Characterization of Asphalt Binder and Mixture for Enhanced Railway Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

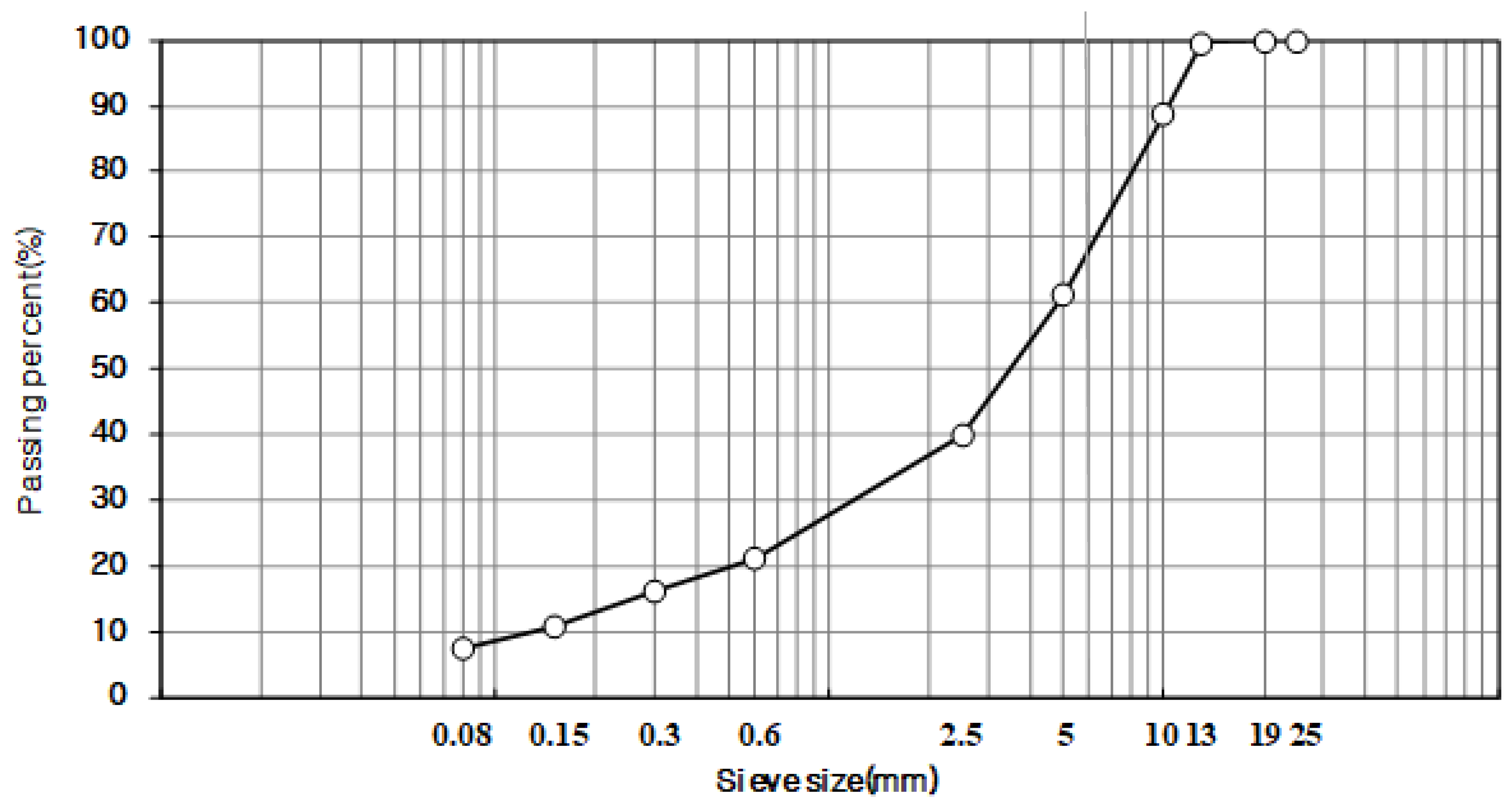

2.1.1. Aggregate

2.1.2. Polymer-Modified Asphalt (PMA) Binders

2.2. Methods

2.2.1. Binder Tests

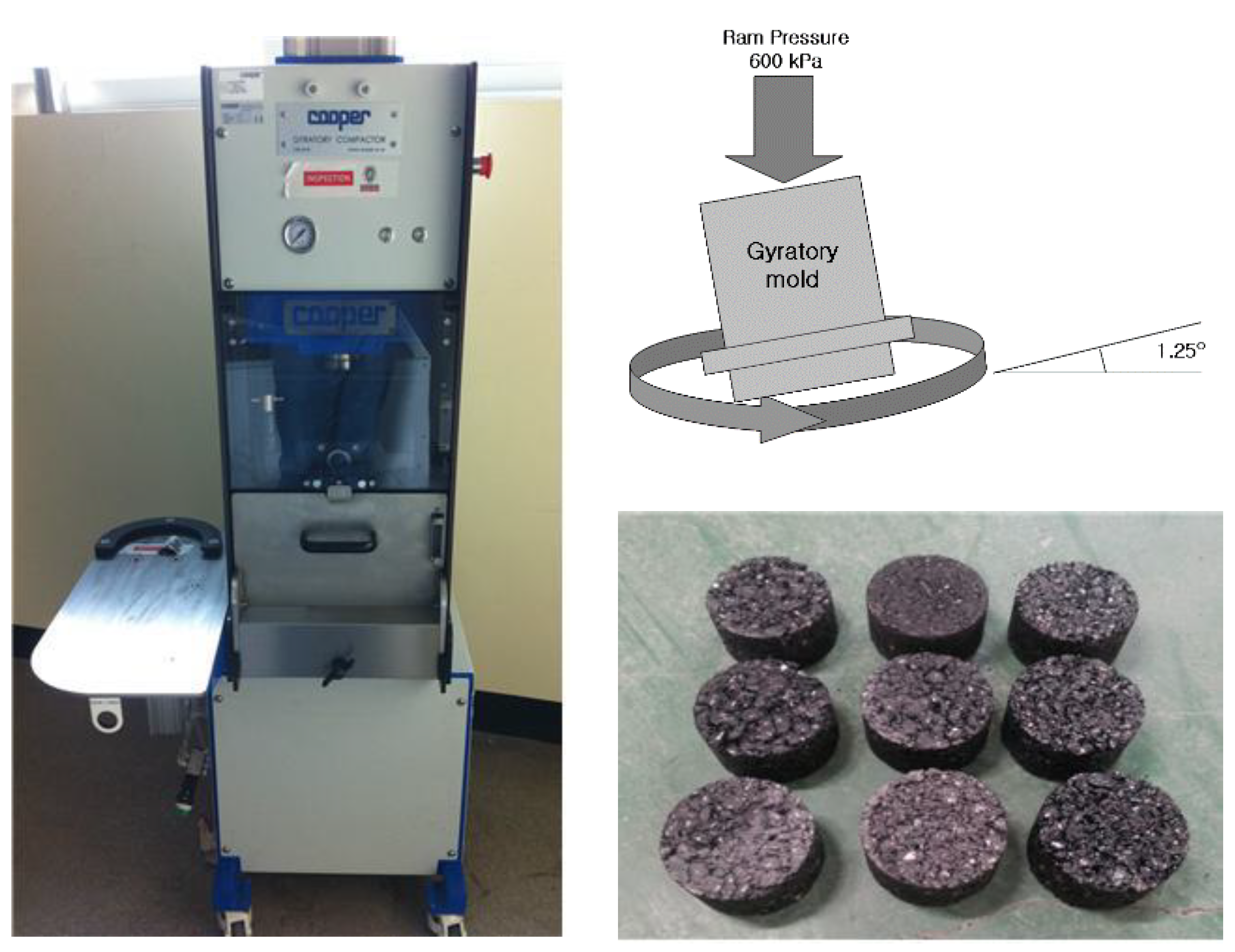

2.2.2. Mix Design

2.2.3. Deformation Strength (SD)

2.2.4. Indirect Tensile Strength (ITS)

2.2.5. Tensile Strength Ratio (TSR)

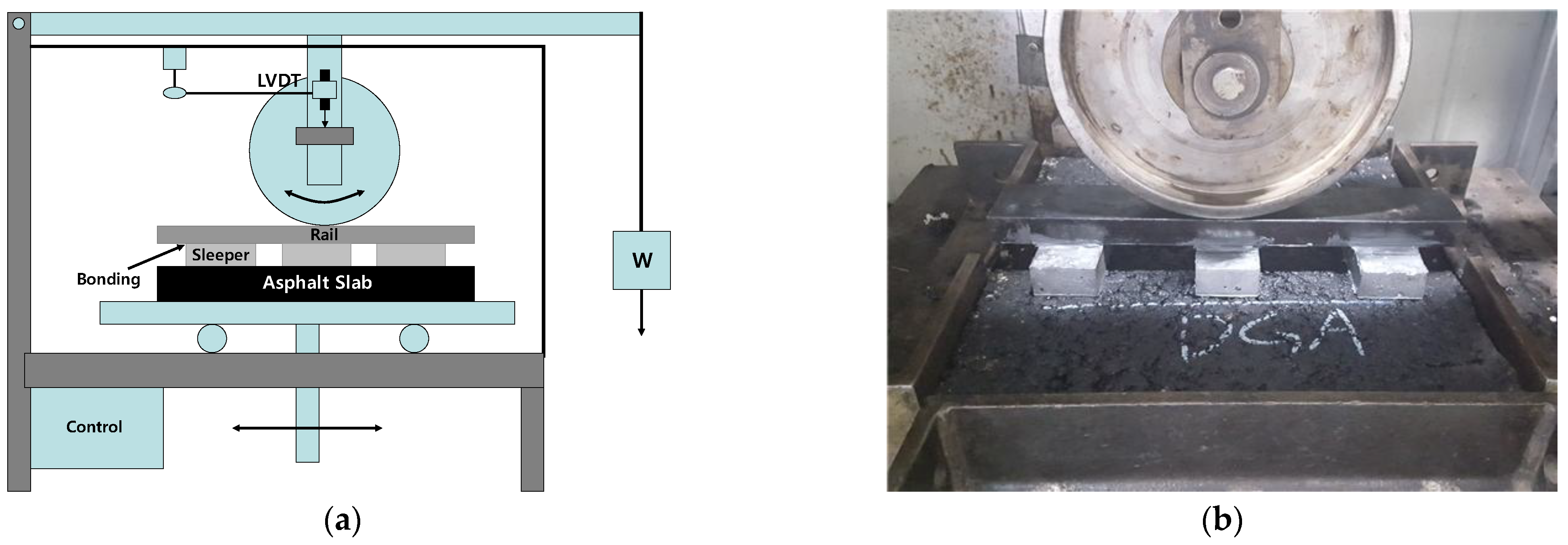

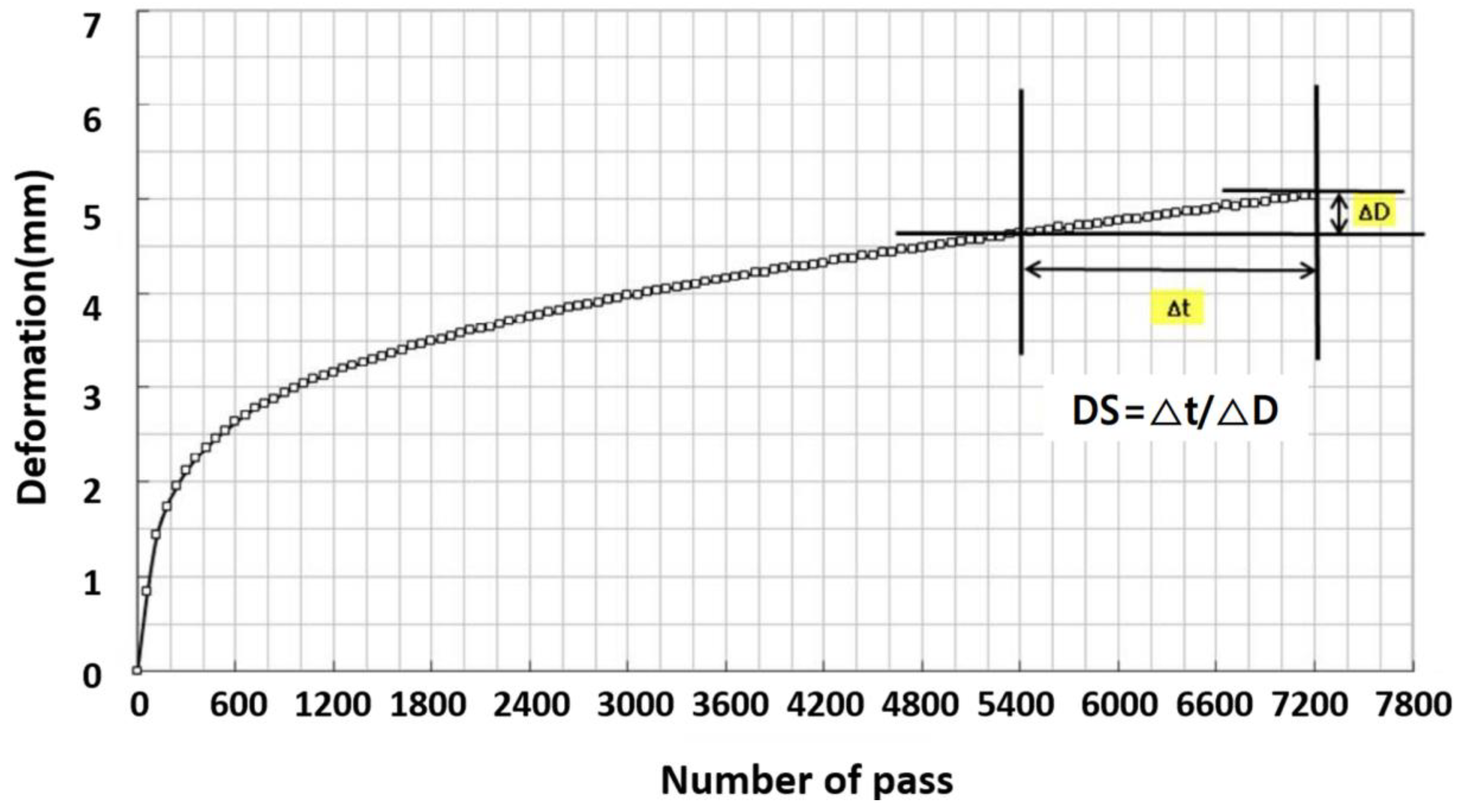

2.2.6. Wheel Tracking Test

3. Results and Discussion

3.1. Asphalt Binders

3.2. Asphalt Mixture

3.2.1. Mix Design

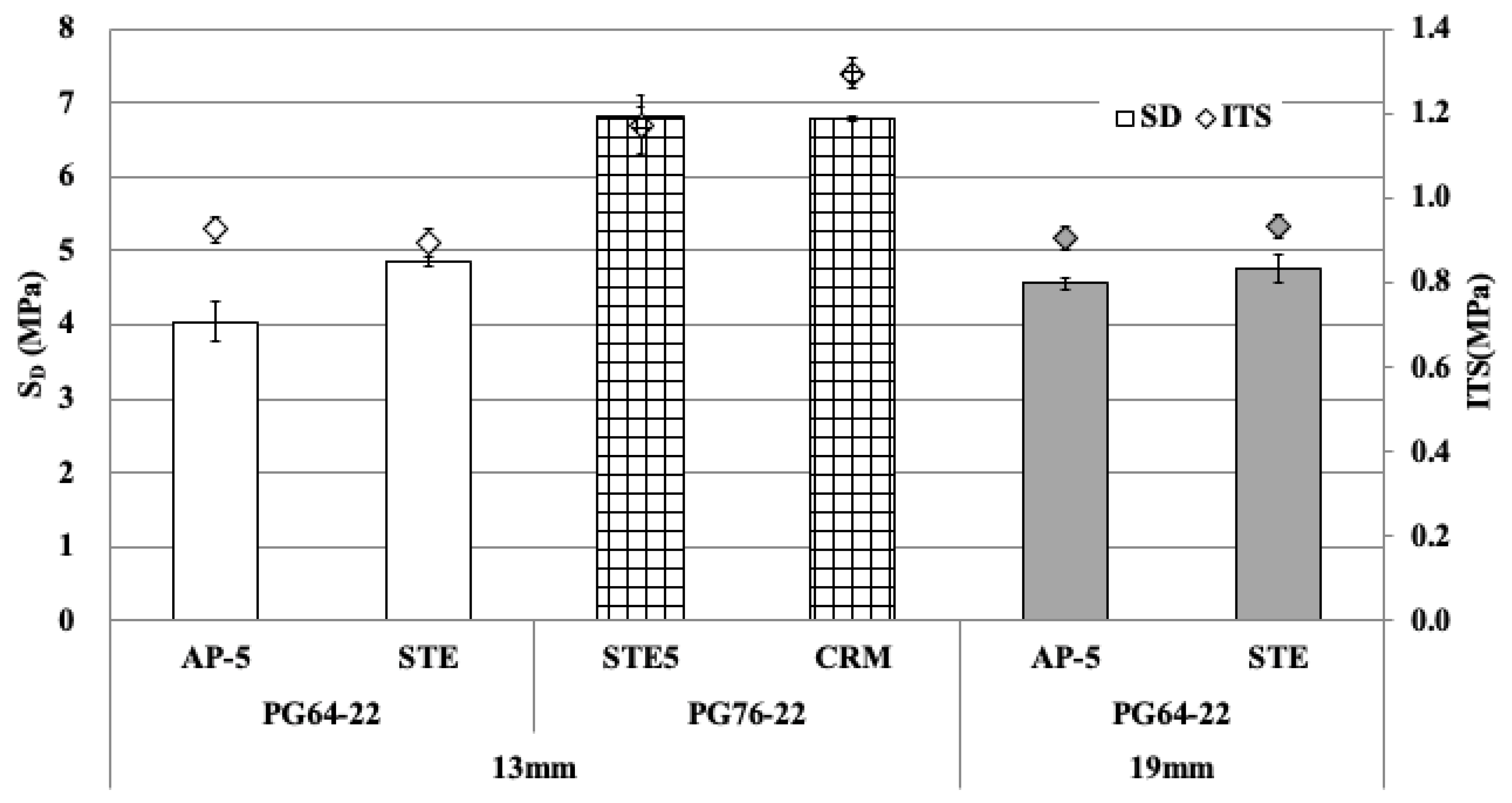

