Induction of Strong Magneto-Optical Effect and High Compatibility with Si of BiFeO3 Thin Film by Sr and Ti Co-Doping

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

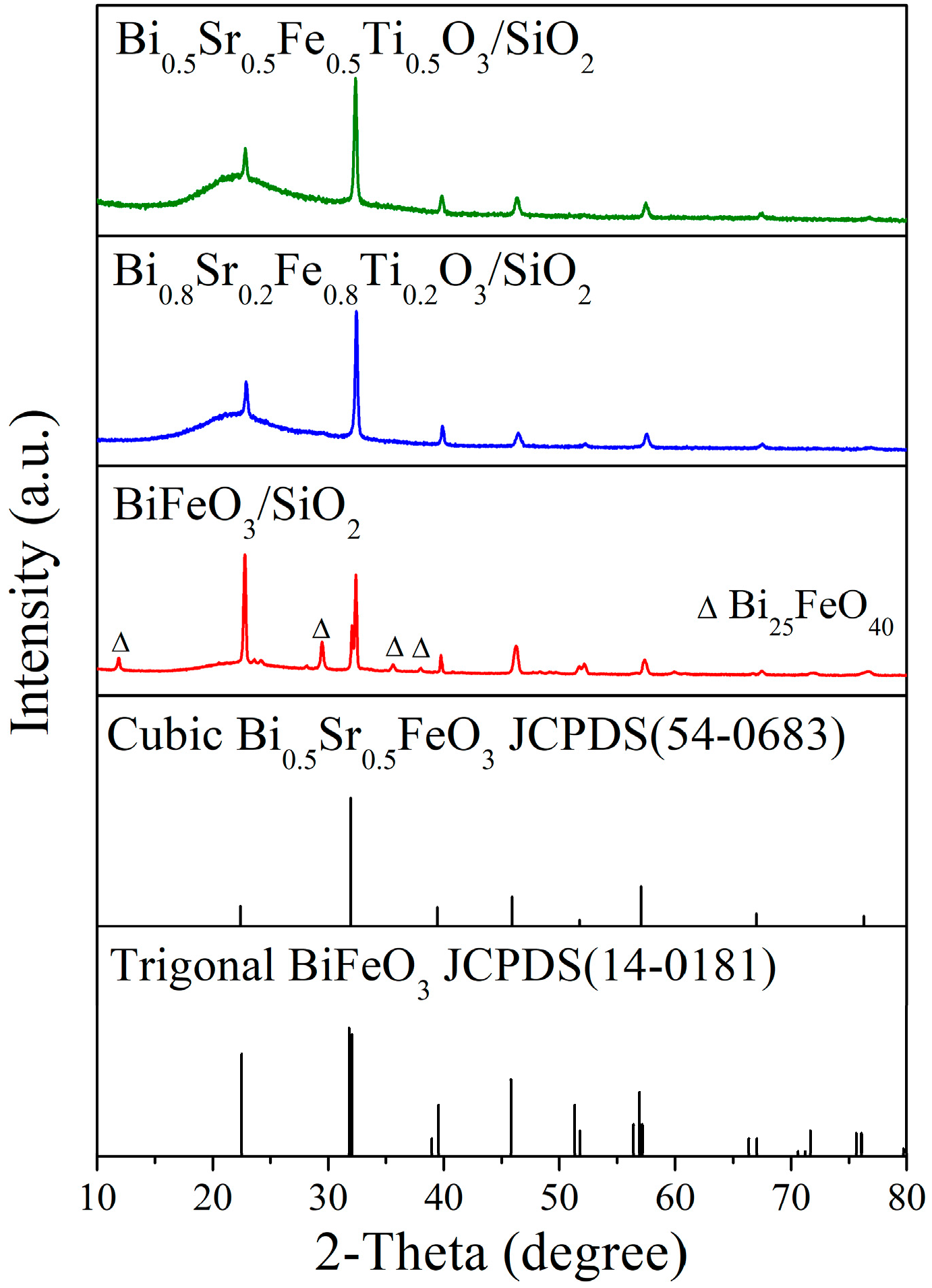

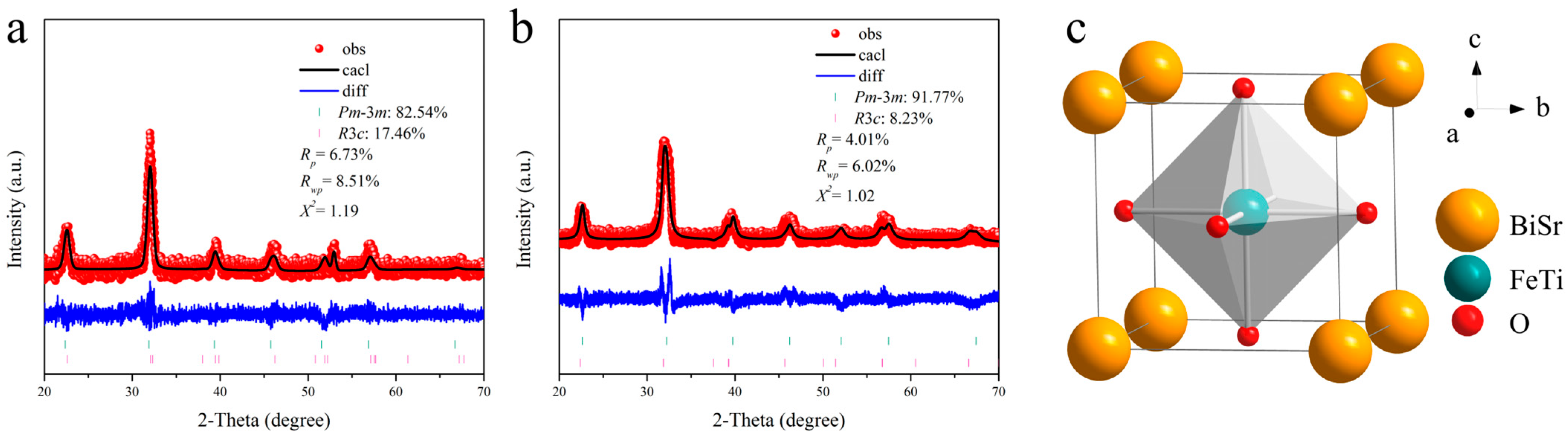

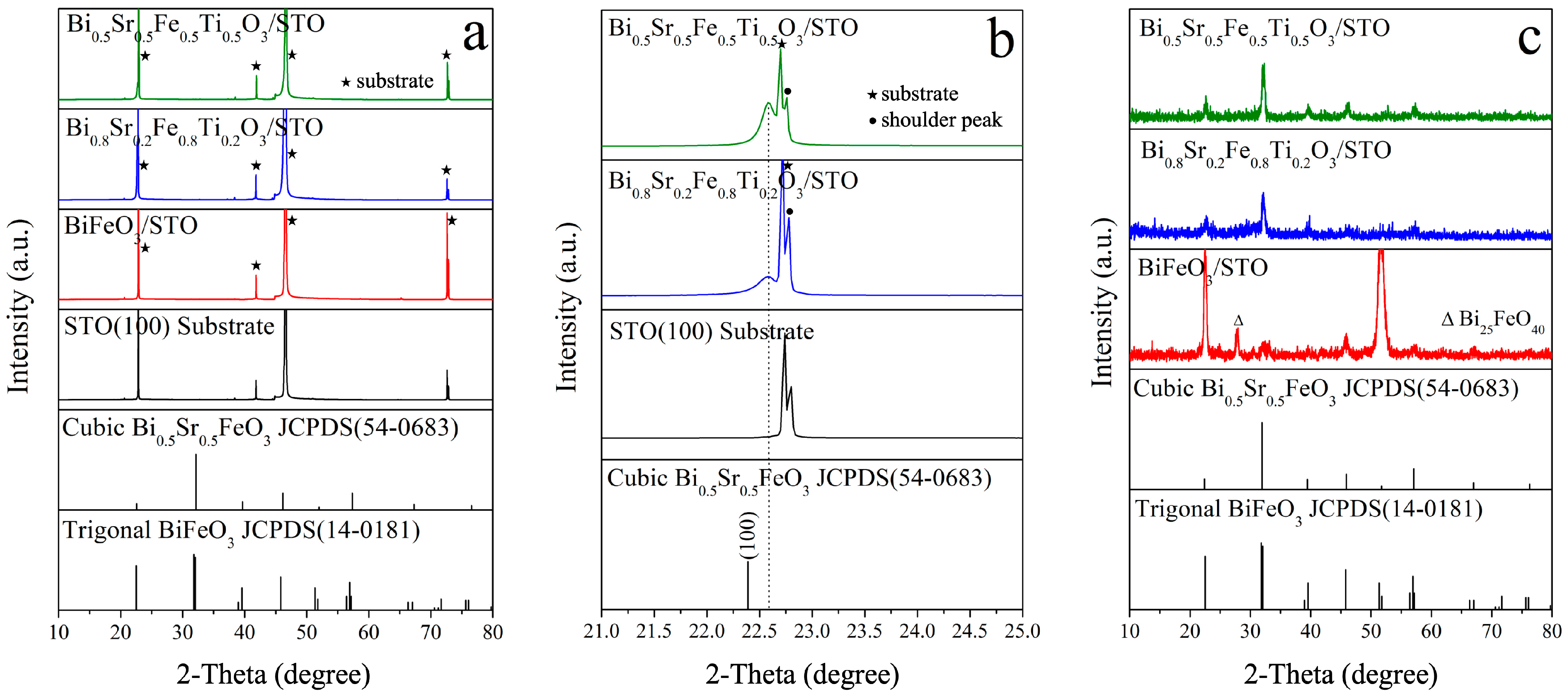

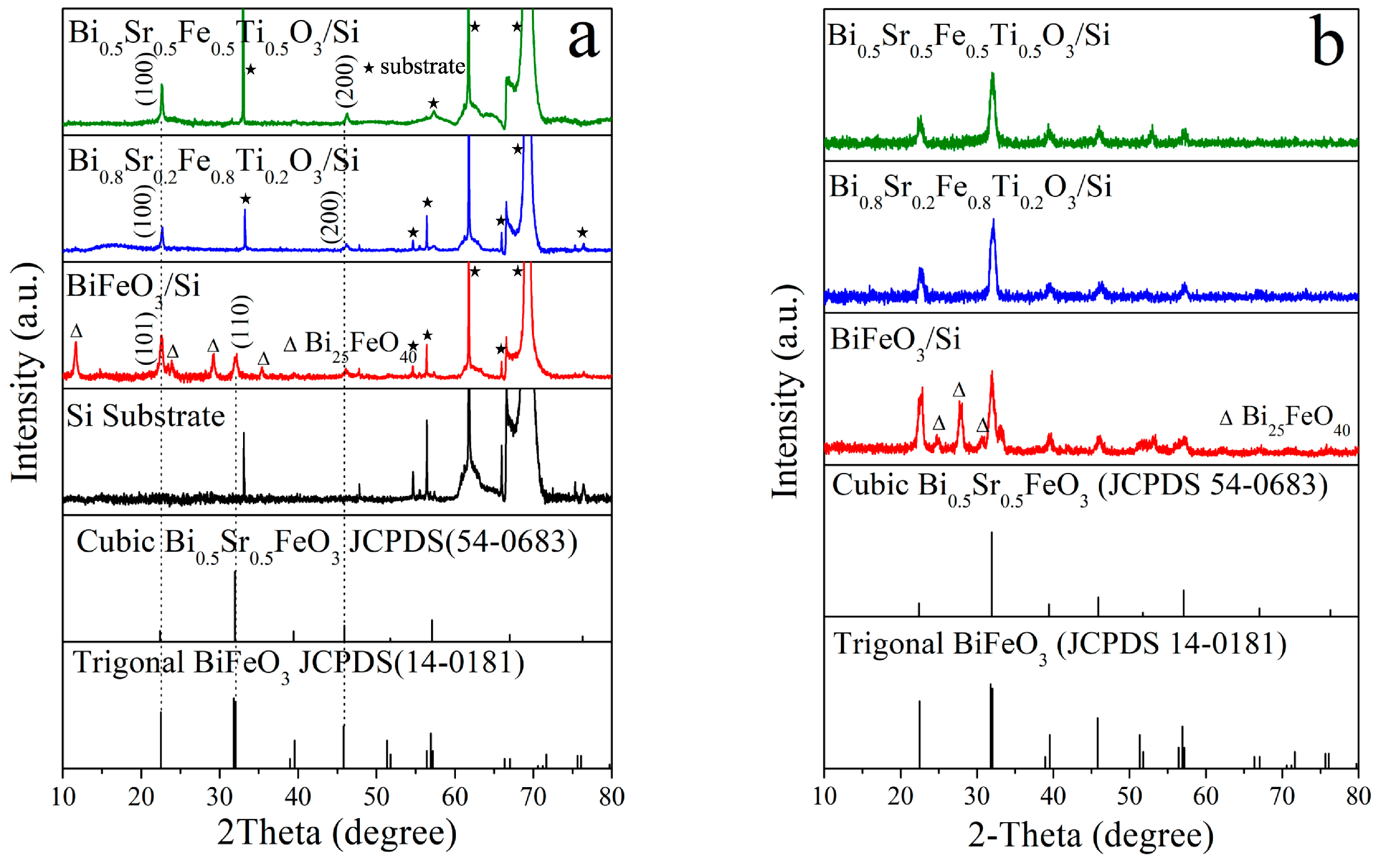

3.1. Crystalline Phase and Structure

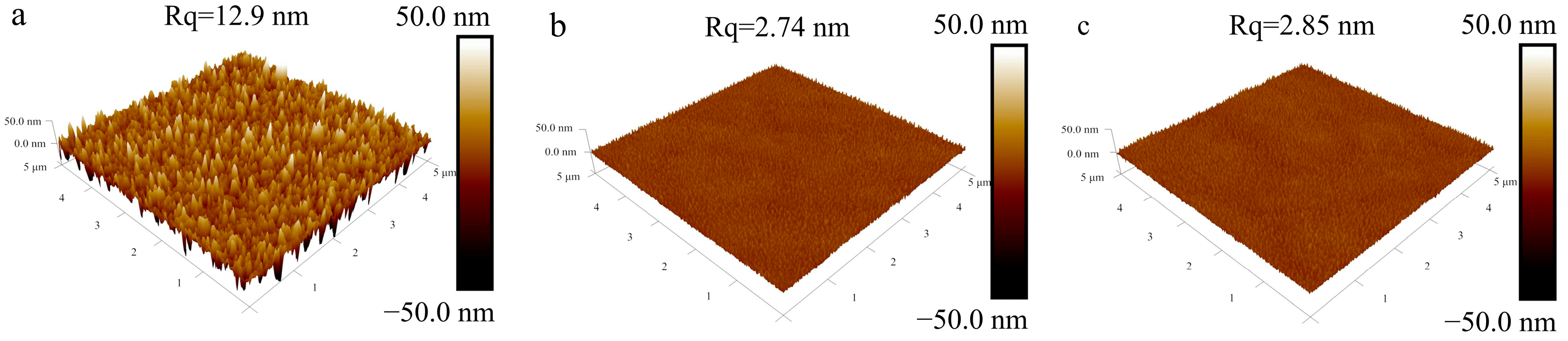

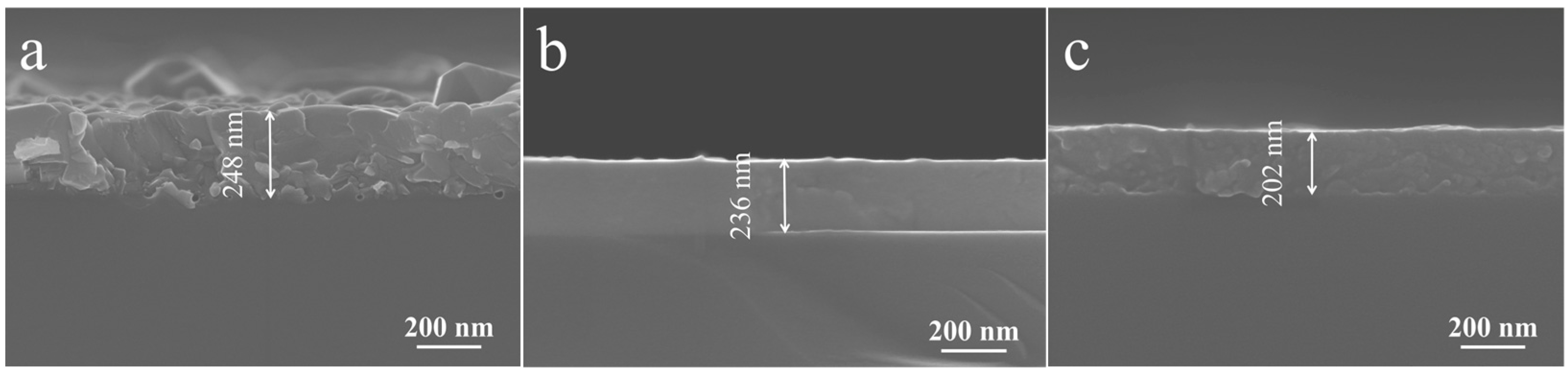

3.2. Surface Morphology and Thickness

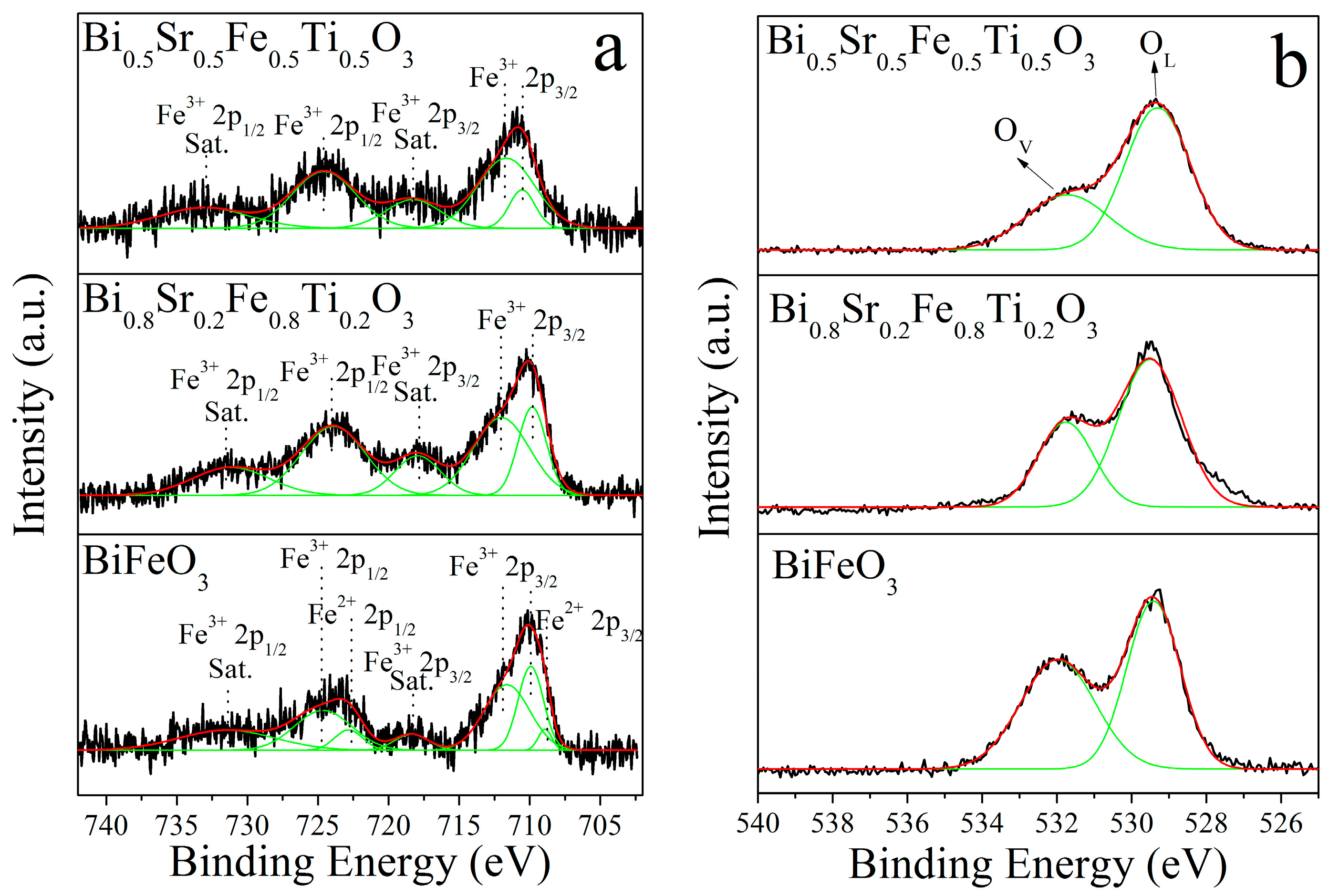

3.3. Valence State

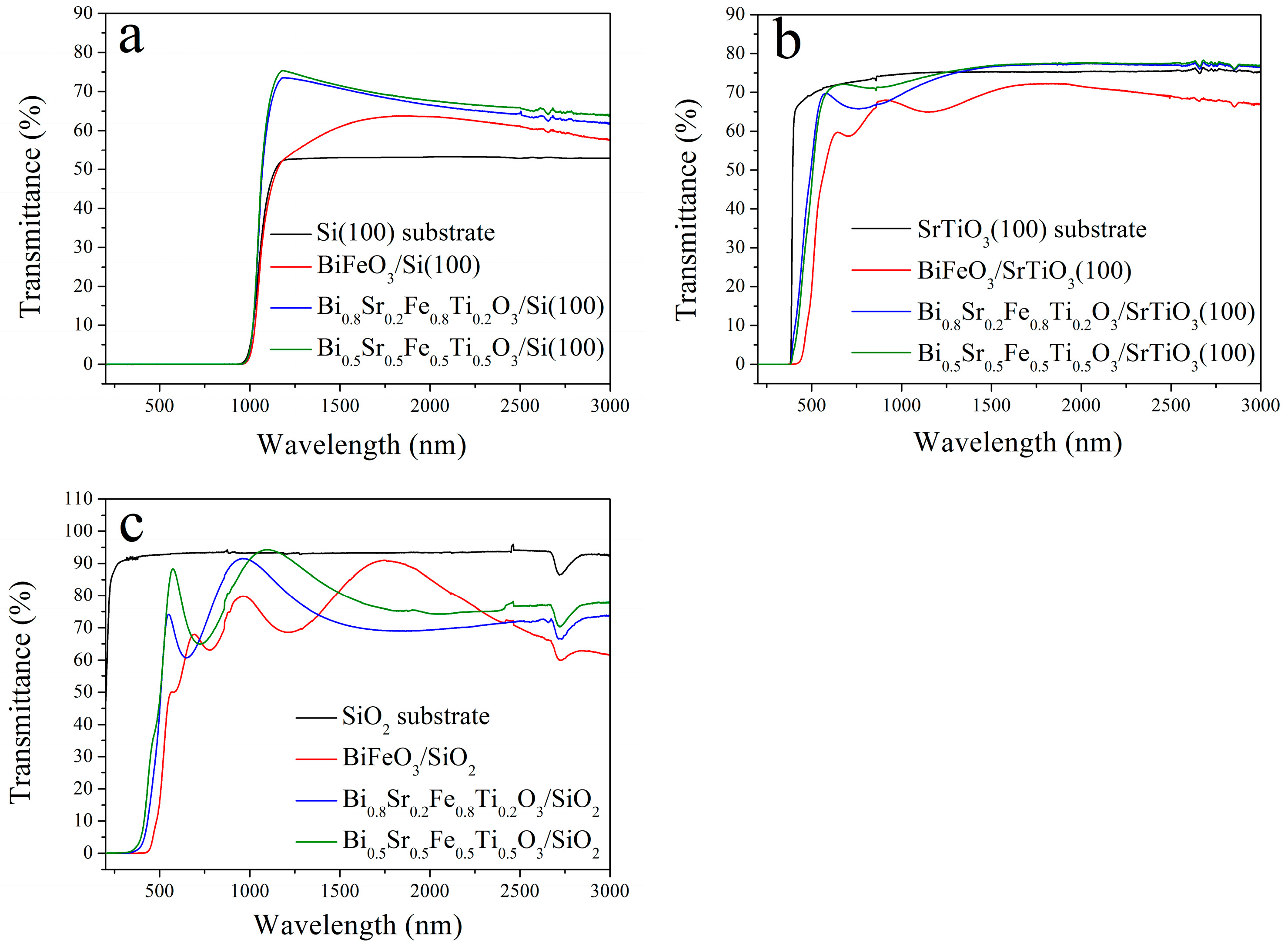

3.4. Transmittance

3.5. Magnetism

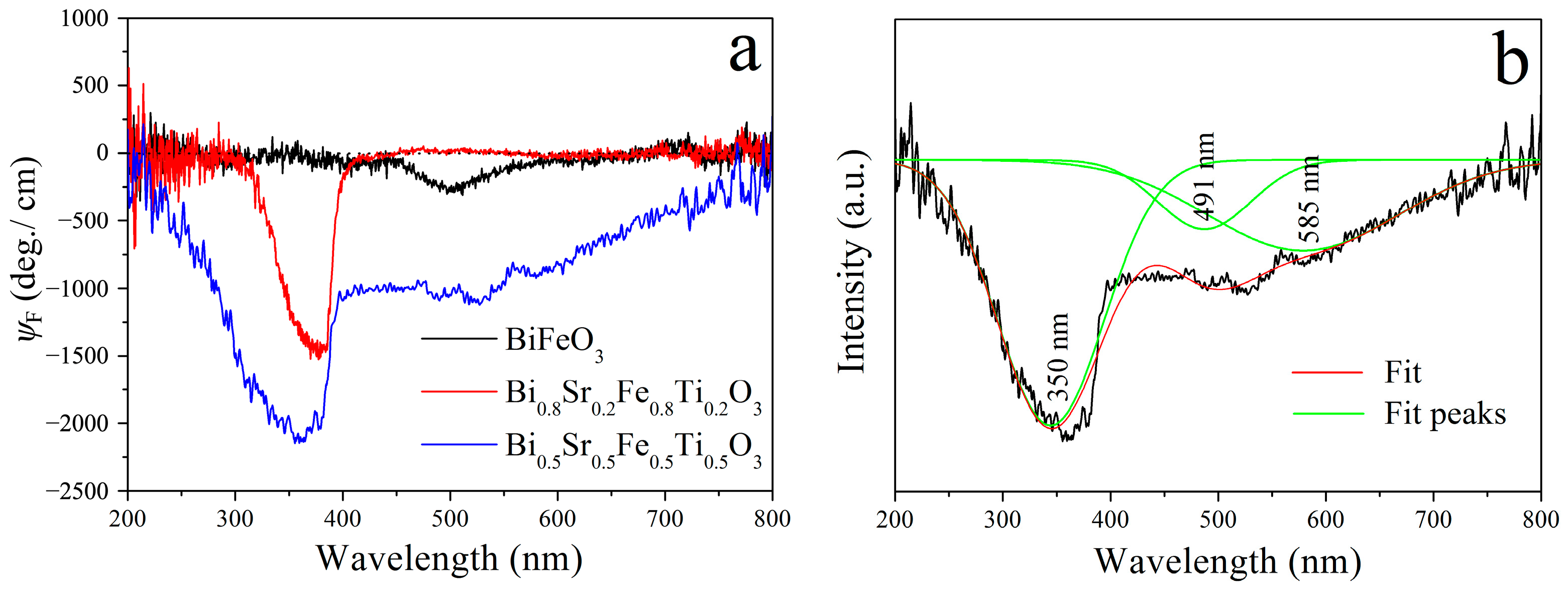

