Real-Time Temperature Effects on Dynamic Impact Mechanical Properties of Hybrid Fiber-Reinforced High-Performance Concrete

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Materials

- (1)

- Copper-coated steel fibers (SFs) with a length of 12 mm, a diameter of 0.22 mm, and an elastic modulus of 200 GPa;

- (2)

- Polypropylene fibers (PPFs) with a length of 12 mm, a diameter of 30–40 μm, and an elastic modulus ≥ 3.5 GPa;

- (3)

- Polyvinyl alcohol fibers (PVAFs) with a length of 12 mm, a diameter of 50–60 μm, and an elastic modulus ≥ 25 GPa.

2.2. Experimental Methods

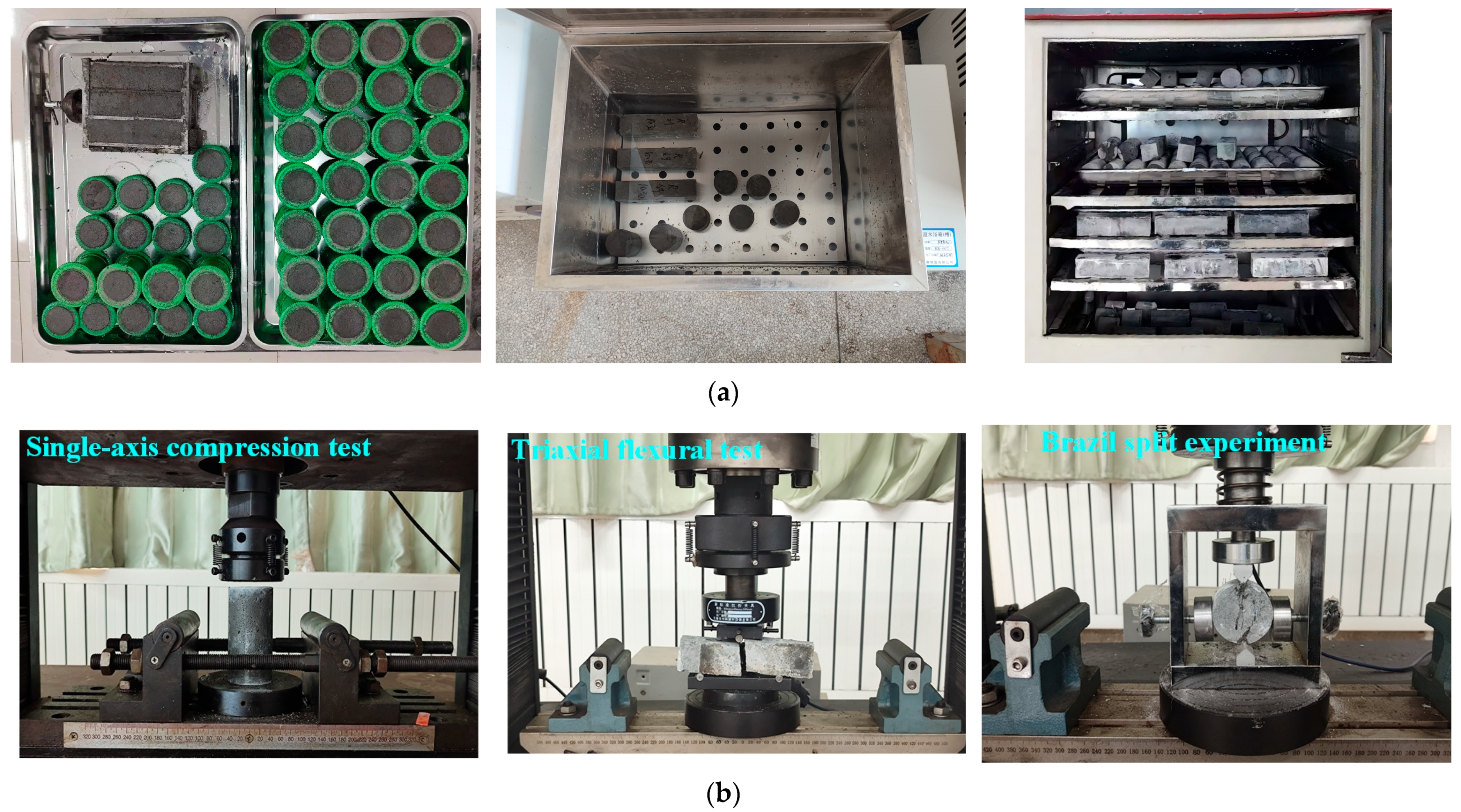

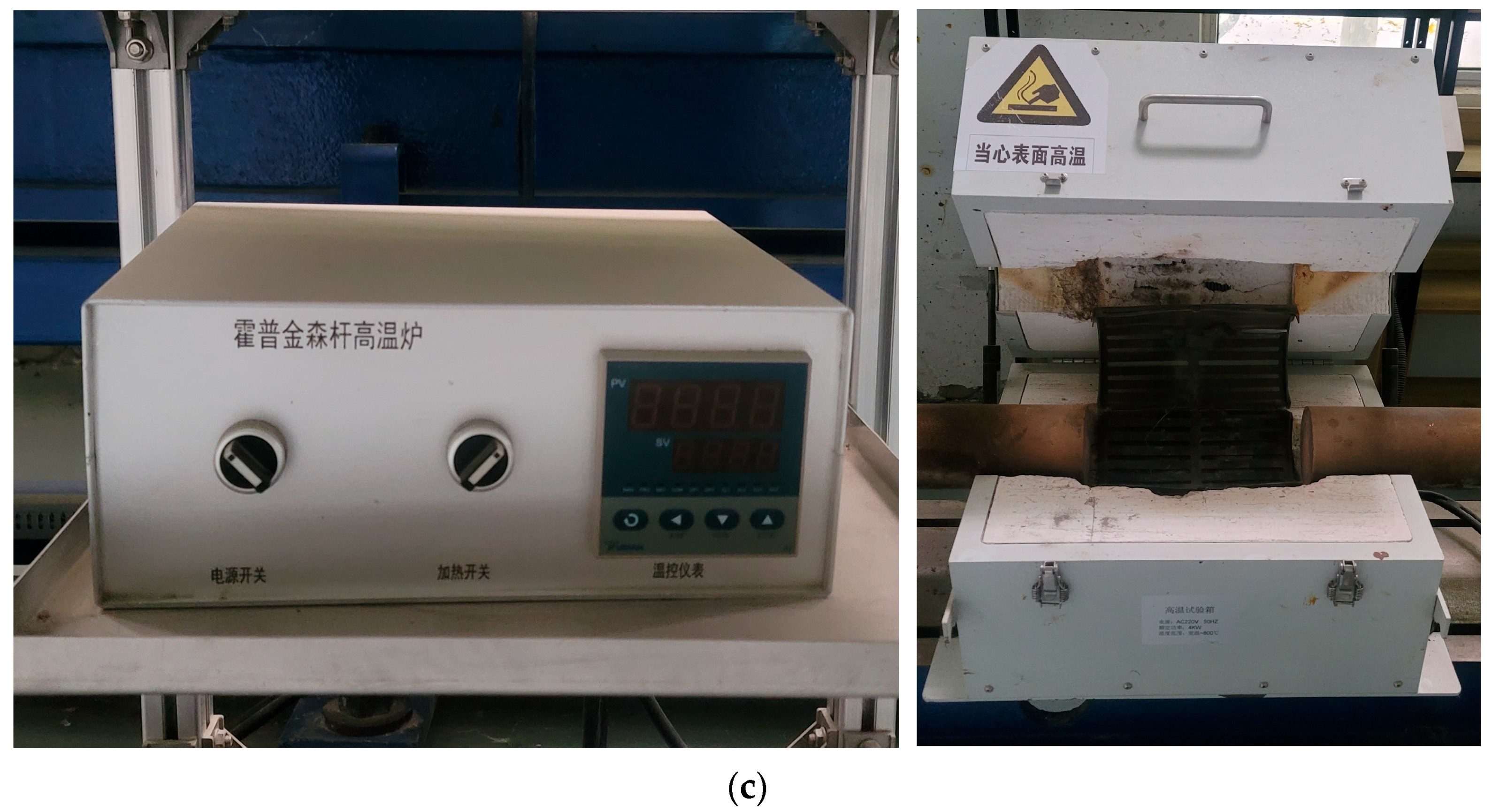

2.2.1. Specimen Preparation and Static Mechanical Testing

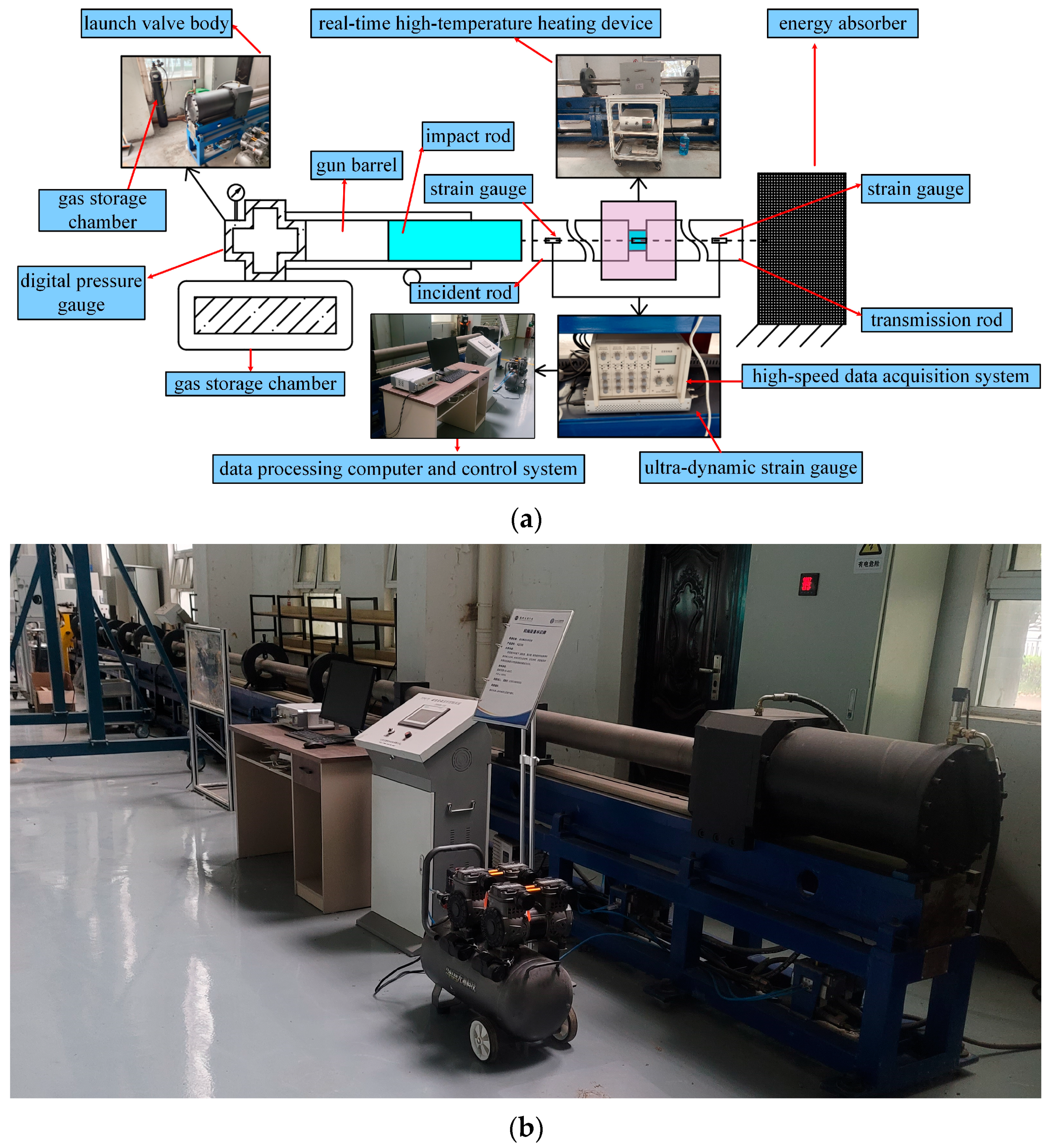

2.2.2. Real-Time High-Temperature Environment Implementation

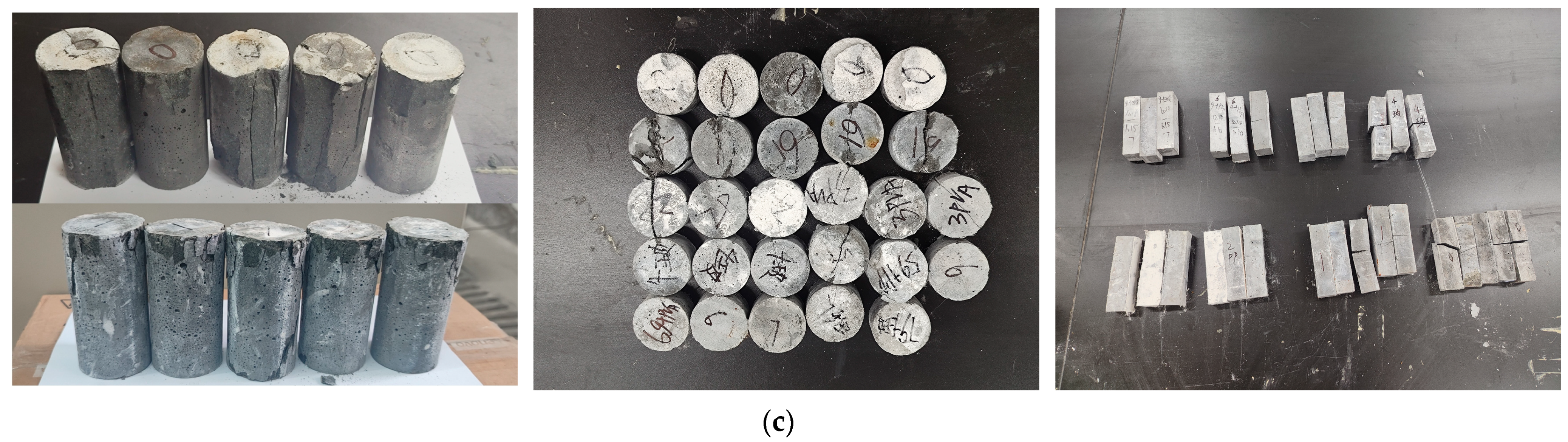

2.2.3. Impact Testing

- (1)

