Strength Enhancement of Clay Through Lime–Sand Stabilization at Various Remolding Water Contents

Abstract

1. Introduction

2. Materials and Methods

2.1. Testing Materials

2.2. Experimental Methods

2.2.1. Sample Preparation

2.2.2. Unconfined Compression Test

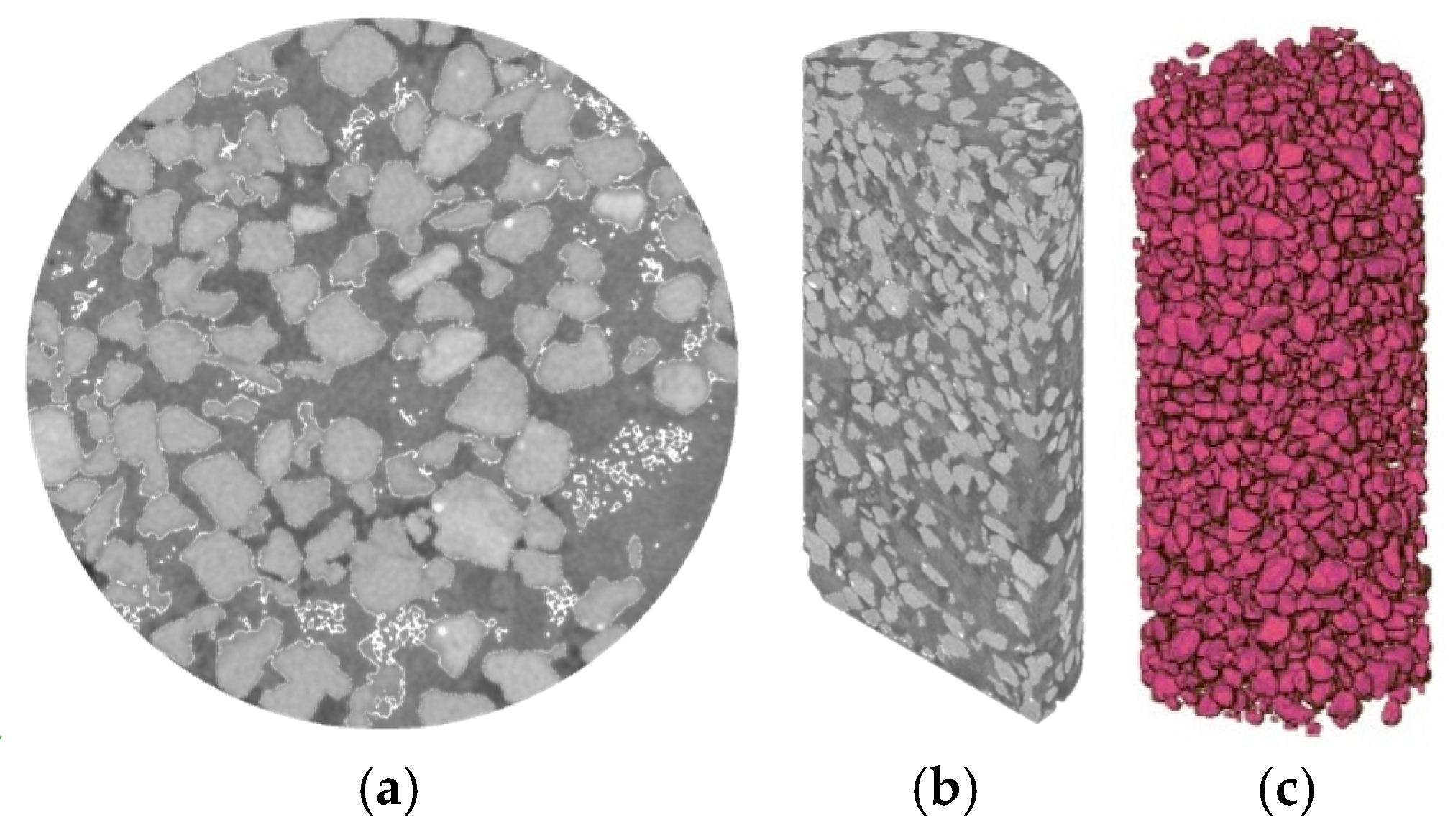

2.2.3. Microscopic Tests

3. Results