3.2.2. SD and ITS

3.2.3. TSR

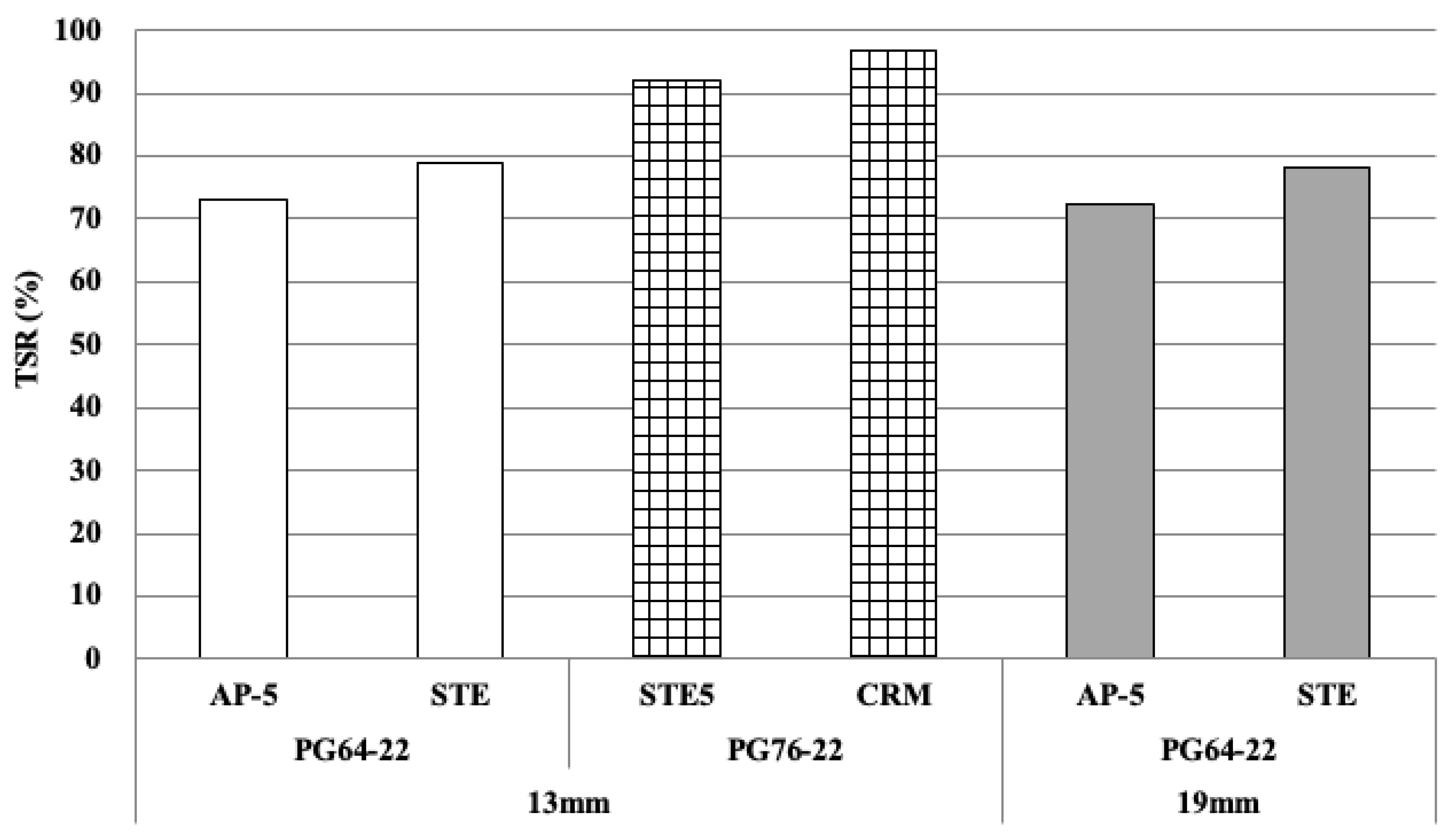

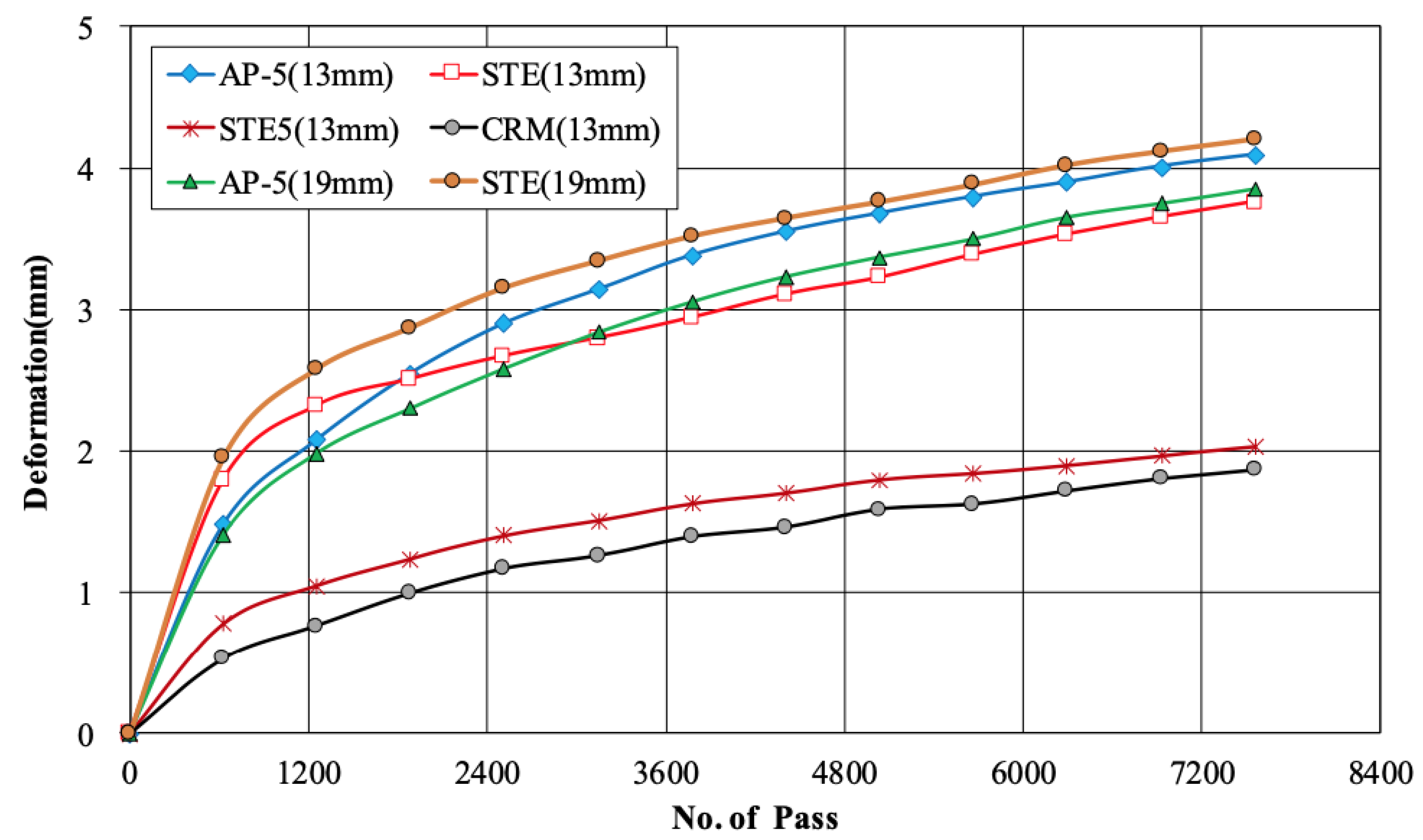

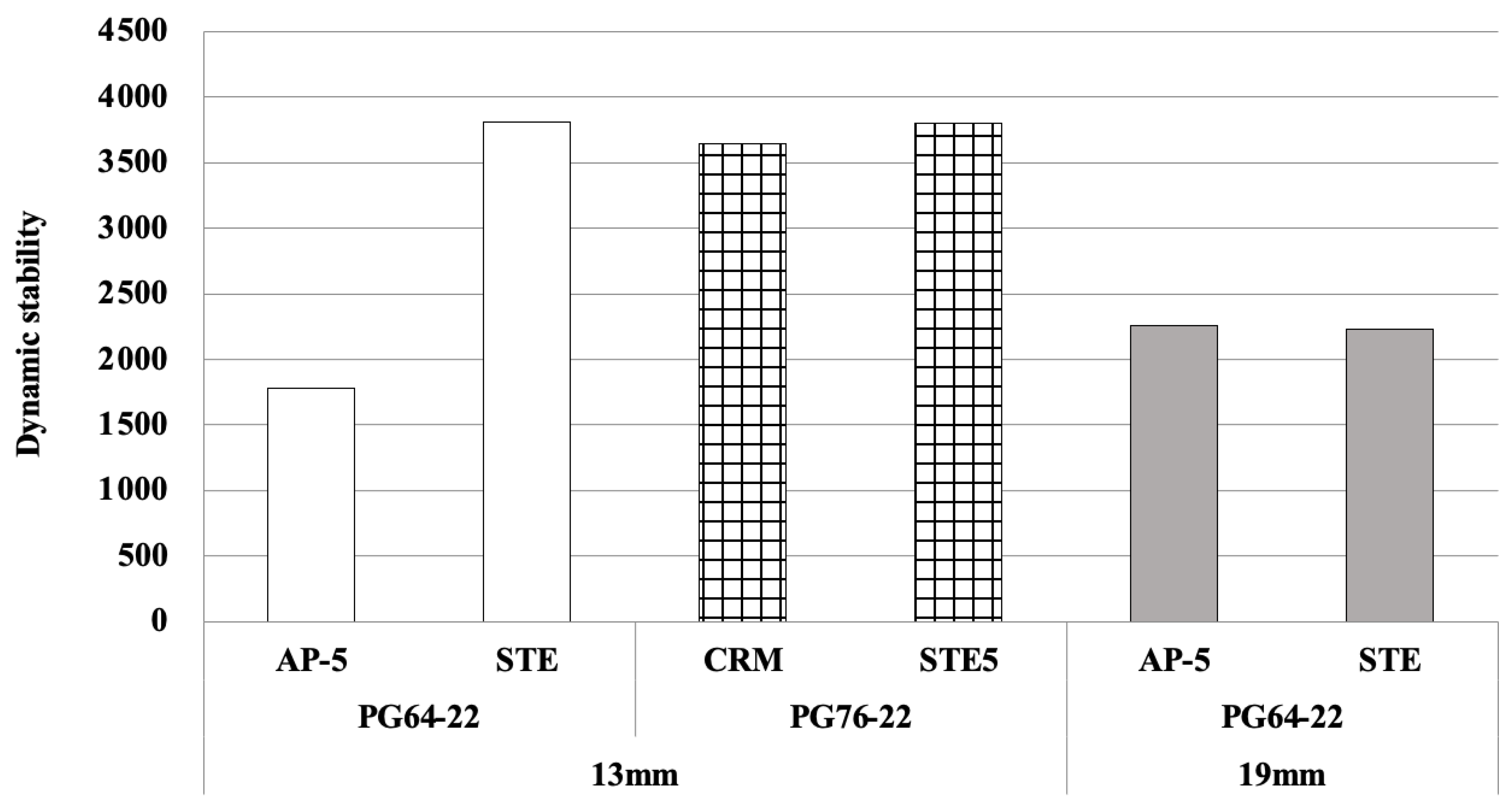

3.2.4. Wheel Tracking Test

4. Summary and Conclusions

- (1)

- As for rotational viscosity among the four asphalt binders (AP-5, STE, CRM, STE5), STE5 showed the highest viscosity of 1.8Pa·s, and CRM showed a value of 1.0Pa·s. AP-5 and STE showed a difference of 0.01P∙s in rotational viscosity, confirming no significant difference. The modified asphalt of CRM and STE5 had a lower penetration value and a higher softening point than AP-5 and STE. This is considered to be a phenomenon