- System Preheating and Calibration:

- (2)

- Specimen Installation and High-Temperature Environment Setup:

- (3)

- Impact Loading:

- (4)

- Data Acquisition, Processing, and Storage:

2.2.4. Observation Methods

3. Results

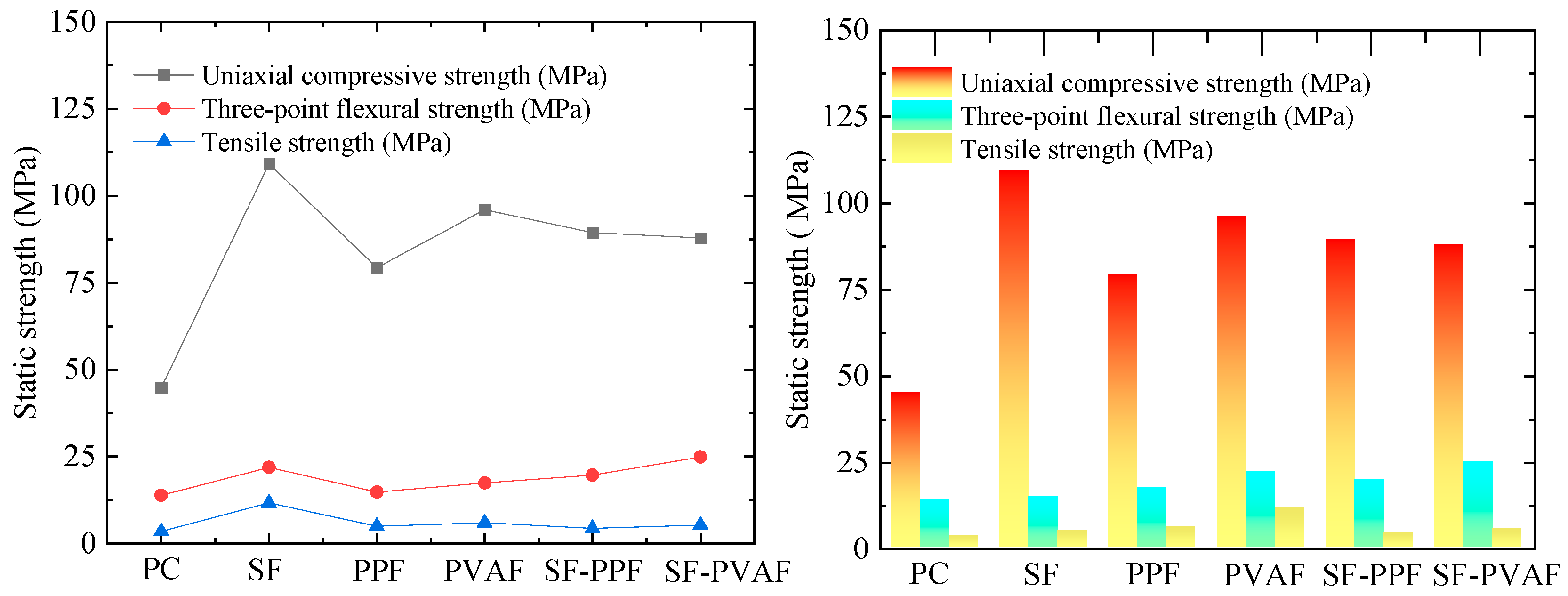

3.1. Static Mechanical Properties at Ambient Temperature

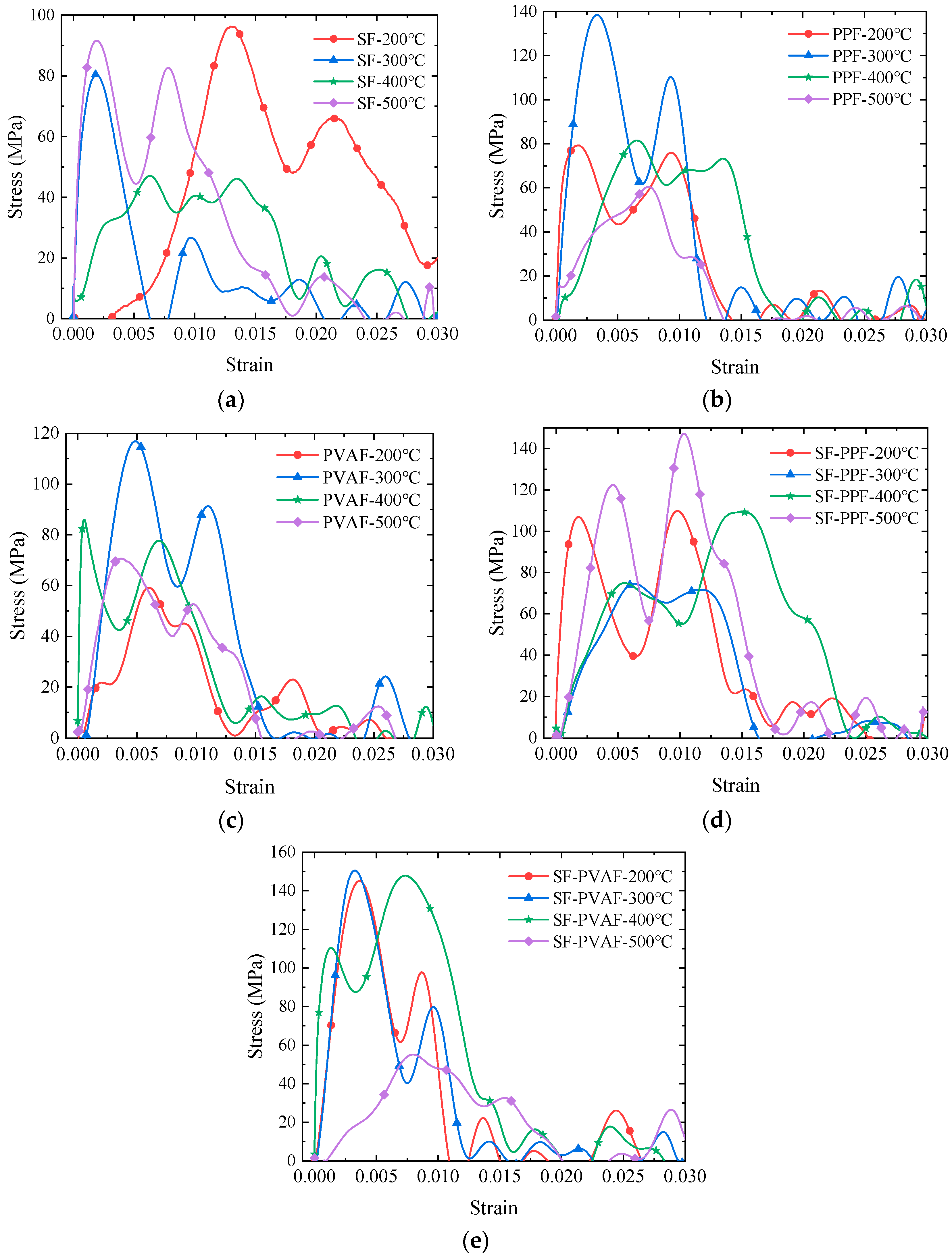

3.2. Dynamic Mechanical Properties Under Real-Time High Temperature

3.2.1. Electrosignal-to-Stress/Strain Transformation in SHPB Testing

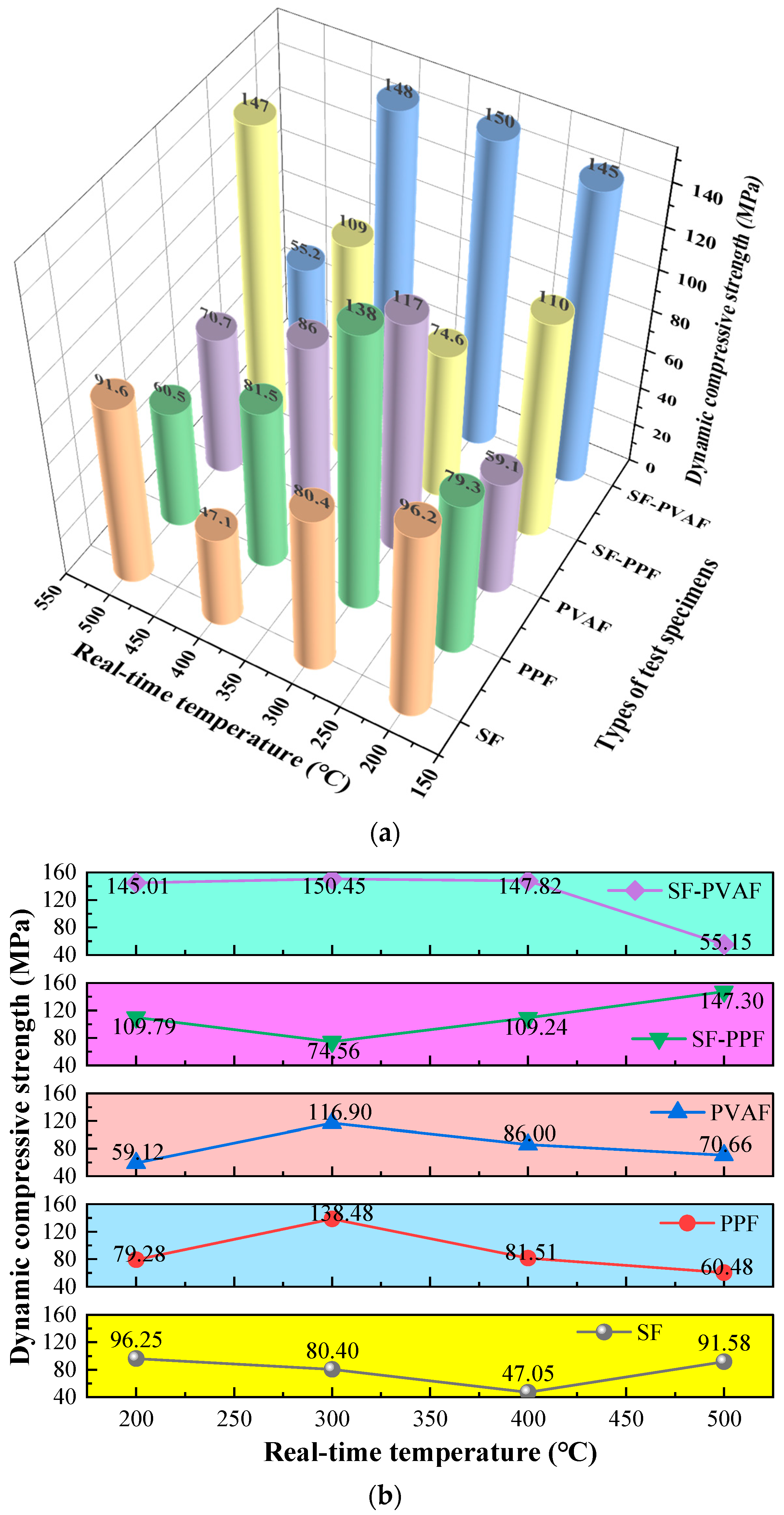

3.2.2. Dynamic Compressive Strength

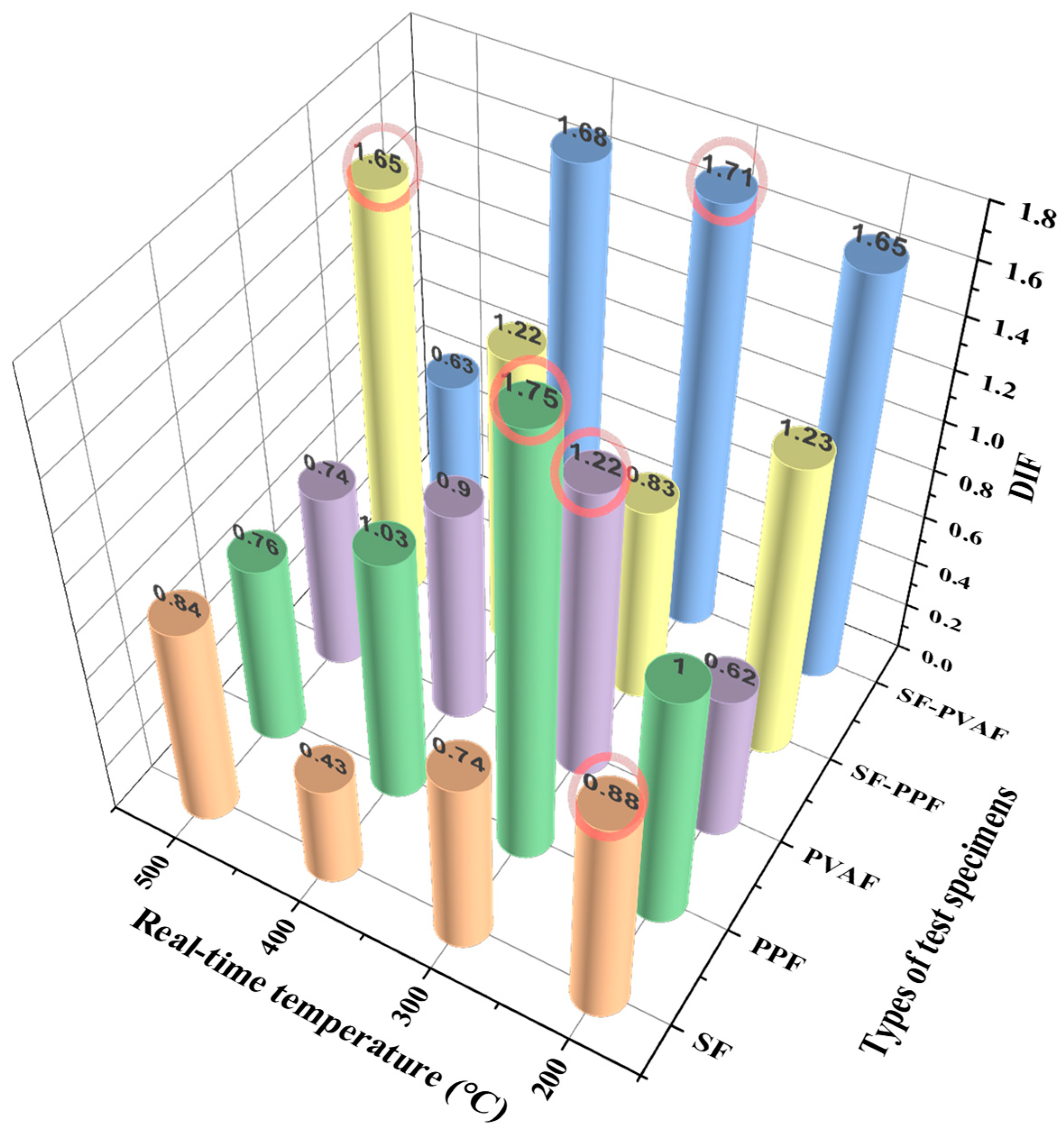

3.2.3. Dynamic Compressive Strength Growth Coefficient

3.2.4. Strain Energy Density (SED)

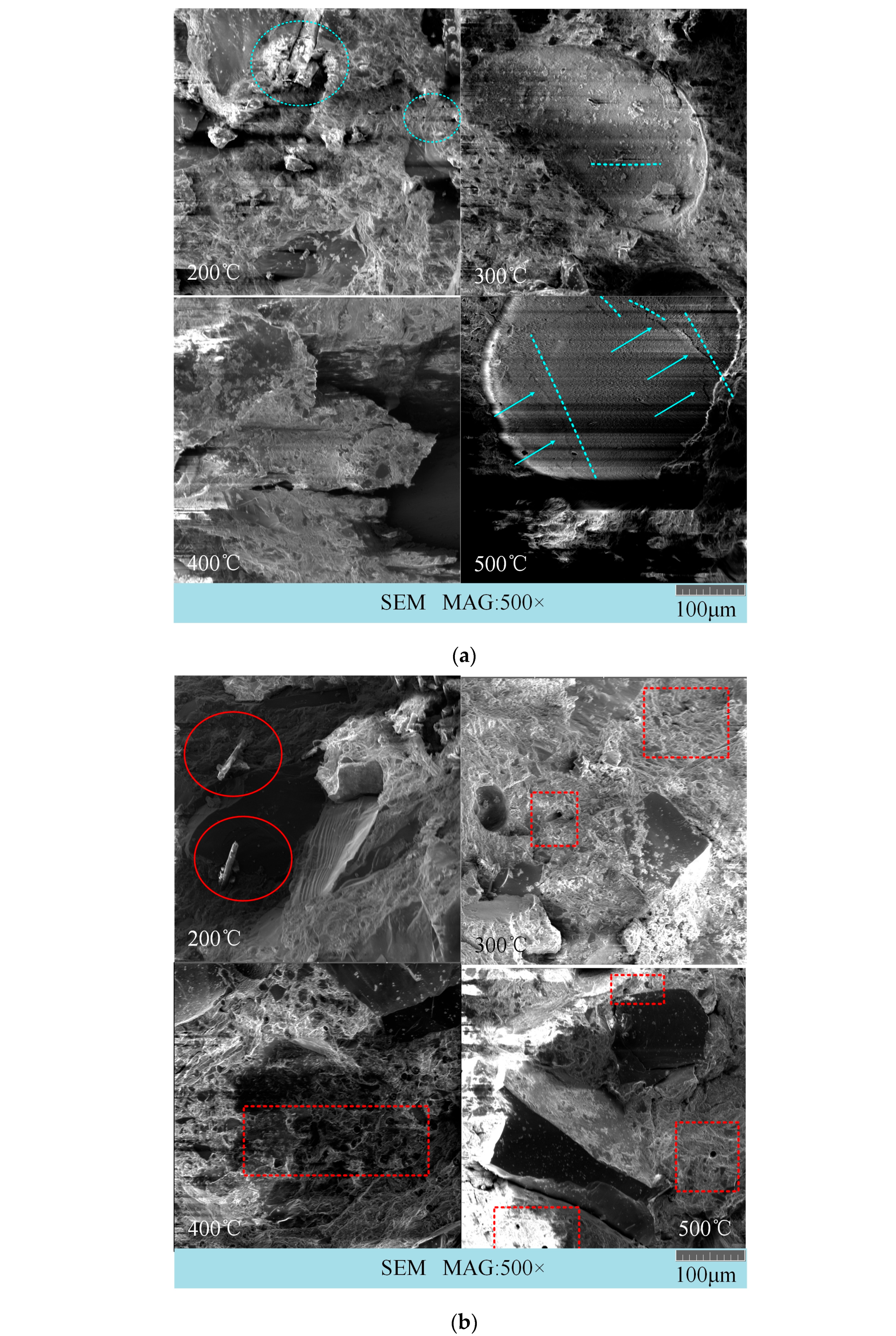

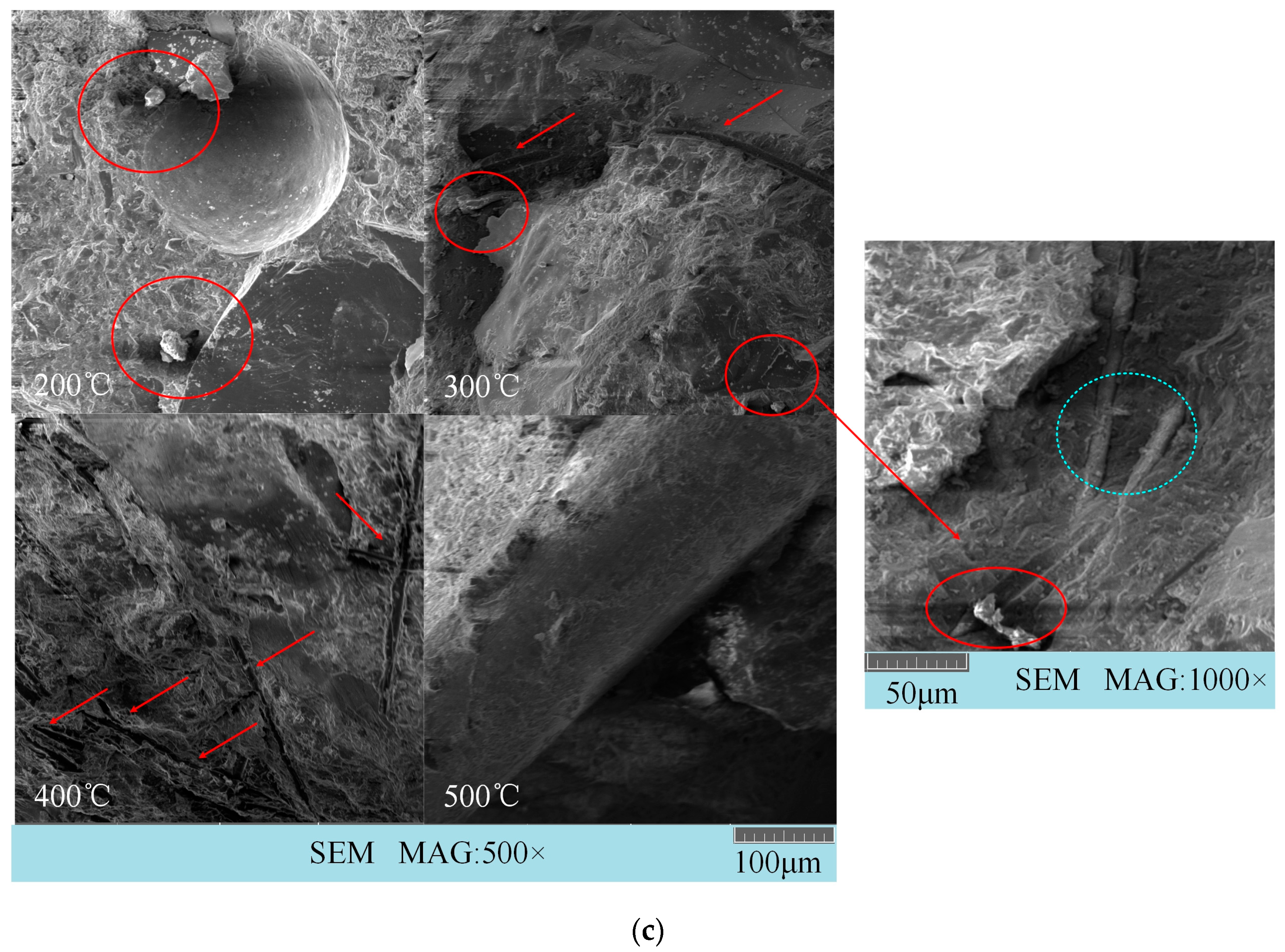

3.3. Microscopic and Macroscopic Failure Modes

4. Discussion

4.1. Synergistic Effects of Hybrid Fibers at Room Temperature

4.1.1. Uniaxial Compressive Strength

4.1.2. Flexural Strength

4.1.3. Tensile Strength

4.2. Temperature-Dependent Dynamic Behavior

4.2.1. Dynamic Compressive Strength Transition

4.2.2. Discussion of the Law of the Dynamic Compressive Strength Growth Coefficient

4.3. Energy Dissipation Mechanisms

