Influence of Zr on Al-Ti-B-Based Grain Refiners in AlSiMgCuZr Alloy

Abstract

1. Introduction

2. Materials and Methods

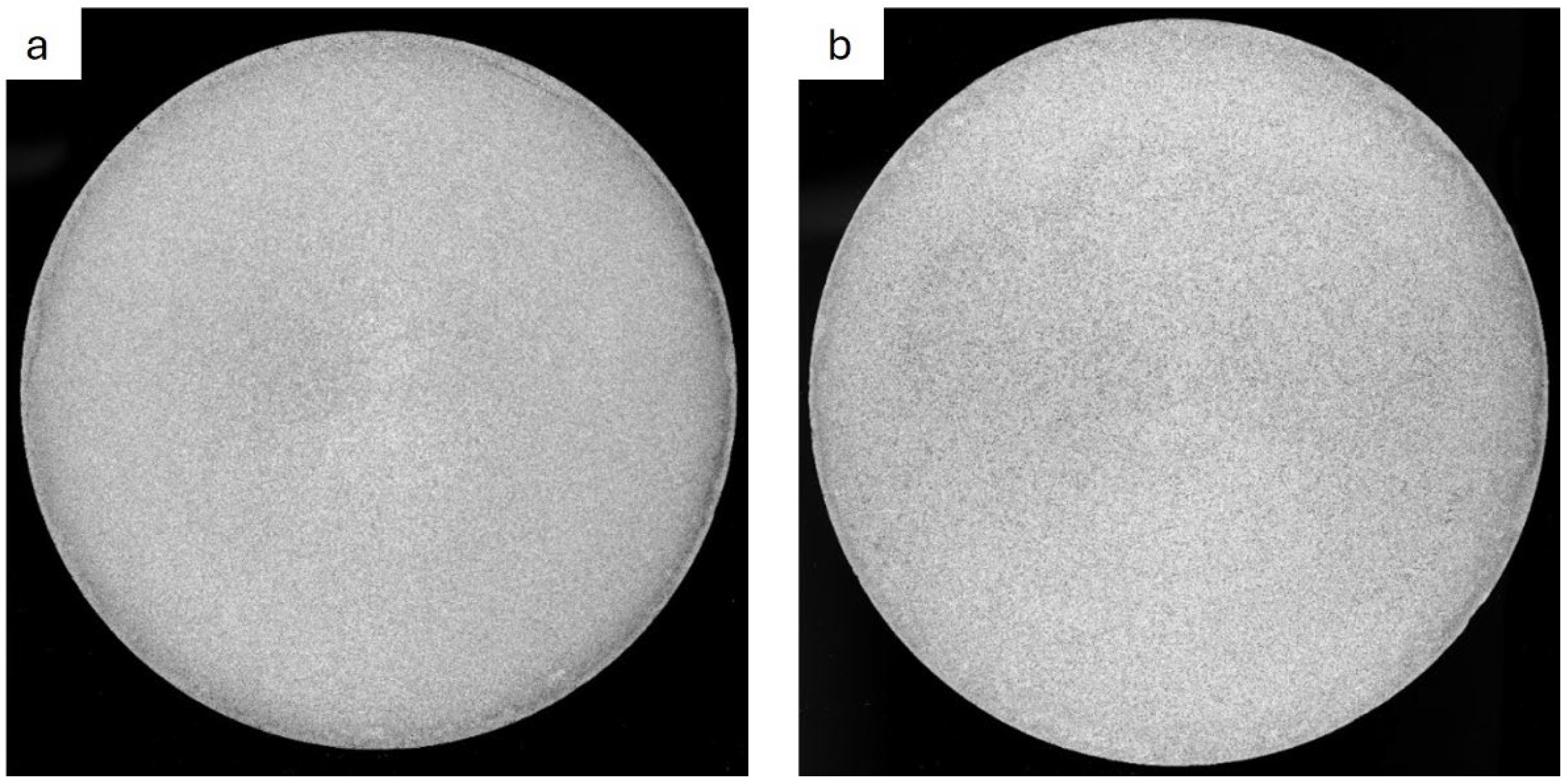

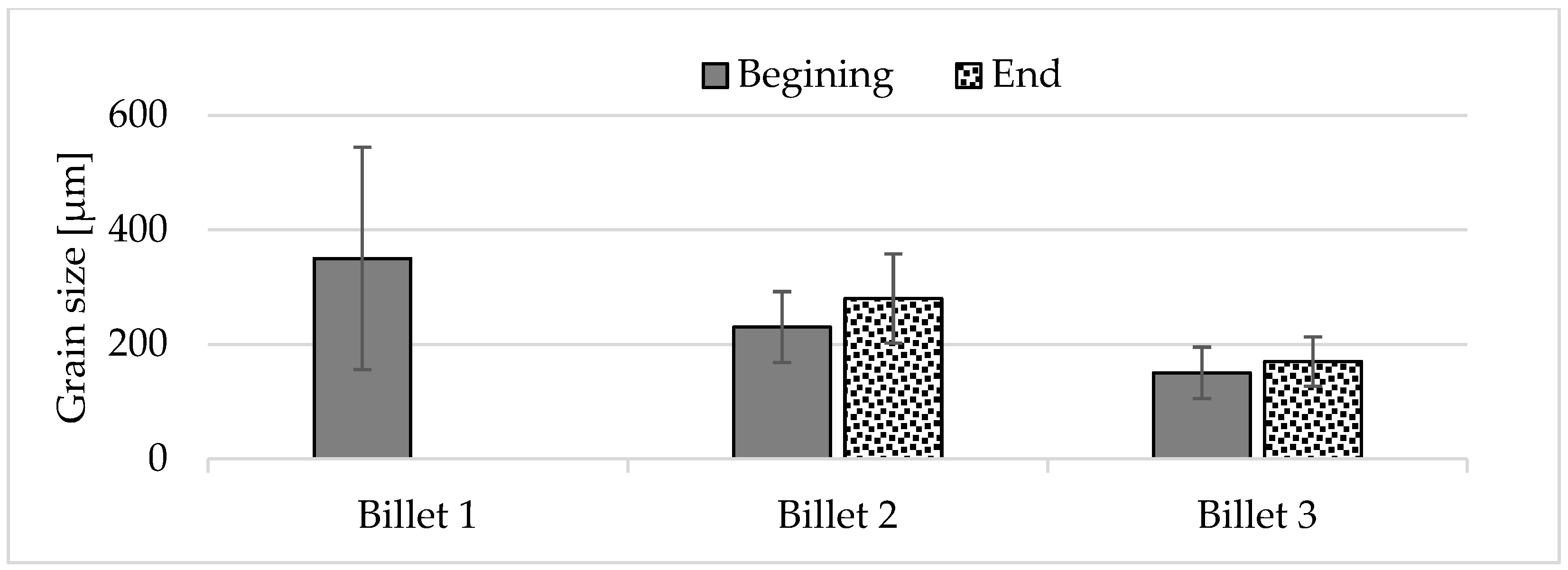

- Billet 1—grain refiner was added to the furnace before the casting process, in an amount calculated to achieve 60 ppm B (0.0060% B), corresponding to 300 ppm Ti. The billets were cast at a length of 2 m.

- Billet 2—grain refiner fed continuously through the feeder during casting into the trough, added at 60 ppm B. The billets were cast to a length of 5 m.

- Billet 3—grain refiner fed continuously through the feeder during casting into the trough, added at 80 ppm B. The billets were cast to a length of 5 m.

3. Results

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | B | Zr | |

|---|---|---|---|---|---|---|---|---|---|---|

| Before casting | 1.03 | 0.11 | 0.63 | 0.60 | 0.71 | 0.26 | 0.018 | 0.031 | 0.005 | 0.15 |

| 1 m | 1.00 | 0.11 | 0.61 | 0.59 | 0.69 | 0.27 | 0.022 | 0.027 | 0.003 | 0.15 |

| 2 m | 1.00 | 0.11 | 0.61 | 0.60 | 0.71 | 0.26 | 0.021 | 0.022 | 0.002 | 0.15 |

| Average | 1.02 | 0.11 | 0.61 | 0.60 | 0.70 | 0.27 | 0.021 | 0.024 | 0.003 | 0.15 |

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | B | Zr | |

|---|---|---|---|---|---|---|---|---|---|---|

| Before casting | 1.07 | 0.07 | 0.67 | 0.55 | 0.67 | 0.27 | 0.023 | 0.013 | 0.000 | 0.15 |

