A Tube Furnace Design for the Oxygen Annealing of a REBCO Superconducting Joint

Abstract

1. Introduction

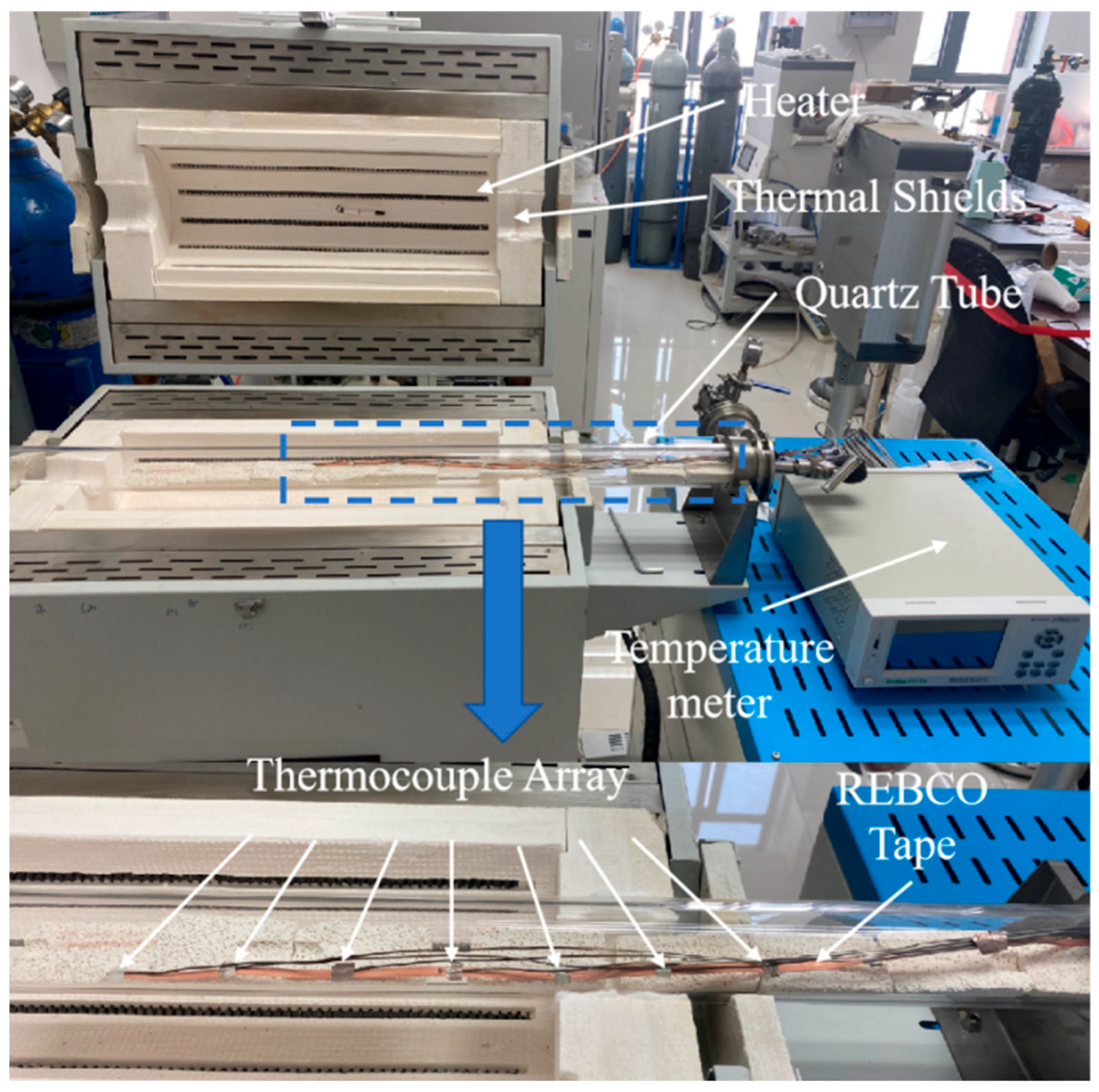

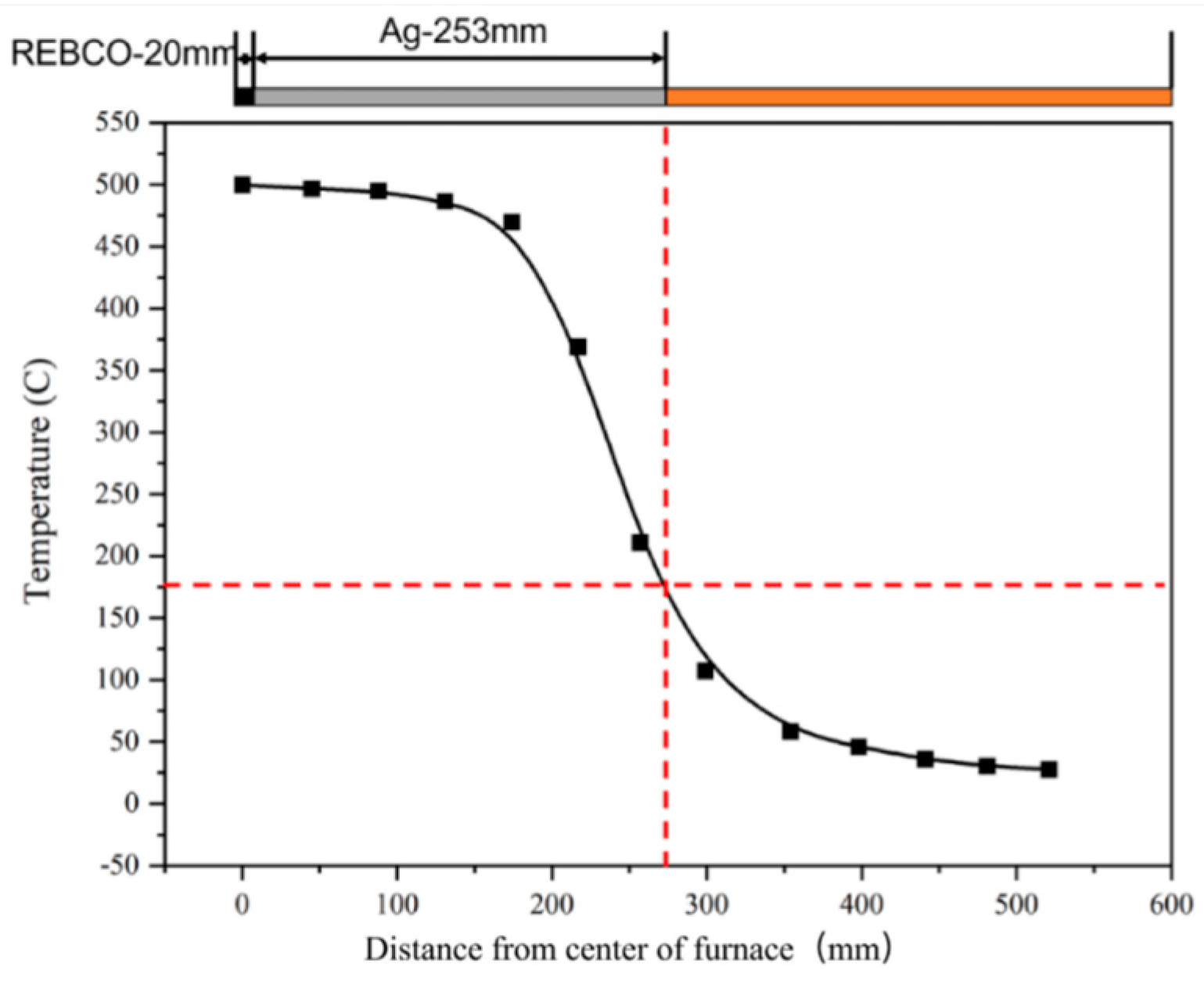

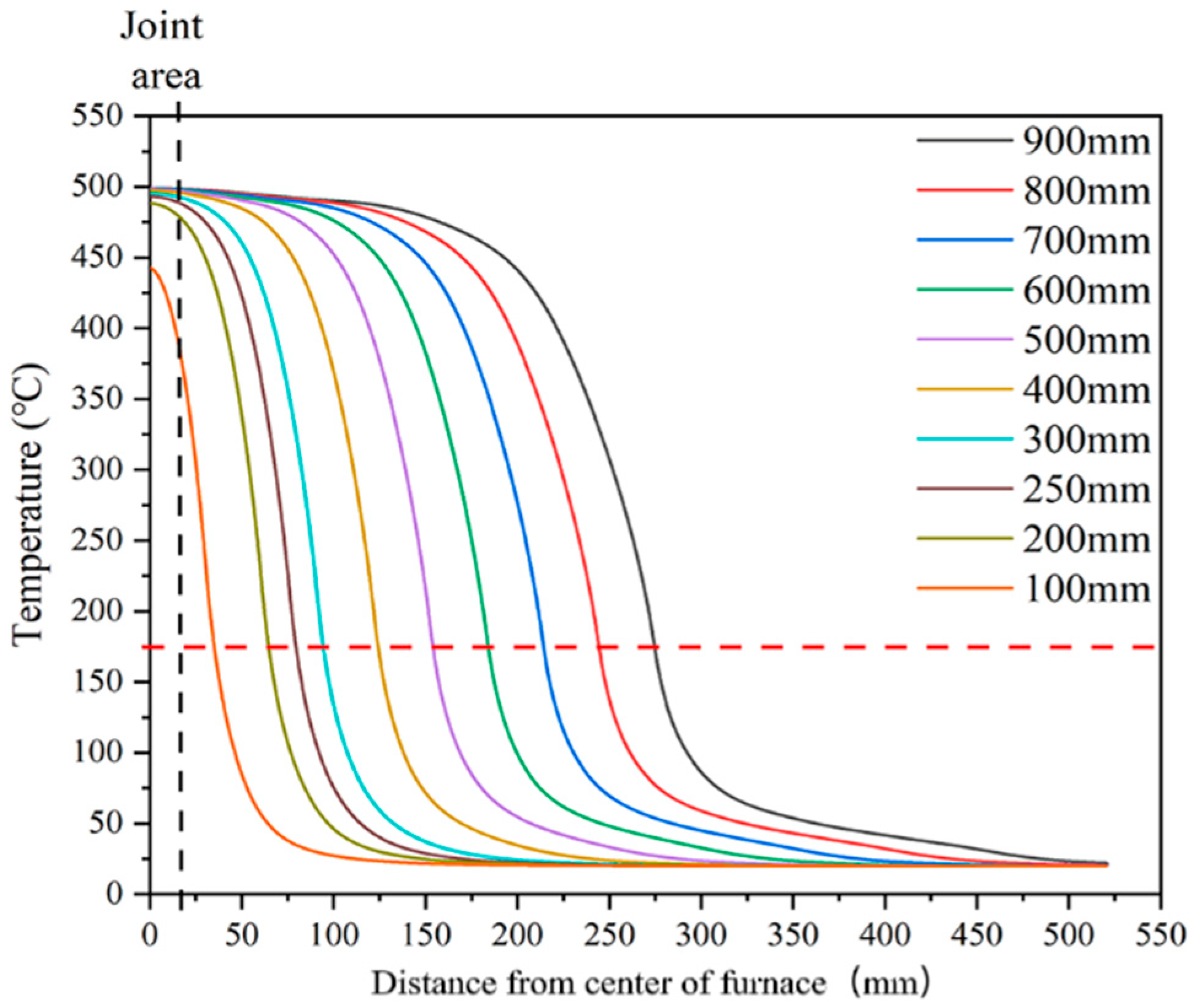