4.4. Correlation Between Macroscopic and Microscopic Failure Modes

4.5. Engineering Implications

4.6. Limitations and Future Directions

- (1)

- The temperature range in this study is limited to 200–500 °C, which restricts its applicability to certain industrial scenarios and lacks guidance for industrial environments at higher temperatures. Additionally, the formulation of the specimens studied (40–70 mesh quartz sand gradation) and the fiber reinforcement scheme (a uniform 1:1 volume ratio mix) were relatively simplistic, making it difficult to determine the materials’ behaviors in complex engineering environments. Future research will expand the temperature range to 800 °C to encompass more high-temperature industrial scenarios and include additional fiber mix ratios to explore the threshold of fiber synergistic effects.

- (2)

- The singular gradation (40–70 mesh quartz sand) led to a relatively low strength of the plain concrete specimens (44.87 MPa), which limited the benchmark evaluation of the fiber reinforcement effects. Future studies will optimize aggregate gradation by utilizing continuously graded quartz sand for specimen casting and improve the curing process by introducing steam curing techniques to enhance the density of the matrix.

- (3)

- The SHPB excitation pressure (0.2 MPa) resulted in a uniform strain rate. Subsequent research will investigate different strain rates corresponding to various scenarios by setting different SHPB excitation pressures, thereby revealing the coupling mechanisms between strain rate effects and real-time temperature.

5. Conclusions

- Enhancement of Compressive/Tensile Strength: Steel fibers (SFs) significantly enhance the compressive and tensile strengths of concrete, increasing them by 143.44% and 240.06%, respectively. The high elastic modulus and bridging effect of SFs dominate the effective stress transfer. Meanwhile, the SF-PVAF combination showed the best improvement in flexural strength, reaching 79.62%, due to the synergistic effect of macro-crack bridging by steel fibers and micro-crack branching suppression by PVA fibers.

- Evolution Pattern of Dynamic Compressive Strength: Under real-time temperature conditions, the dynamic compressive strength of SFs and SF-PPF exhibits a “V-shaped” evolution pattern, while those of PPFs and PVAFs show an “inverted V-shaped” trend, influenced by matrix thermal expansion damage–matrix oxidation hardening and fiber melting–carbonization skeleton effects, respectively. The dynamic compressive strength of SF-PVAF remains stable (DIF ≈ 1.65) at 200–400 °C, with the bridging function of steel fibers and the melting and carbonization behavior of PVA working together to enhance toughness. At 500 °C, SF-PPF maintained a high DIF value (1.65), attributed to the stable porous structure formed by melting holes in PP. The peak SED value for steel fibers occurred at 400 °C, while the highest SED value for SF-PPF at 500 °C resulted from the energy absorption effect of melting holes, reflecting the diversity of energy dissipation paths in hybrid fibers.

- Dynamic Fragmentation Mechanism: The dynamic fracture mechanisms at real-time temperatures revealed that the SF system exhibits a micro “meteorite crater” morphology, indicating that stress concentration leads to brittle spalling, which corresponds to large debris on a macroscopic scale. The low SED value indicates that energy is primarily dissipated through localized fragmentation. In the organic fiber system, melting holes of PVA (200–400 °C) and carbonization channels (500 °C) dissipate energy through crack deflection and multiple branching, resulting in smaller debris particles. The debris size of the SF-PVAF hybrid fiber system lies between those of pure SFs and PVAFs, improving the brittle failure characteristics of pure SFs.