| 1 m | 1.09 | 0.08 | 0.68 | 0.55 | 0.67 | 0.27 | 0.023 | 0.027 | 0.003 | 0.15 |

| 2 m | 1.11 | 0.08 | 0.69 | 0.55 | 0.68 | 0.27 | 0.023 | 0.026 | 0.003 | 0.15 |

| 3 m | 1.11 | 0.08 | 0.68 | 0.55 | 0.67 | 0.27 | 0.023 | 0.027 | 0.003 | 0.15 |

| 4 m | 1.07 | 0.08 | 0.67 | 0.55 | 0.66 | 0.27 | 0.022 | 0.026 | 0.003 | 0.14 |

| 4.5 m | 1.07 | 0.08 | 0.66 | 0.56 | 0.66 | 0.27 | 0.023 | 0.031 | 0.004 | 0.15 |

| Average | 1.09 | 0.08 | 0.68 | 0.55 | 0.67 | 0.27 | 0.023 | 0.027 | 0.003 | 0.15 |

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | B | Zr | |

|---|---|---|---|---|---|---|---|---|---|---|

| Before casting | 1.02 | 0.08 | 0.60 | 0.63 | 0.69 | 0.26 | 0.024 | 0.020 | 0.002 | 0.16 |

| 1 m | 1.03 | 0.09 | 0.62 | 0.61 | 0.70 | 0.26 | 0.025 | 0.035 | 0.005 | 0.15 |

| 2 m | 1.03 | 0.09 | 0.59 | 0.62 | 0.68 | 0.26 | 0.024 | 0.035 | 0.005 | 0.16 |

| 3 m | 1.02 | 0.08 | 0.60 | 0.62 | 0.68 | 0.25 | 0.022 | 0.037 | 0.005 | 0.15 |

| 4 m | 1.01 | 0.09 | 0.59 | 0.62 | 0.67 | 0.25 | 0.022 | 0.036 | 0.005 | 0.15 |

| 4.5 m | 1.04 | 0.09 | 0.61 | 0.62 | 0.69 | 0.25 | 0.021 | 0.041 | 0.006 | 0.15 |

| Average | 1.03 | 0.09 | 0.60 | 0.62 | 0.68 | 0.26 | 0.023 | 0.036 | 0.005 | 0.15 |

4. Discussion

5. Conclusions

- -

- It has been demonstrated that Ti and B content decreases over time, and the final Ti and B content in the billets was approximately 20–50% lower than expected.