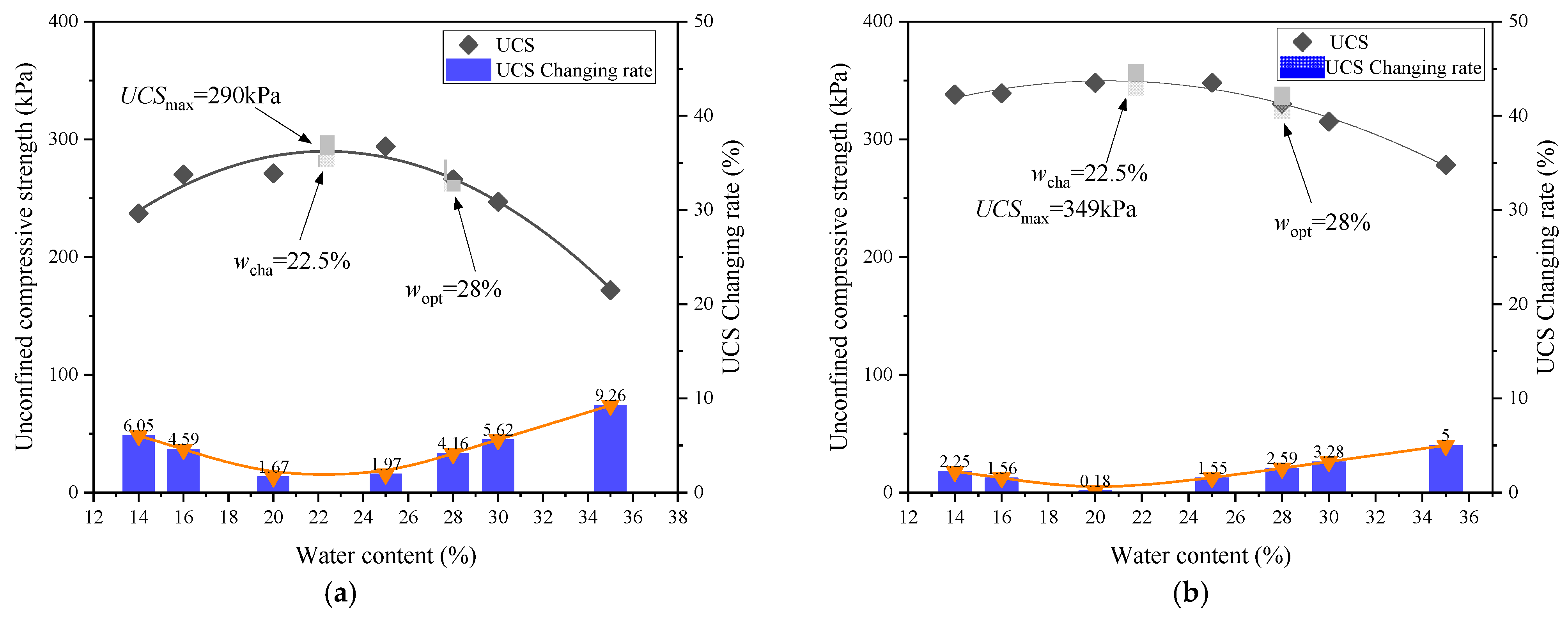

3.1. Mechanical Behavior of Clay Soils

3.2. Mechanical Behavior of Lime–Sand-Stabilized Clay

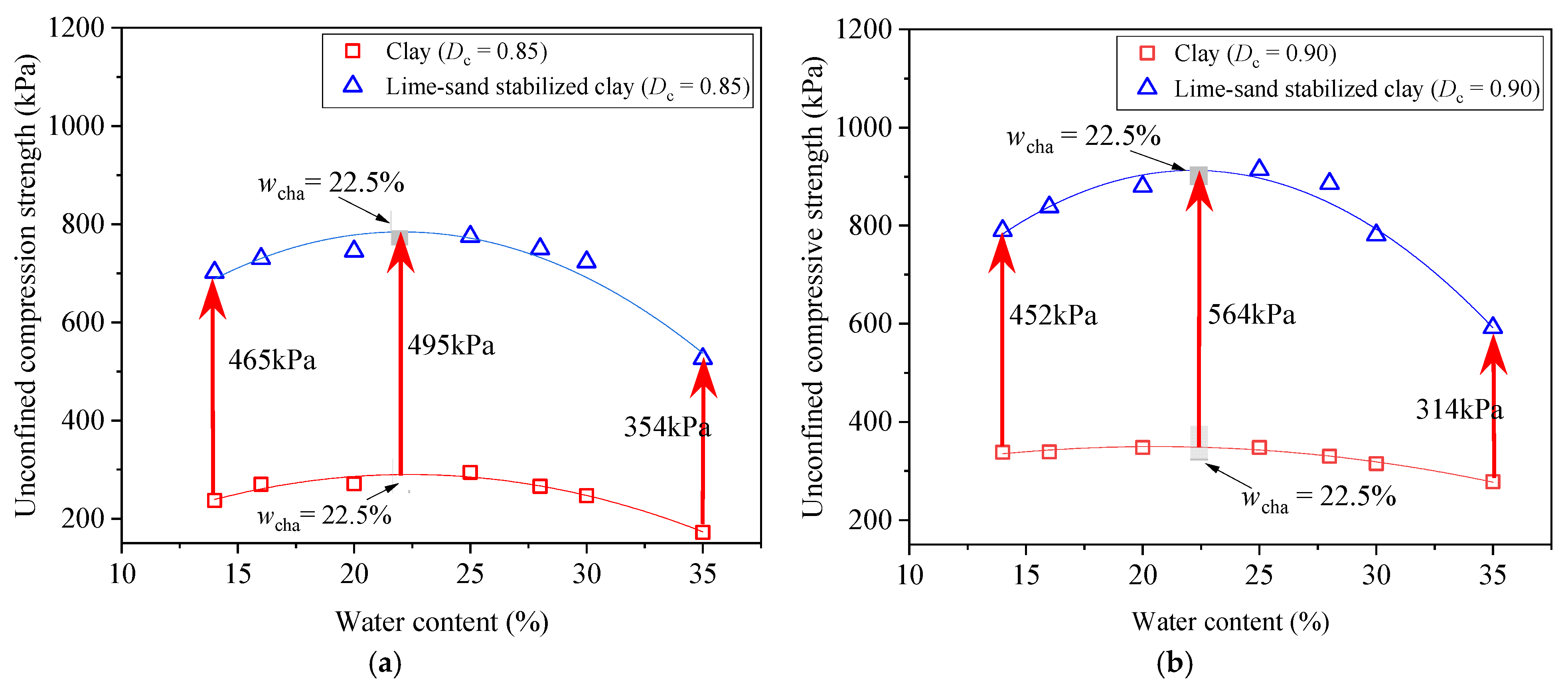

