Mechanical Property Prediction of Industrial Low-Carbon Hot-Rolled Steels Using Artificial Neural Networks

Abstract

1. Introduction

2. Materials and Methods

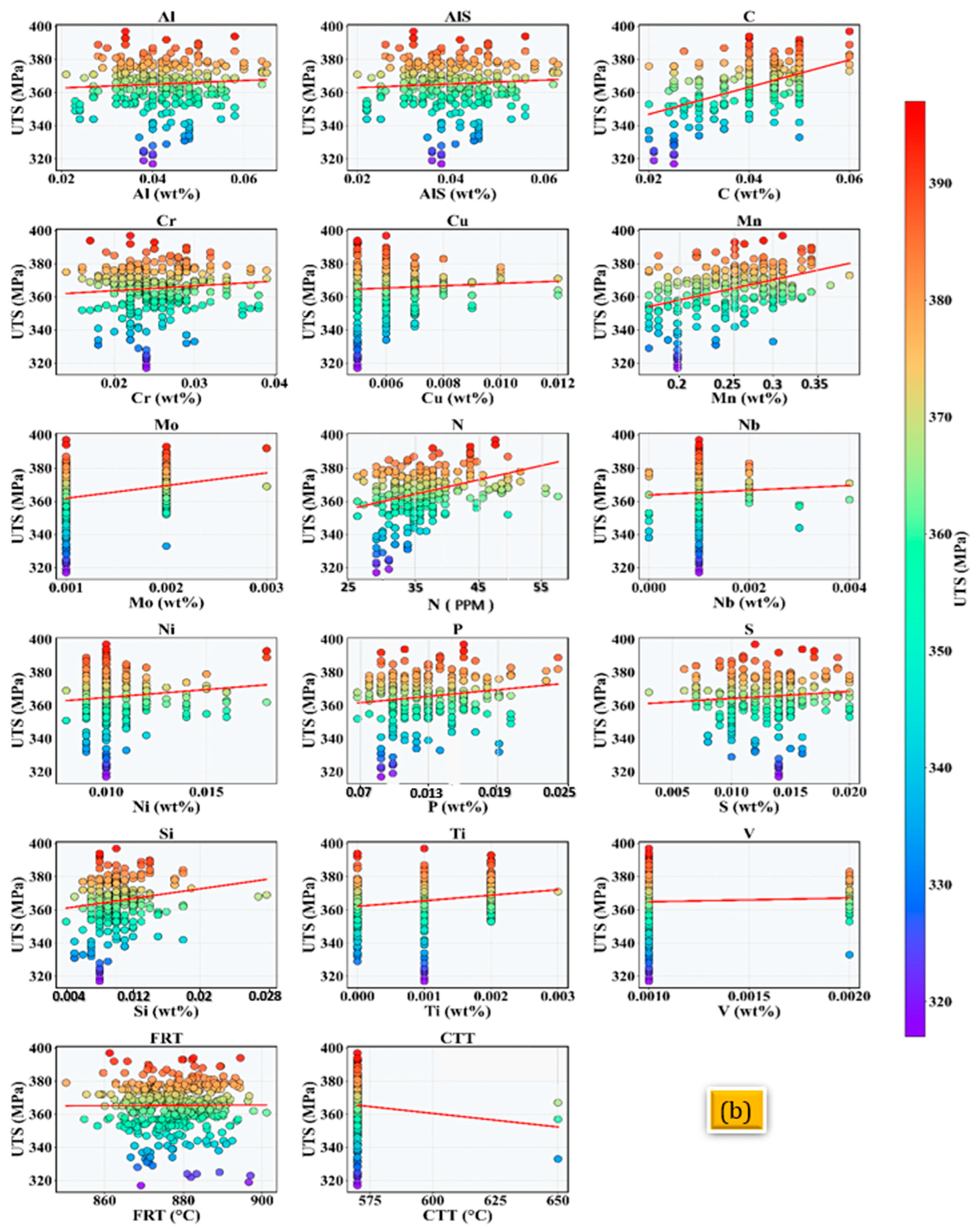

2.1. Data Collection and Preprocessing

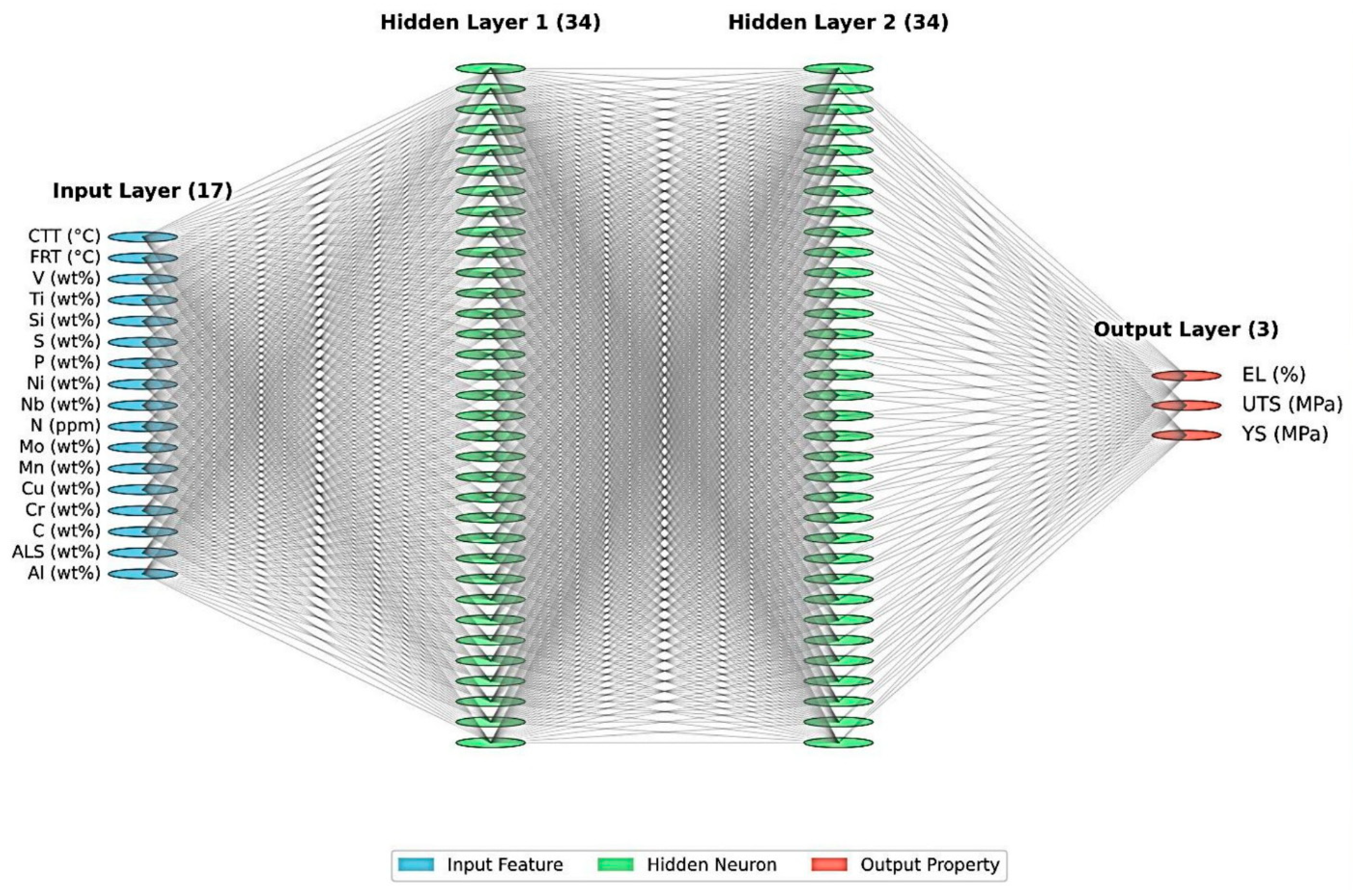

2.2. Neural Network Architecture and Training

2.3. Model Evaluation and Analysis of Processing Parameters