- -

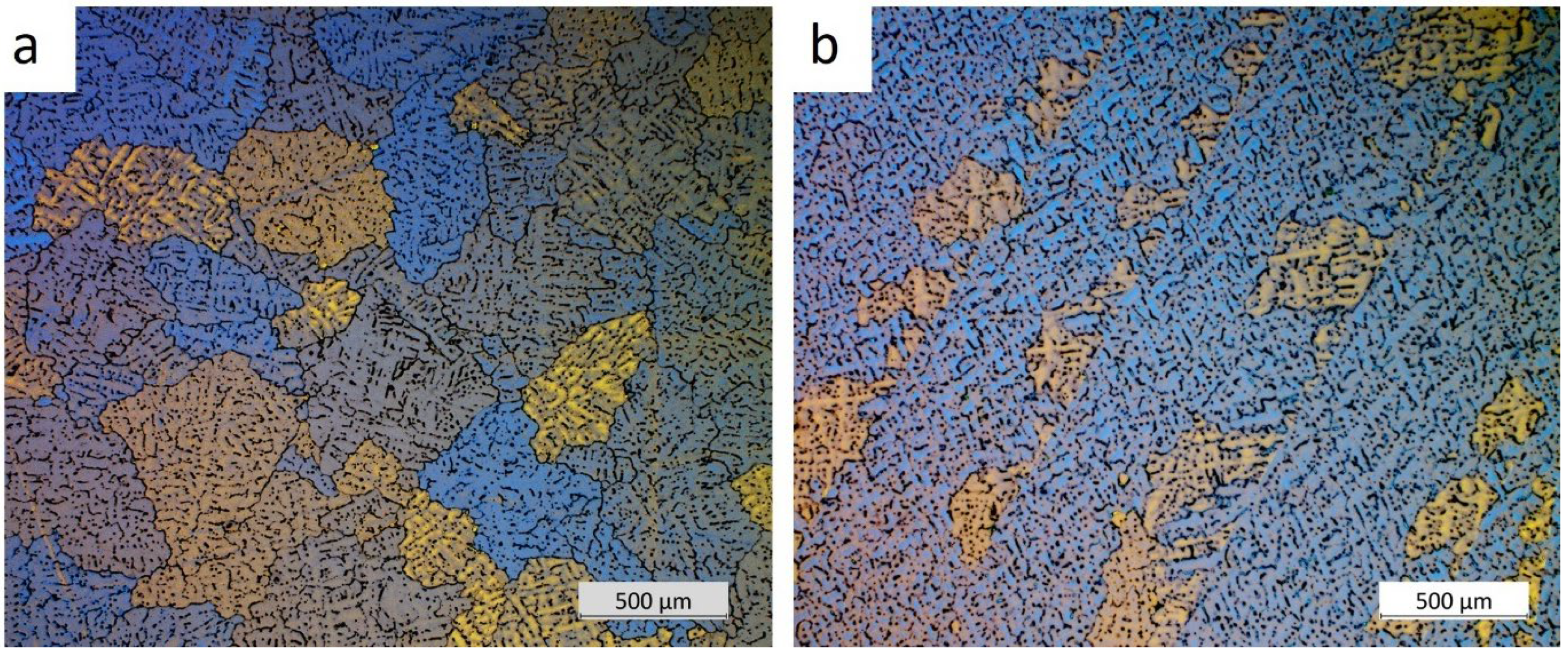

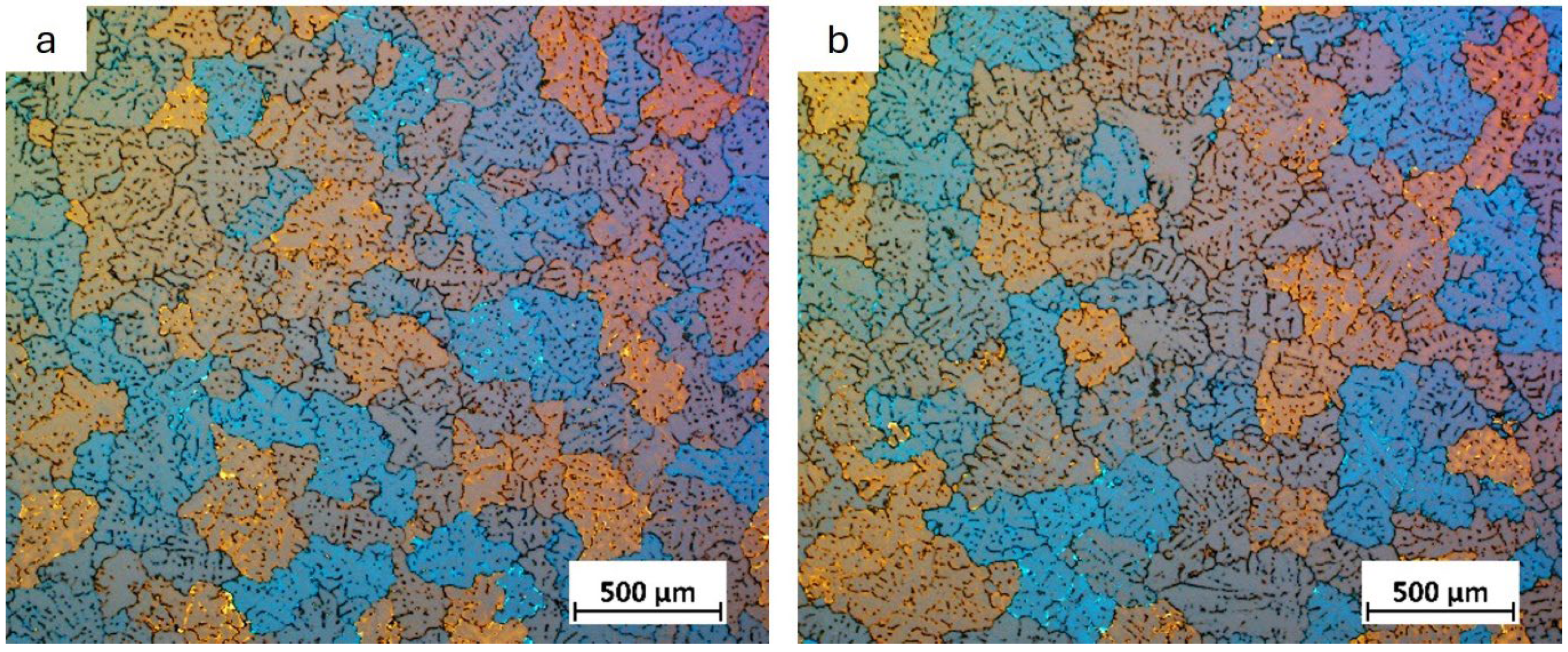

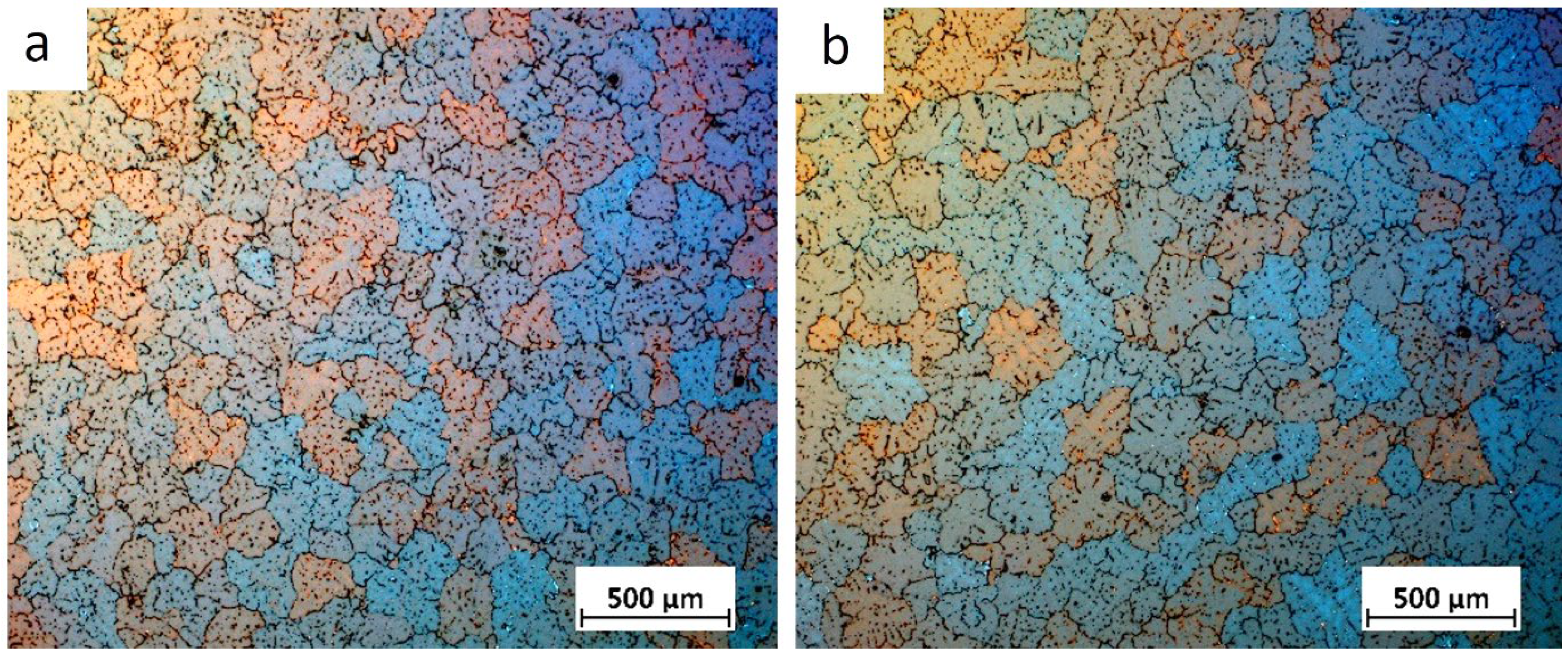

- The presence of 0.15 wt.% Zr, in combination with the Al-5Ti-1B grain refiner in the molten metal, causes grain coarsening over time, thereby disrupting the refiner’s effectiveness.