3.3. Comparison of Mechanical Behavior Between Clay and Lime–Sand-Stabilized Clay

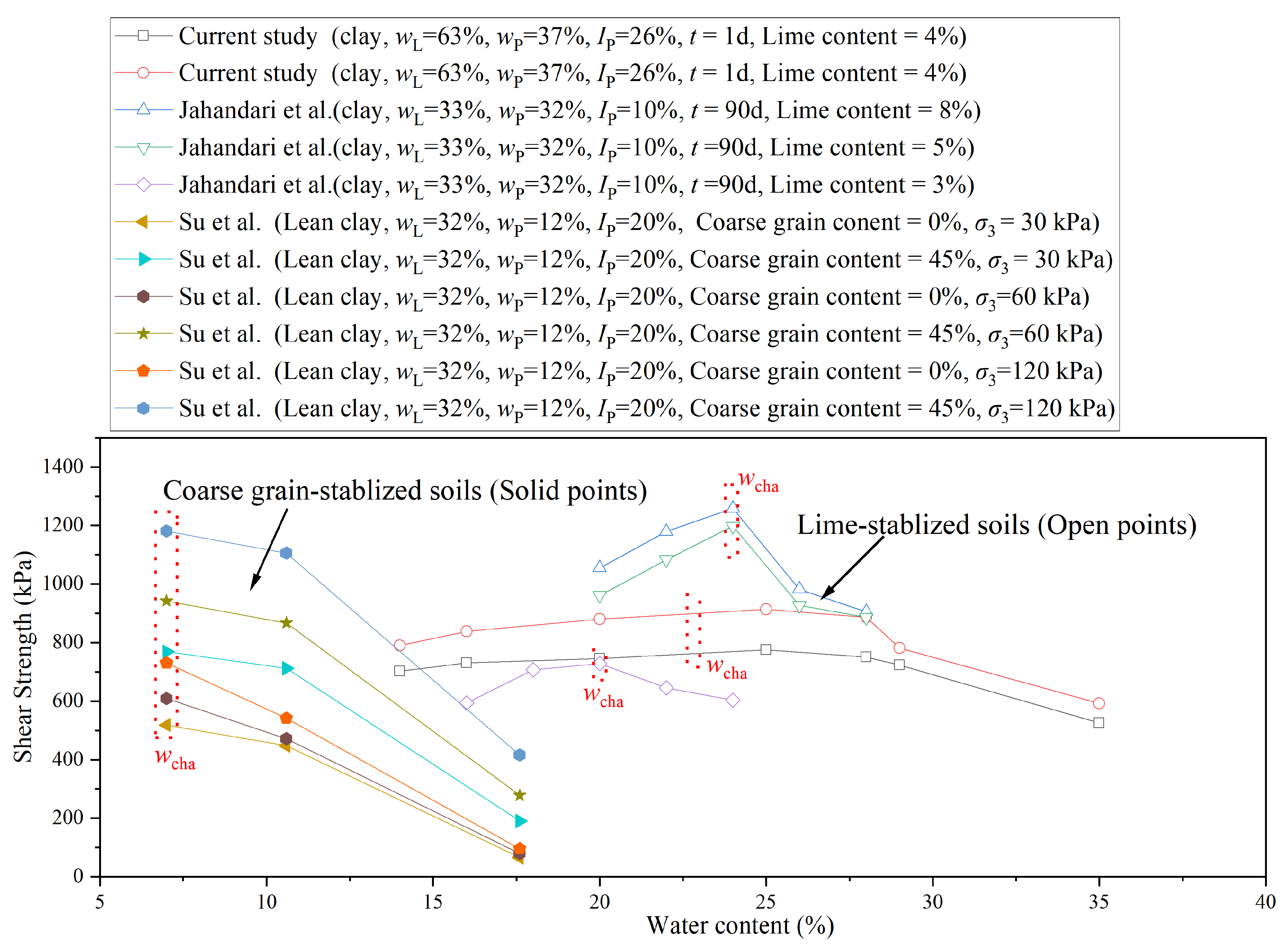

3.4. Comparison with Previous Studies

4. Conclusions

- (1)