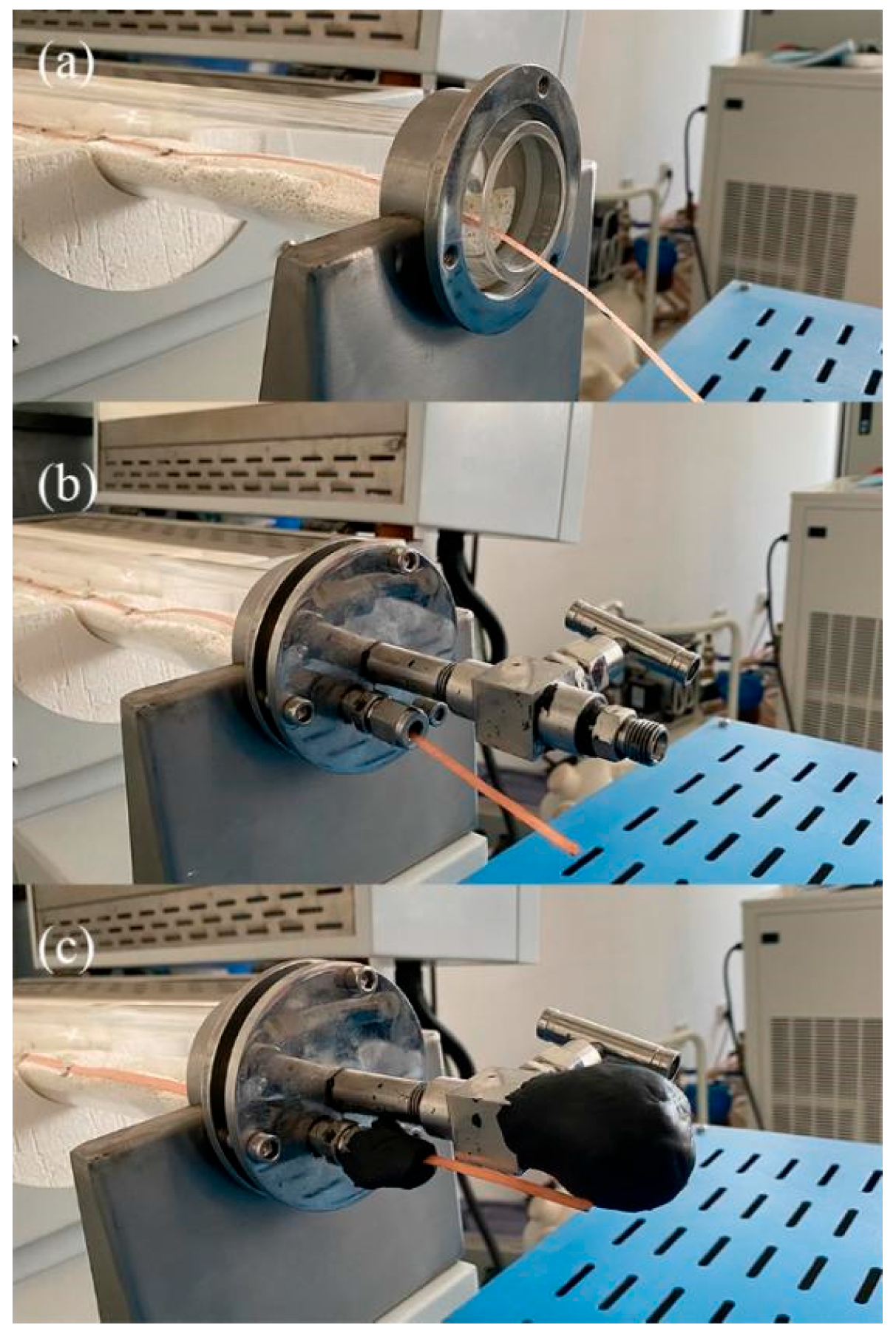

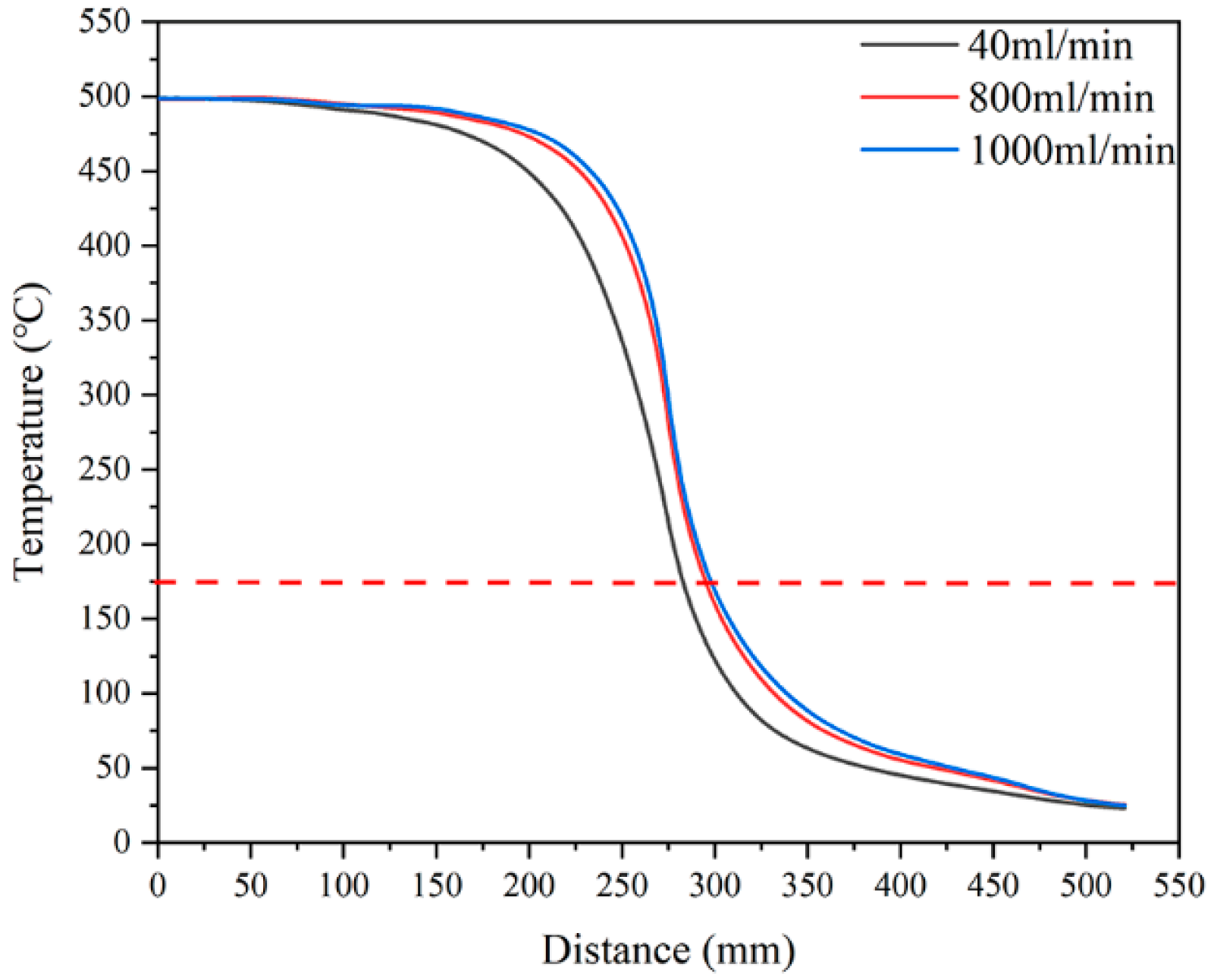

2. Experiment

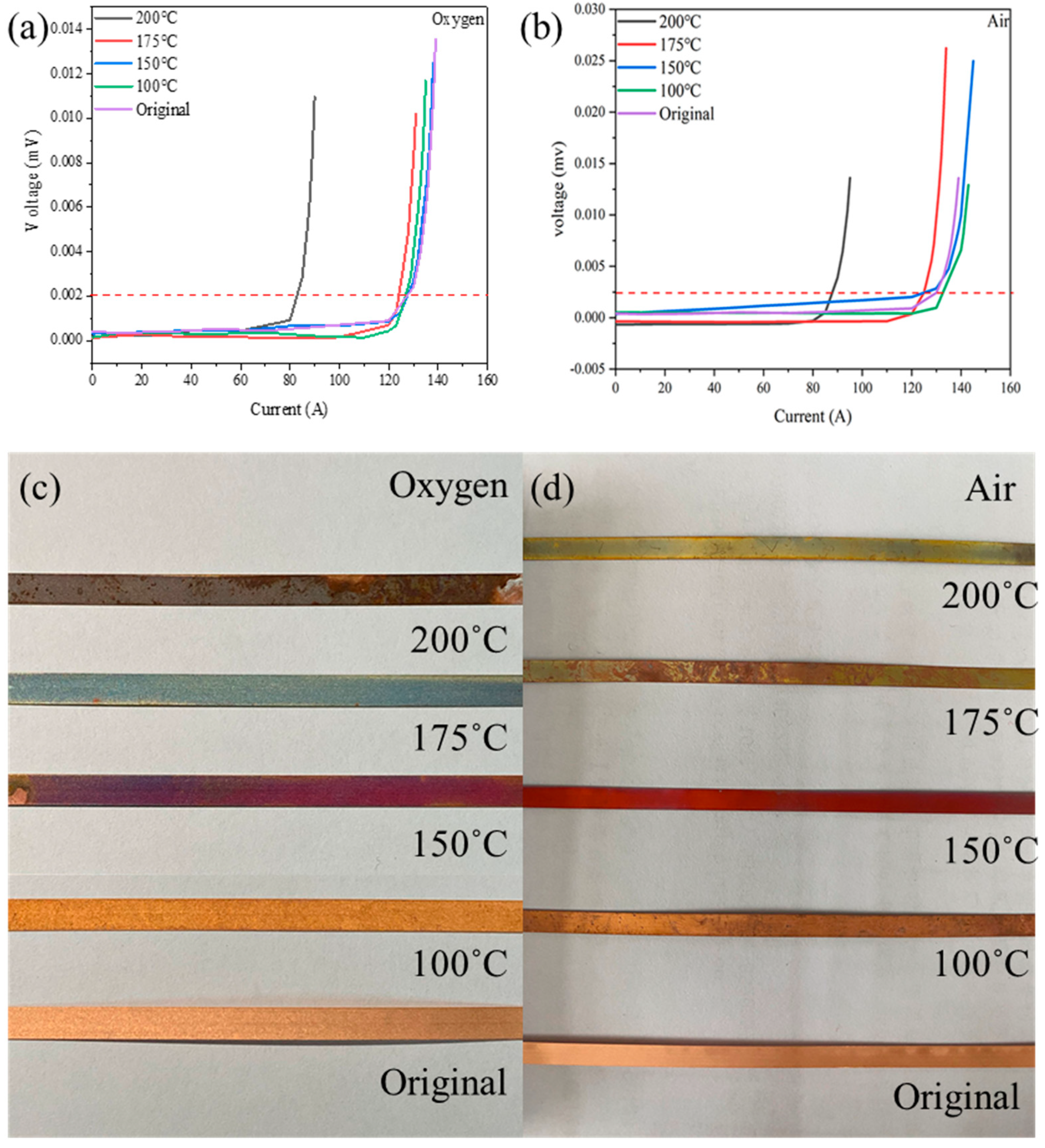

3. Results

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, J.; Wang, Q.; Qin, L.; Zhou, B.; Wang, K.; Wang, Y.; Wang, L.; Zhang, Z.; Dai, Y.; Liu, H.; et al. World record 32.35 tesla direct-current magnetic field generated with an all-superconducting magnet. Supercond. Sci. Technol. 2020, 33, 03LT01. [Google Scholar] [CrossRef]

- Zhao, Z.; Wang, Y.; Gao, Y.; Yang, Z.; Li, Z.; Pi, W. Mechanical characterization of a 10-MJ HTS SMES magnet wound by quasi-isotropic strands and directly stacked tape conductors. Superconductivity 2023, 5, 100042. [Google Scholar] [CrossRef]

- Kambo, P.; Yamanouchi, Y.; Caunes, A.A.; Yamaguchi, K.; Izumi, M.; Ida, T. Concept design of an HTS linear power generator for wave energy conversion. Superconductivity 2023, 6, 100043. [Google Scholar] [CrossRef]