3. Results

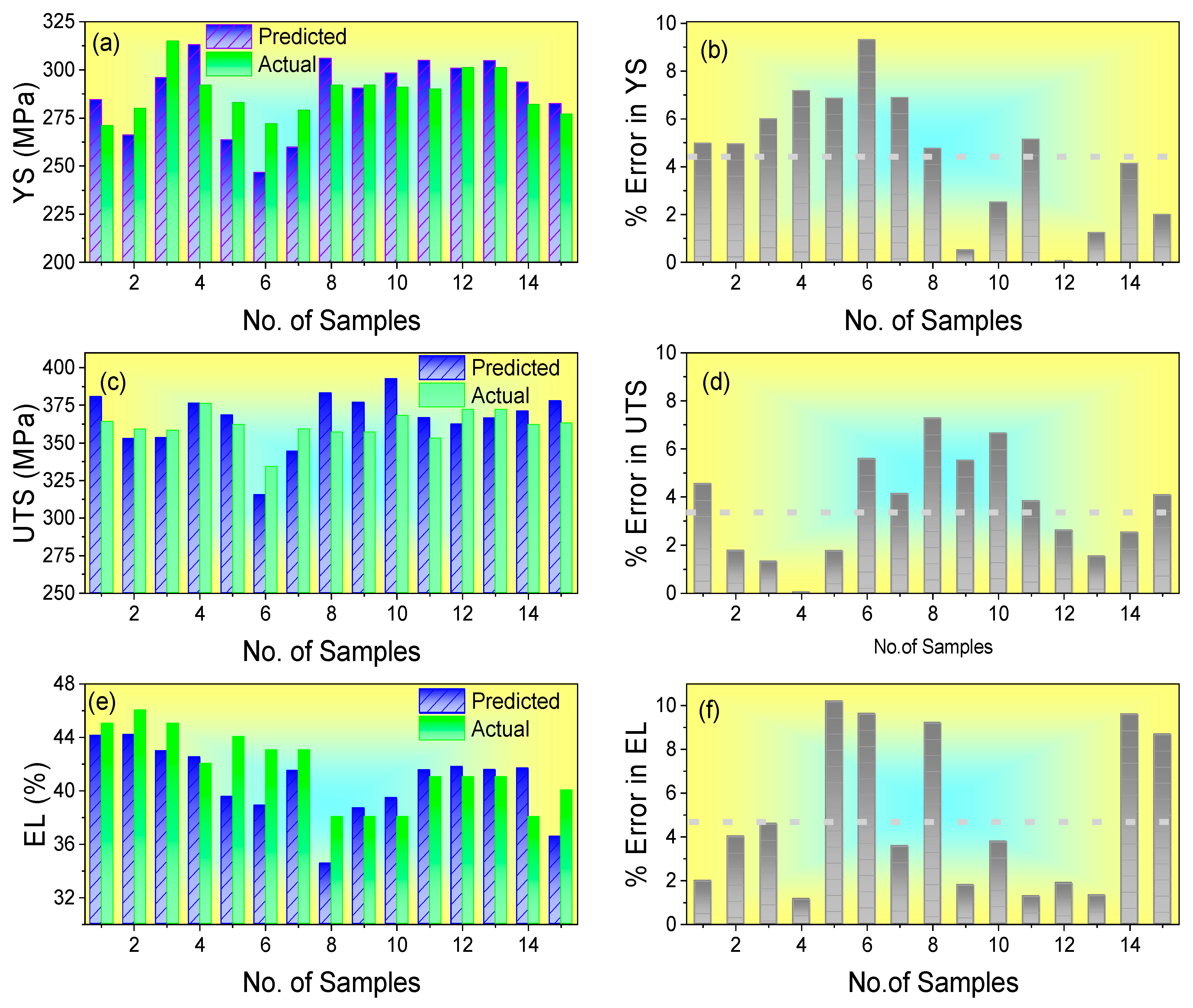

3.1. Model Performance on Test Data

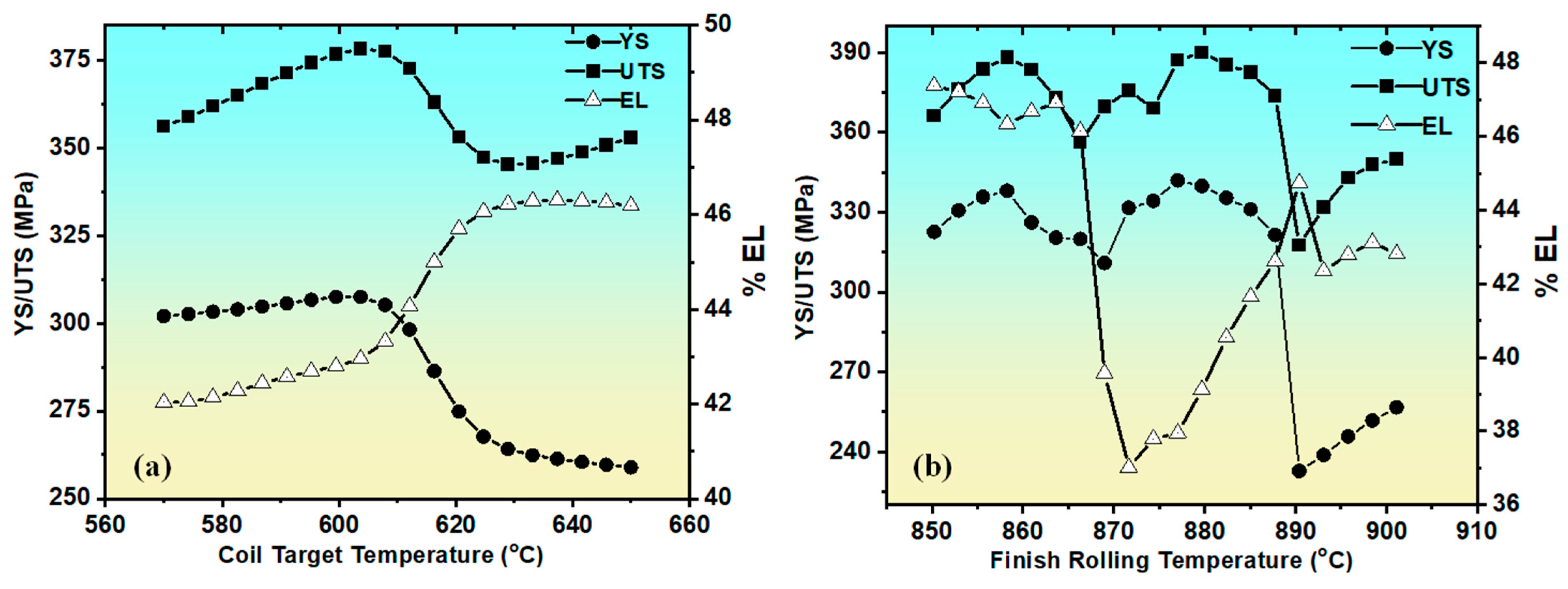

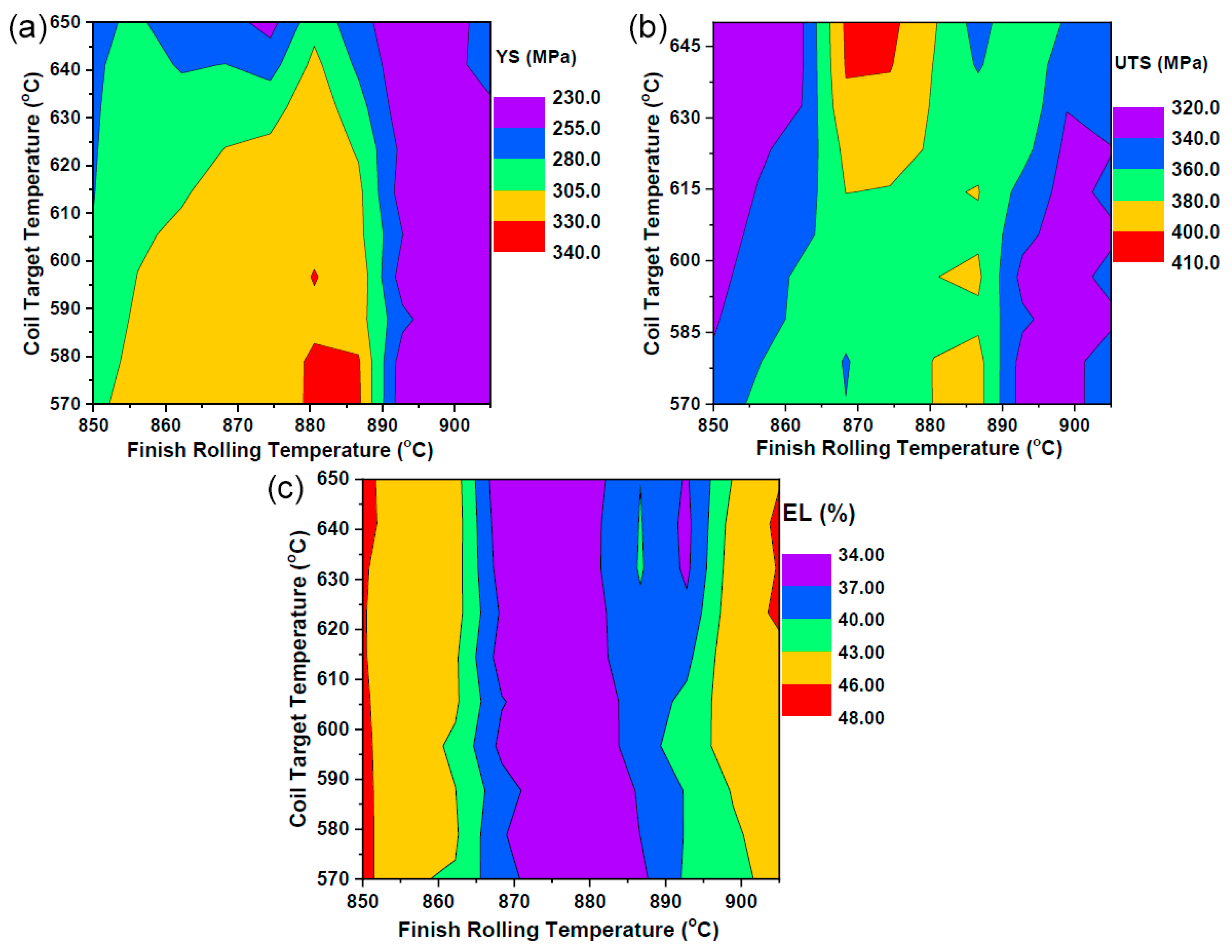

3.2. Effect of Processing Parameters on Mechanical Properties

3.3. Importance of Carbon and Manganese

3.4. Comparison with Existing Models

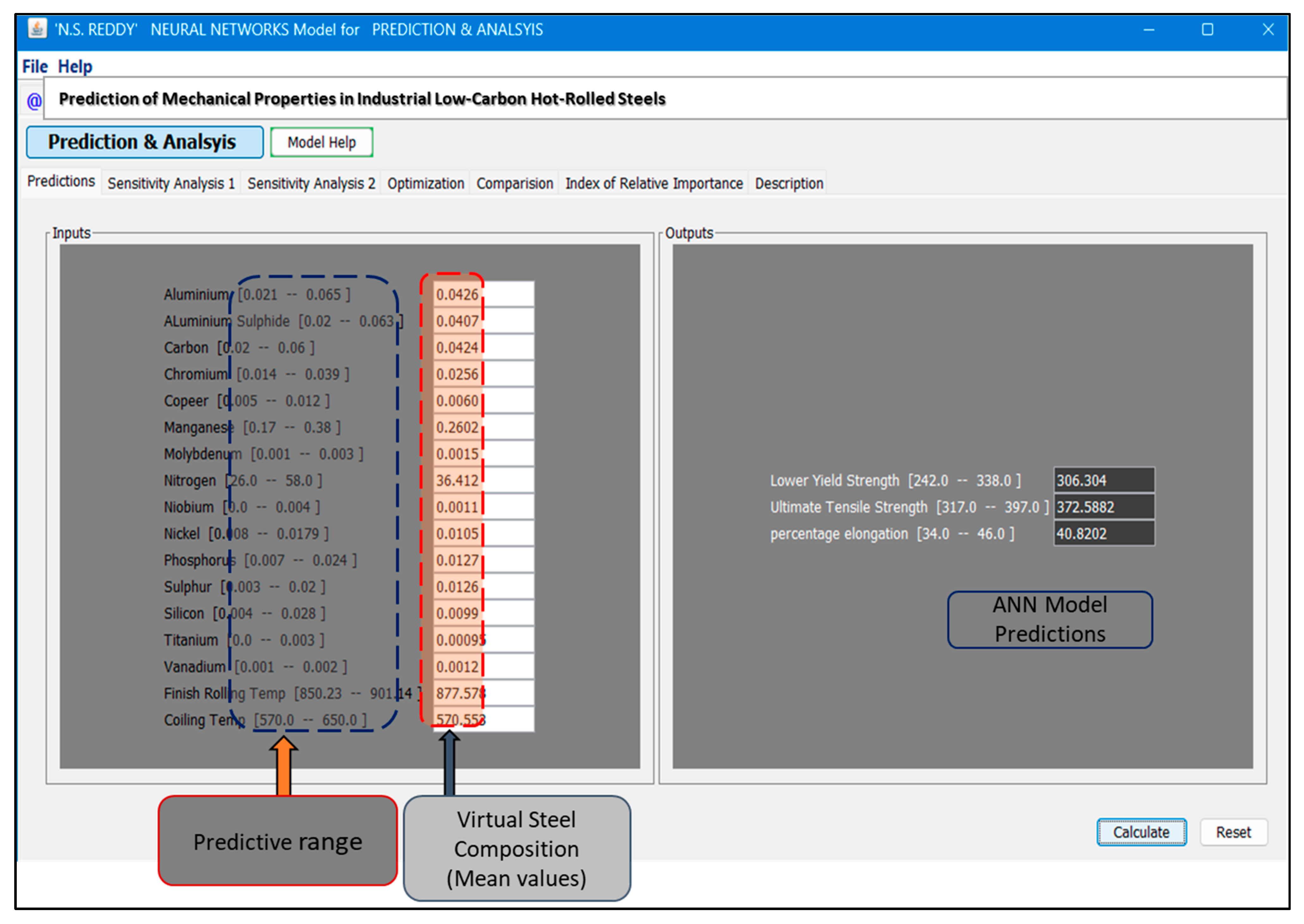

3.5. Graphical User Interface for Mechanical Properties Prediction

4. Conclusions

- The optimized FFNN model with two hidden layers (34 neurons each) demonstrated excellent predictive capability, with mean percentage errors of 4.44%, 3.54%, and 4.84% for YS, UTS, and EL, respectively.

- The finish rolling temperature (FRT) showed a more complex influence on the mechanical properties than the coil target temperature (CTT), which can be attributed to the broader effects of the FRT on the microstructural evolution during hot rolling.

- Among the composition elements, carbon and manganese were identified as the most influential factors affecting the mechanical properties, which aligns with established metallurgical principles.

- The model successfully captured the combined effects of composition and processing parameters on the mechanical properties, thereby providing a valuable tool for alloy design and process optimization in steel manufacturing.

- The prediction accuracy of our model is comparable or superior to that of the existing models in the literature, highlighting the benefits of incorporating a comprehensive set of input parameters and optimizing the neural network architecture.