caused by the increased elasticity rather than viscosity of asphalt because CRM and STE5 have relatively high polymer content. Through this analysis, the Superpave binder tests were additionally performed and showed that each binder satisfied the standard for performance grade.

- (2)

- Deformation strength was measured, showing an average of 4.44 MPa for the 13 mm mix design according to the maximum size of coarse aggregate in PG64-22 grade, whereas for the 19 mm mix design, the average result was 4.67 MPa. The analysis suggests that the optimum asphalt content is low, so the deformation is low due to the low flow of the asphalt binder, causing the deformation strength value to be slightly higher.

- (3)

- Regarding ITS results, the PG76-22 asphalt mixture showed a higher value of about 0.33 MPa compared to the PG64-22 using the 13 mm mix design. The ITS values for both the 13 mm and 19 mm PG64-22 were similar, about 0.91 MPa on average. Also, the higher the PG grade, the higher the indirect tensile strength. Therefore, it is considered advantageous for the upper mixture, which is relatively vulnerable to the dynamic loads of the railway.

- (4)

- After the freeze–thaw test of general mixtures (PG64-22) without modifiers, the TSR was 73.0% and 72.2% for the maximum size of 13 and 19 mm aggregates, respectively. Also, STE mixtures with 13 and 19 mm aggregates had TSR values of 78.9% and 78.0%. The modified asphalt (PG76-22), specifically the 13 mm asphalt mixture modified with STE5 and CRM, showed TSR values of 92.1% and 96.8%. This indicates that the STE and CRM modifiers are effective in improving resistance to moisture for railroad applications.

- (5)

- Overall, in the wheel tracking test, the final rut depth of the 13 mm asphalt mixture was lower than that of the 19 mm mixture. In the case of the PG76-22 mixture, the final rut depth was more than twice as low as that of PG64-22. Based on these results, it is concluded that STE and CRM modifiers greatly affect plastic deformation resistance. It was also found that asphalt mixtures are suitable for use in railroad applications, as all measured rut depths remained below the maximum allowable limits.

- (6)

- The asphalt mixtures prepared with four different binder types and two aggregate sizes successfully met all the required performance criteria, demonstrating their suitability for application in railroad infrastructure. These results highlight the potential of asphalt—traditionally employed in roadway pavement—as a durable and reliable material for railway systems, thereby expanding its utility beyond conventional road construction.