- Zhou, B.; Dai, Y.; Zhang, Z.; Liu, H.; Wang, Y.; Wang, L.; Wang, H.; Chen, S.; Wang, K.; Chen, Y.; et al. Achievement of a high-performance 30-tesla metal-as-insulated user superconducting magnet. Sci. China Tech. Sci. 2024, 67, 1974–1978. [Google Scholar] [CrossRef]

- Li, Z.Y.; Pan, Z.C.; Zhang, Q.J.; Zhu, K.P.; Zhang, C.; Zhang, Z.W.; Dong, G.; Ye, Y.M.; Yang, Z. Development and construction of magnet system for world’s first full high temperature superconducting tokamak. Superconductivity 2024, 12, 100137. [Google Scholar] [CrossRef]

- Tian, X.; Suo, H.; Zhang, Z.; Ye, M.; Wang, L.; Liu, J.; Wang, Q. Meter-length REBCO ultralow resistance joint for the gigahertz NMR magnet. Superconductivity 2024, 12, 100138. [Google Scholar] [CrossRef]

- Wikus, P.; Frantz, W.; Kümmerle, R.; Vonlanthen, P. Commercial gigahertz-class NMR magnets. Supercond. Sci. Technol. 2022, 35, 033001. [Google Scholar] [CrossRef]

- Hashi, K.; Ohki, S.; Matsumoto, S.; Nishijima, G.; Goto, A.; Deguchi, K.; Yamada, K.; Noguchi, T.; Sakai, S.; Takahashi, M.; et al. Achievement of 1020 MHz NMR. J. Magn. Reson. 2015, 256, 30–33. [Google Scholar] [CrossRef]

- Maeda, H.; Shimoyama, J.; Yanagisawa, Y.; Ishii, Y.; Tomita, M. The MIRAI program and the new super-high field NMR initiative and its relevance to the development of superconducting joints in Japan. IEEE Trans. Appl. Supercond. 2019, 29, 4602409. [Google Scholar] [CrossRef]

- Bascuñán, J.; Hahn, S.; Park, D.; Iwasa, Y. A 1.3-GHz LTS/HTS NMR magnet–A progress report. IEEE Trans. Appl. Supercond. 2010, 21, 2092–2095. [Google Scholar] [CrossRef]

- Chemical and Engineering News Bruker Installs World’s First 1.2 GHz. Available online: https://cen.acs.org/business/instrumentation/Bruker-installs-12-GHz-NMR/98/i19 (accessed on 23 June 2025).

- Takeda, Y.; Maeda, H.; Ohki, K.; Yanagisawa, Y. Review of the temporal stability of the magnetic field for ultra-high field superconducting magnets with a particular focus on superconducting joints between HTS conductors. Supercond. Sci. Technol. 2022, 35, 043002. [Google Scholar] [CrossRef]

- Park, Y.; Lee, M.; Ann, H.; Choi, Y.; Lee, H. A superconducting joint for GdBa2Cu3O7−δ-coated conductors. NPG Asia. Mater. 2014, 6, e98. [Google Scholar] [CrossRef]

- Jin, X.; Yanagisawa, Y.; Maeda, H.; Takano, Y. Development of a superconducting joint between a GdBa2Cu3O7-δ-coated conductor and YBa2Cu3O7−δ bulk: Towards a superconducting joint between RE (Rare Earth) Ba2Cu3O7−δ-coated conductors. Supercond. Sci. Technol. 2015, 28, 075010. [Google Scholar] [CrossRef]

- Jin, X.; Yanagisawa, Y.; Maeda, H. Measurement of persistent current in a Gd123 coil with a superconducting joint fabricated by the CJMB method. IEEE Trans. Appl. Supercond. 2018, 28, 4602604. [Google Scholar] [CrossRef]

- Ohki, K.; Nagaishi, T.; Kato, T.; Yokoe, D.; Hirayama, T.; Ikuhara, Y.; Ueno, T.; Yamagishi, K.; Takao, T.; Piao, R.; et al. Fabrication, microstructure and persistent current measurement of an intermediate grown superconducting (iGS) joint between REBCO-coated conductors. Supercond. Sci. Technol. 2017, 30, 115017. [Google Scholar] [CrossRef]

- Yanagisawa, Y.; Piao, R.; Suetomi, Y.; Yamazaki, T.; Yamagishi, K.; Ueno, T.; Takao, T.; Ohki, K.; Yamaguchi, T.; Nagaishi, T.; et al. Development of a persistent-mode NMR magnet with superconducting joints between high-temperature superconductors. Supercond. Sci. Technol. 2021, 34, 115006. [Google Scholar] [CrossRef]

- Maeda, H.; Shimoyama, J.; Yanagisawa, Y.; Ishii, Y.; Tomita, M. Present Status of the MIRAI Program; Towards a Persistent 1.3 GHz NMR and DC Feeder Cables. In Proceedings of the ACASC/Asian-ICMC/CSSJ Joint Conference, Okinawa, Japan, 6–9 January 2020. [Google Scholar]