3.6. Magneto-Optical Performance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, W.; Kong, X.; Fu, B.; Yang, Y.; Chen, R.; Zuo, C.; Liu, H.; Yu, Y.; Zeng, F.; Li, C. Optical properties of CeF3 crystal at high temperature or pressure by first principles and its application in isolators. Opt. Mater. 2024, 154, 115758. [Google Scholar] [CrossRef]

- Bera, S.; Kalimuddin, S.; Bera, A.; Roy, D.S.; Debnath, T.; Das, S.; Mondal, M. Nonlinear Optical Properties of 2D vdW Ferromagnetic Nanoflakes for Magneto-Optical Logic Applications. Adv. Opt. Mater. 2025, 13, 2402318. [Google Scholar] [CrossRef]

- Ji, B.; Jin, Z.; Wu, G.; Li, J.; Wan, C.; Han, X.; Zhang, Z.; Ma, G.; Peng, Y.; Zhu, Y. Ultrafast laser-induced magneto-optical response of CoFeB/MgO/CoFeB magnetic tunneling junction. Appl. Phys. Lett. 2023, 122, 111104. [Google Scholar] [CrossRef]

- Sukhorukov, Y.P.; Telegin, A.V.; Lobov, I.D.; Naumov, S.V.; Dubinin, S.S.; Merencova, K.A.; Artemyev, M.S.; Nosov, A.P. Magnetooptical gyrotropic effects in nanosized BiYIG films and diamagnetic YAG substrates. J. Appl. Phys. 2024, 136, 193905. [Google Scholar] [CrossRef]

- Fakhrul, T.; Khurana, B.; Lee, B.H.; Huang, S.; Nembach, H.T.; Beach, G.S.D.; Ross, C.A. Damping and Interfacial Dzyaloshinskii-Moriya Interaction in Thulium Iron Garnet/Bismuth-Substituted Yttrium Iron Garnet Bilayers. ACS Appl. Mater. Interfaces 2024, 16, 2489–2496. [Google Scholar] [CrossRef] [PubMed]