- The processing parameters employed in the model validation are industrially feasible and representative of actual manufacturing conditions, ensuring practical applicability in real-world steel production environments.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| FRT | Finish rolling temperature |

| CTT | Coil target temperature |

References

- Bhadeshia, H.K.D.H. Neural Networks and Information in Materials Science. Stat. Anal. Data Min. 2009, 1, 296–305. [Google Scholar] [CrossRef]

- Bhadeshia, H. Neural Networks in Materials Science: The Importance of Uncertainty; Tata McGraw-Hill Publishing Company Ltd.: Mumbai, India, 2006. [Google Scholar]

- Sha, W.; Edwards, K.L. The Use of Artificial Neural Networks in Materials Science Based Research. Mater. Des. 2007, 28, 1747–1752. [Google Scholar] [CrossRef]

- Ishtiaq, M.; Tiwari, S.; Nagamani, M.; Kang, S.-G.; Reddy, N.G. Data-Driven ANN-Based Predictive Modeling of Mechanical Properties of 5Cr-0.5Mo Steel: Impact of Composition and Service Temperature. Crystals 2025, 15, 213. [Google Scholar] [CrossRef]

- Reséndiz-Flores, E.O.; Altamirano-Guerrero, G.; Costa, P.S.; Salas-Reyes, A.E.; Salinas-Rodríguez, A.; Goodwin, F. Optimal Design of Hot-Dip Galvanized DP Steels via Artificial Neural Networks and Multi-Objective Genetic Optimization. Metals 2021, 11, 578. [Google Scholar] [CrossRef]

- Narayana, P.L.; Tiwari, S.; Maurya, A.K.; Ishtiaq, M.; Park, N.; Reddy, N.G. Quantitative and Qualitative Analysis of Atmospheric Effects on Carbon Steel Corrosion Using an ANN Model. Metals 2025, 15, 607. [Google Scholar] [CrossRef]

- Guessasma, S.; Montavon, G.; Coddet, C. Neural Computation to Predict In-Flight Particle Characteristic Dependences From Processing Parameters in the APS Process. J. Therm. Spray Technol. 2004, 13, 570–585. [Google Scholar] [CrossRef]

- Ishtiaq, M.; Tiwari, S.; Panigrahi, B.B.; Seol, J.B.; Reddy, N.S. Neural Network-Based Modeling of the Interplay between Composition, Service Temperature, and Thermal Conductivity in Steels for Engineering Applications. Int. J. Thermophys. 2024, 45, 137. [Google Scholar] [CrossRef]

- Dutta, R.K.; Petrov, R.; Delhez, R.; Hermans, M.J.M.; Richardson, I.M.; Böttger, A.J. The Effect of Tensile Deformation by in Situ Ultrasonic Treatment on the Microstructure of Low-Carbon Steel. Acta Mater. 2013, 61, 1592–1602. [Google Scholar] [CrossRef]

- Mukherjee, M.; Singh, S.B. Artificial Neural Network: Some Applications in Physical Metallurgy of Steels. Mater. Manuf. Process. 2009, 24, 198–208. [Google Scholar] [CrossRef]

- Feng, X.; Gao, X.; Luo, L. A ResNet50-Based Method for Classifying Surface Defects in Hot-Rolled Strip Steel. Mathematics 2021, 9, 2359. [Google Scholar] [CrossRef]

- Mandal, A.; Ghosh, A.; Chakrabarti, D.; Davis, C. Effect of Coiling Temperature on Impact Toughness of Hot Rolled Ultra-High-Strength Multiphase Steel Strips. Mater. Sci. Eng.—Struct. Mater. Prop. Microstruct. Process. 2021, 824, 141796. [Google Scholar] [CrossRef]

- Corfar, D.-A.; Tsavdaridis, K.D. A Comprehensive Review and Classification of Inter-Module Connections for Hot-Rolled Steel Modular Building Systems. J. Build. Eng. 2022, 50, 104006. [Google Scholar] [CrossRef]

- Rademacher, D.; Ochojski, W.; Lorenc, W.; Kożuch, M. Advanced Solutions with Hot-Rolled Sections for Economical and Durable Bridges. Steel Constr. 2018, 11, 196–204. [Google Scholar] [CrossRef]

- Saastamoinen, A.; Kaijalainen, A.; Porter, D.; Suikkanen, P.; Yang, J.-R.; Tsai, Y.-T. The Effect of Finish Rolling Temperature and Tempering on the Microstructure, Mechanical Properties and Dislocation Density of Direct-Quenched Steel. Mater. Charact. 2018, 139, 1–10. [Google Scholar] [CrossRef]

- Zhao, Z.; Tang, J.; Tariq, N.u.H.; Liu, H.; Liu, H.; Ren, Y.; Tong, M.; Yin, L.; Du, H.; Wang, J.; et al. Effect of Rolling Temperature on Microstructure and Mechanical Properties of Ti/Steel Clad Plates Fabricated by Cold Spraying and Hot-Rolling. Mater. Sci. Eng.—Struct. Mater. Prop. Microstruct. Process. 2020, 795, 139982. [Google Scholar] [CrossRef]

- Guo, B.; Fan, L.; Wang, Q.; Fu, Z.; Wang, Q.; Zhang, F. Effect of Finish Rolling Temperature on the Microstructure and Tensile Properties of Nb–Ti Microalloyed X90 Pipeline Steel. Metals 2016, 6, 323. [Google Scholar] [CrossRef]

