The Effects of Heat Treatment Temperatures on the Properties of 316L Stainless Steel Produced via Laser Powder Bed Fusion

Abstract

1. Introduction

2. Materials and Methods

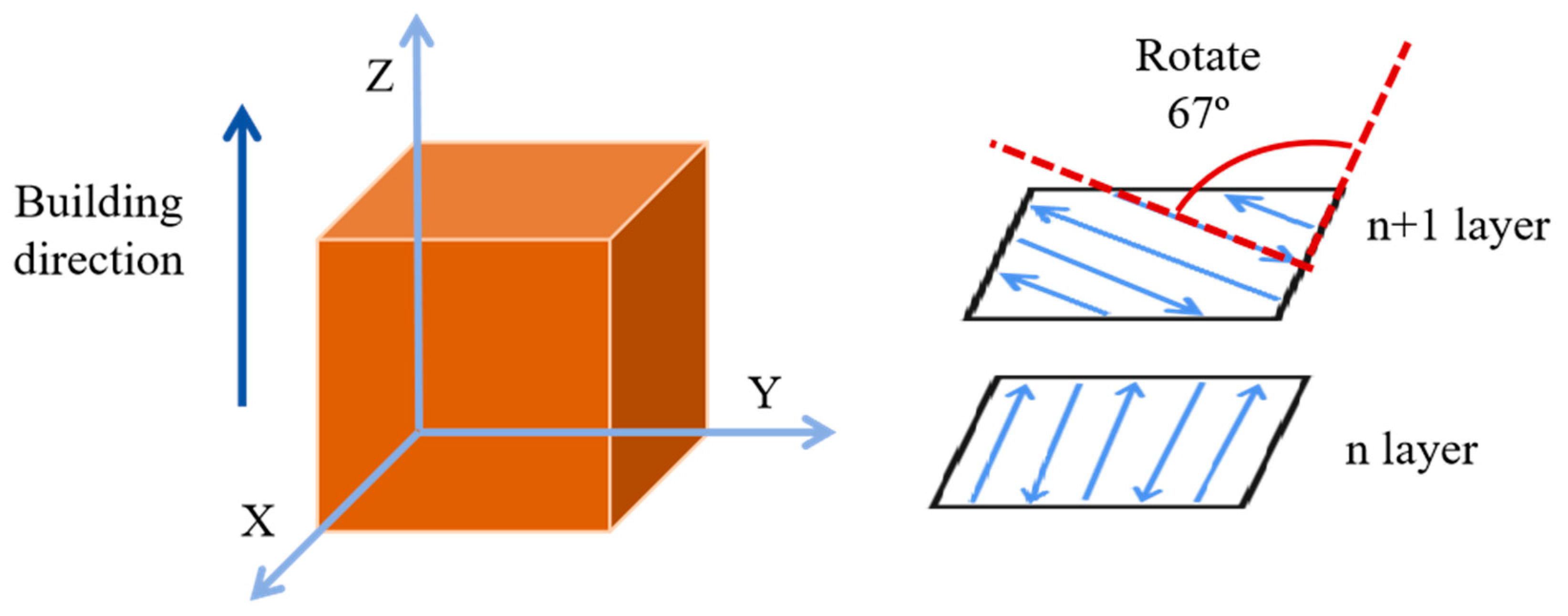

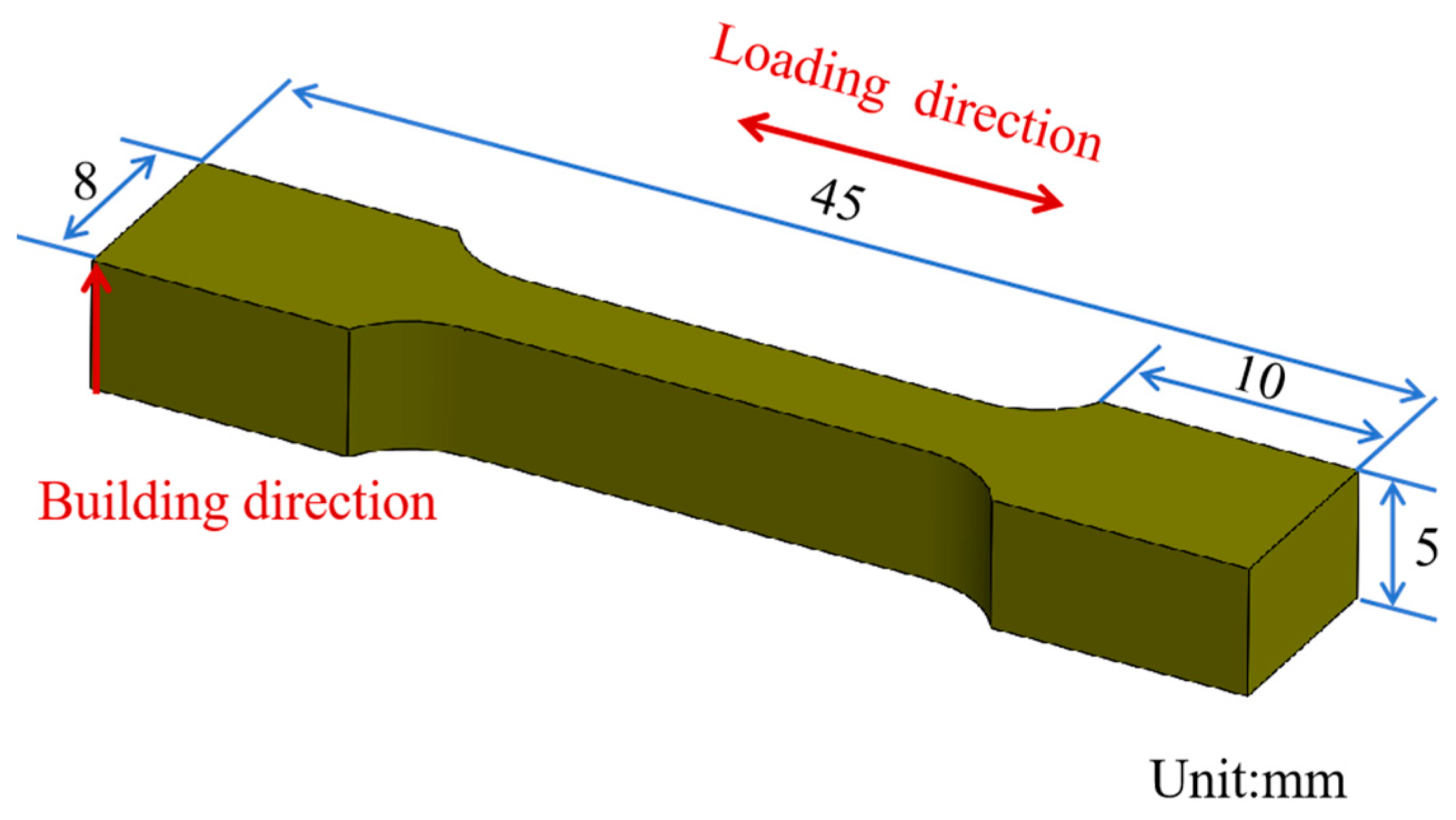

2.1. Materials and Manufacturing

2.2. Heat Treatment Process

2.3. Measurement and Characterization

3. Experimental Results and Discussion

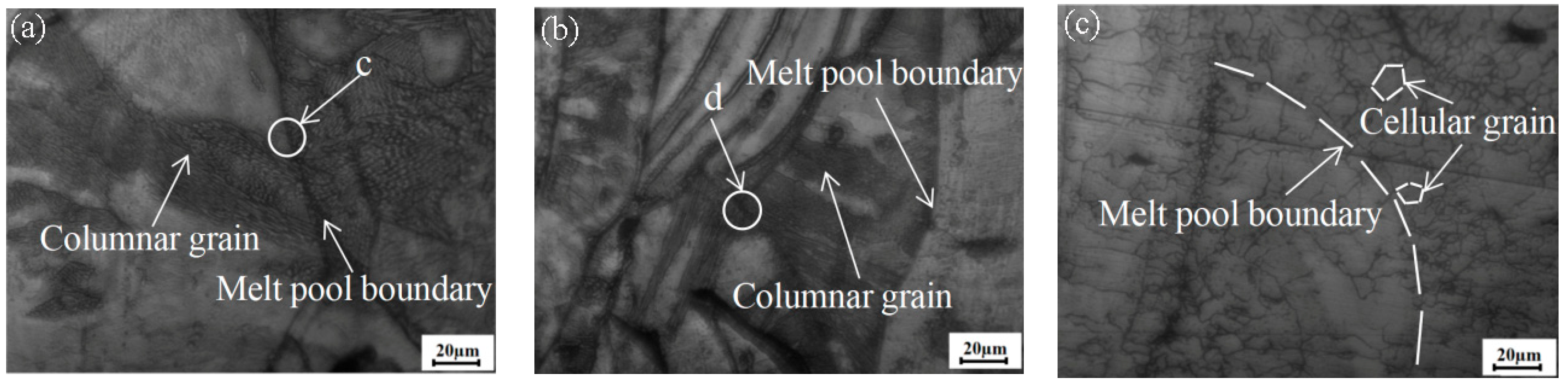

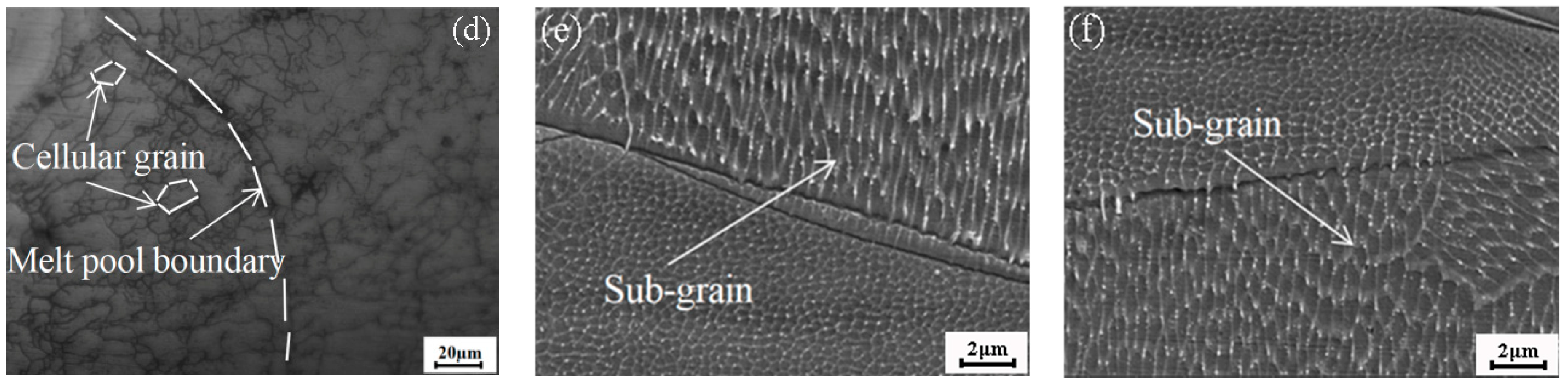

3.1. Microstructure

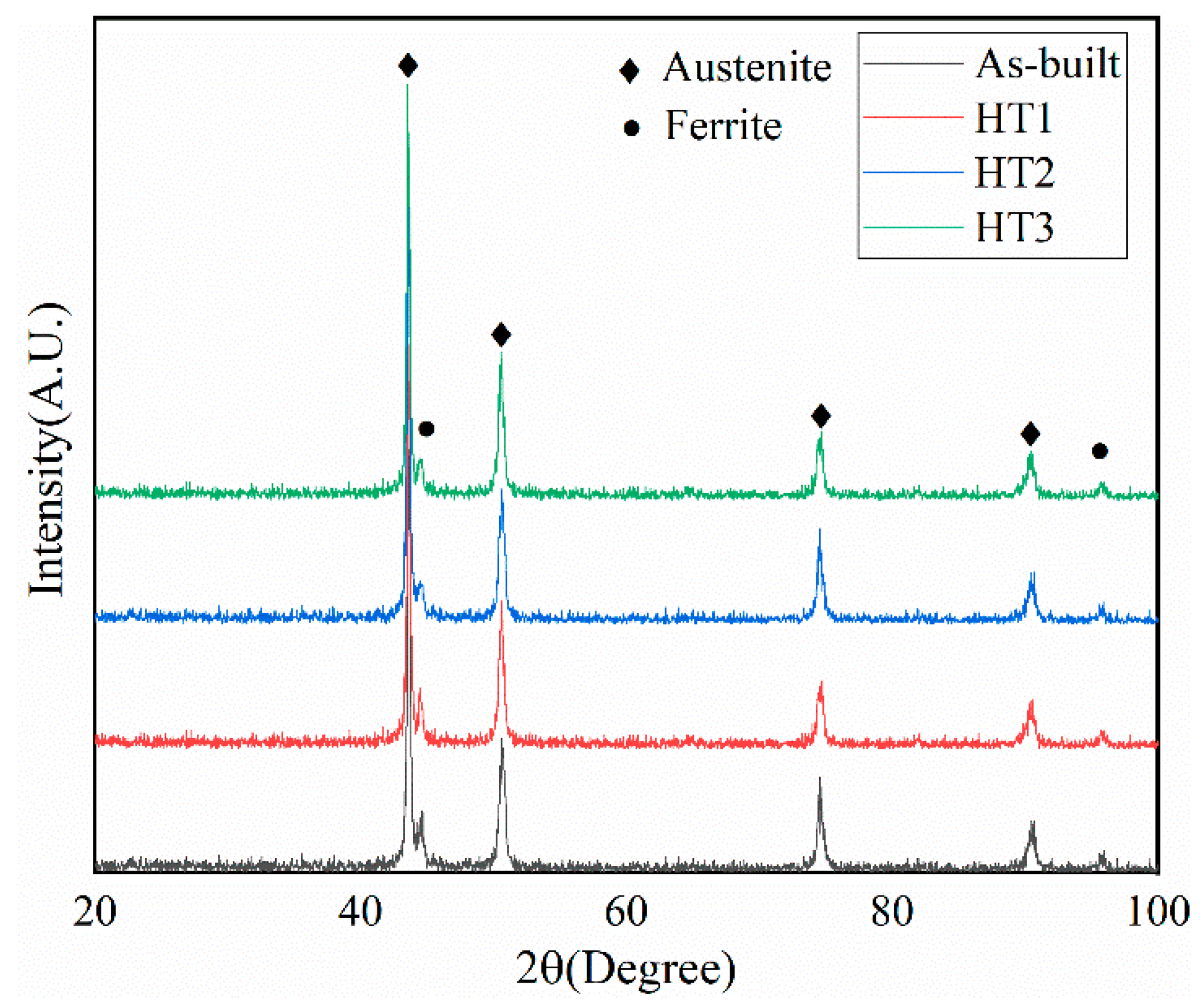

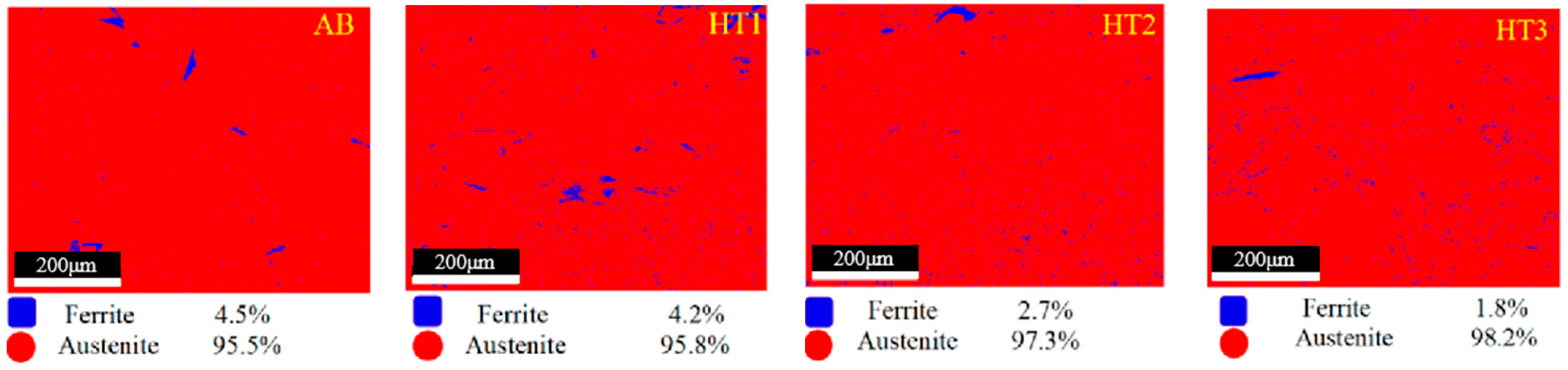

3.2. Phase Analysis

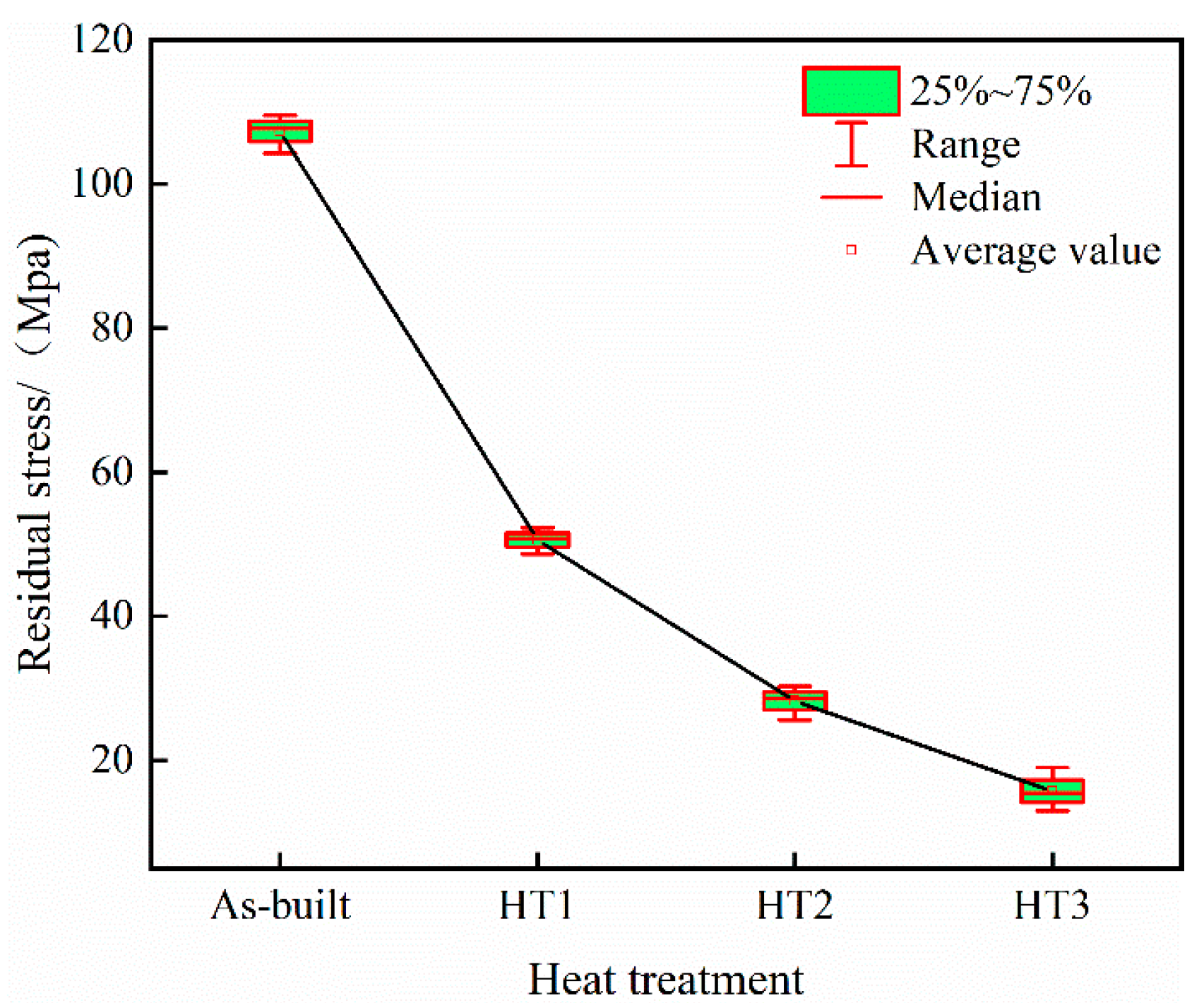

3.3. Residual Stress