- Lucas, C.; Cayado, P.; Rijckaert, H.; Konstantopoulou, K.; Nardelli, D.; Senatore, C. Critical current degradation of commercial REBCO coated conductors under thermomechanical loads. Supercond. Sci. Technol. 2024, 37, 12501. [Google Scholar] [CrossRef]

- Bonura, M.; Cayado, P.; Konstantopoulou, K.; Alessandrini, M.; Senatore, C. Heating-Induced Performance Degradation of REBa2Cu3O7−x Coated Conductors: An Oxygen Out-Diffusion Scenariowith Two Activation Energies. ACS Appl. Electron. Mater. 2022, 4, 1318–1326. [Google Scholar] [CrossRef]

- Zhang, H.; Suo, H.; Wang, L.; Ma, L.; Liu, J.; Zhang, Z.; Wang, Q. Database of the effect of stabilizer on the resistivity and thermal conductivity of 20 different commercial REBCO tapes. Supercond. Sci. Technol. 2022, 35, 045016. [Google Scholar] [CrossRef]

- Kulikov, I.V.; Chernykh, M.Y.; Krylova, T.S.; Ovcharov, A.V.; Chernykh, I.A.; Zanaveskin, M.L. A superconducting joint for 2G HTS tapes. Tech. Phys. Lett. 2019, 45, 324–326. [Google Scholar] [CrossRef]

- Huang, D.; Shang, H.; Xie, B.; Zou, Q.; Dong, H.; Wang, K.; Zhang, L.; Gu, H.; Ding, F. An efficient approach for superconducting joint of YBCO coated conductors. Supercond. Sci. Technol. 2022, 35, 075004. [Google Scholar] [CrossRef]

- Wang, W.; Wang, M.; Liu, L.; Huo, B.; Yu, Z.; Zhang, Y. Influence of a novel heat treatment on structures and superconducting properties of YGdBCO coated conductors. IEEE Trans. Appl. Supercond. 2017, 27, 2667587. [Google Scholar] [CrossRef]

- Park, Y.; Lee, M.; Oh, Y.; Lee, H. Laser drilling: Enhancing superconducting joint of GdBa2Cu3O7−δ coated conductors. Supercond. Sci. Technol. 2014, 27, 085008. [Google Scholar] [CrossRef]

- Song, J.; Choi, Y.; Yang, D.; Kim, Y.; Lee, H. Review of core technologies for development of 2G HTS NMR/MRI magnet: A status report of progress in Korea University. Results. Phys. 2017, 7, 3264–3276. [Google Scholar] [CrossRef]

- Jin, X.; Suetomi, Y.; Piao, R.; Matsutake, Y.; Yagai, T.; Mochida, H.; Yanagisawa, Y.; Maeda, H. Superconducting joint between multi-filamentary Bi2Sr2Ca2Cu3O10+δ tapes based on incongruent melting for NMR and MRI applications. Supercond. Sci. Technol. 2019, 32, 035011. [Google Scholar] [CrossRef]

- Kato, J.; Sakai, N.; Miyata, S.; Ibi, A.; Sutoh, Y.; Yamada, Y.; Chikumoto, N.; Nakao, K.; Izumi, T.; Shiohara, Y. Diffusion joint using silver layer of YBCO coated conductors for applications. Phys. C Supercond. 2008, 468, 1571–1574. [Google Scholar] [CrossRef]

- Maebatake, T.; Mori, N.; Teranishi, R.; Mukaida, M.; Yamada, K.; Miura, M.; Yoshizumi, M.; Izumi, T. Effects of joining conditions on the structures and properties of joints of REBCO coated conductors. Phys. C Supercond. 2010, 470, 1358–1360. [Google Scholar] [CrossRef]

- Celentano, G.; Augieri, A.; Mauretti, A.; Vannozzi, A.; Armenio, A.; Galluzzi, V. Electrical and mechanical characterization of coated conductors lap joints. IEEE Trans. Appl. Supercond. 2010, 20, 1549–1552. [Google Scholar] [CrossRef]

- Wu, X.; Wu, L.; Zhu, J.; Chang, T.; Zhao, Y.; Zhang, Z. Electromechanical performance study on silver diffusion joints of REBCO coated conductors under axial tensile stress. IEEE Trans. Appl. Supercond. 2016, 27, 6600806. [Google Scholar] [CrossRef]

- Kato, J.; Sakai, N.; Tajima, S.; Miyata, S.; Watanabe, T.; Yamada, Y.; Chikumoto, N.; Nakao, K.; Izumi, T.; Shiohara, Y. Low resistance joint of the YBCO coated conductor. J. Phys. Conf. Ser. 2006, 43, 166–169. [Google Scholar] [CrossRef]