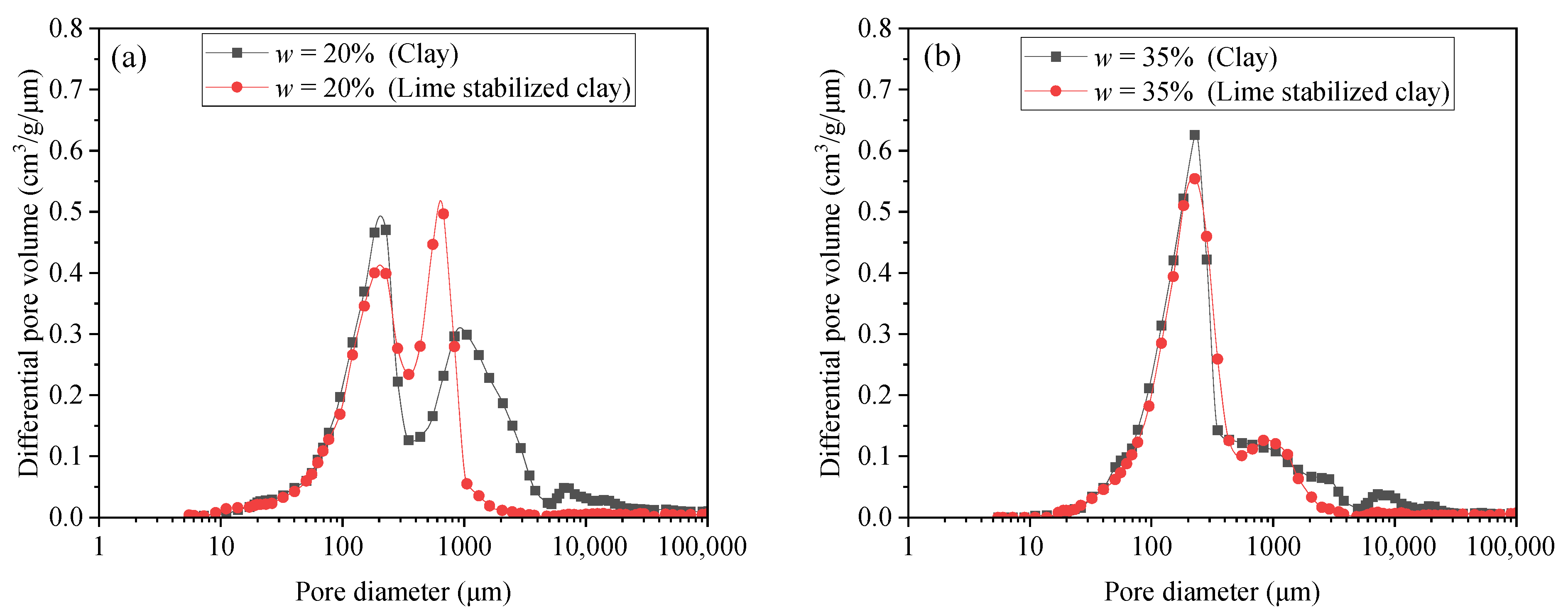

- The soil fabrics of both pure clay and lime-mixed clay were significantly influenced by the remolding water content w. As the w increased from the dry side of optimum to the wet side, the reduction in matric suction led to a weakening of the aggregation effect among fine-grained particles, resulting in progressive disintegration of fine-grained aggregate and an increase in dispersed fine-grained particles. Consequently, when the w increased to w ≤ wcha, the dispersed fine-grained particles gradually filled the large pores between aggregates, leading to continuous densification of the soil fabric. In contrast, at w > wcha, the ongoing disintegration of the aggregate resulted in progressive structural weakening.

- (2)

- As the w increased, both the pure clay and lime–sand-stabilized clay exhibited a bell-shaped UCS variation with wcha as the threshold. In pure clay soils, the increase in the UCS with increasing w at w ≤ wcha was due to structural densification, while the UCS decrement at w > wcha resulted from structural weakening. For lime–sand-stabilized clay in which a sand grain skeleton had formed, the shearing-induced compression of lime-mixed clay by the sand grains activated its contribution to the overall strength. As the compressive capacity of the lime-mixed clay exhibited a bell-shaped response to w, with wcha serving as the threshold, the overall UCS of the lime–sand-stabilized clay followed a similar pattern.

- (3)

- At a low w value, the dominance of the clay aggregate with sand-like mechanical behavior limited the effectiveness of adding sand and lime in improving the UCS. As the w approached wcha, the disintegration of the aggregate enlarged the contrast between pure clay and sand, leading to a greater improvement in the UCS. Beyond wcha, the lubrication effect in sand–sand contact areas reduced the grain interlocking effect, slightly decreasing the effectiveness of UCS enhancement.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| Cu | coefficient of uniformity |

| d | pore diameter |

| D | sample diameter |

| Dc | compaction degree |

| Gs | specific gravity |

| H | sample height |

| Ip | plasticity index |

| q | axial stress |

| UCS | unconfined compression strength |

| UCSmax | maximum value of unconfined compression strength |

| w | remolding water content |

| wcha | characteristic water content |

| wL | liquid limit |

| wopt | optimum water content |

| wp | plastic limit |

| ρd | dry density |

| ρdmax | maximum dry density |

| ε1 | axial strain |

| ΔUCS | variation value of UCS |

References

- Chen, W.; Hou, Y.Z.; Chen, J. Study on physical and mechanical properties and micro-mechanism of modified expansive soil with disintegrated sandstone-cement. Water Resour. Hydropower Eng. 2021, 52, 132–140. [Google Scholar]

- JTG D30-2015; Specifications for Design of Highway Subgrade. Ministry of Communications, People’s Republic of China: Beijing, China, 2015.