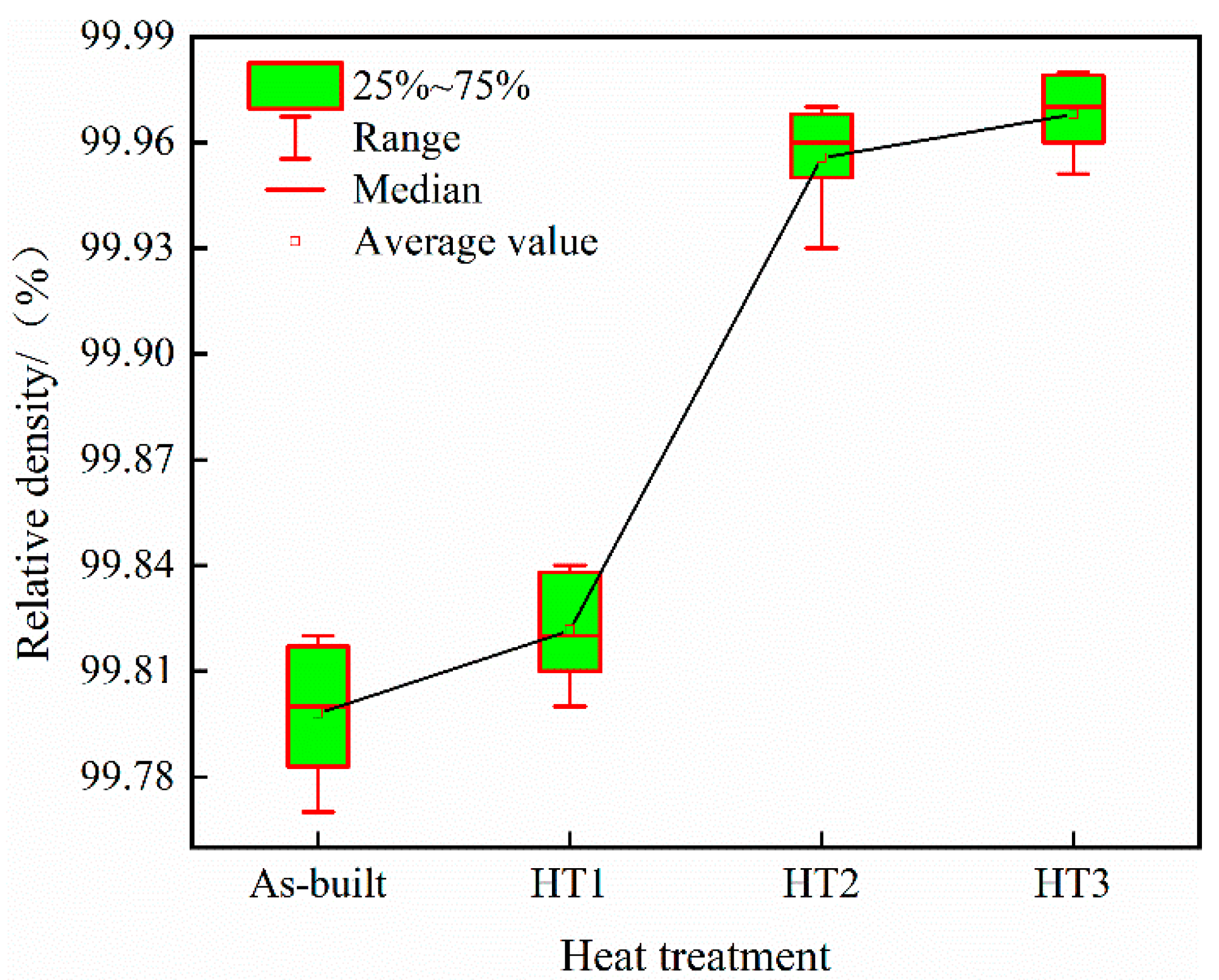

3.4. Relative Density

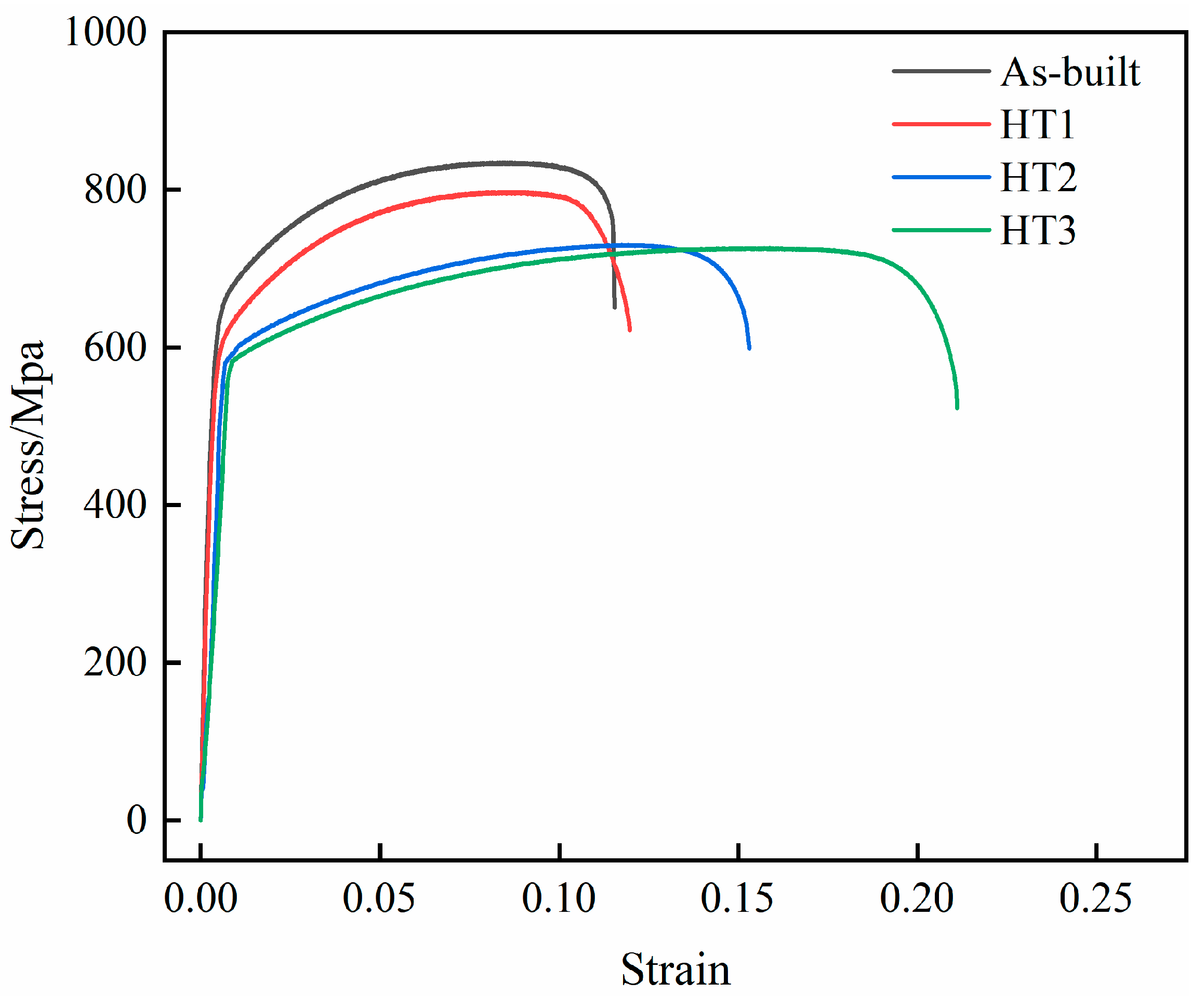

3.5. Mechanical Property

3.6. Comparison with Similar Results

4. Conclusions

- (1)

- The microstructure of the specimens formed via PBF-LB/M is columnar grains growing along the melt pool boundary, in which subgrains are distributed. High-temperature heat treatment (800 °C and above) dissolves subgrains in 316L SS specimens, resulting in refined and more uniform grain structures that contribute to residual stress reduction. Additionally, elevated temperatures enhance the metallurgical bonding strength between metal powders, thereby significantly increasing specimen densification. After the heat