- Fakhrul, T.; Tazlaru, S.; Khurana, B.; Beran, L.; Bauer, J.; Vančík, M.; Marchese, A.; Tsotsos, E.; Kučera, M.; Zhang, Y.; et al. High figure of merit magneto-optical Ce- and Bi-substituted Terbium Iron garnet films integrated on Si. Adv. Opt. Mater. 2021, 9, 2100512. [Google Scholar] [CrossRef]

- Wahid, D.A.; Morioka, T.; Shimizu, H. Preparation of Bi2Gd1Fe5O12 magnetic garnet films showing Faraday rotation of 36.3 deg./µm on glass substrates by metal organic decomposition method. IEICE Electron. Express 2016, 13, 20161011. [Google Scholar] [CrossRef]

- Sun, X.Y.; Du, Q.; Goto, T.; Onbasli, M.C.; Kim, D.H.; Aimon, N.M.; Hu, J.; Ross, C.A. Single-step deposition of cerium-substituted yttrium iron garnet for monolithic on-chip optical isolation. ACS Photon. 2015, 2, 856–863. [Google Scholar] [CrossRef]

- Yang, Q.H.; Zhang, H.W.; Wen, Q.Y.; Liu, Y.L. Effects of off-stoichiometry and density on the magnetic and magneto-optical properties of yttrium iron garnet films by magnetron sputtering method. J. Appl. Phys. 2010, 108, 073901. [Google Scholar] [CrossRef]

- Meng, F.; Qin, L.; Gao, H.; Zhu, H.; Yuan, Z. Perovskite-structured LaFeO3 modified In2O3 gas sensor with high selectivity and ultra-low detection limit for 2-butanone. J. Alloys Compd. 2024, 970, 176424. [Google Scholar] [CrossRef]

- Cheng, Z.; Hong, F.; Wang, Y.; Ozawa, K.; Fujii, H.; Kimura, H.; Du, Y.; Wang, X.; Dou, S. Interface strain-induced multiferroicity in a SmFeO3 film. ACS Appl. Mater. Interfaces 2014, 6, 7356–7362. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Yang, X.; He, X.; Xue, H.; Wang, X.; Dong, H.; Zhu, J.; Mao, W.; Xu, X.; Li, X. Roles of oxygen vacancy and ferroelectric polarization in photovoltaic effects of BiFeO3 based devices. Solid State Commun. 2023, 360, 115042. [Google Scholar] [CrossRef]

- Chauhan, S.; Kumar, M.; Pal, P. Substitution driven structural and magnetic properties and evidence of spin phonon coupling in Sr-doped BiFeO3 nanoparticles. RSC Adv. 2016, 6, 68028. [Google Scholar] [CrossRef]