- Dong, W.; Huang, D.W.; Wang, H.Y. Experimental studies on red clay improved with sand. China Energy Environ. Prot. 2018, 40, 157–162. [Google Scholar]

- Liu, A.M.; Fu, J.B. Research on the improvement methods of using high liquid limit red clay as subgrade filler. J. Ground Improv. 2024, 6 (Suppl. S1), 15–21. [Google Scholar]

- Alnmr, A.; Alsirawan, R.; Ray, R.; Alzawi, M.O. Compressibility of expansive soil mixed with sand and its correlation to index properties. Heliyon 2024, 10, 35711. [Google Scholar] [CrossRef] [PubMed]

- Dafalla, M.; Shaker, A.; Elkady, T.; Almajed, A.; Al-Shamrani, M. Shear strength characteristics of a sand clay liner. Sci. Rep. 2020, 10, 18226. [Google Scholar] [CrossRef]

- Bessaim, M.M.; Bessaim, A.; Missoum, H.; Bendani, K. Effect of quick lime on physicochemical properties of clay soil. MATEC Web Conf. EDP Sci. 2018, 149, 02065. [Google Scholar] [CrossRef][Green Version]

- Ghazouani, N. Quicklime-stabilized Tuff and Clayey Soils for Highway A3 Construction in Northern Tunisia. Eng. Technol. Appl. Sci. Res. 2024, 14, 13511–13516. [Google Scholar] [CrossRef]

- Wang, Y.; Cui, Y.J.; Tang, A.M.; Tang, C.S.; Benahmed, N. Changes in thermal conductivity, suction and microstructure of a compacted lime-treated silty soil during curing. Eng. Geol. 2016, 202, 114–121. [Google Scholar] [CrossRef]

- Wang, Y.; Duc, M.; Cui, Y.J.; Tang, A.M.; Benahmed, N.; Sun, W.J.; Ye, W.M. Aggregate size effect on the development of cementitious compounds in a lime-treated soil during curing. Appl. Clay Sci. 2017, 136, 58–66. [Google Scholar] [CrossRef]

- Wang, Y.; Cui, Y.J.; Tang, A.M.; Benahmed, N.; Duc, M. Effects of aggregate size on the compressibility and air permeability of lime-treated fine-grained soil. Eng. Geol. 2017, 228, 167–172. [Google Scholar] [CrossRef]

- Shi, Y.; Li, S.; Zhang, T.; Liu, J.; Zhang, J. Compaction and shear performance of lime-modified high moisture content silty clay. Case Stud. Constr. Mater. 2024, 21, 03529. [Google Scholar] [CrossRef]

- Wang, Y.H.; Yang, C.Y.; Wang, Y.N. Durability of Lime-Stabilized Clay Subgrade in Seasonal Frozen Region. Sci. Technol. Eng. 2024, 24, 14787–14795. [Google Scholar]

- Li, S.G.; Liu, S.S.; Zhang, T.B.; Wang, Z.G.; Zhao, W. Experimental study on the durability and microstructural characteristics of lime-stabilized silty clay in seasonally frozen region. Constr. Build. Mater. 2025, 463, 140158. [Google Scholar] [CrossRef]

- Tunono, C.; Fall, M. THMC Behavior of Lime-Stabilized Clay Subgrade Under Daily Thermal Cycles: Column Experiments. Geotech. Geol. Eng. 2024, 42, 915–944. [Google Scholar] [CrossRef]

- Yang, J.; Tong, L.; Zhang, G.D.; Zhang, G.; Tang, Y. Impact of Initial Water Content and Weathered Sandon Load-free Swelling of Expansive Soil. Water Resour. Power 2014, 32, 162–166. [Google Scholar]

- Dafalla, M.; Mutaz, E.; Al-Shamrani, M. Compressive strength variations of lime-treated expansive soils. In Proceedings of the International Foundations Congress and Equipment Expo (IFCEE 2015), San Antonio, TX, USA, 17–21 March 2015; pp. 1402–1409. [Google Scholar]

- ASTM D422–63; Standard Test Method for Particle-Size Analysis of Soils. ASTM: West Conshohocken, PA, USA, 2007.

- ASTM D2850-15; Standard Test Method for Unconsolidated-Undrained Triaxial Compression Test on Cohesive Soils. ASTM: West Conshohocken, PA, USA, 2019.

- Liu, J.; Xiao, J. Experimental study on the stability of railroad silt subgrade with increasing train speed. J. Geotech. Geoenviron. Eng. 2010, 136, 833–841. [Google Scholar] [CrossRef]

- Prusinski, J.R.; Bhattacharja, S. Effectiveness of Portland cement and lime in stabilizing clay soils. Transp. Res. Rec. 1999, 1652, 215–227. [Google Scholar] [CrossRef]

- AASHTO T208-15; Standard Method of Test for Unconfined Compressive Strength of Cohesive Soil. American Association of State Highway and Transportation: Washington, DC, USA, 2019.