- (7)

- This study evaluated the overall characteristics of asphalt mixtures based on road specification standards. Although all the results met or exceeded the standards, it is concluded that there is a need to conduct more in-depth research in the future, considering the various mechanical loads present in the railway.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, E.; Wang, K.C.; Qiu, Y.; Luo, Q. Asphalt concrete for high-speed railway infrastructure and performance comparisons. J. Mater. Civ. Eng. 2016, 28, 04015202. [Google Scholar] [CrossRef]

- Huang, Y.H.; Lin, C.; Deng, X. Hot mix asphalt for railroad trackbeds-structural analysis and design. Assoc. Asph. Paving Technol. Proc. 1984, 53, 475–494. [Google Scholar]

- Liu, H.; Duan, G.; Wang, F.; Zhang, J.; Zhou, Y.; Feng, Y.; Zhang, K. Investigation on mechanical behaviors of Self-compacting concrete containing reclaimed asphalt pavement. Constr. Build. Mater. 2022, 346, 128421. [Google Scholar] [CrossRef]

- Jadidi, K.; Esmaeili, M.; Kalantari, M.; Khalili, M.; Karakouzian, M. A review of different aspects of applying asphalt and bituminous mixes under a railway track. Materials 2020, 14, 169. [Google Scholar] [CrossRef] [PubMed]

- Nanjegowda, V.H.; Biligiri, K.P. Utilization of high contents of recycled tire crumb rubber in developing a modified-asphalt-rubber binder for road applications. Resour. Conserv. Recycl. 2023, 192, 106909. [Google Scholar] [CrossRef]

- Yan, X.; Wu, D.; Hu, K.; Zhang, W.; Xing, J.; Cui, L.; Shi, S.; Yang, J.; Yang, C. The Modification Mechanism, Evaluation Method, and Construction Technology of Direct-to-Plant SBS Modifiers in Asphalt Mixture: A Review. Polymers 2023, 15, 2768. [Google Scholar] [CrossRef] [PubMed]

- Xiao, X.; Cai, D.; Lou, L.; Shi, Y.; Xiao, F. Application of asphalt based materials in railway systems: A review. Constr. Build. Mater. 2021, 304, 124630. [Google Scholar] [CrossRef]

- Fang, M.; Hu, T.; Rose, J.G. Geometric composition, structural behavior and material design for asphalt trackbed: A review. Constr. Build. Mater. 2020, 262, 120755. [Google Scholar] [CrossRef]

- Dudkin, E.; Sultanov, N.; Malakhov, M. Application of ballastless construction of the railroad track in the Arctic zone. In E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2023; Volume 383, p. 01014. [Google Scholar]

- Qatamin, J.; Amir, I. Asphalt layers within railway tracks’ substructure. Acta Tech. Jaurinensis 2021, 14, 612–631. [Google Scholar] [CrossRef]

- Wang, W.; Deng, Z.; Niu, Y.; Li, Y.; Huang, Z.; Dong, M.; Su, Q. Analysis of Behaviors of the Railway Subgrade with a New Waterproof Seal Layer. Materials 2022, 15, 1180. [Google Scholar] [CrossRef] [PubMed]

- Castro, G.; Pires, J.; Motta, R.; Bernucci, L.; Fortunato, E.; Futai, M. Evaluating environmental effects on the structural behavior of the railroad track subgrade considering different sub-ballast design solutions. Transp. Geotech. 2022, 34, 100761. [Google Scholar] [CrossRef]

- Guo, Y.; Markine, V.; Jing, G. Review of ballast track tamping: Mechanism, challenges and solutions. Constr. Build. Mater. 2021, 300, 123940. [Google Scholar] [CrossRef]

- Lim, Y.; Lee, J.; Lee, S.; Lee, B. Analysis of Permanent Deformations in Asphalt Mixtures for Design of Asphalt Trackbed Foundation. J. Korean Soc. Railw. 2014, 17, 123–132. [Google Scholar] [CrossRef]

- Zhang, L.; Hoff, I.; Zhang, X.; Liu, J.; Yang, C.; Wang, F. A Methodological Review on Development of Crack Healing Technologies of Asphalt Pavement. Sustainability 2023, 15, 9659. [Google Scholar] [CrossRef]

- Lou, K.; Xiao, P.; Kang, A.; Wu, Z.; Dong, X. Effects of asphalt pavement characteristics on traffic noise reduction in different frequencies. Transp. Res. Part D Transp. Environ. 2022, 106, 103259. [Google Scholar] [CrossRef]

- Zhao, Y.; Gong, X.; Liu, Q. Research on rheological properties and modification mechanism of waterborne polyurethane modified bitumen. Constr. Build. Mater. 2023, 371, 130775. [Google Scholar] [CrossRef]

- Gong, Y.; Wu, S.; Zhang, Y.; Pang, Y.; Ma, Y. Investigation of the High-Temperature and Rheological Properties for Asphalt Sealant Modified by SBS and Rubber Crumb. Polymers 2022, 14, 2558. [Google Scholar] [CrossRef] [PubMed]

- Ministry of Land, Infrastructure and Transport. Asphalt Concrete Pavement Construction Guide; Ministry of Land, Infrastructure and Transport: Sejong-si, Republic of Korea, 2021. [Google Scholar]

- Kim, K.W.; Doh, Y.D.; Amirkhanian, S.N. Feasibility of deformation strength for estimation of rut resistance of asphalt concrete. Road Mater. Pavement Des. 2004, 5, 303–322. [Google Scholar] [CrossRef]

- Kim, K.W.; Kim, J.E.; Kim, B.C.; Doh, Y.S. Determination of Valid Dynamic Stability in Wheel Tracking Test of Asphalt Concretes. Int. J. Highw. Eng. 2004, 6, 37–46. [Google Scholar]