- Xue, J.; Zhao, Z.; Bin, C.; Liu, X.; Wu, H.; Li, H.; Xiong, W. Effects of Rolling and Coiling Temperature on the Microstructure and Mechanical Properties of Hot-Rolled High Strength Complex Phase Steel. Mater. Res. Express 2019, 6, 0965c8. [Google Scholar] [CrossRef]

- Singh, S.B.; Bhadeshia, H.K.D.H. Estimation of Bainite Plate-Thickness in Low-Alloy Steels. Mater. Sci. Eng.—Struct. Mater. Prop. Microstruct. Process. 1998, 245, 72–79. [Google Scholar] [CrossRef]

- Chang, L.C.; Bhadeshia, H.K.D.H. Microstructure of Lower Bainite Formed at Large Undercoolings below Bainite Start Temperature. Mater. Sci. Technol. 1996, 12, 233–236. [Google Scholar] [CrossRef]

- Wang, X.; Li, X.; Yuan, H.; Zhou, N.; Wang, H.; Zhang, W.; Ji, Y. Prediction and Analysis of Mechanical Properties of Hot-Rolled Strip Steel Based on an Interpretable Machine Learning. Mater. Today Commun. 2024, 40, 109997. [Google Scholar] [CrossRef]

- Wu, H.; Zhang, B.; Li, Z. Small Sample-Oriented Prediction Method of Mechanical Properties for Hot Rolled Strip Steel Based on Model Independent Element Learning. IEEE Access 2024, 12, 197300–197311. [Google Scholar] [CrossRef]

- Fang, W.; Huang, J.X.; Peng, T.X.; Long, Y.; Yin, F.X. Machine Learning-Based Performance Predictions for Steels Considering Manufacturing Process Parameters: A Review. J. Iron Steel Res. Int. 2024, 31, 1555–1581. [Google Scholar] [CrossRef]

- NBC Engineers. The Complete Technology Book on Steel and Steel Products (Fasteners, Seamless Tubes, Casting, Rolling of Flat Products & Others): How to Start Steel Rolling Mill, Iron and Steel Making by-Products, Manufacturing of Steel, Manufacturing Process for Steel Products, Metal Fasteners Manufacturing, Mill Automation for Pipe and Tubing Production, Modern Rolling Plant, Modern Small and Cottage Scale Industries, Most Profitable Steel Business Ideas, New Small Scale Ideas in Steel Rolling Industry, Opportunity Steel Rolling Mill, Plate Mill, Production of Welded Pipe, Profitable Small and Cottage Scale Industries; NIIR Project Consultancy Services; National Institute of Industrial Research: Delhi, India, 2008; ISBN 978-81-7833-018-1. [Google Scholar]

- Seetharaman, S. Fundamentals of Metallurgy; Elsevier Science: Amsterdam, The Netherlands, 2005; ISBN 978-1-85573-927-7. [Google Scholar]

- Reddy, N.S.; Panigrahi, B.B.; Krishnaiah, J. Modeling Mechanical Properties of Low Carbon Hot Rolled Steels; Springer: New Delhi, India, 2013; pp. 221–228. [Google Scholar]

- Paupler, P.G.E. Dieter. Mechanical Metallurgy. 3rd Ed., Mc Graw-Hill Book Co., New York 1986. XXIII + 751 p., DM 138.50, ISBN 0–07–016893–8. Cryst. Res. Technol. 1988, 23, 194. [Google Scholar] [CrossRef]

- Laz’ko, V.G.; Nikitin, V.N.; Karchevskaya, N.I. Effect of Carbon Content on the Structure and Mechanical Properties of High-Strength Weldable Steel 03G4N2MAF. Met. Sci. Heat Treat. 1986, 28, 186–188. [Google Scholar] [CrossRef]

- Goritskii, V.M.; Shneiderov, G.R.; Guseva, I.A. Effect of Chemical Composition and Structure on Mechanical Properties of High-Strength Welding Steels. Metallurgist 2019, 63, 21–32. [Google Scholar] [CrossRef]

- Khorrami, M.; Hanzaki, A.Z.; Abedi, H.R.; Moallemi, M.; Mola, J.; Chen, G. On the Effect of Mn-Content on the Strength-Ductility Balance in Ni-Free High N Transformation Induced Plasticity Steels. Mater. Sci. Eng.—Struct. Mater. Prop. Microstruct. Process. 2021, 814, 141260. [Google Scholar] [CrossRef]

- Song, R.; Ponge, D.; Raabe, D. Influence of Mn Content on the Microstructure and Mechanical Properties of Ultrafine Grained C-Mn Steels. Isij Int. 2005, 45, 1721–1726. [Google Scholar] [CrossRef][Green Version]

- Olalla, V.C.; Petrov, R.; Thibaux, P.; Liebeherr, M.; Gurla, P.; Kestens, L.A. Influence of Rolling Temperature and Cooling Rate on Microstructure and Properties of Pipeline Steel Grades. Mater. Sci. Forum 2012, 706, 2710–2715. [Google Scholar] [CrossRef]