- Delage, P.; Audiguier, M.; Cui, Y.J.; Howat, M.D. Microstructure of a compacted silt. Can. Geotech. J. 1996, 33, 150–158. [Google Scholar] [CrossRef]

- Zhang, T.W.; Cui, Y.J.; Lamas-Lopez, F.; Calon, N.; Costa D’Aguiar, S. Compacted soil behaviour through changes of density, suction, and stiffness of soils with remoulding water content. Can. Geotech. J. 2018, 55, 182–190. [Google Scholar] [CrossRef]

- Li, X.; Zhang, L.M. Characterization of dual-structure pore-size distribution of soil. Can. Geotech. J. 2009, 46, 129–141. [Google Scholar] [CrossRef]

- Su, Y.; Cui, Y.J.; Dupla, J.C.; Canou, J.; Qi, S. Developing a sample preparation approach to study the mechanical behavior of unsaturated fine/coarse soil mixture. Geotech. Test. J. 2021, 44, 912–928. [Google Scholar] [CrossRef]

- Monkul, M.M.; Ozden, G. Compressional behavior of clayey sand and transition fines content. Eng. Geol. 2007, 89, 195–205. [Google Scholar] [CrossRef]

- Tang, C.S.; Pei, X.J.; Wang, D.Y.; Shi, B.; Li, J. Tensile strength of compacted clayey soil. J. Geotech. Geoenviron. Eng. 2015, 141, 04014122. [Google Scholar] [CrossRef]

- Su, Y.; Cui, Y.J.; Dupla, J.C.; Canou, J. Investigation of the effect of water content on the mechanical behavior of track-bed materials under various coarse grain contents. Constr. Build. Mater. 2020, 263, 120206. [Google Scholar] [CrossRef]

- Jahandari, S.; Tao, Z.; Saberian, M.; Shariati, M.; Li, J.; Abolhasani, M.; Kazemi, M.; Rahmani, A.; Rashidi, M. Geotechnical properties of lime-geogrid improved clayey subgrade under various moisture conditions. Road Mater. Pavement Des. 2021, 23, 2057–2075. [Google Scholar] [CrossRef]

| Chemical Composition | Quicklime | Clay |

|---|---|---|

| CaO | >97.3% | None |

| SiO2 | None | 47% |

| Al2O3 | None | 38% |

| Soil Type | Index Property | Value |

|---|---|---|

| Clay soils | Specific gravity, Gs | 2.60 |

| Clay content (<2 μm) | 85% | |

| Liquid limit, wL | 63% | |

| Plastic limit, wP | 37% | |

| Plasticity index, Ip | 26% | |

| USCS classification | CH | |

| Optimum water content, wopt | 28% | |

| Maximum dry density, ρdmax | 1.50 | |

| Sand | Mean grain size | 4.95 mm |

| Coefficient of uniformity, Cu | 1.72 | |

| Water absorption | 0.3% | |

| Specific gravity, Gs | 2.66 | |

| Plasticity index, Ip | Non-plastic |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qi, S.; Liu, J.; Ma, W.; Wang, J. Strength Enhancement of Clay Through Lime–Sand Stabilization at Various Remolding Water Contents. Materials 2025, 18, 3282. https://doi.org/10.3390/ma18143282

Qi S, Liu J, Ma W, Wang J. Strength Enhancement of Clay Through Lime–Sand Stabilization at Various Remolding Water Contents. Materials. 2025; 18(14):3282. https://doi.org/10.3390/ma18143282

Chicago/Turabian StyleQi, Shuai, Jinhui Liu, Wei Ma, and Jing Wang. 2025. "Strength Enhancement of Clay Through Lime–Sand Stabilization at Various Remolding Water Contents" Materials 18, no. 14: 3282. https://doi.org/10.3390/ma18143282

APA StyleQi, S., Liu, J., Ma, W., & Wang, J. (2025). Strength Enhancement of Clay Through Lime–Sand Stabilization at Various Remolding Water Contents. Materials, 18(14), 3282. https://doi.org/10.3390/ma18143282