- -

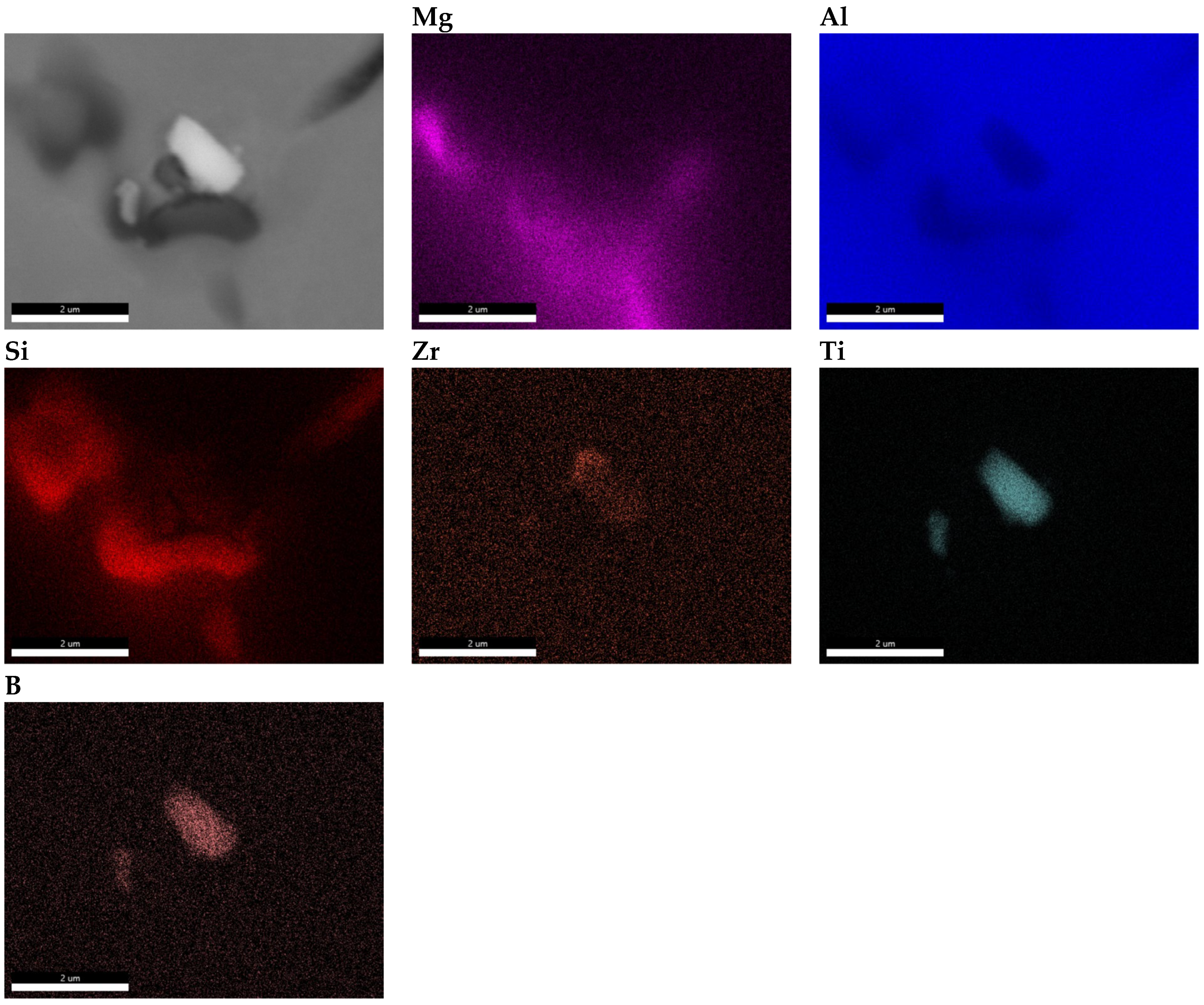

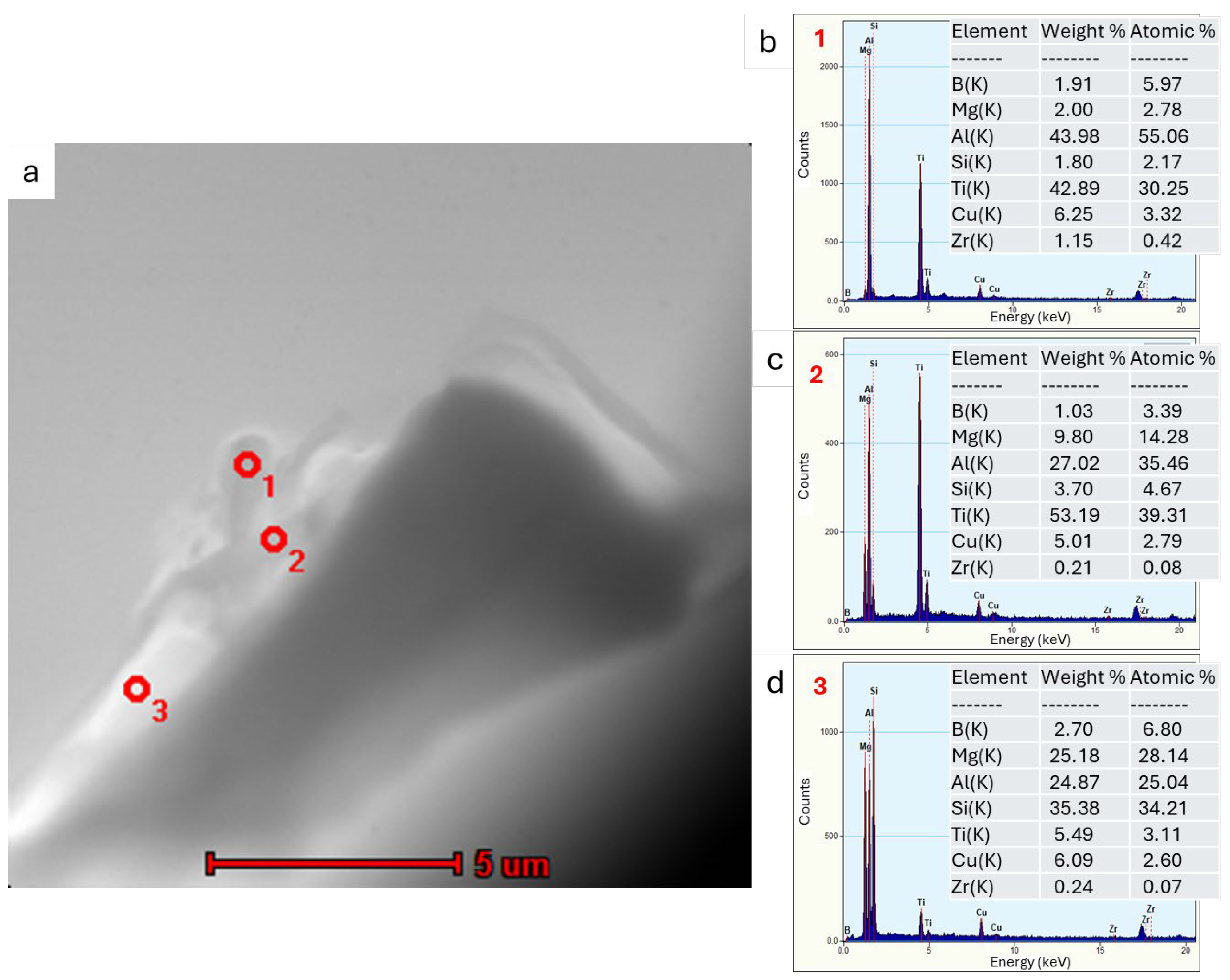

- Analysis of the microstructure revealed the presence of TiB2 metallic compounds derived from the grain refiner in the presence of Zr.

