology of underground metalliferous mine. J. China Coal Soc. 2022, 47, 4182–4200. [Google Scholar]

- Hu, Y.; Li, Z.; Su, Y.; Wu, Y.; Li, X.; Gao, W.; Zhang, X. Analyzing the Energy and Damage Constitutive of Cemented Backfill with Different Water Content under Dynamic Load. Materials 2023, 16, 5677. [Google Scholar] [CrossRef]

- Zhang, S.S.; Yin, T.B. Analysis of stability of tunnel in backfill based on FLAC3D. Chin. Saf. Sci. J. 2017, 27, 85–90. [Google Scholar]

- Lai, J.Z. Analysis of the influence of digging roadways in backfill on the stability of the pillar. Min. Technol. 2024, 24, 226–231. [Google Scholar]

- Jiang, K. Research on excavation roadway support technology in the filling body in stopes. Gold 2022, 43, 38–43. [Google Scholar]

- Jiang, Z.X.; Su, H.; Huang, Y.Q. Optimization and selection of pre support schemes for roadway excavation in the backfill. Min. Technol. 2015, 15, 57–60. [Google Scholar]

- Cheng, A.P.; Dai, S.Y.; Shu, P.F.; Fu, Z.X.; Huang, S.B.; Ye, Z.Y. Creep characteristics and constitutive model of cemented backfill considering stress and damage. J. Chin. Coal Soc. 2021, 46, 439–449. [Google Scholar]

- Hou, G.Y.; Liang, J.P.; Li, X.R. Research on principles and methods of roadway support design under conventional conditions. Chin. J. Rock Mech. Eng. 2022, 41, 691–711. [Google Scholar]

- Xiang, W.H.; Sun, L.L.; Wang, L.J.; Ma, N.; He, W.; Zhou, T. Research on Optimization of Stope Roadway Graded Support Based on BP Neural Network. Coal Technol. 2025, 44, 103–107. [Google Scholar]

- He, W.; Liu, L.; Fang, Z.Y.; Gao, Y.; Sun, W. Effect of polypropylene fiber on properties of modified magnesium-coal-based solid waste backfill materials. Constr. Build. Mater. 2023, 362, 129695. [Google Scholar] [CrossRef]

- Xue, X.L.; Gu, Y.T.; Zhang, X.; Wu, S.; Sun, P.; Cui, J.; Wang, X. Mechanical behavior and microscopic mechanism of fiber reinforced coarse aggregate cemented backfill. Constr. Build. Mater. 2023, 366, 130093. [Google Scholar] [CrossRef]

- Xue, G.L. Research on Multi-Scale Mechanical Properties and Failure Evolution Mechanism of Fiber Reinforced Cemented Tailings Backfill; University of Science and Technology: Beijing, China, 2020. [Google Scholar]

- Li, X.F.; Xiong, Z.Q.; Wang, P. Experimental study on improvement of mechanical properties of high-water filling materials in gob-side entry retaining. Chin. Saf. Sci. J. 2020, 30, 95–100. [Google Scholar]

- Xu, W.B.; Li, Q.L.; Tian, M.M. Strength and deformation properties of polypropylene fiber-reinforced cemented tailings backfill. Chin. J. Eng. 2019, 41, 1618–1626. [Google Scholar]

- Wu, S.H.; Song, L.; Yao, Y.F. Experimental study on the effect of polycopylene fiber, glass fiber and slag on Mechanical properties of cemented tailings backfill. Min. Saf. Environ. Prot. 2022, 49, 62–67. [Google Scholar]

- Zhang, J.; Li, J. Effect of alkalized straw fiber on mechanical properties of tailings backfill. Chin. Concr. Cem. Prod. 2022, 7, 60–63. [Google Scholar]

- Liu, X.S.; Wang, W.J.; Wu, H.; Chen, J.; Zhang, X.; Zhang, L. Experimental study of the mechanical properties of a flexible grid filling body. Appl. Sci. 2023, 13, 5858. [Google Scholar] [CrossRef]

- Zhao, B.C.; Zhai, D.; Chen, P.; Wei, Q.; Wang, R. Damage evolution law and crack expansion characteristics of gangue mented paste backfill. J. Xi’an Univ. Sci. Technol. 2023, 43, 18–27. [Google Scholar]

- Gan, D.Q.; Zhang, Y.J.; Liu, Z.Y.; Sun, H.K. Study on the mechanism of the influence of early damage of cemented backfill on later mechanical properties. Chin. J. Rock Mech. Eng. 2023, 04, 821–832. [Google Scholar]

- Cao, S.; Song, W.D.; Xue, G.L.; Ma, R.W.; Zhu, P.R. Mechanical characteristics variation of standardized cemented tailing backfilling and its failure modes. J. Chin. Univ. Min. Technol. 2016, 45, 717–722. [Google Scholar]

- Wang, J.; Song, W.D.; Cao, S.; Tan, Y. Mechanical properties and failure modes of stratified backfill under triaxial cyclic loading and unloading. Int. J. Min. Sci. Technol. 2019, 29, 809–814. [Google Scholar] [CrossRef]

| Classification | Density (kg/m3) | Max Porosity (%) | Min Porosity (%) | Natural Repose Angle (°) |

|---|---|---|---|---|

| value | 1943 | 49.5 | 37.5 | 37.6 |

| Group | Control Group | 30 mm | 40 mm | 50 mm |

|---|---|---|---|---|

| UCS/MPa | 6.10 | 6.92 | 6.65 | 6.35 |

| tensile strength/MPa | 0.47 | 0.90 | 0.94 | 0.74 |

| shear strength/MPa | 0.72 | 1.74 | 1.84 | 1.44 |

| Group | 30 mm | 40 mm | 50 mm |

|---|---|---|---|

| UCS/MPa | 1.13 | 1.09 | 1.04 |

| tensile strength/MPa | 1.91 | 2.00 | 1.57 |

| shear strength/MPa | 2.42 | 2.56 | 2.00 |

| Normal Stiffness (GPa/m) | Stiffness (GPa/m) | Compressive Strength (MPa) | Tensile Strength (MPa) | Internal Friction Angle (°) | Cohesion (MPa) |

|---|---|---|---|---|---|

| 0.3 | 0.3 | 2.116 | 0.181 | 36.94 | 0.171 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Wang, W.; Li, H. A Study on Three-Dimensional Flexible Mesh Influence on the Stability of Reserved Tunnels in Cemented Backfill. Materials 2025, 18, 3291. https://doi.org/10.3390/ma18143291

Liu X, Wang W, Li H. A Study on Three-Dimensional Flexible Mesh Influence on the Stability of Reserved Tunnels in Cemented Backfill. Materials. 2025; 18(14):3291. https://doi.org/10.3390/ma18143291

Chicago/Turabian StyleLiu, Xiaosheng, Weijun Wang, and Hao Li. 2025. "A Study on Three-Dimensional Flexible Mesh Influence on the Stability of Reserved Tunnels in Cemented Backfill" Materials 18, no. 14: 3291. https://doi.org/10.3390/ma18143291

APA StyleLiu, X., Wang, W., & Li, H. (2025). A Study on Three-Dimensional Flexible Mesh Influence on the Stability of Reserved Tunnels in Cemented Backfill. Materials, 18(14), 3291. https://doi.org/10.3390/ma18143291