- Chen, M.; Ma, J.; Peng, R.; Zhang, Q.; Nan, C.W. Robust polarization switching in self-assembled BiFeO3 nanoislands with quad-domain structures. Acta Mater. 2019, 175, 324–330. [Google Scholar] [CrossRef]

- Wei, Y.; Liu, Z.; Xu, D.; Dong, L.; Li, G.; Wang, Y.; Fan, F.; Meng, X.; Song, J. Dielectric properties and ferroelectric resistive switching mechanism in the epitaxial (111) BiFeO3 films. Ferroelectrics 2023, 613, 97–103. [Google Scholar] [CrossRef]

- Kathirvel, A.; Maheswari, A.U.; Sivakumar, M. Enhanced responsivity of Zr-doped BiFeO3 based self-powered UV-visible heterojunction photodetector fabricated via spray pyrolysis technique. Appl. Surf. Sci. 2023, 618, 156640. [Google Scholar] [CrossRef]

- Eriksson, A.; Tran, T.; Saxin, S.; Svensson, G.; Svedlindh, P.; Eriksson, S.-G.; Knee, C. Effects of A-site substitution on the structure and magnetic properties of Bi0.15Sr0.85-yAeyCo1-xFexO3-δ perovskites. Solid State Sci. 2009, 11, 1945–1954. [Google Scholar] [CrossRef]

- Kuhn, J.N.; Matter, P.H.; Millet, J.M.M.; Watson, R.B.; Ozkan, U.S. Oxygen Exchange Kinetics over Sr- and Co-doped LaFeO3. J. Phys. Chem. C 2008, 112, 12468–12476. [Google Scholar] [CrossRef]

- Jabeen, F.; Shahid, R.; Khan, M.S.; Pandey, R. Effect of Mn doping on the structural, spectral, electrical, ferromagnetic and piezoelectric properties of 0.7BFO-0.3BTO lead-free ceramics. J. Alloys Compd. 2022, 917, 165303. [Google Scholar] [CrossRef]

- Kumar, P.; Kar, M. Effect of Structural Transition on Magnetic and Dielectric Properties of La and Mn co-substituted BiFeO3 Ceramics. Mater. Chem. Phys. 2014, 148, 968–977. [Google Scholar] [CrossRef]

- Lin, N.; Zhang, S.; Chen, H.; Chen, Y.; Chen, X.; Zhang, Y.; Hu, X.; Zhuang, N. Structural design of cubic Sr,V:CeFeO3 thin films with a strong magneto-optical effect and high compatibility with a Si substrate. Dalton Trans. 2020, 49, 7713. [Google Scholar] [CrossRef] [PubMed]

- Kersch, A.; Fischer, D. Phase stability and dielectric constant of ABO3 perovskites from first principles. J. Appl. Phys. 2009, 106, 014105. [Google Scholar] [CrossRef]

- Li, Z.; Yang, M.; Park, J.-S.; Wei, S.-H.; Berry, J.J.; Zhu, K. Stabilizing perovskite structures by tuning tolerance factor: Formation of formamidinium and Cesium Lead Iodide solid-state alloys. Chem. Mater. 2016, 28, 284–292. [Google Scholar] [CrossRef]

- Ali, S.; Sheeraz, M.; Ullah, A.; Yun, W.S.; Ullah, A.; Kim, I.W.; Ahn, C.W. Mapping the low tolerance factor Bi(Li1/3Zr2/3)O3 end member and MPB composition nexus in Bi1/2Na1/2TiO3-based ceramics. Chem. Eng. J. 2024, 485, 150087. [Google Scholar] [CrossRef]

- Sheeraz, M.; Tran, V.-D.; Jo, Y.J.; Kim, G.; Cho, S.; Sohn, C.; Kim, I.W.; Shin, Y.-H.; Ahn, C.W.; Kim, T.H. Defect Engineering of Ferroelectric Hysteresis in Lead-Free Bi1/2(Na,K)1/2TiO3 Thin Films. ACS Appl. Electron. Mater. 2024, 6, 8328–8338. [Google Scholar] [CrossRef]

- Yin, X. Application of Poisson Effect in Rock and Soil Mass. J. Phys. Conf. Ser. 2025, 3005, 012004. [Google Scholar] [CrossRef]

- Grosvenor, A.P.; Kobe, B.A.; Biesinger, M.C.; McIntyre, N.S. Investigation of multiplet splitting of Fe 2p XPS spectra and bonding in iron compounds. Surf. Interface Anal. 2004, 36, 1564–1574. [Google Scholar] [CrossRef]

- Omran, M.; Fabritius, T.; Elmahdy, A.M.; Abdel-Khalek, N. XPS and FTIR spectroscopic study on microwave treated high phosphorus iron ore. Appl. Surf. Sci. 2015, 345, 127–140. [Google Scholar] [CrossRef]

- Qi, K.; Liu, S.; Qiu, M. Photocatalytic performance of TiO2 nanocrystals with/without oxygen defects. Chin. J. Catal. 2018, 39, 867–875. [Google Scholar] [CrossRef]

- Ismail, M.; Chand, U.; Mahata, C.; Nebhen, J.; Kim, S. Demonstration of synaptic and resistive switching characteristics in W/TiO2/HfO2/TaN memristor crossbar array for bioinspired neuromorphic computing. J. Mater. Sci. Technol. 2022, 1, 94–102. [Google Scholar] [CrossRef]

- Arbuzov, V.I.; Voroshilova, M.V.; Gusev, P.E.; Fedorov, N.Y.K. Influence of the redox conditions of melting on the quantitative ratio of ions Fe2+/Fe3+ in aluminum potassium barium phosphate glass. Glass Phys. Chem. 2007, 33, 556–561. [Google Scholar] [CrossRef]