treatment at 1100 °C, the residual stress is reduced by 85.59% compared with the original component, and the density can reach up to 99.97%.

- (2)

- The main composition of the 316L SS specimens manufactured via PBF-LB/M was austenite with a small amount of ferrite. Heat treatment at 500 °C did not result in a significant change in the composition of the specimens, whereas heat treatments at 800 °C and 1100 °C resulted in the transformation of the high-temperature ferrite phase formed during PBF-LB/M fabrication, with the ferrite content of the specimens reaching a minimum of 1.8% at a heat treatment of 1100 °C.

- (3)

- Heat treatment led to a reduction in the strength of 316L SS specimens fabricated via PBF-LB/M, while elongation increased. This trend became more significant with increasing heat treatment temperature. Specifically, at 1100 °C, the tensile and yield strengths decreased by 13.03% and 8.33%, respectively, compared to the as-built specimens, while elongation markedly increased by 83.48%. These results indicate that high-temperature heat treatments have beneficial effects on the overall mechanical performance of the material.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Navarro, M.; Michiardi, A.; Castaño, O.; Planell, J.A. Biomaterials in Orthopaedics. J. R. Soc. Interface 2008, 5, 1137–1158. [Google Scholar] [CrossRef] [PubMed]

- D’Andrea, D. Additive Manufacturing of AISI 316L Stainless Steel: A Review. Metals 2023, 13, 1370. [Google Scholar] [CrossRef]

- Savolainen, J.; Collan, M. How Additive Manufacturing Technology Changes Business Models?—Review of Literature. Addit. Manuf. 2020, 32, 101070. [Google Scholar] [CrossRef]

- Simoes, M.; Harris, J.A.; Ghouse, S.; Hooper, P.A.; McShane, G.J. Process Parameter Sensitivity of the Energy Absorbing Properties of Additively Manufactured Metallic Cellular Materials. Mater. Des. 2022, 224, 111398. [Google Scholar] [CrossRef]

- Mercelis, P.; Kruth, J. Residual Stresses in Selective Laser Sintering and Selective Laser Melting. Rapid Prototyp. J. 2006, 12, 254–265. [Google Scholar] [CrossRef]

- Wang, Z.; Yang, S.; Huang, Y.; Fan, C.; Peng, Z.; Gao, Z. Microstructure and Fatigue Damage of 316L Stainless Steel Manufactured by Selective Laser Melting (SLM). Materials 2021, 14, 7544. [Google Scholar] [CrossRef]

- Peng, T.; Chen, C. Influence of Energy Density on Energy Demand and Porosity of 316L Stainless Steel Fabricated by Selective Laser Melting. Int. J. Precis. Eng. Manuf. Green Technol. 2018, 5, 55–62. [Google Scholar] [CrossRef]

- Yang, D.C.; Kan, X.F.; Gao, P.F.; Zhao, Y.; Yin, Y.J.; Zhao, Z.Z.; Sun, J.Q. Influence of Porosity on Mechanical and Corrosion Properties of SLM 316L Stainless Steel. Appl. Phys. A 2022, 128, 51. [Google Scholar] [CrossRef]