- -

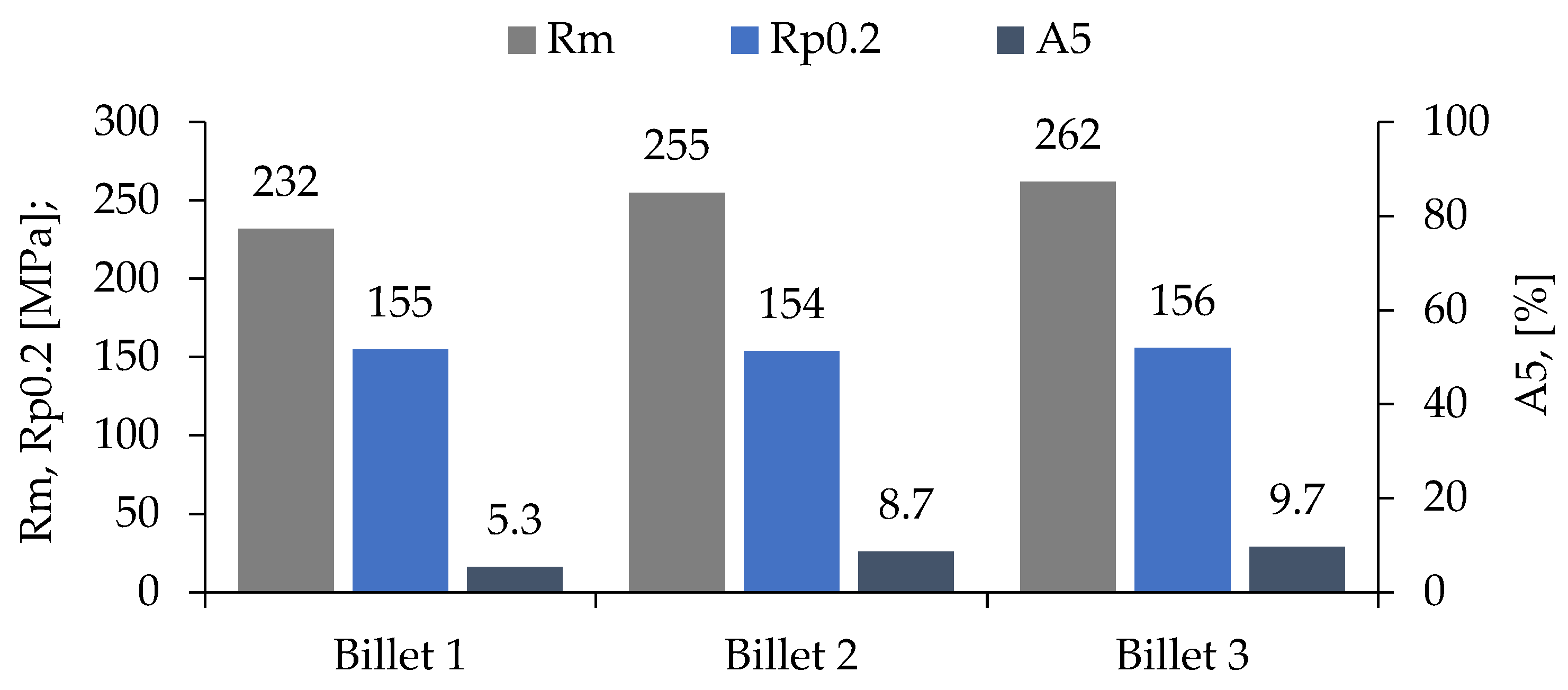

- Increasing the Al-5Ti-1B addition to 80 ppm B (400 ppm Ti) in an AlSiMgCu alloy containing 0.15 wt.% Zr significantly improves grain refinement.