- Kato, J.; Sakai, N.; Miyata, S.; Konishi, M.; Yamada, Y.; Chikumoto, N.; Nakao, K.; Izumi, T.; Shiohara, Y. Optimization of the diffusion joint process for the Ag layers of YBCO coated conductors. Phys. C Supercond. 2007, 463, 747–750. [Google Scholar] [CrossRef]

- Watanabe, T.; Kamata, T.; Maebatake, T.; Teranishi, R.; Kiss, T.; Yamada, K.; Kaneko, K.; Yoshizumi, M.; Izumi, T. Study of factors in joint resistance for GdBCO coated conductors. Phys. Procedia. 2013, 45, 165–168. [Google Scholar] [CrossRef]

- Kim, H.; Song, J.; Kwon, N.; Kim, K.; Lee, H. The influence of heat-treatment and oxygenation annealing on the superconducting properties of YBCO coated conductors. Supercond. Sci. Technol. 2009, 22, 125016. [Google Scholar] [CrossRef]

- Wang, M.; Wang, W.; Liu, L.; Xia, Y.; Huo, B.; Yang, X. The Optimization of Oxygen Partial Pressure for Preparing a Superconducting Joint Between YGdBCO-Coated Conductors. IEEE Trans. Appl. Supercond. 2019, 29, 6602505. [Google Scholar] [CrossRef]

- Huang, D.; Gu, H.; Shang, H.; Li, T.; Xie, B.; Zou, Q. Achievement of low-resistivity diffusion joint of REBCO coated conductors by improving the interface connection of Ag stabilizer. IEEE Trans. Appl. Supercond. 2021, 31, 4600507. [Google Scholar] [CrossRef]

| Sintering Temperature (°C) | Ic Value After Sintering in Oxygen (A) | Ic Value After Sintering in Air (A) |

|---|---|---|

| Original | 127.3 | 130.1 |

| 100 | 126.6 | 132.3 |

| 150 | 127.1 | 124.6 |

| 175 | 123.6 | 124.9 |

| 200 | 82.5 | 87.8 |

| Reference | Temperature (°C) | Time (h) | Atmosphere |

|---|---|---|---|

| REBCO superconducting joint | |||

| [14] | 450 | 2 | O2 |

| [7] | 500 | 350 | O2 |

| [15] | 500 | 10 | O2 |

| [10] | 500 | 6 | O2 |

| [16] | 350–550 | 15–100 | O2 |

| [17] | 500 | 350 | O2 |

| [18] | 500 | 350 | O2 |

| [22] | 770 | 1 | O2 |

| REBCO Ag diffusion joint | |||

| [23] | 500 | 50 or 100 | O2 |

| [24] | 400 | 1 | O2 |

| [25] | 350–400 | 1 | O2 |

| [26] | 400 | 3 | O2 |

| [36] | 400 | 2 | O2 |

| [37] | 500 | 1 | O2 |

| [28] | 500 | 1 | O2 |

| [29] | 350–400 | 1 | O2 |

| Bi2223 superconducting joint | |||

| [30] | 350 | 10 | O2 |

| Flow Rate (mL/min) | Maximum Oxygen Fraction (%) | Oxygen Fraction After the Reading Is Stable (%) |

|---|---|---|

| Fully open end | ||

| 400 | 97 | 81 |

| 600 | 99 | 85 |

| 800 | 100 | 89 |

| 1000 | 100 | 91 |

| 1200 | 100 | 91 |

| 1400 | 100 | 90 |

| Flange without seal | ||

| 400 | 100 | 89 |

| 600 | 100 | 93 |

| 800 | 100 | 99 |

| 1000 | 100 | 99 |

| Flange with seal | ||

| 40 | 100 | 100 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Liu, C.; Gao, Y.; Suo, H.; Wang, L.; Chen, S.; Liu, J.; Wang, Q. A Tube Furnace Design for the Oxygen Annealing of a REBCO Superconducting Joint. Materials 2025, 18, 3053. https://doi.org/10.3390/ma18133053

Zhang Z, Liu C, Gao Y, Suo H, Wang L, Chen S, Liu J, Wang Q. A Tube Furnace Design for the Oxygen Annealing of a REBCO Superconducting Joint. Materials. 2025; 18(13):3053. https://doi.org/10.3390/ma18133053

Chicago/Turabian StyleZhang, Zili, Chuangan Liu, Yang Gao, Hongli Suo, Lei Wang, Shunzhong Chen, Jianhua Liu, and Qiuliang Wang. 2025. "A Tube Furnace Design for the Oxygen Annealing of a REBCO Superconducting Joint" Materials 18, no. 13: 3053. https://doi.org/10.3390/ma18133053

APA StyleZhang, Z., Liu, C., Gao, Y., Suo, H., Wang, L., Chen, S., Liu, J., & Wang, Q. (2025). A Tube Furnace Design for the Oxygen Annealing of a REBCO Superconducting Joint. Materials, 18(13), 3053. https://doi.org/10.3390/ma18133053