- Röttger, A.; Boes, J.; Theisen, W.; Thiele, M.; Esen, C.; Edelmann, A.; Hellmann, R. Microstructure and Mechanical Properties of 316L Austenitic Stainless Steel Processed by Different SLM Devices. Int. J. Adv. Manuf. Technol. 2020, 108, 769–783. [Google Scholar] [CrossRef]

- Jiang, H.Z.; Li, Z.Y.; Feng, T.; Wu, P.Y.; Chen, Q.S.; Feng, Y.L.; Chen, L.F.; Hou, J.Y.; Xu, H.J. Effect of Process Parameters on Defects, Melt Pool Shape, Microstructure, and Tensile Behavior of 316L Stainless Steel Produced by Selective Laser Melting. Acta Metall. Sin. Engl. Lett. 2021, 34, 495–510. [Google Scholar] [CrossRef]

- Antony, K.; Arivazhagan, N.; Senthilkumaran, K. Numerical and Experimental Investigations on Laser Melting of Stainless Steel 316L Metal Powders. J. Manuf. Processes 2014, 16, 345–355. [Google Scholar] [CrossRef]

- Deng, Y.; Mao, Z.; Yang, N.; Niu, X.; Lu, X. Collaborative Optimization of Density and Surface Roughness of 316L Stainless Steel in Selective Laser Melting. Materials 2020, 13, 1601. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, M.; Shi, W.; Ma, Y.; Yang, J. Study on Performance Optimization of 316L Stainless Steel Parts by High-Efficiency Selective Laser Melting. Opt. Laser Technol. 2021, 138, 106872. [Google Scholar] [CrossRef]

- Wang, D.; Wu, S.; Yang, Y.; Dou, W.; Deng, S.; Wang, Z.; Li, S. The Effect of a Scanning Strategy on the Residual Stress of 316L Steel Parts Fabricated by Selective Laser Melting (SLM). Materials 2018, 11, 1821. [Google Scholar] [CrossRef]

- Shin, W.S.; Son, B.; Song, W.; Sohn, H.; Jang, H.; Kim, Y.J.; Park, C. Heat Treatment Effect on the Microstructure, Mechanical Properties, and Wear Behaviors of Stainless Steel 316L Prepared via Selective Laser Melting. Mater. Sci. Eng. A 2021, 806, 140805. [Google Scholar] [CrossRef]

- Kamariah, M.S.I.N.; Harun, W.S.W.; Khalil, N.Z.; Ahmad, F.; Ismail, M.H.; Sharif, S. Effect of Heat Treatment on Mechanical Properties and Microstructure of Selective Laser Melting 316L Stainless Steel. IOP Conf. Ser. Mater. Sci. Eng. 2017, 257, 12021. [Google Scholar] [CrossRef]

- Sistiaga, M.L.M.; Nardone, S.; Hautfenne, C.; Humbeeck, J.V. Effect of Heat Treatment of 316L Stainless Steel Produced by Selective Laser Melting (SLM). In Proceedings of the 27th Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, Austin, TX, USA, 8–10 August 2016; pp. 558–565. [Google Scholar]

- Zhou, Y.; Duan, L.; Li, F.; Chen, K.; Wen, S. Effect of Heat Treatment on the Microstructure and Mechanical Property of W/316L Multi-Material Fabricated by Selective Laser Melting. J. Alloys Compd. 2022, 890, 161841. [Google Scholar] [CrossRef]

- Tascioglu, E.; Karabulut, Y.; Kaynak, Y. Influence of Heat Treatment Temperature on the Microstructural, Mechanical, and Wear Behavior of 316L Stainless Steel Fabricated by Laser Powder Bed Additive Manufacturing. Int. J. Adv. Manuf. Technol. 2020, 107, 1947–1956. [Google Scholar] [CrossRef]

- Morozova, I.; Kehm, C.; Obrosov, A.; Yang, Y.; Miah, K.U.M.; Uludintceva, E.; Fritzsche, S.; Weiß, S.; Michailov, V. On the Heat Treatment of Selective-Laser-Melted 316L. J. Mater. Eng. Perform. 2023, 32, 4295–4305. [Google Scholar] [CrossRef]

- Ronneberg, T.; Davies, C.M.; Hooper, P.A. Revealing Relationships between Porosity, Microstructure and Mechanical Properties of Laser Powder Bed Fusion 316L Stainless Steel through Heat Treatment. Mater. Des. 2020, 189, 108481. [Google Scholar] [CrossRef]

- Kurzynowski, T.; Gruber, K.; Stopyra, W.; Kuźnicka, B.; Chlebus, E. Correlation between Process Parameters, Microstructure and Properties of 316 L Stainless Steel Processed by Selective Laser Melting. Mater. Sci. Eng. A 2018, 718, 64–73. [Google Scholar] [CrossRef]

- Chao, Q.; Thomas, S.; Birbilis, N.; Cizek, P.; Hodgson, P.D.; Fabijanic, D. The Effect of Post-Processing Heat Treatment on the Microstructure, Residual Stress and Mechanical Properties of Selective Laser Melted 316L Stainless Steel. Mater. Sci. Eng. A 2021, 821, 141611. [Google Scholar] [CrossRef]

- Kong, D.C.; Ni, X.Q.; Dong, C.F.; Zhang, L.; Man, C.; Yao, J.Z.; Xiao, K.; Li, X.G. Heat Treatment Effect on the Microstructure and Corrosion Behavior of 316L Stainless Steel Fabricated by Selective Laser Melting for Proton Exchange Membrane Fuel Cells. Electrochim. Acta 2018, 276, 293–303. [Google Scholar] [CrossRef]