- Li, Y.P.; Wang, N.; Che, X.S.; Chen, H.B.; Liu, Z.T. Infrared transmissive and rain-erosion resistant performances of GeC/GaP double-layer thin films on ZnS substrates. Appl. Surf. Sci. 2013, 264, 538–544. [Google Scholar] [CrossRef]

- Gouveia, A.F.; Assis, M.; Ribeiro, L.K.; Lima, A.E.B.; Gomes, E.d.O.; Souza, D.; Galvão, Y.G.; Rosa, I.L.V.; da Luz, G.E.; Guillamón, E.; et al. Photoluminescence emissions of Ca1-xWO4:xEu3+:Bridging between experiment and DFT calculations. J. Rare Earths 2022, 10, 1527–1534. [Google Scholar] [CrossRef]

- Sen, S.; Parida, R.K.; Parida, B.N. The enhanced multifunctional behavior in G-type antiferromagnetic BiFeO3 due to the modification by MgTiO3. Phys. B 2023, 650, 414559. [Google Scholar] [CrossRef]

- Kotov, V.A.; Popkov, A.F.; Soloviev, S.V.; Vasiliev, M.; Alameh, K.; Nur-E-Alam, M.; Balabanov, D.E. Magnetic heterostructures with low coercivity for high-performance magneto-optic devices. J. Phys. D Appl. Phys. 2013, 46, 035001. [Google Scholar] [CrossRef]

- Nur-E-Alam, M.; Vasiliev, M.; Kotov, V.A.; Alameh, K. Highly bismuth-substituted, record-performance magneto-optic garnet materials with low coercivity for applications in integrated optics, photonic crystals, imaging and sensing. Opt. Mater. Express 2011, 1, 413–427. [Google Scholar] [CrossRef]

- Fu, Q.; Xu, Q.; Zhao, Z.; Liu, X.; Huang, Y.; Hu, X.; Zhuang, N.; Chen, J.; French, R.H. New magneto-optical film of Ce,Ga:GIG with high performance. J. Am. Ceram. Soc. 2016, 99, 234–240. [Google Scholar] [CrossRef]

- Wettling, W. Magneto-optics of ferrites. J. Magn. Magn. Mater. 1976, 3, 147–160. [Google Scholar] [CrossRef]

- Kucera, M.; Bok, J.; Nitsch, K. Faraday rotation and MCD in Ce doped yig. Solid State Commun. 1989, 69, 1117–1121. [Google Scholar] [CrossRef]

| Catalog | Parameter |

|---|---|

| Target | Bi1−xSrxFe1−xTixO3 (x = 0, 0.2, and 0.5) |

| Substrate | SiO2 quartz glass, Si(100) and STO(100) |

| Substrate temperature | room temperature |

| Substrate-target distance (cm) | 5.0 |

| Background pressure (Pa) | 1 × 10−4 |

| Sputter gas | Ar |

| Sputter gas flow (Sccm) | 20 |

| Sputter pressure (Pa) | 1.6 |

| Radio frequency power (W) | 80 |

| Deposition time (min) | 90 |

| Chemical Formula | Atom | Wyckoff-Site | x | y | z | Occupancy |

|---|---|---|---|---|---|---|

| Bi0.8Sr0.2Fe0.8Ti0.2O3 | Bi1 | 1a | 0 | 0 | 0 | 0.8 |

| Sr1 | 1a | 0 | 0 | 0 | 0.2 | |

| Fe1 | 1b | 0.5 | 0.5 | 0.5 | 0.8 | |

| Ti1 | 1b | 0.5 | 0.5 | 0.5 | 0.2 | |

| O1 | 3c | 0 | 0.5 | 0.5 | 1 | |

| Bi0.5Sr0.5Fe0.5Ti0.5O3 | Bi1 | 1a | 0 | 0 | 0 | 0.5 |

| Sr1 | 1a | 0 | 0 | 0 | 0.5 | |

| Fe1 | 1b | 0.5 | 0.5 | 0.5 | 0.5 | |

| Ti1 | 1b | 0.5 | 0.5 | 0.5 | 0.5 | |

| O1 | 3c | 0 | 0.5 | 0.5 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, N.; Zhang, H.; Shi, Y.; Xu, C.; Xie, Z.; Chen, Y. Induction of Strong Magneto-Optical Effect and High Compatibility with Si of BiFeO3 Thin Film by Sr and Ti Co-Doping. Materials 2025, 18, 2953. https://doi.org/10.3390/ma18132953

Lin N, Zhang H, Shi Y, Xu C, Xie Z, Chen Y. Induction of Strong Magneto-Optical Effect and High Compatibility with Si of BiFeO3 Thin Film by Sr and Ti Co-Doping. Materials. 2025; 18(13):2953. https://doi.org/10.3390/ma18132953

Chicago/Turabian StyleLin, Nanxi, Hong Zhang, Yunye Shi, Chenjun Xu, Zhuoqian Xie, and Yunjin Chen. 2025. "Induction of Strong Magneto-Optical Effect and High Compatibility with Si of BiFeO3 Thin Film by Sr and Ti Co-Doping" Materials 18, no. 13: 2953. https://doi.org/10.3390/ma18132953

APA StyleLin, N., Zhang, H., Shi, Y., Xu, C., Xie, Z., & Chen, Y. (2025). Induction of Strong Magneto-Optical Effect and High Compatibility with Si of BiFeO3 Thin Film by Sr and Ti Co-Doping. Materials, 18(13), 2953. https://doi.org/10.3390/ma18132953