- Recommendation for Optimal Dynamic Performance: Structures exposed to environmental temperatures of 200–400 °C can achieve optimal dynamic performance with the SF-PVAF hybrid mix during transient thermal shocks. When the environmental temperature reaches 400–500 °C, the SF-PPF combination is recommended to enhance the impact resistance and high-temperature performance of the material.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sohail, M.G.; Kahraman, R.; Al Nuaimi, N.; Gencturk, B.; Alnahhal, W. Durability characteristics of high and ultra-high performance concretes. J. Build. Eng. 2021, 33, 101669. [Google Scholar] [CrossRef]

- Ozyildirim, H.C.; Sharifi, M. High-Performance Fiber Reinforced Concretes in Virginia. Transp. Res. Rec. 2022, 2676, 686–694. [Google Scholar] [CrossRef]

- Doostkami, H.; de Jesús Estacio Cumberbatch, J.; Formagini, S.; Serna, P.; Roig-Flores, M. Self-healing capability of conventional, high-performance, and Ultra High-Performance Concrete with commercial bacteria characterized by means of water and chloride penetration. Constr. Build. Mater. 2023, 401, 132903. [Google Scholar] [CrossRef]

- Dong, S.; Gu, J.; Ouyang, X.; Jang, S.-H.; Han, B. Enhancing mechanical properties, durability and multifunctionality of concrete structures via using ultra-high performance concrete layer: A review. Compos. Part B Eng. 2025, 297, 112329. [Google Scholar] [CrossRef]

- Wen, Y.; Wang, Z.; Yuan, X.; Yang, X. Optimization of Mechanical Properties and Durability of Steel Fiber-Reinforced Concrete by Nano CaCO3 and Nano TiC to Improve Material Sustainability. Sustainability 2025, 17, 641. [Google Scholar] [CrossRef]

- He, J.; Wang, H.; Yu, Q. Flexural fracture behavior of ultra-high performance concrete after high-temperature exposure. Constr. Build. Mater. 2025, 481, 141544. [Google Scholar] [CrossRef]

- Agrawal, S.; Yulianti, E.; Amran, M.; Hung, C.-C. Behavior of unconfined steel-fiber reinforced UHPC post high-temperature exposure. Case Stud. Constr. Mater. 2025, 22, e04173. [Google Scholar] [CrossRef]

- Tai, Y.-S.; Lee, M.-H. Tensile behavior and damage mechanisms of ultra-high-performance concrete with blended steel fibers under elevated temperatures. J. Build. Eng. 2025, 107, 112742. [Google Scholar] [CrossRef]

- Felicetti, R.; Yarmohammadian, R.; Pont, S.D.; Tengattini, A. Fast vapour migration next to a depressurizing interface: A possible driving mechanism of explosive spalling revealed by neutron imaging. Cem. Concr. Res. 2024, 180, 107508. [Google Scholar] [CrossRef]

- Zhang, T.; Zhu, H.; Zhou, L.; Yan, Z. Multi-level micromechanical analysis of elastic properties of ultra-high performance concrete at high temperatures: Effects of imperfect interface and inclusion size. Compos. Struct. 2021, 262, 113548. [Google Scholar] [CrossRef]

- Li, Y.; Tan, K.H.; Yang, E.-H. Influence of aggregate size and inclusion of polypropylene and steel fibers on the hot permeability of ultra-high performance concrete (UHPC) at elevated temperature. Constr. Build. Mater. 2018, 169, 629–637. [Google Scholar] [CrossRef]

- Zhao, X.; Lu, J.-X.; Tian, W.; Cyr, M.; Tagnit-Hamou, A.; Poon, C.S. Self-healing performance of thermally damaged ultra-high performance concrete: Rehydration and recovery mechanism. Cem. Concr. Res. 2025, 191, 107825. [Google Scholar] [CrossRef]

- Wang, F.; Xiong, T.; Liu, J.; Zeng, J.; Luo, C. Experimental study on temperature characteristics and multi-field analysis for concrete spalling of tunnel linings exposed to high temperatures. Struct. Concr. 2025. [Google Scholar] [CrossRef]

- Shu, R.; Cheng, J.; Xu, G.; Lai, Y.; Huang, L. Dynamic tensile properties of thermally treated concrete specimens subjected to varied heating rates: An investigation using the digital image correlation method. Mech. Time-Depend. Mater. 2024, 29, 1. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, W.; Chen, Y.; Chen, R.; Liu, Y.; Zhang, Y. Study on the dynamic impact mechanical properties of high-temperature resistant ultra-high performance concrete (HTRUHPC) after high temperatures. J. Build. Eng. 2024, 91, 109752. [Google Scholar] [CrossRef]

- Yang, J.; Yan, K.; Doh, J.-H.; Zhang, X. Experimental study on shear performance of ultra-high-performance concrete beams at elevated temperatures. Eng. Struct. 2023, 291, 116304. [Google Scholar] [CrossRef]

- Zhang, Z.; Abdalla, J.A.; Yu, J.; Chen, Y.; Hawileh, R.A.; Mahmoudi, F. Use of polypropylene fibers to mitigate spalling in high strength PE-ECC under elevated temperature. Case Stud. Constr. Mater. 2025, 22, e04381. [Google Scholar] [CrossRef]

- Khan, M.; Lao, J.; Ahmad, M.R.; Dai, J.-G. Influence of high temperatures on the mechanical and microstructural properties of hybrid steel-basalt fibers based ultra-high-performance concrete (UHPC). Constr. Build. Mater. 2024, 411, 134387. [Google Scholar] [CrossRef]

- Shahidzadeh Arabani, A.; Dashti Naserabadi, H.; Aminyavari, S. Experimental investigation of energy absorption in fiber-reinforced ultra high-performance concrete after exposure to elevated temperatures. Case Stud. Constr. Mater. 2025, 22, e04451. [Google Scholar] [CrossRef]

- Xiao, L.; Yan, H.; Zhu, Z.; Xu, C. Mechanical Performance of Steel-PVA Hybrid Fiber Concrete After Elevated Temperature Exposure. Arab. J. Sci. Eng. 2024, 1–17. [Google Scholar] [CrossRef]

- Hung, C.-C.; Yulianti, E.; Agrawal, S. Microstructures, durability, and mechanical behavior of hybrid steel and PP fiber reinforced UHPC at elevated temperatures. Constr. Build. Mater. 2024, 447, 138208. [Google Scholar] [CrossRef]

- Abed, F.; Khalaf, S.; Alhoubi, Y.; Moustafa, M.A.; Al Jamal, M. Effect of fiber types on fire-induced spalling and thermal performance of UHPC circular columns. Dev. Built Environ. 2024, 19, 100523. [Google Scholar] [CrossRef]

- Lin, J.; Zhang, Y.; Huang, S.; Du, H.; Jiang, K. Influence of synthetic fibers on the performance of ultra-high performance concrete (UHPC) at elevated temperatures. J. Build. Eng. 2024, 97, 110735. [Google Scholar] [CrossRef]

- Lin, J.; Zhang, Y.; Guo, Z.; Du, H. Impact of synthetic fibers on spalling and intrinsic pore structure of ultra-high performance concrete (UHPC) under elevated temperatures. Constr. Build. Mater. 2024, 439, 137325. [Google Scholar] [CrossRef]

- Dziomdziora, P.; Smarzewski, P. Effect of Hybrid Fiber Compositions on Mechanical Properties and Durability of Ultra-High-Performance Concrete: A Comprehensive Review. Materials 2025, 18, 2426. [Google Scholar] [CrossRef]

- Wang, T.; Yu, M.; Tian, J.; Sun, Z.; Yu, C.; Ye, J. Residual properties of ultra-high performance concrete containing steel-polypropylene hybrid fiber exposed to elevated temperature at early age. J. Build. Eng. 2025, 99, 111507. [Google Scholar] [CrossRef]

- Shen, X.; Li, X.; Liu, L.; Chen, X.; Du, J. Research on Mechanical Properties of Steel-Polypropylene Fiber-Reinforced Concrete after High-Temperature Treatments. Appl. Sci. 2024, 14, 3861. [Google Scholar] [CrossRef]