- -

- The Al-5Ti-1B grain refiner should be added in the form of a rod directly before casting to minimise the Zr poisoning effect, which enhances the nucleation efficiency of α(Al) grains and allows the desired grain size in billets to be achieved.

- -

- These results confirm previous literature findings and support the theory of Zr poisoning via modification of TiB2 particles.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cibula, A. The Mechanism of Grain Refinement of Sand Castings in Aluminum Alloys. J. Inst. Met. 1950, 76, 321–360. [Google Scholar]

- Cibula, A. The Grain Refinement of Aluminium Alloy Castings by Additions of Titanium and Boron. J. Inst. Met. 1951, 80, 1–16. [Google Scholar]

- Greer, L. Overview: Application of Heterogeneous Nucleation in Grain-Refining of Metals. J. Chem. Phys. 2016, 145, 211704. [Google Scholar] [CrossRef]

- Jones, G.P.; Pearson, J. Factors Affecting the Grain-Refinement of Aluminum Using Titanium and Boron Additives. Metall. Trans. B 1976, 7, 223–234. [Google Scholar] [CrossRef]

- Birch, M.E.J.; Fisher, P. Grain Refining of Commercial Aluminium Alloys with Titanium Boron Aluminium. In Conference on Aluminium Technology 86; Shepard, T., Ed.; The Institute of Metals: London, UK, 1986; pp. 117–124. [Google Scholar]

- Birch, M.E.J.; Cowell, A.J.J. Grain Refinement of Aluminium Alloys Containing Chromium and Zirconium. In Conference on Solidification Processing; The Institute of Metals: London, UK, 1988; pp. 149–152. [Google Scholar]

- Abdel-Hamid, A.A. Effect of Other Elements on the Grain Refinement of Al by Ti or Ti and B. Int. J. Mater. Res. 1989, 1, 566–569. [Google Scholar] [CrossRef]

- Johnsson, M. Influence of Zr on the Grain Refinement of Aluminium. Int. J. Mater. Res. 1994, 85, 786–789. [Google Scholar] [CrossRef]

- Kearns, M.A.; Cooper, P. Effects of Solutes on Grain Refinement of Selected Wrought Aluminium Alloys. Mater. Sci. Technol. 1997, 13, 650–654. [Google Scholar] [CrossRef]

- Read, P.J.; Ferrolegeringar AG Zurych. Stopy Przejściowe Aluminium w Odlewnictwie. In Proceedings of the IMN OML Conference on Aluminium Technology 96; IMN: Mogilany, Poland, 1996. [Google Scholar]

- Bunn, A.M.; Schumacher, P.; Kearns, M.A.; Boothroyd, C.B.; Greer, A.L. Grain Refinement by Al-Ti-B Alloys in Aluminium Melts: A Study of the Mechanisms of Poisoning by Zirconium. Mater. Sci. Technol. 1999, 15, 1115–1123. [Google Scholar] [CrossRef]

- Spittle, J.A.; Sadli, S. The Influence of Zirconium and Chromium on the Grain Refining Efficiency of Al-Ti-B Inoculants. Cast Metals 1995, 8, 247–253. [Google Scholar] [CrossRef]

- Qiu, D.; Taylor, J.A.; Zhang, M.-X. Understanding the Co-Poisoning Effect of Zr and Ti on the Grain Refinement of Cast Aluminum Alloys. Metall. Mater. Trans. A 2010, 41, 3412–3421. [Google Scholar] [CrossRef]

- McCartney, D.G. Grain Refining of Aluminium and Its Alloys Using Inoculants. Int. Mater. Rev. 1989, 34, 247–260. [Google Scholar] [CrossRef]

- Rao, A.A.; Murty, B.S.; Chakraborty, M. Influence of Chromium and Impurities on the Grain-Refining Behavior of Aluminum. Metall. Mater. Trans. A 1996, 27, 791–800. [Google Scholar] [CrossRef]

- Murty, B.S.; Kori, S.A.; Chakraborty, M. Grain Refinement of Aluminium and Its Alloys by Heterogeneous Nucleation and Alloying. Int. Mater. Rev. 2002, 47, 3–29. [Google Scholar] [CrossRef]

- Grandfield, J.F.; Eskin, D.G.; Bainbridge, I.F. Direct-Chill Casting of Light Alloys, 1st ed.; Wiley & Sons: New York, NY, USA, 2013. [Google Scholar]

- Schumacher, P.; Cizek, P.; Bunn, A. Zr-Poisoning of Grain Refiner Particles Studied in Al-Ni-Zr Amorphous Alloys. In Essential Readings in Light Metals; Grandfield, J.F., Eskin, D.G., Eds.; Springer: New York, USA, 2016; pp. 381–386. [Google Scholar] [CrossRef]

- Wang, Y.; Fang, C.M.; Zhou, L.; Hashimoto, T.; Zhou, X.; Ramasse, Q.M.; Fan, Z. Mechanism for Zr Poisoning of Al-Ti-B Based Grain Refiners. Acta Mater. 2019, 164, 428–439. [Google Scholar] [CrossRef]