- Park, T.W.; Doh, Y.S.; Kim, K.W. Determination of radius of edge round cut of loading head for deformation strength test. Int. J. Highw. Eng. 2008, 10, 183–191. [Google Scholar]

| Classification | Apparent Specific Gravity (g/cm3) | Absorption (%) | Abrasion (%) | |

|---|---|---|---|---|

| Specification | >2.5 | <3.0 | <40 | |

| Coarse agg. | 13 mm | 2.65 | 0.81 | 19.5 |

| 19 mm | 2.71 | 1.33 | 30.7 | |

| Fine agg. | 2.67 | 1.01 | - | |

| Mineral filler | 2.75 | - | - | |

| Base Binder | Binder | Description |

|---|---|---|

| PG64-22 | AP-5 | Straight asphalt |

| STE | STE (1.5%)-modified asphalt mixture | |

| PG76-22 | STE5 | STE (5%)-modified asphalt mixture |

| CRM | CRM (8%)-modified asphalt mixture |

| Agg. | Max. Size | PG Grade | Mixture | Description |

|---|---|---|---|---|

| Granite | 13 mm | PG64-22 | AP | Granite 13 mm DGA grade, AP-5 |

| STE | Granite 13 mm DGA grade, STE 1.5% | |||

| PG76-22 | STE5 | Granite 13 mm DGA grade, STE 5% | ||

| CRM | Granite 13 mm DGA grade, CRM 8% | |||

| 19 mm | PG64-22 | AP | Granite 19 mm DGA grade, AP-5 | |

| STE | Granite 19 mm DGA grade, STE 1.5% |

| Material | Designation (Type, Grain Size, Layer Type) | Unit | ACT20MC | ACT13WC | |

|---|---|---|---|---|---|

| Aggregate | Maximum aggregate size | mm | 20 | 13 | |

| Passing on sieve (%) | 30 mm | % | – | – | |

| 25 mm | % | 100 | – | ||

| 20 mm | % | 95–100 | 100 | ||

| 13 mm | % | 80–92 | 95–100 | ||

| 10 mm | % | 70–85 | 83–92 | ||

| 5 mm | % | 48–65 | 55–70 | ||

| 2.5 mm | % | 30–50 | 35–50 | ||

| 0.6 mm | % | 15–30 | 18–30 | ||

| 0.3 mm | % | 11–23 | 13–22 | ||

| 0.15 mm | % | 7–15 | 8–15 | ||

| 0.08 mm | % | 4–10 | 4–10 | ||

| Asphalt | Asphalt performance grade | PG64-22 | PG76-22 | ||

| Number of gyratory compactions (Marshall compaction) | time | 75 (50) | 100 (75) | ||

| Air void | % | 2–4 | 1–3 | ||

| VFA | % | 75–85 | 80–90 | ||

| VMA | % | ≥12.0 | ≥12.0 | ||

| Minimum binder content | % | 4.3 | 5.5 | ||

| Deformation strength (Marshall stability) | N (MPa) | ≥3.2 (7000) | ≥4.25 (8500) | ||

| Flow value | 1/100 cm | 30–60 | 40–60 | ||

| TSR | % | ≥0.7 | ≥0.8 | ||

| Dynamic stability | pass/mm | ≥800 | ≥3000 | ||

| Permanent deformation | mm | ≤8 | ≤3 | ||

| Property | PG64-22 | PG76-22 | |||

|---|---|---|---|---|---|

| AP-5 | STE | CRM | STE5 | ||

| Kinematic viscosity @135 °C (Pa∙s) | 0.39 | 0.4 | 1.0 | 1.8 | |

| Softening point (°C) | 46.4 | 47.5 | 63.0 | 68.5 | |

| Penetration (1/10 cm) | 74 | 71 | 44 | 49 | |

| 15 °C Ductility (cm) | >100 | >100 | 65 | 59 | |

| G*/sin δ, kPa, (Temp.) @10 rad/s | Original | 1.14 (64 °C) | 1.31 (64 °C) | 2.36 (76 °C) | 1.81 (76 °C) |

| RTFO | 2.34 (64 °C) | 2.82 (64 °C) | 3.50 (76 °C) | 3.10 (76 °C) | |

| G*·sin δ, kPa, (Temp.) @ 10 rad/s | PAV | 3250 (25 °C) | 3540 (25 °C) | 1820 (25 °C) | 1680 (25 °C) |

| Creep stiffness (−12 °C) | 155 | 160 | 170 | 155 | |

| m-value (−12 °C) | 0.34 | 0.35 | 0.33 | 0.32 | |

| Agg. Size (mm) | PG | Binder | AP Cont. (%) | Density (g/cm3) | Air Void (%) | VMA (%) | VFA (%) |

|---|---|---|---|---|---|---|---|

| 13 | 64-22 | AP-5 | 5.2 | 2.423 | 2.47 | 14.80 | 83.31 |

| STE | 5.1 | 2.422 | 2.62 | 14.71 | 82.18 | ||

| 76-22 | STE5 | 5.6 | 2.401 | 1.62 | 14.54 | 88.85 | |

| CRM | 5.6 | 2.375 | 2.61 | 15.62 | 83.31 | ||

| 19 | 64-22 | AP-5 | 5.0 | 2.428 | 2.52 | 14.40 | 82.47 |

| STE | 4.9 | 2.430 | 2.43 | 14.32 | 83.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Na, I.; Park, H.; Yun, J.; Park, J.D.; Kim, H. Characterization of Asphalt Binder and Mixture for Enhanced Railway Applications. Materials 2025, 18, 3265. https://doi.org/10.3390/ma18143265

Na I, Park H, Yun J, Park JD, Kim H. Characterization of Asphalt Binder and Mixture for Enhanced Railway Applications. Materials. 2025; 18(14):3265. https://doi.org/10.3390/ma18143265

Chicago/Turabian StyleNa, Ilho, Hyemin Park, Jihyeon Yun, Ju Dong Park, and Hyunhwan Kim. 2025. "Characterization of Asphalt Binder and Mixture for Enhanced Railway Applications" Materials 18, no. 14: 3265. https://doi.org/10.3390/ma18143265

APA StyleNa, I., Park, H., Yun, J., Park, J. D., & Kim, H. (2025). Characterization of Asphalt Binder and Mixture for Enhanced Railway Applications. Materials, 18(14), 3265. https://doi.org/10.3390/ma18143265