- Huang, Y.; Han, J.; Liu, W.; Li, F.; Zhao, A.; Liu, Y. Effect of the Final Rolling Temperature on the Precipitation Behavior and Toughening Mechanism of Nanoparticles in Ferritic Steel. J. Mater. Eng. Perform. 2020, 29, 1724–1731. [Google Scholar] [CrossRef]

- Kim, K.H.; Hwang, N.-M.; Lee, B.-J.; Yoon, J.-K. Effects of the Finish Rolling Temperature on Mechanical Properties and Microstructure Evolution of Line Pipe Steel. Mater. Sci. Forum 2005, 475, 89–92. [Google Scholar] [CrossRef]

- An, Y.F.; Chen, X.P.; Mei, L.; Tan, X.; Ren, P.; Zhang, X.Y.; Cao, W.Q. Overcoming the Strength-Ductility Trade-off Dilemma in Austenitic Lightweight Steel via Stepwise Controllable Intragranular Dual Nanoprecipitation. Mater. Sci. Eng. A 2024, 908, 146773. [Google Scholar] [CrossRef]

- Li, X.T.; Liu, R.; Hou, J.; Zhang, Z.J.; Zhang, Z.F. Trade-off Model for Strength-Ductility Relationship of Metallic Materials. Acta Mater. 2025, 289, 120942. [Google Scholar] [CrossRef]

| Parameter | Minimum | Maximum | Average | Std. Deviation |

|---|---|---|---|---|

| Al (wt%) | 0.021 | 0.065 | 0.043 | 0.011 |

| ALS (wt%) | 0.020 | 0.063 | 0.041 | 0.010 |

| C (wt%) | 0.020 | 0.060 | 0.040 | 0.008 |

| Cr (wt%) | 0.014 | 0.039 | 0.026 | 0.006 |

| Cu (wt%) | 0.005 | 0.012 | 0.008 | 0.002 |

| Mn (wt%) | 0.170 | 0.380 | 0.275 | 0.052 |

| Mo (wt%) | 0.001 | 0.003 | 0.002 | 0.001 |

| N (ppm) | 26 | 58 | 42 | 8 |

| Nb (wt%) | 0.000 | 0.004 | 0.002 | 0.001 |

| Ni (wt%) | 0.008 | 0.018 | 0.013 | 0.002 |

| P (wt%) | 0.007 | 0.024 | 0.015 | 0.004 |

| S (wt%) | 0.003 | 0.020 | 0.011 | 0.004 |

| Si (wt%) | 0.004 | 0.028 | 0.016 | 0.006 |

| Ti (wt%) | 0.000 | 0.003 | 0.001 | 0.001 |

| V (wt%) | 0.001 | 0.002 | 0.001 | 0.0004 |

| FRT (°C) | 850.23 | 901.14 | 875.68 | 12.73 |

| CTT (°C) | 570 | 650 | 610 | 20.41 |

| YS (MPa) | 242 | 338 | 290 | 24.12 |

| UTS (MPa) | 317 | 397 | 357 | 20.15 |

| EL (%) | 34 | 46 | 40 | 3.02 |

| System | YS (MPa) | UTS (MPa) | EL (%) |

|---|---|---|---|

| Actual | 302 | 356 | 42 |

| Hypothetical alloy based on C (0.04) (wt%) | 301.5 | 356.3 | 41.8 |

| Hypothetical alloy based on Mn (0.22) (wt%) | 301.8 | 357.3 | 42.1 |

| Hypothetical alloy based on FRT (868 °C) | 313 | 365 | 41.8 |

| Hypothetical alloy based on CTT (570 °C) | 303 | 358 | 42.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tiwari, S.; Ahn, H.; Reddy, M.H.; Park, N.; Reddy, N.G.S. Mechanical Property Prediction of Industrial Low-Carbon Hot-Rolled Steels Using Artificial Neural Networks. Materials 2025, 18, 2966. https://doi.org/10.3390/ma18132966

Tiwari S, Ahn H, Reddy MH, Park N, Reddy NGS. Mechanical Property Prediction of Industrial Low-Carbon Hot-Rolled Steels Using Artificial Neural Networks. Materials. 2025; 18(13):2966. https://doi.org/10.3390/ma18132966

Chicago/Turabian StyleTiwari, Saurabh, Hyoju Ahn, Maddika H. Reddy, Nokeun Park, and Nagireddy Gari S. Reddy. 2025. "Mechanical Property Prediction of Industrial Low-Carbon Hot-Rolled Steels Using Artificial Neural Networks" Materials 18, no. 13: 2966. https://doi.org/10.3390/ma18132966

APA StyleTiwari, S., Ahn, H., Reddy, M. H., Park, N., & Reddy, N. G. S. (2025). Mechanical Property Prediction of Industrial Low-Carbon Hot-Rolled Steels Using Artificial Neural Networks. Materials, 18(13), 2966. https://doi.org/10.3390/ma18132966