- Xu, Z.; He, T.; Liu, Y.; Chen, X.; Liu, L. Study on Dynamic Splitting Properties of S-PP Hybrid Fiber Concrete after High Temperatures. Appl. Sci. 2022, 12, 8437. [Google Scholar] [CrossRef]

- Qiu, H.; Lai, H.; Liao, F.; Chen, Y. Experimental study on dynamic fracture of UHPC-NC specimens after high temperature burning treatment. Theor. Appl. Fract. Mech. 2024, 131, 104384. [Google Scholar] [CrossRef]

- Zhuang, J.; Ni, P.; Chen, J.; Wu, M. Study on the impact resistance of steel fiber-reinforced self-compacting concrete after high temperature. Structures 2023, 57, 105281. [Google Scholar] [CrossRef]

- Chen, M.; Wang, Y.; Zhang, T.; Zhang, M. Microstructural evolution and dynamic compressive properties of engineered cementitious composites at elevated temperatures. J. Build. Eng. 2023, 71, 106519. [Google Scholar] [CrossRef]

- Ping, Q.; Wu, M.; Yuan, P.; Su, H.; Zhang, H. Dynamic Splitting Experimental Study on Sandstone at Actual High Temperatures under Different Loading Rates. Shock Vib. 2020, 2020, 8867102. [Google Scholar] [CrossRef]

- Zhang, L.; Li, B.; Wu, P.; Guo, S.; Zheng, Y.; Li, M.; Zhu, F. Experimental Study on the Dynamic Mechanical Properties and Crashing Behaviors of Limestone Under High Temperatures in Real-Time. Appl. Sci. 2024, 14, 10486. [Google Scholar] [CrossRef]

- Li, Y.; Zhai, Y.; Xie, Y.; Meng, F. Research on the Impact Mechanical Properties of Real-Time High-Temperature Granite and a Coupled Thermal–Mechanical Constitutive Model. Materials 2023, 16, 2773. [Google Scholar] [CrossRef]

- Li, M.; Zhu, F.; Mao, Y.; Fan, F.; Wu, B.; Deng, J. Dynamic Mechanical Characteristics and Fracture Size Effect of Coal Sandstone Under High-Temperature and High-Strain Rate Coupling Action. Fractal Fract. 2025, 9, 381. [Google Scholar] [CrossRef]

- Wu, P.; Zhang, L.; Li, B.; Zheng, Y.; Li, M.; Zhu, F. Mechanical properties and microscopic damage characteristics of coal series limestone under coupling effects of high temperature and impact. Sci. Rep. 2024, 14, 32093. [Google Scholar] [CrossRef]

- Li, R.; Liu, L.; An, H.; Wang, Y. Study on Dynamic Constitutive Model of Polypropylene Concrete under Real-Time High-Temperature Conditions. Appl. Sci. 2022, 12, 1482. [Google Scholar] [CrossRef]

- Sucharda, O.; Gandel, R.; Cmiel, P.; Jerabek, J.; Bilek, V. Utilization of High-Performance Concrete Mixtures for Advanced Manufacturing Technologies. Buildings 2024, 14, 2269. [Google Scholar] [CrossRef]

- Yang, Y.; Li, Q.; Qiao, L. Review of SHPB Dynamic Load Impact Test Characteristics and Energy Analysis Methods. Processes 2023, 11, 3029. [Google Scholar] [CrossRef]

| Material | Specification | Mass per Unit Volume (kg/m3) |

|---|---|---|

| Cement | P∙Ⅱ52.5 Portland cement | 900.00 |

| Quartz sand | High-purity, 40–70 mesh | 940.00 |

| Silica fume | Premium grade | 160.00 |

| Additive | Polycarboxylate superplasticizer | 17.00 |

| Water | Deionized water | 190.00 |

| Fibers | SF/PP/PVA fibers (12 mm length) | Volume fraction: 2% |

| Group Designation | Types of Fiber Reinforcement | Fiber Volume Fraction (vol.%) |

|---|---|---|

| PC | No fiber, plain concrete | 0 |

| SF | Steel fiber | 2 |

| PPF | PP fiber | 2 |

| PVAF | PVA fiber | 2 |

| SF-PPF | Steel + PP fiber | 1 + 1 |

| SF-PVAF | Steel + PVA fiber | 1 + 1 |

| Strength/Type of Specimen | PC | SF | PPF | PVAF | SF-PPF | SF-PVAF |

|---|---|---|---|---|---|---|

| Single-axis compressive strength (MPa) | 44.87 | 109.23 | 79.31 | 95.99 | 89.39 | 87.85 |

| Triaxial flexural strength (MPa) | 13.84 | 21.9 | 14.78 | 17.39 | 19.66 | 24.86 |

| Tensile strength (MPa) | 3.42 | 11.63 | 4.95 | 5.94 | 4.32 | 5.29 |

| Compression strength improvement rate (%) | - | 143.44 | 76.76 | 113.93 | 99.22 | 95.79 |

| Triaxial flexural strength improvement rate (%) | - | 58.24 | 6.79 | 25.65 | 42.05 | 79.62 |

| Tensile strength improvement rate (%) | - | 240.06 | 44.74 | 73.68 | 26.32 | 54.68 |

| Temperature (°C)/Type of Specimen | SFs | PPFs | PVAFs | SF-PPF | SF-PVAF |

|---|---|---|---|---|---|

| 200 | 0.88 | 1.00 | 0.62 | 1.23 | 1.65 |

| 300 | 0.74 | 1.75 | 1.22 | 0.83 | 1.71 |

| 400 | 0.43 | 1.03 | 0.90 | 1.22 | 1.68 |

| 500 | 0.84 | 0.76 | 0.74 | 1.65 | 0.63 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, P.; Li, Y.; Ding, F.; Liu, X.; Bi, X.; Xu, T. Real-Time Temperature Effects on Dynamic Impact Mechanical Properties of Hybrid Fiber-Reinforced High-Performance Concrete. Materials 2025, 18, 3241. https://doi.org/10.3390/ma18143241

Huang P, Li Y, Ding F, Liu X, Bi X, Xu T. Real-Time Temperature Effects on Dynamic Impact Mechanical Properties of Hybrid Fiber-Reinforced High-Performance Concrete. Materials. 2025; 18(14):3241. https://doi.org/10.3390/ma18143241

Chicago/Turabian StyleHuang, Pengcheng, Yan Li, Fei Ding, Xiang Liu, Xiaoxi Bi, and Tao Xu. 2025. "Real-Time Temperature Effects on Dynamic Impact Mechanical Properties of Hybrid Fiber-Reinforced High-Performance Concrete" Materials 18, no. 14: 3241. https://doi.org/10.3390/ma18143241

APA StyleHuang, P., Li, Y., Ding, F., Liu, X., Bi, X., & Xu, T. (2025). Real-Time Temperature Effects on Dynamic Impact Mechanical Properties of Hybrid Fiber-Reinforced High-Performance Concrete. Materials, 18(14), 3241. https://doi.org/10.3390/ma18143241