- Pang, X.; Yang, L.; Yang, J.; Pang, M.; Xu, Z.; Li, A.; Wei, B.; Tang, H. Understanding the poisoning mechanisms of Si and Zr atoms on L12 Al3Ti (111) surface: A first-principles investigation. Vacuum 2023, 210, 111891. [Google Scholar] [CrossRef]

- Whitehead, A.J.; Danilak, S.A.; Granger, D.A. The Development of a Commercial Al-3%Ti-0.15%C Grain Refining Master Alloy. In Proceedings of Light Metals 1997; Huglen, R., Ed.; TMS: Warrendale, PA, USA, 1997; pp. 785–793. [Google Scholar]

- Schneider, W.; Kearns, M.A.; McGarry, M.J.; Whitehead, A.J. A Comparison of the Behaviour of AlTiB and AlTiC Grain Refiners. In Essential Readings in Light Metals; Grandfield, J.F., Eskin, D.G., Eds.; Springer: New York, NY, USA, 2016; pp. 400–408. [Google Scholar] [CrossRef]

- Birol, Y. Grain Refining Efficiency of Al–Ti–C Alloys. J. Alloy. Compd. 2006, 422, 128–131. [Google Scholar] [CrossRef]

- Kumar, G.S.V.; Murty, B.S.; Chakraborty, M. Development of Al-Ti-C Grain Refiners and Study of Their Grain Refining Efficiency on Al and Al-7Si Alloy. J. Alloy. Compd. 2005, 396, 143–150. [Google Scholar] [CrossRef]

- Ding, H.M.; Liu, X.F.; Yu, L.N. Influence of Zirconium on Grain Refining Efficiency of Al-Ti-C Master Alloys. J. Mater. Sci. 2007, 42, 9817–9821. [Google Scholar] [CrossRef]

- Li, D.; Wang, Y.; Zhang, Y.; Liu, Y.; Liu, J.; Chen, Z. An Anti Si/Zr-Poisoning Strategy of Al Grain Refinement by the Evolving Effect of Doped Complex. Acta Mater. 2023, 249, 118812. [Google Scholar] [CrossRef]

- Fang, X.; Li, J.; Zhang, W.; Wang, H.; Liu, Y.; Chen, Q. Simultaneous refinement of α-Al and modification of Si in Al–Si alloy achieved via the addition of Y and Zr. J. Mater. Res. Technol. 2024, 30, 1822–1833. [Google Scholar] [CrossRef]

- EN ISO 6892-1:2020; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. ISO: Geneva, Switzerland, 2020.

- Zhang, L.; Yang, L.; Zhao, J.; Shen, Z.; Li, Q.; Jiang, H. A Novel Insight Toward Zr Poisoning on Grain Refinement of Al–5Ti–1B and Its Solution. Metall. Mater. Trans. B 2024, 55, 2765–2775. [Google Scholar] [CrossRef]

- Wu, J.; Ruan, Q.; Chen, S.; Meng, C.; Xu, Z.; Wei, C.; Tang, H.; Wang, J. Insights into Poisoning Mechanism of Zr by First Principle Calculation on AdhesionWork and Adsorption Energy between TiB2, Al3Ti, and Al3Zr. Metals 2022, 12, 286. [Google Scholar] [CrossRef]

- Rao, A.A.; Murty, B.S.; Chakraborty, M. Role of Zirconium and Impurities in Grain Refinement of Aluminium with Al-Ti-B. Mater. Sci. Technol. 1997, 13, 769–777. [Google Scholar] [CrossRef]

| Parameter | Value | ||

|---|---|---|---|

| Metal temperature in the transition plate [°C] | 690–670 |  |  |

| Casting speed [mm/min] | 66–73 | ||

| Cooling water flow rate [L/min] | 95–105 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kapinos, D.; Augustyn, B.; Boczkal, S.; Limanówka, K.; Płonka, B.; Garbacz-Klempka, A.; Piękoś, M.; Kozana, J. Influence of Zr on Al-Ti-B-Based Grain Refiners in AlSiMgCuZr Alloy. Materials 2025, 18, 3000. https://doi.org/10.3390/ma18133000

Kapinos D, Augustyn B, Boczkal S, Limanówka K, Płonka B, Garbacz-Klempka A, Piękoś M, Kozana J. Influence of Zr on Al-Ti-B-Based Grain Refiners in AlSiMgCuZr Alloy. Materials. 2025; 18(13):3000. https://doi.org/10.3390/ma18133000

Chicago/Turabian StyleKapinos, Dawid, Bogusław Augustyn, Sonia Boczkal, Kamila Limanówka, Bartłomiej Płonka, Aldona Garbacz-Klempka, Marcin Piękoś, and Janusz Kozana. 2025. "Influence of Zr on Al-Ti-B-Based Grain Refiners in AlSiMgCuZr Alloy" Materials 18, no. 13: 3000. https://doi.org/10.3390/ma18133000

APA StyleKapinos, D., Augustyn, B., Boczkal, S., Limanówka, K., Płonka, B., Garbacz-Klempka, A., Piękoś, M., & Kozana, J. (2025). Influence of Zr on Al-Ti-B-Based Grain Refiners in AlSiMgCuZr Alloy. Materials, 18(13), 3000. https://doi.org/10.3390/ma18133000