- Xiao, Q.; Chen, J.J.; Lee, H.B.; Jang, C.; Jang, K. Effect of Heat Treatment on Corrosion Behaviour of Additively Manufactured 316L Stainless Steel in High-Temperature Water. Corros. Sci. 2023, 210, 110830. [Google Scholar] [CrossRef]

- Liu, W.; Liu, C.S.; Wang, Y.; Zhang, H.; Ni, H.W. Effect of Heat Treatment on the Corrosion Resistance of 316L Stainless Steel Manufactured by Laser Powder Bed Fusion. J. Mater. Res. Technol. 2024, 32, 3896–3912. [Google Scholar] [CrossRef]

- Laleh, M.; Hughes, A.E.; Xu, W.; Cizek, P.; Tan, M.Y. Unanticipated Drastic Decline in Pitting Corrosion Resistance of Additively Manufactured 316L Stainless Steel after High-Temperature Post-Processing. Corros. Sci. 2020, 165, 108412. [Google Scholar] [CrossRef]

- ASTM E8/E8M-24; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: Con-shohocken, PA, USA, 2024.

- Saeidi, K.; Gao, X.; Zhong, Y.; Shen, Z.J. Hardened Austenite Steel with Columnar Sub-Grain Structure Formed by Laser Melting. Mater. Sci. Eng. A 2015, 625, 221–229. [Google Scholar] [CrossRef]

- Saeidi, K.; Akhtar, F. Subgrain-Controlled Grain Growth in the Laser-Melted 316 L Promoting Strength at High Temperatures. R. Soc. Open Sci. 2018, 5, 172394. [Google Scholar] [CrossRef]

- Benarji, K.; Ravi Kumar, Y.; Jinoop, A.N.; Paul, C.P.; Bindra, K.S. Effect of Heat-Treatment on the Microstructure, Mechanical Properties and Corrosion Behaviour of SS 316 Structures Built by Laser Directed Energy Deposition Based Additive Manufacturing. Met. Mater. Int. 2021, 27, 488–499. [Google Scholar] [CrossRef]

- Waqar, S.; Liu, J.W.; Sun, Q.D.; Guo, K.; Sun, J. Effect of Post-Heat Treatment Cooling on Microstructure and Mechanical Properties of Selective Laser Melting Manufactured Austenitic 316L Stainless Steel. Rapid Prototyp. J. 2020, 26, 1739–1749. [Google Scholar] [CrossRef]

| Element | Fe | Cr | Ni | Mo | Mn | Si | C | P | S |

|---|---|---|---|---|---|---|---|---|---|

| Mass fraction (%) | 68.635 | 16.92 | 10.63 | 2.46 | 0.74 | 0.59 | 0.011 | 0.01 | 0.004 |

| Laser Power (W) | Scanning Speed (mm/s) | Hatching Distance (μm) | Layer Thickness (μm) |

|---|---|---|---|

| 190 | 750 | 100 | 30 |

| Heat Treatment (HT) | HT Cycle |

|---|---|

| As-built | - |

| HT1 | 500 °C + 1 h + furnace cooling |

| HT2 | 800 °C + 1 h + furnace cooling |

| HT3 | 1100 °C + 1 h + furnace cooling |

| No. | Cooling Methods | Microstructure | Phase Analysis | Residual Stress | Relative Density | Mechanical Property | Ref. |

|---|---|---|---|---|---|---|---|

| 1 | air cooling or water cooling | no grain enlargement, but the cellular dendritic structure is completely dissolved | N.A. 1 | N.A. | N.A. | hardness and yield strength decrease | [17] |

| 2 | water quenching | more uniform | ferrite phase reduction | N.A. | N.A. | hardness decreases | [31] |

| 3 | furnace cooling or air cooling | subgrain structures and melting pool boundary dissolution | no comparative analysis | N.A. | N.A. | hardness and strength decrease; ductility increases | [32] |

| 4 | air cooling | more uniform | N.A. | decrease | increase | N.A. | [19] |

| 5 | air cooling | subgrain structures dissolution | no change | decrease | no change | strength decrease | [23] |

| 6 | furnace cooling | subgrain structures dissolution | ferrite phase reduction | decrease | increase | strength decrease | this work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Y.; Chai, M.; Zheng, F.; Li, Z. The Effects of Heat Treatment Temperatures on the Properties of 316L Stainless Steel Produced via Laser Powder Bed Fusion. Materials 2025, 18, 3167. https://doi.org/10.3390/ma18133167

Zhou Y, Chai M, Zheng F, Li Z. The Effects of Heat Treatment Temperatures on the Properties of 316L Stainless Steel Produced via Laser Powder Bed Fusion. Materials. 2025; 18(13):3167. https://doi.org/10.3390/ma18133167

Chicago/Turabian StyleZhou, Yizhi, Mingxia Chai, Fu Zheng, and Zhiyong Li. 2025. "The Effects of Heat Treatment Temperatures on the Properties of 316L Stainless Steel Produced via Laser Powder Bed Fusion" Materials 18, no. 13: 3167. https://doi.org/10.3390/ma18133167

APA StyleZhou, Y., Chai, M., Zheng, F., & Li, Z. (2025). The Effects of Heat Treatment Temperatures on the Properties of 316L Stainless Steel Produced via Laser Powder Bed Fusion. Materials, 18(13), 3167. https://doi.org/10.3390/ma18133167